C-ring mechanical expanding shaft

A mechanical, expanding and shrinking shaft technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of affecting the bending strength of the expanding shaft, high processing cost, reducing shaft strength, etc. The effect of taking accuracy and reliability, reducing processing cost, and improving coiling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

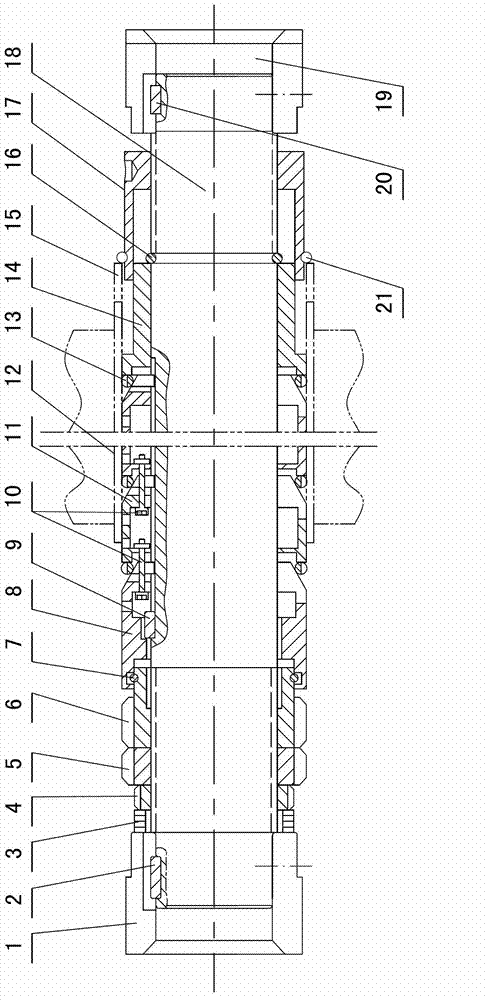

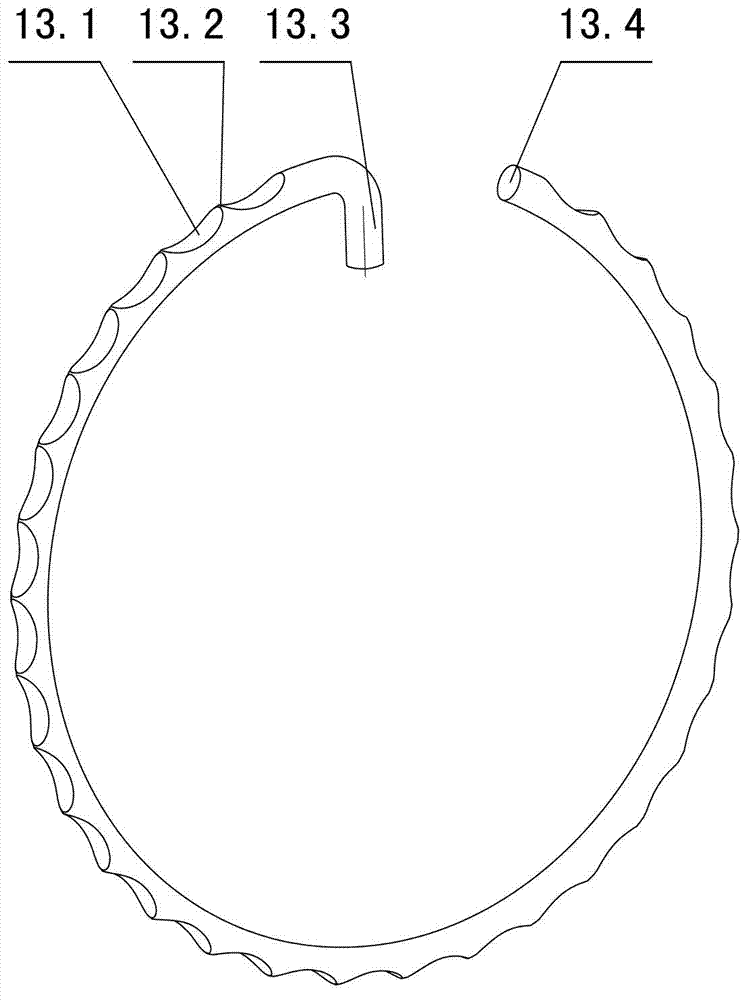

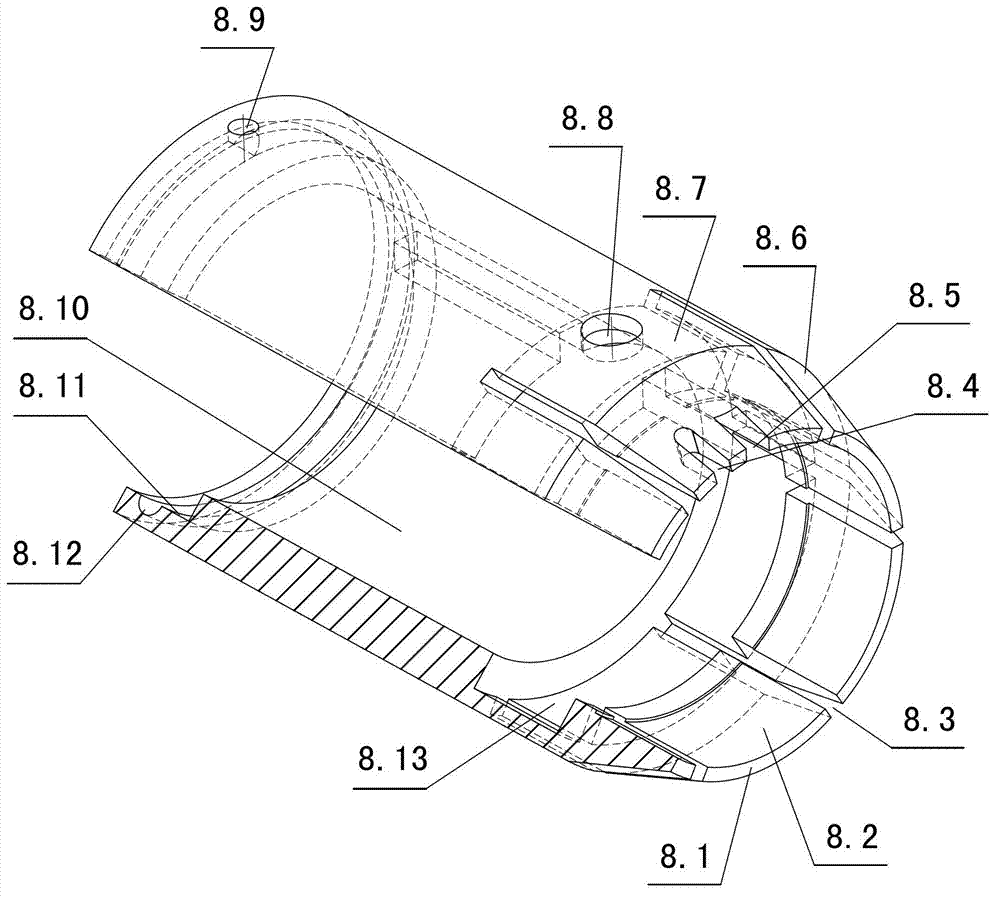

[0041] Such as figure 1 , figure 2 As shown, the C-shaped ring mechanical expansion and contraction shaft includes a cylindrical shaft 18, on which a pushing mechanism, a tapered wedge tube group and a positioning mechanism are sequentially installed from left to right, and the tapered wedge tube group consists of a plurality of side-by-side Composed of cone wedge tubes 11, C-shaped rings 13 are installed between the cone wedge tubes 11 and the pushing mechanism, between two adjacent cone wedge tubes 11, and between the cone wedge tubes 11 and the positioning mechanism. There is a circle head key 13.3 extending along the center of the circle at one end, and the distance between the circle head key 13.3 and the circle tail 13.4 at the other end is 10-50mm. Among them, an anti-skid piece is provided on the outer diameter surface of the C-shaped circle 13, and the anti-skid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com