Patents

Literature

122results about How to "Eliminate fit gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

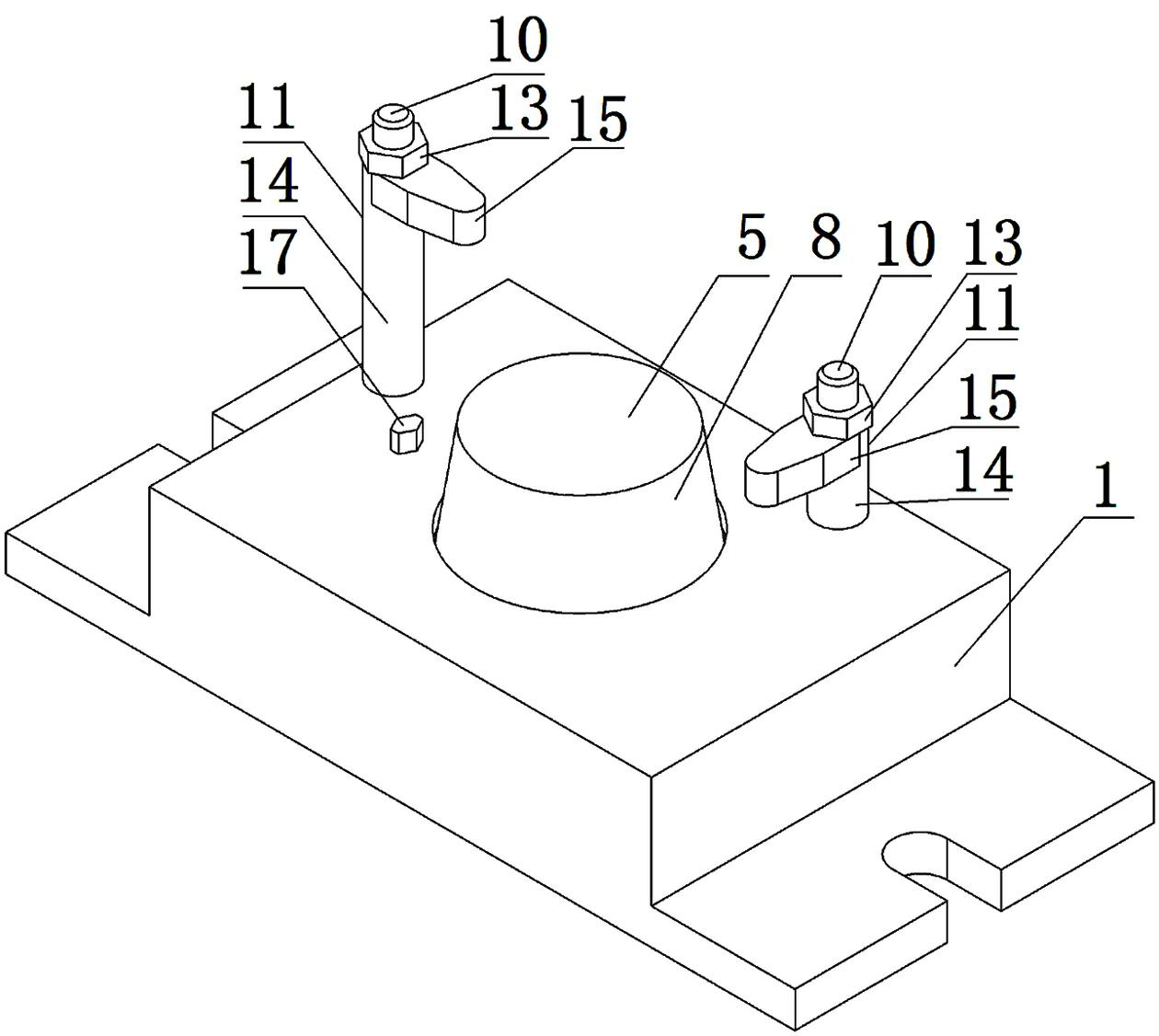

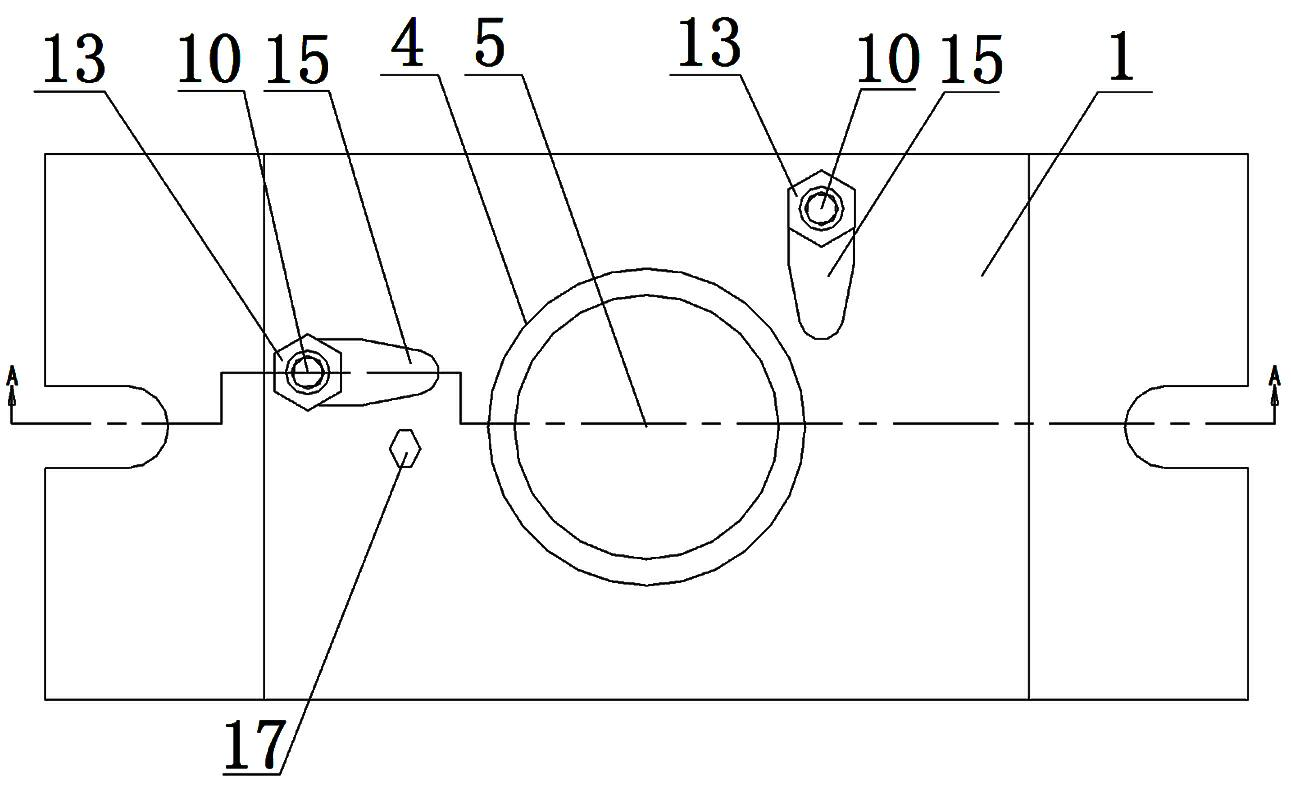

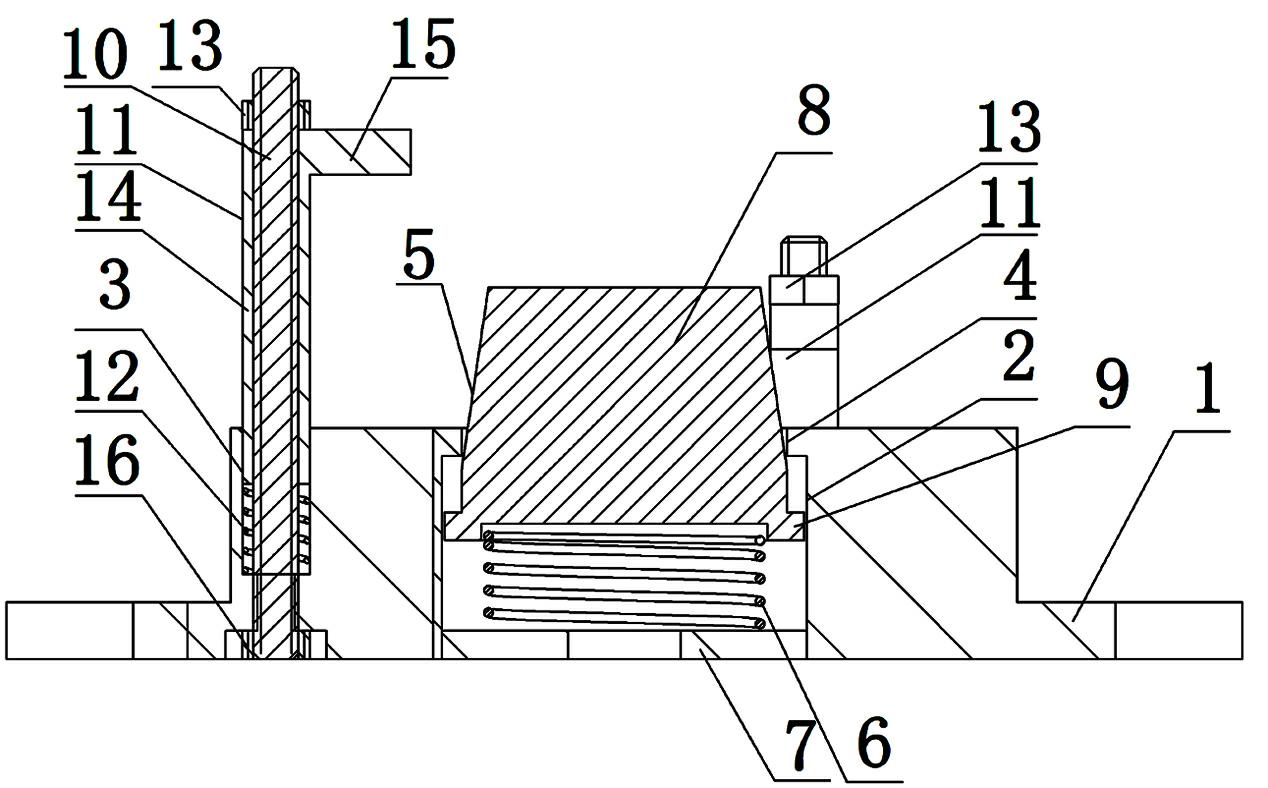

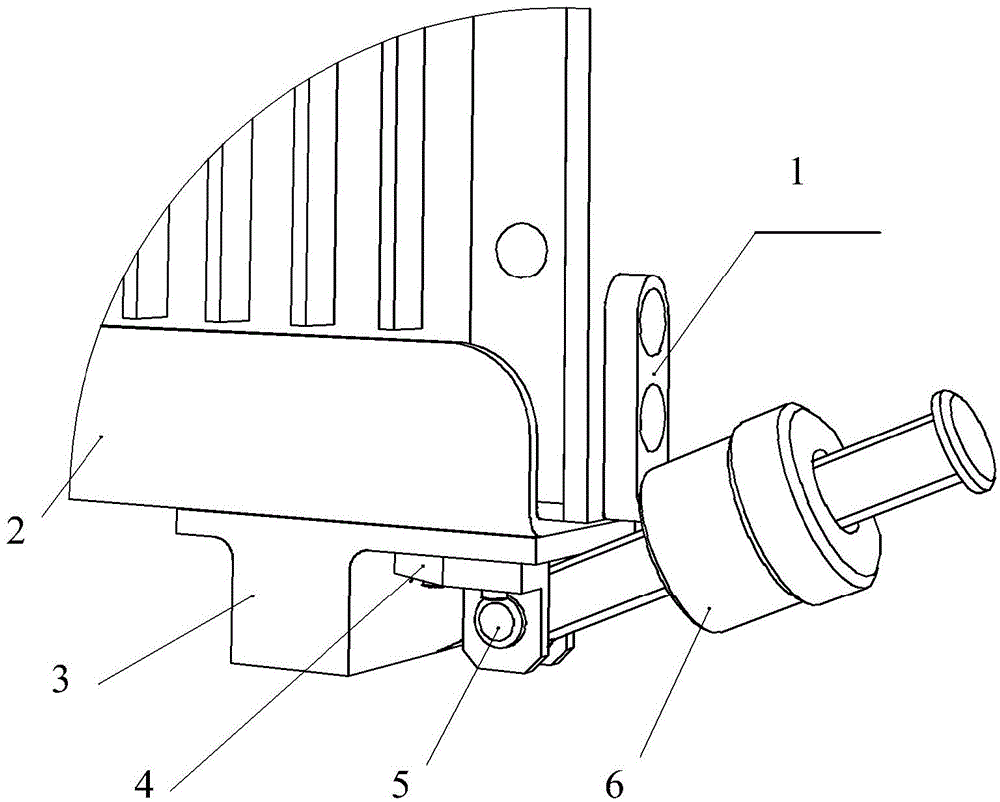

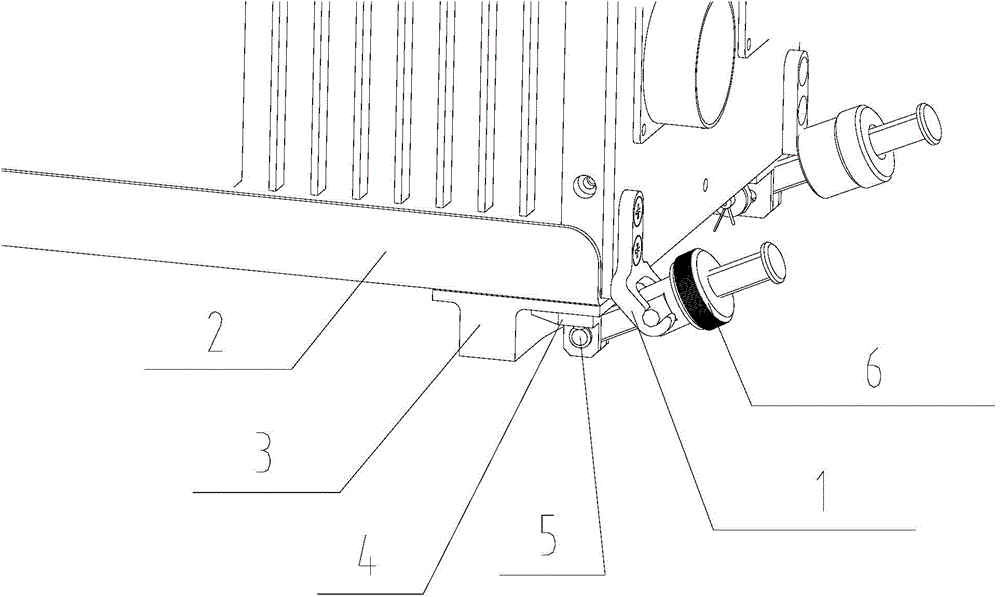

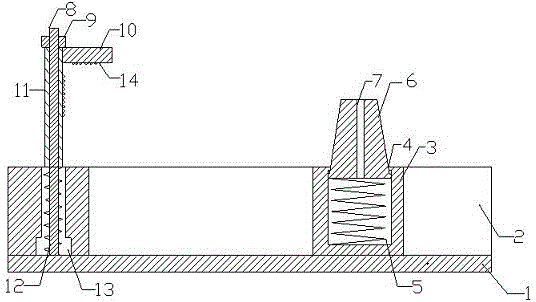

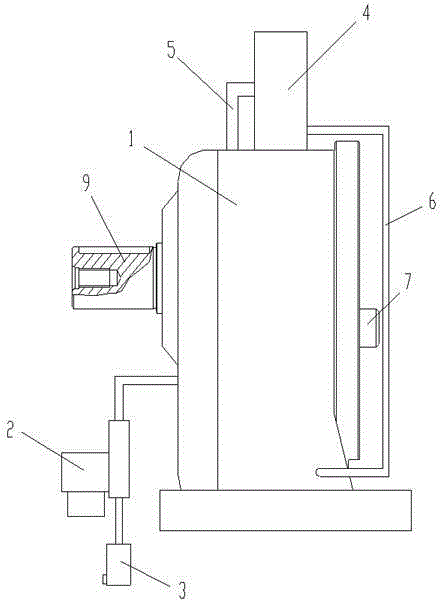

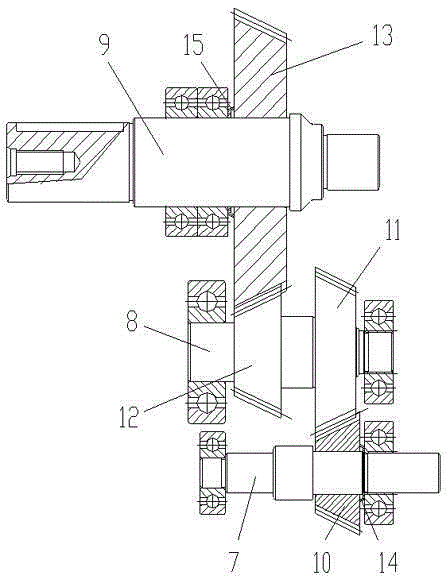

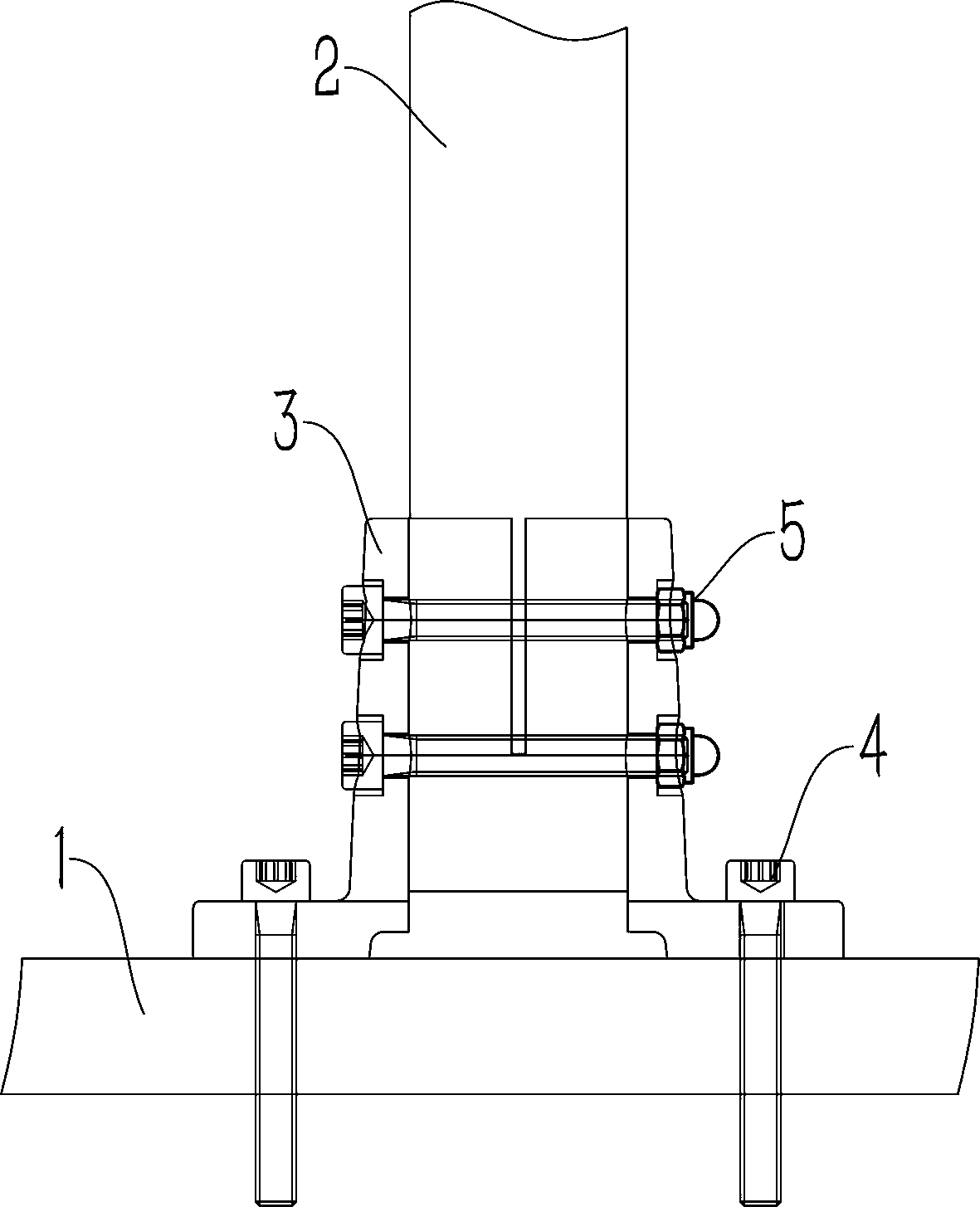

Mechanical processing positioning device

InactiveCN102490037AWide range of positioningOvercome sizePositioning apparatusMetal-working holdersEngineeringMachining

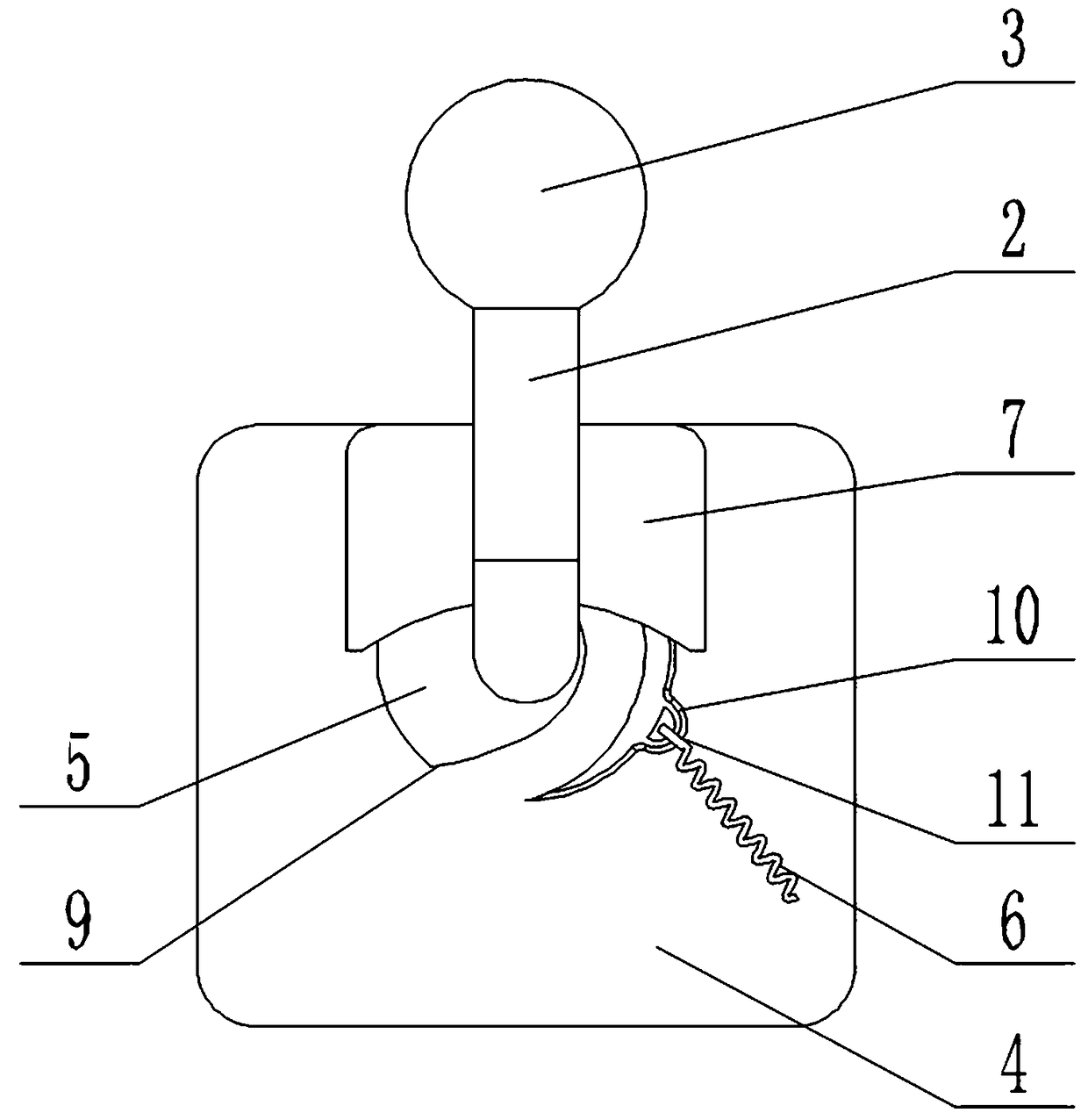

The invention disclose a mechanical processing positioning device, which comprises a base (1), an adjusting support assembly and an adjustable clamping mechanism, wherein the adjusting support assembly comprises a cylindrical taper pin (5), a compression spring A (6) and a screw plug (7), the cylindrical taper pin (5) is arranged in an inner cavity (2), the adjustable clamping mechanism comprises an adjusting screw rod (10), a press plate (11) and a compression spring B (12), the press plate (11) and the compression spring B (12) are sheathed outside the adjusting screw rod (10), and the adjusting screw rod (10) penetrates through a through hole (3) arranged on the base (1) and is fixed by a locking screw bolt (16). The mechanical processing positioning device has the beneficial effects that the diameter of the large end of a cone front part (8) is greater than the diameter of a blank hole, the wider positioning range is realized, the cylindrical taper pin (5) is tightly matched with the blank hole by the adjusting support assembly via the extension and retraction of the compression spring A (6), the influence of size and roundness errors of the blank hole can be overcome, the matching clearance is eliminated, and the positioning error is greatly reduced.

