Patents

Literature

103results about How to "Control cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

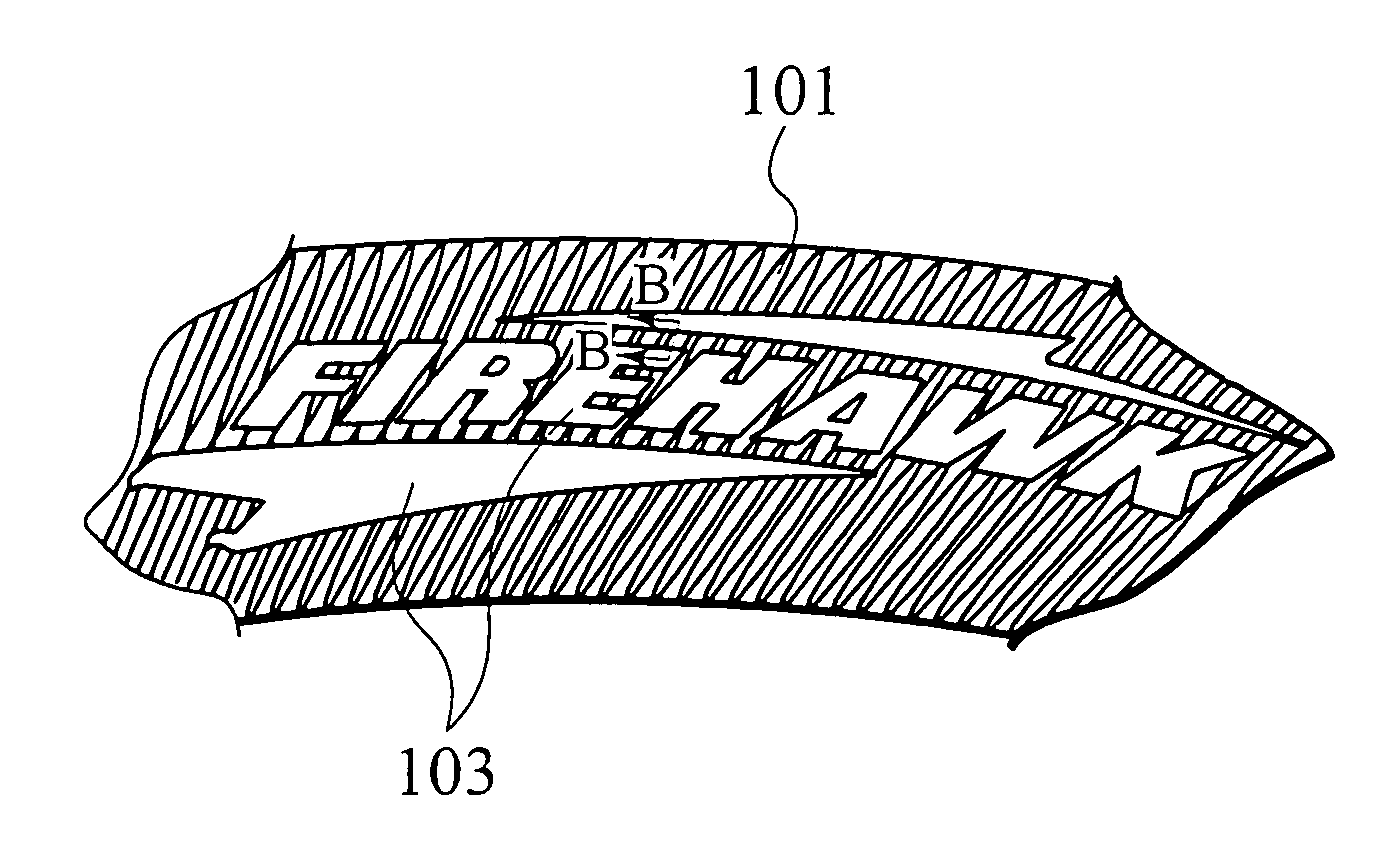

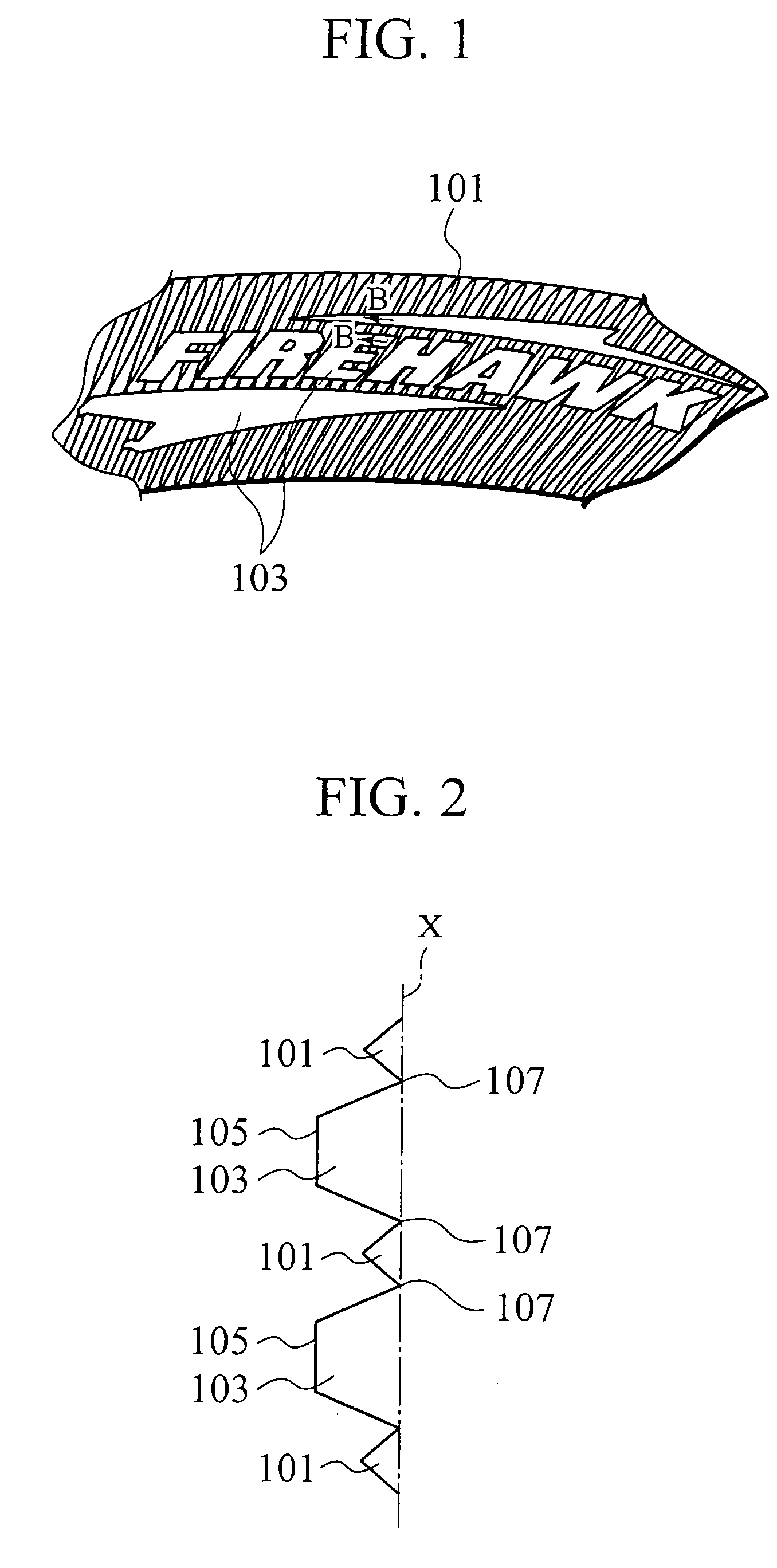

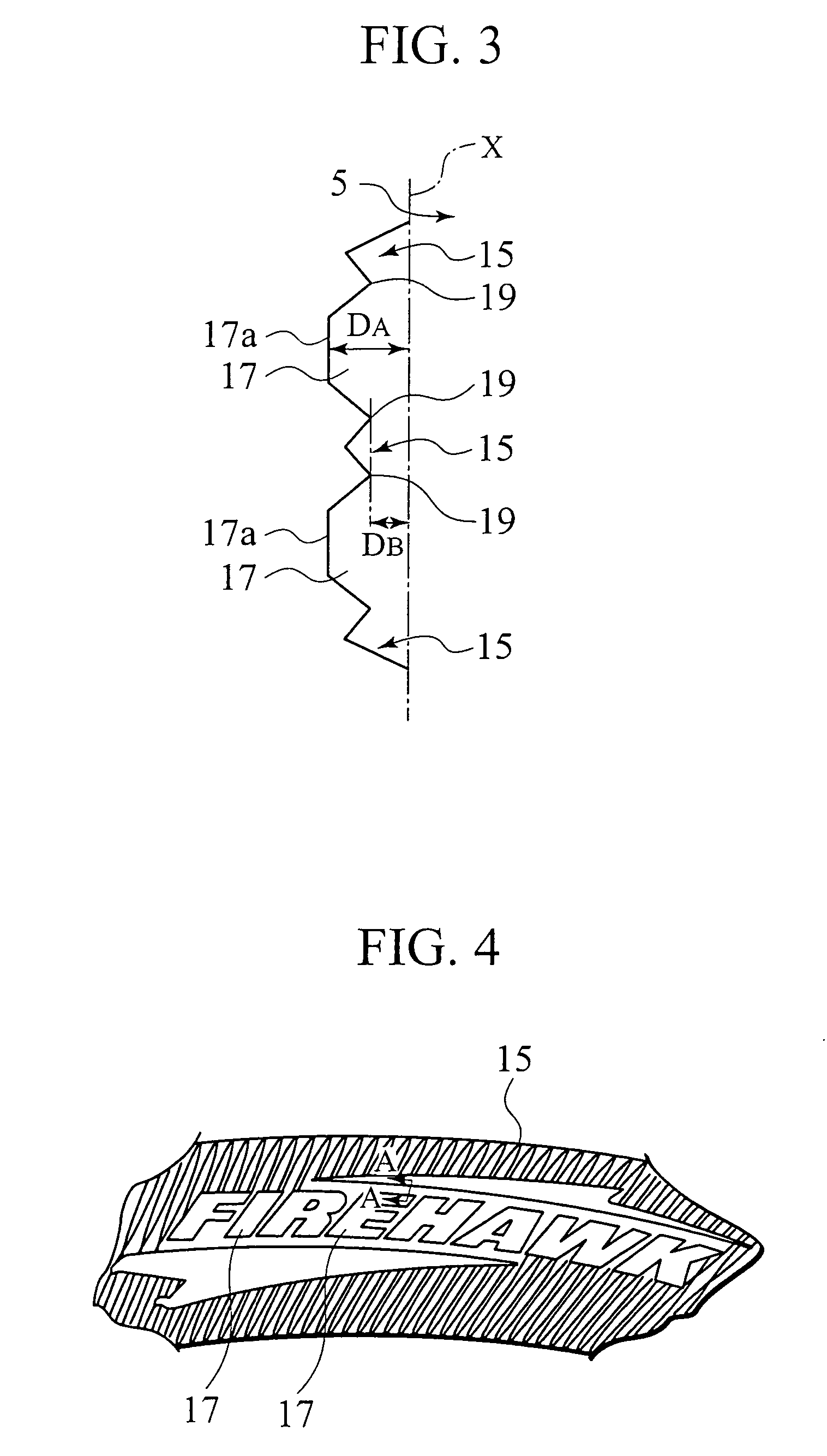

Pneumatic tire

InactiveUS20050081975A1Increased durabilityReduce generationInflatable tyresTyre sidewallsStress concentrationMechanical engineering

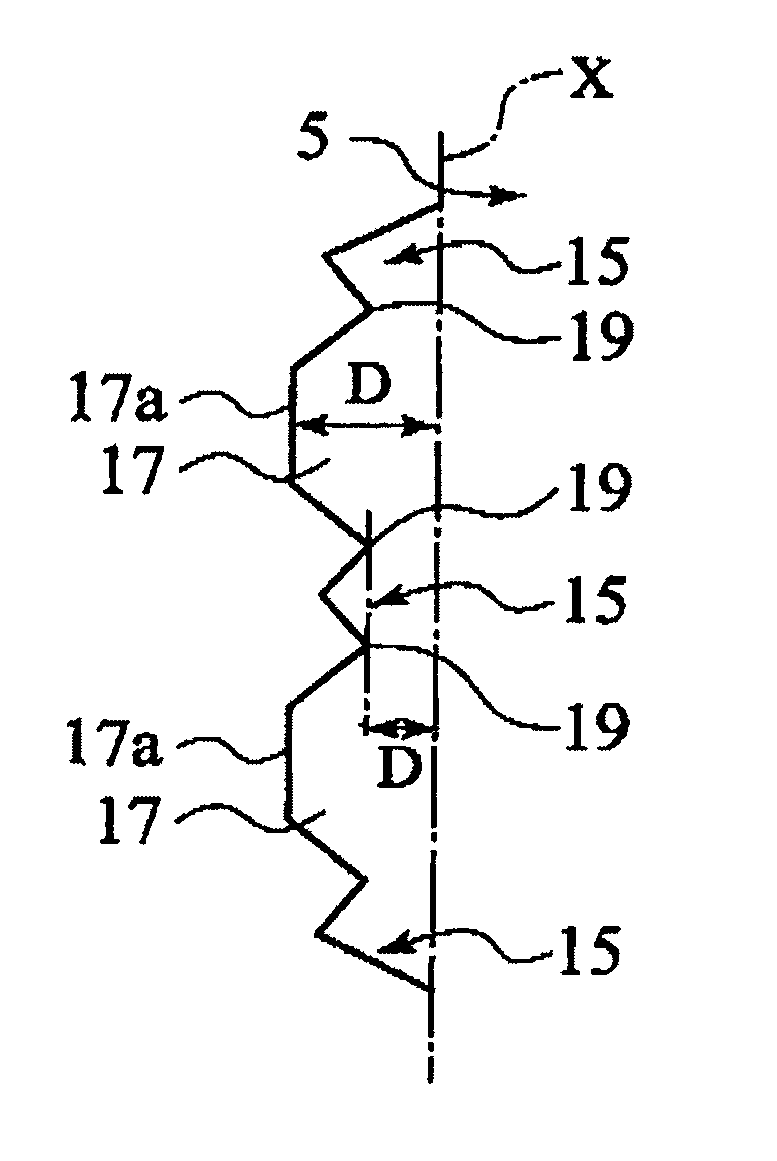

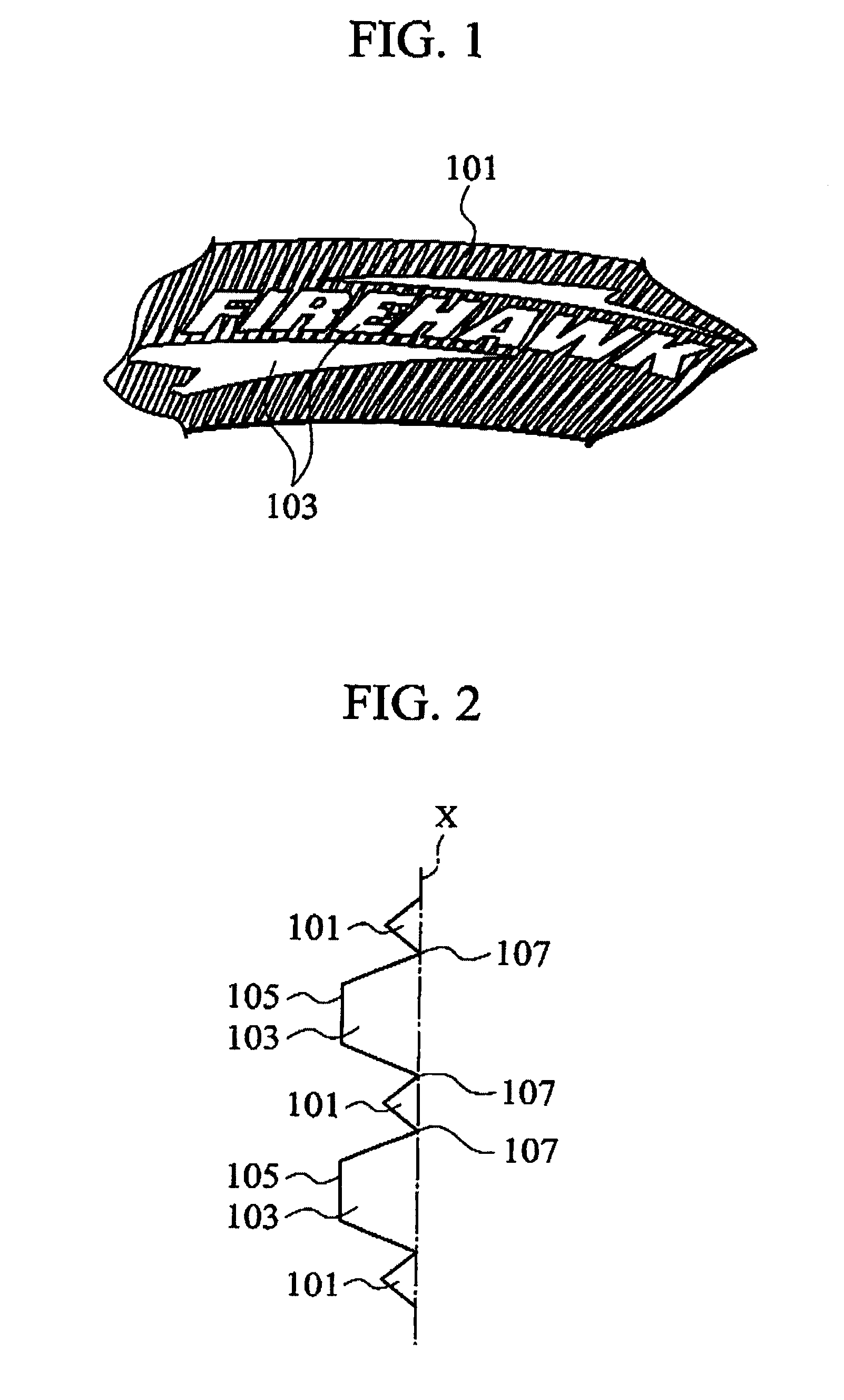

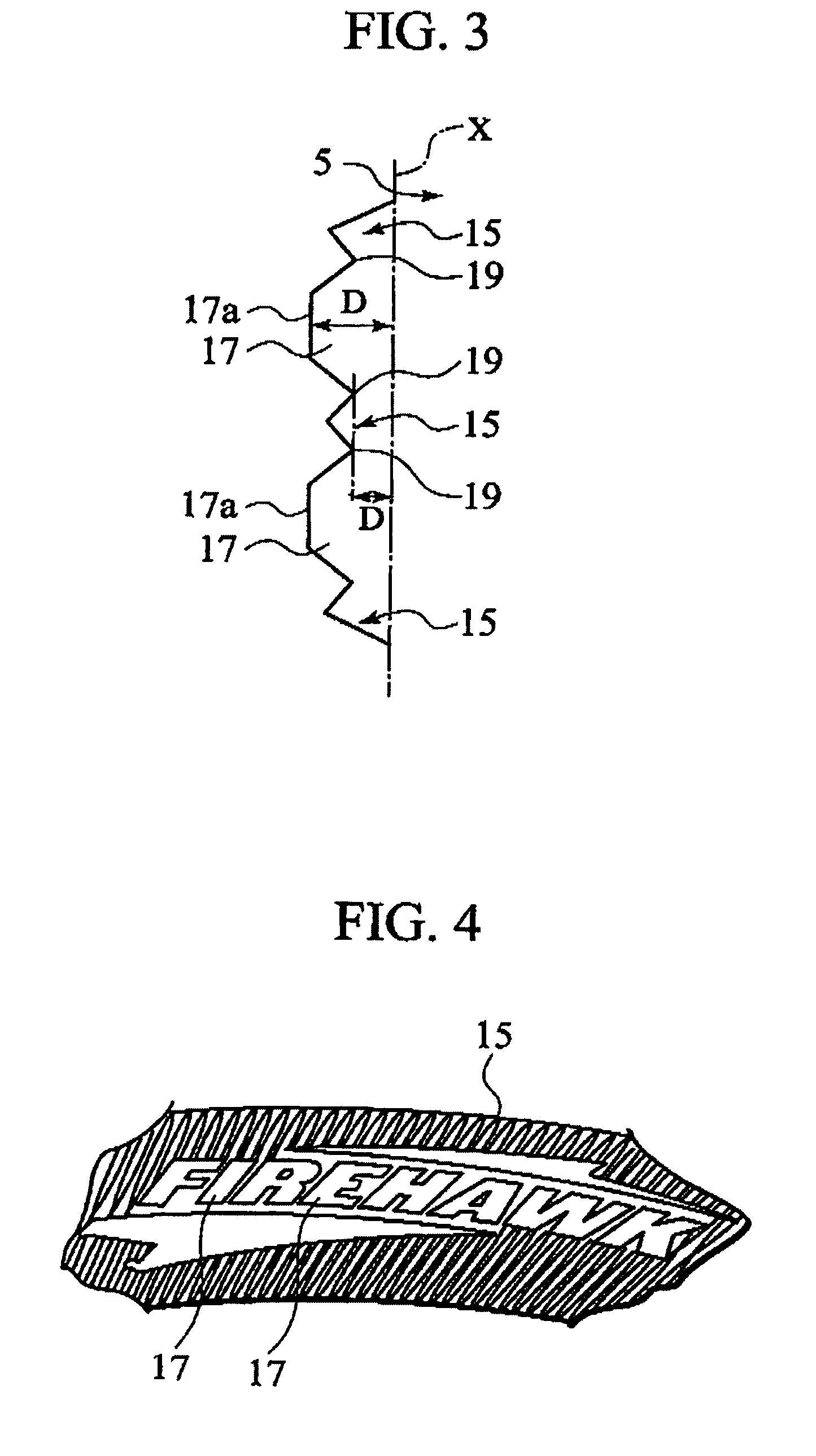

On a region of a ring-shaped continuous decorative portion 15 formed of tops and bottoms in cross-section, protruding portions 17 higher than the decorative portion 15 and having a predetermined surface area are provided. A joined portion of the decorative portion 15 and each protruding portion 17 or of the protruding portions is set higher than the bottoms of the decorative portion 15, and a rigidity difference between the protruding portions 17 and the decorative portion 15 is resolved, thus restricting an occurrence of a stress concentration.

