Amorphous magnetic ring inductor facilitating wire winding

A magnetic ring inductance and winding technology, which is applied in the field of inductors, can solve the problems of low installation efficiency, low production efficiency, and difficulty in making high impedance values, and achieve the effects of convenient installation, connection and disassembly, improved production efficiency, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

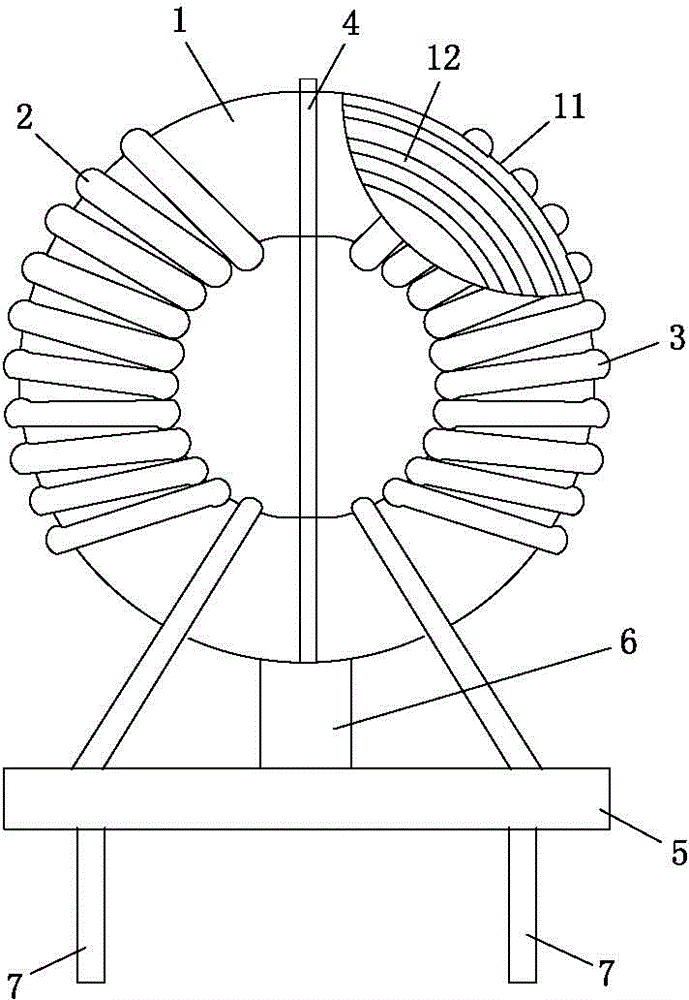

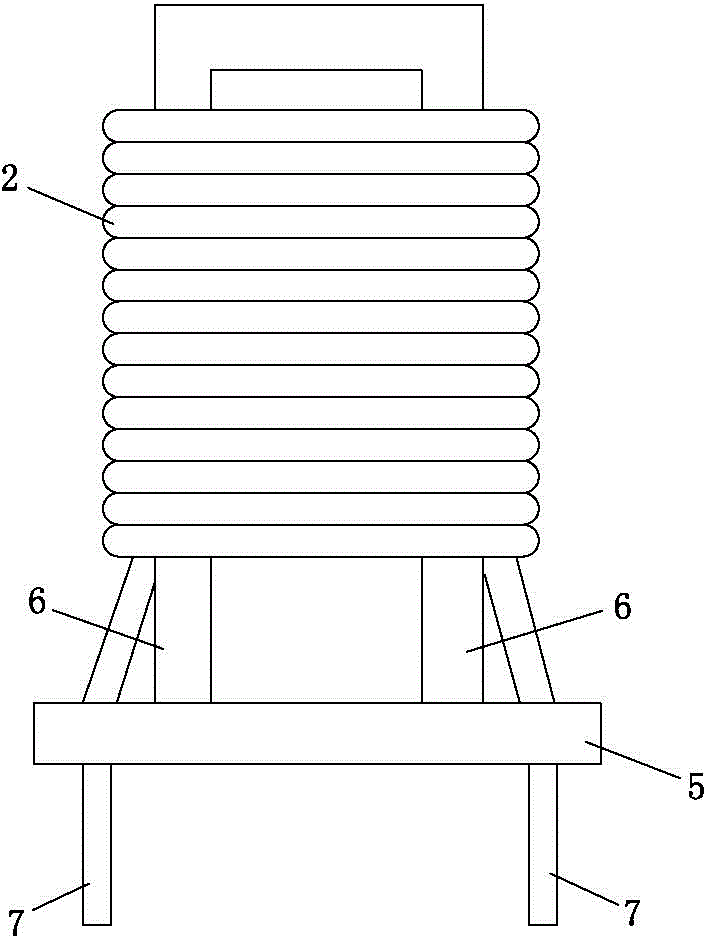

[0031] See figure 1 and figure 2 . An easy-to-wind amorphous magnetic toroidal inductor in this embodiment comprises a toroidal core 1, a first coil 2 and a second coil 3 wound on both sides of the toroidal core 1, and is arranged on the toroidal core 1 and used Based on the separator 4 separating the first coil 2 and the second coil 3, it also includes a bottom plate 5, and a bracket 6 detachably connected to the bottom plate 5 and the annular magnetic core 1; wherein the annular magnetic core 1 includes a casing 11 , and the nanocrystalline alloy 12 disposed in the shell 11. Wherein, the bracket 6 is detachably connected with the bottom plate 5 and the shell 11 of the annular magnetic core 1 respectively. Because the magnetic material adopted in the ring magnetic core 1 is nanocrystalline alloy 12, because nanocrystalline alloy 12 has high initial magnetic permeability, therefore, the volume of the magnetic loop inductor that the present invention utilizes nanocrystallin...

Embodiment 2

[0039] Embodiment 2 of an easy-to-wind amorphous magnetic ring inductor of the present invention, the difference between this embodiment and embodiment 1 lies in that the ring magnetic core 1 is a square ring magnetic core. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] Embodiment 2 of an easy-to-wind amorphous magnetic toroidal inductor of the present invention differs from embodiment 1 in that the toroidal magnetic core 1 is an elliptical toroidal magnetic core. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com