Owner:成都恒高机械电子有限公司

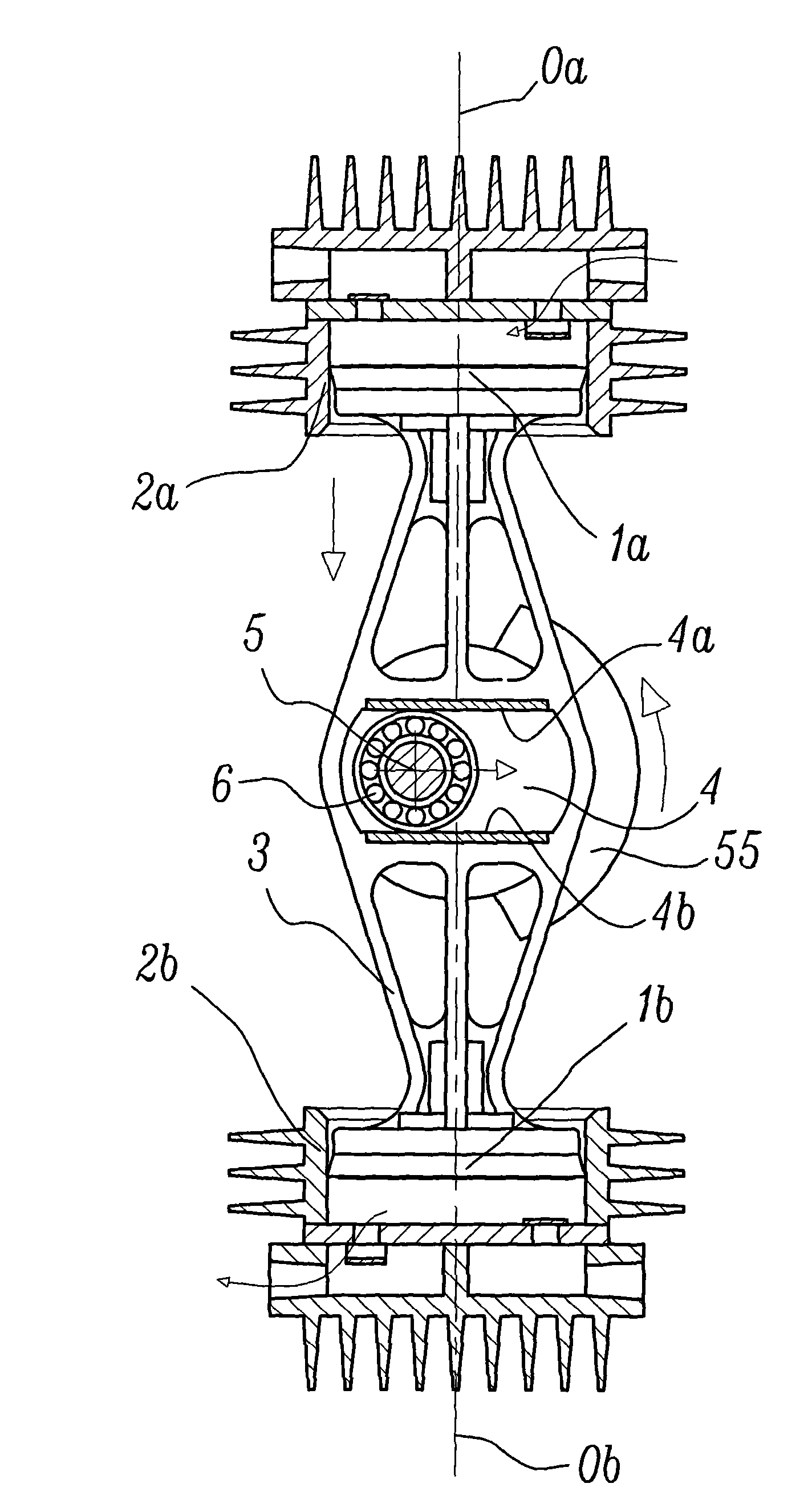

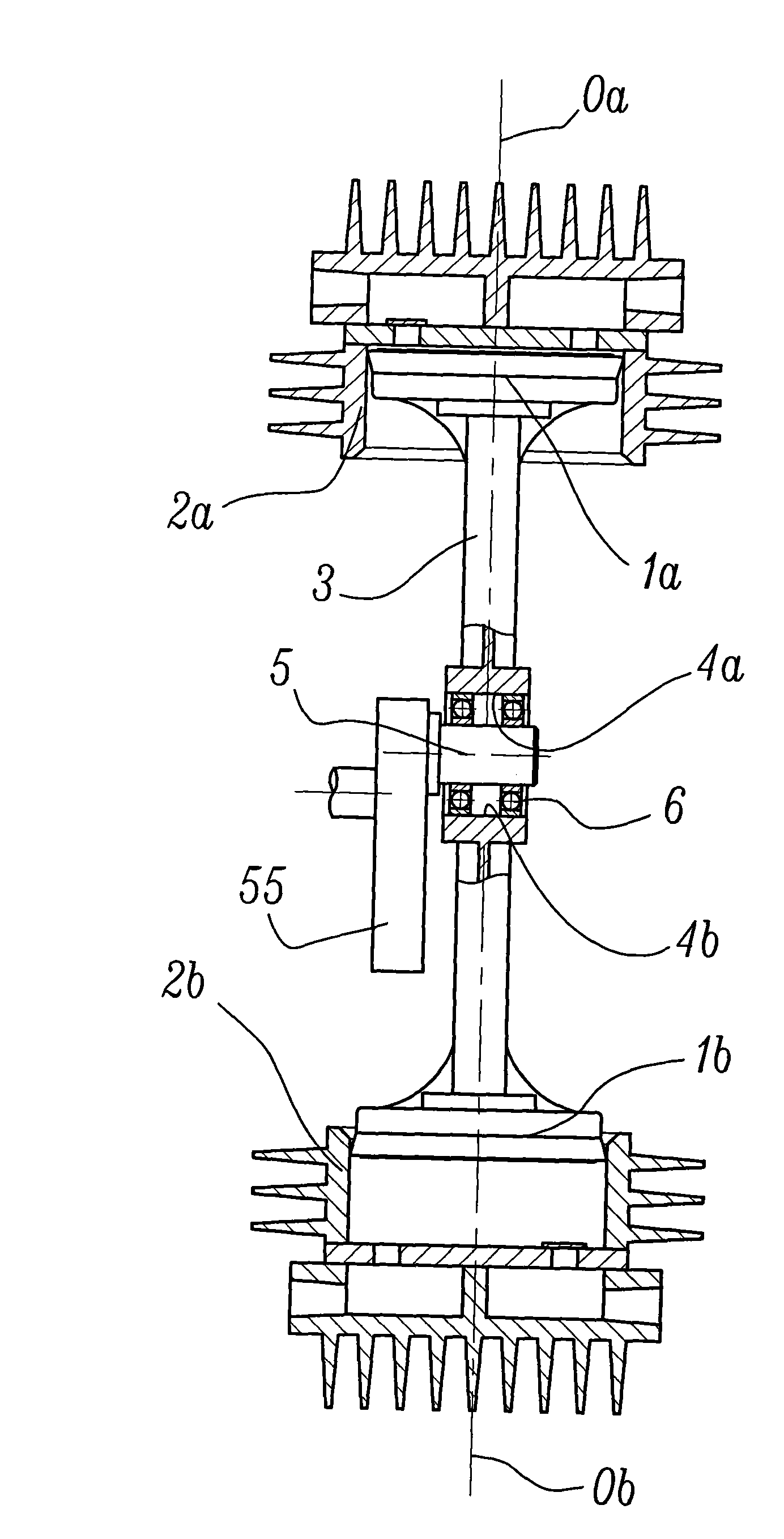

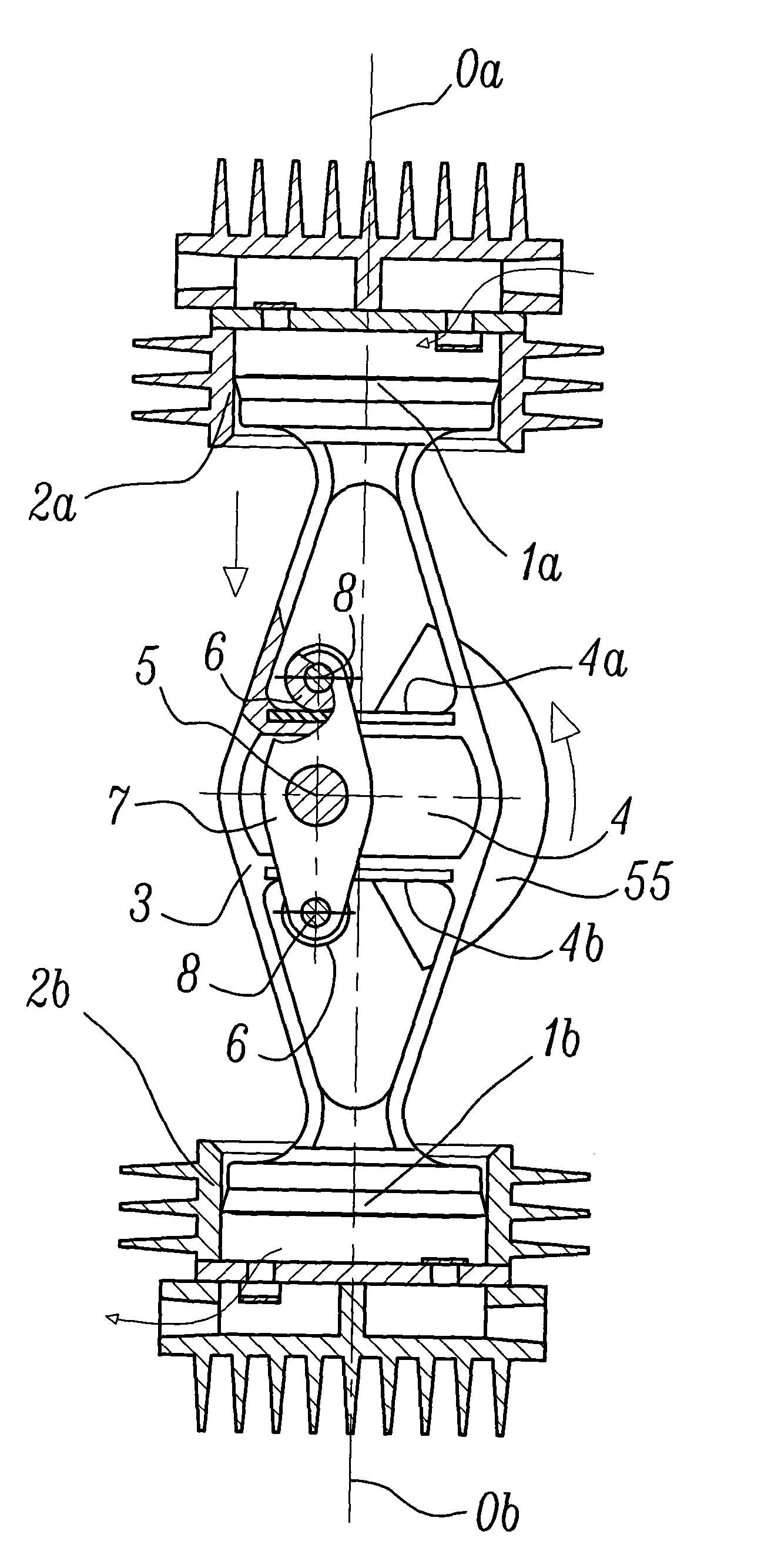

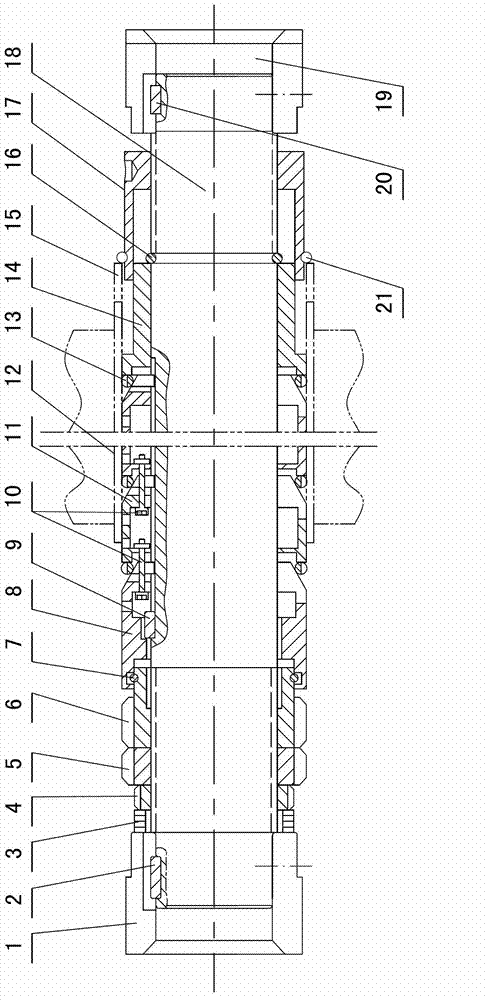

Linearly-reciprocating piston compressor

ActiveCN101672264AEliminate fit gapsReduce frictionPositive displacement pump componentsPiston pumpsHydraulic pumpEngineering

The invention relates to a linearly-reciprocating piston compressor, belonging to the filed of the compressor. The linearly-reciprocating piston compressor comprises a crank pin, a connecting rod, twopistons and two air cylinders; the two pistons and the two air cylinders are distributed oppositely; the two pistons are arranged in the air cylinders and are matched with the air cylinders in a sliding way; two ends of the connecting rod are respectively connected with the two pistons; the middle part of the connecting rod is provided with two parallel guide rails and an auxiliary connecting rod; the ends of the auxiliary connecting rod are provided with shaft pins; rollers are rotationally sleeved on the shaft pins; and the rollers are matched with the guide rails in a rolling contact way.One of the two guide rails is used for driving one piston to carry out compression stroke, the other guide rail is used for driving the other piston to carry out air inlet stroke, and the two guide rails work alternatively, thus the match clearance between the rollers and the guide rails can be effectively reduced or fully eliminated, the rollers are kept contacting the guide rails in a rolling way, the friction between the rollers and the guide rails is mitigated, and the noise from the impact of the rollers and the guide rails is reduced. The linearly-reciprocating piston compressor can be used for producing the compressor, the vacuum pump, the hydraulic pump and the water pump.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

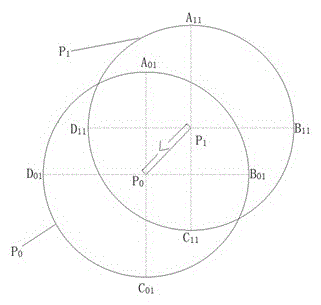

Coaxiality detection method

ActiveCN105004254ASimplify detection stepsEasy to operateMechanical measuring arrangementsPhysicsEngineering

Owner:NEWAY VALVE SUZHOU

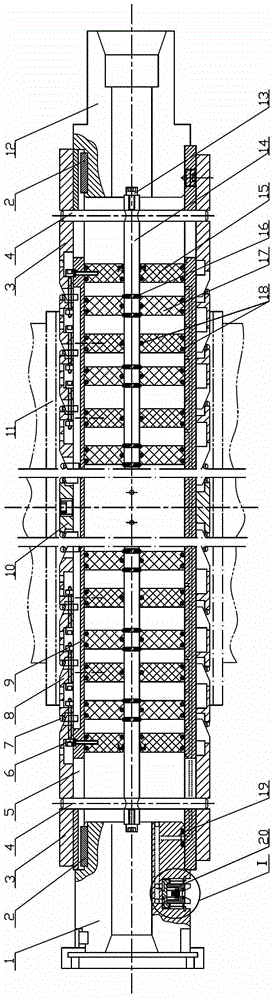

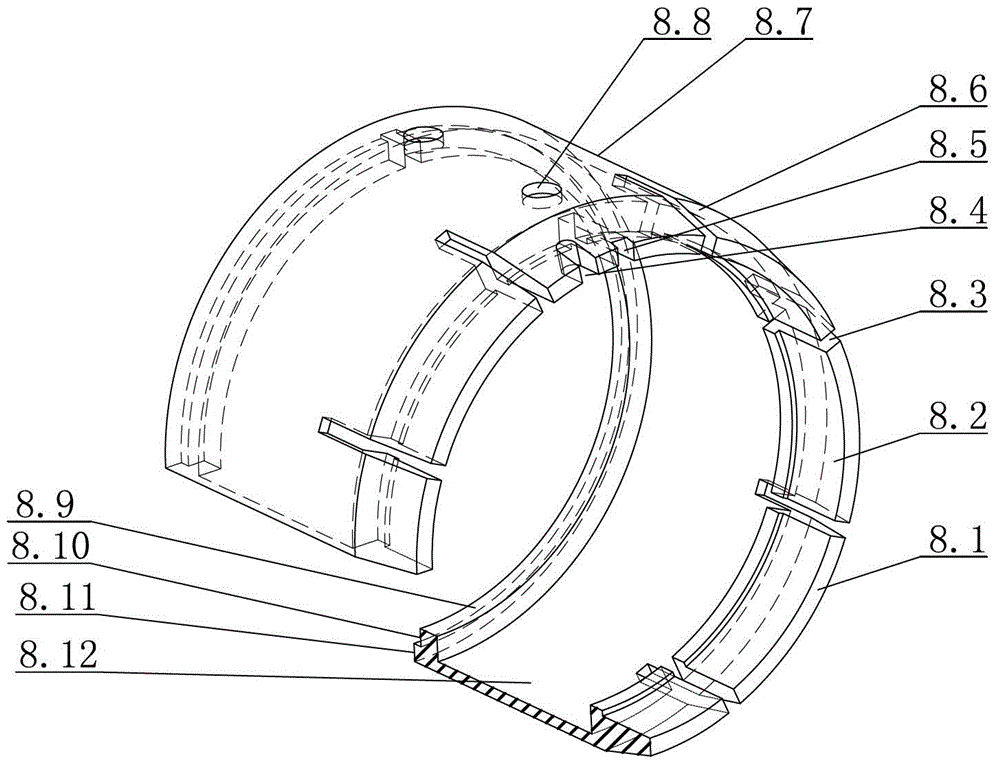

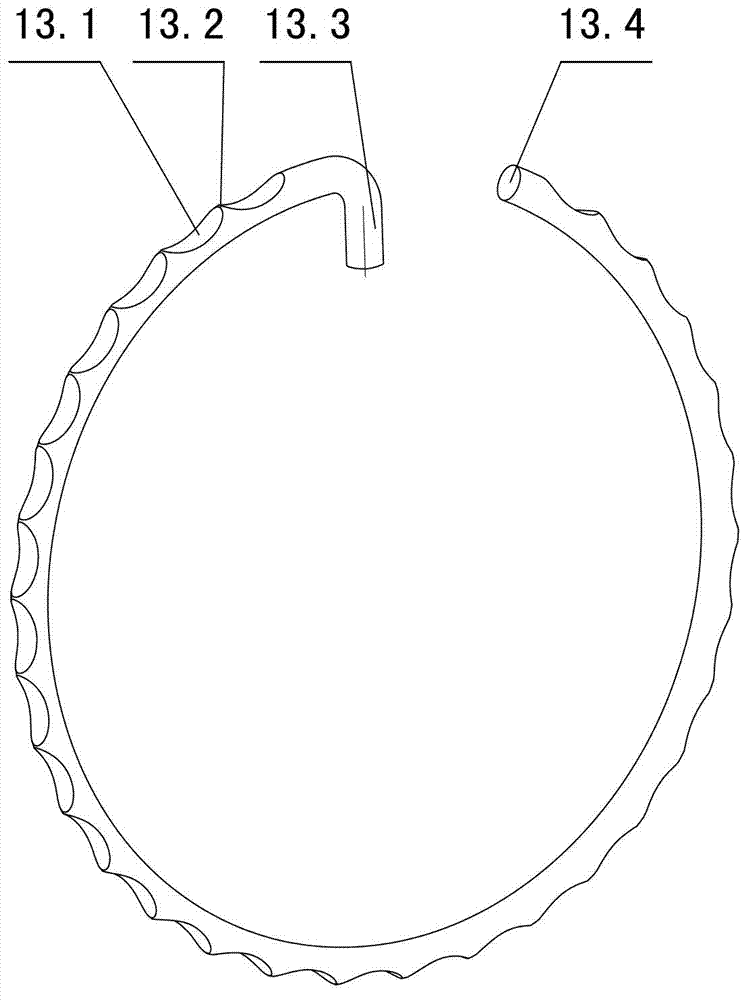

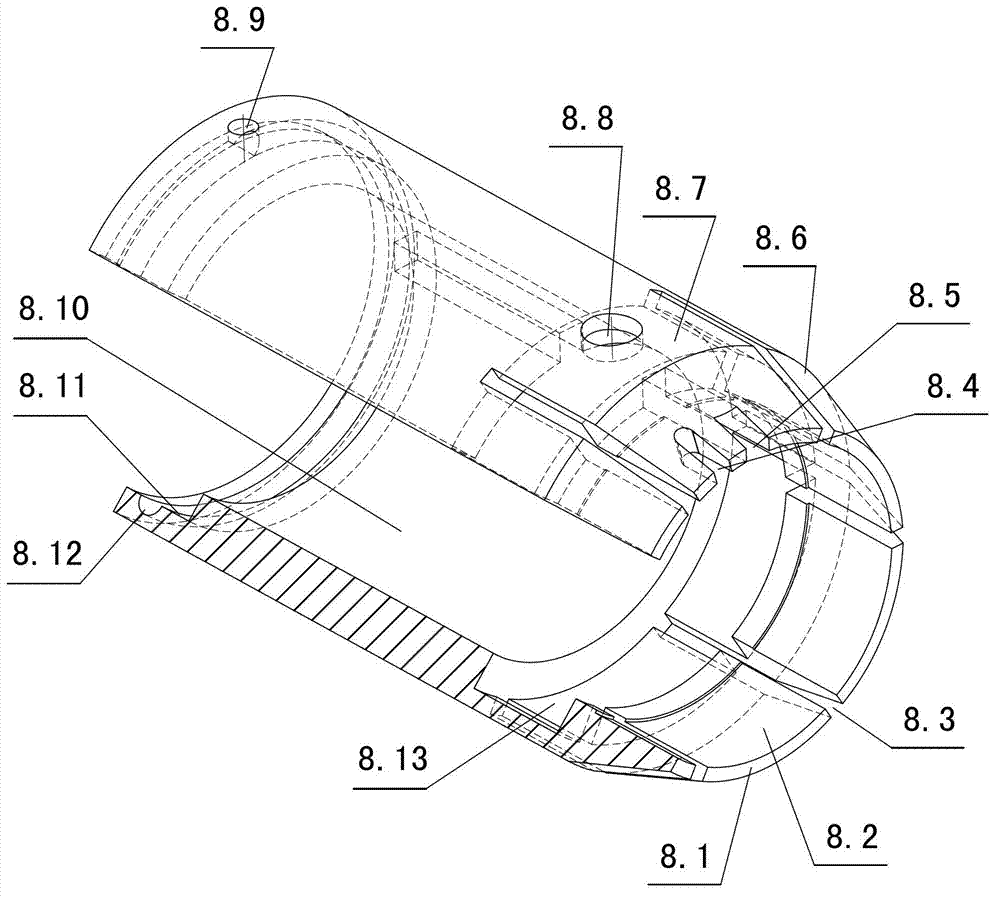

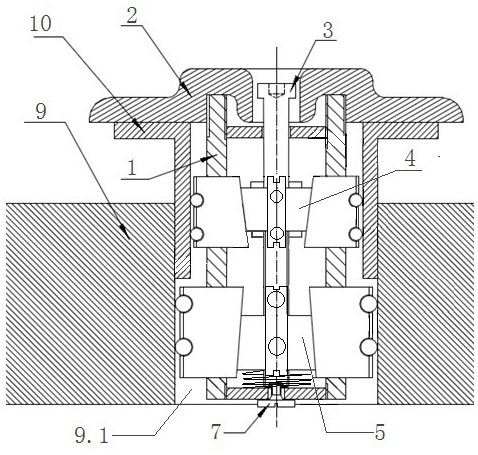

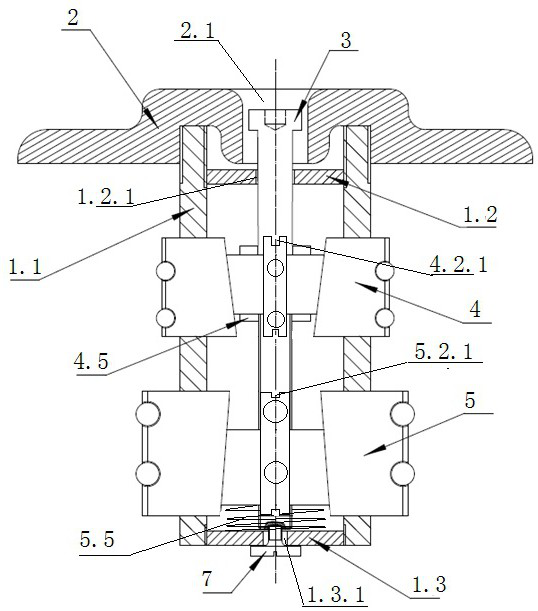

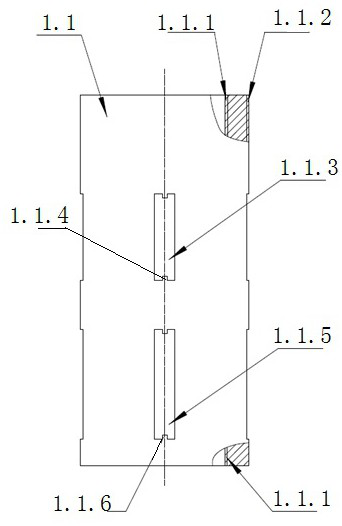

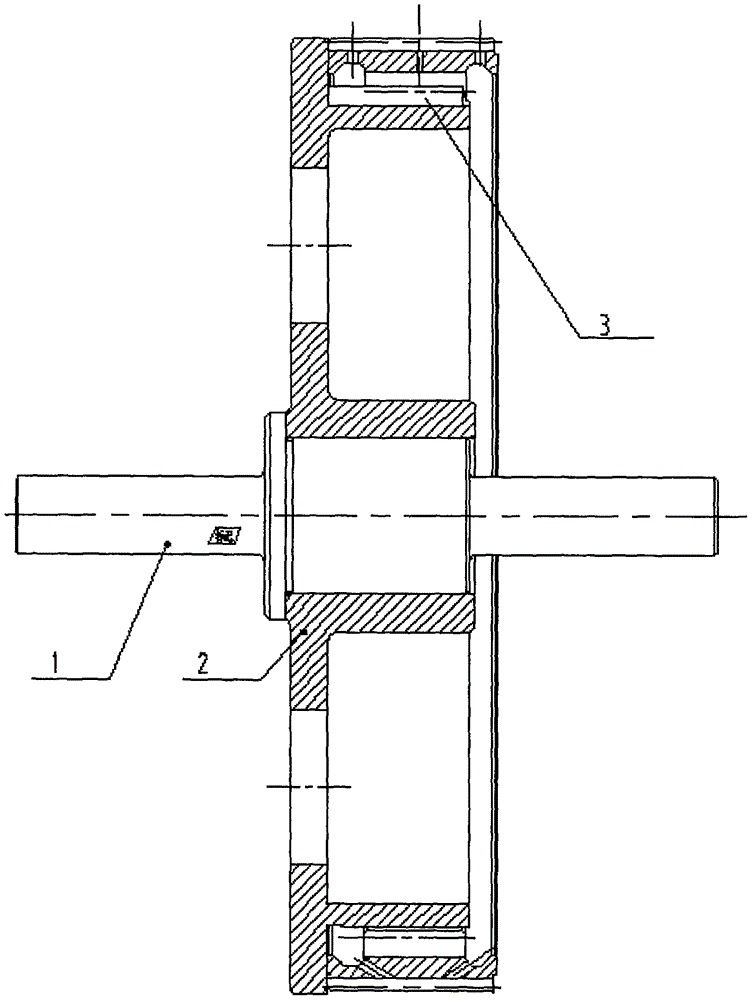

Mechanical expansion shaft of air control C-shaped rings

The invention discloses a mechanical expansion shaft of air control C-shaped rings, which is used for metal and non-metal foil and a film-shaped coiled material and is suitable for production of an aluminium strip and foil. In order to solve the problem of compressibility of an expanded strip, no foundation in friction of an slope expansion block and low precision and structural strength in the existing gasbag type and slope-to-slope type mechanical expansion shaft, the invention provides a novel slope-to-round structure with automatically retracting capacity to replace the typical slope-to-slope old-fashioned structure; the novel slope-to-round structure comprises a main shaft pipe and an expansion mechanism; a plurality cone-shaped wedge pipes and a plurality of C-shaped rings are symmetrically sleeved on the expansion mechanism; and propulsion of the cone-shaped wedge pipes in opposite directions lead the C-shaped rings with a plurality of anti-skidding blades on the conical surface in a sleeving way to expand outward, so as to become secondary mechanical increasing force to tightly clamp a core rolling pipe. According to the invention, the slope-to-round structure is small in radial size, so that the strength of the expansion shaft is enhanced; the radial run-out error of the shaft is reduced due to disappearance of gaps between the blades and the shaft during the clamping; and the mechanical expansion shaft is applicable to the production for rolling thick pipe cores in wide roll width.