Owner:BRIDGESTONE CORP

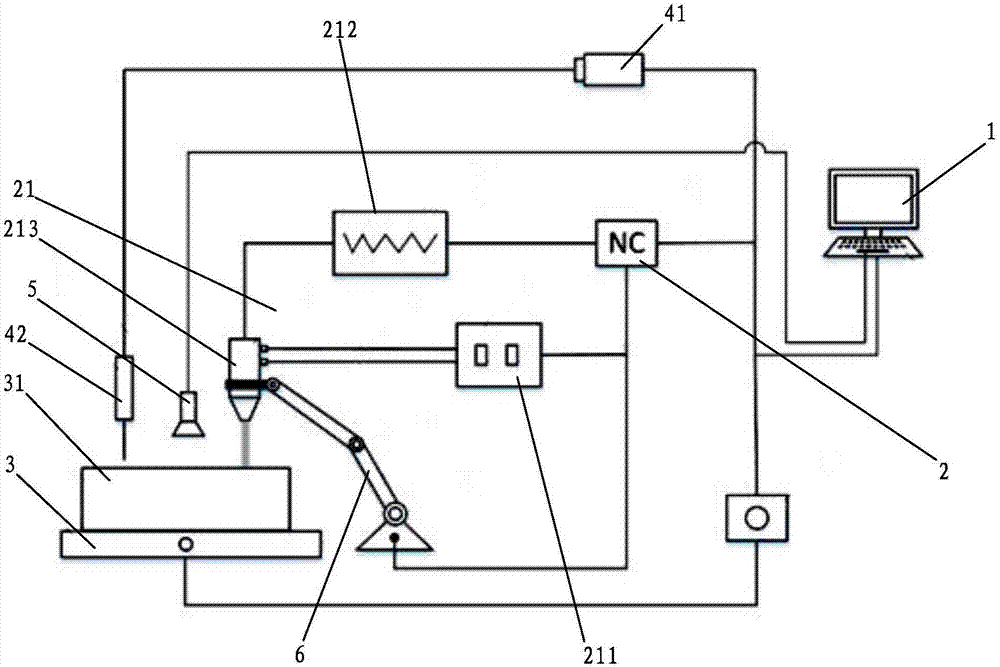

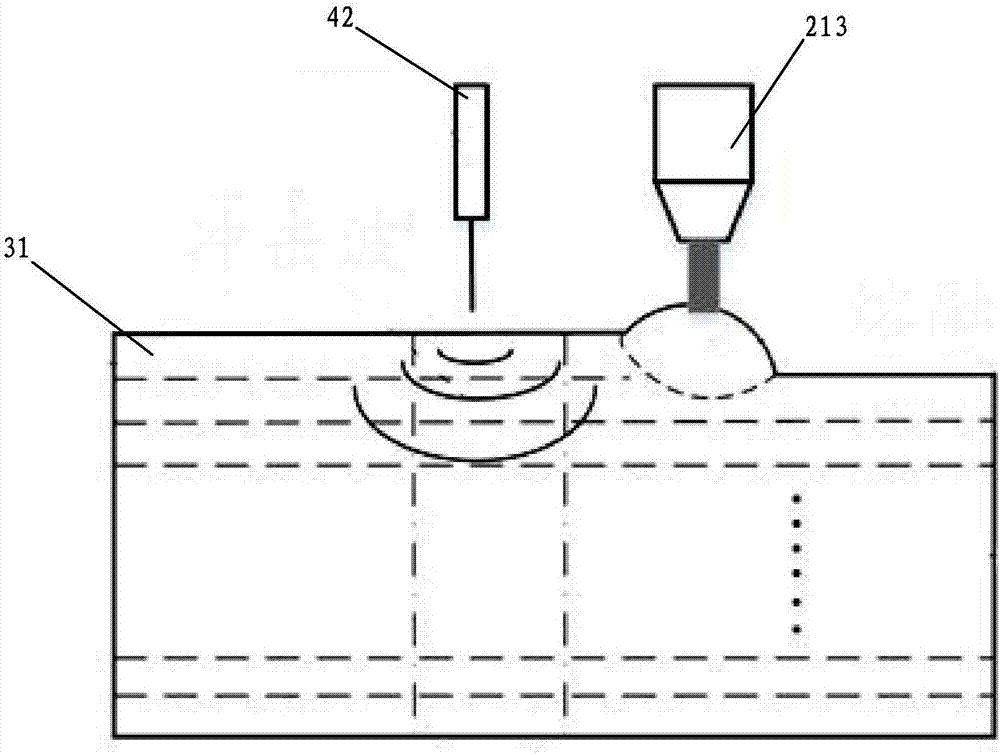

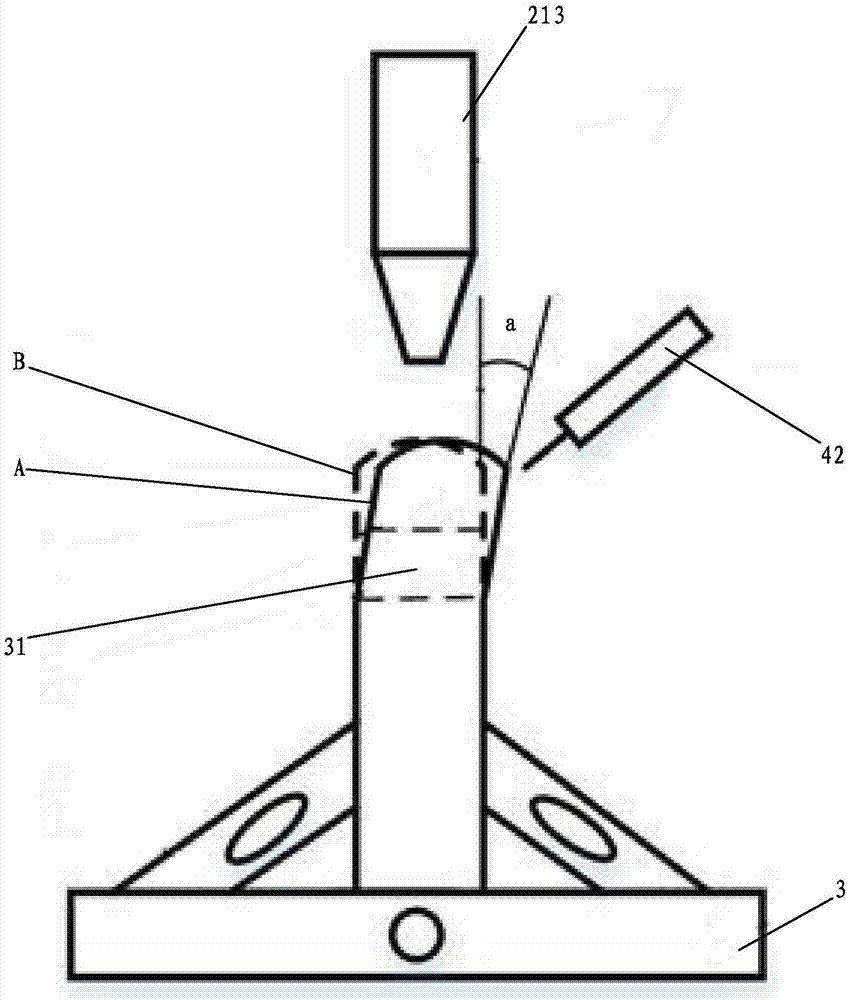

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

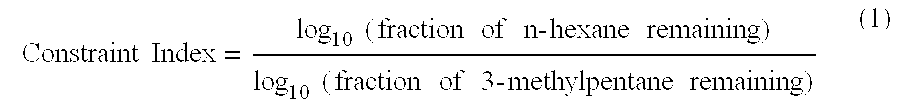

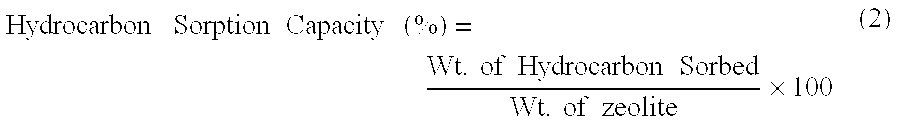

Noble metal containing low acidic hydrocracking catalysts

InactiveUS6362123B1Reduce acidityControl crackingMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAlkane

A hydrocracking catalyst is provided that includes a crystalline molecular sieve material component having a faujasite structure and an alpha acidity of less than 1, preferably 0.3 or less, and a dispersed Group VIII noble metal component. The extremely low acidity allows selective hydrocracking of the aromatic and naphthenic species in a feedstock, while limiting the cracking of paraffins. The catalyst produces improved yields of products, such as diesel fuel, at high conversion rates and with high cetane values.

Owner:MOBIL OIL CORP

Method of converting effluents of renewable origin into fuel of excellent quality by using a molybdenum-based catalyst

ActiveUS20100163458A1Yield maximizationOptimization mechanismRefining with non-metalsMolecular sieve catalystsHydrodeoxygenationActive phase

The invention is concerned with a supported or unsupported catalyst comprising an active phase constituted by a sulfur-containing group VIB element, the group VIB element being molybdenum, and a hydrodeoxygenation process with a yield of hydrodeoxygenation product which is greater than or equal to 90% of charges from renewable sources using a catalyst according to the invention.

Owner:INST FR DU PETROLE

Method of converting effluents of renewable origin into fuel of excellent quality by using a molybdenum-based catalyst

ActiveUS8546626B2Lightweight productionControl crackingRefining with non-metalsMolecular sieve catalystsHydrodeoxygenationActive phase

The invention is concerned with a supported or unsupported catalyst comprising an active phase constituted by a sulfur-containing group VIB element, the group VIB element being molybdenum, and a hydrodeoxygenation process with a yield of hydrodeoxygenation product which is greater than or equal to 90% of charges from renewable sources using a catalyst according to the invention.

Owner:INST FR DU PETROLE

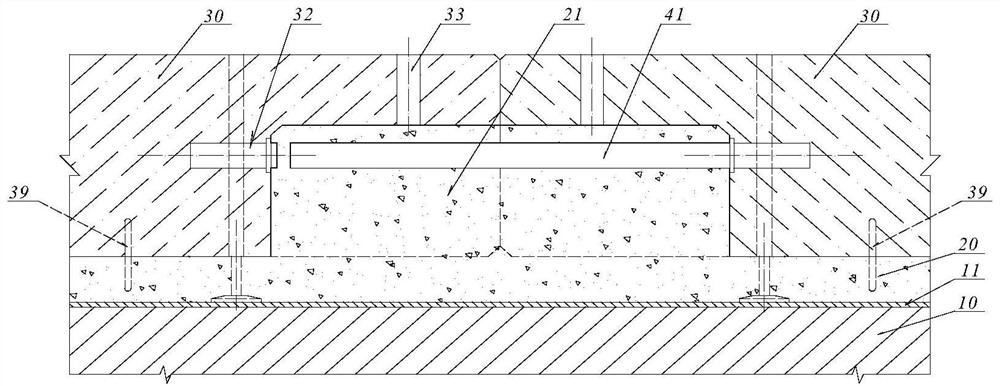

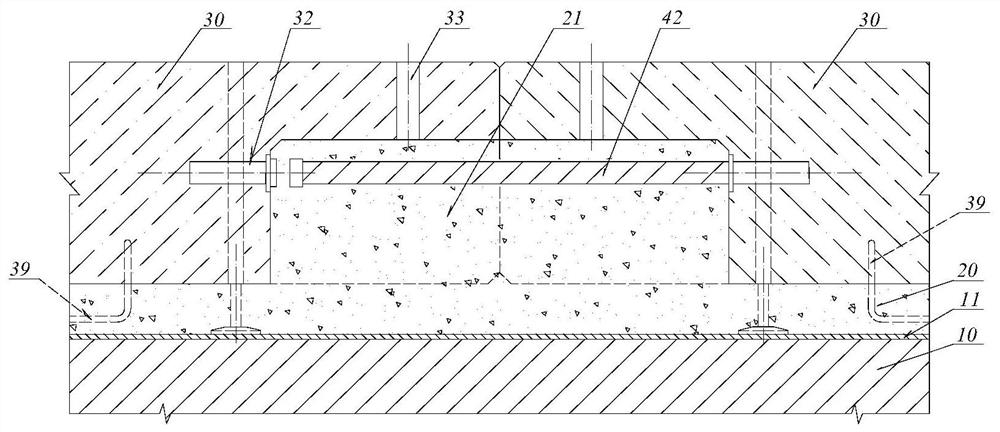

Cast-in-place box girder low-temperature steam maintenance operating method

InactiveCN1830644ASolve insulation problemsGuaranteed uniformityCeramic shaping apparatusEngineeringUltimate tensile strength

A low-temp steam curing method for in-situ cast box beam includes such steps as spraying insulating layer on external mould, laying down steam tubes, building steam curing shed, burying a temp strain gauge at each measuring point, parallelly connecting them via a switch to a reader, laying aside, heating, making temp constant, cooling and post curing. Its advantages are high speed, high strength and no crack.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

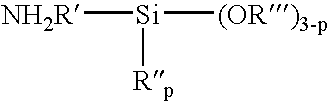

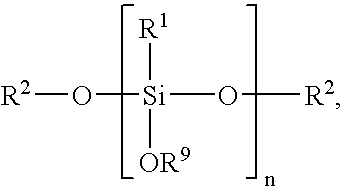

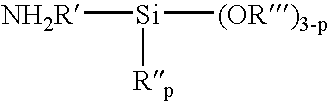

Low temperature, moisture curable coating compositions and related methods

Disclosed are low temperature, moisture curable coating compositions, related coated substrates, and methods for coating a substrate. The coating compositions include an ungelled, secondary amine-containing Michael addition reaction product of reactants including a compound comprising more than one site of ethylenic unsaturation, and an aminofunctional silane.

Owner:PPG IND OHIO INC

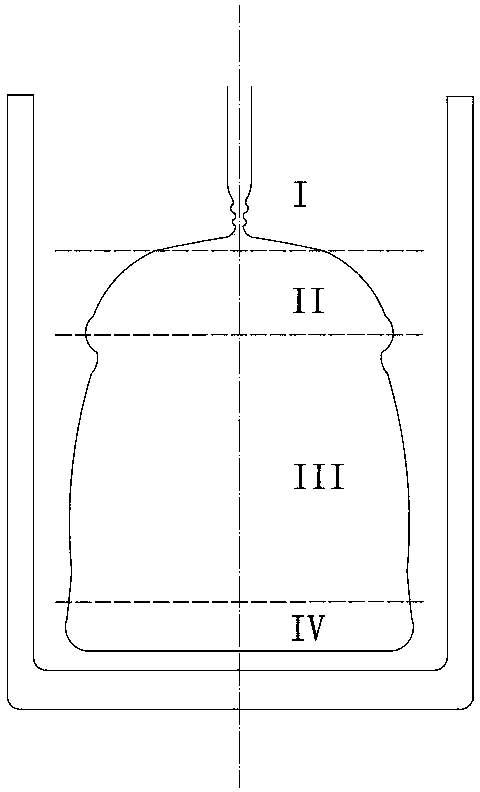

Growth method for preparing sapphire single crystal with Kyropoulos method

ActiveCN103966661APull speed decreaseEasy to liftPolycrystalline material growthUsing seed in meltGrowth phaseVoltage regulation

The invention provides a growth method for preparing a sapphire single crystal with a Kyropoulos method. The growth method mainly comprises the following control phases: a shouldering phase, an equal-diameter growth phase and an ending phase, wherein the shouldering phase is performed after seeding ending and comprises an initial shouldering stage and a later shouldering stage, the cooling speed is controlled by adjusting the voltage and matched with the crystal pulling speed to achieve stable growth at the initial shouldering stage, the crystal grows to about 1.5 kg after 20-25 h growth, and the crystal enters the later shouldering stage, the voltage adjusting quantity is smaller than that in the initial shouldering stage, the pulling speed is increased at the later shouldering stage and cooling is performed gradually, growth is performed for 45-52 h, and the crystal grows to about 4 kg and enters the equal-diameter growth phase; the crystal pulling speed is decreased at the equal-diameter growth phase, cooling is accelerated simultaneously, growth is performed for 75 h, and the crystal grows to about 28 kg-32 kg and enters the ending phase; and the cooling speed is further decreased and fast pulling is performed at the ending phase, and automatic draw-off is achieved. The growth method for preparing the sapphire single crystal with the Kyropoulos method can solve the problem that more bubbles exist in the sapphire single crystal grown with the conventional Kyropoulos method.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

