Wire or cable waterproof fast-installed connector

A connector and wire technology, applied in the field of waterproof quick-install connectors, can solve the problems of non-recyclable use, normal transmission of power and communication signals, low construction and installation efficiency, etc., to achieve waterproof sealing performance and anti-destructive pull-off Enhanced performance, convenient and fast installation, connection or disassembly, and convenient and fast installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

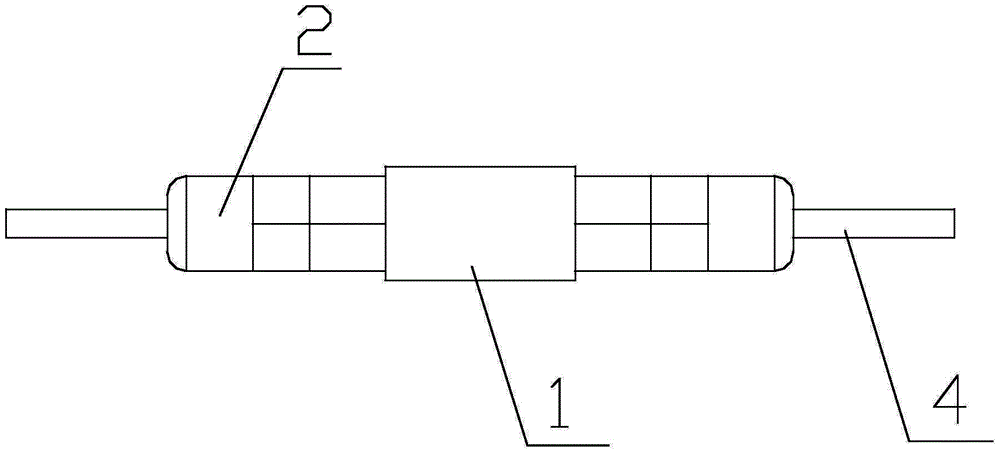

[0022] Wire or cable waterproof quick connector, including housing 1, end cap 2, sealing ring 3 and wires or cables for connection, the wires include single-strand and multi-strand wires, and the cables include single-core and multi-core Cables, two adjacent sections of wires or cables are connected to each other to form a number of wires or cable joints, the housing 1 is set as a hollow tubular structure, the two ends of the housing 1 are symmetrically provided with ring teeth 5, and the ring teeth 5 are A number of open tooth grooves 6 are arranged, and the outer surface of the annular tooth 5 is provided with an arc surface or a conical surface, and an external thread connection surface is provided between the annular tooth 5 and the main body of the housing, and the inner surface of the end cover is provided with a corresponding The internal thread connection surface, circular arc surface or tapered surface matching the two ends of the shell.

[0023] Such as figure 1 , ...

Embodiment 2

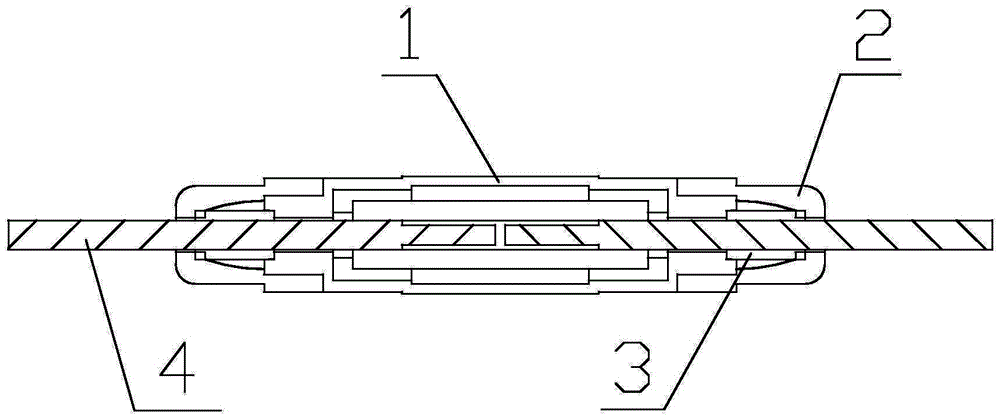

[0026] Such as Figure 4 , Figure 5 and Figure 6 As shown, the wire or cable waterproof quick-loading connector, the wire or cable is provided with one or more than one connector, each connector includes two end caps 2, two sealing rings 3, and a housing 1, each of which Two wires or cable joints are respectively threaded in the housing 1, two sealing rings 3 are respectively embedded in the annular teeth 5 at both ends of the housing 1, and then the two end caps 2 are respectively connected to the external threads on both sides of the housing 1. The connection surface is tightly connected so that all the joints of the wire or cable form a sealed and waterproof structure.