Owner:柳燕明

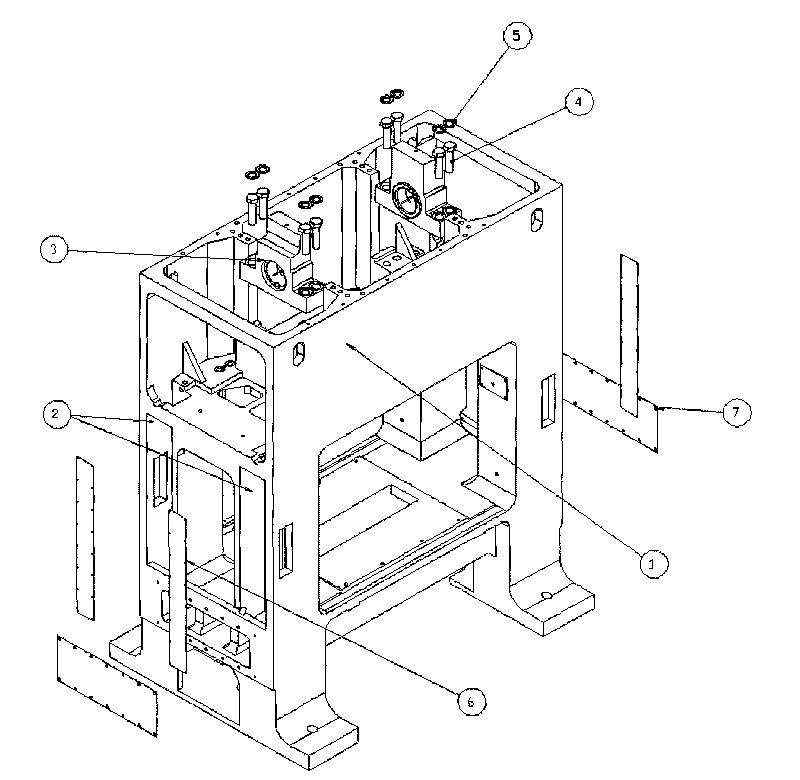

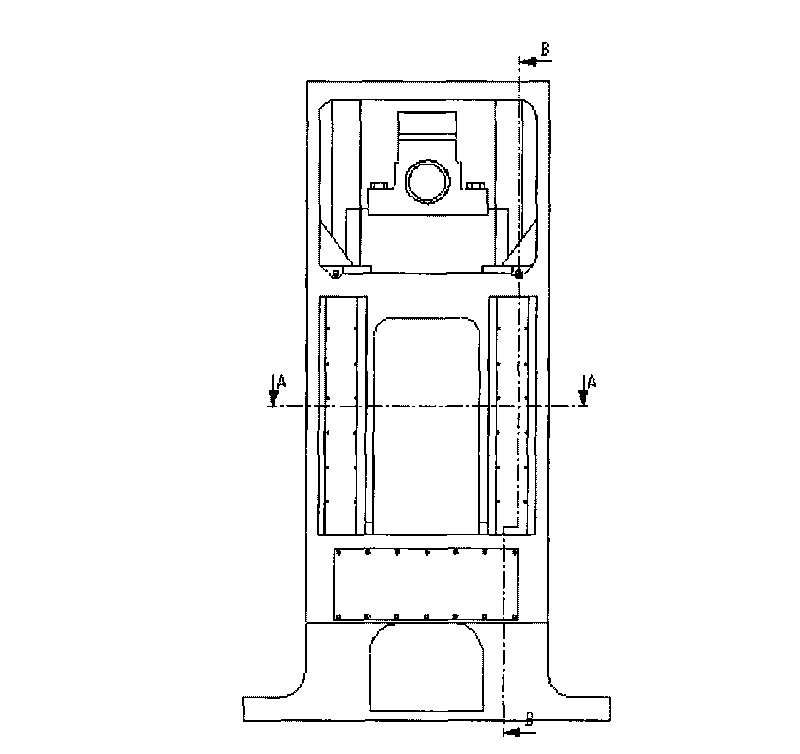

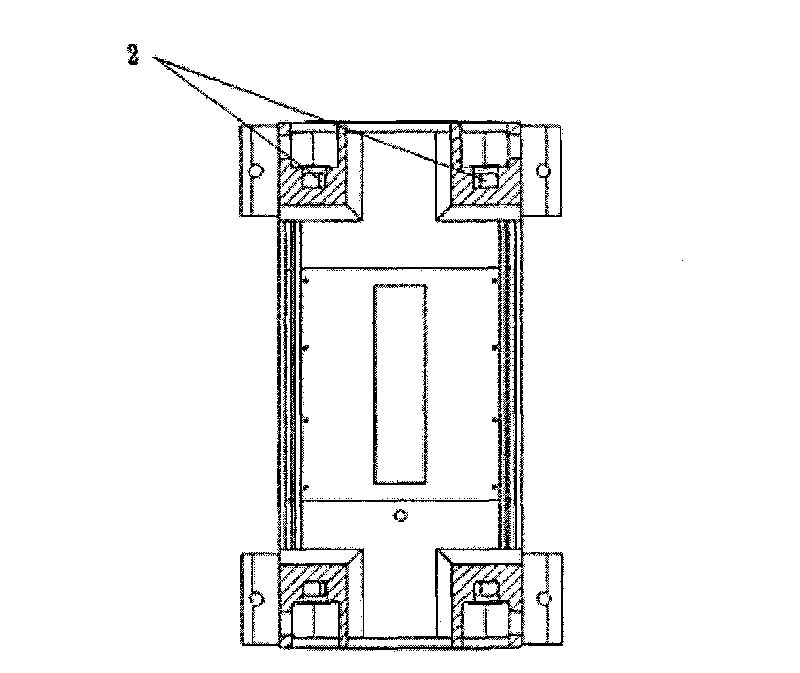

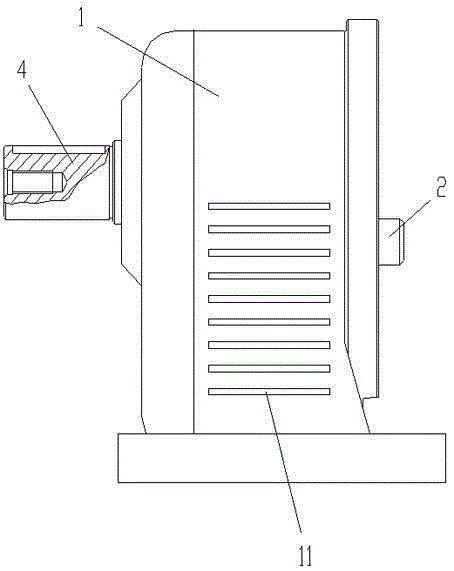

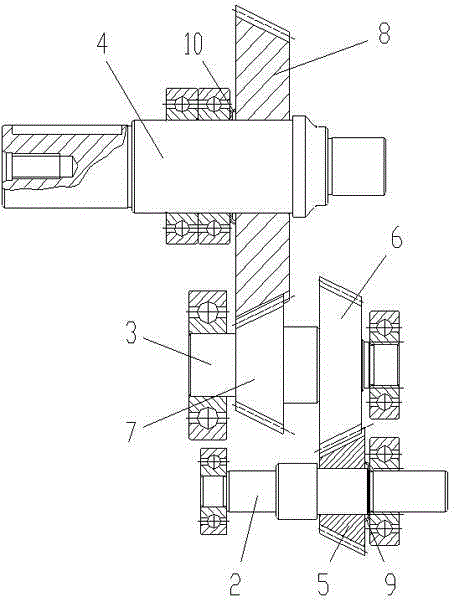

Closed type portal high-speed punch press stand

ActiveCN101733965AEliminate fit gapsHigh precisionPressesEngine lubricationPunch pressHigh intensity

The invention relates to a closed type portal high-speed punch press stand which comprises a table body (1) used as a main working part on the upper part, a lubricating oil channel (2), an oil tank (8), a crankshaft tilting fillet (3), a bolt (4) and a hard thickening flat washer (5), wherein the bottom of the crankshaft tilting fillet (3) is a plane and is positioned on a corresponding plane in the table body (1) and fixed through the bolt (4) and the hard thickening flat washer (5); the lubricating oil channel (2) is distributed on the inner wall on the periphery of the punch press stand, and the upper part of the lubricating oil channel (2) is communicated with a top box (9), while the lower part is communicated with the oil tank (8); both sides at the bottom of the top box (9) are provided with a hole channel (10) communicated with the top box (9) and the lubricating oil channel (2); the bolt (4) is a grade-12.9 high-strength bolt; and the hard thickening flat washer (5) is flat washer chamfered grade A with a hardness grade of HV300. The invention can solve the problems of large mounting difficulty of the crankshaft tilting fillet, high processing expense and device lubricating oil return in the prior art.

Owner:宁波澳玛特高精冲压机床股份有限公司

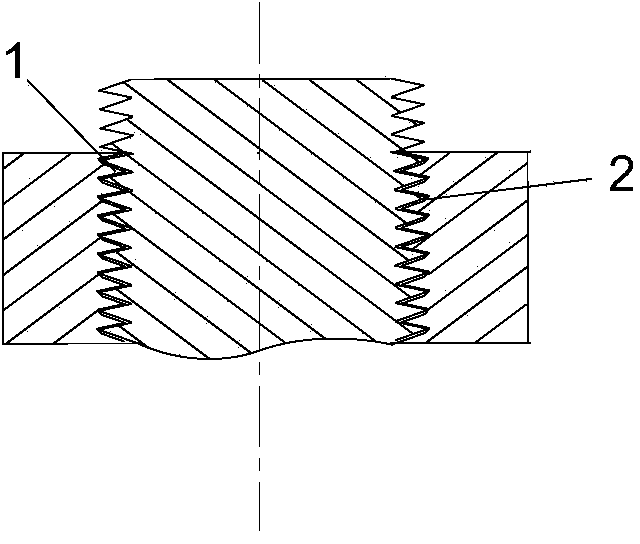

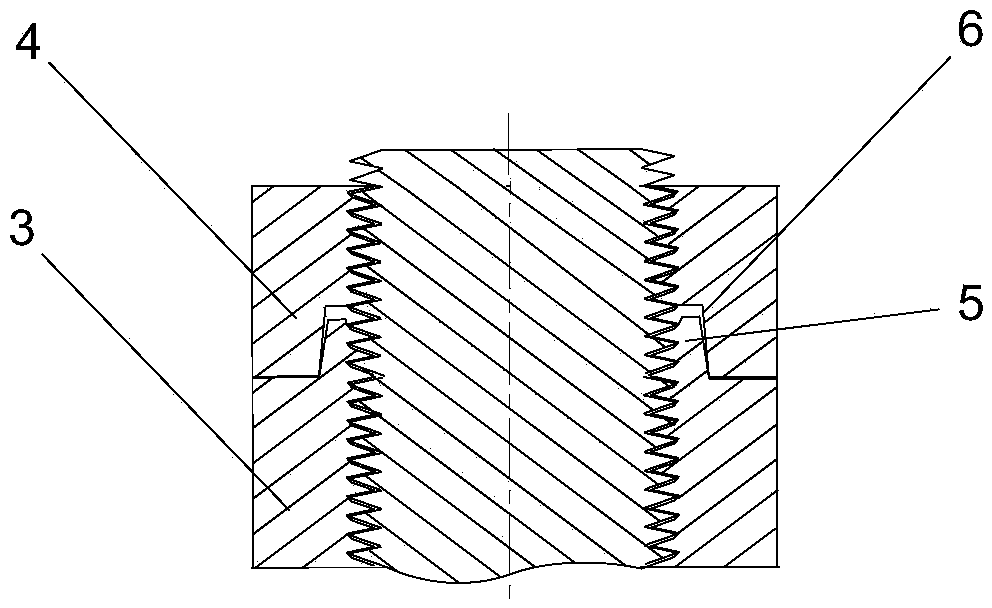

Anti-loose thread fastening structure

InactiveCN104141670AOptimize the force structureUniform force structureNutsBoltsClassical mechanicsScrew thread

The invention discloses an anti-loose thread fastening structure which comprises a bolt and a nut matched with the bolt, wherein variable angle oblique planes are arranged at the root of an internal thread of the nut, and the included angle between each variable angle oblique plane and a bisector of a thread angle of the internal thread is larger than a half of the thread angle of the internal thread. Threads of each pair of matched bolt and nut can be sufficiently contacted and interacted in the spinning length of the anti-loose thread fastening structure, so that load can be uniformly distributed, the stress structure is more balanced, the working life of the structure is prolonged, and the condition that the fastening effect is weakened early and even lost due to fast abrasion damage caused by overlarge local stress of an ordinary screw pair is avoided; and besides, the thread matching gaps between the threads of the bolt and the nut can be eliminated by means of the variable angle oblique planes of the nut, so that the bolt and the nut can be tightly matched in a longer spinning length, higher anti-loose torsional moment can be produced, and an ideal fastening effect can be kept on the use occasion with frequent vibration.

Owner:宁波华路汽车电器有限公司

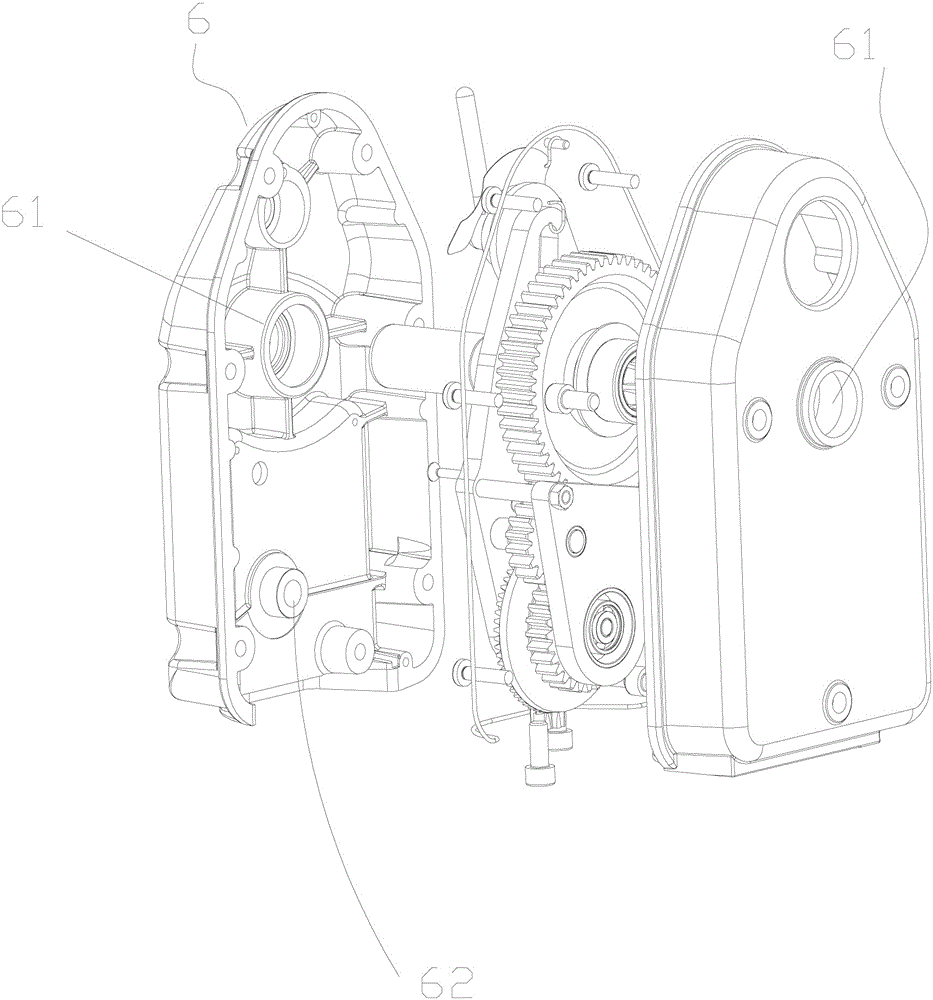

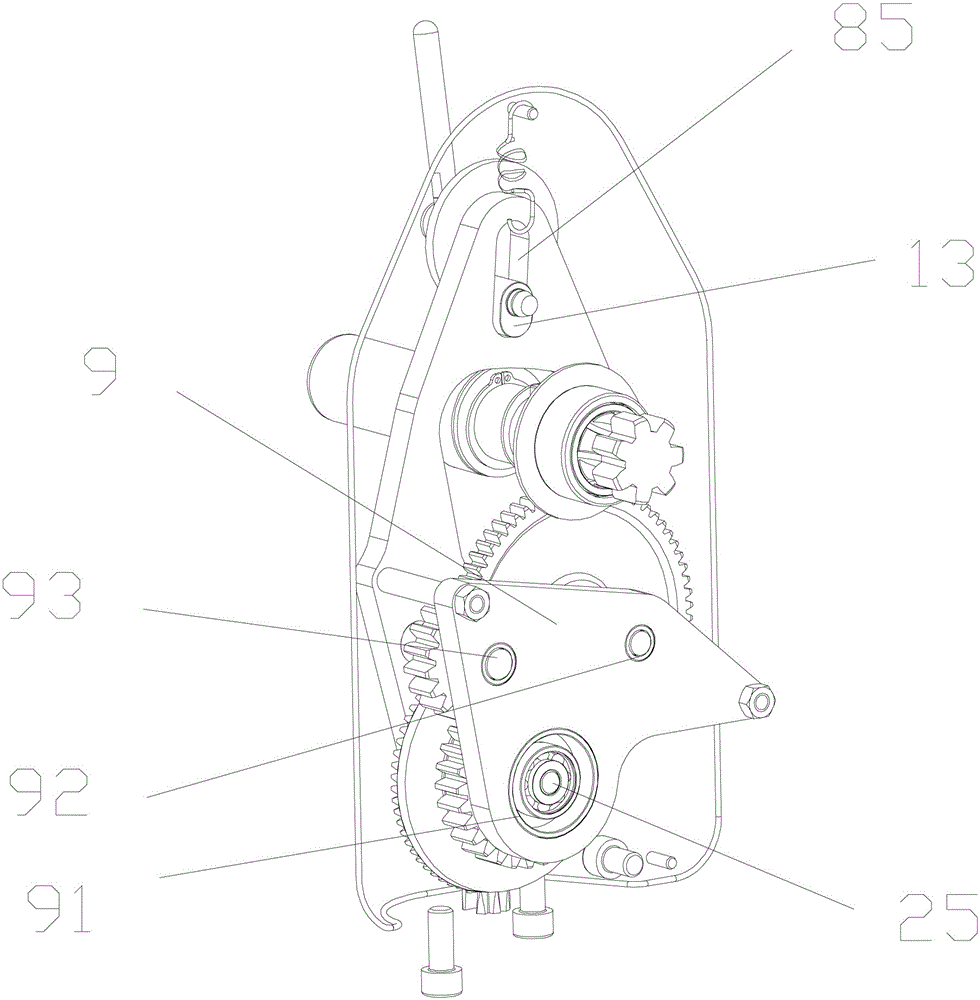

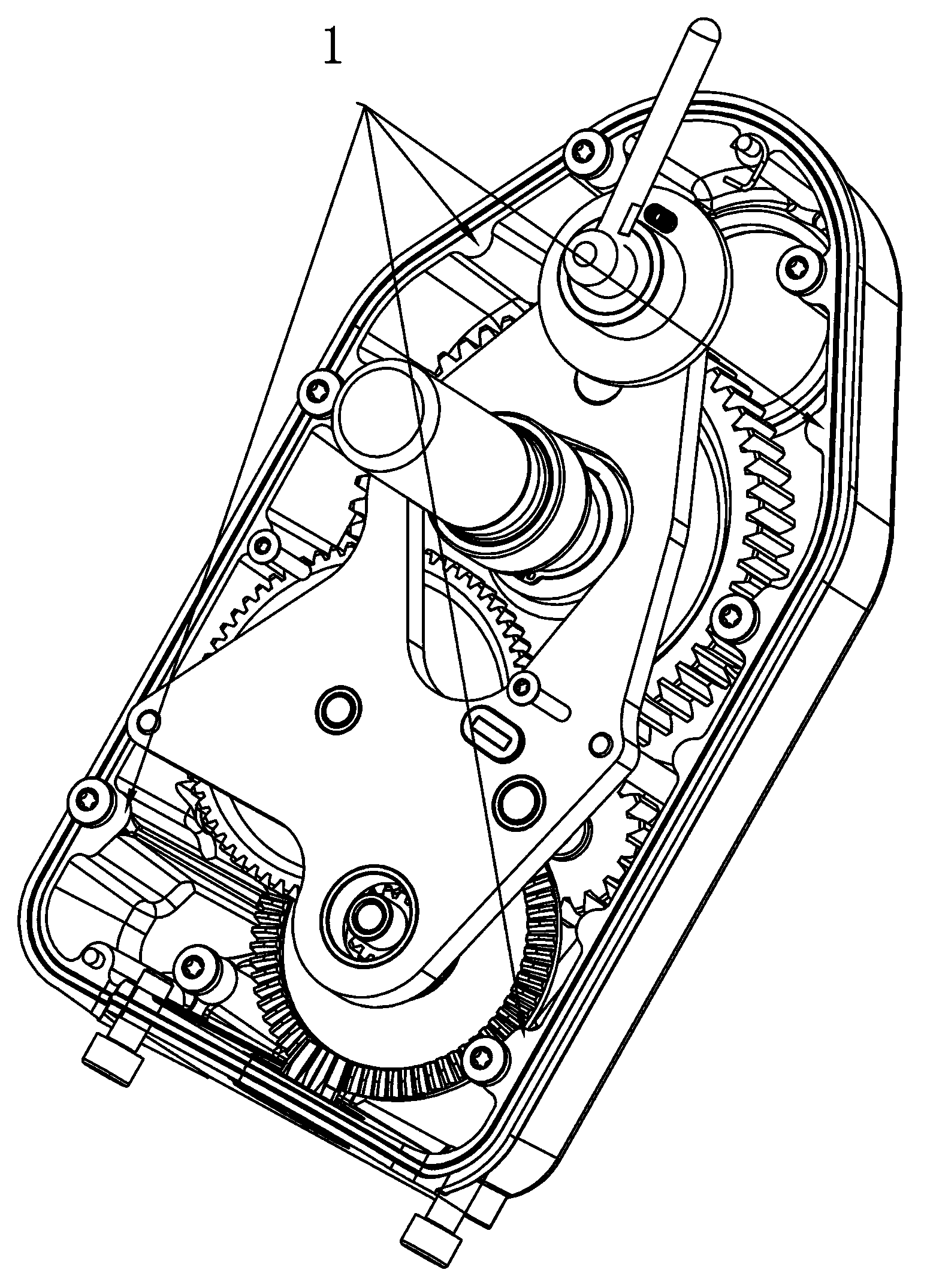

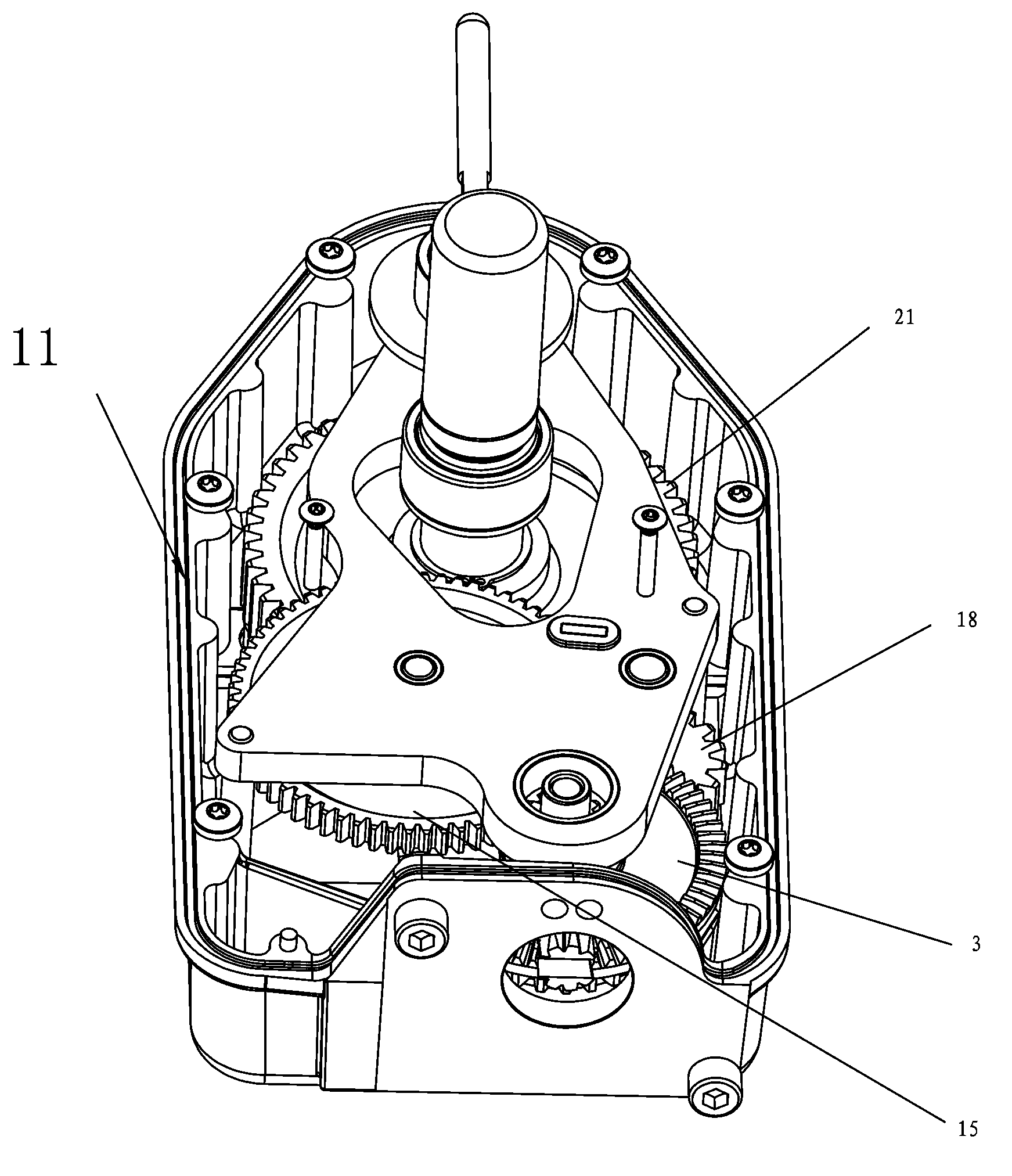

Novel electric supporting leg

ActiveCN105128828AConvenient up and down telescopic movementReduce labor intensityVehicle fittings for liftingLow speedGear wheel

The invention relates to a novel electric supporting leg. The novel electric supporting leg comprises a left supporting leg body, a right supporting leg body, a middle shaft for connecting the left supporting leg body and the right supporting leg body and an electric driving mechanism. The electric driving mechanism comprises a motor, a shell, a front swing plate and a poking rod mechanism, an output shaft, an output shaft gear, an input shaft and an input shaft multi-speed-ratio gear are installed in the shell, a motor shaft is connected with a bevel pinion, the bevel pinion is meshed with conical teeth of the input shaft multi-speed-ratio gear, a high-speed transmission gear and a low-speed duplicate gear assembly are installed on the front swing plate, and the poking rod mechanism makes the front swing plate swing left and right with the input shaft as the fulcrum, so that the output shaft gear is in drive connection with the input shaft multi-speed-ratio gear through the high-speed transmission gear or the low-speed duplicate gear assembly, and the motor shaft provides power for the output shaft with different speed ratios. The input shaft multi-speed-ratio gear and the low-speed duplicate gear assembly are manufactured in a pressure casting mode through powder metallurgy. The novel electric supporting leg can be controlled in a manual mode, or an electric high-speed mode or an electric low-speed mode, is reasonable in structure and saves labor in the operating process.

