Pitch circle positioning type static balance structure for static balance of gear ring

A technology of static balance and pitch circle, applied in the field of static balance structure, can solve the problem of low balance accuracy, and achieve the effects of improving machining accuracy, convenient and fast clamping parts, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

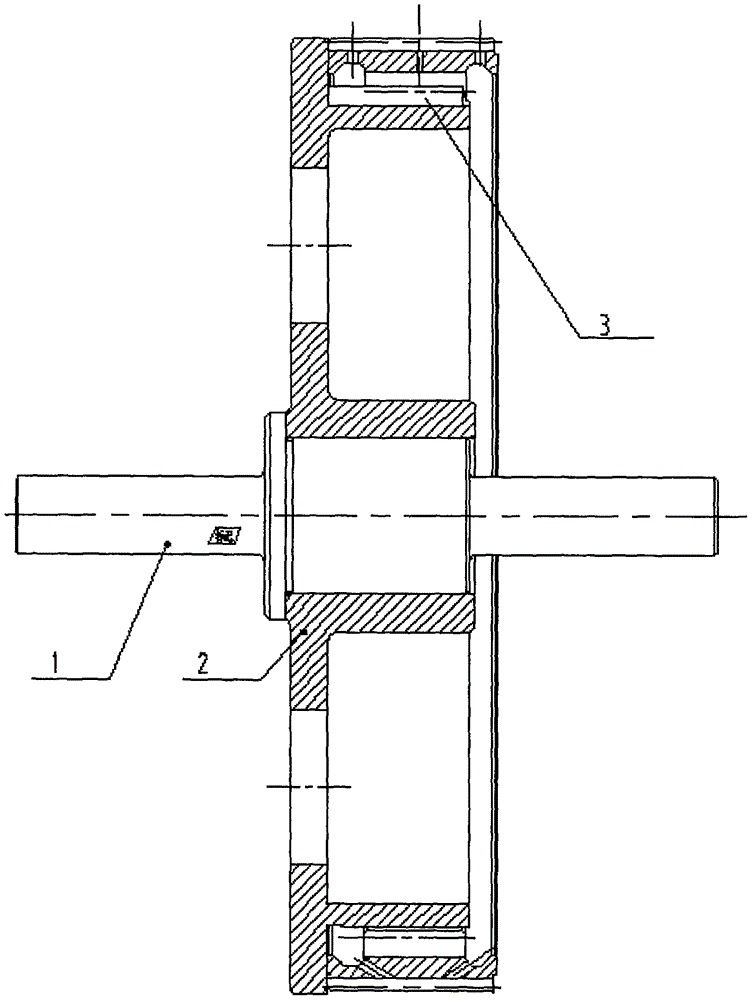

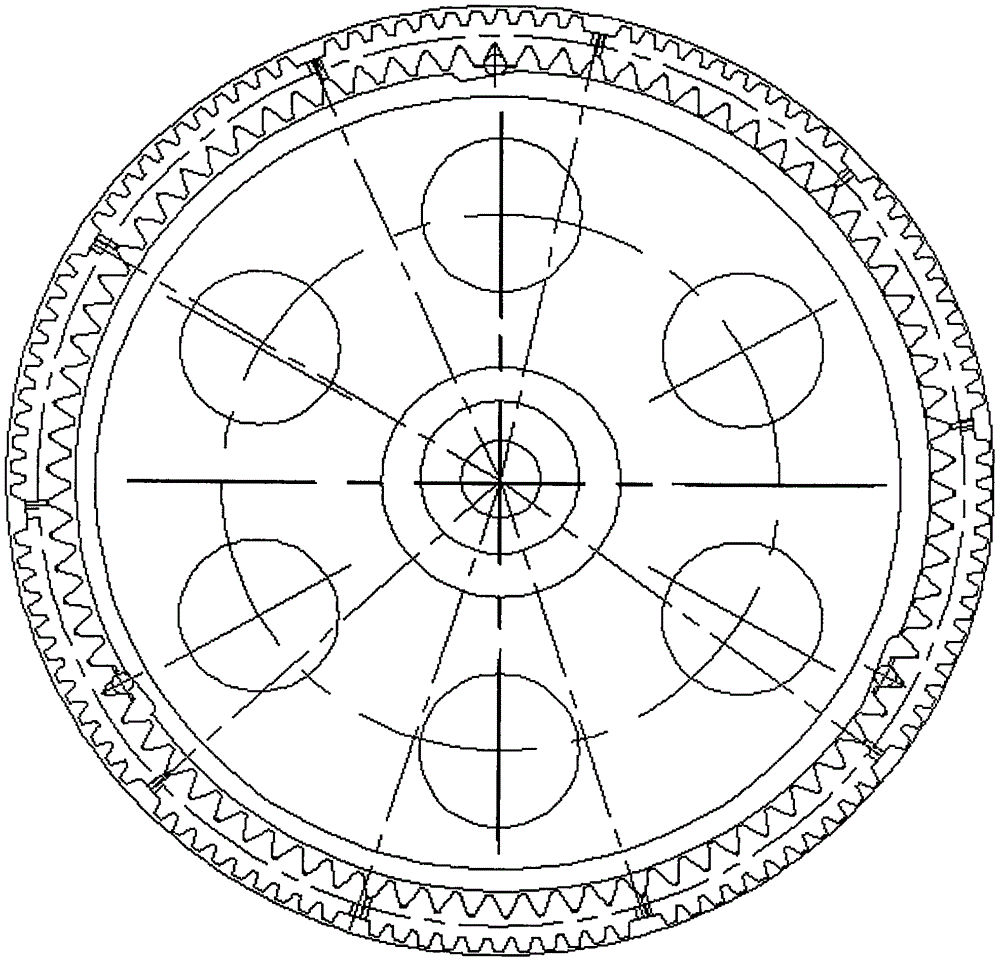

[0017] Such as Figure 1-2 As shown, the present invention is a static balance structure for the static balance of the ring gear positioned by the tooth pitch circle, including the mandrel body 1, the mandrel positioning plate 2 and the rolling rod 3, and the mandrel positioning plate 2 is press-fitted with interference on mandrel body 1. The mandrel positioning disc 2 is provided with three circular arc grooves which ensure that the three rolling rods 3 are evenly distributed as far as possible and correspond to the positions of the inner teeth of the ring gear, and three accurately positioned circular arc cam surfaces tangent to the circular arc grooves.

[0018] After the three rollers 3 are put into the tooth grooves of the ring gear, the ring gear is rotated, and the rollers 3 are pushed by the arc cam surface to realize the gapless positioning of the mandrel and the tooth pitch circle. Self-locking can be realized between the arc cam surface and the rolling rod 3, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com