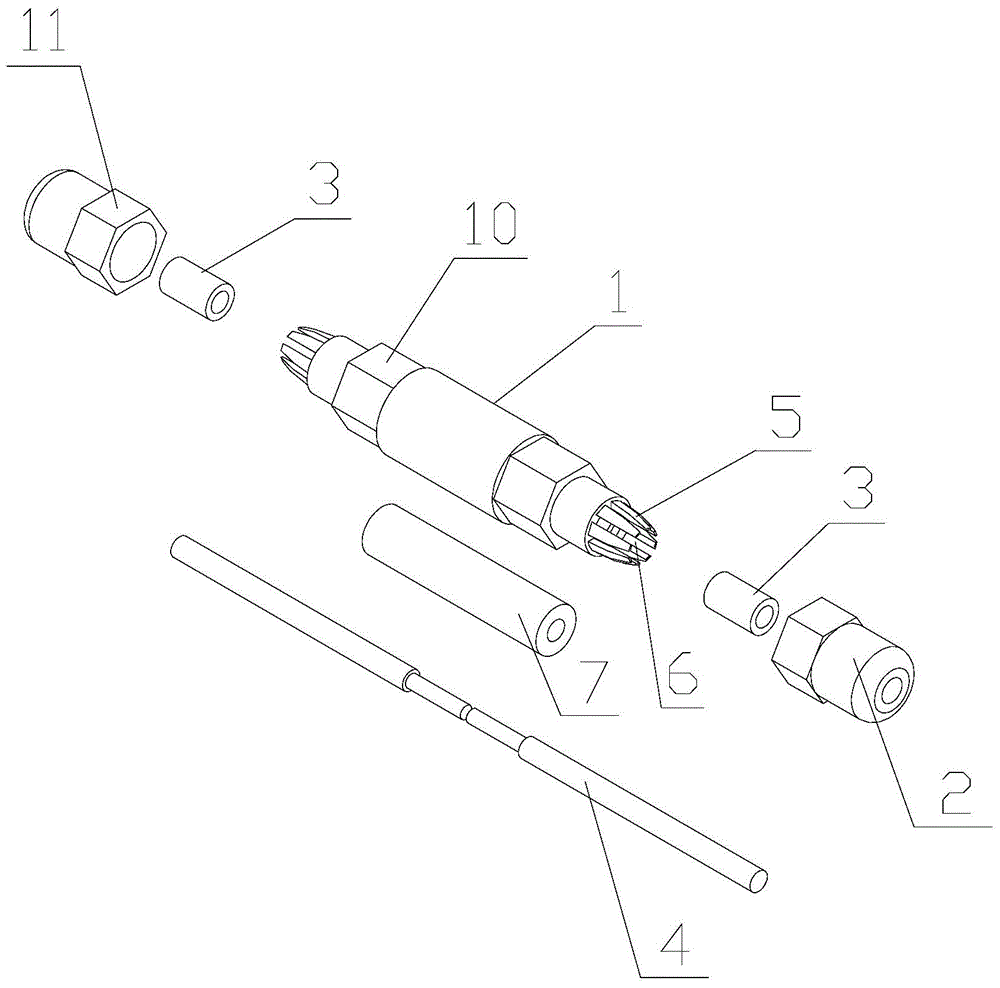

[0027] In this embodiment, the connection mode of the wire or cable connector is a male-female plug-in plug-in connection, including a male plug 8 and a female plug 9 . The main body of the first housing 1 is configured as a cylindrical structure. The main body of the first housing 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com