Owner:GUANGDONG FUHUA MACHINERY EQUIP MFG CO LTD

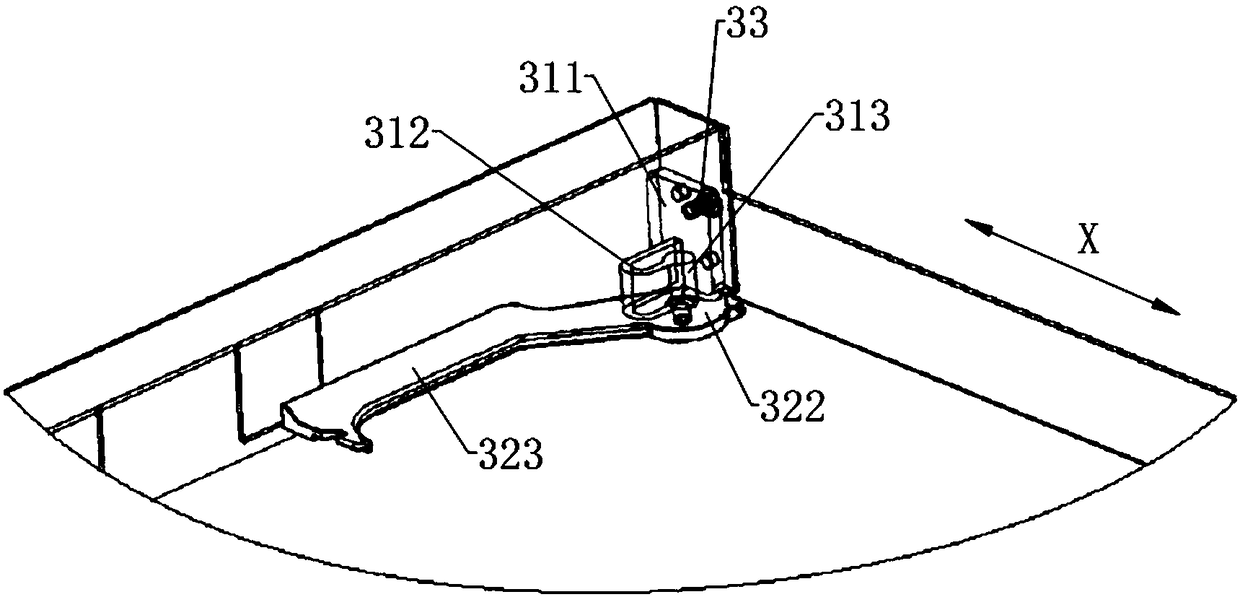

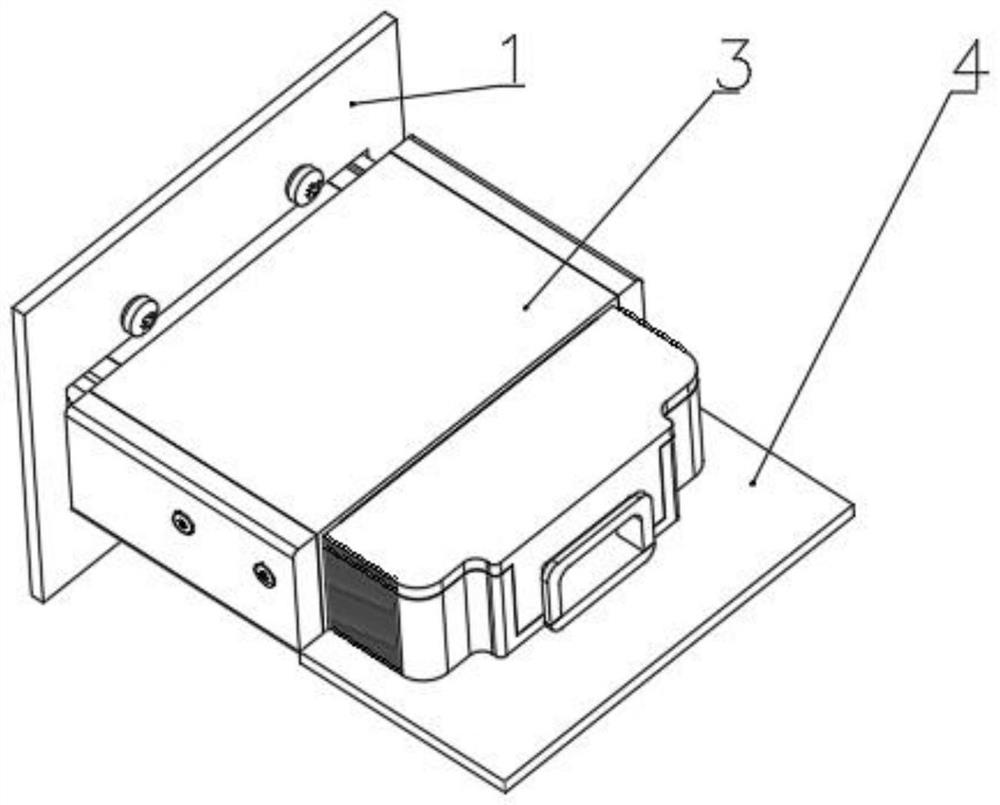

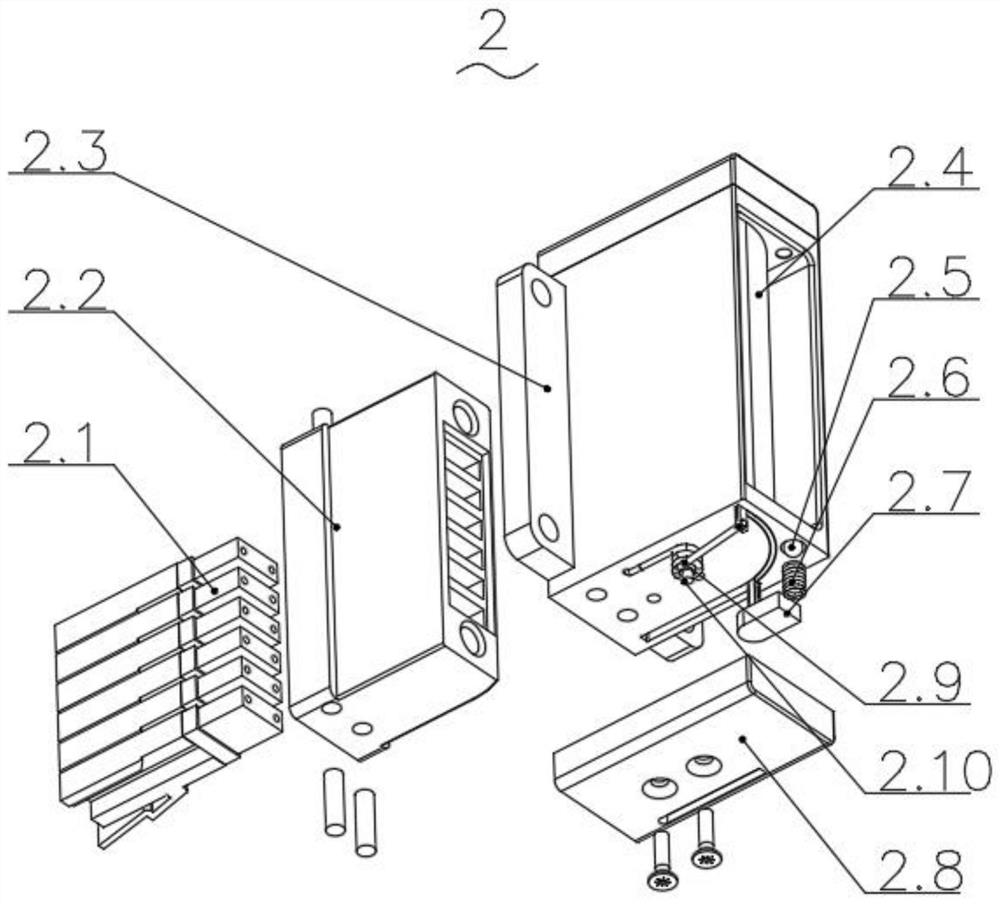

Quick release component for pin-joint latch hook

ActiveCN104486920AEliminate fit gapsImprove connection reliabilityCasings/cabinets/drawers detailsInterconnectionEngineering

The invention relates to a quick release component for a pin-joint latch hook. The quick release component for the pin-joint latch hook comprises a hinge, the pin-joint latch hook and a pin-joint front latch, wherein the pin-joint latch hook is fixedly arranged on a cabinet front faceplate; the pin-joint front latch is hinged to the hinge through a dowel; the pin-joint front latch is matched with the pin-joint latch hook; after the pin-joint front latch is tightened, the pin-joint latch hook is fastened towards a cabinet installation direction. According to the quick release component, the structure is simple; the fit clearance between the latch hook and a front latch component is effectively eliminated; the stress between the latch hook and the front latch component is prevented from being amplified; the reliability of structural interconnection between a cabinet and an installation rack is improved.

Owner:AVIC NO 631 RES INST

C-ring mechanical expanding shaft

The invention discloses a C-ring mechanical expanding shaft suitable for processing metal and nonmetal foil / film coils and aluminum belts and foils. An inclined surface-to-circle novel structure which has self-retraction capability, and has a thin blade which is capable of marking deeply is provided, aiming to solve the problems of no foundation and no self-locking in friction caused by the execution expansion strip and the inclined surface expansion block of the existing air bag type or inclined surface-to-inclined surface type mechanical expanding shaft, and the problems of skidding, and low accuracy and low structural strength of the shaft caused thereby. The C-ring mechanical expanding shaft takes the place of the typical structure of inclined surface to inclined surface, and comprises a cylindrical shaft and a plurality of tapered wedge tubes sleeved to the cylindrical shaft. A push-pull nut is turned so that the C-ring having a plurality of blades sleeved to the conical surface are expanded outwards so as to clamp a coiled core tube. Such an inclined surface-to-circle structure is small in radial dimension, so that the strength of the expansion shaft is improved; and due to vanishing of the gap between the circle and the shaft in clamping, the radial jumping error of the shaft is reduced. Besides, the C-ring mechanical expanding shaft is suitable for coiling processing of thin tube core, large breadth and no air pressure source.

Owner:柳燕明

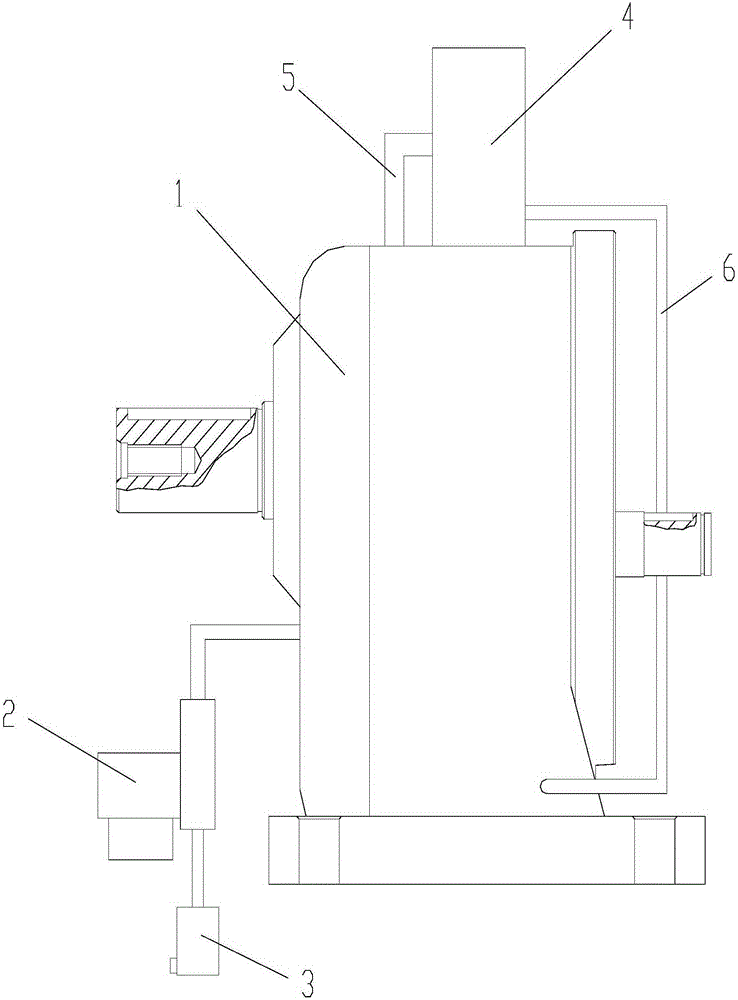

Speed reducer with anti-backlash structure

InactiveCN105333066AEliminate fit gapsAvoid noiseToothed gearingsGearing detailsReduction driveEngineering

The invention discloses a speed reducer with an anti-backlash structure. The speed reducer with the anti-backlash structure comprises a speed reducer outer shell and a gear transmission mechanism. The gear transmission mechanism comprises an input shaft, a middle shaft and an output shaft, wherein the input shaft is provided with a first bevel gear, the middle shaft is provided with a second bevel gear and a third bevel gear engaged with the first bevel gear, and the output shaft is provided with a fourth bevel gear engaged with the third bevel gear. A first butterfly spring used for applying axial thrust force on the first bevel gear is arranged between the first bevel gear and a bearing. A second butterfly spring used for applying axial thrust force on the fourth bevel gear is arranged between the fourth bevel gear and the bearing. According to the speed reducer with the anti-backlash structure, when the gears are abraded, the butterfly springs automatically push the first bevel gear and the fourth bevel gear to move in the axial direction, and therefore a gear matching gap caused by friction abrasion is eliminated. The problems of increase of noise and impact force on the gears and the like caused by the increase of the gear matching gap can be avoided.

Owner:QIJIANG YONGYUE GEAR

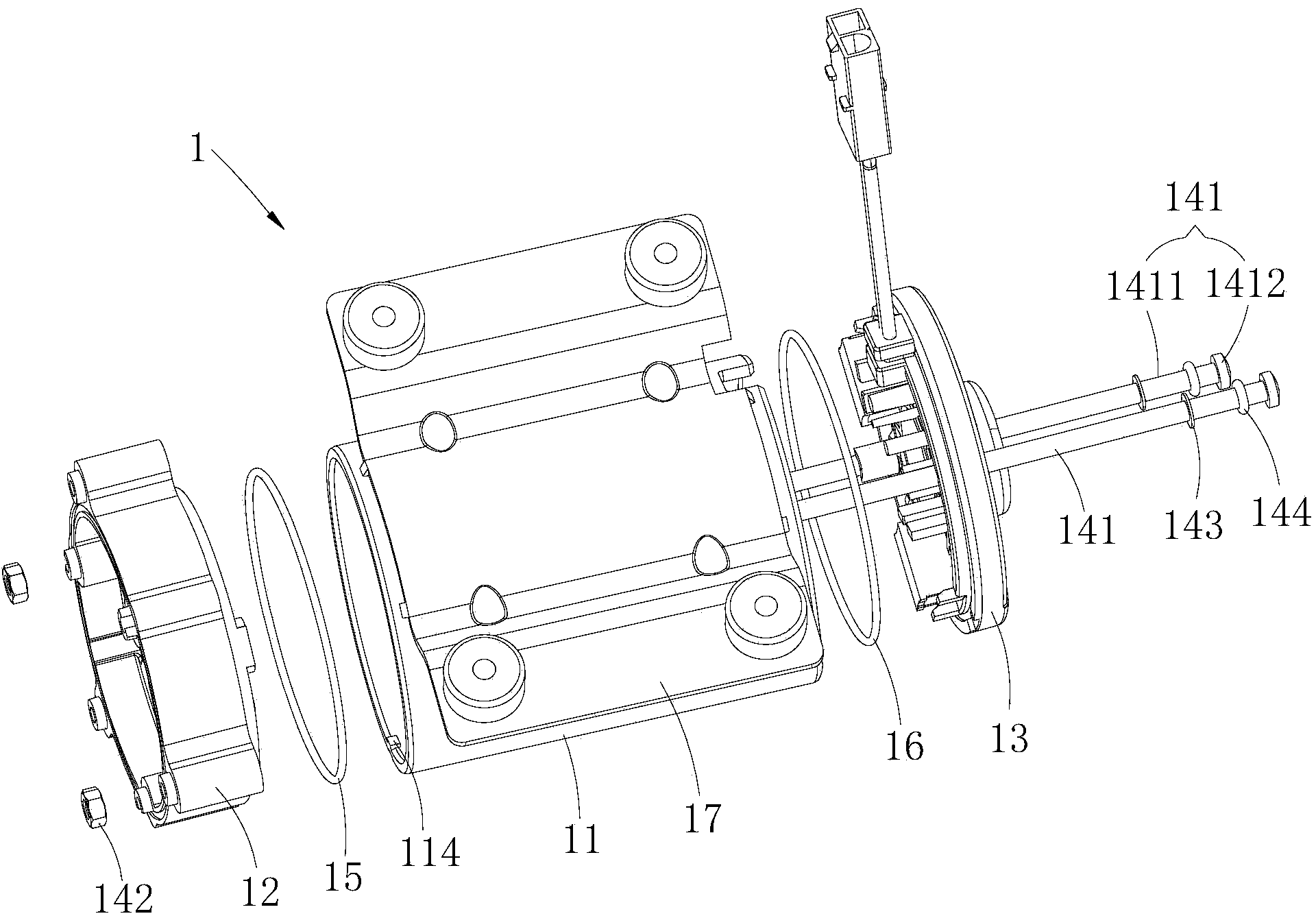

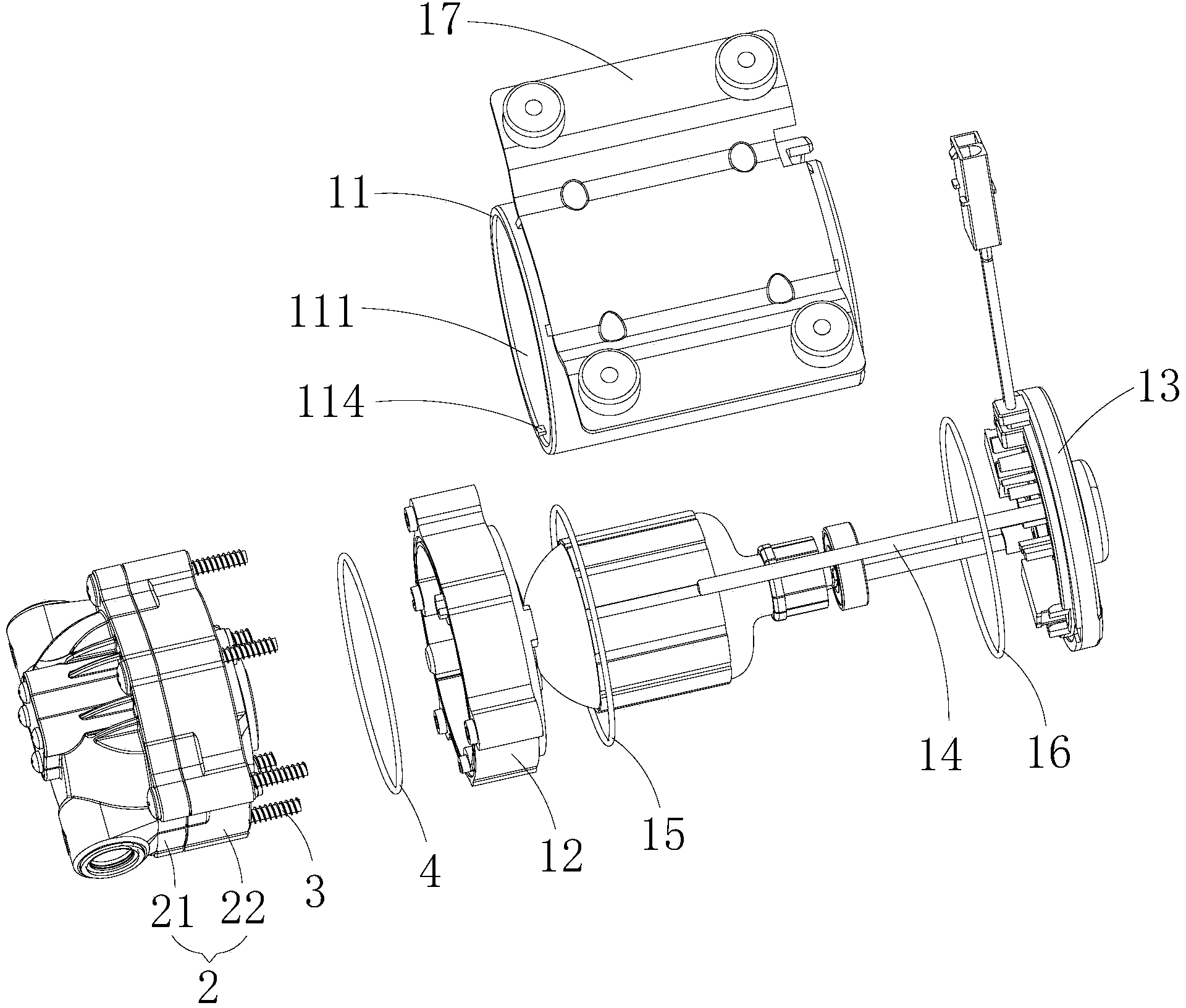

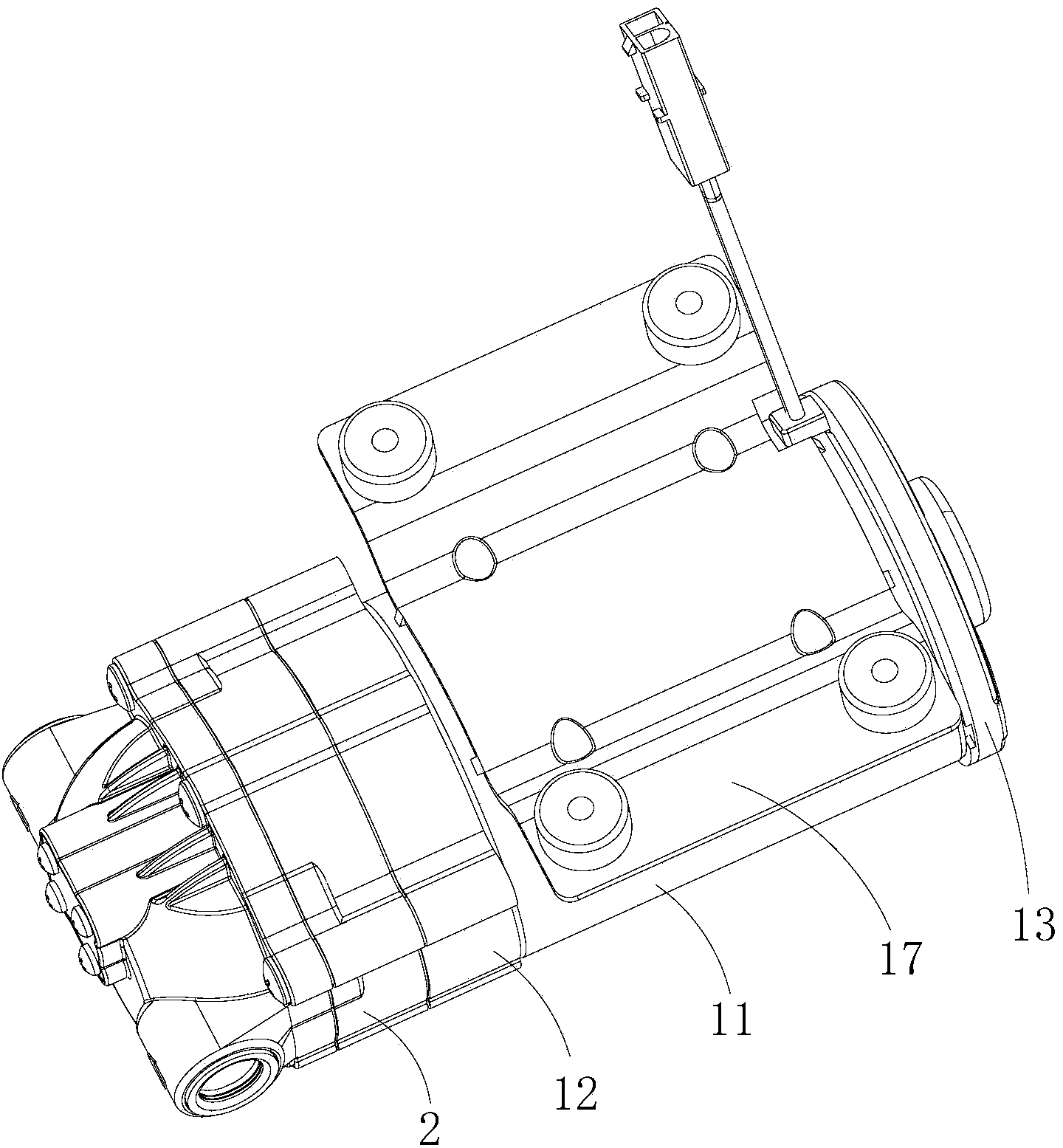

Motor of booster pump and booster pump with the same

InactiveCN104022593AImprove waterproof sealing performanceGuaranteed service lifePumpsPositive-displacement liquid enginesEngineeringMechanical engineering

The invention is suitable for the technical field of a motor, and discloses a motor of a booster pump and the booster pump with the same. The motor of the booster pump comprises a housing, a front end cap, a back end cap, a first connector, a first elastic sealing member and a second elastic sealing member. The front end cap and the back end cap are respectively arranged at two ends of the housing and are connected with the housing in a fastening manner through the first connector. A first accommodating tank is arranged on the front end cap in a concave manner. The first elastic sealing manner is accommodated in the first accommodating tank and is provided with a first sealing part which projects from the first accommodating tank. A second accommodating tank is arranged on the back end cap in a concave manner. The second elastic sealing member is accommodated in the second accommodating tank and is provided with a second sealing part which projects from the second accommodating tank. The housing is provided with a front matching surface which abuts against the first sealing part and a back matching surface that abuts against the second sealing part. The motor of the booster pump successively settles a problem of insufficient waterproof sealing in the motor of the booster pump. Long service life and high use safety of the motor are ensured. Furthermore the flatness requirement for the matching surfaces among the front end cap, the back end cap and the housing of the motor can be reduced.

Owner:FOSHAN WEILING WASHER MOTOR MFG

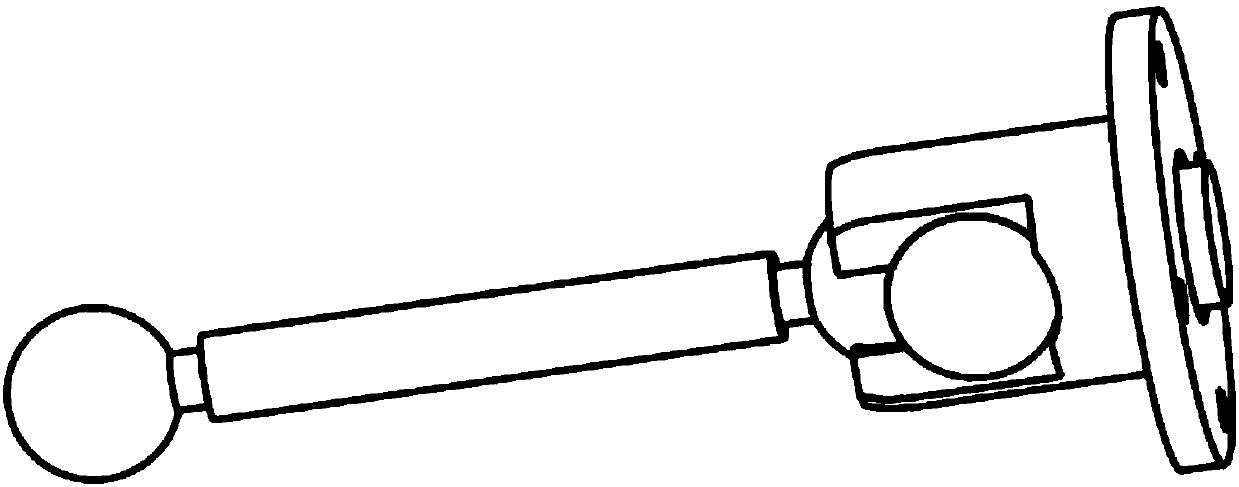

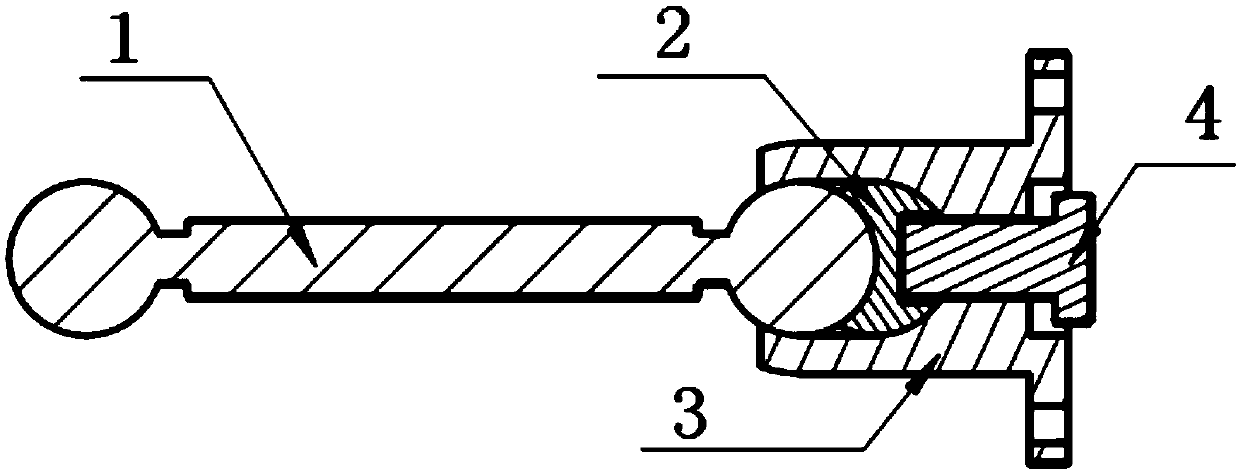

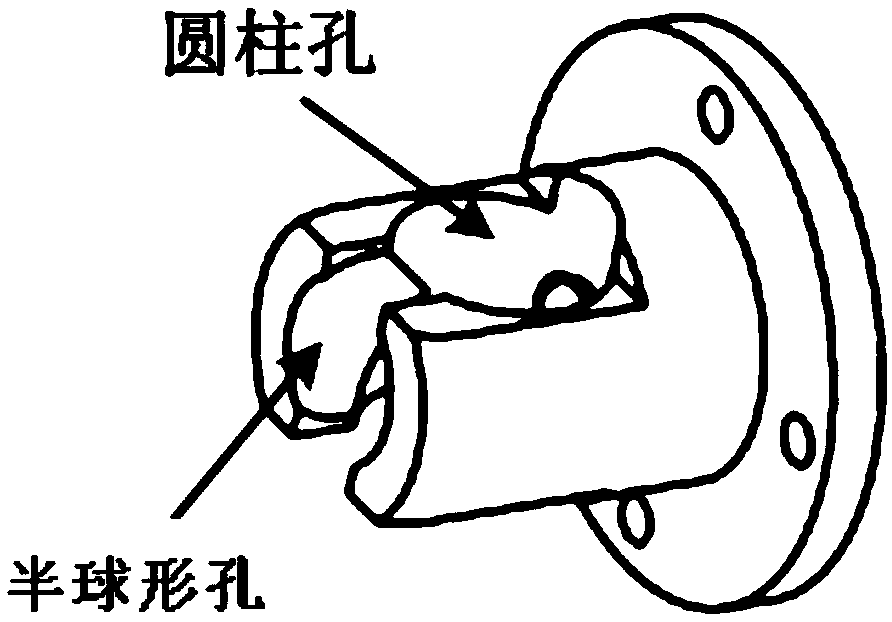

Spherical joint pair with low friction and no gap, assembly method and application thereof

