A test device for testing the impact resistance of coated tools

A technology of impact resistance and test device, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of single impact force signal form, large test bench volume, fixed occupancy ratio, etc., to achieve reliable design, The effect of eliminating fit clearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

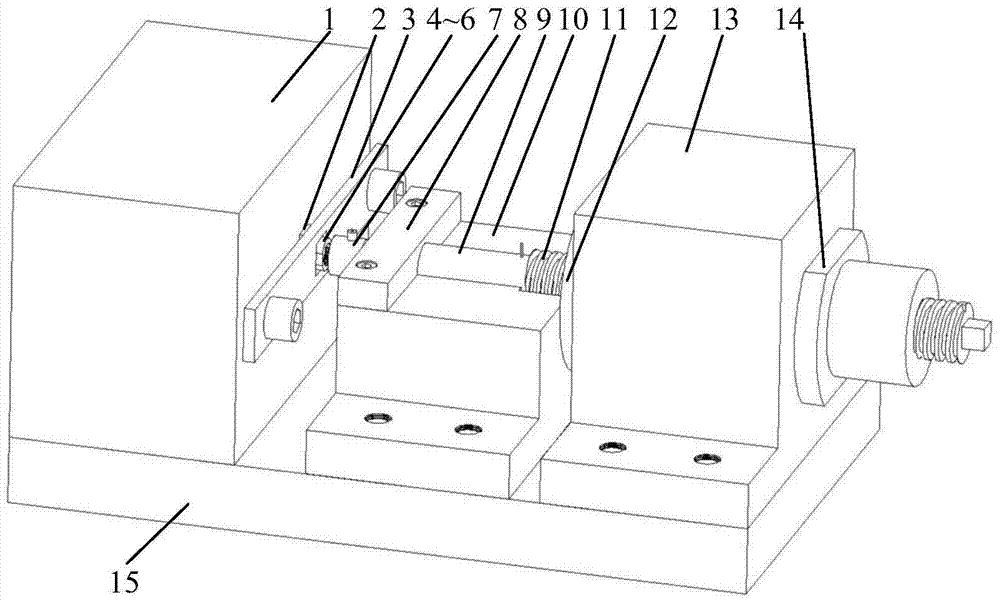

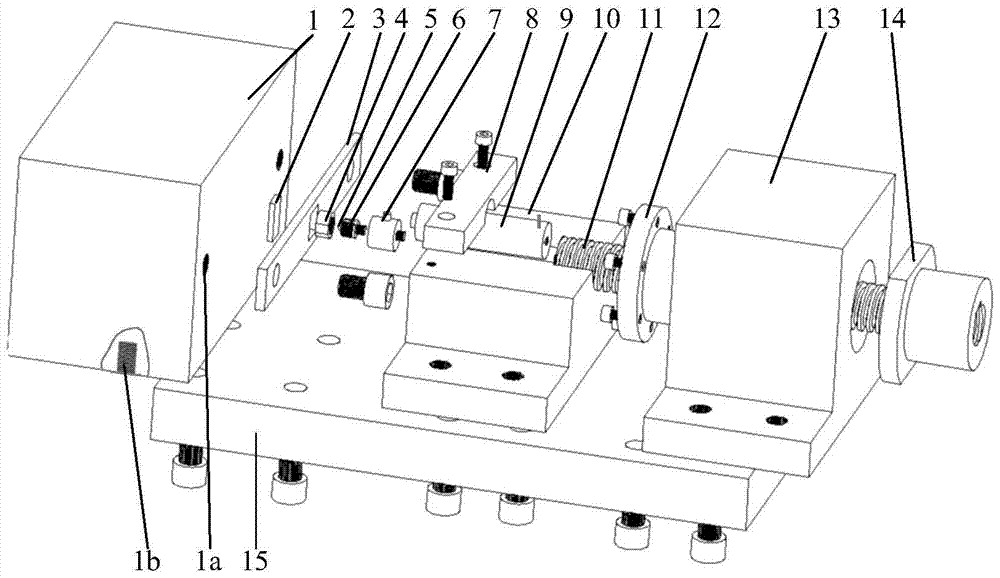

[0034] Such as figure 1 , figure 2 As shown, a test bench for testing the impact resistance of coated tools includes workbenches (1, 10, 13, 15), adapters (4-6) connected to force sensors 7, and piezoelectric actuators 9 The piezoelectric actuator 7 is connected to the force sensor 7 and the lead screw 11 respectively, and the piezoelectric actuator 7 is fixed on the workbench through the piezoelectric actuator platen 8 and the lead screw 11 through the support nut 12 and the fastening nut 14 .

