Mechanical expansion shaft of air control C-shaped rings

A mechanical expansion and contraction shaft technology, which is applied in the field of air-controlled C-ring mechanical expansion and contraction shafts, can solve the problems of affecting the bending strength of expansion shafts, small shaft expansion force, and reduced shaft strength, so as to improve coiling Accuracy and reliability, high bending and torsional rigidity, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

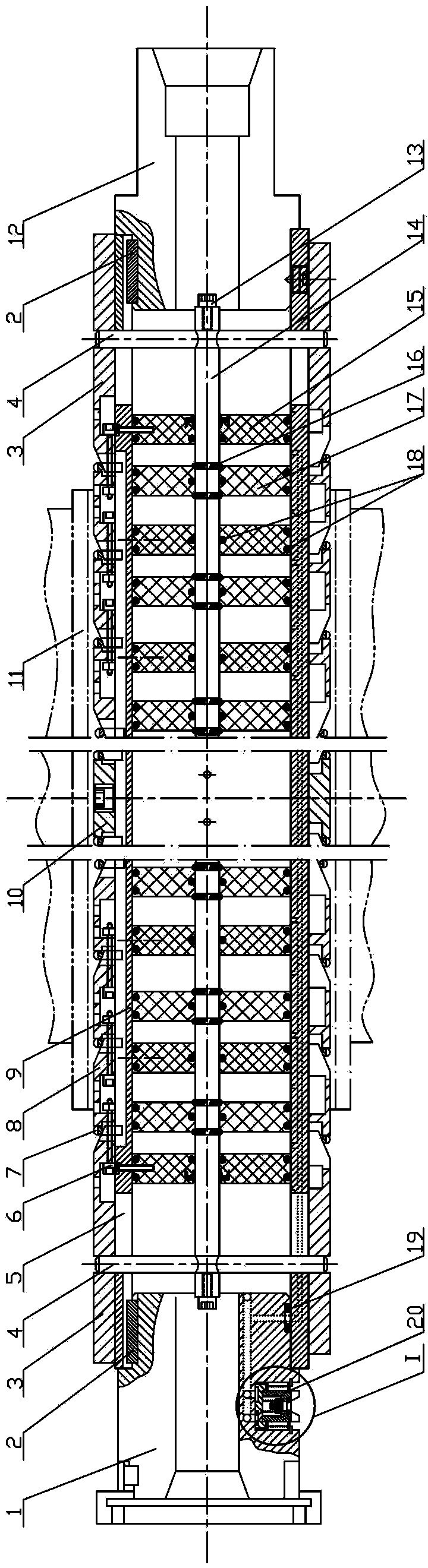

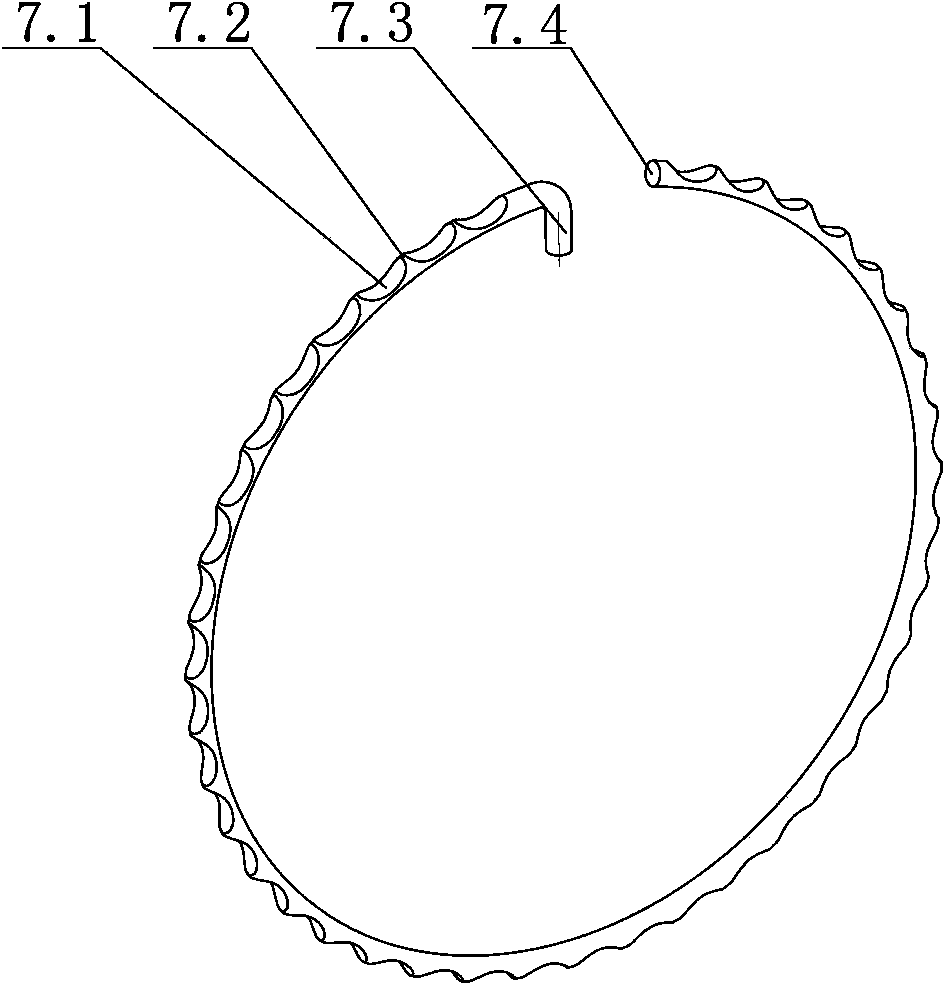

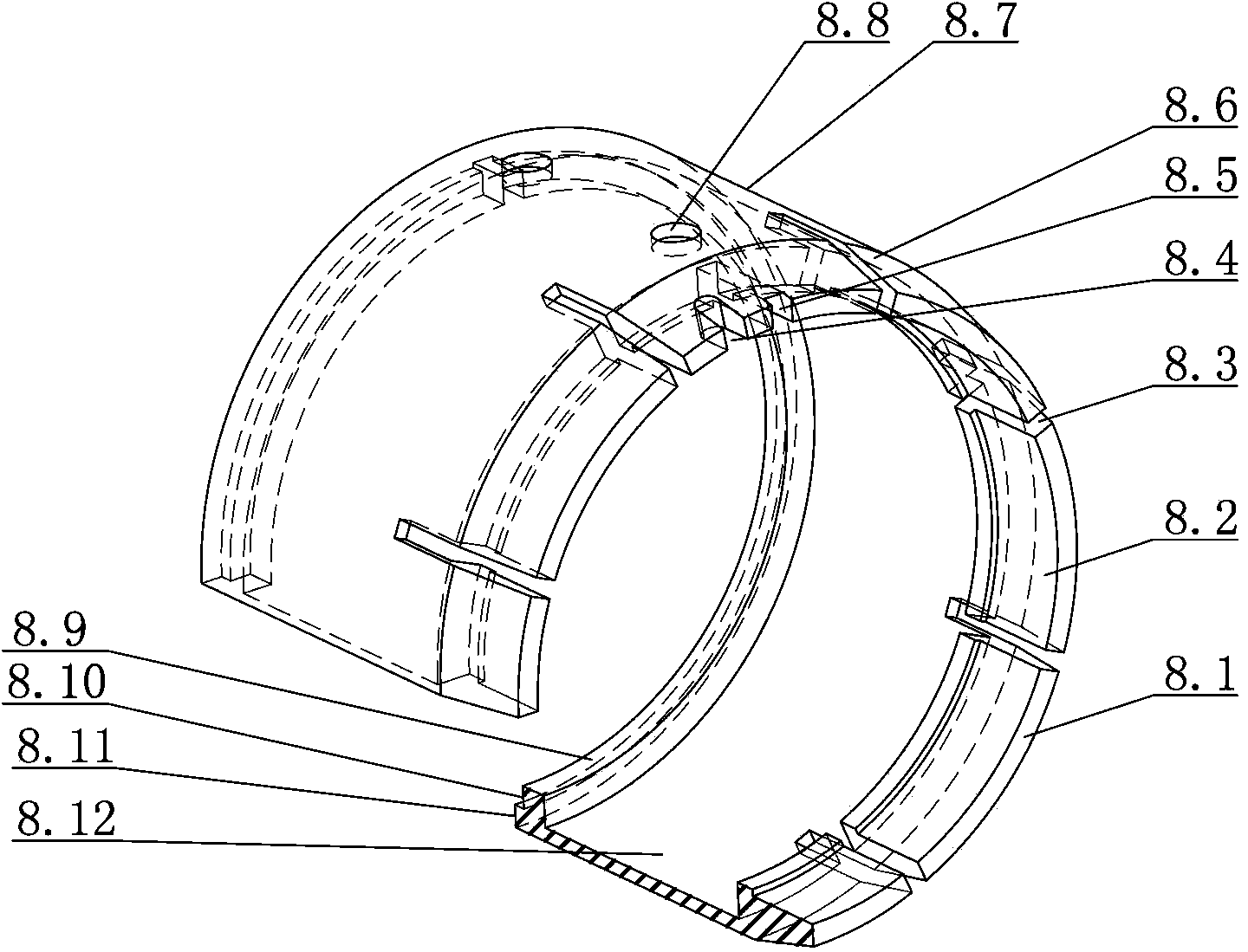

[0038] Such as figure 1 As shown, the air-controlled C-ring mechanical expansion and contraction shaft includes the main shaft tube 9, the two ends of the main shaft tube 9 are respectively installed with the transmission side shaft head 1 and the working side shaft head 12 through the shaft head key 2, and the main shaft tube 9 is covered with The cone wedge tube group and the center tube 10, the center tube 10 is fixed in the middle of the main shaft tube 9, the two ends of the center tube 10 are symmetrically provided with the same limiting platform, there is a screw hole in the middle, and the cone wedge tube group is installed symmetrically On both sides of the central pipe 10, the tapered wedge tube group is formed by connecting at least two tapered wedge pipes 8 in sequence. A C-shaped ring 7 is set on the top, and the cylindrical pin 4 runs through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com