Patents

Literature

1904results about "Connection insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

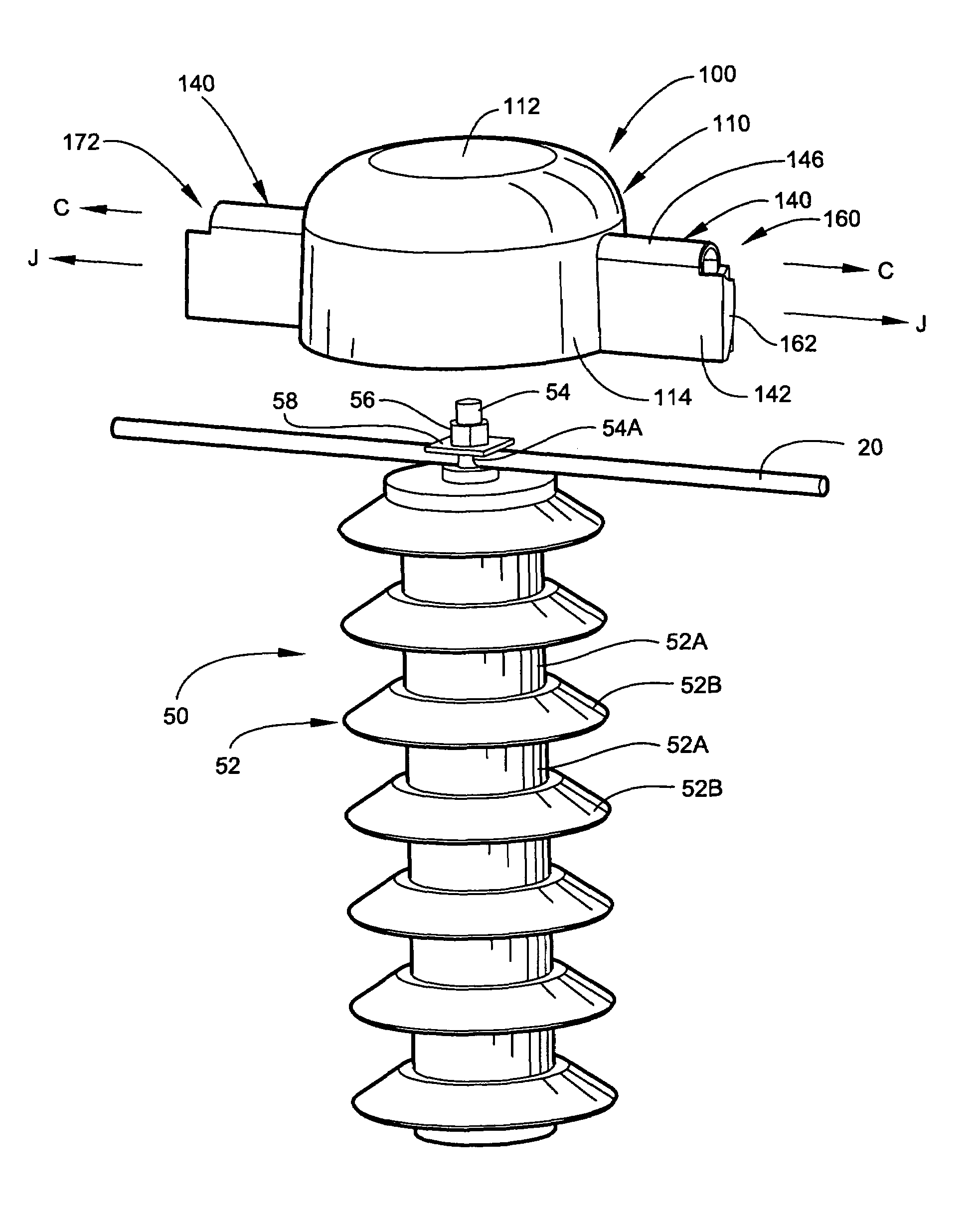

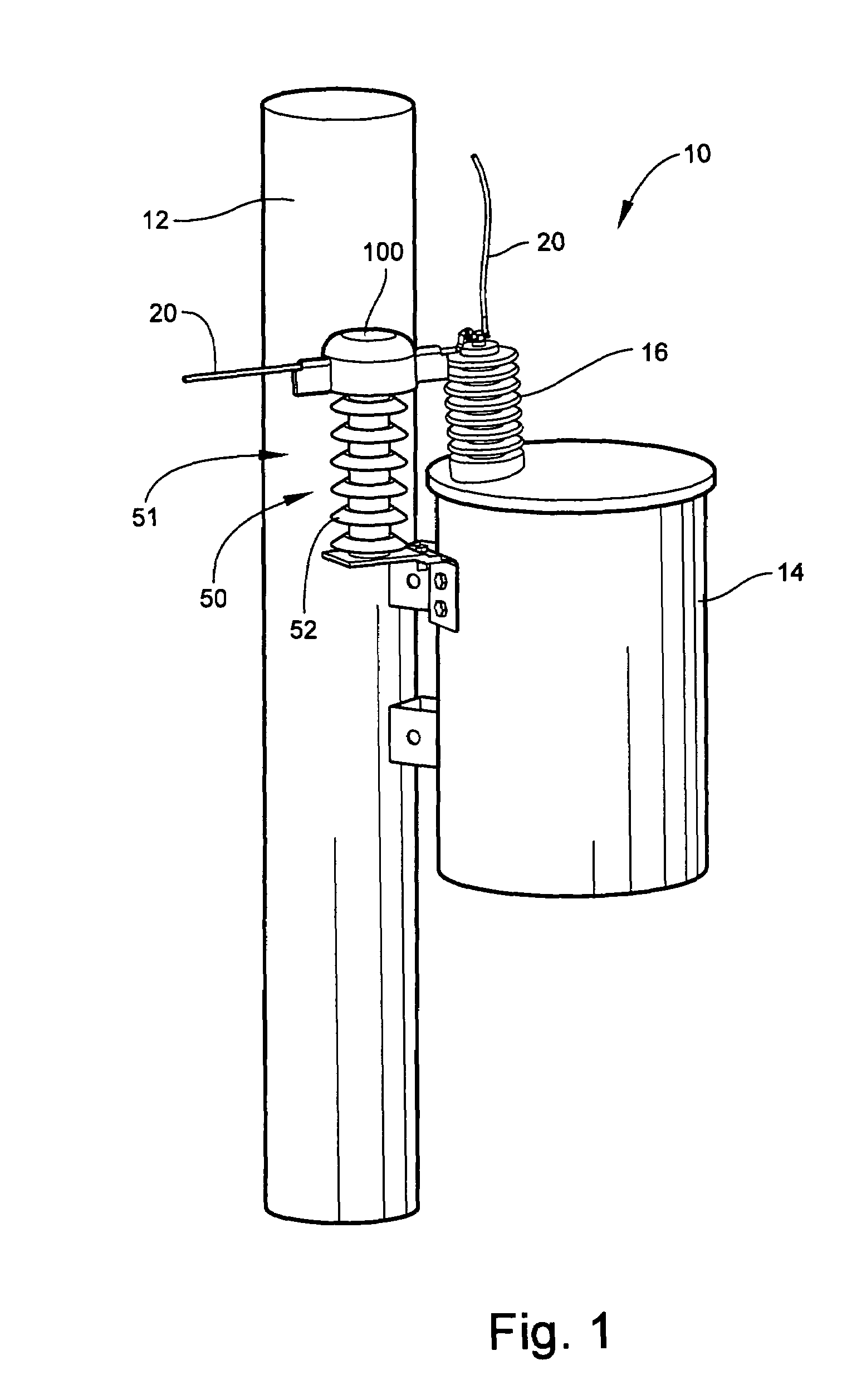