ActiveCN109519468ARealization of precision transmissionAchieve cooperationPivotal connectionsPivotsManufacturing technologyDirect effects

The invention relates to a spherical joint pair with low friction and no gap, an assembly method and application thereof, and belongs to the technical field of multi-degree of freedom mechanism and micro-transmission control. The spherical joint pair is a very effective transmission mode to realize multi-degree of freedom motion in a single joint. The manufacturing technology and cooperation of the spherical joint pair directly affect the transmission accuracy and efficiency of a joint. By using the close cooperation between a non-metallic material-polytetrafluoroethylene and a metal ball headconnecting rod, the ball joint transmission with low friction, no gap and high reliability is realized.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

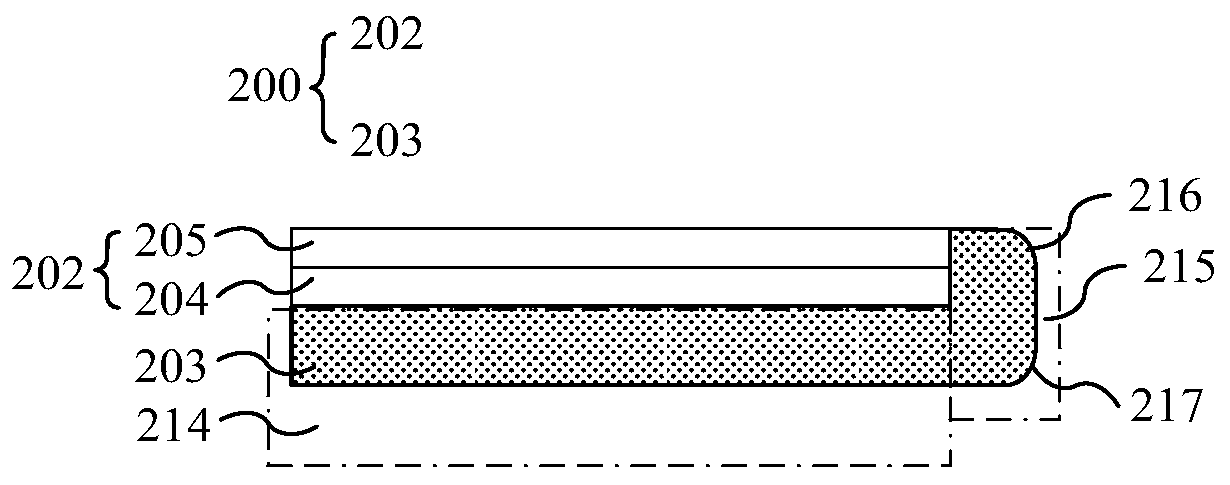

Display panel and preparation method thereof

ActiveCN110942720ASolve the problem of splitting signal linesAvoid technical issues affecting displayInput/output processes for data processingIdentification meansMechanical engineeringIndustrial engineering

The invention discloses a display panel and a preparation method thereof. A support structure is arranged in the display panel, and the support structure is used for supporting a bent section of the display panel. The supporting structure comprises a first supporting part and a second supporting part. The second supporting part is manufactured on the surface of the first supporting part and the side edge of the first supporting part through the additive printing technology, so the manufacturing process of manufacturing the supporting part through machining and then attaching the supporting part to the corresponding position of the display panel is simplified, the attaching gap is eliminated, and the bent section of the display panel can obtain the more complete supporting effect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

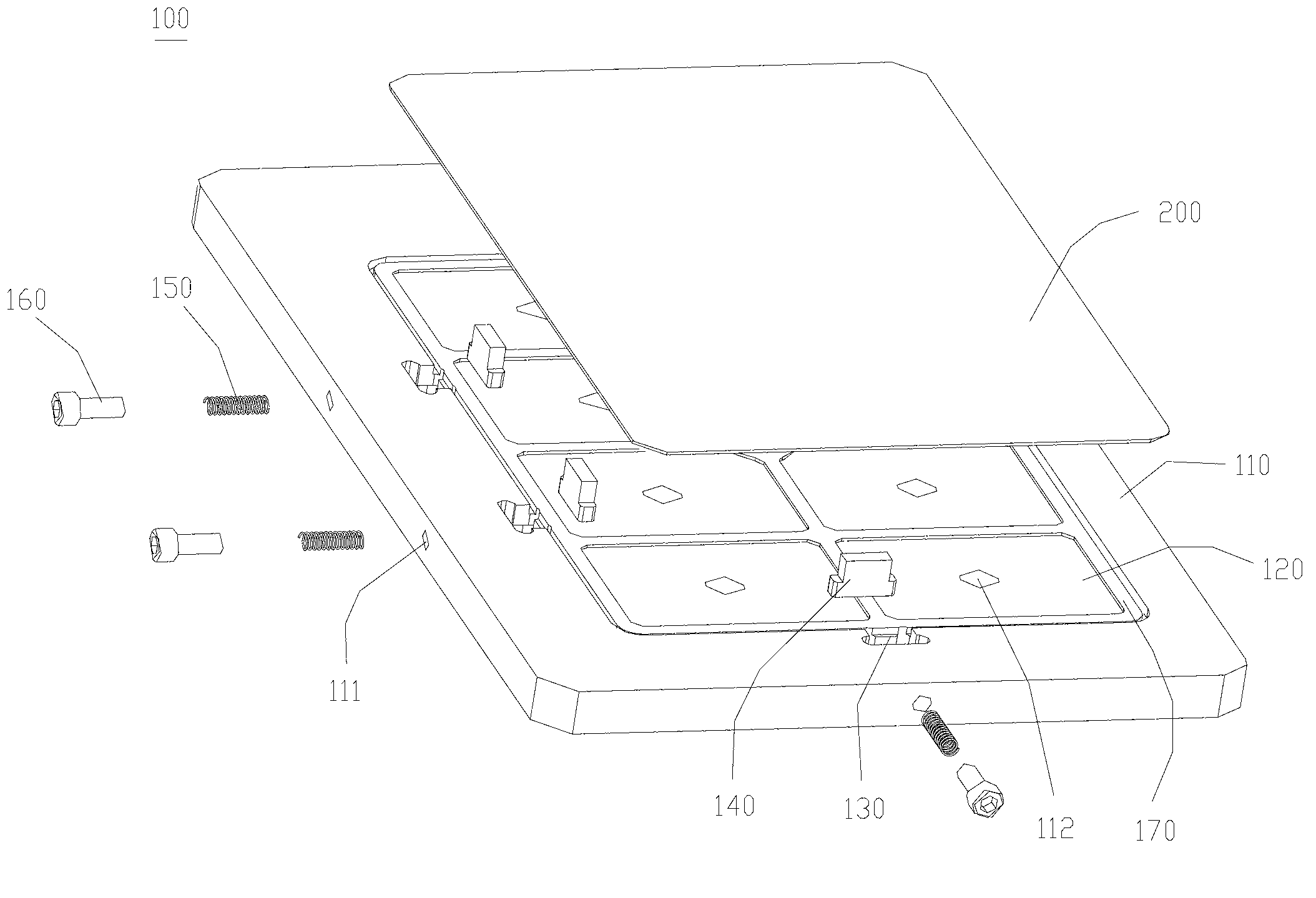

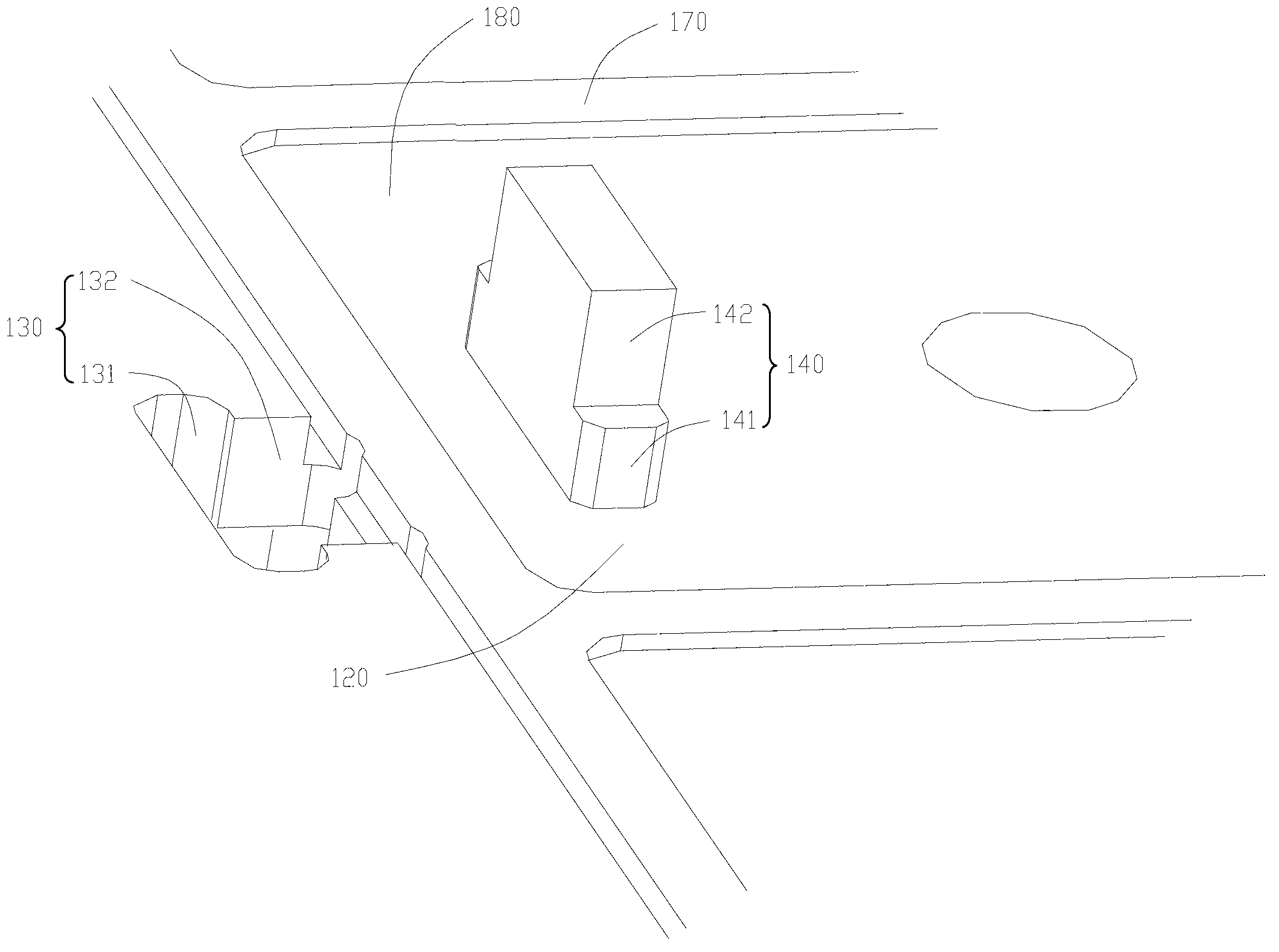

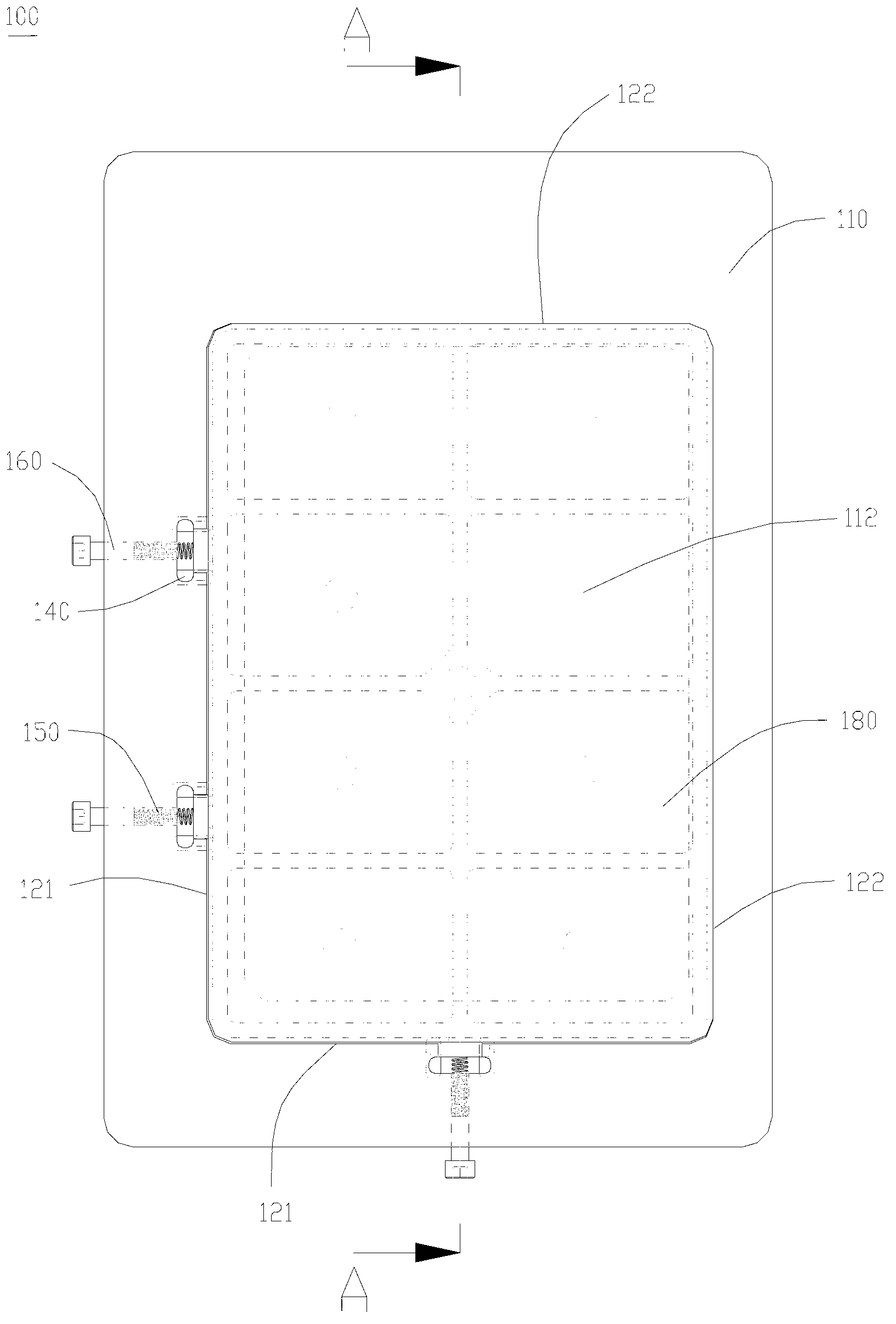

Silk-screen printing fixture and using method thereof

InactiveCN103302957AReduce positioning impactEliminate fit gapsScreen printersKey pressingScreen printing

A silk-screen printing fixture comprises a bottom plate and a pressing mechanism, wherein a cavity which can be in clearance fit with a to-be-printed piece is formed in the bottom plate; the bottom plate comprises a first inner wall and a second inner wall which are opposite; a slide way groove is formed in the first inner wall; the pressing mechanism is glidingly arranged in the slide way groove and is propped against the to-be-printed piece; and the pressing mechanism tightly presses the to-be-printed piece and tightly attaches the side surface of the to-be-printed piece to the second inner wall. When the silk-screen printing fixture is required for printing patterns, such as a window or keys and the like, on the to-be-printed piece such as a piece of glass of a cover plate of a mobile phone, the to-be-printed piece is placed in the cavity formed in the bottom plate, and the pressing mechanism tightly presses the to-be-printed piece to the second inner wall opposite to the first inner wall, so that the influences of fit clearance on positioning of the to-be-printed piece is reduced, the fit clearance between the silk-screen printing fixture and the to-be-printed piece can even be eliminated, the positioning accuracy of the window, the patterns and the like of the to-be-printed piece is improved, and accurate positioning is realized.

Owner:NANCHANG O FILM OPTICAL TECH

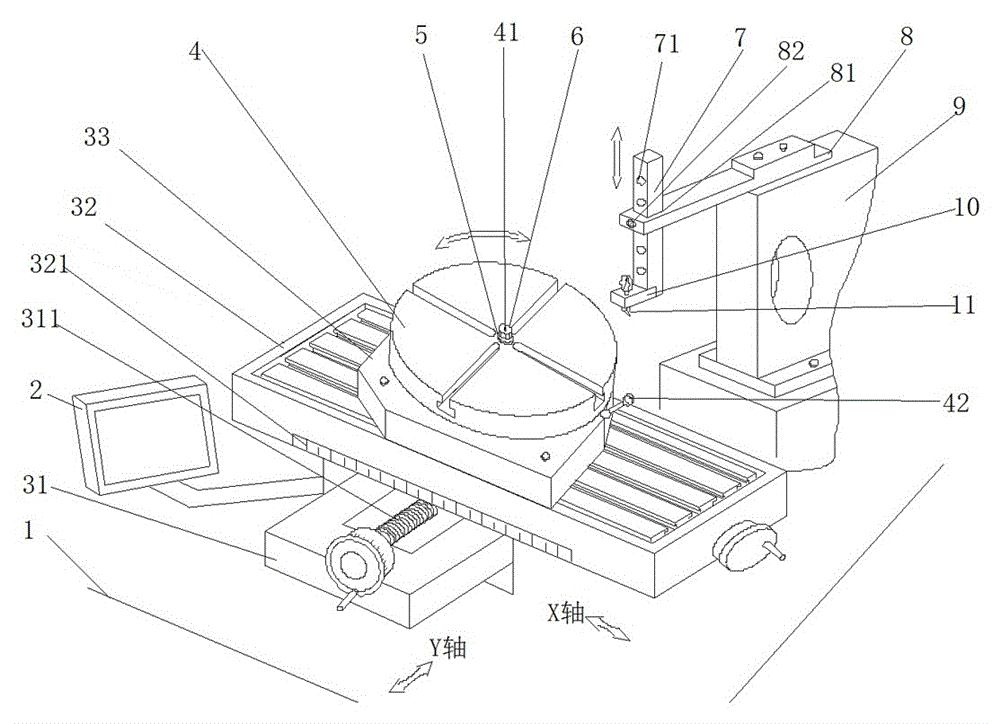

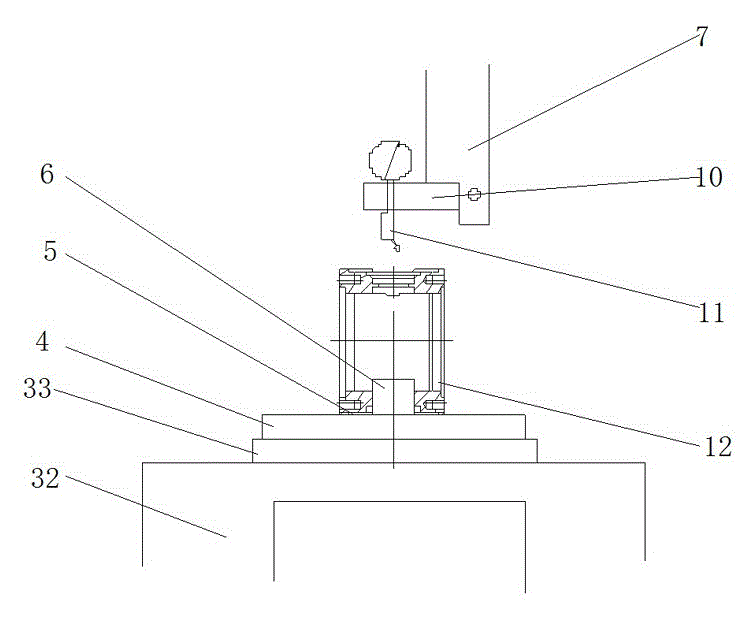

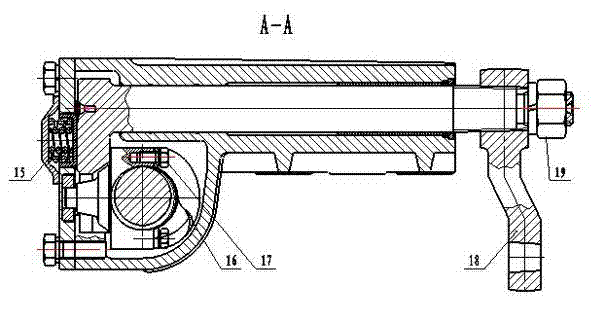

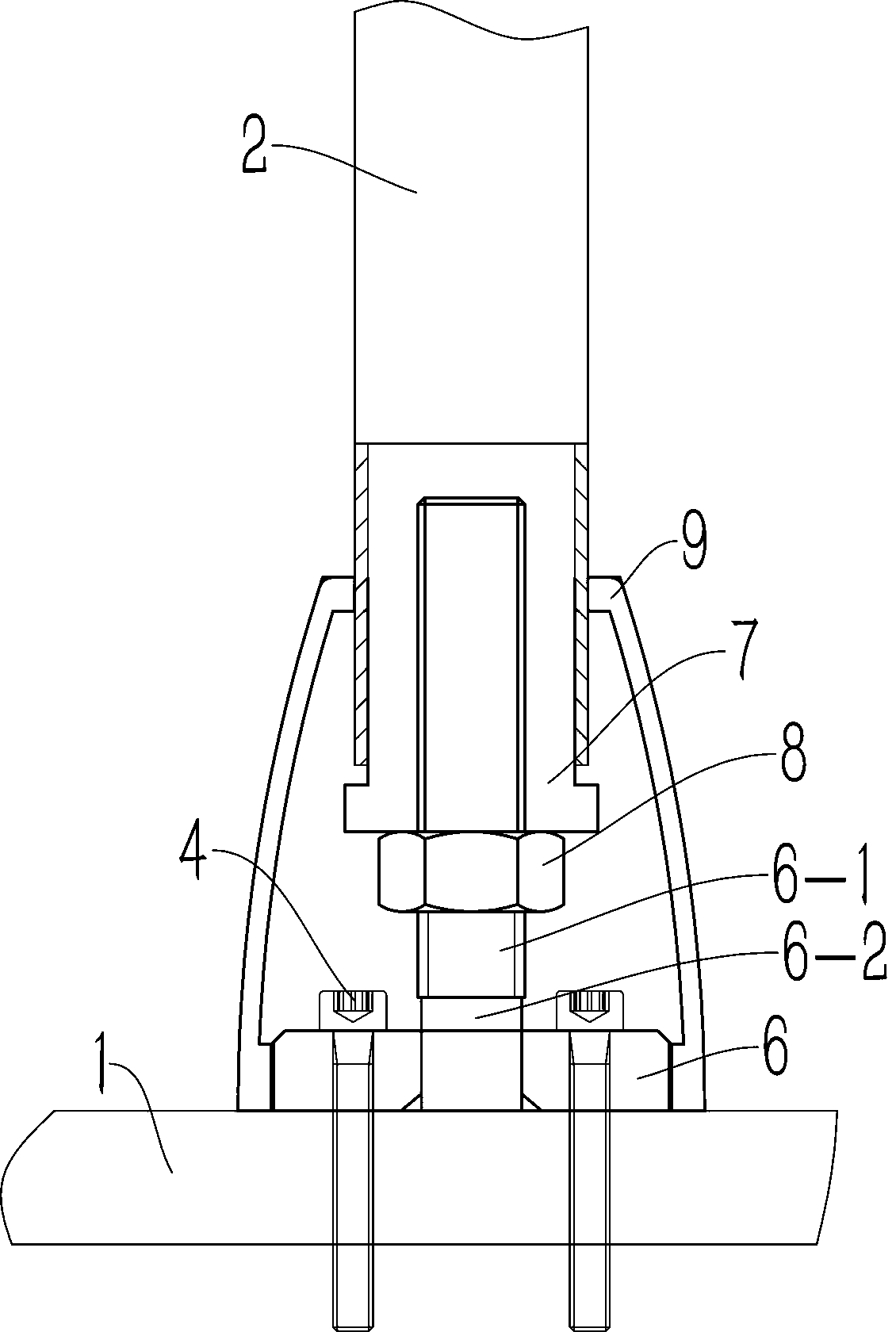

High-precision bushing assembly centering device and bushing centering assembly method

ActiveCN113369839AImprove assembly qualityMeet the needs of useMetal working apparatusControl theoryElectrical and Electronics engineering

The invention relates to the field of bushing assembly, in particular to a high-precision bushing assembly centering device and a bushing centering assembly method. The device is a simple auxiliary tool, and comprises a centering shaft, a supporting shaft sleeve, a bushing supporting device and a shaft seat hole supporting device. The device is ingenious in structure and easy to control, and is tightly matched with a bushing and a shaft seat when used for guiding bushing assembly, so that the fit clearance is eliminated, the coaxiality between the bushing and the shaft seat is remarkably improved, and the bushing assembly quality is remarkably improved; and the use requirements of bushings and shaft seat holes with different diameters can be met by adjusting the bushing supporting device and the shaft seat hole supporting device, and the technical scheme has high universality.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

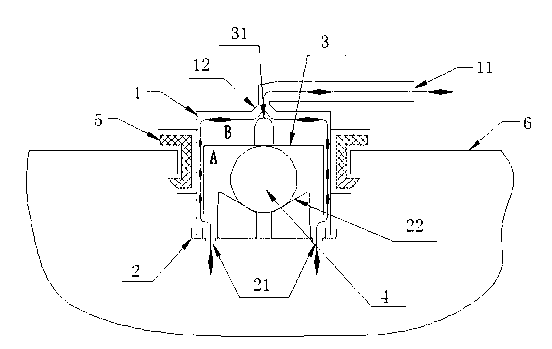

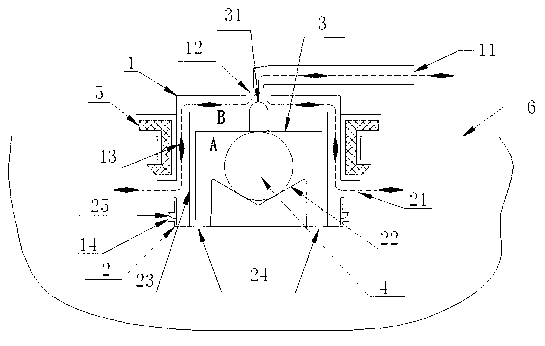

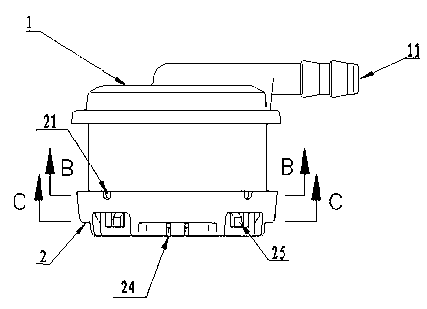

Anti-dumping valve

ActiveCN103306867AImprove securityHigh dimensional accuracyNon-fuel substance addition to fuelMachines/enginesEngineeringSteel ball

The invention discloses an anti-dumping valve. A valve body (1) is connected with a valve seat (2) to form a valve cavity (B); a cover-shaped floater (3) is arranged above the valve seat (2); a steel ball (4) which can move freely and allow the floater (3) to move up and down in the valve cavity (B) is placed between the floater (3) and the valve seat (2); a rubber sealing ring (5) is mounted on an external wall of the valve body (1) in an embedded manner; a mounting surface of the rubber sealing ring (5) is higher than the valve seat (2); in addition, an outer ring of the floater (3) is provided with an isolation cylinder (23) protruding upwards from the bottom of the valve seat (2); a second air vent (21) is formed close to the lower edge of the rubber sealing ring (5); and the valve body (1) is connected with the valve seat (2) by an elastic buckled structure perferably. According to the anti-dumping valve, since the isolation cylinder is adopted, and the position of the second air vent is changed, accident closing of the anti-dumping valve can be avoided, the anti-dumping valve has a better leakproof effect; and with the adoption of the elastic buckled mode, the dimensional precision and production efficiency are improved.