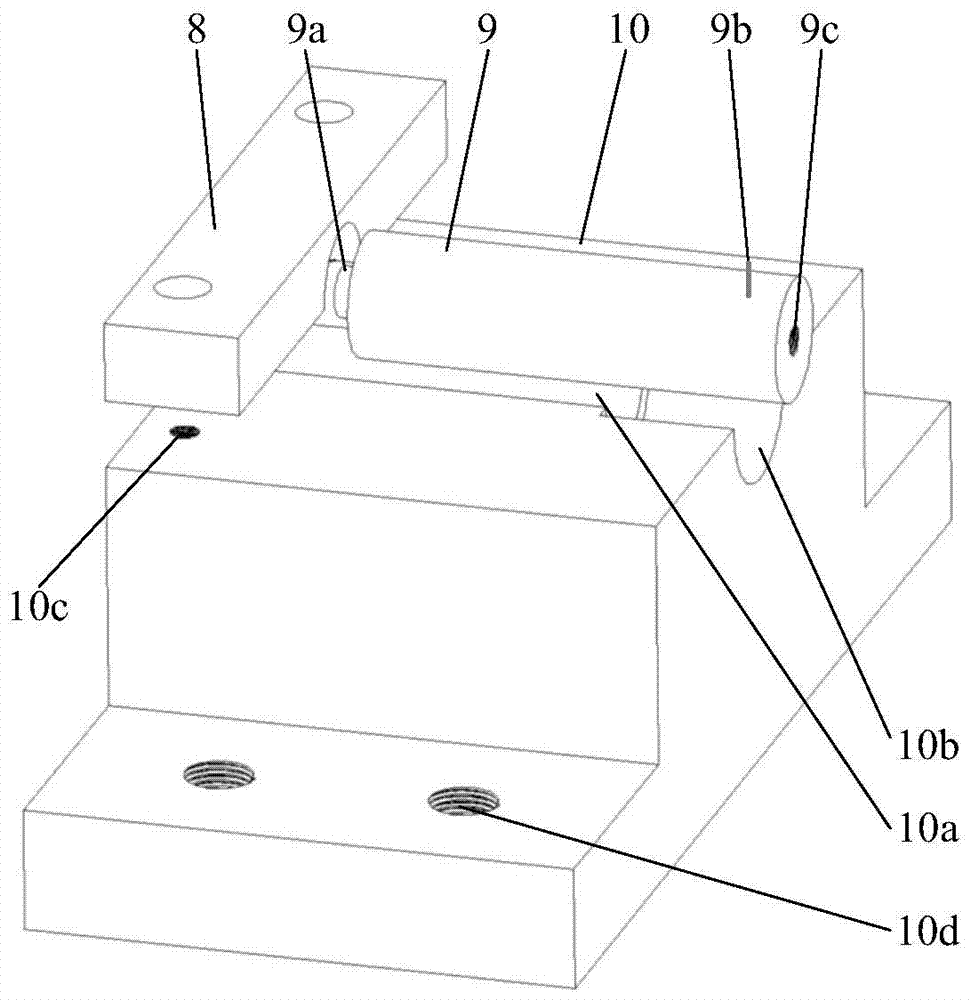

[0035] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the workbench includes an object stage 1, a piezoelectric actuator base 10, a nut base 13 and a fixed table 15, and the object stage 1, the piezoelectric actuator base 10 and the nut base 13 are respectively It is connected with the fixed platform 15 by bolts. There are two threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com