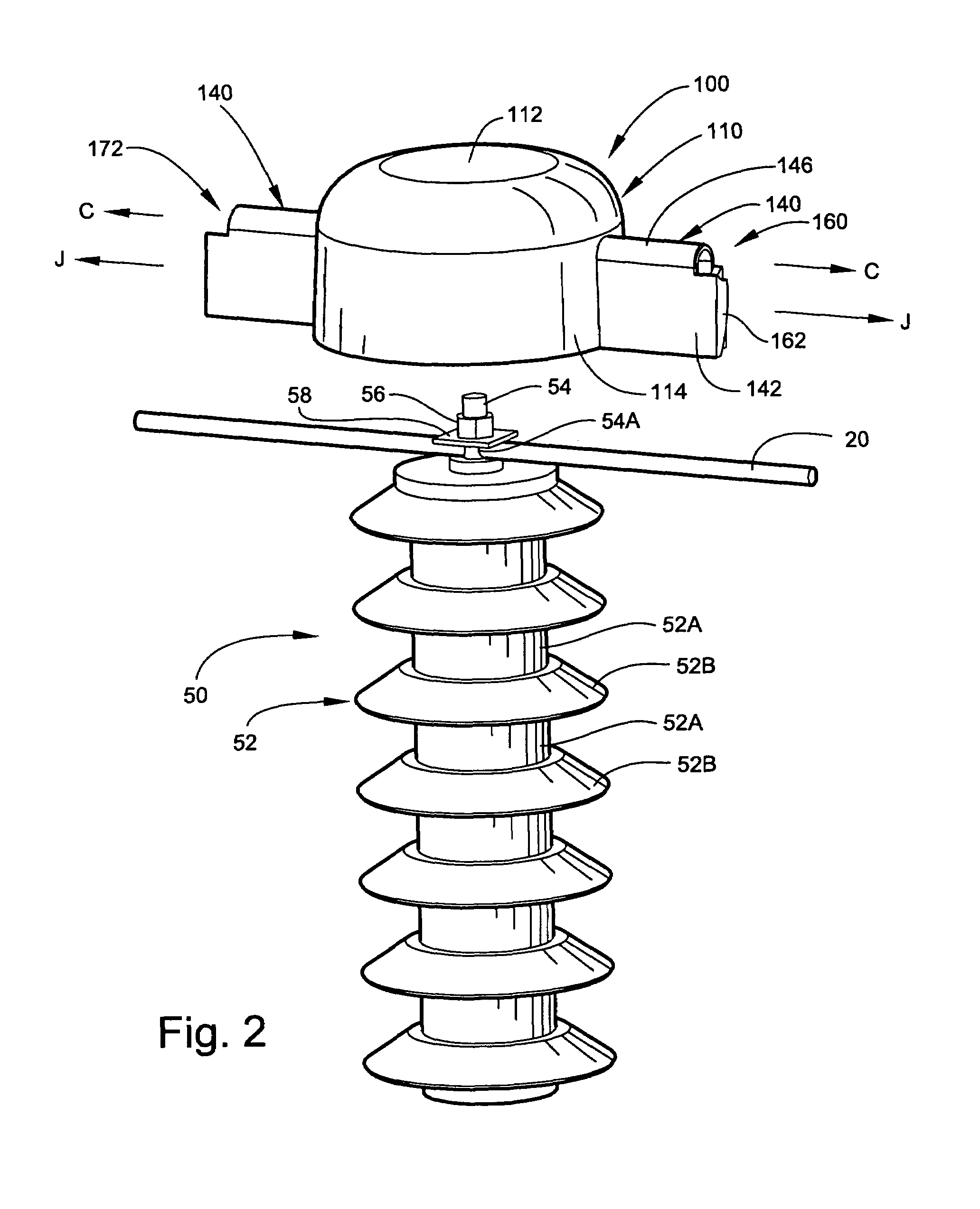

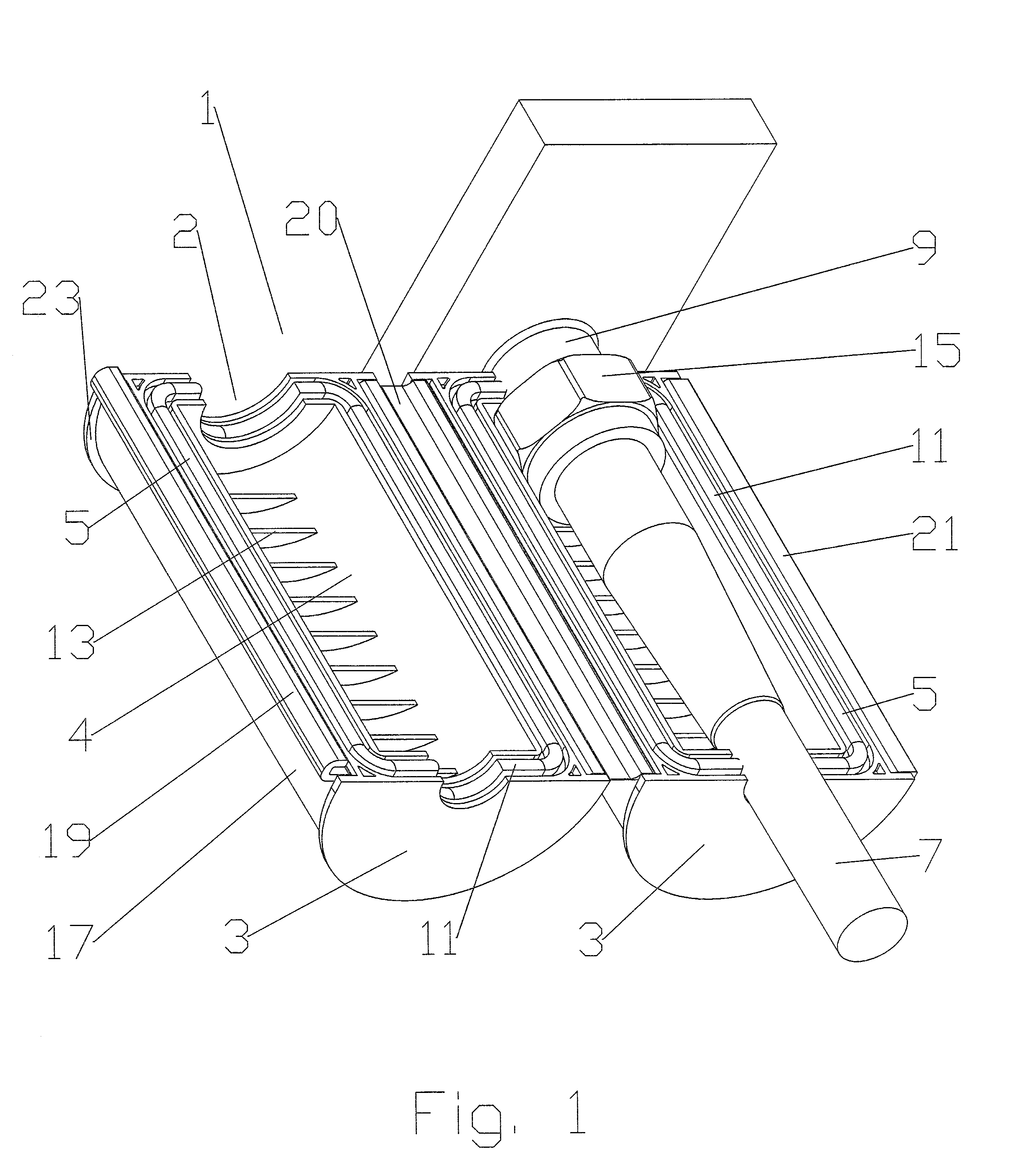

