Novel electric supporting leg

An electric and new technology, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve time-consuming and labor-intensive problems, prevent dust and rainwater from entering, eliminate fit gaps, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

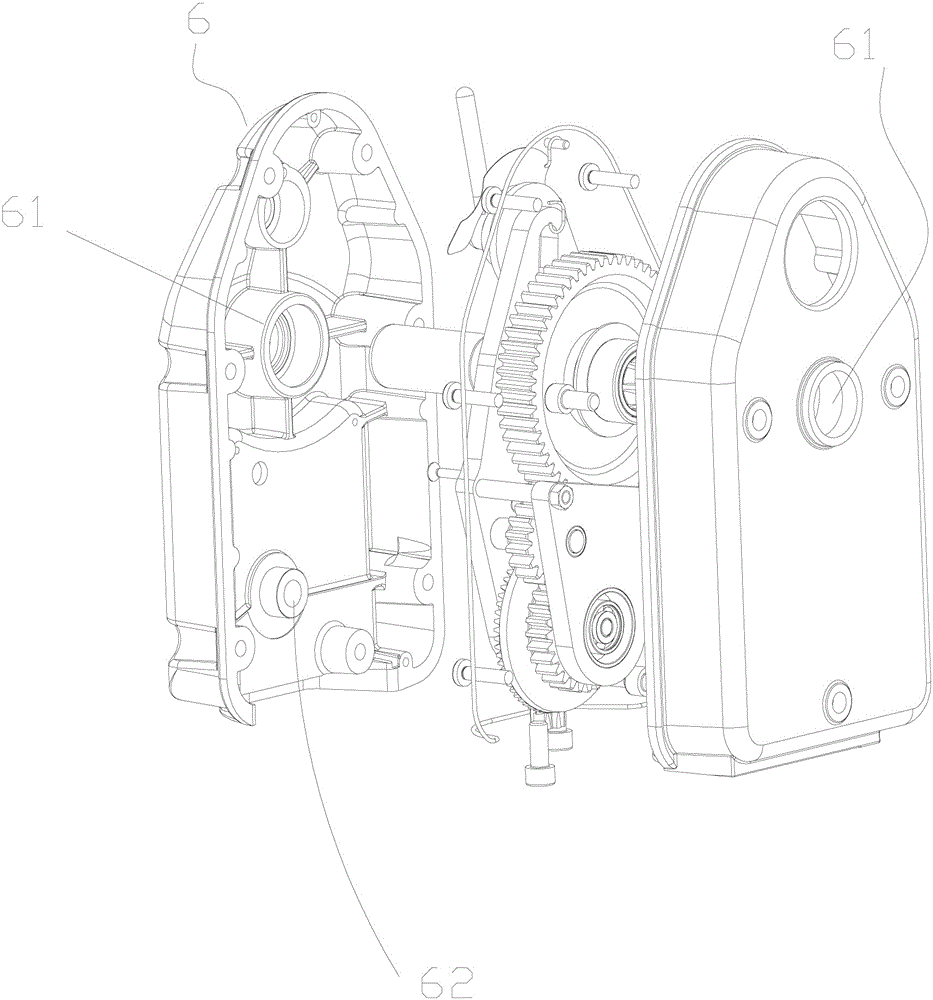

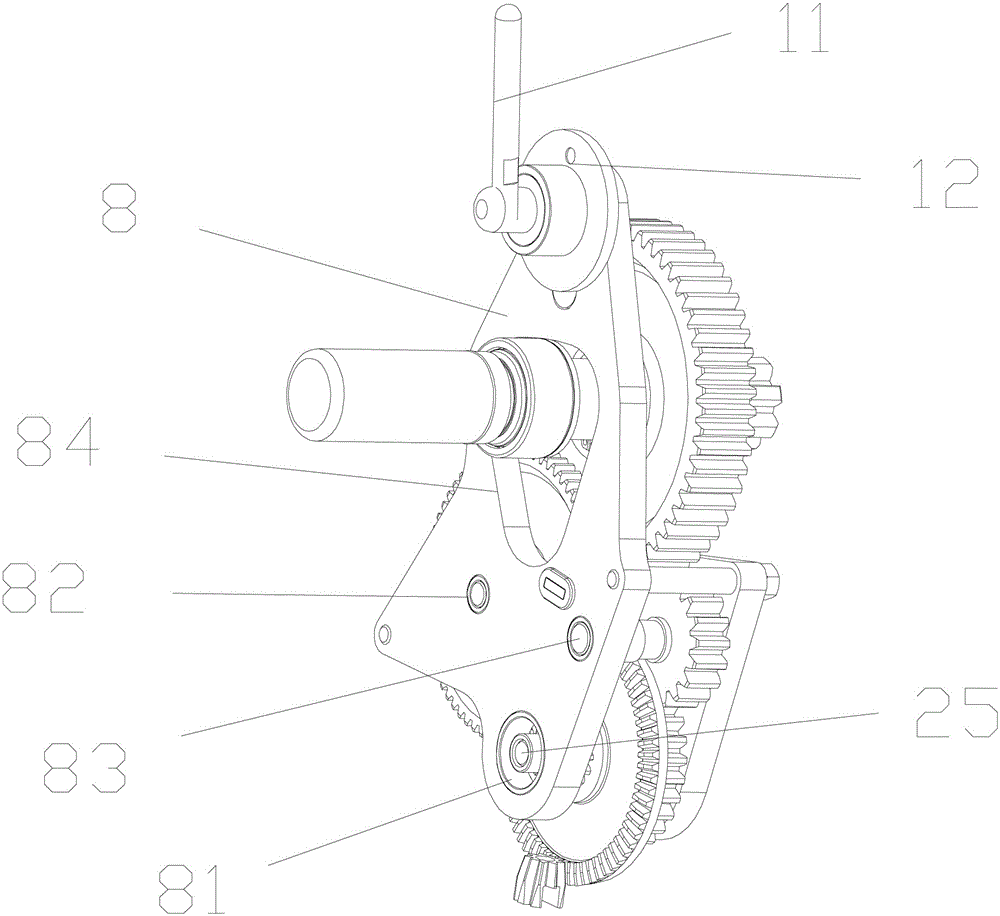

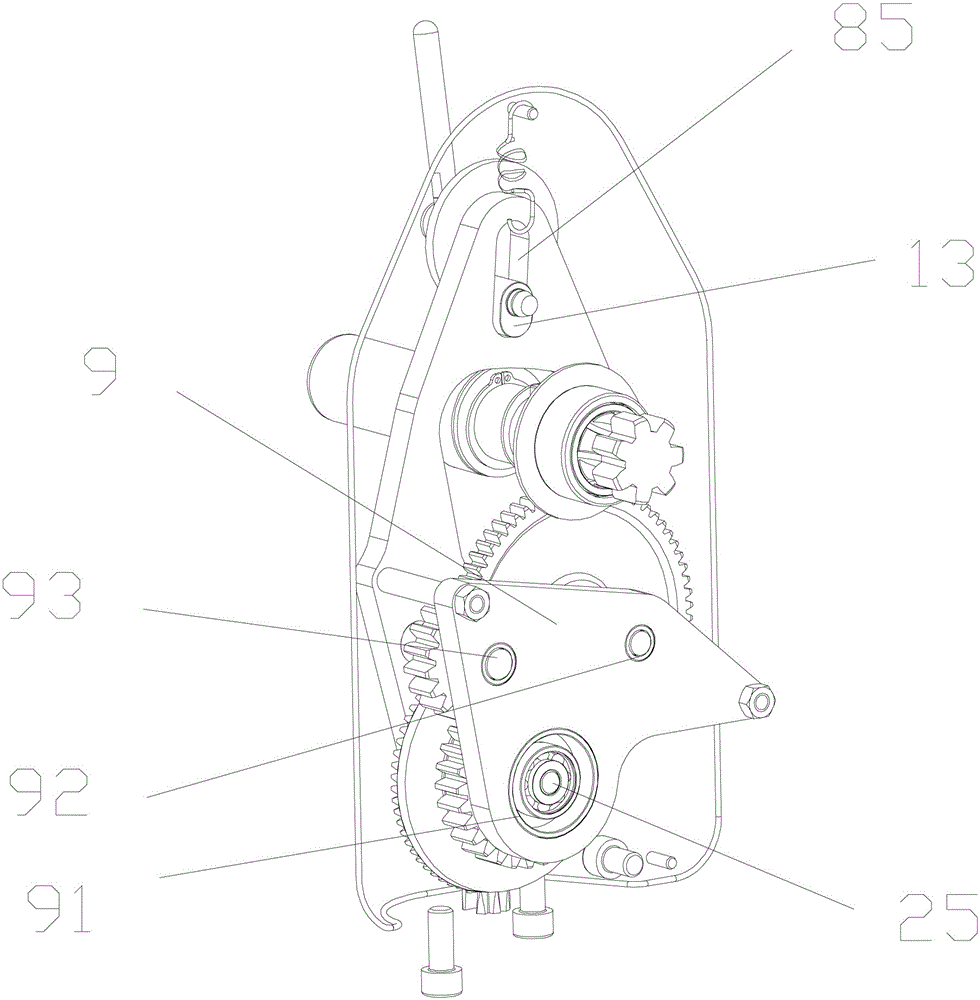

[0024] Such as Figure 1-7 As shown, the new electric outrigger includes left and right outriggers, an intermediate shaft connecting the left and right outriggers, and an electric drive mechanism. The output shaft of the electric drive mechanism is connected to the main gear transmission mechanism on the left or right outrigger , the electric drive mechanism includes a motor, a housing 6, a front rocker plate 8, a puller mechanism, an output shaft 51, an output shaft gear 5, an input shaft, and an input shaft multi-speed ratio gear 2 are installed in the housing, and the motor shaft is connected with a small cone Gear 1, the small bevel gear meshes with the bevel teeth of the multi-speed ratio gear of the input shaft, the high-speed transmission gear 3 and the low-speed double gear assembly 4 are installed on the front rocker plate, and the pull-out mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com