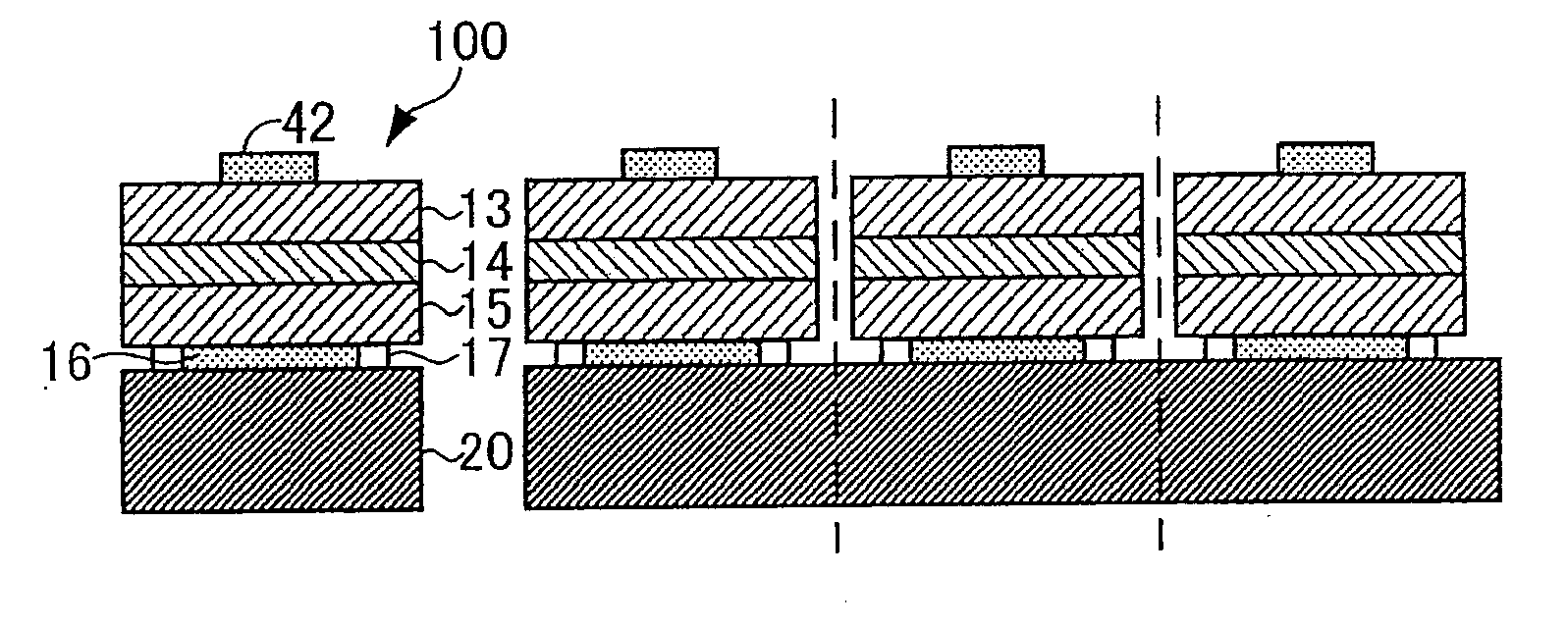

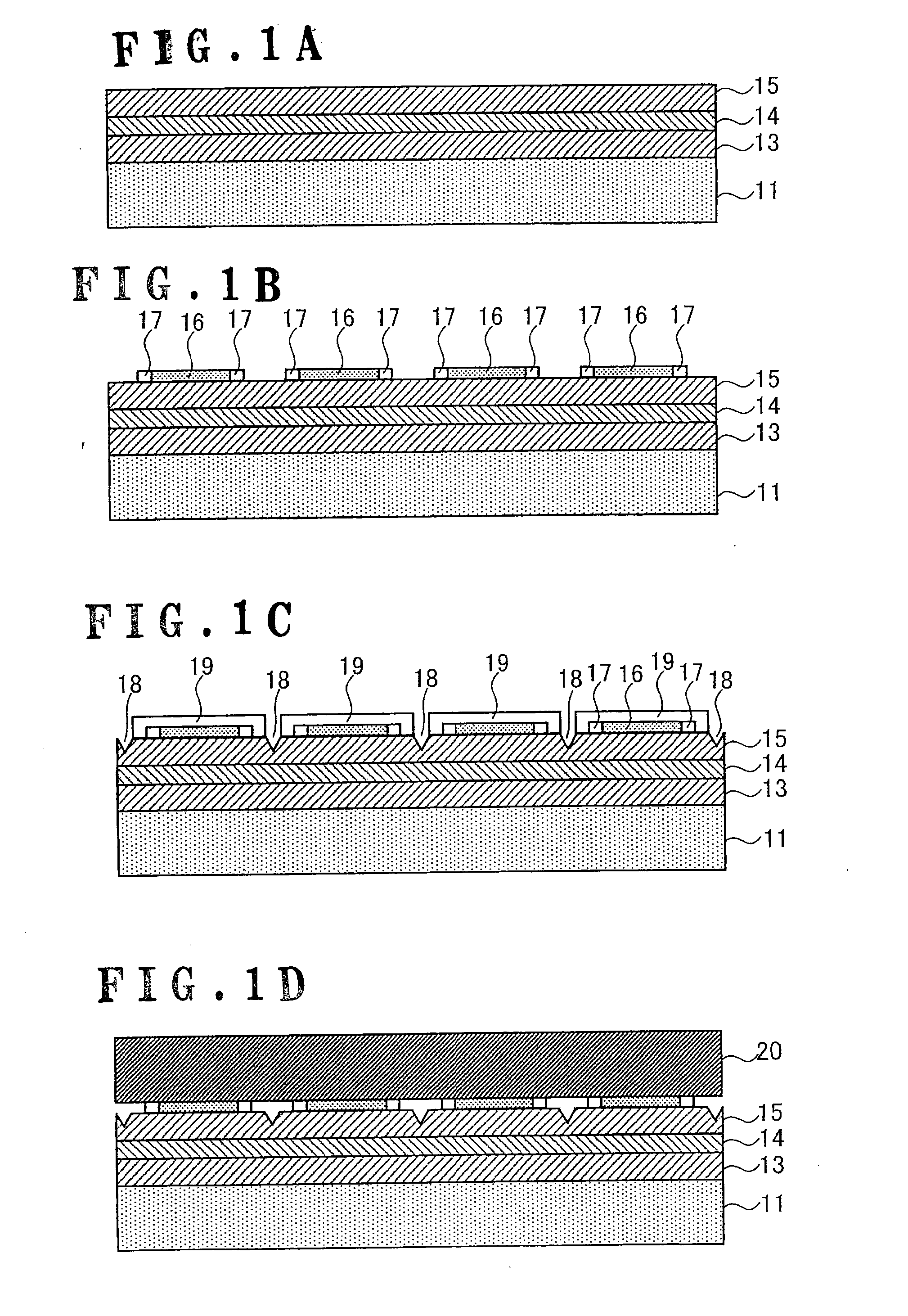

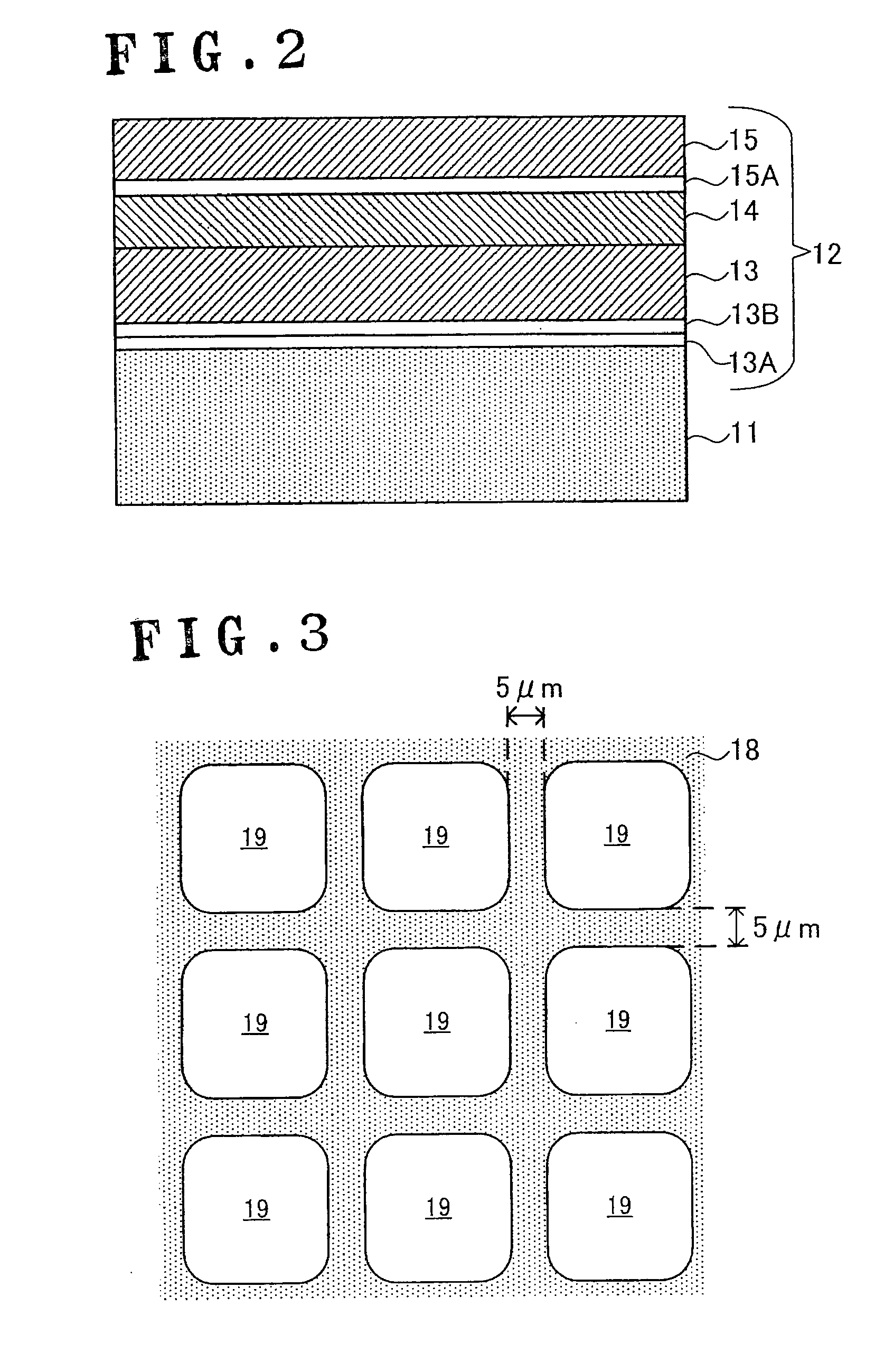

Method of manufacturing semiconductor light emitting elements

InactiveUS20110104835A1Minimize damageControl crackingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorSemiconductor package

A method of manufacturing semiconductor light emitting elements with improved yield and emission power uses laser lift-off and comprises the steps of forming a semiconductor grown layer formed of a first semiconductor layer, an active layer, and a second semiconductor layer on a first principal surface of a growth substrate; forming a plurality of junction electrodes apart on the second semiconductor layer and forming guide grooves arranged in a lattice to surround each of the junction electrodes in the second semiconductor layer; joining together a support and the semiconductor grown layer via the junction electrodes; projecting a laser to separate the growth substrate; dividing the semiconductor grown layer into respective element regions for the semiconductor light emitting elements; and cutting the support, thereby separating into the semiconductor light emitting elements. Removed regions include regions where the guide grooves are formed, and side walls of the second semiconductor layer formed by the guide grooves have a beveled shape at intersections of the guide grooves.

Owner:STANLEY ELECTRIC CO LTD

Method for reinforcing sand adhesion strength on epoxy resin impregnated fiber woven net surface

The present invention belongs to the field of civil engineering technology, relates to fiber net and concrete adhering technology, and is especially method of strengthening adhesion of sand onto epoxy resin soaked woven fiber net. The present invention features that woven fiber net is first soaked inside in the mixed liquid of epoxy resin and curing agent in the weight ratio of 4-5 and dilute in proper amount based on the flowing performance of the liquid; spreading fine sand to the surface of soaked fiber net; and burying the fiber net with completely cured epoxy resin inside concrete. The present invention can raise the binding strength between woven fiber net and concrete, and limit cracking in concrete for form fine, dense and homogeneous cracks.

Owner:DALIAN UNIV OF TECH

Ink jet recording material

InactiveUS20060045998A1Large particle sizeSmall contentCoatingsThermographyGas phaseColloidal particle

An ink jet recording material having excellent ink-absorption and appropriate for high speed recording has an ink receiving layer formed on a substrate material and including a first coating layer formed on the substrate material and including a pigment (for example, wet process silica fine particles) and a binder; a second coating layer formed on the first coating layer and including a pigment (for example, gas phase process silica or alumina) and a binder; and a third coating layer formed on the second coating layer and including a pigment containing colloidal particles, and alumina and / or pseudo boehmite fine particles.