Owner:SUZHOU YUANNENG DONGLI TECH CO LTD

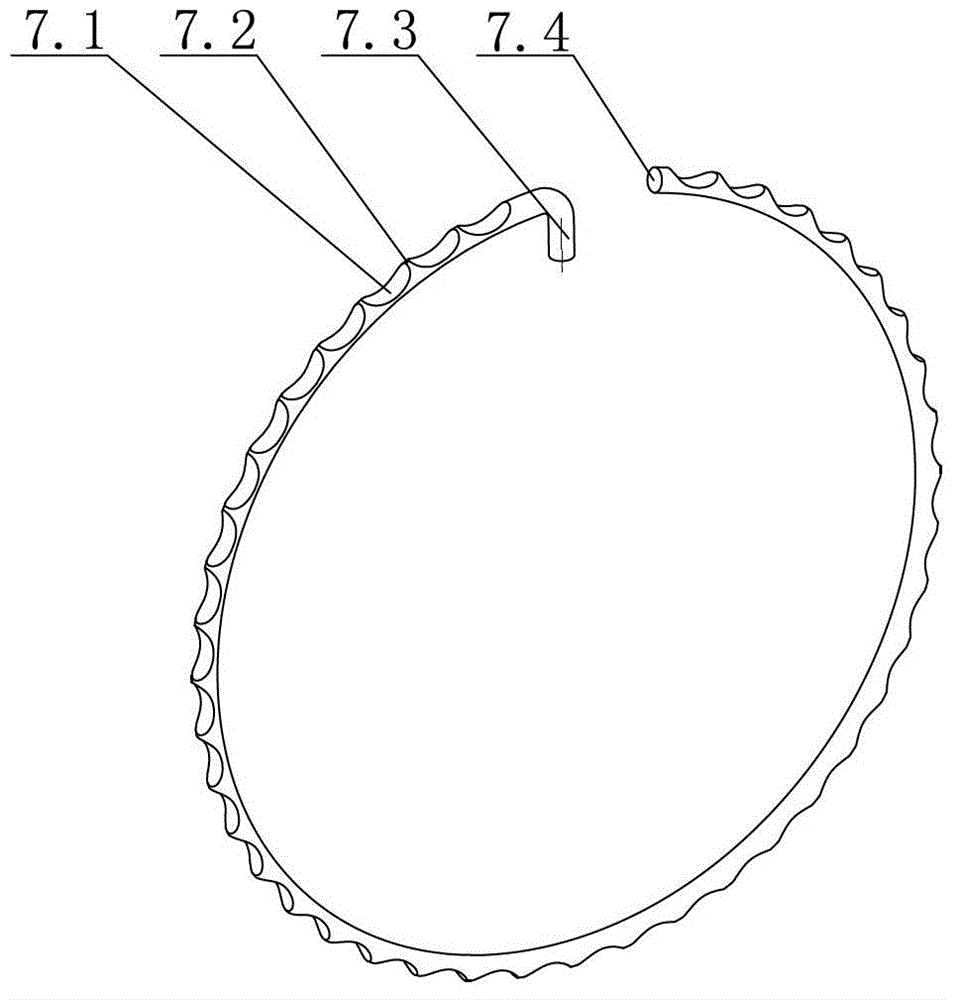

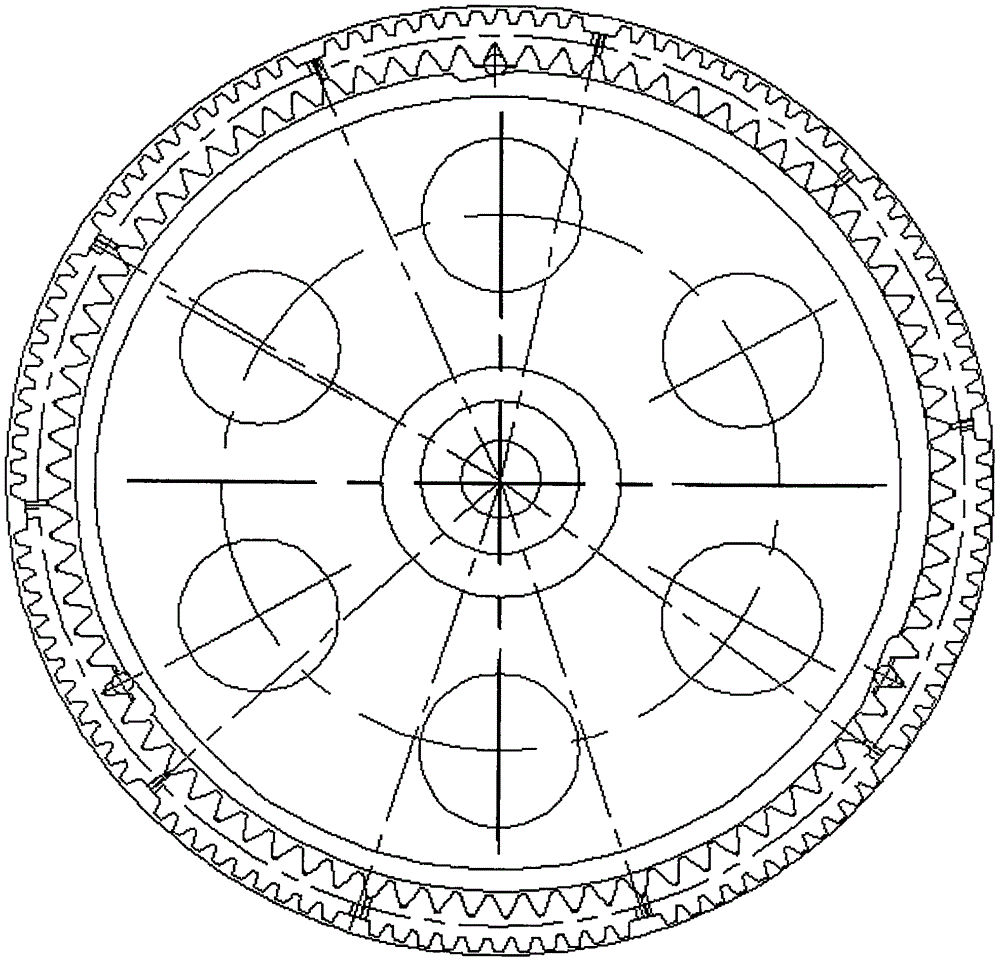

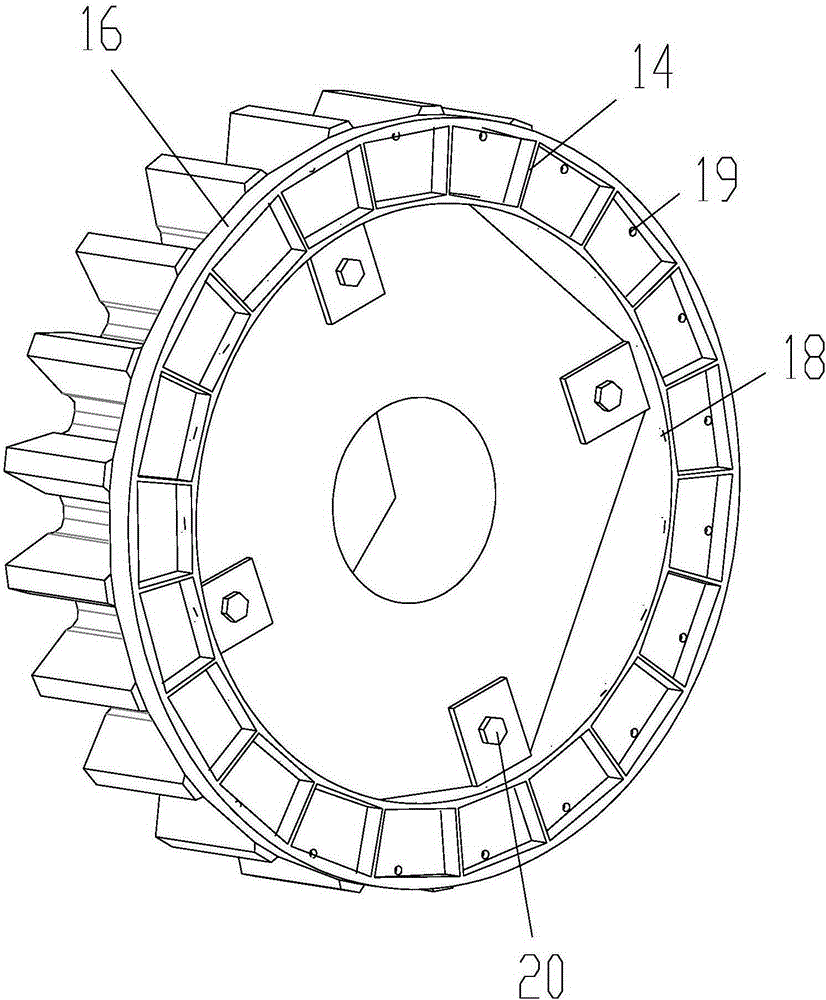

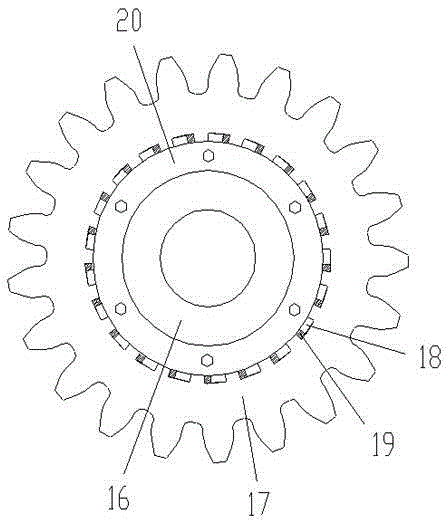

Pitch circle positioning type static balance structure for static balance of gear ring

InactiveCN106017799AImprove machining accuracyReduce manufacturing costStatic/dynamic balance measurementEngineeringCam

The invention relates to a pitch circle positioning type static balance structure for the static balance of a gear ring. The structure comprises a mandrel body, a mandrel positioning disc and a rolling bar. The mandrel positioning disc is arranged on the mandrel body. The outer circumferential surface of the mandrel positioning disc is provided with more than two uniformly distributed arc grooves along the axial direction, and an arc cam surface tangent with the arc grooves. During operation, the rolling bar can roll within the arc grooves and the arc cam surface tangent with the arc grooves along the circumferential direction of the positioning disc. Meanwhile, during operation, the uniformly distributed arc grooves are respectively corresponding to the positions of the internal tooth slots of the gear ring. According to the technical scheme of the invention, conventional parts arranged on the mandrel of the static balance structure, such as nuts, glands and the like, are eliminated, so that the weight of the mandrel of the static balance structure is greatly reduced. The accuracy of the static balance test is improved. Parts can be loaded and clamped more conveniently and more quickly compared with a conventional static balance mandrel.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

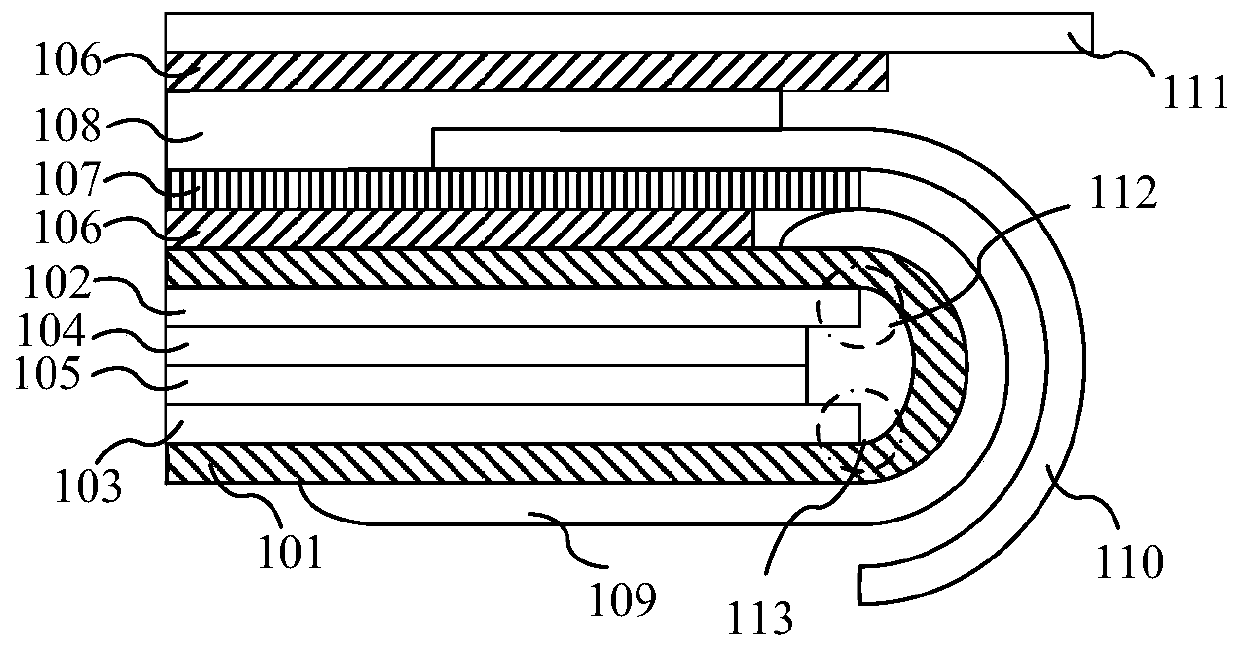

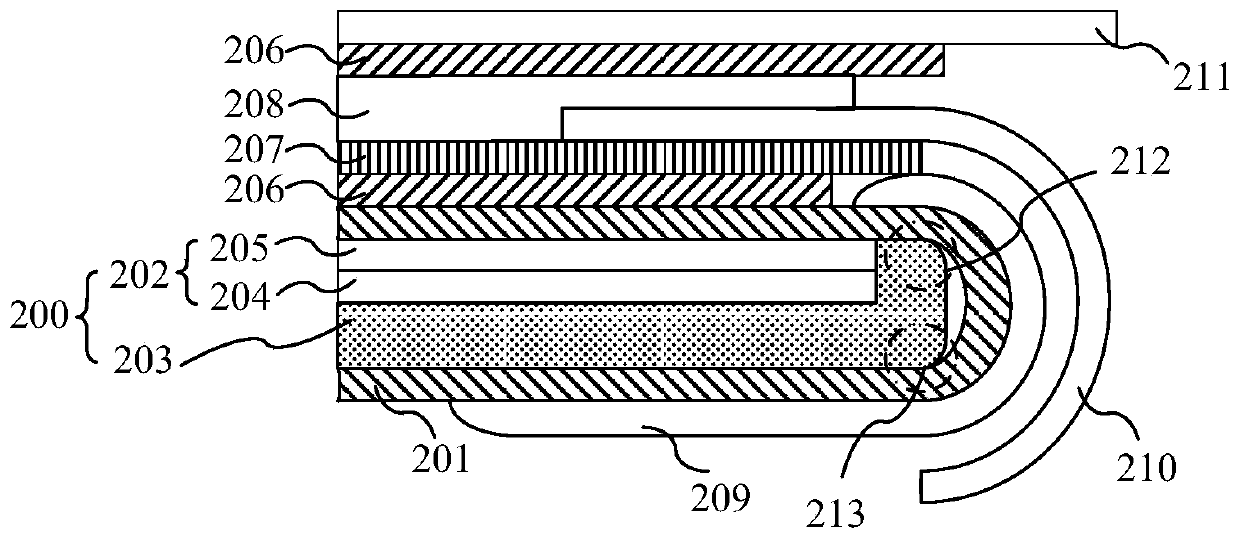

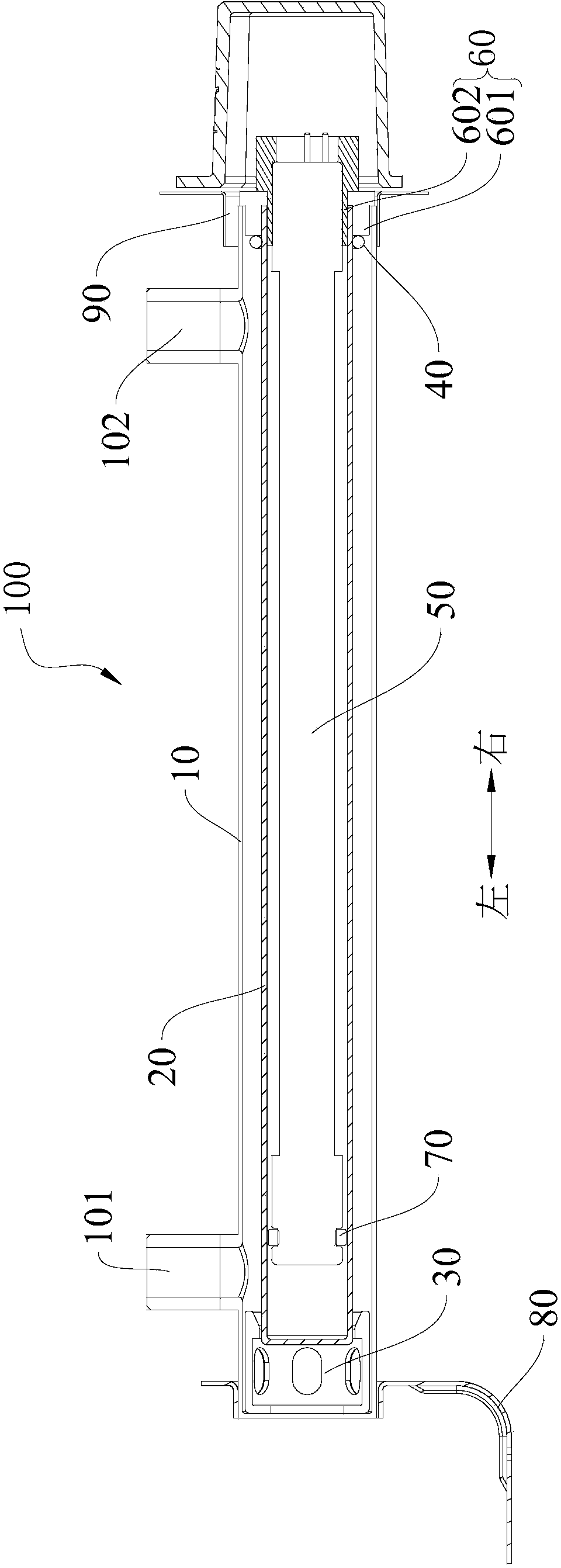

Ultraviolet sterilization apparatus for water heaters

ActiveCN105502570AEliminate fit gapsPlay a role of buffer protectionFluid heatersWater/sewage treatment by irradiationUltravioletEngineering

The present invention provides an ultraviolet sterilization apparatus for water heaters. The ultraviolet sterilization apparatus comprises: a housing provided with a water inlet and a water outlet; a bushing arranged inside the housing; a sealing sleeve arranged inside the housing and positioned on the left end of the housing, wherein the left end of the bushing is received inside the sealing sleeve; a first sealing ring arranged between the outer peripheral wall of the bushing and the inner peripheral wall of the housing; an ultraviolet sterilization lamp tube arranged inside the bushing; a plugging head connected to the right end of the housing; and a second sealing ring arranged between the outer peripheral wall of the ultraviolet sterilization lamp tube and the inner peripheral wall of the bushing. The ultraviolet sterilization apparatus according to the embodiments of the present invention has characteristics of simple structure and prevention of damage caused by collision shock.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

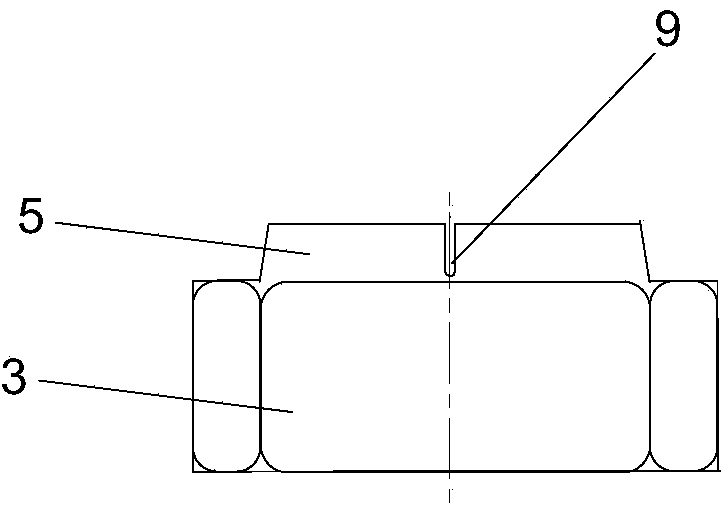

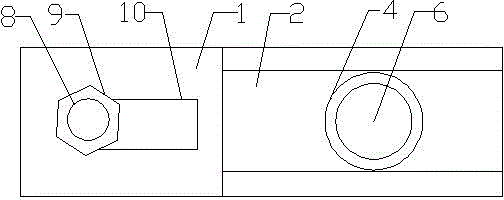

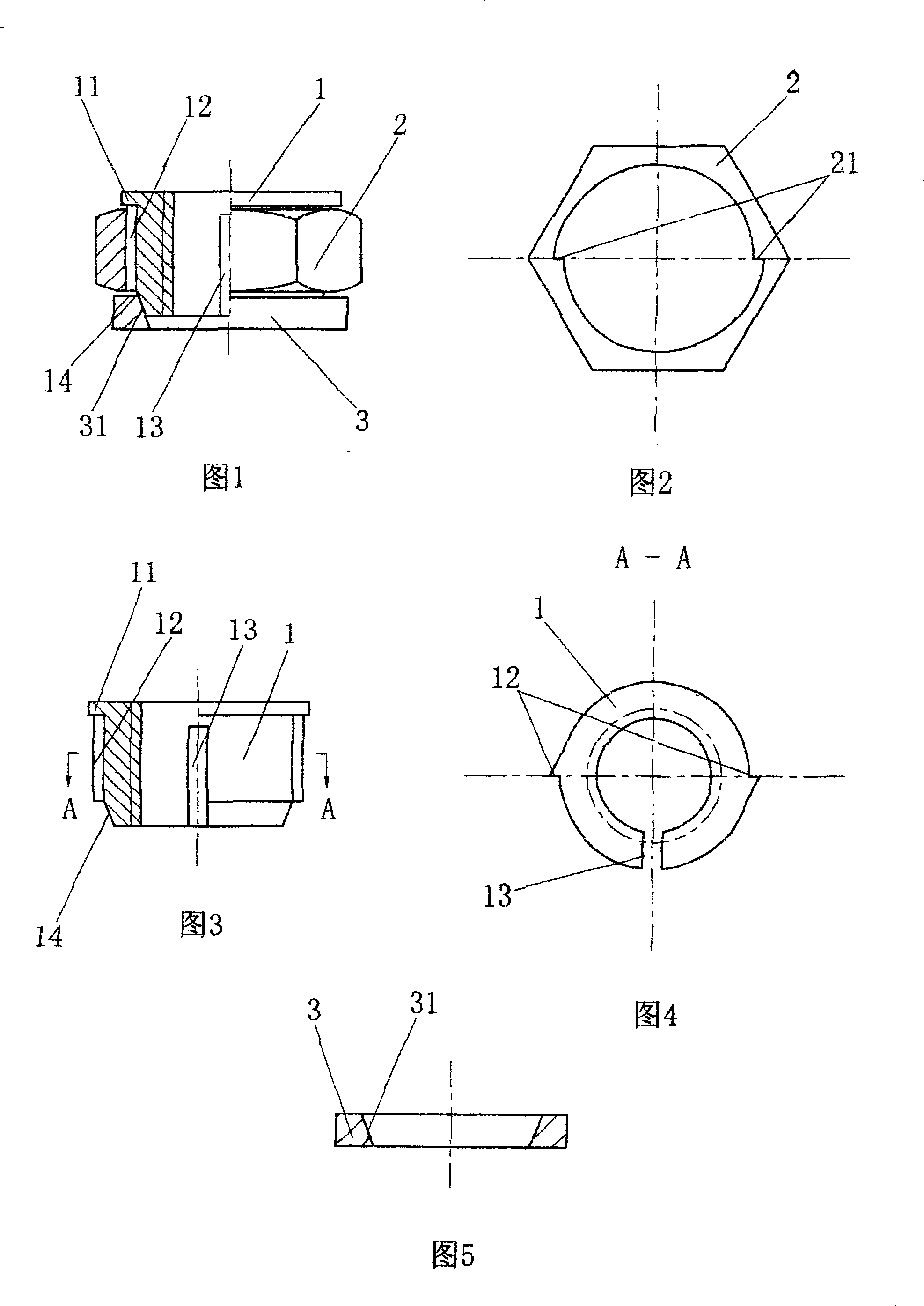

Positioning pin

InactiveCN105983865AEasy to slideOvercome sizePositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to the field of machining, in particular to a positioning pin. The positioning pin comprises a base and an adjustable clamping mechanism. The positioning pin is characterized in that a sliding groove is formed in the base; a cylinder capable of sliding in the sliding groove is arranged in the sliding groove; a compression spring is arranged at the bottom of the cylinder; and a circular truncated cone is arranged above the compression spring and is in sliding fit with the cylinder. The adjustable clamping mechanism comprises a blind hole in the base. An adjusting screw is fixedly arranged at the bottom of the blind hole. The adjusting screw is sequentially sleeved with an adjusting screw, a tubular body and an adjusting nut from bottom to top. A flat panel is arranged at the upper end of the tubular body. Sawteeth are arranged on the side, facing the sliding groove, of the tubular body and the lower surface of the flat panel. A vertical vent hole is formed in the circular truncated cone. The positioning pin is not affected by the size of a blank hole or the circularity error, the fit clearance between the blank hole and the positioning pin can be eliminated, positioning errors are reduced, and the positioning pin is convenient to use, capable of saving time and labor and firm in positioning.