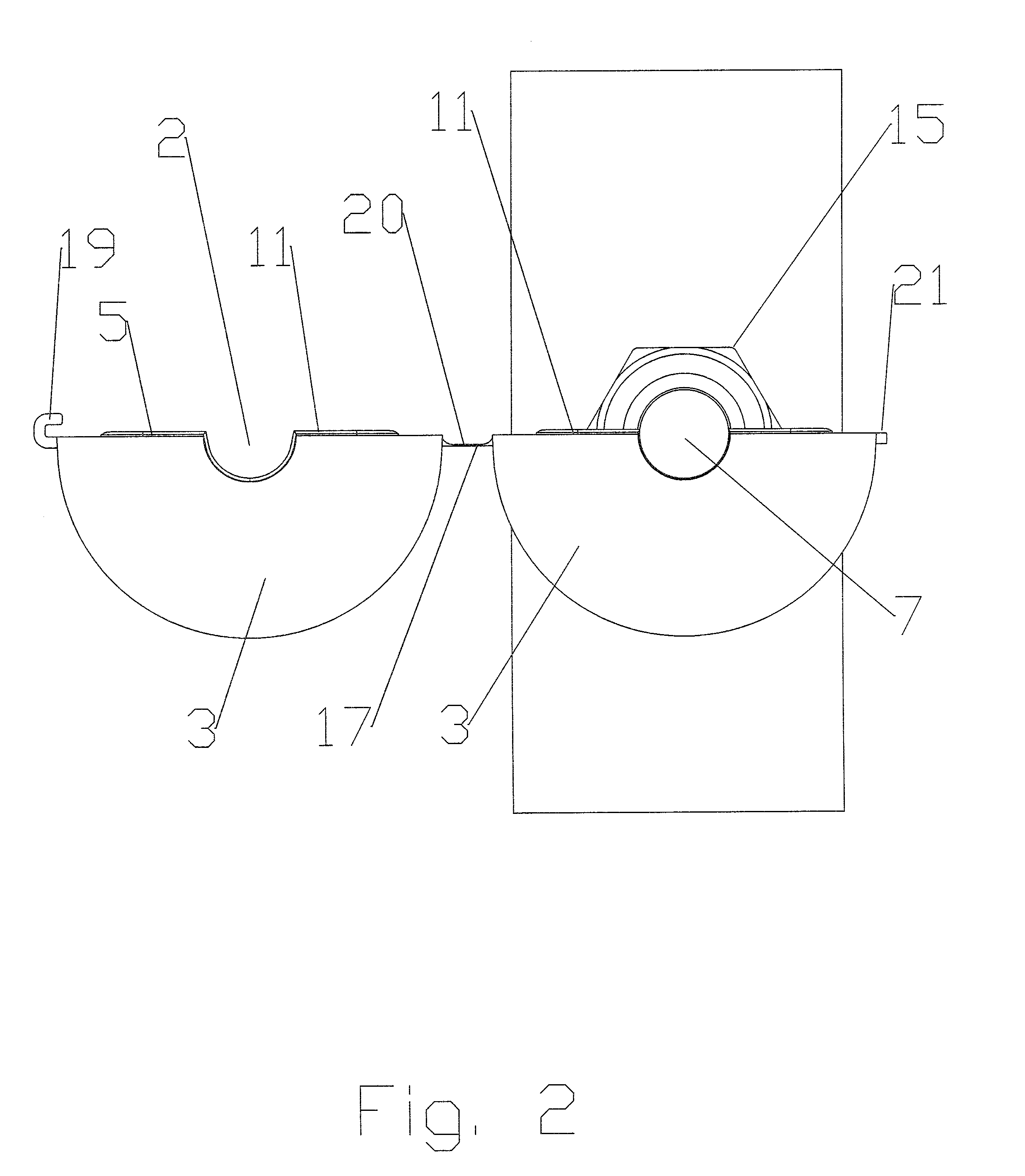

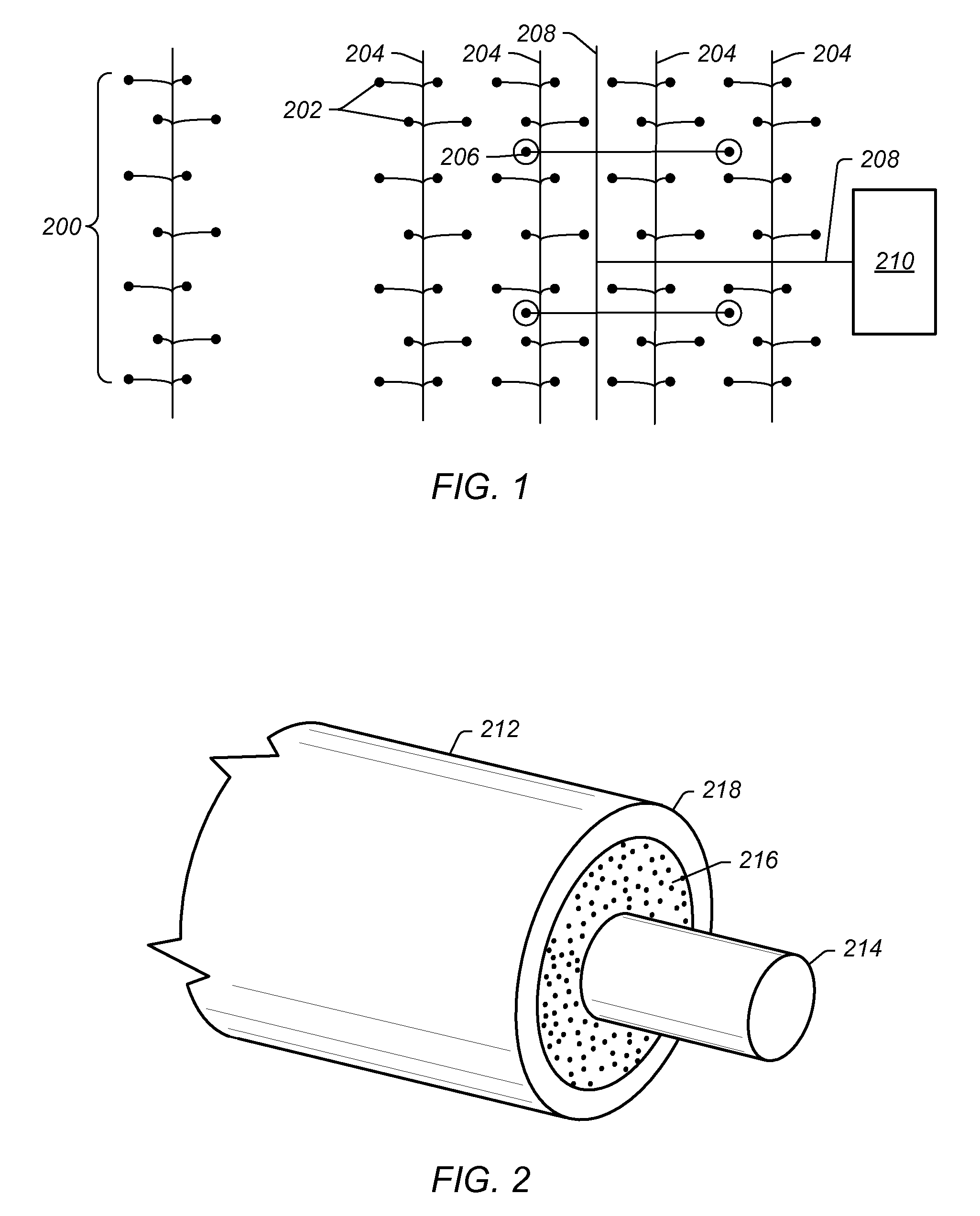

Covers for distribution lines and insulators

ActiveUS7297869B2Maintaining distance between parallel conductorsSuspension arrangements for electric cablesElectrical conductorEngineering