Owner:OJI PAPER CO LTD

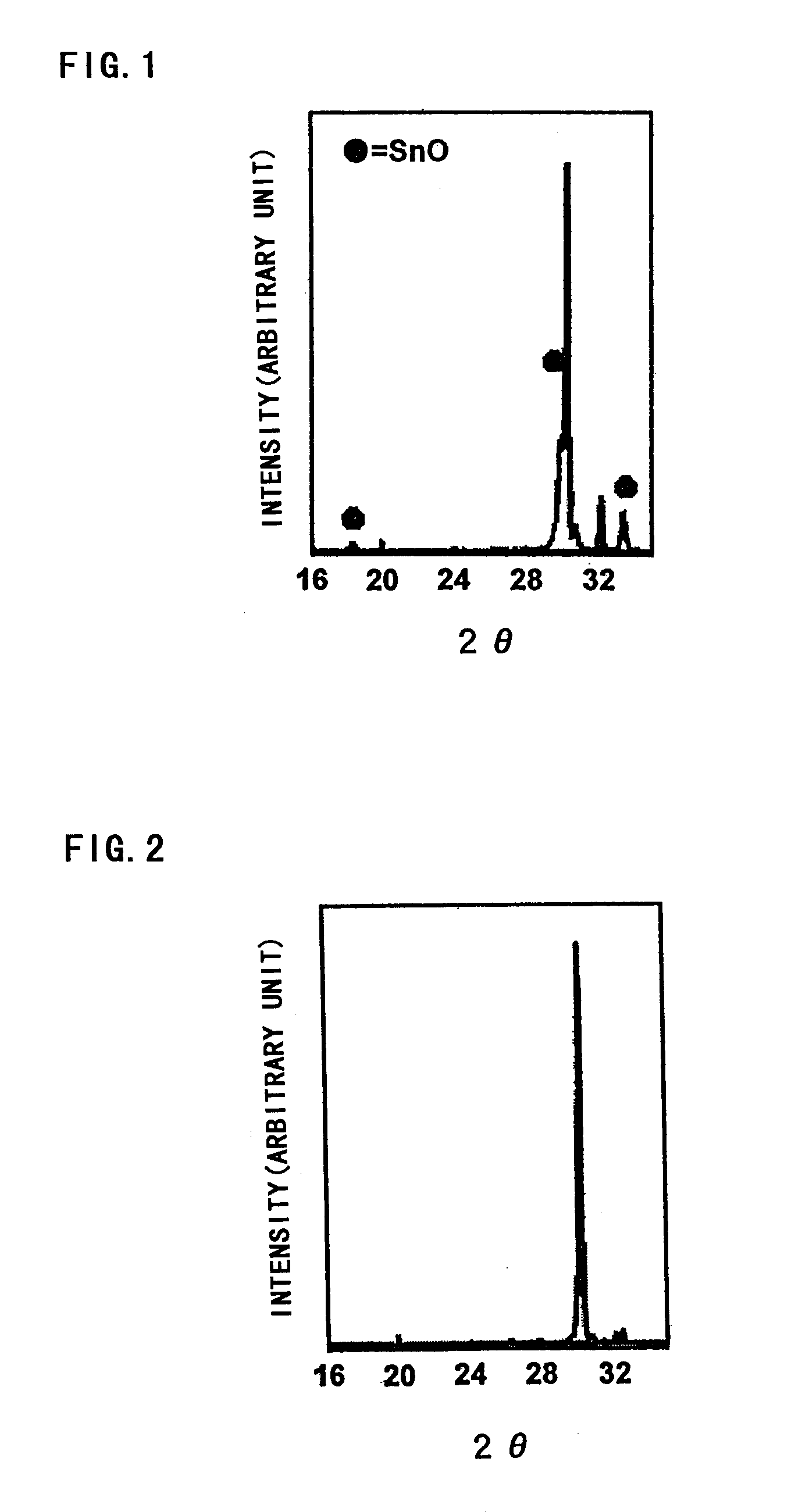

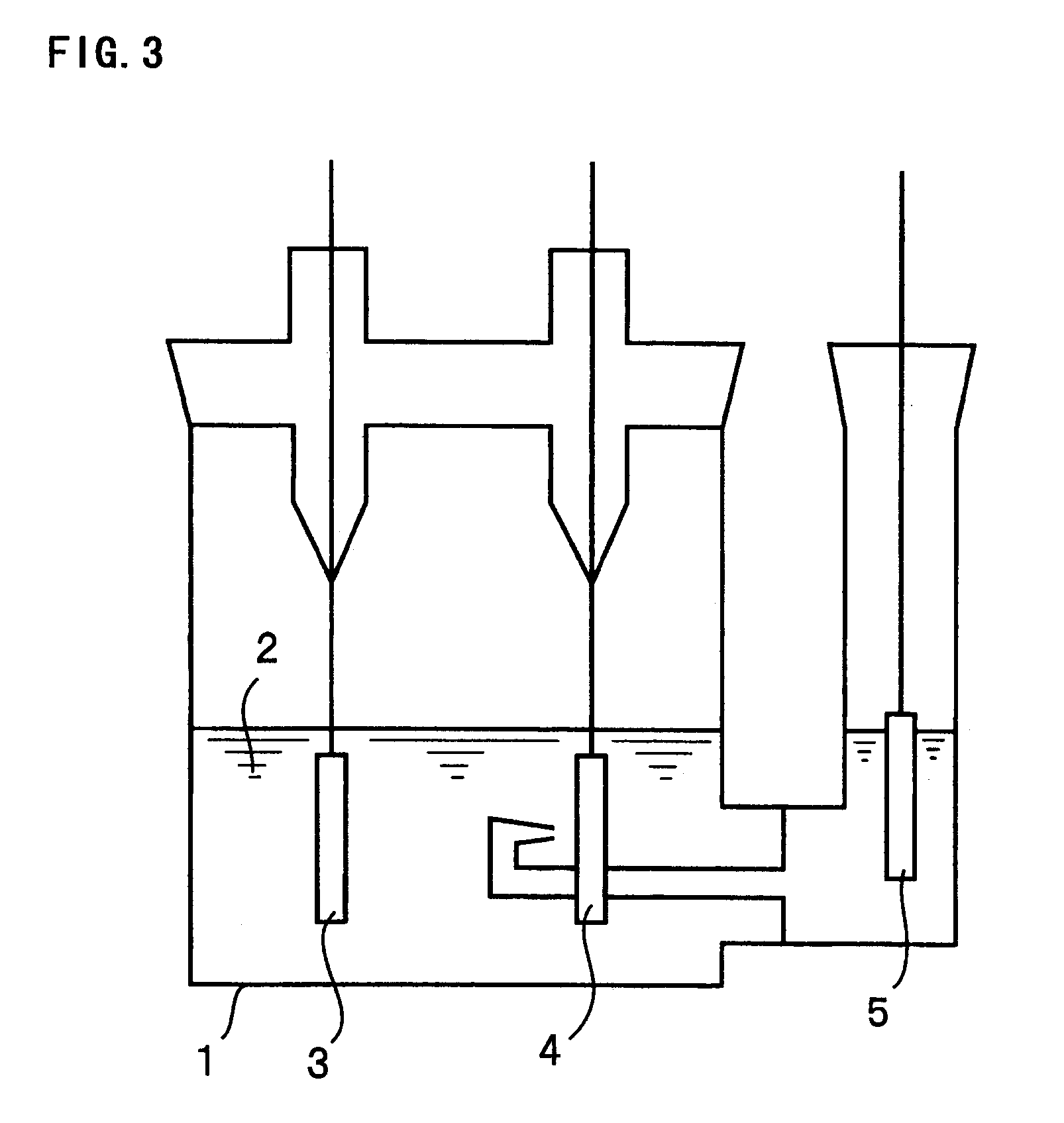

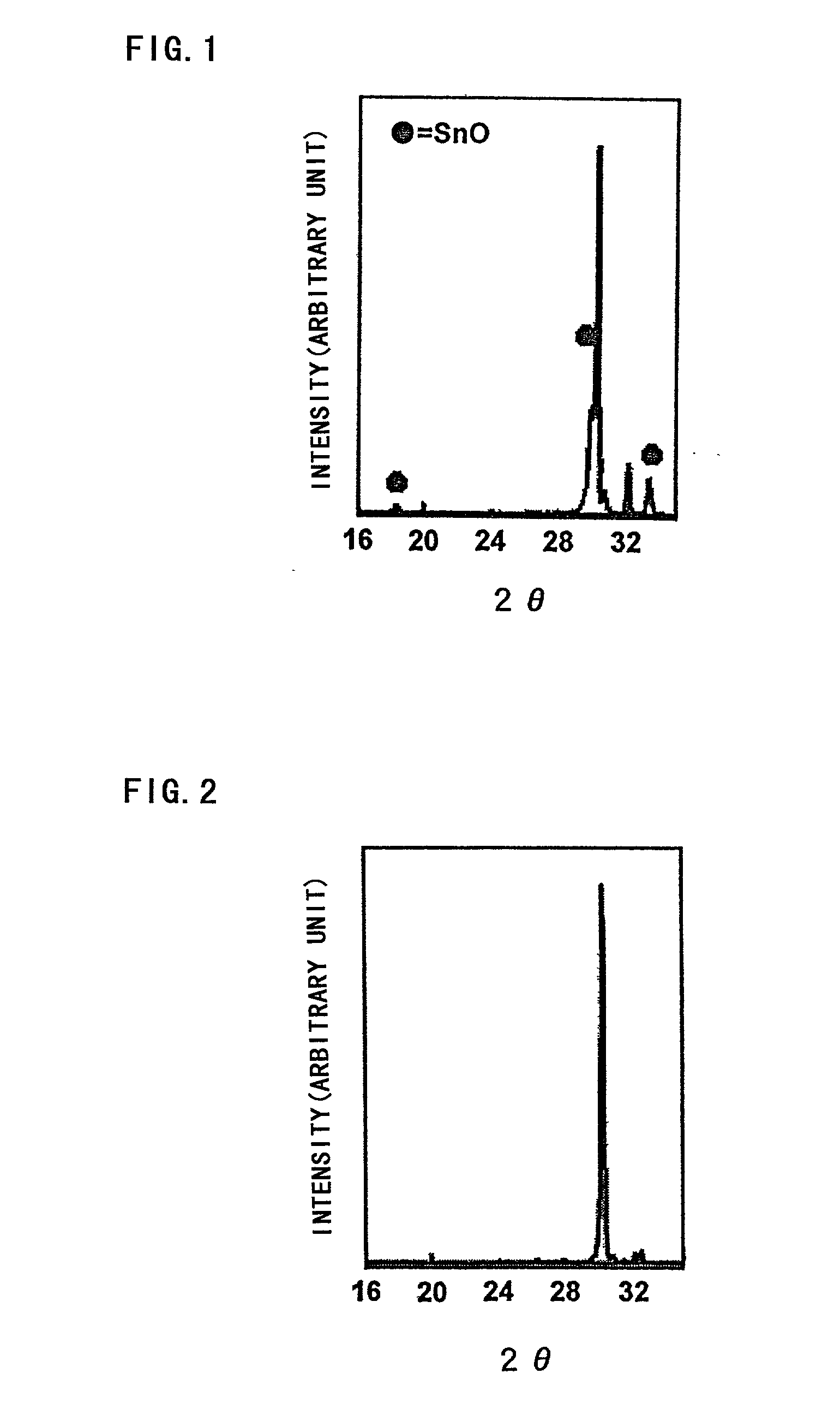

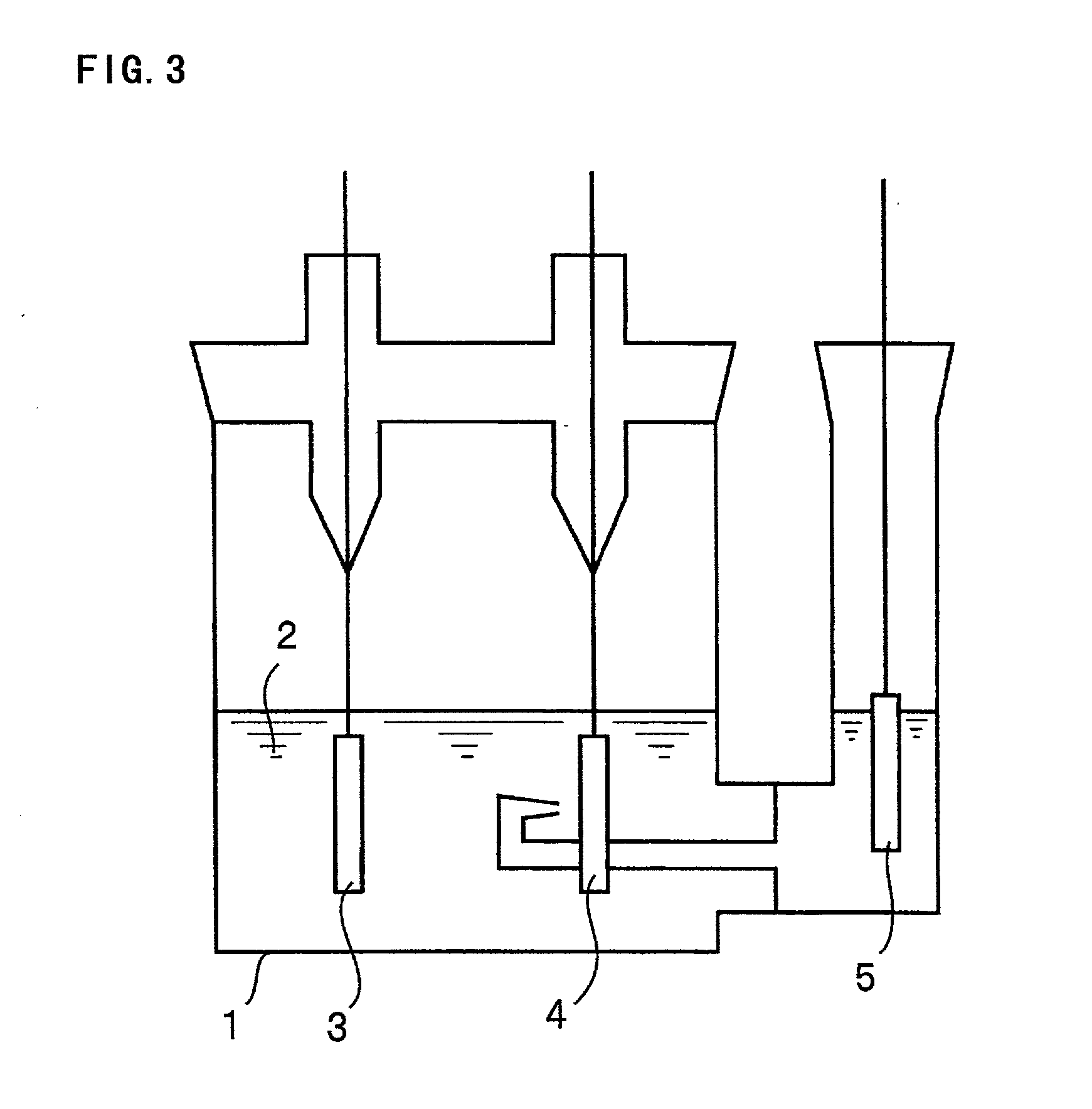

Electrode for lithium secondary battery and lithium secondary battery

InactiveUS6746802B2Improve efficiencyImprove featuresElectrode manufacturing processesElectrode carriers/collectorsLithiumAlloy

An electrode for a lithium secondary battery comprises a current collector composed of a metal incapable of alloy formation with lithium, a thin film formed by depositing on the current collector and composed of an active material containing tin as a main component, and a tin oxide layer formed on the surface of the thin film.

Owner:SANYO ELECTRIC CO LTD

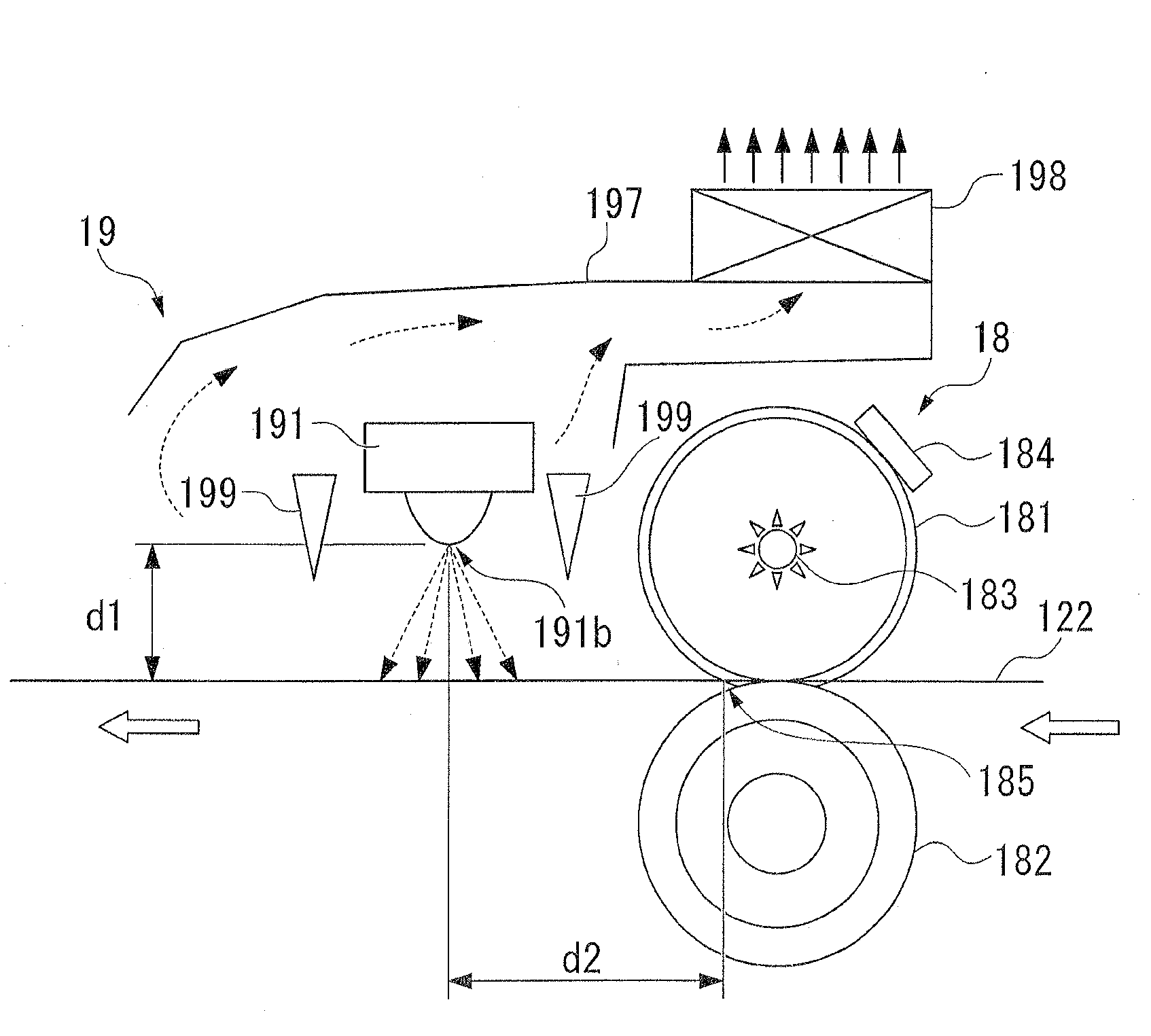

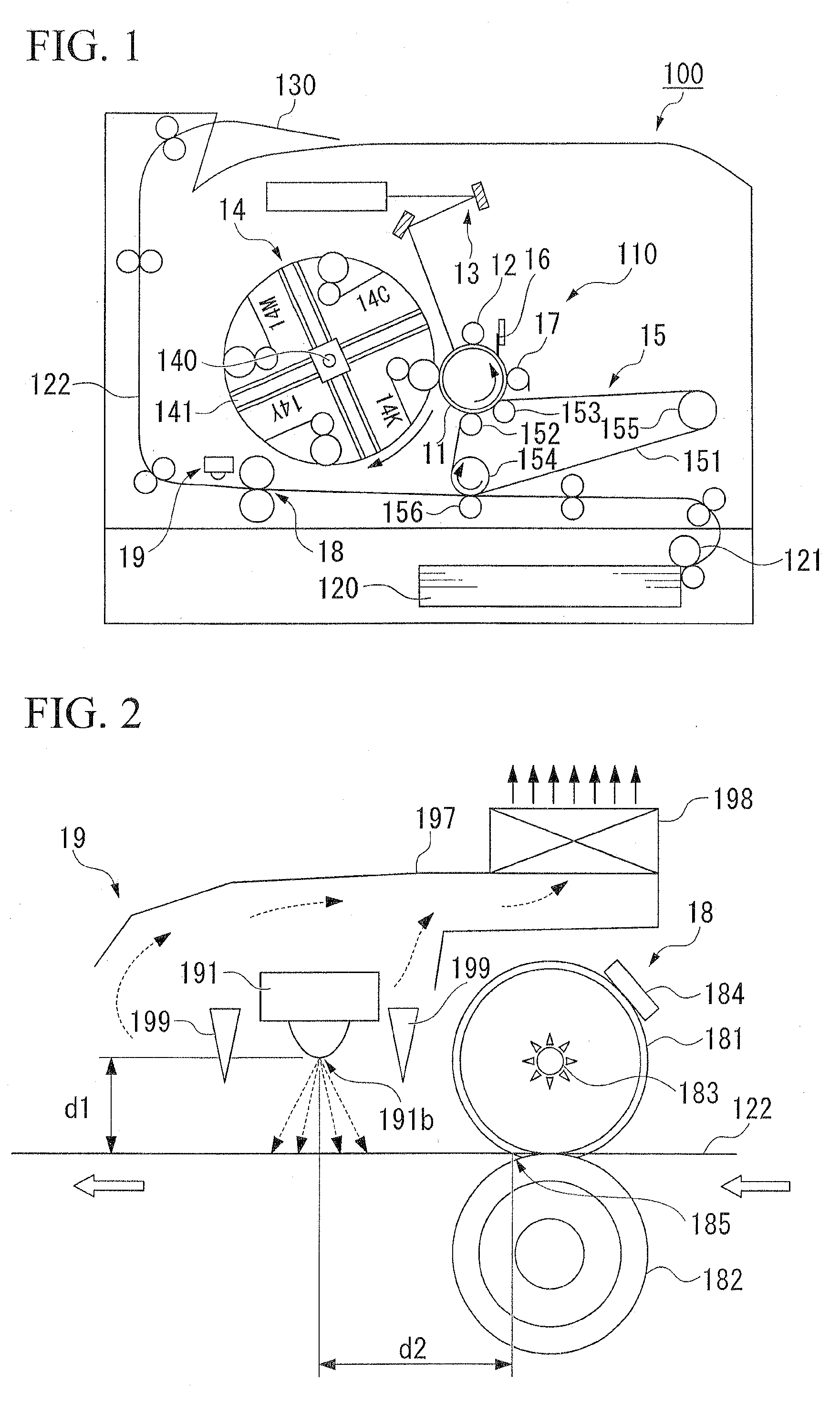

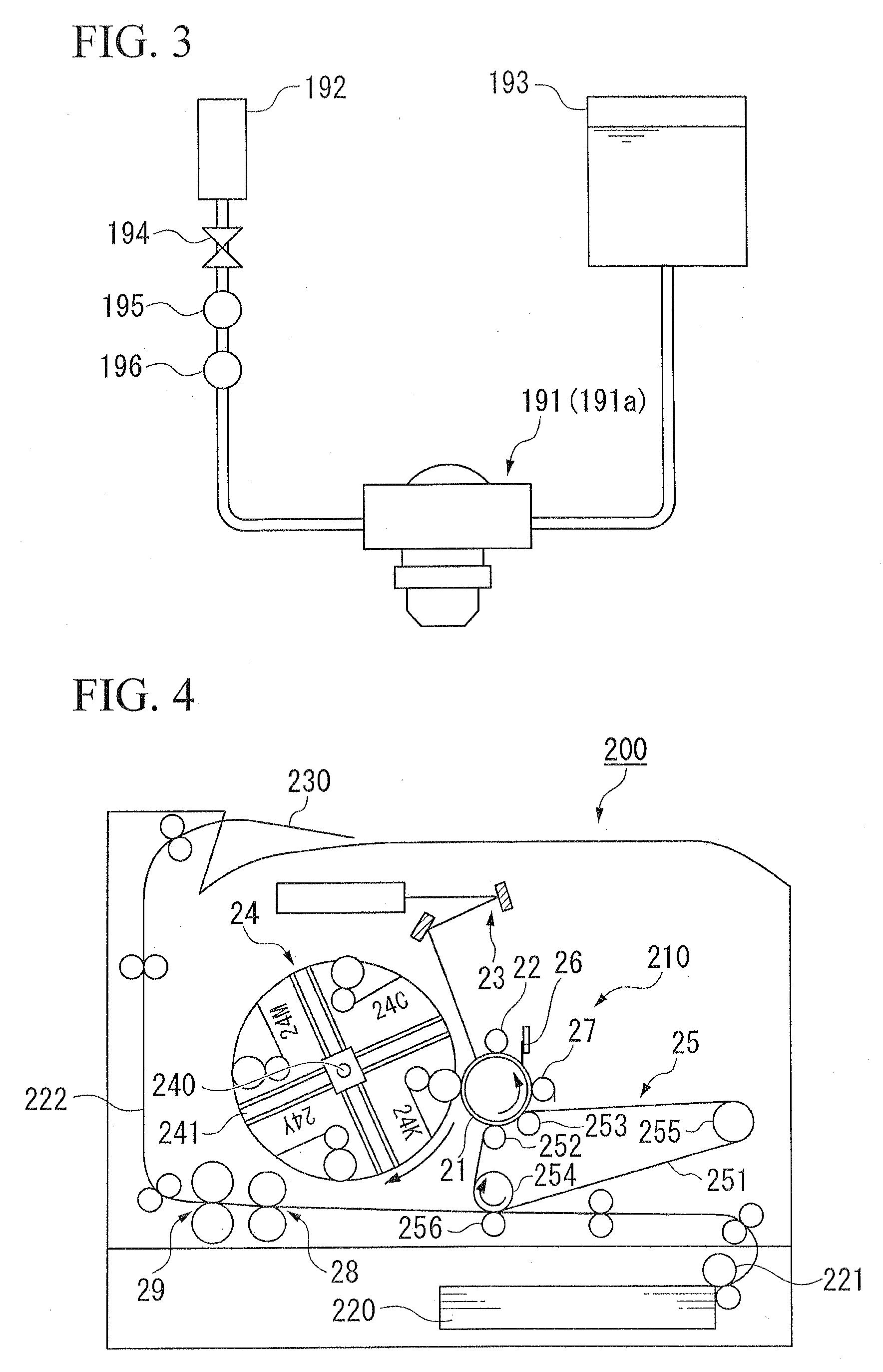

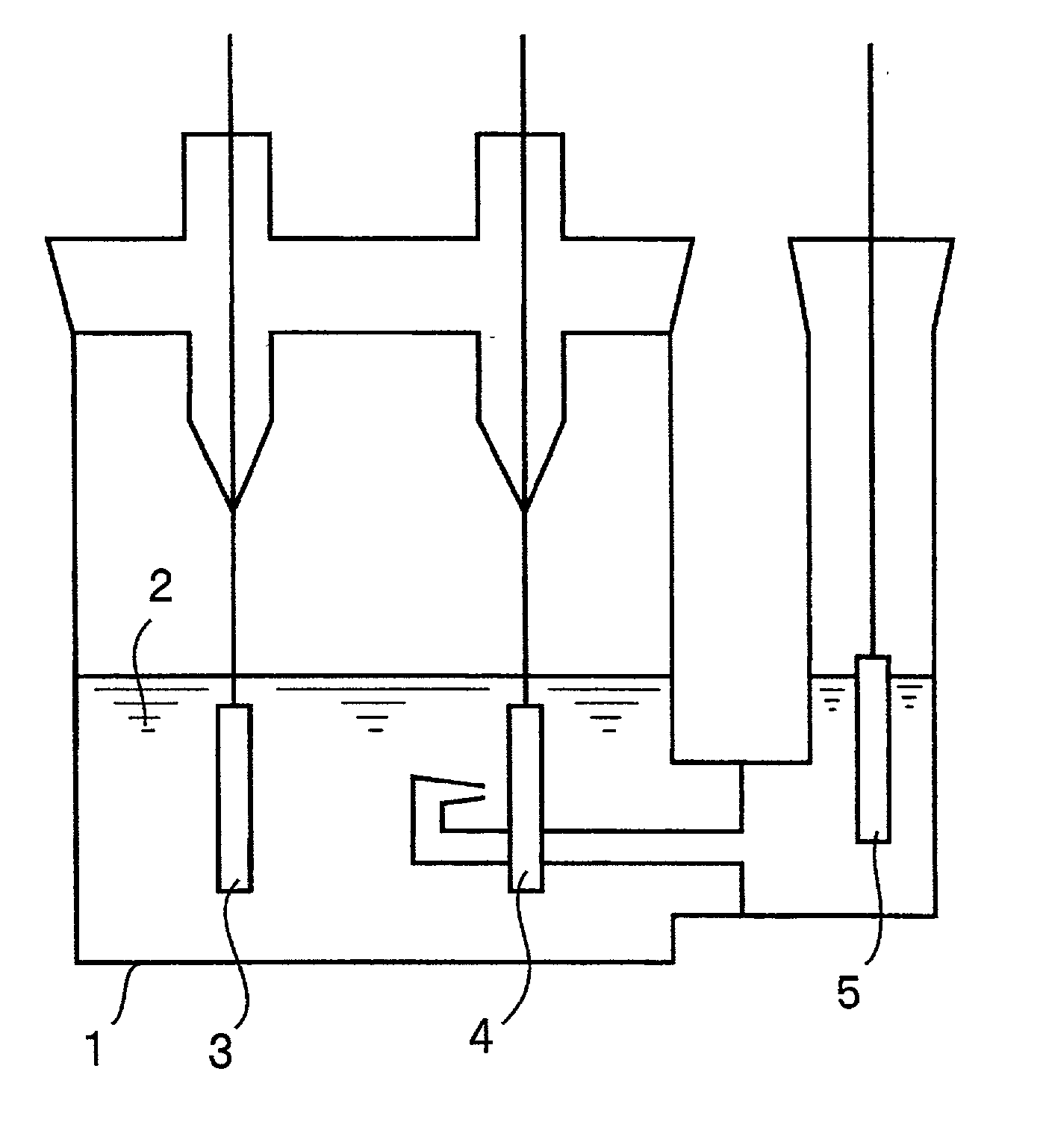

Image Forming Device and Image Forming Method

InactiveUS20090016765A1Improve smoothnessImprove glossElectrographic process apparatusCooling UnitsElectrical and Electronics engineering

An image forming device including: a fixing unit that fixes a toner image formed on a recording medium by heating the toner image to a temperature that is higher than the softening point of a toner that forms the toner image; and a cooling unit that cools the fixed toner image from a temperature that is higher than the softening point of the toner, to a temperature that is lower than the softening point of the toner, at a predetermined cooling speed.

