Method for controlling the defect of sintering expansion of powder metallurgy material and products thereof and mold

A technology of powder metallurgy and sintering expansion, which is applied in the field of sintering and molds to control the sintering expansion defects of powder metallurgy materials and products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Sintering of TiAl intermetallic compound

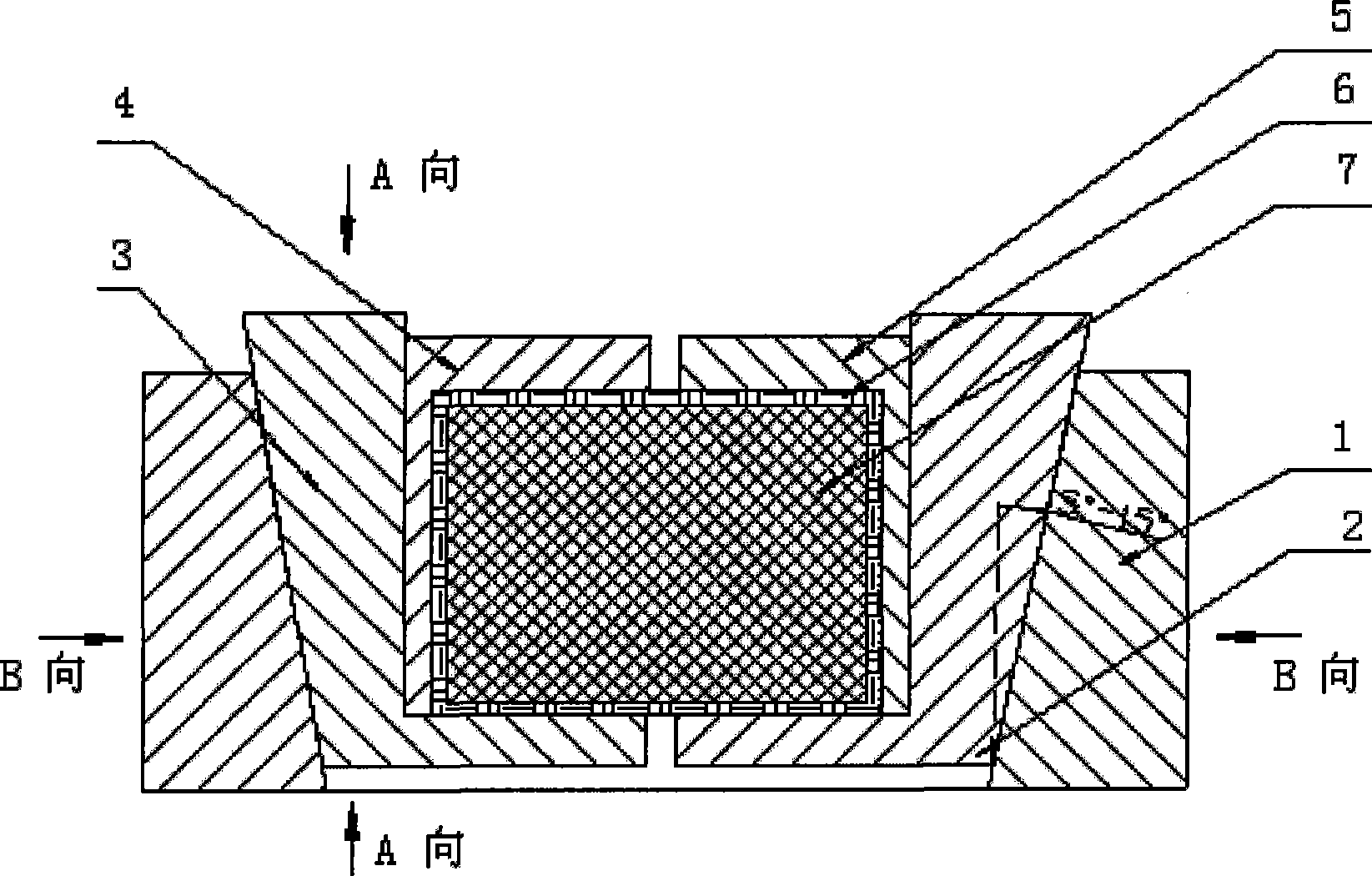

[0032] Ti powder with a particle size of less than 43 μm and Al powder with a particle size of 10-100 μm are used for mixing according to the atomic ratio of Ti:Al at 1:1, and molded under a pressure of 500 MPa to make a blank with a size of 100mm×15mm body. then put it in figure 1 After being assembled in the mold shown, it is put into a sintering furnace, and sintered according to the sintering process of TiAl alloy. The volume expansion rate of the obtained sintered green body is less than 1.77%, and there are no defects such as deformation and cracks.

Embodiment 2

[0033] Example 2: Sintering of NiAl intermetallics

[0034] Use Ni powder with a particle size of 1-10 μm and Al powder with a particle size of 10-100 μm, mix according to the Ni:Al atomic ratio of 1:1, and mold it under a pressure of 500 MPa to make a size of 100mm×15mm of cold blanks, and then put one of them into figure 1After being assembled in the mold shown, it is put into a sintering furnace, and sintered according to the sintering process of NiAl alloy. The volume expansion rate of the obtained sintered green body is less than 1.15%, and there are no defects such as deformation and cracks.

Embodiment 3

[0035] Example 3: Sintering of FeAl intermetallic compound

[0036] Fe powder with a particle size of less than 147 μm and Al powder with a particle size of 10-100 μm are used for mixing according to the Fe:Al atomic ratio of 1:1, and molded under a pressure of 500 MPa to make a cold steel with a size of φ100mm×15mm. body, and then put one of them into the figure 1 After being assembled in the mold shown, it is put into a sintering furnace, and sintered according to the sintering process of FeAl alloy. The volume expansion rate of the obtained sintered body is less than 1.02%, and there are no defects such as deformation and cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com