Owner:肖建峰

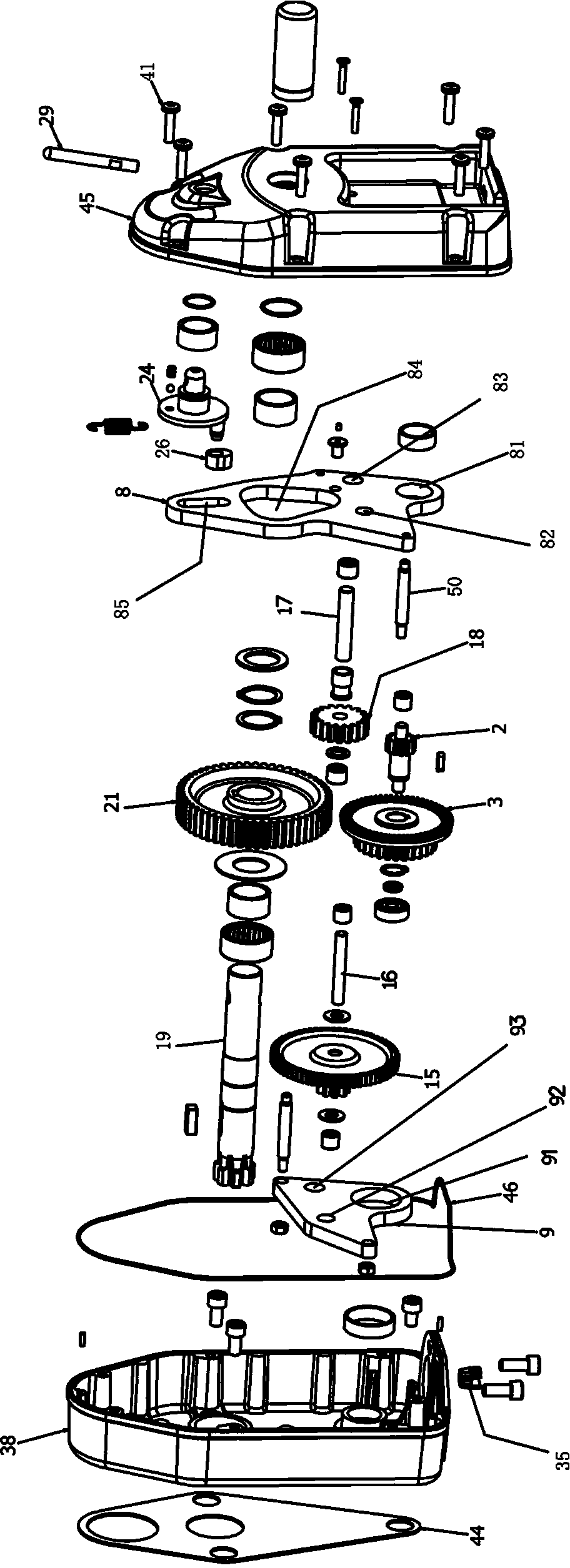

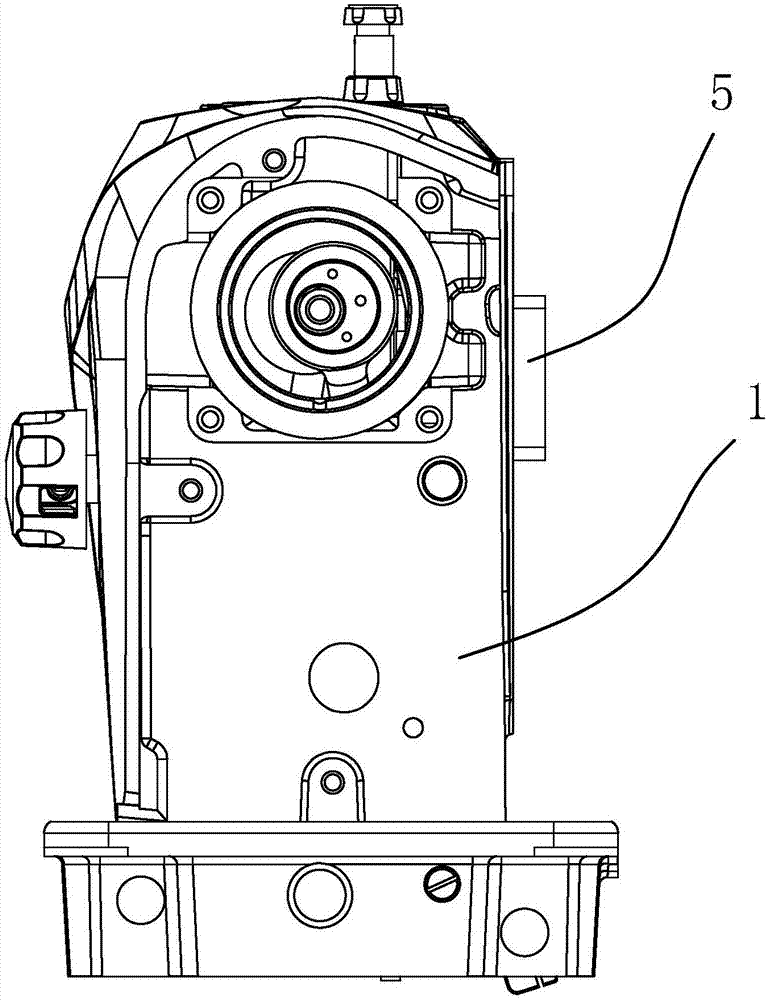

Electric support leg

InactiveCN103707860AAvoid enteringProtective structureVehicle fittings for liftingHigh speed controlGear drive

The invention relates to an electric support leg which comprises a support leg body as well as a gearbox and a motor arranged at the side part of one support leg assembly, wherein a main output shaft, a three-stage gear, a high-speed transmission gear, a low-speed transmission gear, an input bevel gear set, a shifting rod mechanism and a rocker plate are arranged inside a gearbox; the main output shaft is sleeved with the three-stage gear; the main output shaft is connected with a main gear transmission mechanism inside a left support leg assembly and a right support leg assembly; the input bevel gear set is driven by the motor; the high-speed transmission gear and the low-speed transmission gear are arranged on the rocker plate and are meshed with the input bevel gear set; the shifting rod mechanism is used for controlling the rocker plate to swing in three different shifts, so as to enable the three-stage gear to be meshed with the high-speed transmission gear, meshed with the low-speed transmission gear or dissociated from both the high-speed transmission gear and the low-speed transmission gear. The electric support leg has three options of manual control, electric high speed control and electric low speed control, and is reasonable in structure and labor-saving in operation.

Owner:GUANGDONG FUHUA MACHINERY EQUIP MFG CO LTD

Cantilever-type human body electrostatic discharger

The invention discloses a cantilever-type human body electrostatic discharger, which comprises a human body electrostatic discharger body. The human body electrostatic discharger body comprises a mounting assembly, a metal arm and a touch ball head device. The mounting assembly comprises a positioning plate, a connection tray and a limit spring. The positioning plate is provided with a hollow stopper, the inner cavity of which is communicated with the outside through the bottom of the stopper. A support shaft is arranged in the inner cavity of the stopper. One side of the connection tray is connected with the tail end of a horizontal section of the metal arm, and a through hole is disposed in the connection tray. A notch is disposed at the edge of the connection tray, and the notch extendsalong an involute line towards the through hole and is communicated with the through hole. A suspension loop is disposed on the side wall of the connection tray. The support shaft is snapped into theconnection tray through a port and moves into the through hole. One end of the limit spring is connected to the positioning plate, and the other end of the limit spring is hung on the support lug bya round hook. The invention has the advantages as follows: installation steps are simple; the installation speed is fast; there is no need to repeatedly screw bolts; and disassembly is fast, which isconvenient for disassembly and maintenance in the later stage.

Owner:萧县众科电磁检测有限公司

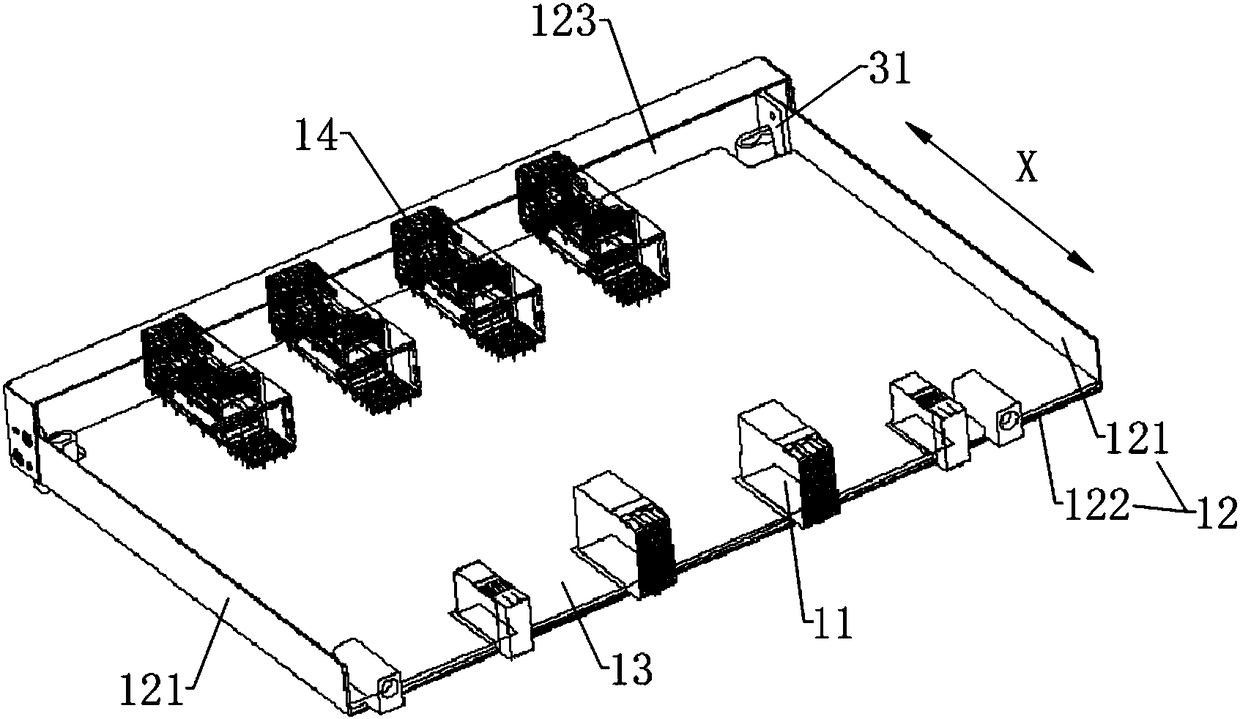

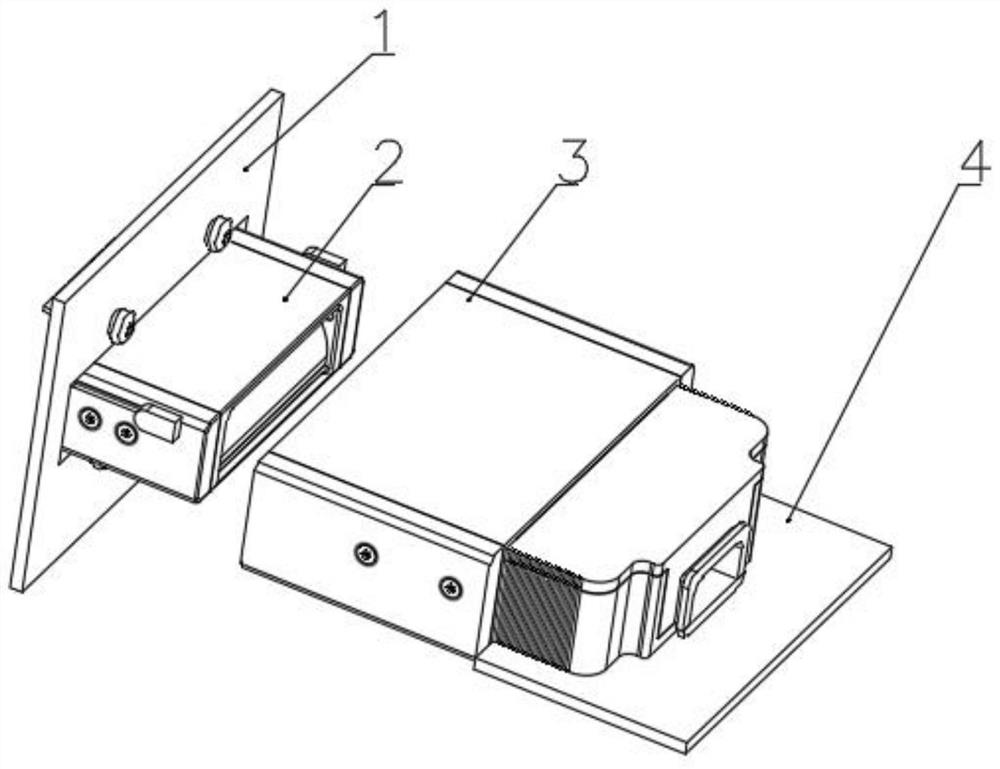

Unplugging assistant device, plug-unplugging component and communication equipment

ActiveCN109327992AEliminate fit gapsSo as not to damageCoupling device engaging/disengagingSupport structure mountingWrench

An embodiment of the invention discloses an unplugging assistant device which is used for realizing plugging and unplugging of a module relative to a cabinet. The module comprises a first connector, and the cabinet comprises a second connector. The unplugging assistant device is characterized by comprising a fixing member and a wrench, the fixing member comprises a fixed portion, a connection portion and a moving portion in sequential connection, the fixed portion is used for being fixed on the module, the connection portion has elastic deformation ability, the wrench sequentially comprises aclamping portion, a rotating portion and a handle portion in sequential connection, the rotating portion is rotatably connected with the moving portion, the clamping portion is used for being matchedwith the cabinet, and the handle portion is used for driving the module to move relative to the cabinet under action of external force to enable the first connector and the second connector to be in inserting connection or break away from each other. The unplugging assistant device can eliminate matching gap without causing damage to the connectors. The embodiment of the invention further discloses a plug-unplugging component and communication equipment.

Owner:HUAWEI TECH CO LTD

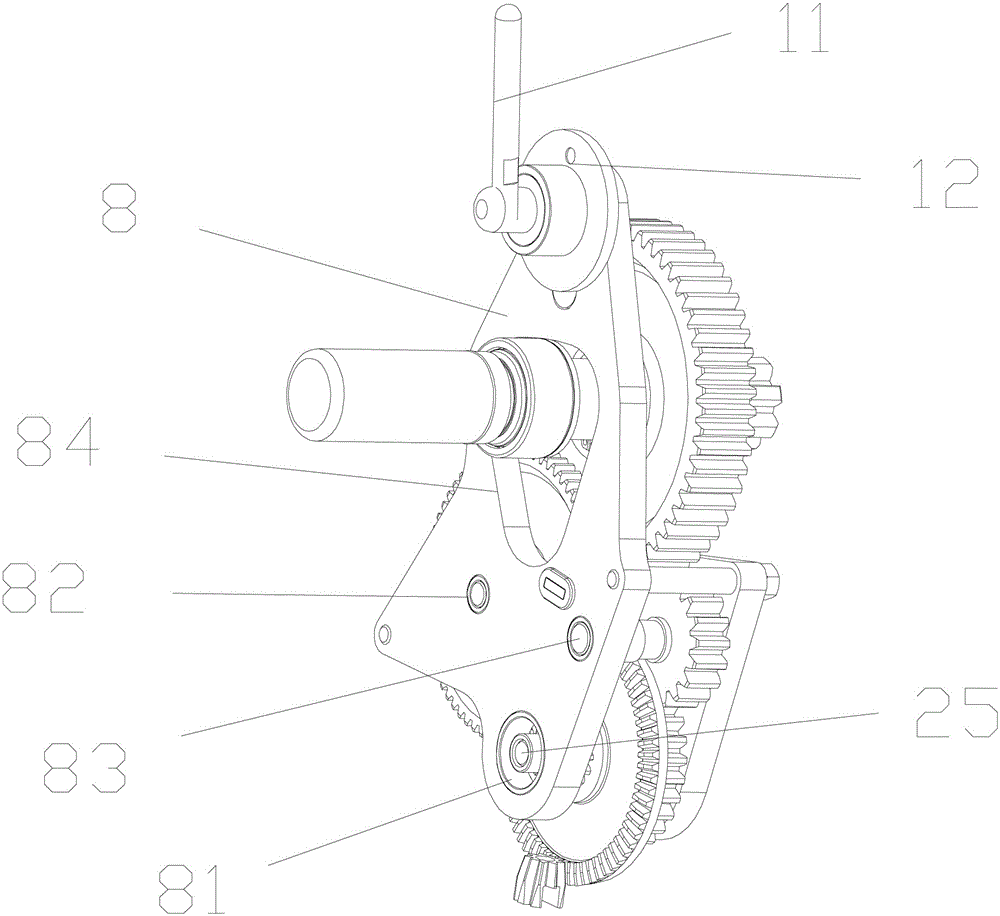

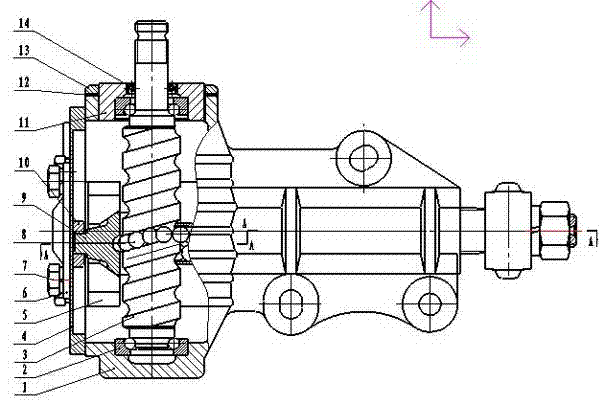

Micro-clamping cycling ball crank stud steering gear assembly

InactiveCN103241280AEliminate the phenomenon of "thugs"Improve positive drive efficiencyMechanical steering gearsBall bearingBall screw

The invention discloses a micro-clamping cycling ball crank stud steering gear assembly which is composed of two-stage transmission pairs. A first-stage cycling ball screw nut rolling transmission pair is composed of a screw rod (3), a nut (9), a steel ball (8), a pipe (16) and a pipe screw (17), wherein the screw rod (3) and the nut (9) are arranged between two angular contact thrust ball bearings supported on a steering casing (1) and arranged in an upper cover (11). A second-stage sliding transmission pair is composed of a conical stud on the nut (9), a radial dovetail groove on a crank of a steering rocking arm shaft (5) and a guide wheel (10), wherein the conical stud is matched with the radial dovetail groove in a gapless mode under the effect of the pressure of a compression spring device (15), and the guide wheel rolls in a linear guiding groove fastened on the inner side of a lateral cover (4) on the steering casing (1) through a screw (7). During use, conversion between input and output is achieved through the two-stage transmission pairs. A steering gear is simple in structure and low in manufacture cost and has good transmission specific characteristics and operation stability.

Owner:山东风帆电机有限公司

Speed reducer provided with air cooling, oil collecting, lubricating and clearance eliminating structure

InactiveCN105333120AAvoid temperatureAvoid performance degradationGear lubrication/coolingToothed gearingsReduction driveAir filter

The invention discloses a speed reducer provided with an air cooling, oil collecting, lubricating and clearance eliminating structure. The speed reducer comprises a speed reducer shell, a gear transmission mechanism, an air cooling device and an oil collecting device. The air cooling device comprises a draught fan, an air filter and an oil-gas separator. The speed reducer further comprises a first belleville spring used for applying axial thrust to a first bevel gear and a second belleville spring used for applying axial thrust to a fourth bevel gear. The oil collecting device comprises a circular pipe body, a partition board, an oil storage cavity, an oil inlet and an oil outlet. According to the speed reducer, the gears and lubricating oil in the speed reducer shell are cooled through the air cooling device, and thus the problems that due to long-term working of the speed reducer, the temperature of the lubricating oil is increased, and the performance is reduced can be solved; in addition, when the gears are abraded, the belleville springs can automatically push the first bevel gear and the fourth bevel gear to move in the axial direction, and thus a gear fit clearance caused by frictional abrasion is eliminated; furthermore, the lubricating oil is carried into a gear engagement area through the oil collecting device to lubricate the gears, and thus the lubricating and cooling effects on the gears can be improved.

Owner:QIJIANG BENLI GEAR CO LTD

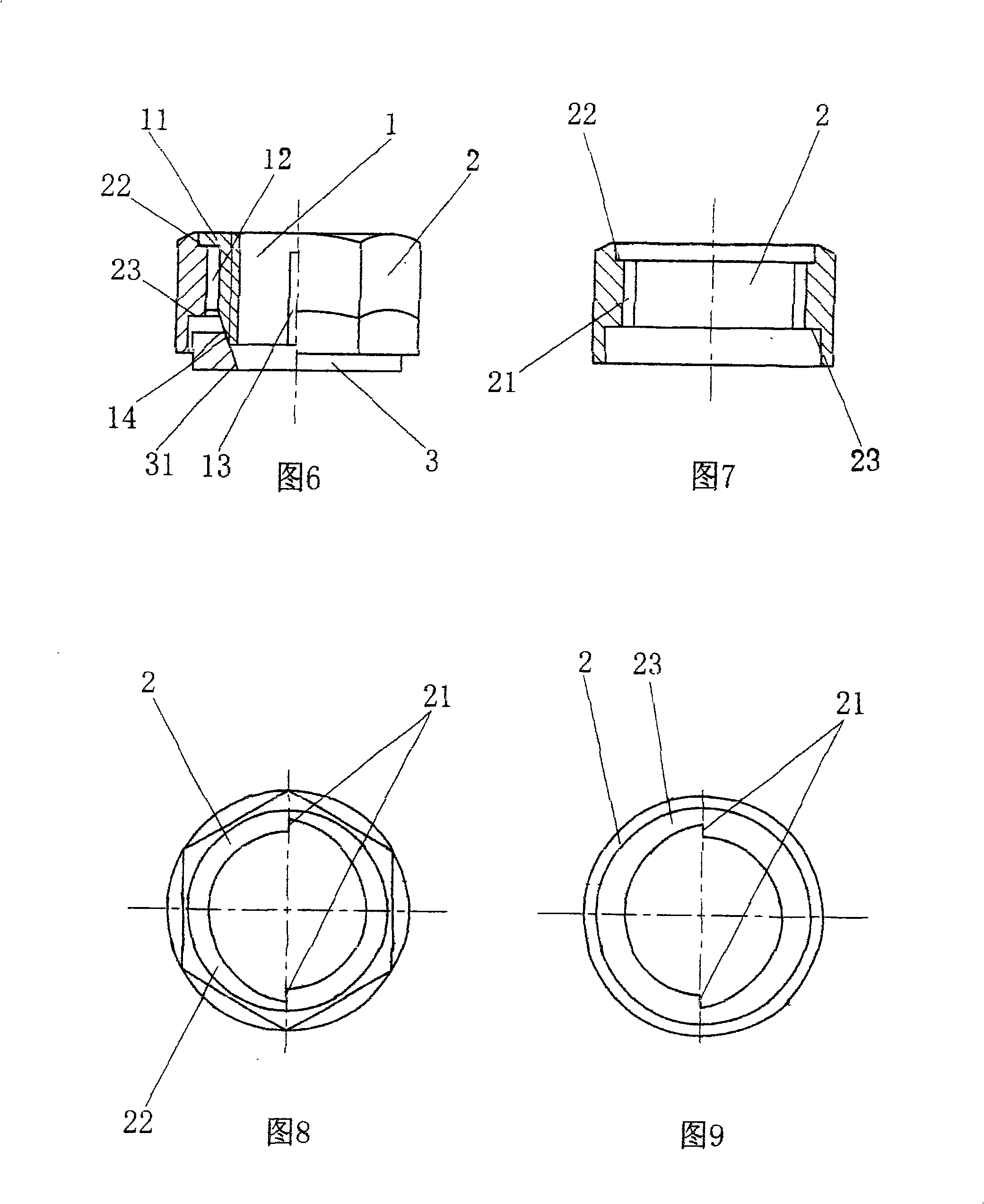

Compound nut

The invention relates to a fastening piece, in particular to a compound nut. The compound nut comprises a nut body and a outer sleeve, wherein, a penetrated internal thread is arranged on the nut body, a circular bead is arranged on the external diameter of the upper end of the nut body, the external diameter of the circular bead is larger than the internal diameter of the outer sleeve, a ratchet mechanism forming one-way meshing is arranged at the matching position between the nut body and the outer sleeve, and the ratchet mechanism is composed of one or more ratchet wheels arranged on the external diameter of the nut body and one or more ratchet wheels which are arranged on the internal diameter of the outer sleeve. The compound nut has the functions of fastening, anti-loosing and anti-unloading, and has the advantages of simple structure and strong practicability.

Owner:招远金王仪表科技有限公司

Dustproof optical backboard connector

ActiveCN112162360AImprove connection tightnessAvoid enteringCoupling light guidesStructural engineeringDaughterboard

A dustproof optical backboard connector comprises a backboard connector and a daughter board connector, and the backboard connector and the daughter board connector are connected in a mutually inserted manner. The backboard connector comprises a seat shell and a seat dustproof door assembly, and the seat dustproof door assembly is arranged in the opening end of the seat shell. The daughter board connector comprises a head shell and a head dustproof door assembly, the head dustproof door assembly is arranged in the opening end of the head shell, and the head shell is inserted into the seat shell. The dustproof door assembly comprises a first dustproof door, a first reset assembly and a first pushing assembly, and the head dustproof door assembly comprises a second dustproof door, a second reset assembly and a second pushing assembly. According to the present invention, the first dustproof door blocks the opening of the backboard connector, and the second dustproof door blocks the opening of the daughter board connector, so that the connection sealing performance of the dustproof door and the connector is effectively improved, the fit clearance is eliminated, and external dust is prevented from entering.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Speed reducer having air cooling and vibration reducing gear and gap eliminating structure

InactiveCN105299203AImprove the lubrication effectImprove cooling effectGear lubrication/coolingGear wheelReduction drive

The invention discloses a speed reducer having an air cooling and vibration reducing gear and a gap eliminating structure. The speed reducer comprises a speed reducer shell, a gear transmission mechanism and an air cooling device, wherein the air cooling device comprises a fan, an air filter and an oil-air separator. The speed reducer further comprises a first butterfly spring for applying axial thrust to a first bevel gear, and a second butterfly spring for applying axial thrust to a fourth bevel gear; and the second bevel gear and the fourth bevel gear of the speed reducer both comprise inner ring bodies, outer ring bodies and vibration reducing blocks. The speed reducer cools a gear and lubricating oil through the air cooling device, and can prevent the problems of temperature rise and performance reduction of the lubricating oil caused by long-time work of the speed reducer; when the gear is worn, the butterfly springs can automatically push the first bevel gear and the fourth bevel gear to axially move so as to eliminate the gear fit gap caused by friction and wear; and as the vibration reducing blocks are arranged between the inner ring bodies and the outer ring bodies, the gear vibration reduction is realized, the noise can be lowered, and the harm of impact to wheel teeth is prevented.