Owner:KYOCERTA MITA

Electrode for lithium secondary battery and lithium secondary battery

InactiveUS20020172862A1Improve efficiencyImprove featuresElectrode carriers/collectorsNegative electrodesCurrent collectorLithium

An electrode for a lithium secondary battery comprises a current collector composed of a metal incapable of alloy formation with lithium, a thin film formed by depositing on the current collector and composed of an active material containing tin as a main component, and a tin oxide layer formed on the surface of the thin film.

Owner:SANYO ELECTRIC CO LTD

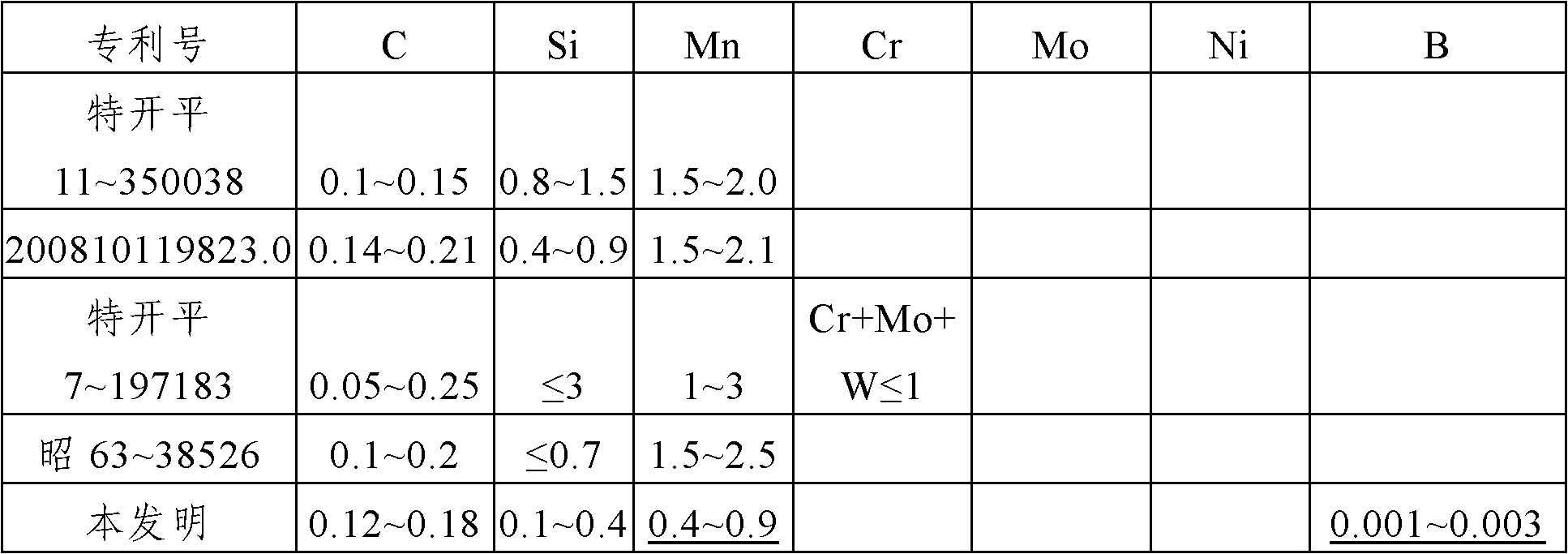

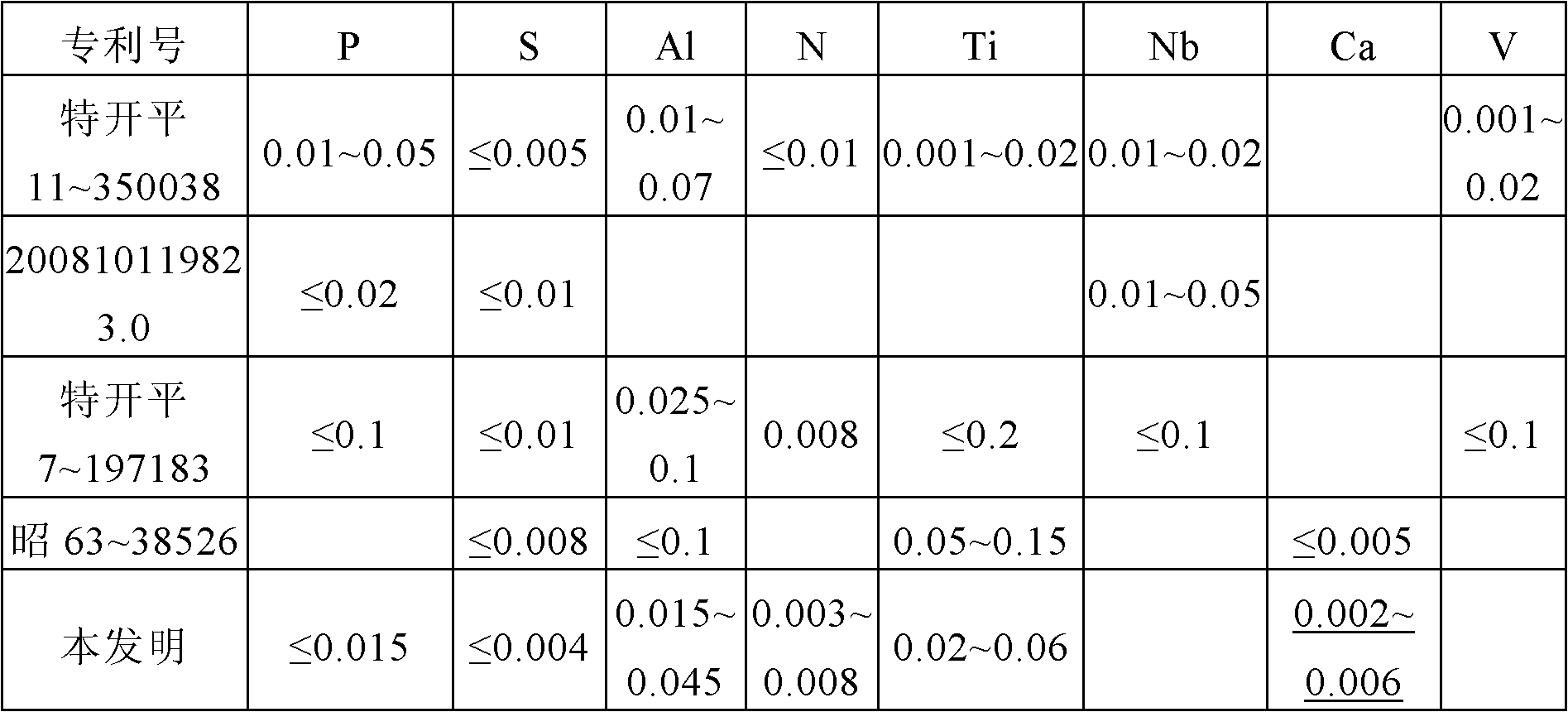

Super-high strength cold rolled steel belt suitable for rolling formation and manufacture method of super-high strength cold rolled steel belt

The invention provide a super-high strength cold rolled steel belt suitable for rolling formation and a manufacture method of the super-high strength cold rolled steel belt. The super-high strength cold rolled steel belt comprises the following ingredients by weight percent: 0.12 to 0.18 percent of C; 0.1 to 0.4 percent of Si; 0.4 to 0.9 percent of Mn; 0.001 to 0.003 percent of B; 0 to 0.015 percent of P; 0 to 0.004 percent of S; 0.003 to 0.008 percent of N; 0.02 to 0.06 percent of Ti; 0.015 to 0.045 percent of Al; 0.002 to 0.006 percent of Ca; and Fe and unavoidable impurities in balancing amount. Through a reasonable ingredient design and a process design, the super-high strength cold rolled steel belt suitable for rolling formation is obtained; the tissue distribution is uniform; the performance uniformity is high; and a steel belt-type tissue is light and small, so that the cold bending performance is high. Moreover, the hardenability is moderate; the weld joint strength of the super-high strength cold rolled steel belt after being welded is approximately the same as that of a base metal; and the content of Si in the super-high strength cold rolled steel belt is lower, so that the surface quality of the super-high strength cold rolled steel belt is better, which meets the requirements for rolling and manufacturing vehicle components.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-carbon boron-containing steel continuous casting slab corner crack control method

ActiveCN109852891AReduce grain boundary precipitationControl crackingManufacturing convertersGeneration rateSmelting process

The invention relates to a low-carbon boron-containing steel continuous casting slab corner crack control method. The method includes the steps that firstly, component control is conducted; secondly,the hot metal ratio in the converter smelting process is controlled to range from 85.0% to 87.0%, a bottom blowing mode is adopted in the whole process, nitrogen is blown firstly and argon is blown secondary in the blowing process, blowing is achieved through one shot, and the use proportion of nitrogen and argon is 1:9; thirdly, the C content of the smelting end point is controlled to range from0.035+ / -0.02, and the tapping temperature ranges from 1660+ / -5 DEG C; fourthly, a half-deoxygenation technology is adopted for tapping in the converter smelting tapping process; fifthly, deoxidizing and alloying are conducted at the same time in the tapping process; sixthly, after tapping is conducted, a steel ladle is directly converted into an argon station for argon blowing refining; and seventhly, in the continuous casting process, strong cooling control is conducted on a wide and narrow foot roll area of the continuous casting billet, a second area, a third area and a fourth area of a vertical bending area and a first section of an arc section, and then conventional cooling control is adopted on the second section, the third section, the fourth section, the fifth section, the sixth section, the seventh section and the eighth section of the arc shape. By means of the low-carbon boron-containing steel continuous casting slab corner crack control method, the casting billet corner crack generation rate of the low-carbon boron containing steel is stably controlled to be smaller than 0.1%.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

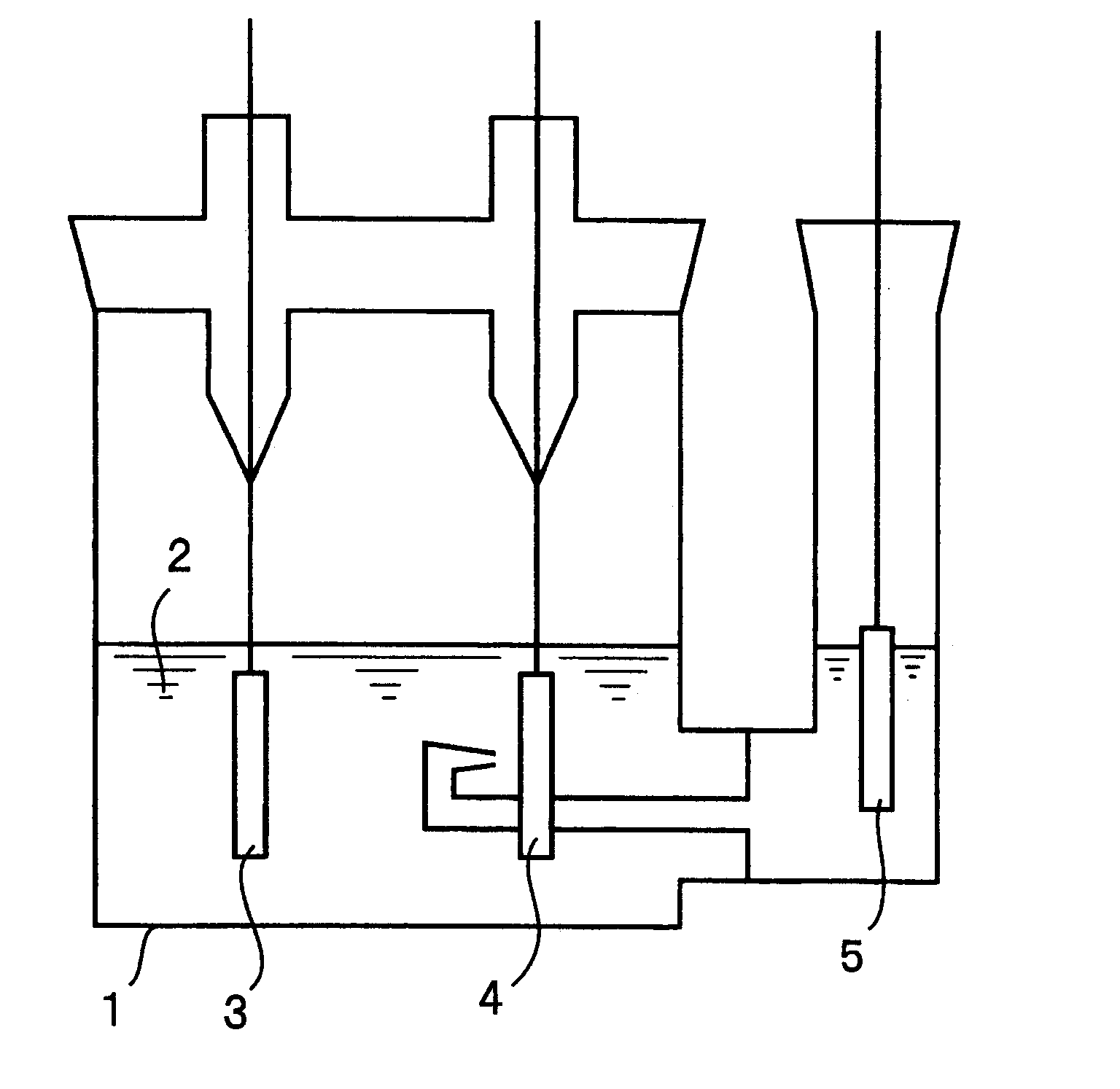

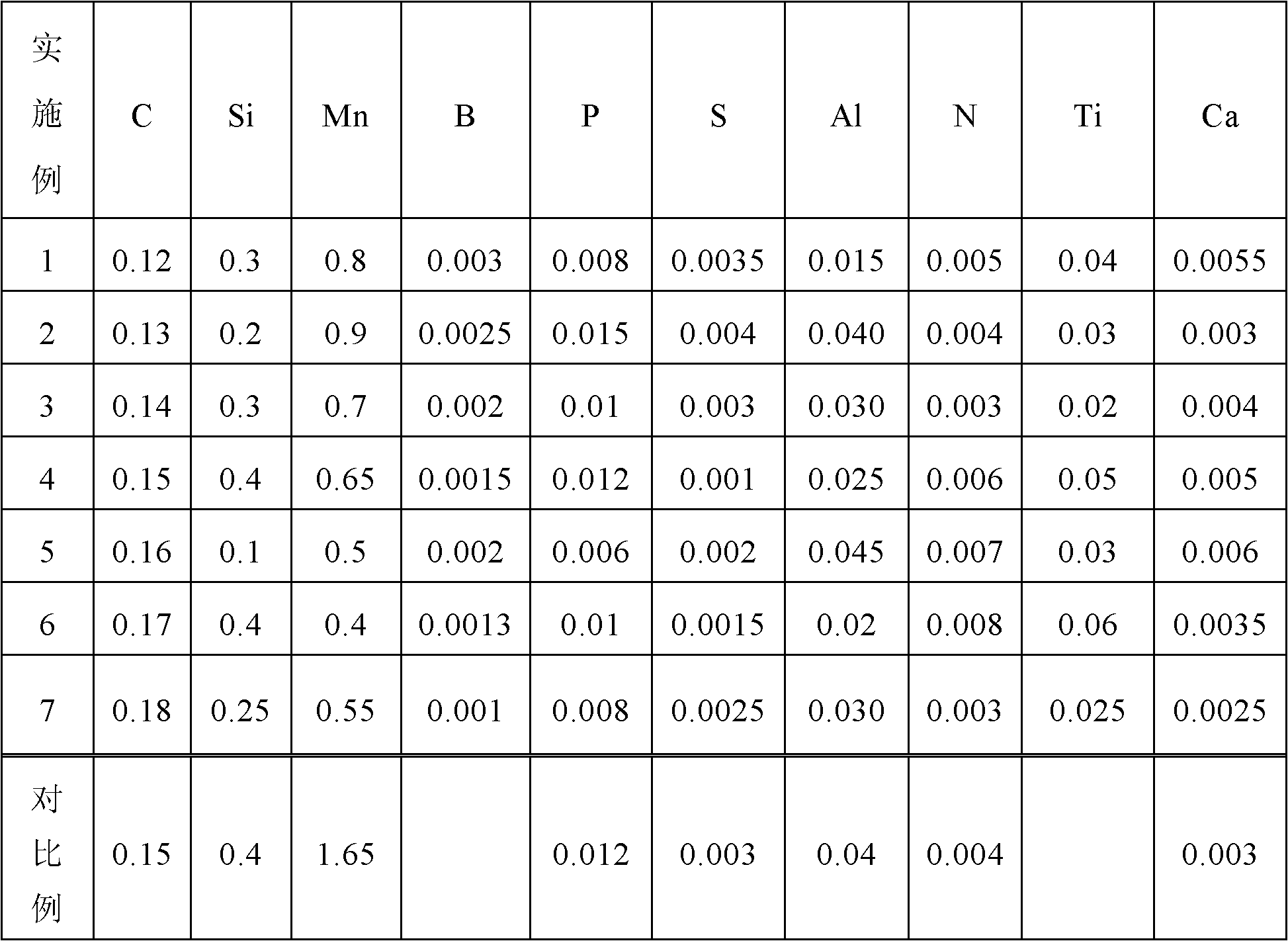

Method for controlling the defect of sintering expansion of powder metallurgy material and products thereof and mold

ActiveCN101530916AControl axial displacementControlling Constrained Axial Displacement of Sintering Expansion Defects in Powder Metallurgy Materials and Their ProductsChemical reactionVolumetric Mass Density

The invention discloses a method for controlling the defect of sintering expansion of powder metallurgy material and products thereof and a mold. In the sintering process of powder body, three-dimensional restraint compressive stress is applied to the body, thus generating restraint action to the body, restraining volume expansion generated by physical or chemical reactions of the body in the sintering process, realizing restraint sintering, controlling sintering densification thereof and eliminating the defects of sintering expansion. A restraint mold (1) is internally provided with an external mold; the matching conicity between the restraint mold (1) and the external mold is Theta which is larger than 5 degrees and smaller than 15 degrees; the external mold is internally provided with an internal mold; and a spacer (6) which is used for preventing the reaction of the body and the mold is arranged between the internal mold and the sintering body. The invention is a restraint sintering method which can effectively prevent the powder metallurgy material and products thereof from generating expansion, deformation, cracking and pore / hole and the like and can improve the sintering density and quality; and the using method of the mold is simple and easy to operate.

