Joint treatment method for gas and coal spontaneous combustion in night distance seam mining

A very short-distance, coal spontaneous combustion technology, applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., to achieve the effect of avoiding gas exceeding the limit, reducing costs, and increasing the speed of recovery and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

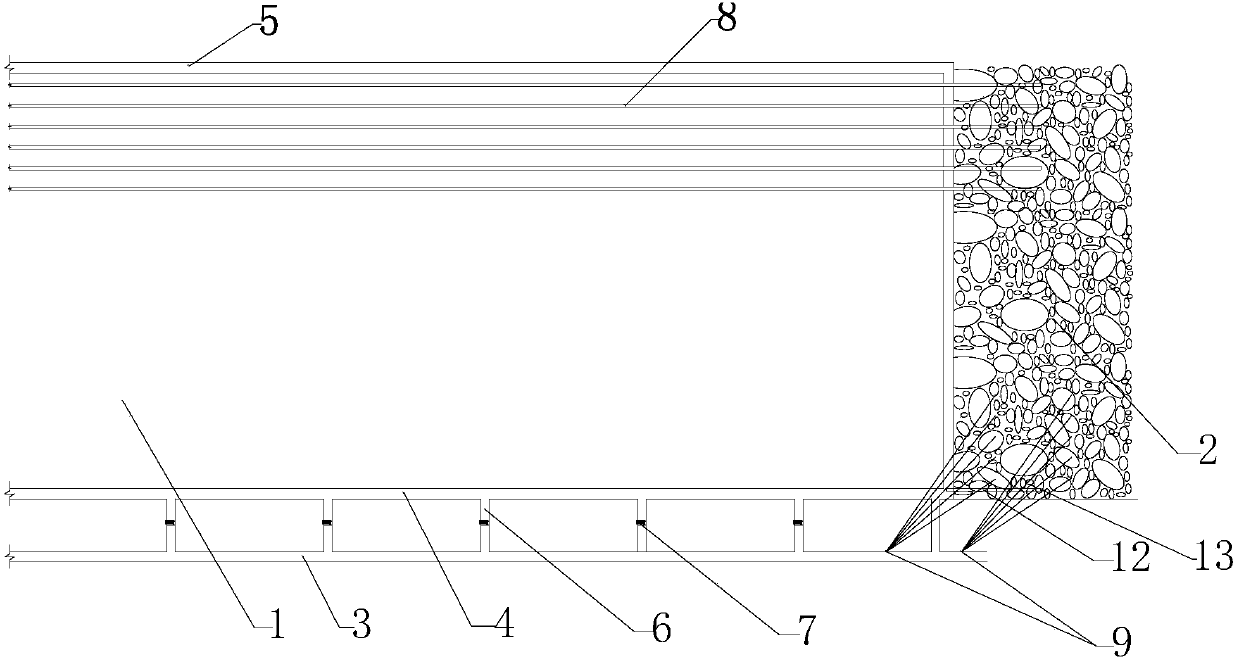

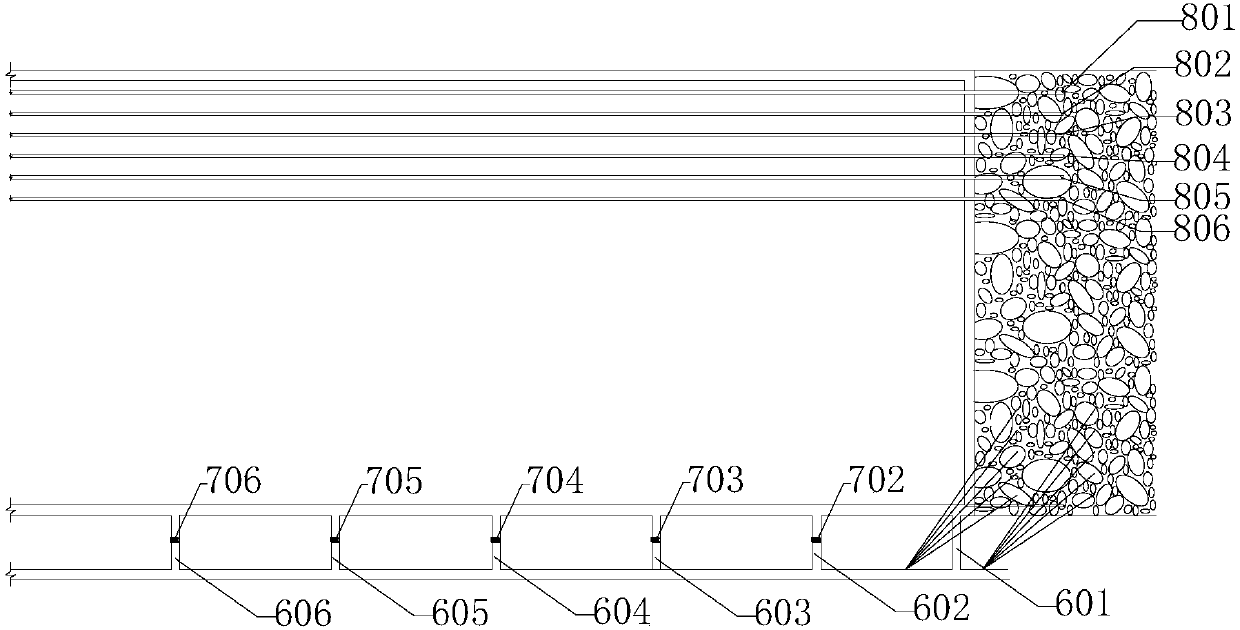

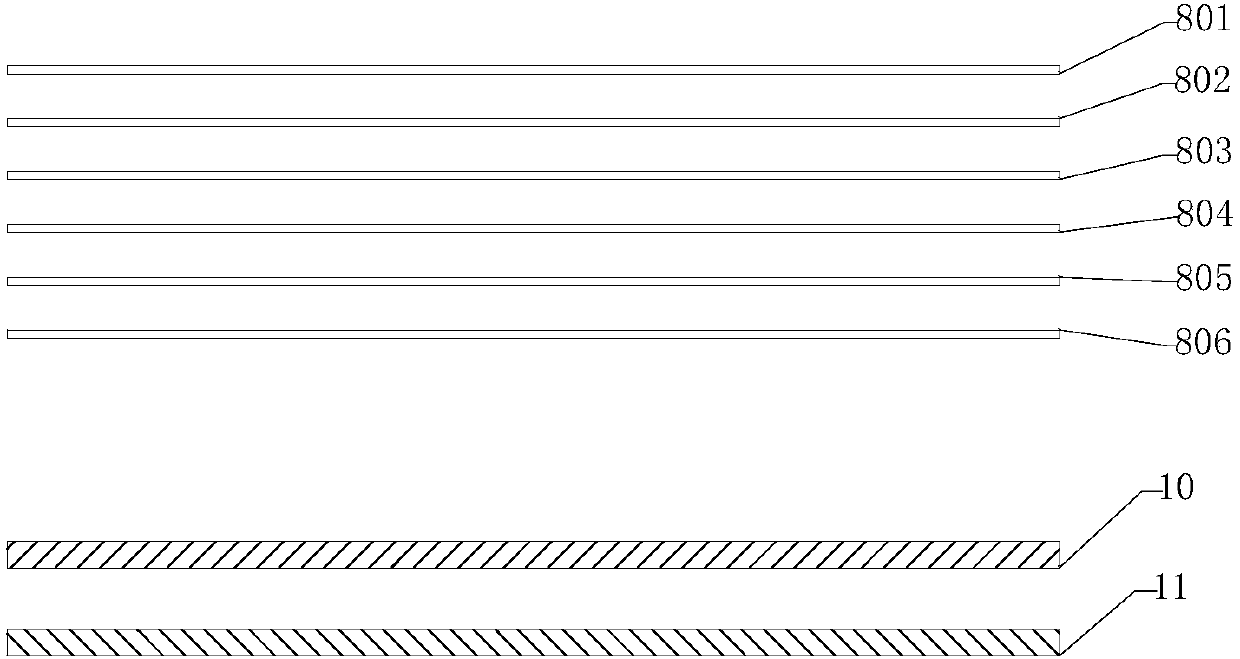

[0018] Such as Figure 1~5 As shown, a method for co-governing gas and coal spontaneous combustion in extremely close-distance coal seam mining of the present invention includes a "two-entry and one-return" working face ventilation system, a long borehole in the direction of the fracture zone, and a gas injection pipeline that continuously injects liquid into the goaf Carbon dioxide and low-level boreholes are injected with nitrogen, and the "two inlets and one return" working face ventilation system is used to control the gas gushing out of the mining face 1, and the extremely close coal seam 10 and the remaining coal seam 11 are extracted through the fracture zone to the long borehole 8. The gas gushed out from the coal is continuously injected into the goaf 2 by the gas injection pipeline 12 arranged along the belt groove 4 in the mining face to suppress the spontaneous combustion of the remaining coal in the coal seam 11 . By arranging the low drill hole 9 injecting nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com