Trussed type reinforced concrete beam

A reinforced concrete beam and truss technology, which is applied to truss structures, trusses, joists, etc., can solve the problems of uneconomical, the steel bar does not really bear the force, time-consuming and labor-intensive, etc., saving time, convenient construction methods, The effect of strong engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments.

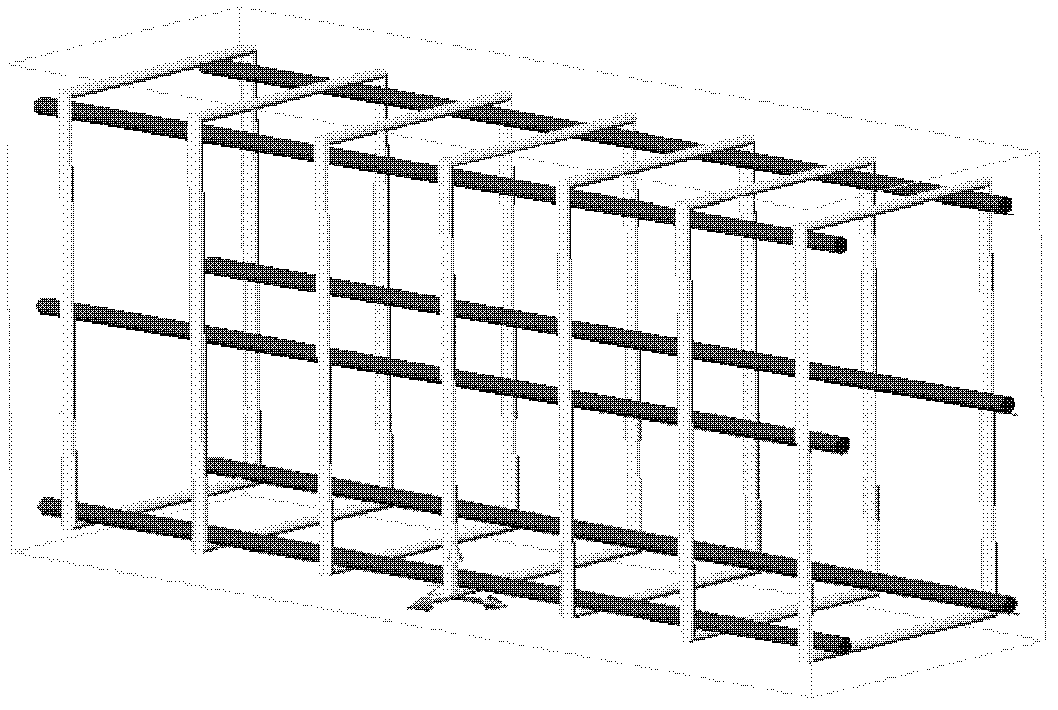

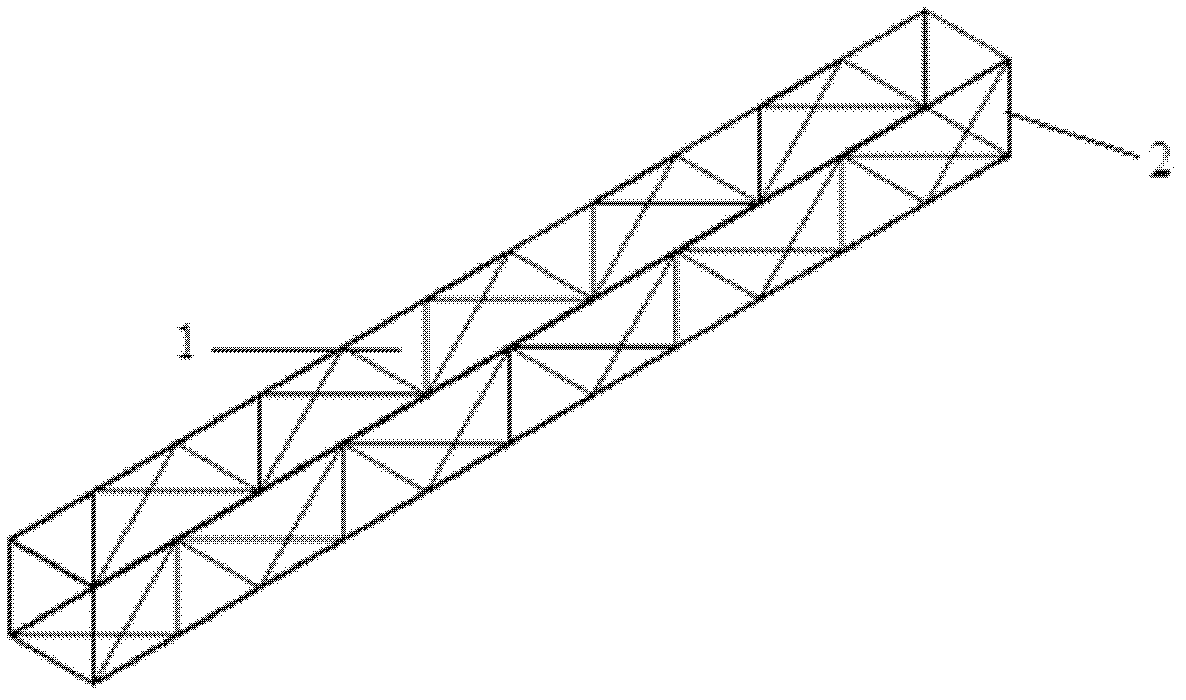

[0021] Such as Figure 3-4 As shown, a truss-type reinforced concrete beam includes a concrete beam body and a space truss arranged inside the concrete beam body. The space truss includes four-product steel trusses 1: the left and right