Owner:CENT SOUTH UNIV

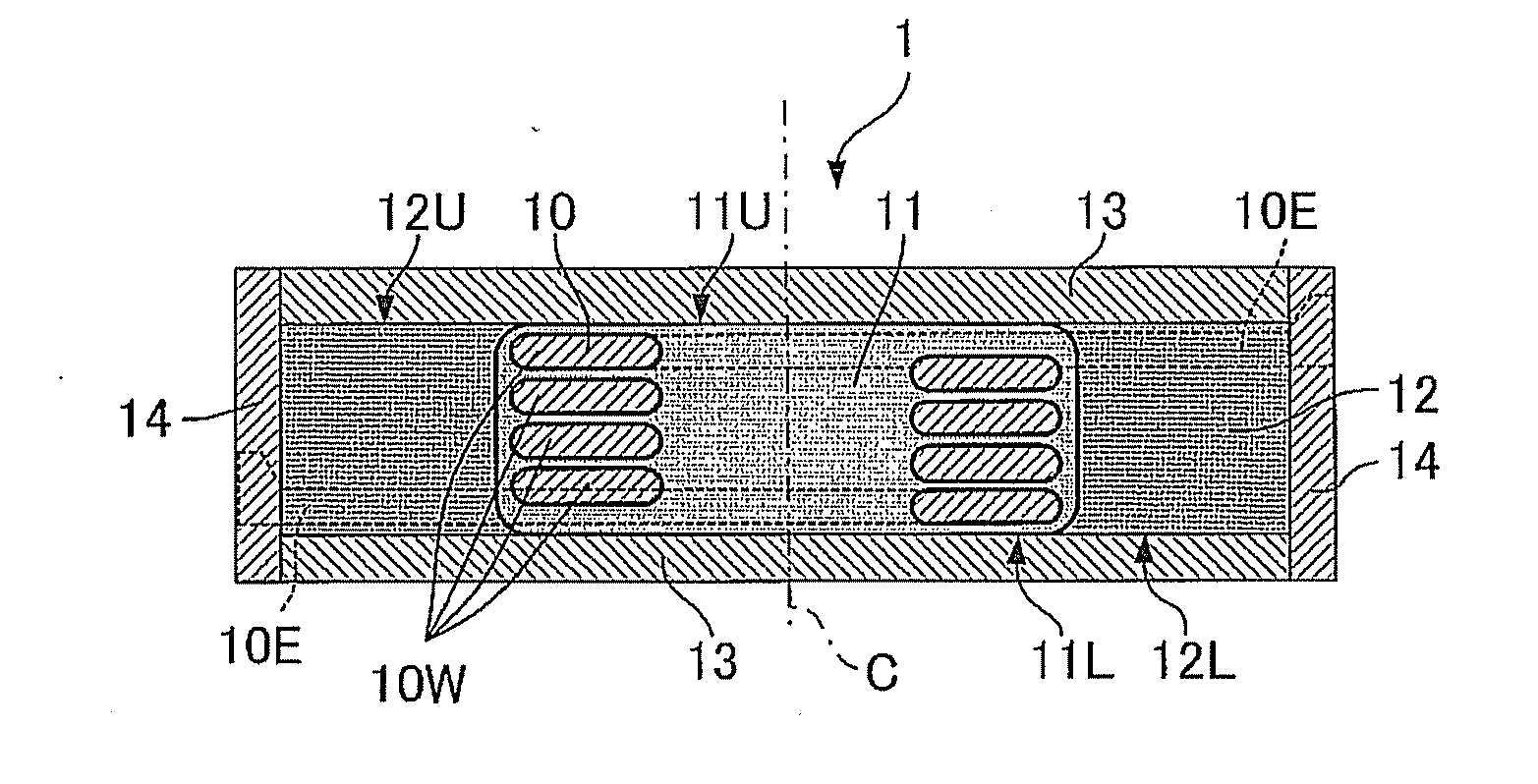

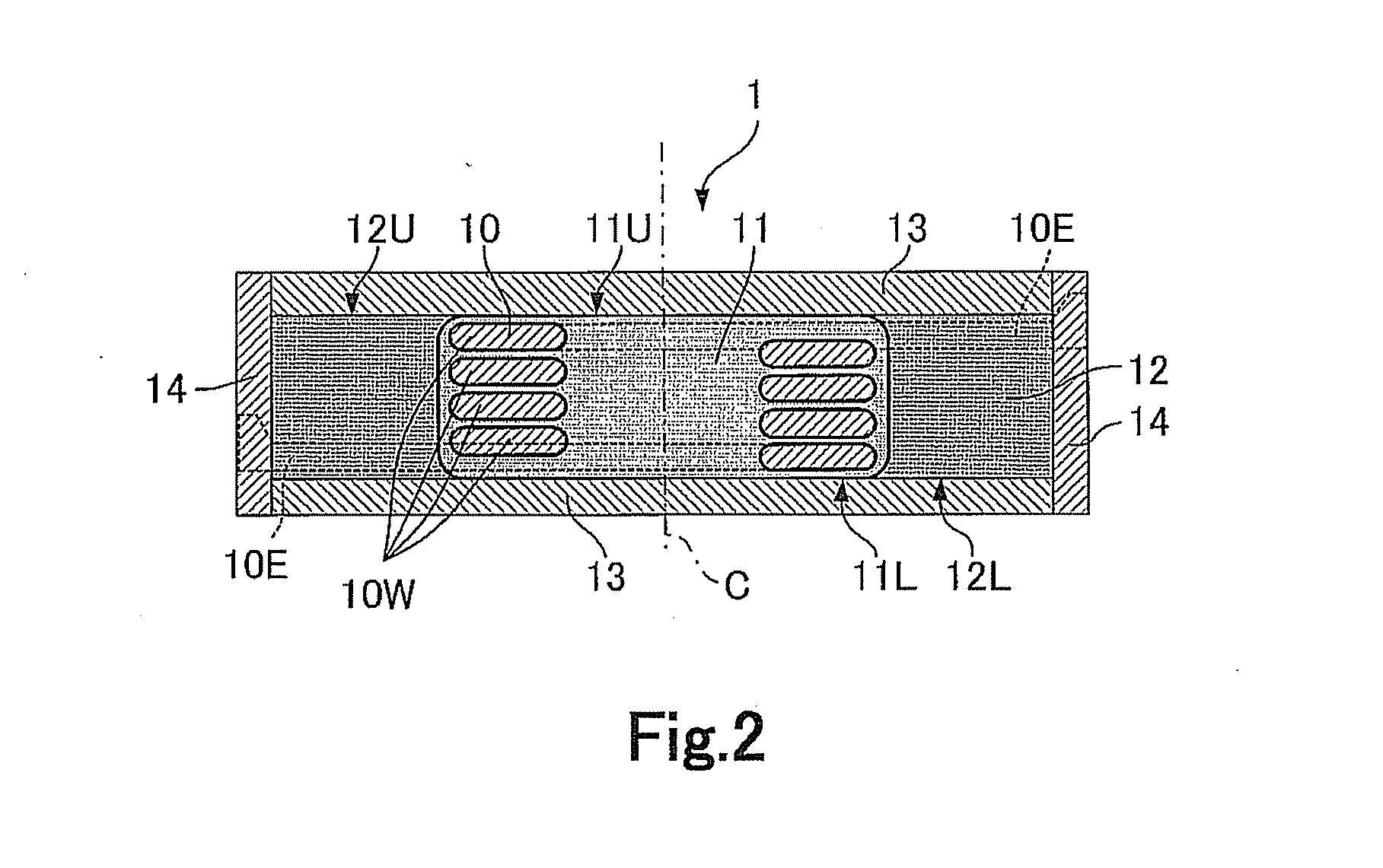

Coil-buried type inductor and a method for manufacturing the same

InactiveUS20110121930A1Simple manufacturing processLarge porosityTransformers/inductances casingsCoils manufacturePorosityInductor

The invention relates to a coil-buried type inductor. The inductor comprises a conductive coil, a first fired ceramics body arranged at least in an area along an inner periphery of the coil, and a second fired ceramics body arranged so as to surround the entire of the coil along with the first fired ceramics body. The first fired ceramics body has porosity equal to or larger than 40 percent and smaller than 70 percent.

Owner:NGK INSULATORS LTD

Metal-based anodes for aluminium electrowinning cells

InactiveUS20030066755A1Solution to short lifeEliminate pollutionMachining electrodesIsotope separationSurface layerNickel compounds

An anode of a cell for the electrowinning of aluminium comprises a nickel-iron alloy substrate having an openly porous nickel metal rich outer portion whose surface is electrochemically active. The outer portion is optionally covered with an external integral nickel-iron oxide containing surface layer which adheres to the nickel metal rich outer portion of the nickel-iron alloy and which in use is pervious to molten electrolyte. During use, the nickel metal rich outer portion contains cavities some or all of which are partly or completely filled with iron and nickel compounds, in particular oxides, fluorides and oxyfluorides.

Owner:MOLTECH INVENT

Metal-based anodes for aluminium electrowinning cells

InactiveUS6998032B2Eliminate pollutionSolution to short lifeMachining electrodesIsotope separationSurface layerDissolution

Owner:MOLTECH INVENT

Metal-based anodes for aluminium electrowinning cells

InactiveUS20050194066A1Eliminate pollutionSolution to short lifeSolid state diffusion coatingElectrodesSurface layerNickel compounds

An anode of a cell for the electrowinning of aluminium comprises a nickel-iron alloy substrate having an openly porous nickel metal rich outer portion whose surface is electrochemically active. The outer portion is optionally covered with an external integral nickel-iron oxide containing surface layer which adheres to the nickel metal rich outer portion of the nickel-iron alloy and which in use is pervious to molten electrolyte. During use, the nickel metal rich outer portion contains cavities some or all of which are partly or completely filled with iron and nickel compounds, in particular oxides, fluorides and oxyfluorides.

Owner:DURUZ JEAN JACQUES +2

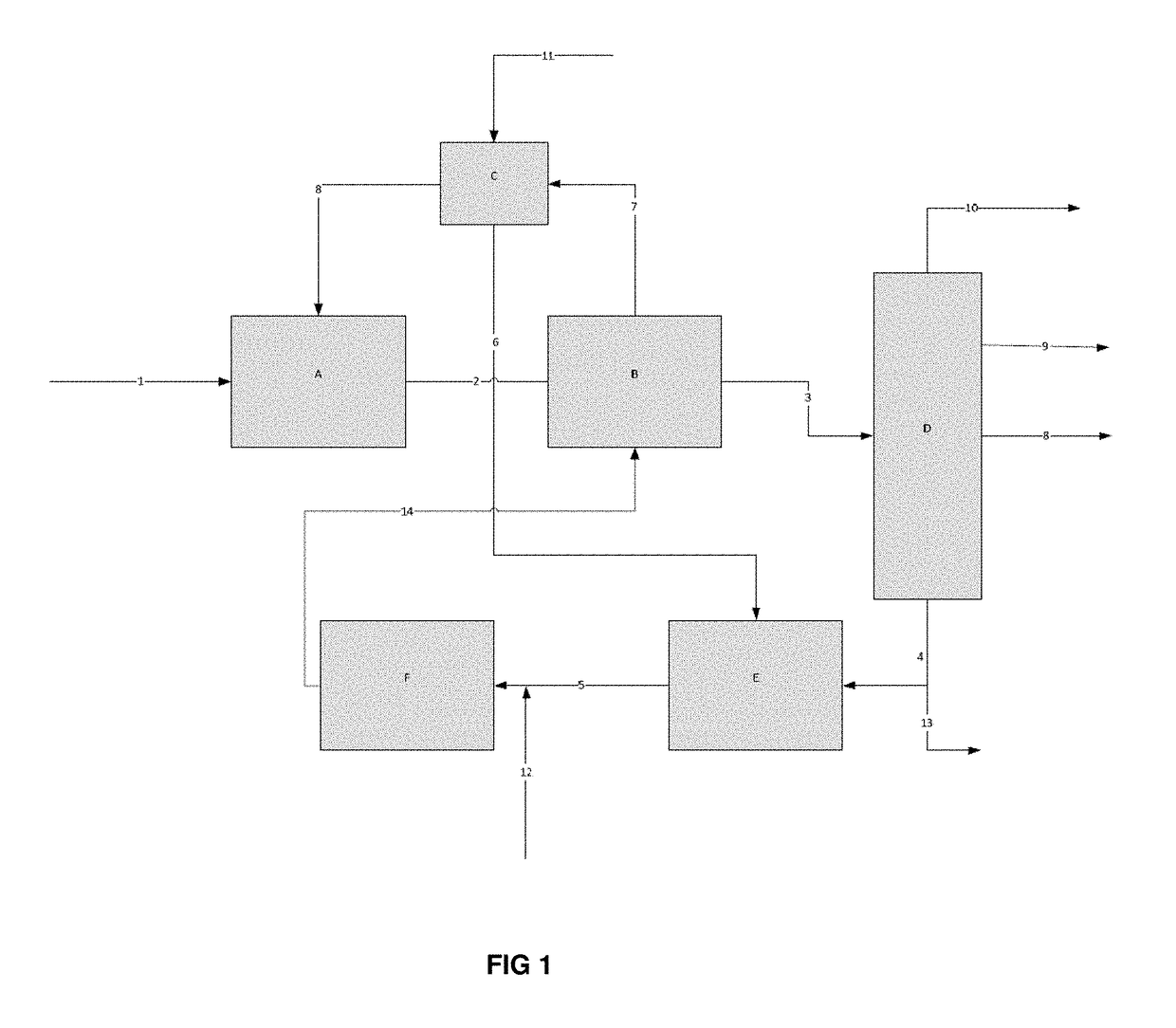

Process integrating two-stage hydrocracking and a hydrotreatment process

ActiveUS20180362864A1Reduce consumptionReduce investmentHydrocarbon oils treatment control/regulationHydrocarbon oil crackingHydrogenBoiling point

A process for hydrocracking hydrocarbon-containing VD feedstocks allowing the improved production of middle distillates: a) hydrocracking of feedstocks in hydrogen and at least one hydrocracking catalyst, b) gas / liquid separation of effluent originating from a) producing a liquid effluent and a gaseous effluent with hydrogen, c) comprising the gaseous effluent before recycling into hydrocracking a), d) fractionation of liquid effluent into at least one effluent of converted hydrocarbon-containing products having boiling points less than 340° C. and an unconverted liquid fraction having a boiling point greater than 340° C., e) hydrocracking unconverted liquid fraction from d), in hydrogen and a hydrocracking catalyst, f) hydrotreating effluent from e) in a mixture with a hydrocarbon-containing gas-oil liquid feedstock having at least 95% by weight of compounds boiling at a boiling point between 150 and 400° C., hydrotreating f) operating in hydrogen and with at least one hydrotreating catalyst.

