Axial force and displacement control mechanism

A technology of displacement control and axial force, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low control precision, time-consuming and laborious, difficult to adapt to nuts, etc., and achieve high control precision and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

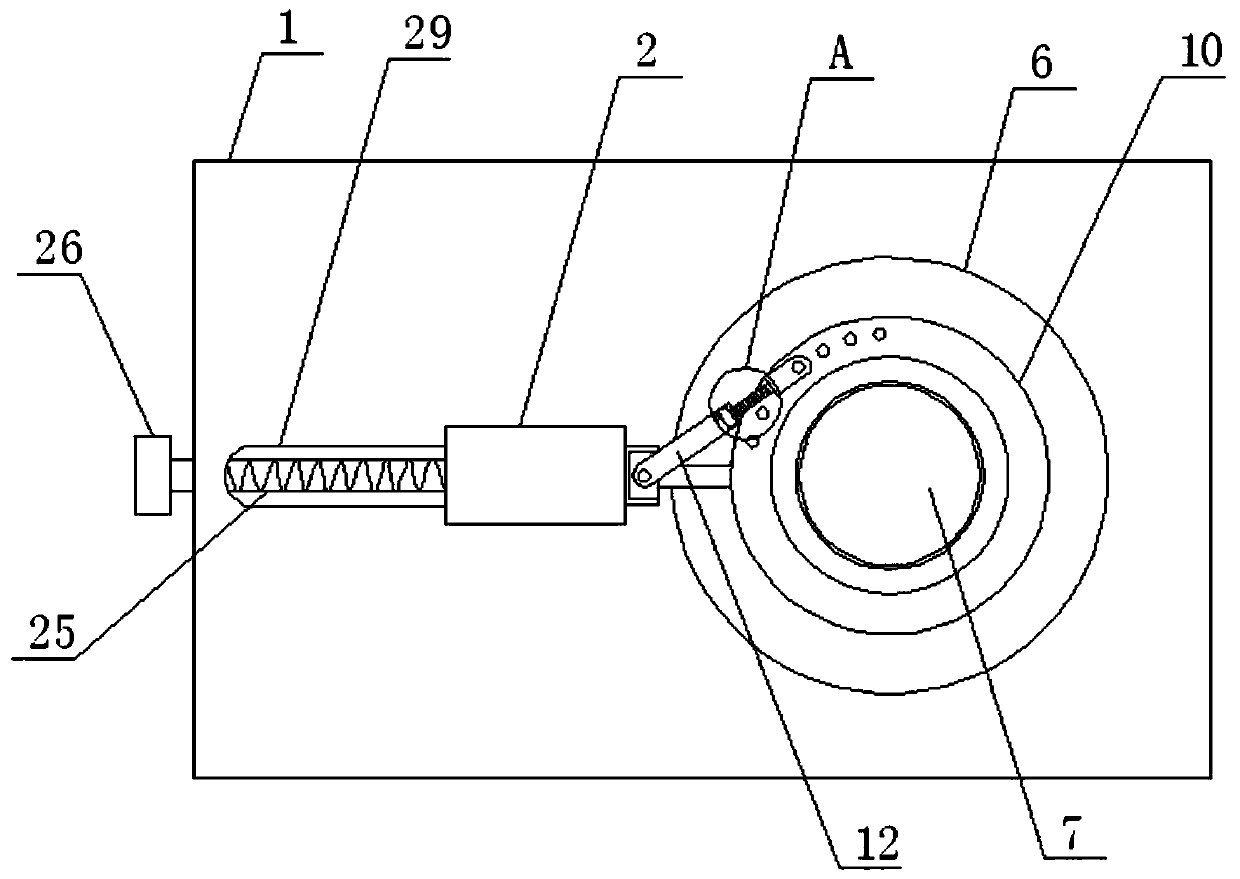

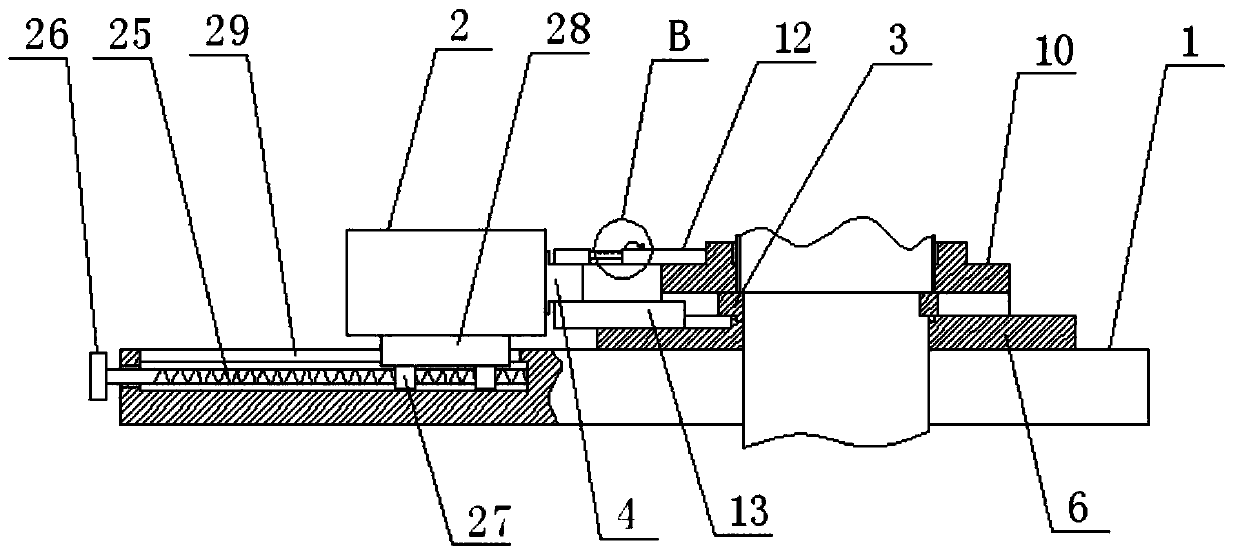

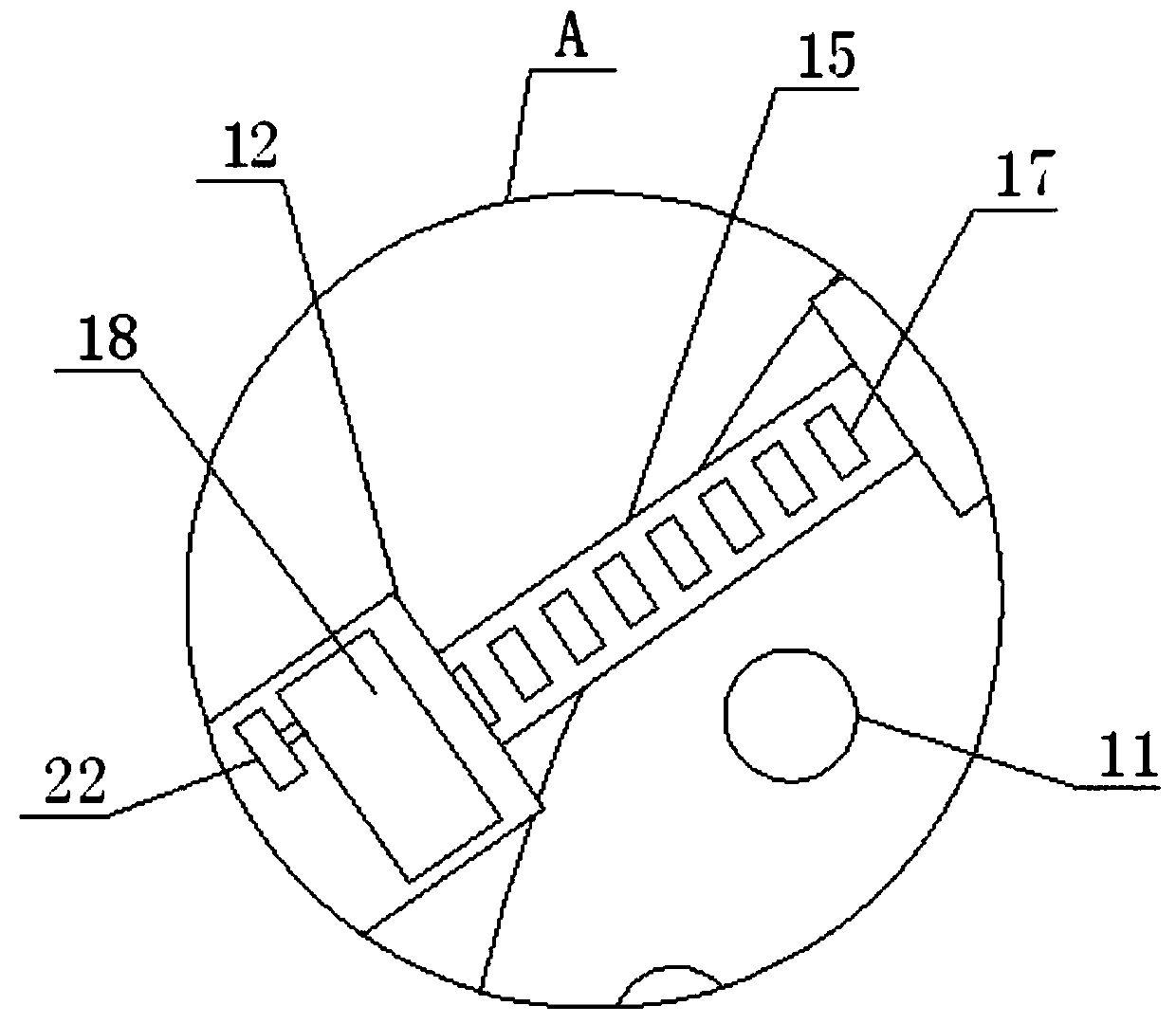

[0031] according to Figure 1-11 The axial force and displacement control mechanism shown includes a base 1 and a hydraulic cylinder 2. A fixed disc 3 is arranged on the top of the base 1. The hydraulic cylinder 2 includes a protruding rod 4. The fixed disc 3 The top surface is provided with a first positioning groove 5 near one side. By providing the first positioning groove 5, when the slider 13 is moved to a certain position, the slider 13 enters the inside of the first positioning groove 5, and the extension rod 4 is increased. The length of extension, the top of the fixed disc 3 is placed with a positioning disc 6, the center of the fixed disc 3 and the positioning disc 6 are provided with a transparent shaft hole 7, the shaft hole of the positioning disc 6 7 is provided with a keyway 8 inside, and the positioning disc 6 is fixed to the shaft by using a special positioning key for the shaft. A second positioning slot 9 is provided on one side of the positioning disc 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com