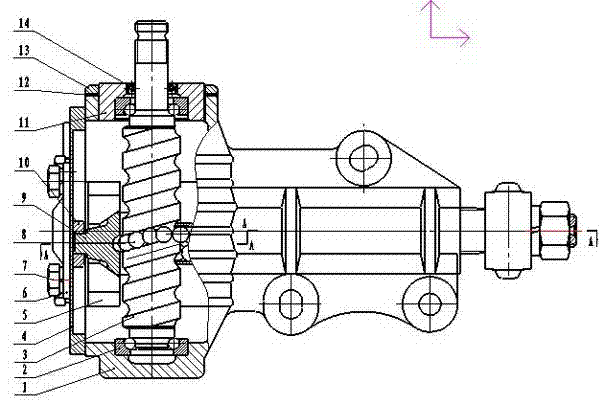

Micro-clamping cycling ball crank stud steering gear assembly

A recirculating ball and steering gear technology, applied in mechanical steering gear and other directions, can solve the problems of poor transmission ratio characteristic stability, driver's hand fatigue and other problems, and achieve the effect of small intermediate transmission ratio, light steering angle and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

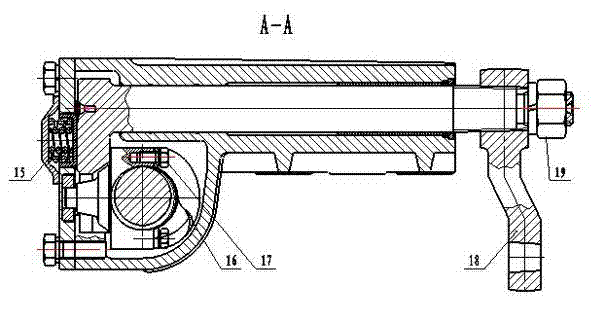

[0011] figure 1 The middle steering housing 1 is fixed on the steering gear bracket of the vehicle frame. The steering housing 1 is equipped with a first-stage single-stage recirculating ball screw nut transmission pair, and its active part is the steering screw 3. The steering screw 3 with double arc threads is supported on the centripetal thrust ball bearing at the bottom end of the steering housing 1. 2 and the centripetal thrust ball bearing on the loam cake 11. The upper cover 11 is screwed on the steering gear housing 1 by threads, and is locked with a locking nut 13 after adjusting the preload of the screw rod 3 . The follower is a nut 9 with a tapered finger. The steel ball 8 enclosed in the guide screw 17 and the steel ball guide 16 rolls circularly in the double-arc thread raceway to complete the first-stage rolling transmission, and the screw rod 3 The rotary motion of the nut 9 is converted into a linear motion of the nut 9.

[0012] figure 1 The middle side co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com