Owner:INST FR DU PETROLE

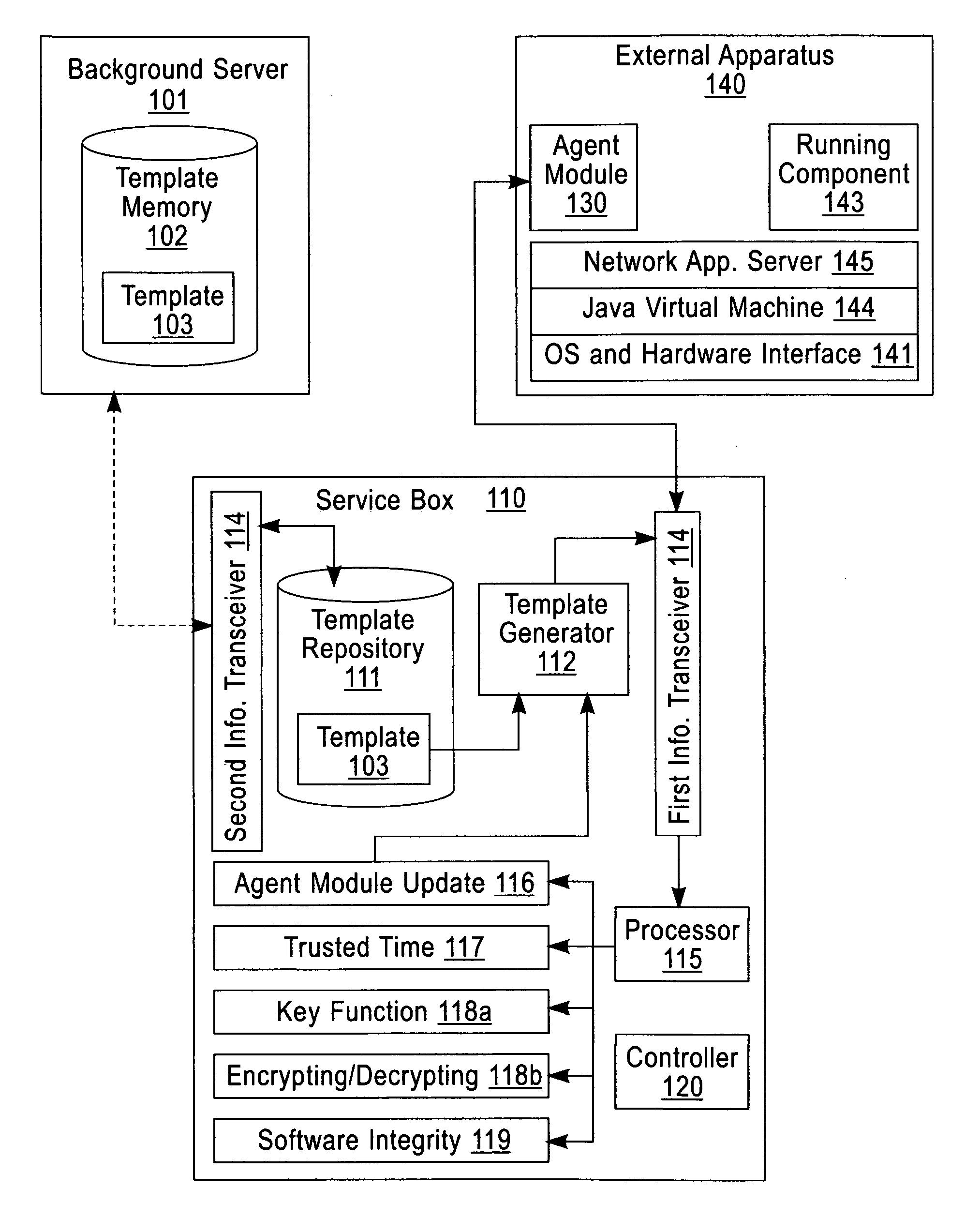

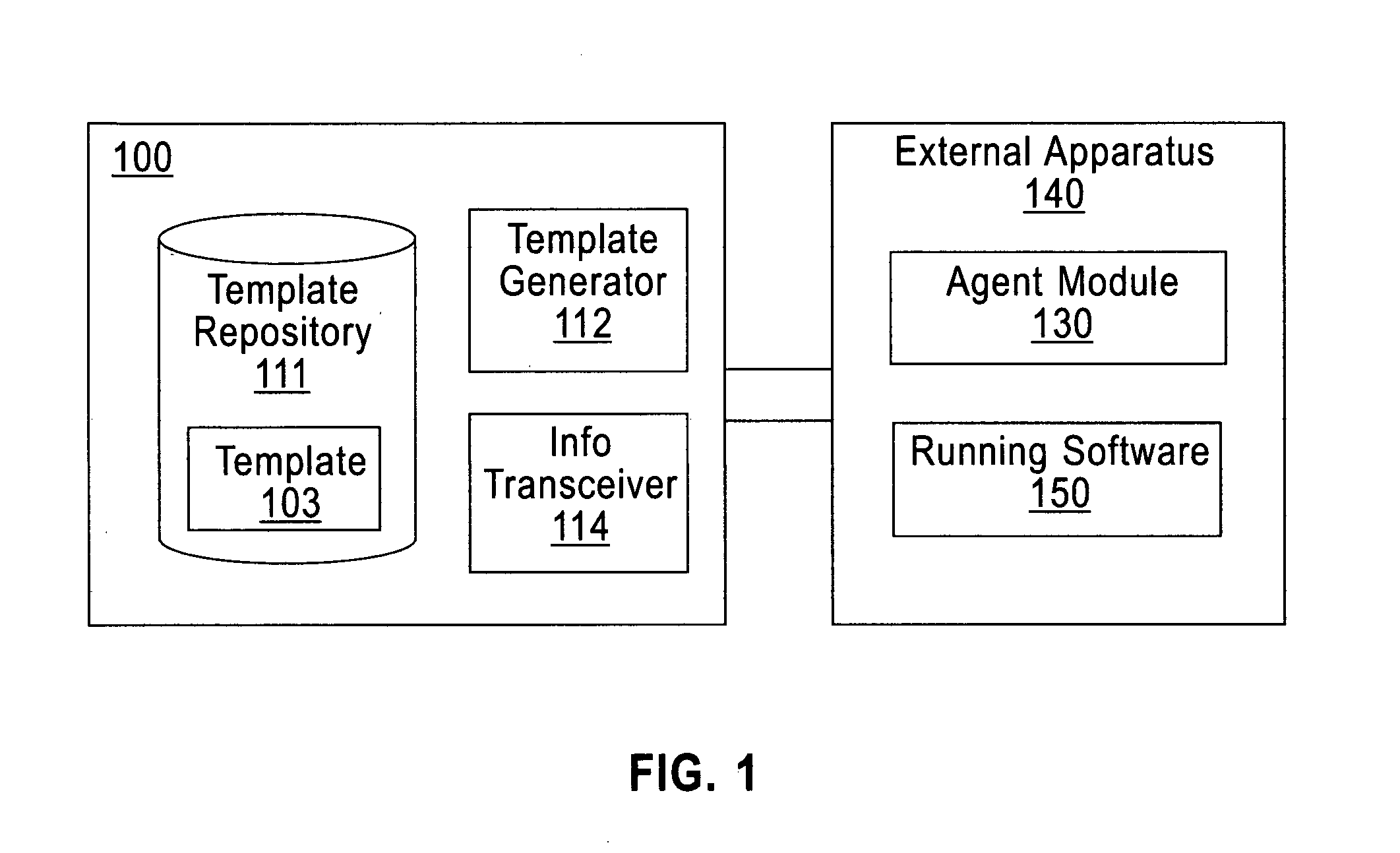

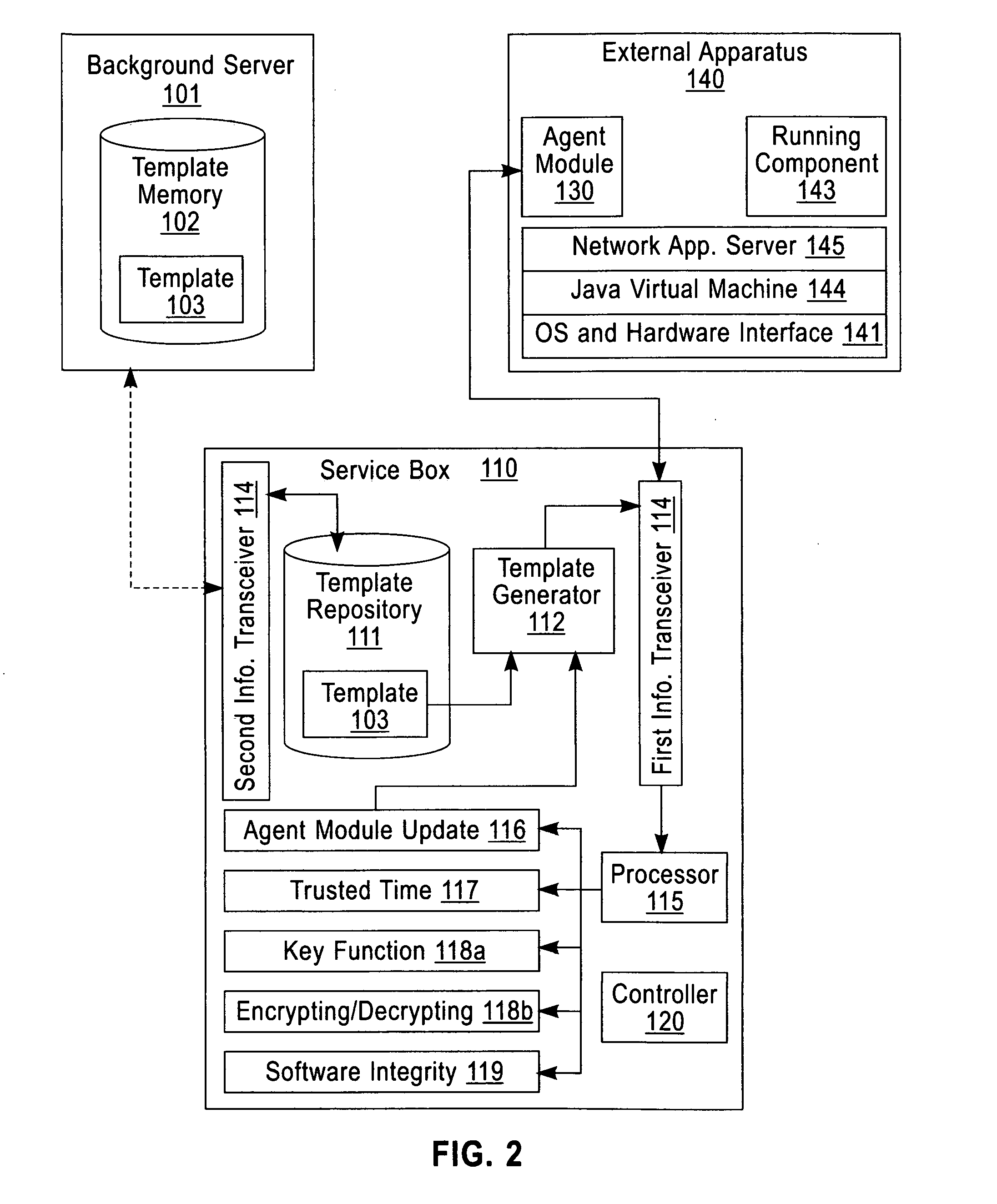

Secure apparatus and method for protecting integrity of software system and system thereof

InactiveUS20090327745A1Convenient and cost-efficient for customerLow costDigital data processing detailsUnauthorized memory use protectionComputer hardwareTransceiver

Provided is a secure apparatus for protecting the integrity of a software system and a method thereof. The apparatus comprises: a template repository for storing templates required for generating an agent template; a template generator for randomly selecting one template from said template repository and generating a new agent template according to the selected template; and a transceiver for sending said new agent module to an external apparatus communicating with said secure apparatus to update a current agent module which is running in said external apparatus, wherein said current agent module is used to verify the integrity of said software system running in said external apparatus. The secure apparatus can protect software in an insecure environment with a high software protection level to prevent the software from being tampered or bypassed.

Owner:IBM CORP

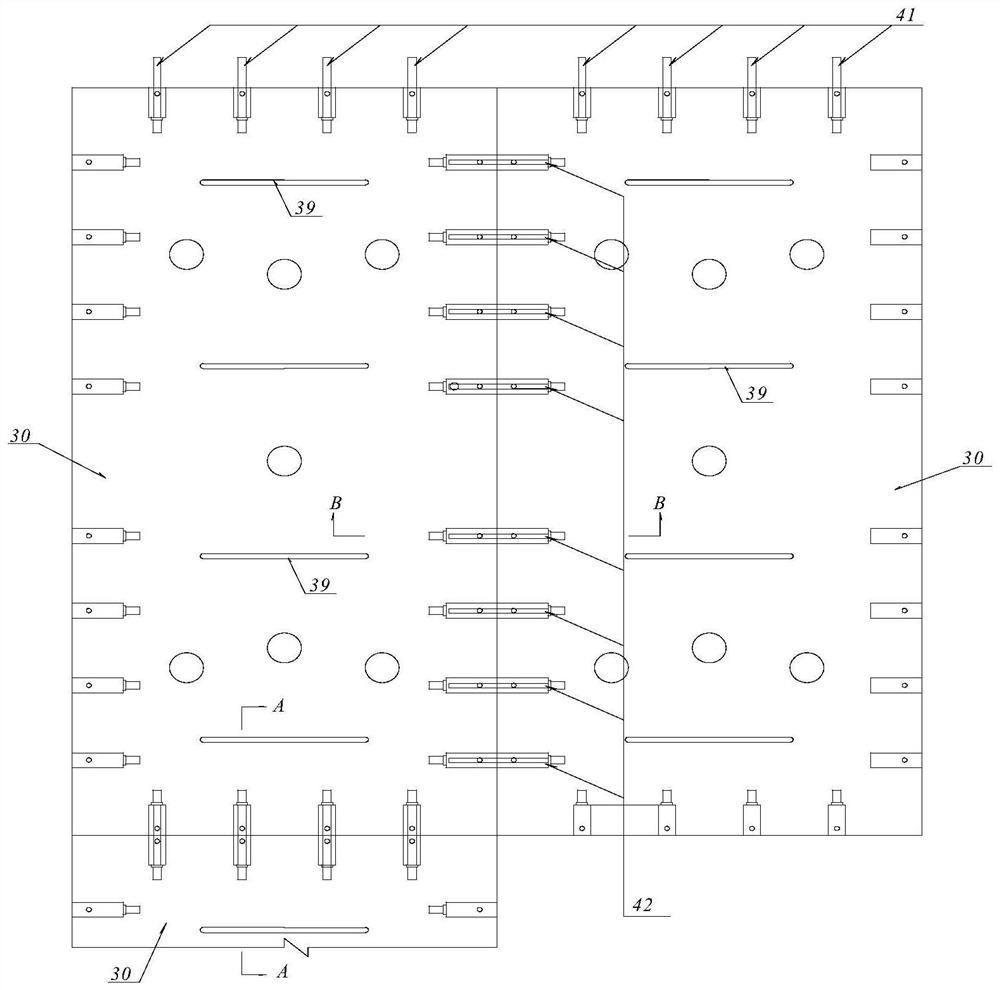

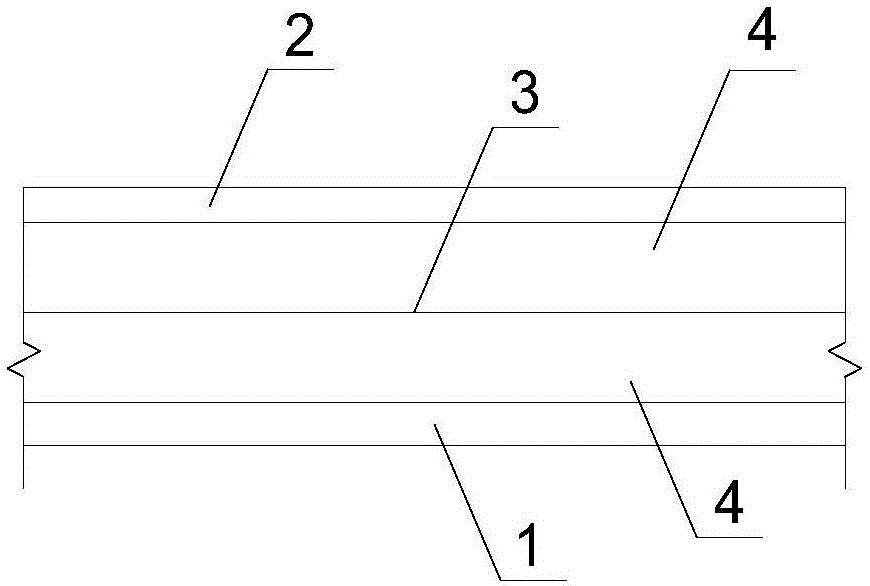

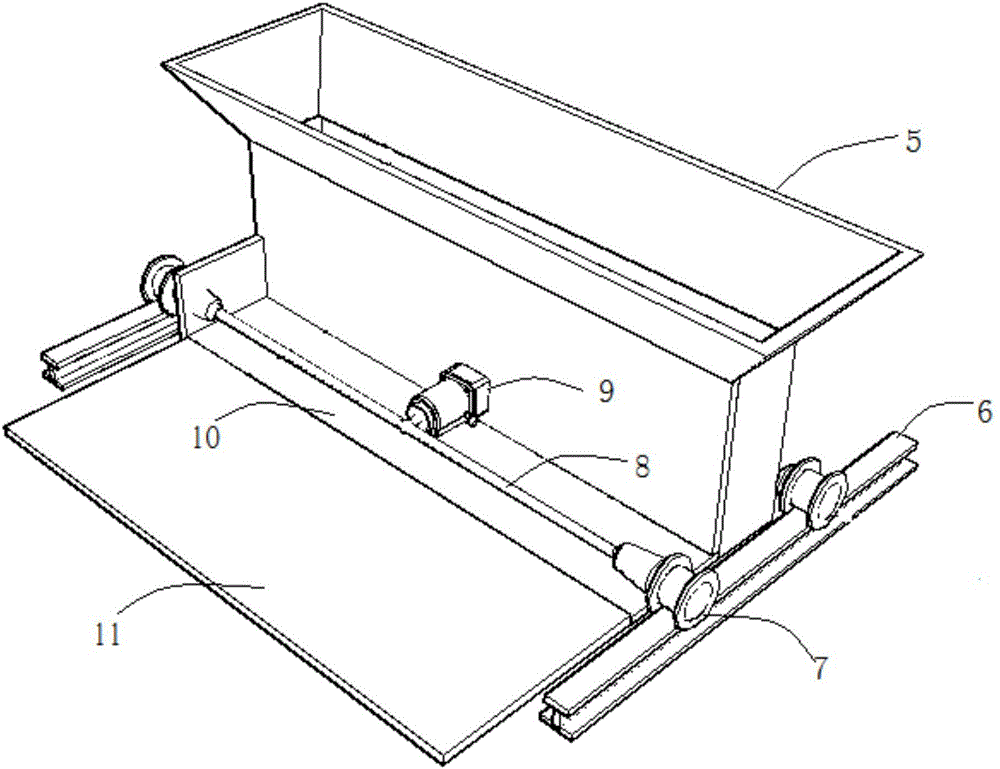

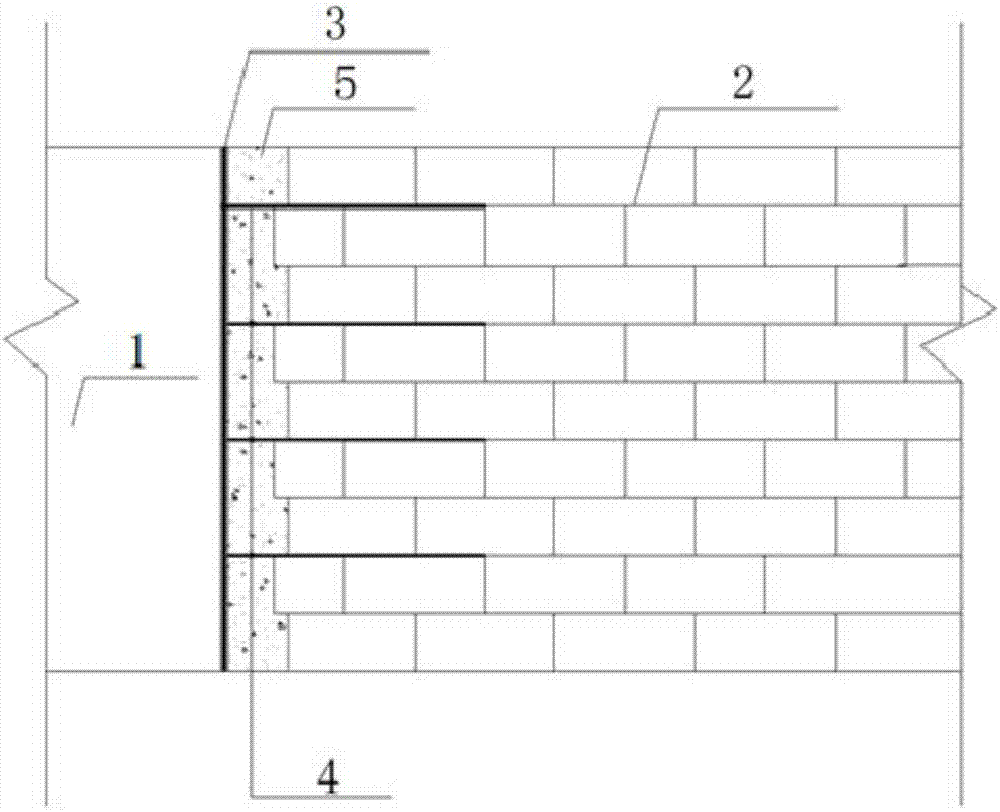

Assembly type pavement structure and construction method

PendingCN112626962AImprove connection securityHigh strengthSingle unit pavingsReinforced concreteArchitectural engineering

The invention discloses an assembly type pavement structure and a construction method, and aims to effectively improve the connection safety, the adjustment capability and the repairable capability of a prefabricated pavement, facilitate the manufacturing and transportation of the prefabricated pavement, and facilitate the assembly, repair, replacement and construction. Prefabricated pavement slabs are assembled on a roadbed to form an assembled pavement, each prefabricated pavement slab is of a prestressed reinforced concrete structure, longitudinal lower grooves are formed in the two longitudinal connecting ends of each prefabricated pavement slab at intervals in the width direction, and transverse lower grooves are formed in the two transverse connecting ends of each prefabricated pavement slab at intervals in the width direction. Rod-shaped connecting components are arranged in the corresponding longitudinal lower grooves or the corresponding transverse lower grooves of every two adjacent prefabricated pavement slabs. An isolation layer is laid on the surface of the roadbed, after the assembled prefabricated pavement slab is leveled, self-compacting concrete is densely poured into a gap between the laid isolation layer and the prefabricated pavement slab to form an adjusting layer, and positioning bosses which protrude upwards and are embedded into longitudinal lower grooves and transverse lower grooves of the prefabricated pavement slab are formed on the adjusting layer.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

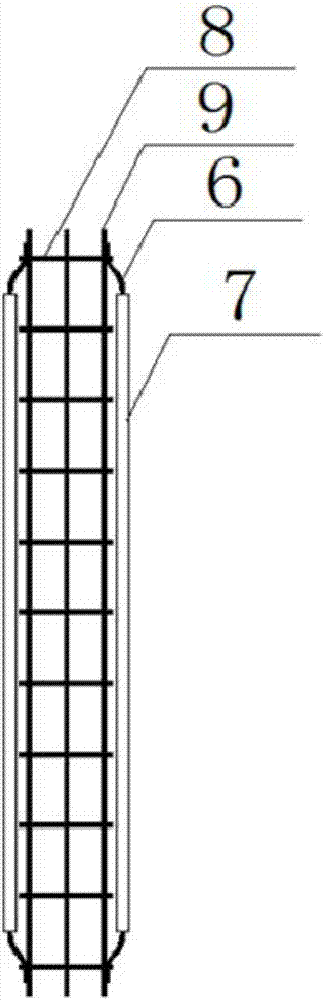

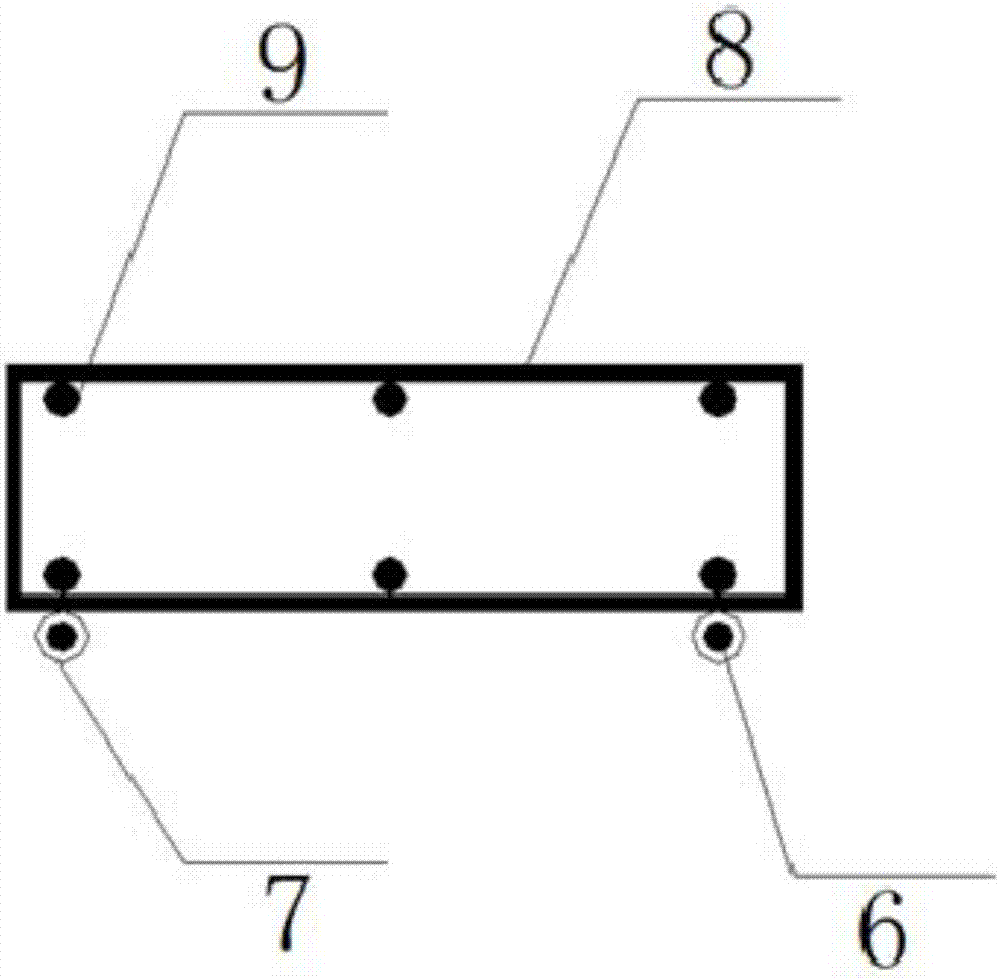

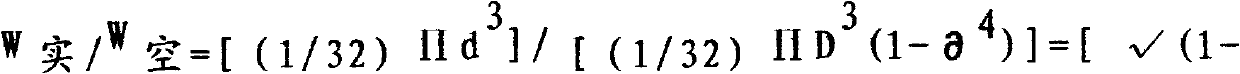

Fiber net-ultra high toughness cementitious compound material composite bridge deck structure and method

ActiveCN106835973AImprove patencyImprove comfortClimate change adaptationBridge structural detailsBridge deckMaterials science

The invention discloses a fiber net-ultra high toughness cementitious compound material composite bridge deck structure and a method. The fiber net-ultra high toughness cementitious compound material composite bridge deck structure comprises a bridge deck plate and a fiber net-reinforced ultra high toughness cementitious compound material pavement layer poured onto the bridge deck plate, wherein an asphalt concrete wearing layer is paved on the fiber net-reinforced ultra high toughness cementitious compound material pavement layer. In the fiber net-ultra high toughness cementitious compound material composite bridge deck structure, due to the adoption of the fiber net-reinforced ultra high toughness cementitious compound material pavement layer, damages, such as longitudinal cracks and wave pass which are caused by repeated action of temperature and vehicle load, local upheaval and comminuted racks of the traditional asphalt concrete paving method are avoided; patency and comfort of vehicles are improved; the durability of a bridge structure is also improved.

