Gear-shaped precast concrete segment pile

A prefabricated concrete, gear-shaped technology, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of ineffective control of construction quality, impact on construction, mud pollution, etc., and achieve easy guarantee of pile foundation quality and horizontal shear resistance The effect of increasing the shearing force and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The gear-shaped prefabricated concrete segmental pile of the present invention includes a plurality of pile foundation segments, and the pile foundation segments are sequentially fixedly connected to form a whole.

[0040] In each pile foundation segment, except for the first pile foundation segment, the structural forms of other pile foundation segments at all levels are the same, so as to facilitate large-scale prefabrication and reduce mold cost. The structure of one of the pile foundation segments is detailed below.

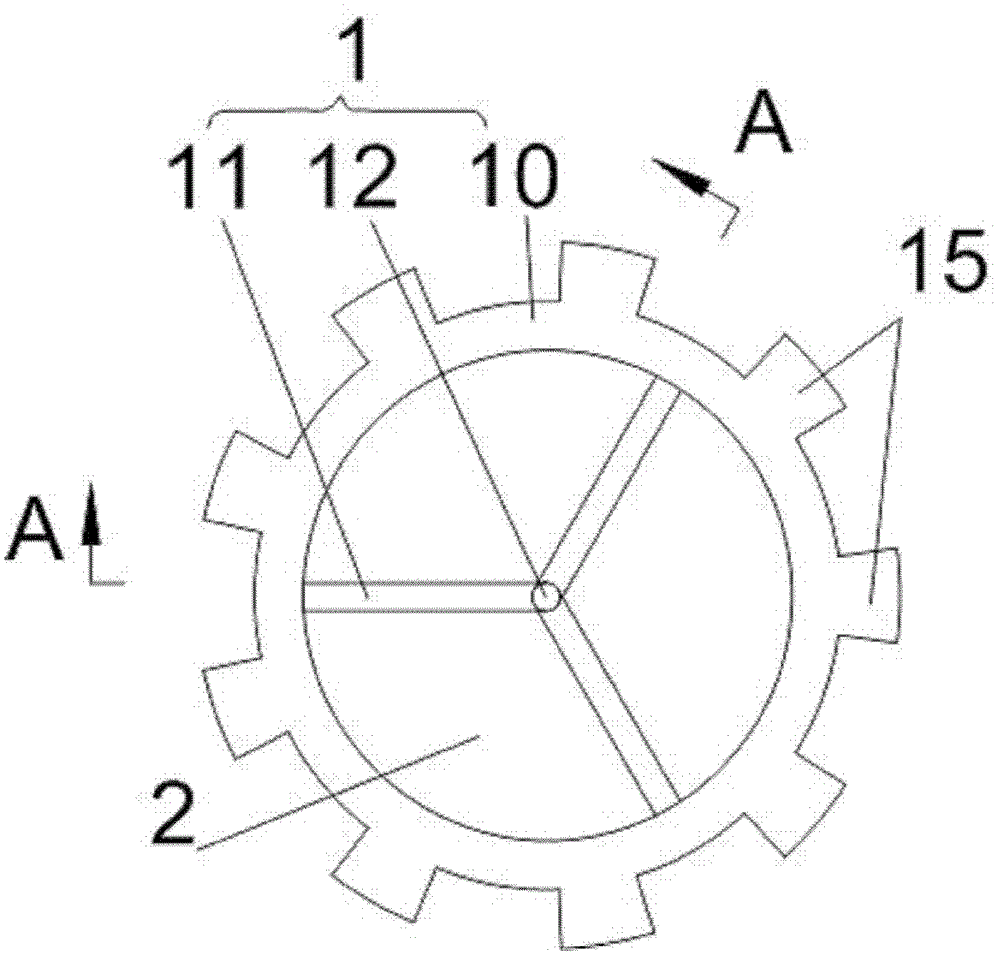

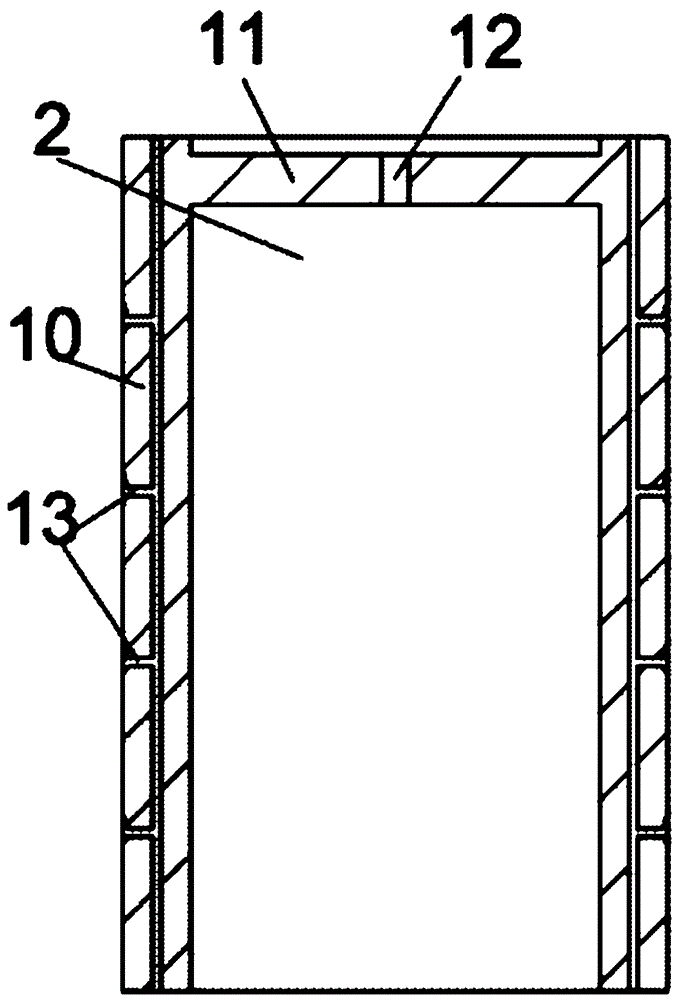

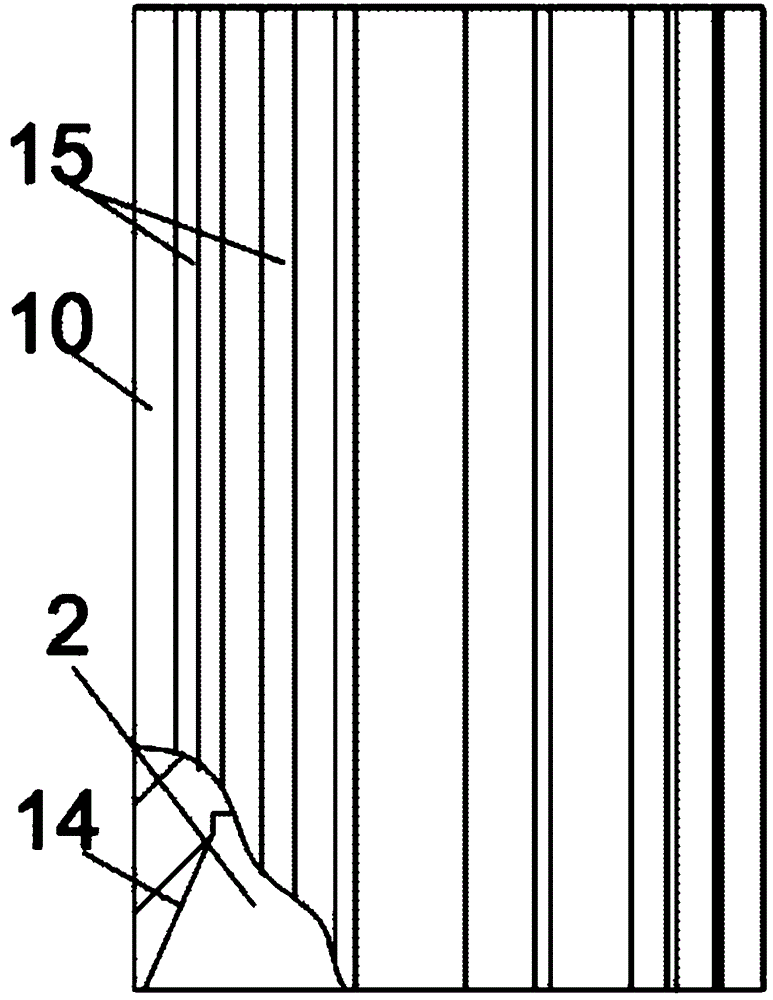

[0041] Such as figure 1 , figure 2 As shown, a pile foundation segment 1 is surrounded by side walls 10 to form an inner cavity 2 , which runs through the inner cavity 2 and also serves as a soil-taking channel, and a guiding structure is also arranged in the inner cavity 2 .

[0042] In the present invention, the cross-section of the pile foundation segment is gear-shaped, specifically having a plurality of gear teeth 15 on the side wall 10 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com