two-product steel trusses bear most of the bottom tensile force and part of the bending moment of the beam; the upper and lower two products mainly play the role of erection. Through welding or lashing, the four-product steel truss is assembled into a space truss to form a rigid whole. The said steel truss is provided with diagonal rods 2.

[0022] The construction steps of the above reinforced concrete beam have the following characteristics:

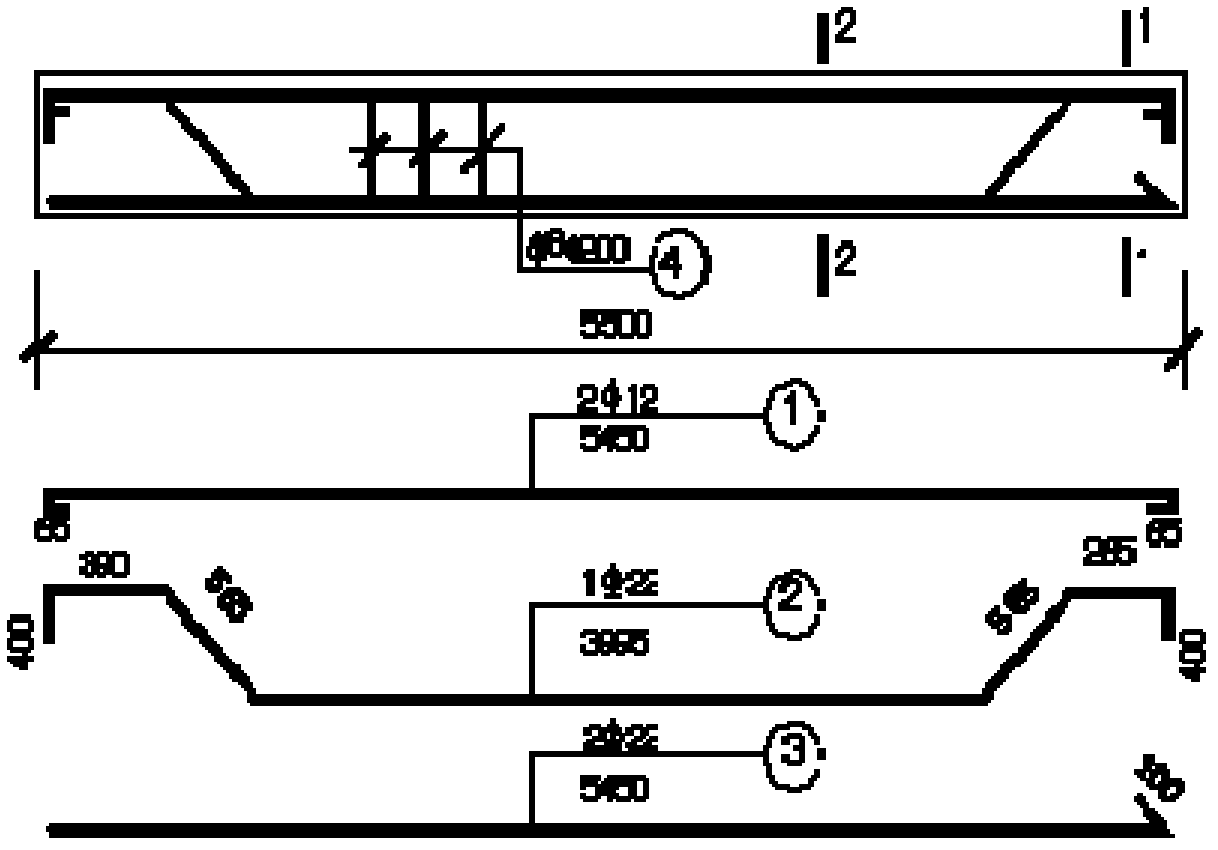

[0023] Prefabricated single-product steel trusses (such as Figure 4 ), the width of each steel truss can be produced according to the modulus specified in the "Reinforced Concrete Beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com