Owner:SHANDONG UNIV

Pneumatic tire

InactiveUS7665496B2Increased durabilityReduce generationInflatable tyresTyre sidewallsStress concentrationEngineering

Owner:BRIDGESTONE CORP

Construction method for tying and lacing main body structure and filler wall

InactiveCN107237424APut an end to the problem of not satisfying the block modulusReduce processWallsEngineeringRebar

The invention discloses a construction method for tying and lacing a main body structure and a filler wall. The construction method includes the following steps of 1, machining pre-buried rebar into an n shape; 2, covering a pearl cotton foam pipe on the direct section of the pre-buried rebar, and sealing the two ends with tape; 3, welding the bending section of the pre-buried rebar with a horizontal hoop and vertical rebar of main body structure rebar; 4, mounting a main body structure formwork, attaching the pearl cotton foam pipe to the formwork tightly, and casting the main body structure; 5, conducting positioning and paying off according to a drawing, lining the moduli of a masonry wall well, and reserving the position of a concrete transition zone; 6, before bricklaying the filler wall, using a utility knife to cut the pearl cotton foam pipe, eliminating and cleaning out, using a tie bar to conduct tying and lacing on the pre-buried rebar and the filler wall, and using a tie bar with a bending hook to hook the pre-buried rebar directly and then conducting tying and binding; and 7, adopting a backward-first and forward-later mode to bricklaying the filler wall so as to form combed joints on the concrete transition zone to achieve the effect of a constructional column. The construction method for tying and lacing the main body structure and the filler wall has the advantages of being simpler in construction and good in construction quality.

Owner:TIANJIN SANJIAN CONSTR ENG

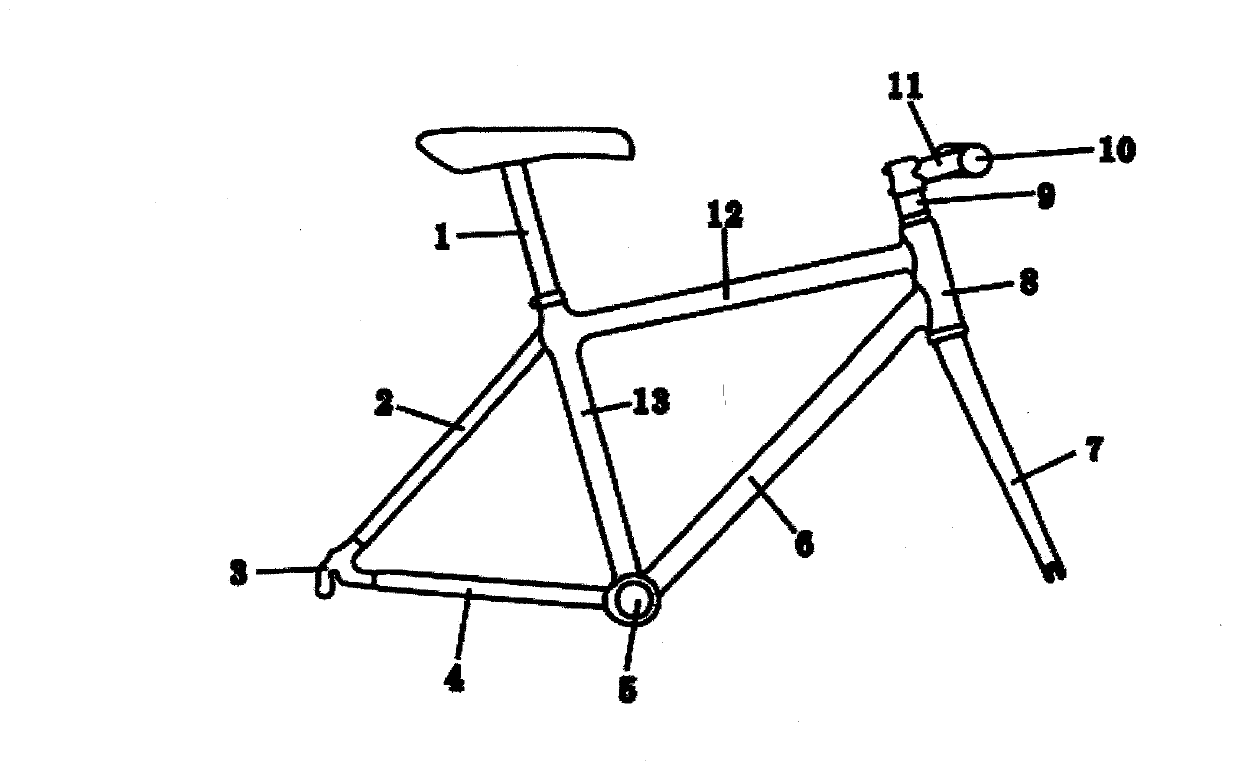

Method for manufacturing novel, energy-saving and environmental-friendly bicycle pipe support components through bamboo skin coiled materials

ActiveCN103659991AFree from mothsControl crackingWood treatment detailsFlat articlesPipe supportEnvironmental resistance

The invention discloses a method for manufacturing novel, energy-saving and environmental-friendly bicycle pipe support components through bamboo skin coiled materials. The method comprises the following steps that firstly, moso bamboo is selected and steamed; secondly, the bamboo is flattened, pressure maintaining and rolling-in are carried out on the bamboo, and the bamboo is processed in a planing mode; thirdly, drying is carried out, and gluing and machining are carried out; fourthly, assembling and hot-pressing are carried out, and bamboo skin coils are pressed into the bamboo skin coiled materials; fifthly, the components (some components can be made of bamboo pressing sheets according to the practical application) needed by all pipe supports are made of the bamboo skin coiled materials, and component assembling is carried out. By the adoption of the technical scheme, a bicycle is better in stability, the weight of the bicycle can be reduced, and meanwhile the overall strength of the bicycle is further improved; the bicycle is firmer, so that guarantee is provided for safe use; the bicycle and the manufacturing method are economical and practical, economic benefits and social benefits are obvious, and therefore the method can be popularized and applied conveniently.

Owner:苏州天健竹业科技有限公司

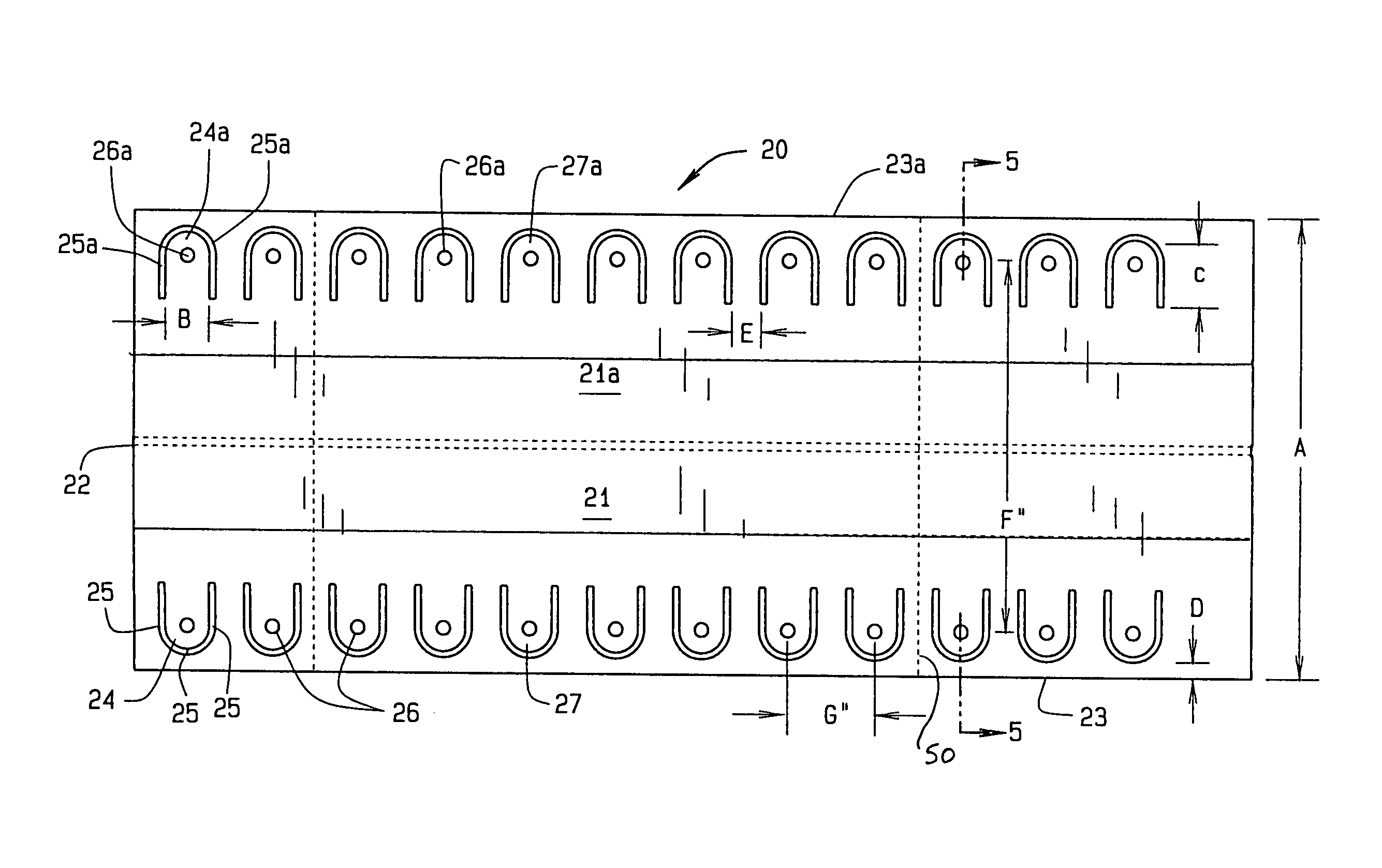

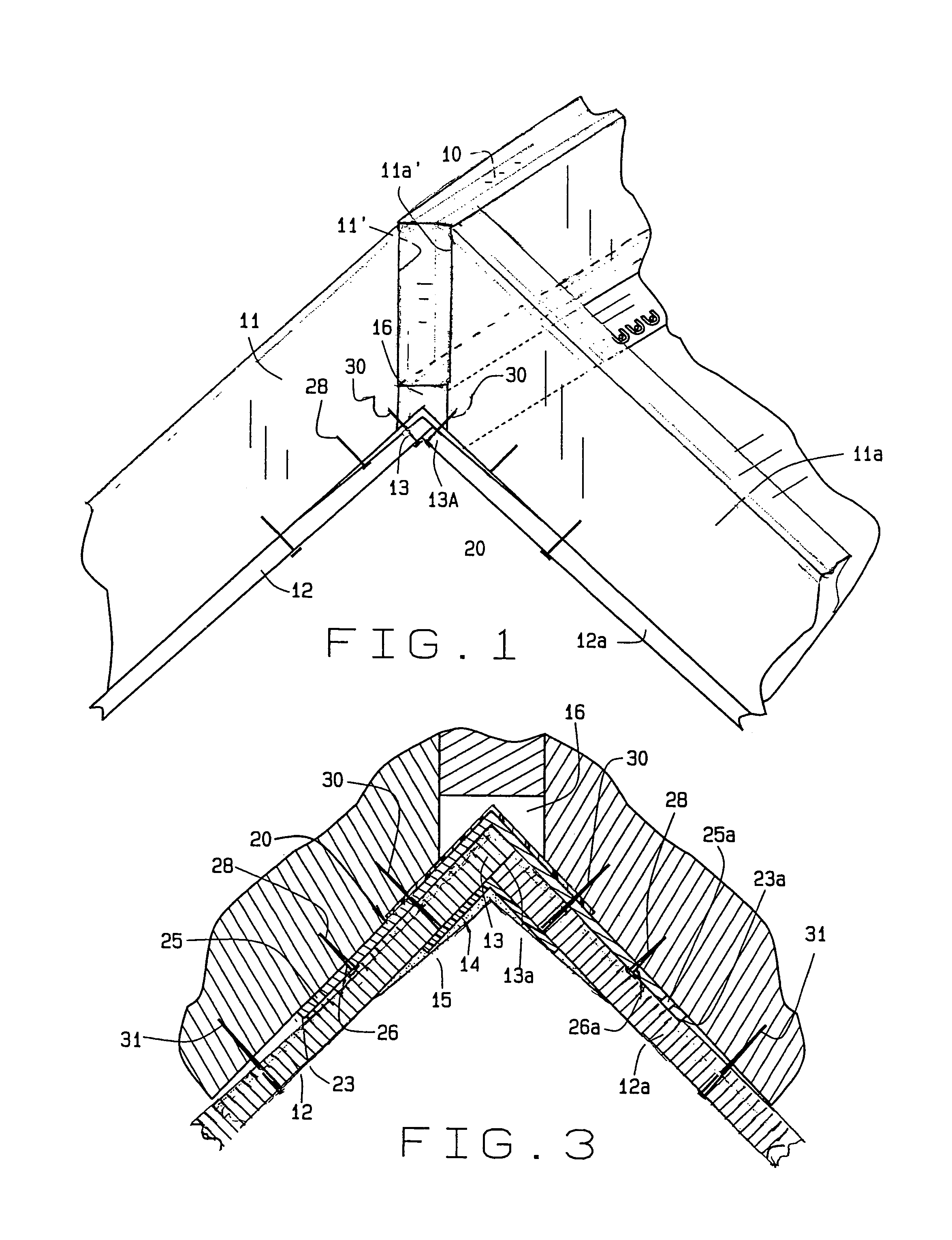

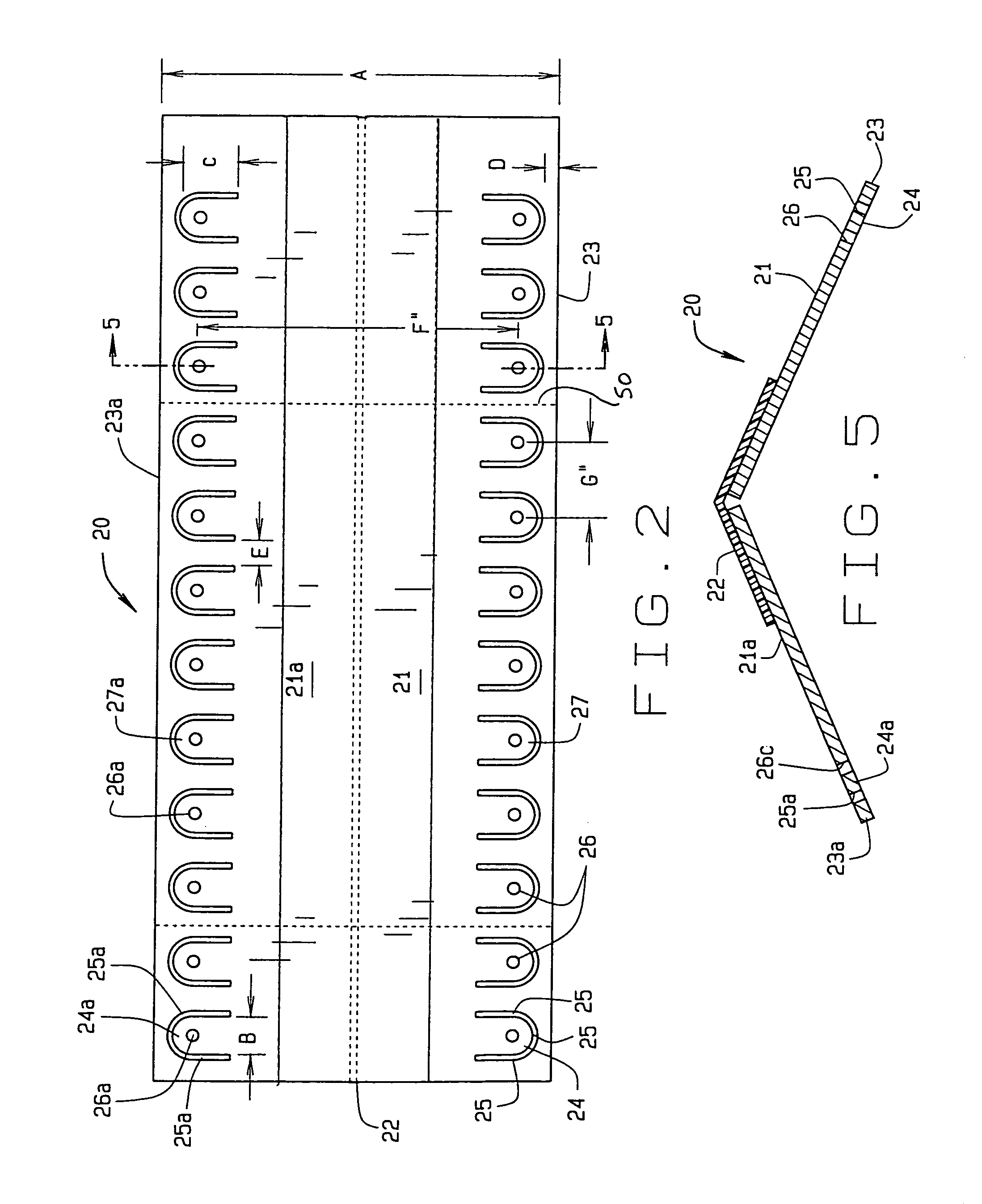

Hinged metal connectors and joint constructions

A method of preventing disruption of a taped finished drywall board joint in a room having a center ridge member and angularly inclined ceiling rafters which involves a metallic connector positioned between the wallboard sections and the ridge member and rafters. The connector has two metallic wings with a center longitudinal bendable connection. The wings have flexible tabs at their free edges which are attached to the rafters and the connector itself is attached to the wallboard adjacent to the ridge member. The wallboard also is attached to the rafters 8-12 inches from the edges of the wings. Because the tabs can bend away from the wings, this construction allows the joint to flex if the rafters warp or shrink without disrupting the finish coating on the outside of the wallboard joint at the ridge member. The connector also can be applied to other critical joints in a home where the framing members are subject to movement such as flat ceilings to avoid truss uplift or rafter movement. The wings have longitudinal corrugations in the wings and tabs to strengthen the tape. In one embodiment two wings are connected by a polymeric tape. In another embodiment, the connector is a unitary metallic part with a longitudinal line of perforations connecting the wings along the centerline to allow the connector to be bent to form the two diverging wings.

Owner:CLARKWESTERN DIETRICH BUILDING SYST

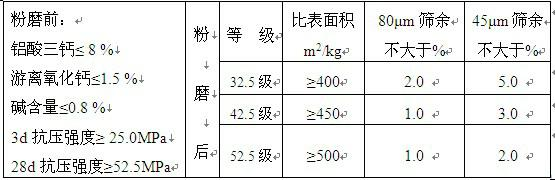

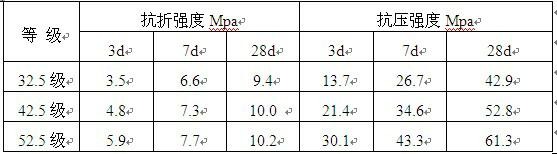

High Performance Dam Portland Cement

InactiveCN102276176AIncrease dosageImprove performanceCement productionPortland cementMixed materials

The invention provides a high-performance Portland cement for dams, and the problem to be solved is: instead of using admixtures in medium-heat and low-heat Portland cements, all clinker is used. This is not conducive to environmental protection, but also increases the cost of cement. The gist of the present invention is that it is composed of pulverized general Portland cement clinker and mixed material after homogenization, wherein the mixed material accounts for 30-75% of the total weight of cement. The beneficial effect of the invention is that after the amount of the mixed material is increased, the performance of the cement is remarkably improved, especially the effect of reducing the heat of hydration is remarkable. After greatly increasing the amount of mixed materials, the proportion of clinker in cement is reduced, which is not only beneficial to environmental protection, but also reduces costs, and at the same time realizes the effective and recycling of industrial waste residues.

Owner:DANDONG HAIGONG CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com