Motor of booster pump and booster pump with the same

A booster pump and casing technology, applied in the field of motors, can solve the requirement of increasing the flatness of the mating surfaces of the front end cover, rear end cover and casing, the flatness is difficult to be guaranteed, and affects the service life and safety of the motor and other issues, to achieve the effect of improving waterproof sealing requirements, improving waterproof sealing performance, ensuring service life and using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

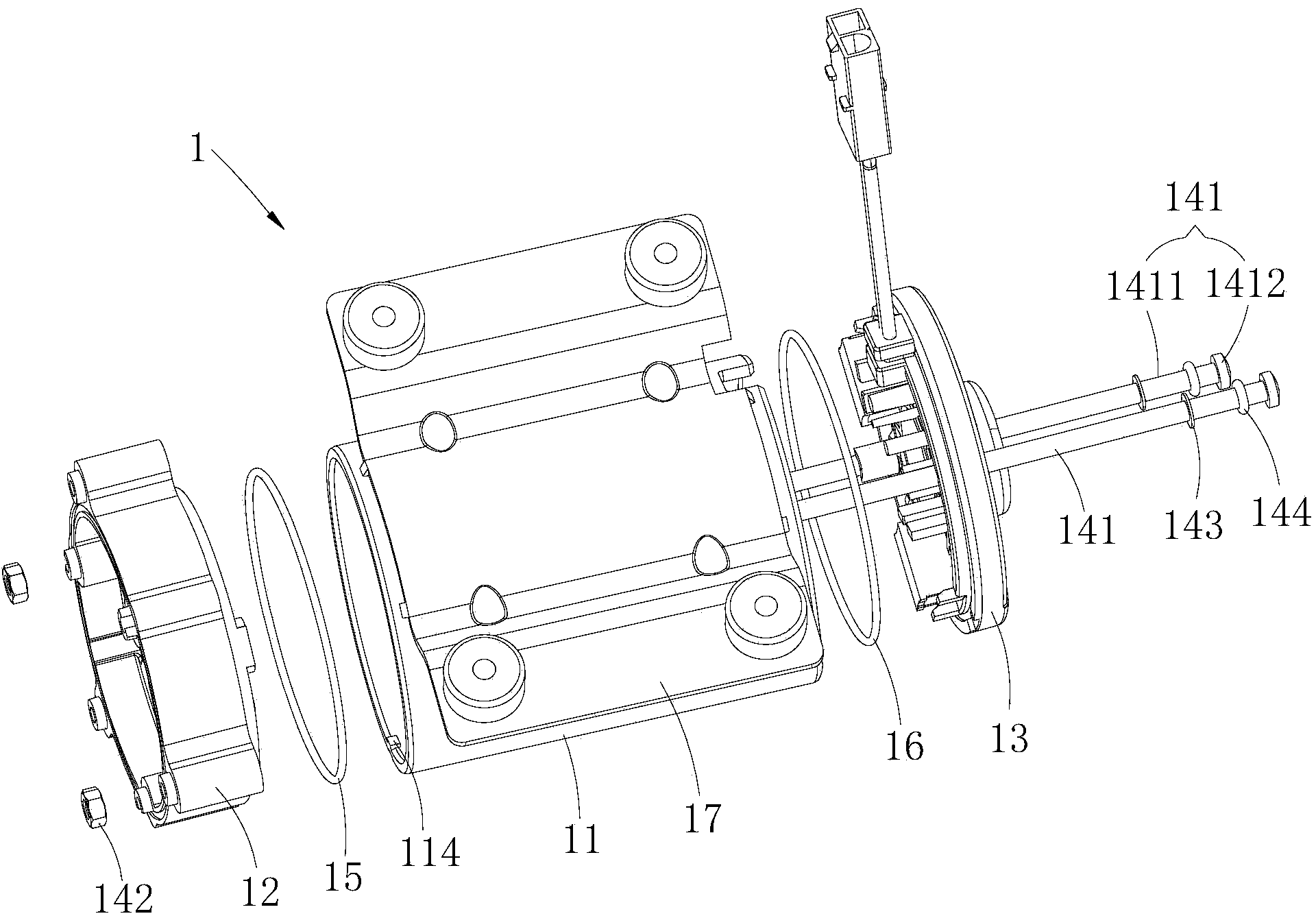

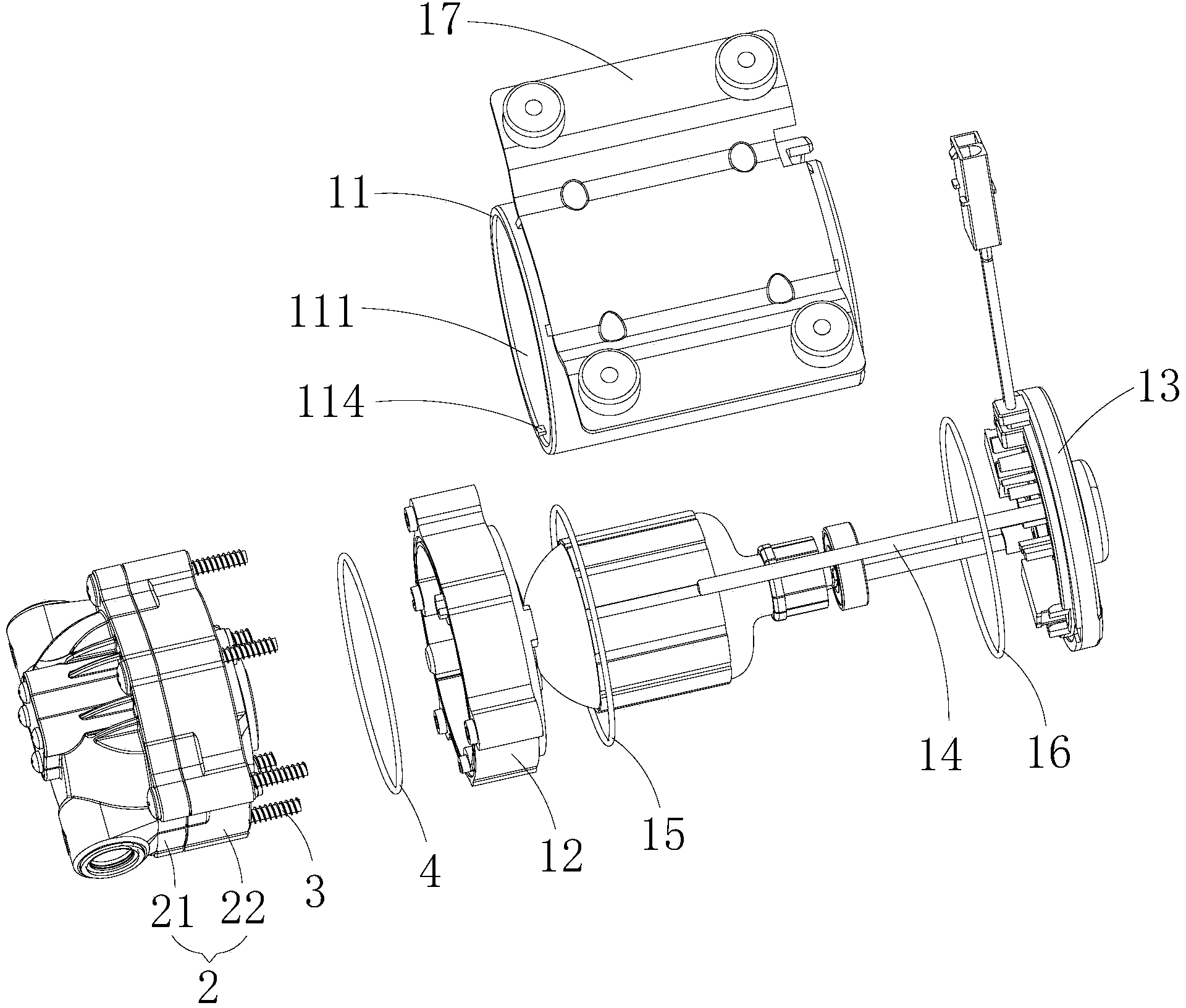

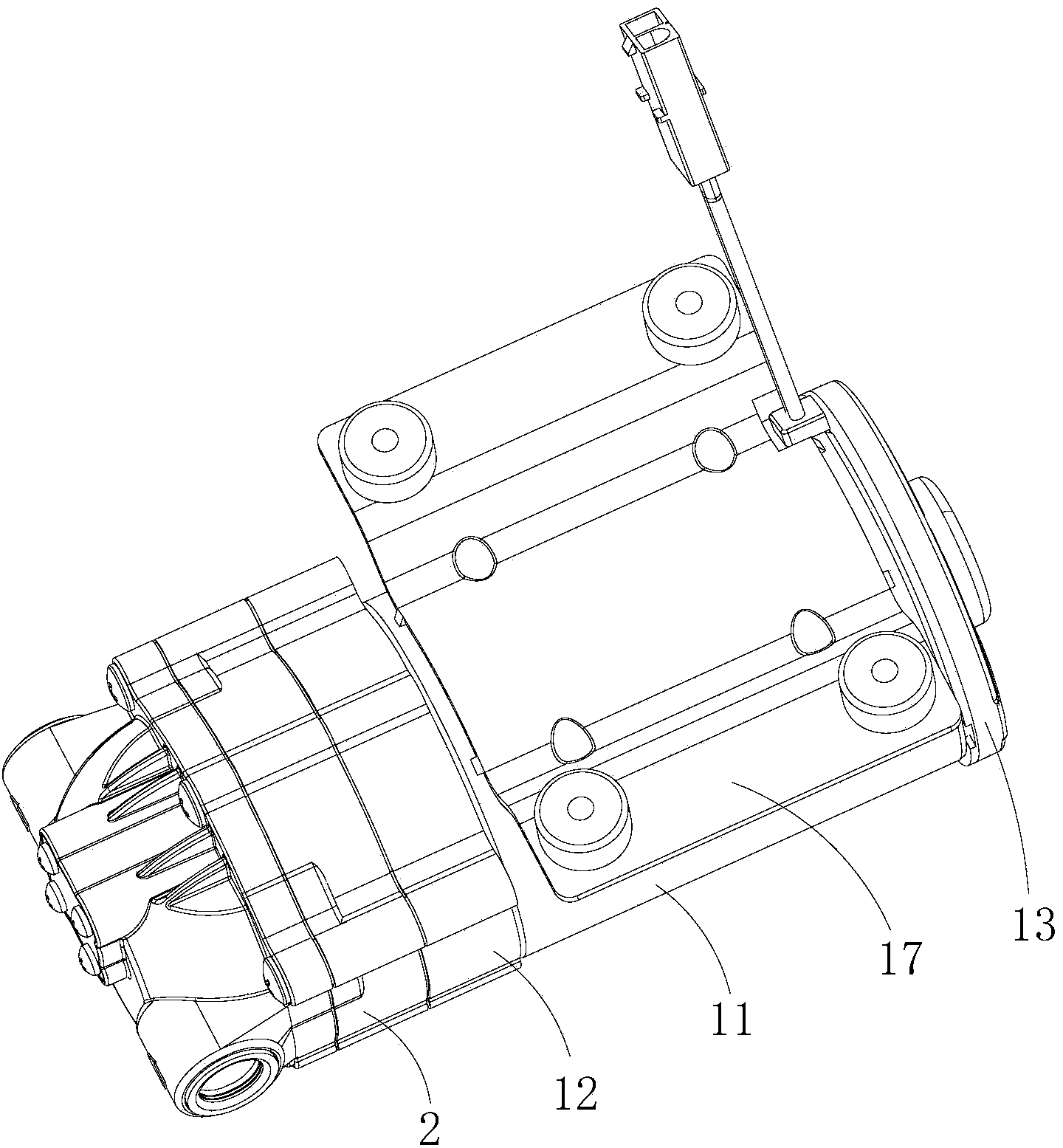

[0029] Such as figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 8As shown, the motor 1 of the booster pump provided by the embodiment of the present invention includes a casing 11, a front end cover 12, a rear end cover 13 and a first connector 14, the casing 11 has a hollow inner chamber 111, the front end cover 12 and the rear end cover 12 The end covers 13 are respectively arranged at both ends of the casing 11 and fastened to the casing 11 through the first connector 14. The motor 1 of the booster pump also includes a first elastic seal 15 and a second elastic seal 16, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com