Positioning pin

A positioning pin and sliding groove technology, applied in the field of positioning pins, can solve the problems of large positioning error, blank hole size and roundness error, inconvenient removal, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

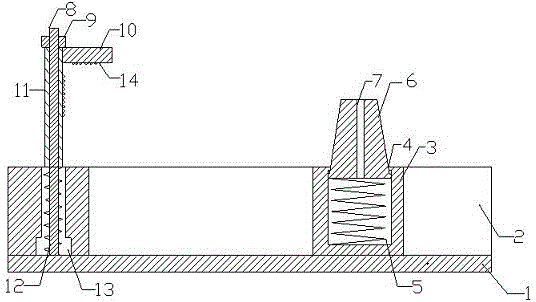

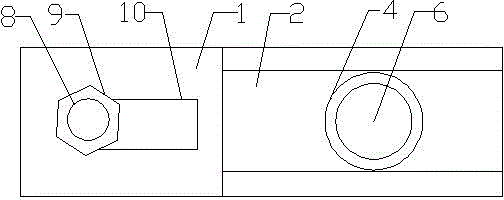

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. Such as figure 1 , 2 As shown, this kind of positioning pin includes a base 1, a sliding groove 2 is provided on the base 1, a cylinder 3 is arranged in the sliding groove 2, the cylinder 3 can slide in the sliding groove 2, and the top of the cylinder 3 is a round hole 4 , the diameter of the round hole 4 is smaller than the inner diameter of the cylinder 3, a compression spring 5 is provided at the bottom of the cylinder 3, a round table 6 is arranged above the compression spring 5, the upper part of the round table 6 protrudes from the round hole 4, and the round table 6 slides with the cylinder 3 Cooperate. The round table 6 plays the positioning effect of the hair hole, and the round table 6 is provided with a vent hole 7 in the vertical direction, which is convenient for the round table to slide in the cylinder.

[0017] The adjustable clamping mechanism includes a blind hole 13 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com