Owner:QIJIANG BENLI GEAR CO LTD

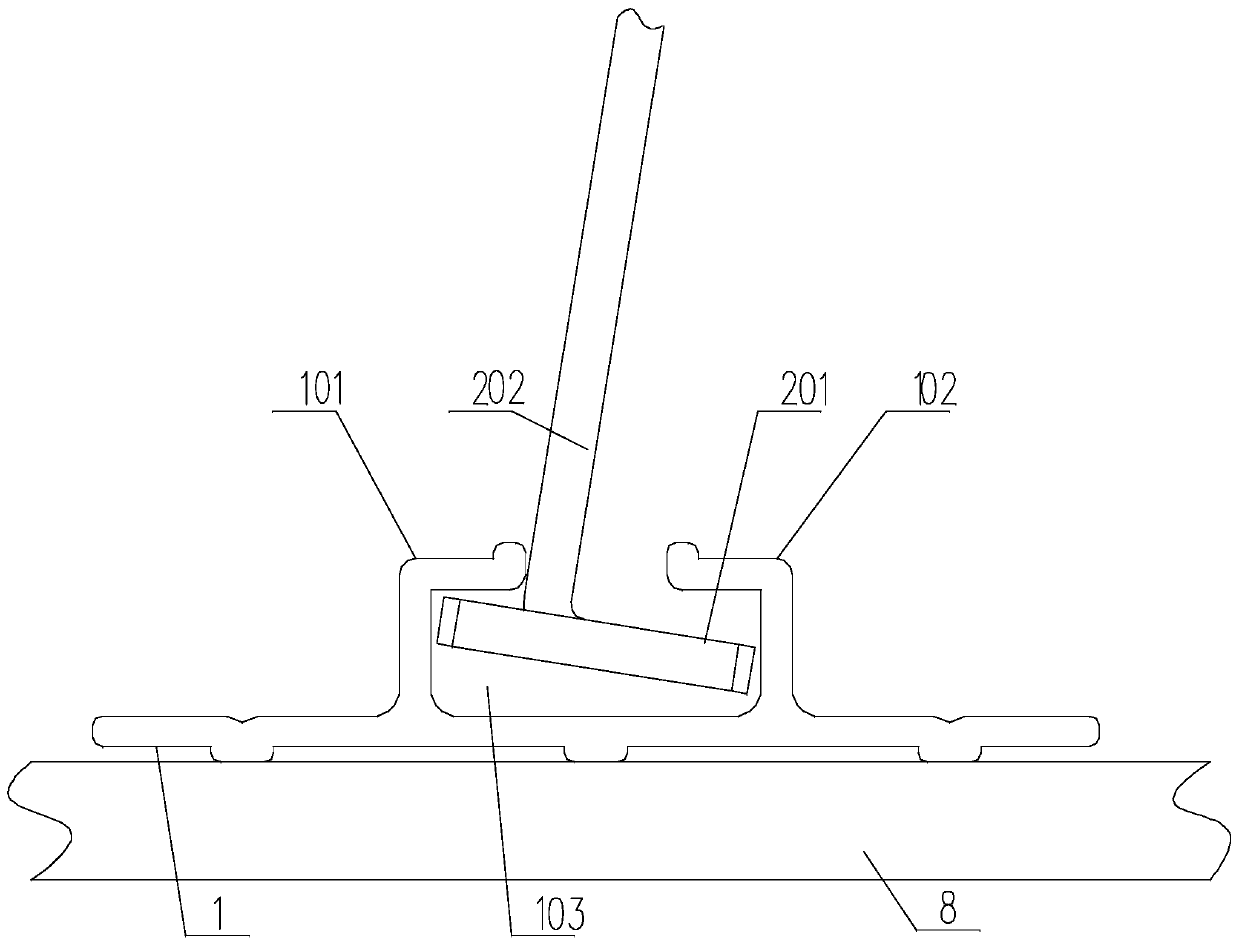

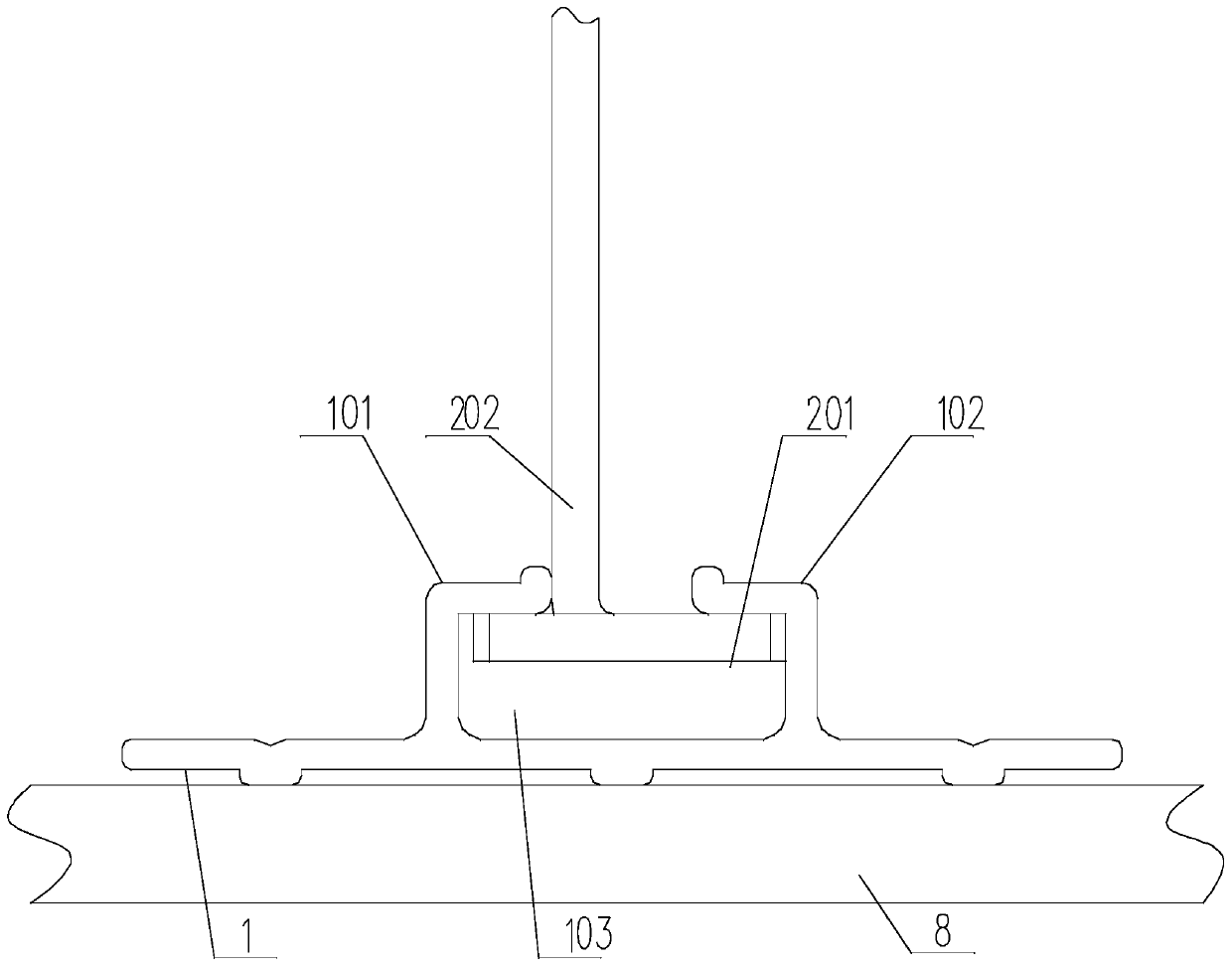

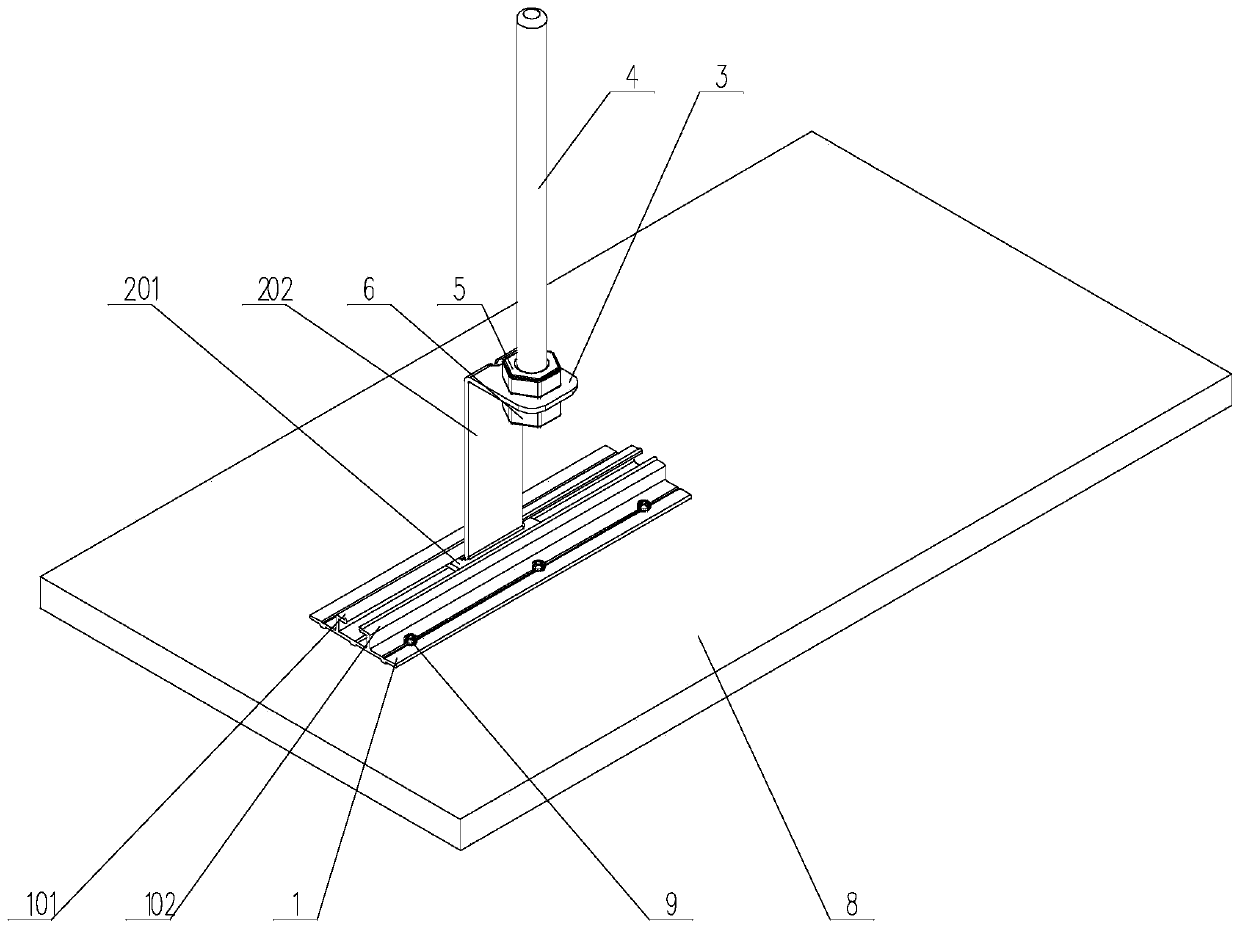

Suspending method capable of preventing suspending plate from shaking

ActiveCN111075098AAvoid shakingEliminate fit gapsCeilingsStructural engineeringMechanical engineering

The invention discloses a suspending method capable of preventing a suspending plate from shaking. The suspending method comprises the following steps that S1, a positioning plate is fixed to the upper surface of the suspending plate; S2, a clamping plate is placed on one side of the positioning plate to make the clamping plate be located between a left strip plate and a right strip plate; S3, theclamping plate is rotated to make the end, away from a vertical plate B, of a horizontal plate B be inclined downwards; S4, the clamping plate is inserted into a mounting through groove; S5, the clamping plate is rotated reversely to make the horizontal plate B be parallel to the positioning plate, the tail end, away from the vertical plate B, of the horizontal plate B abuts against the inner wall of a vertical plate A of the right strip plate, and the side, close to the left strip plate, of the vertical plate B abuts against the tail end of a horizontal plate A of the left strip plate; and S6, the top of the clamping plate is connected with a ceiling through a ceiling connection rod part. A mating gap between the positioning plate in a suspended state and the clamping plate is eliminated, synchronization between the positioning plate and the clamping plate is ensured, and then stability of a suspended buckle part suspended on the lower part of the ceiling is ensured.

Owner:成都劲启家居有限公司

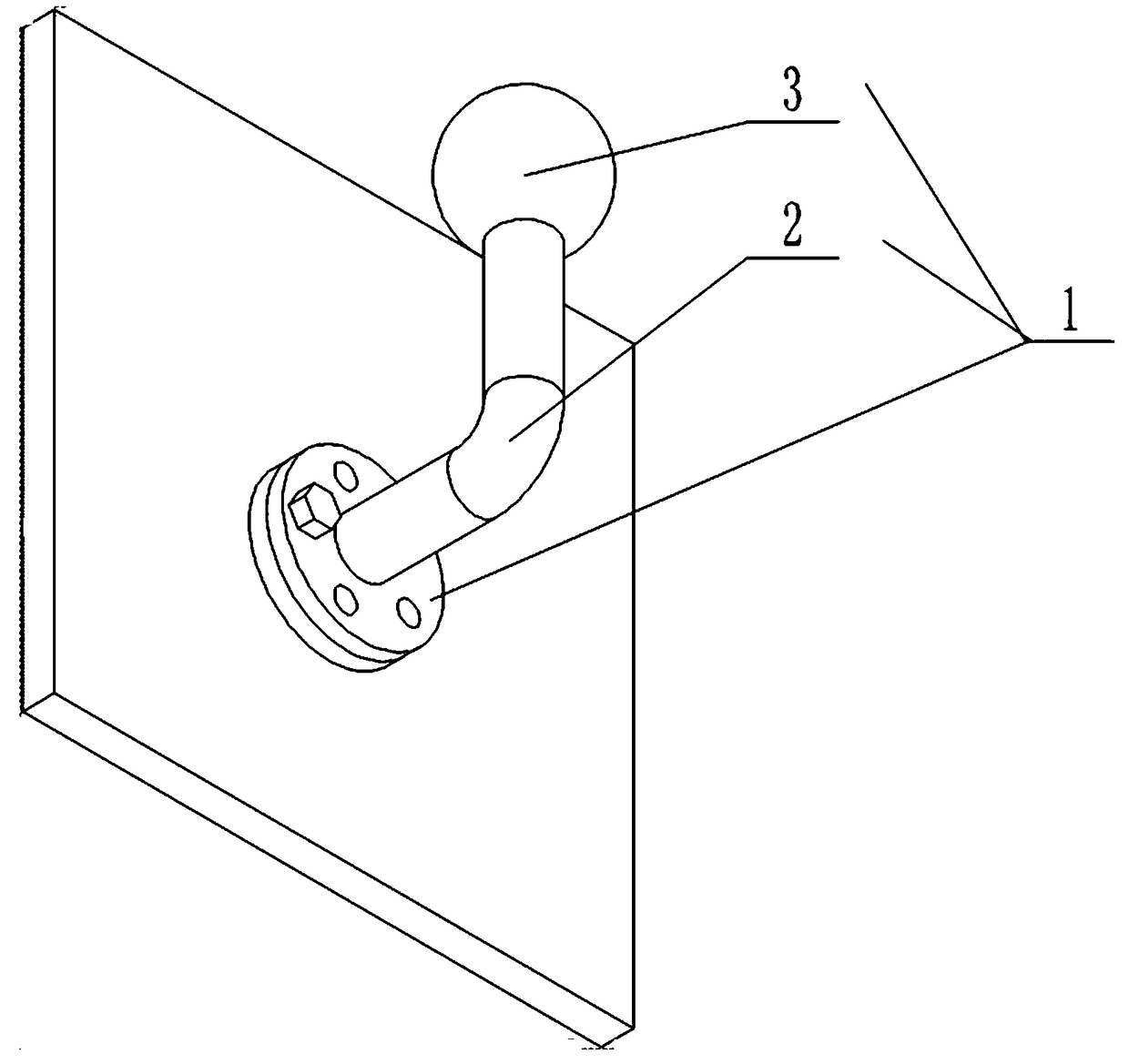

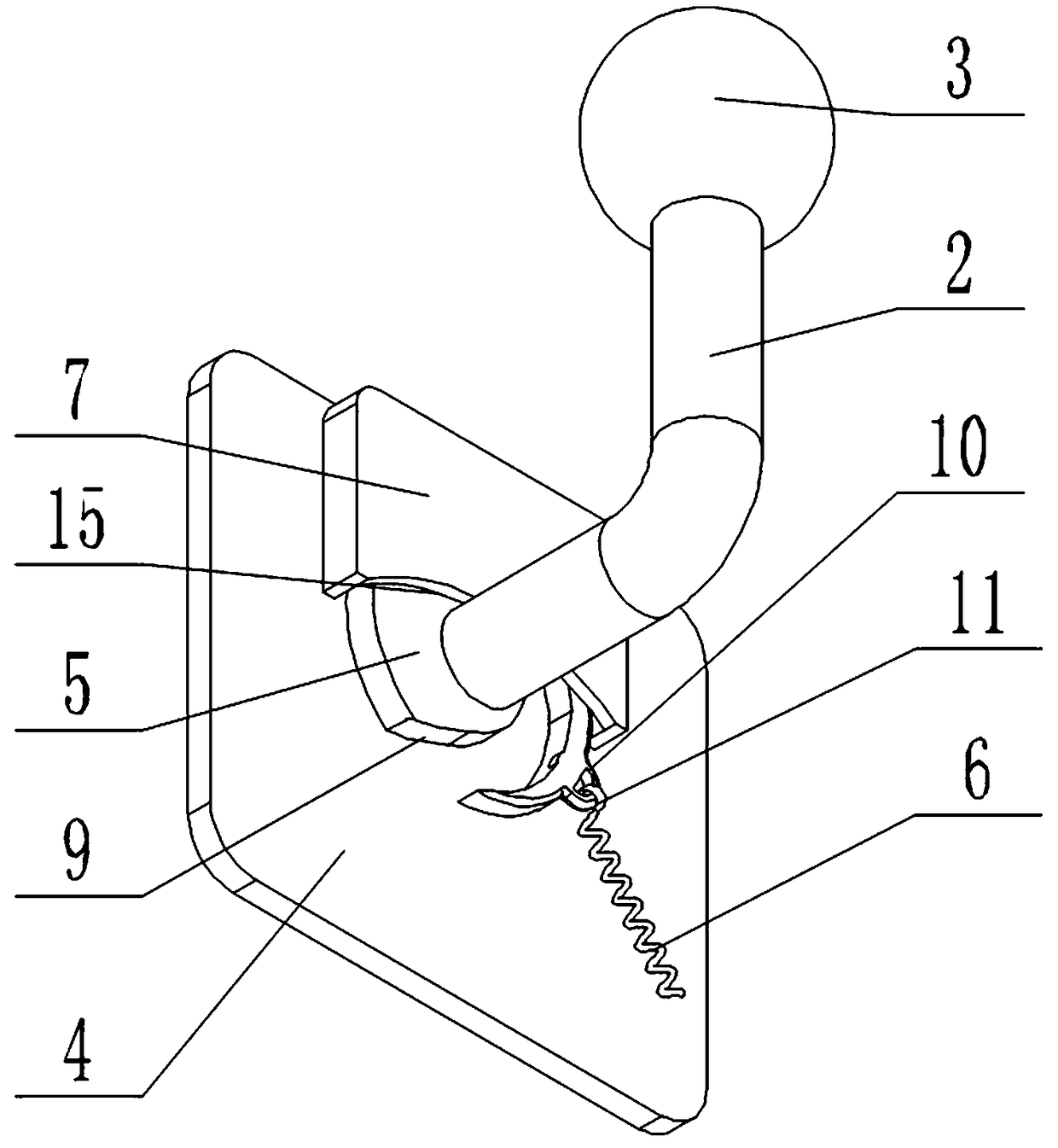

Novel adjustable armrest rod connecting structure

PendingCN108087402AAdjustable installation heightEliminate fit gapsVehicle arrangementsFastening meansEngineeringScrew thread

The invention belongs to the field of passenger car trims, particularly relates to a connecting structure of passenger car armrest rods, and provides a novel adjustable armrest rod connecting structure. The novel adjustable armrest rod connecting structure comprises a fixed seat. The bottom of the fixed seat is fixed to a mounting face. A screw is arranged on the upper portion of the fixed seat. The bottom of an armrest rod is connected with a shaft sleeve. An internal thread is arranged in the shaft sleeve. The screw cooperates with the internal thread of the shaft sleeve. The armrest rod isfixed to the fixed seat through threaded connection, a fit clearance between the armrest rod and the fixed seat is eliminated, no colliding happens during operation, and the noise problem is solved. The armrest rod is fixed to the mounting face through the fixed seat, and connecting reliability is high. The mounting height of the armrest rod is adjustable and can be conveniently adjusted during actual mounting.

Owner:HIGER

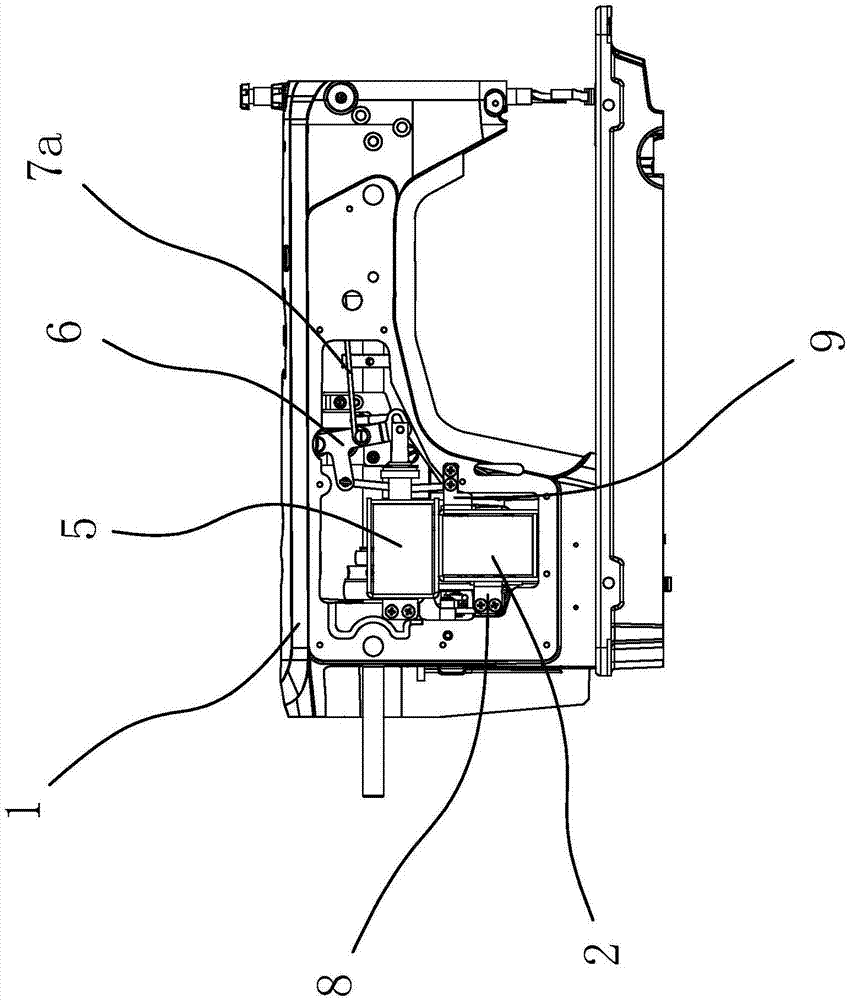

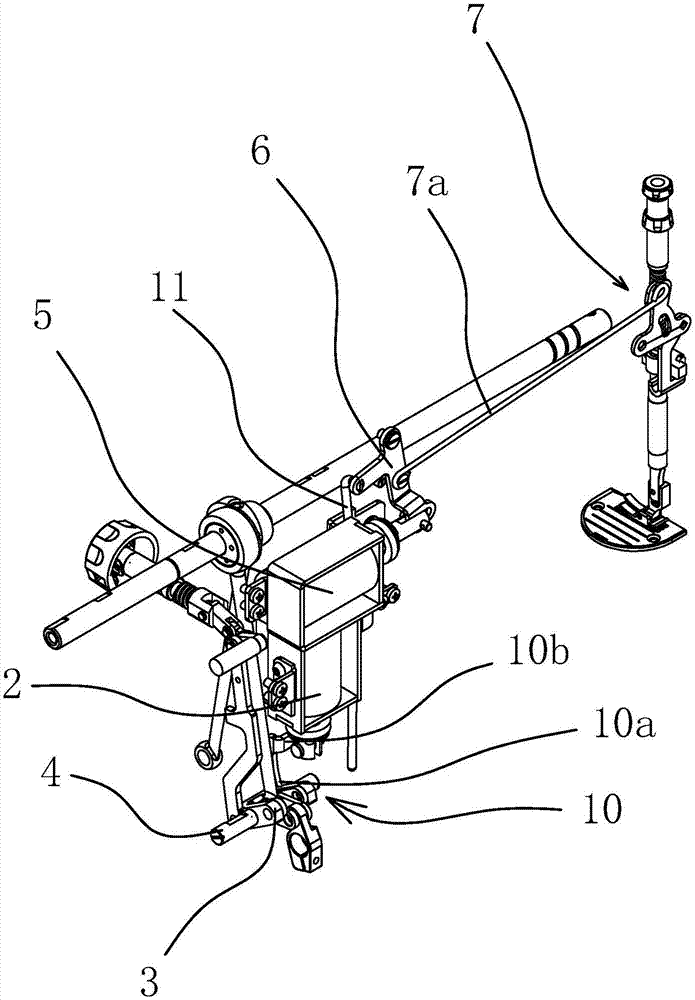

Sewing machine

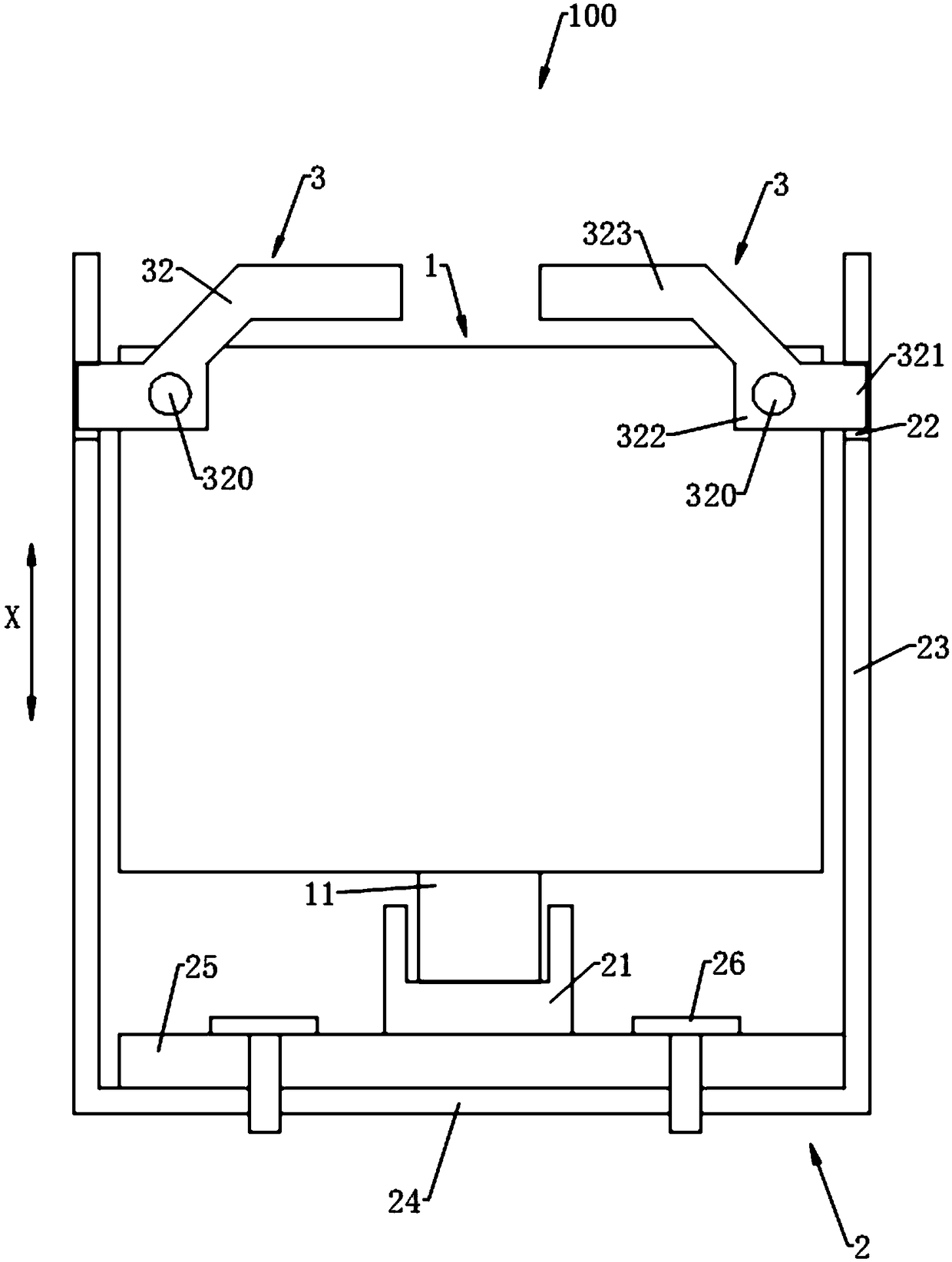

InactiveCN107245813AReduce noiseEliminate fit gapsWork-feeding meansSewing-machine control devicesEngineeringElectromagnet

The invention provides a sewing machine and belongs to the technical field of machinery with an aim to solve the problem that a reverse-feed electromagnet and a presser-foot-lift electromagnet of an existing sewing machine cannot be built in simultaneously due to large space occupation. The sewing machine comprises a main case, the reverse-feed electromagnet, a swing seat, a reverse-seat pull rod, the presser-foot-lift electromagnet, a presser-foot-lift crank and a presser-foot-lift pull rod; the reverse-feed electromagnet is vertically arranged with the iron core facing downwards, the reverse-feed pull rod and a rotating shaft are vertically arranged with each other, two ends of the reverse-feed pull rod are hinged with the iron core of the reverse-feed electromagnet and the swing seat, the presser-foot-lift electromagnet is horizontally arranged with the iron core facing to the front end of the main case and is located above the reverse-feed electromagnet, the upper end of the presser-foot-lift crank is hinged to the main case while the lower end is hinged with the iron core of the presser-foot-lift electromagnet, and the presser-foot-lift pull rod is hinged to the middle portion of the presser-foot-lift crank. By the arrangement, matching compatibility with an original built-in type presser-foot-lift structure is achieved on the premise of trying not to change the structure of the built-in type presser-foot-lift structure, and the presser-foot-lift electromagnet and the reverse-feed electromagnet can be built in simultaneously through reasonable structural design.

Owner:JACK SEWING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com