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

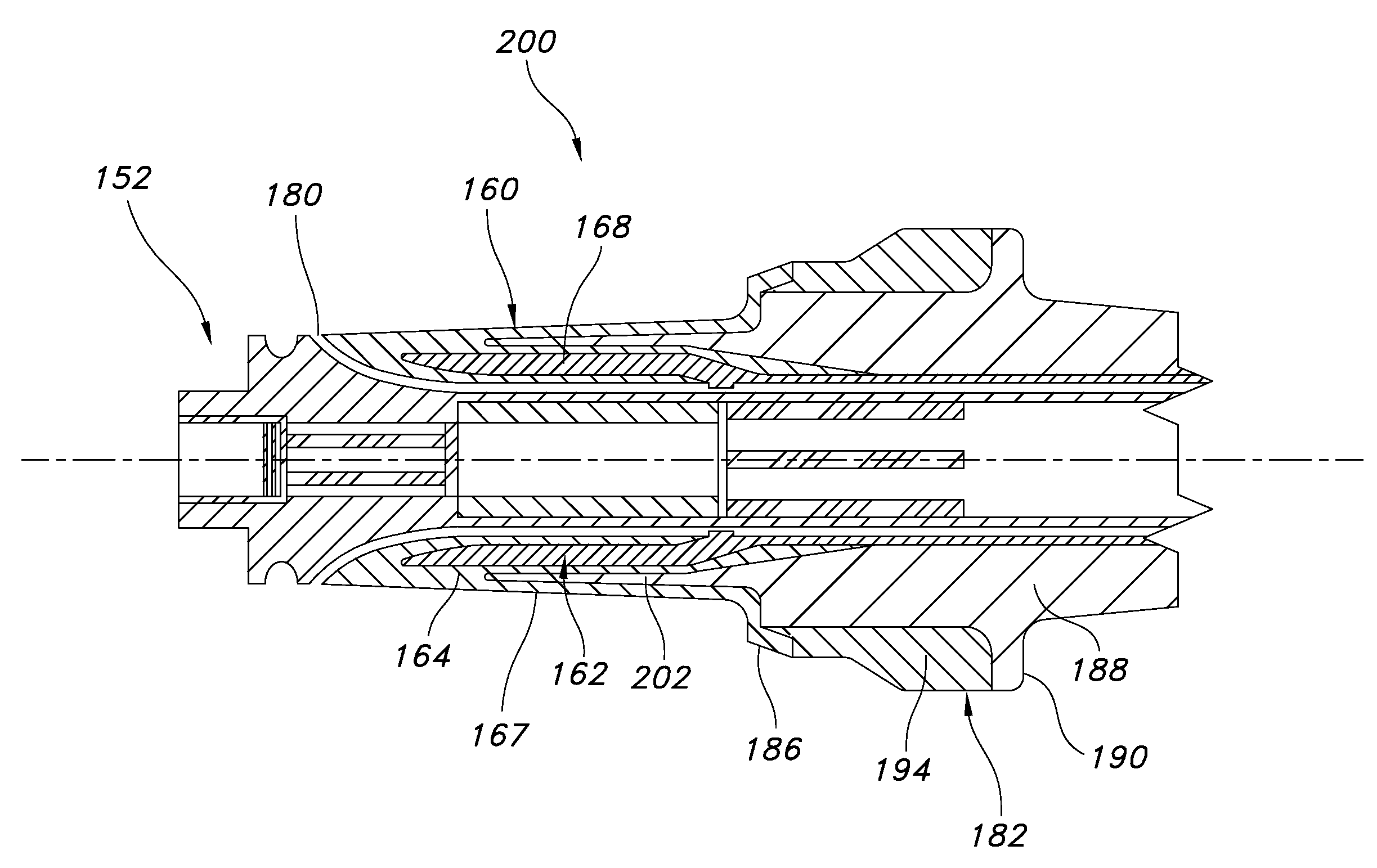

Thermoplastic interface and shield assembly for separable insulated connector system

InactiveUS7494355B2Couplings bases/casesCoupling protective earth/shielding arrangementsThermoplasticEngineering

A separable insulated connector assembly provided with a thermoplastic interface formed on a surface of a shield.

Owner:COOPER TECH CO

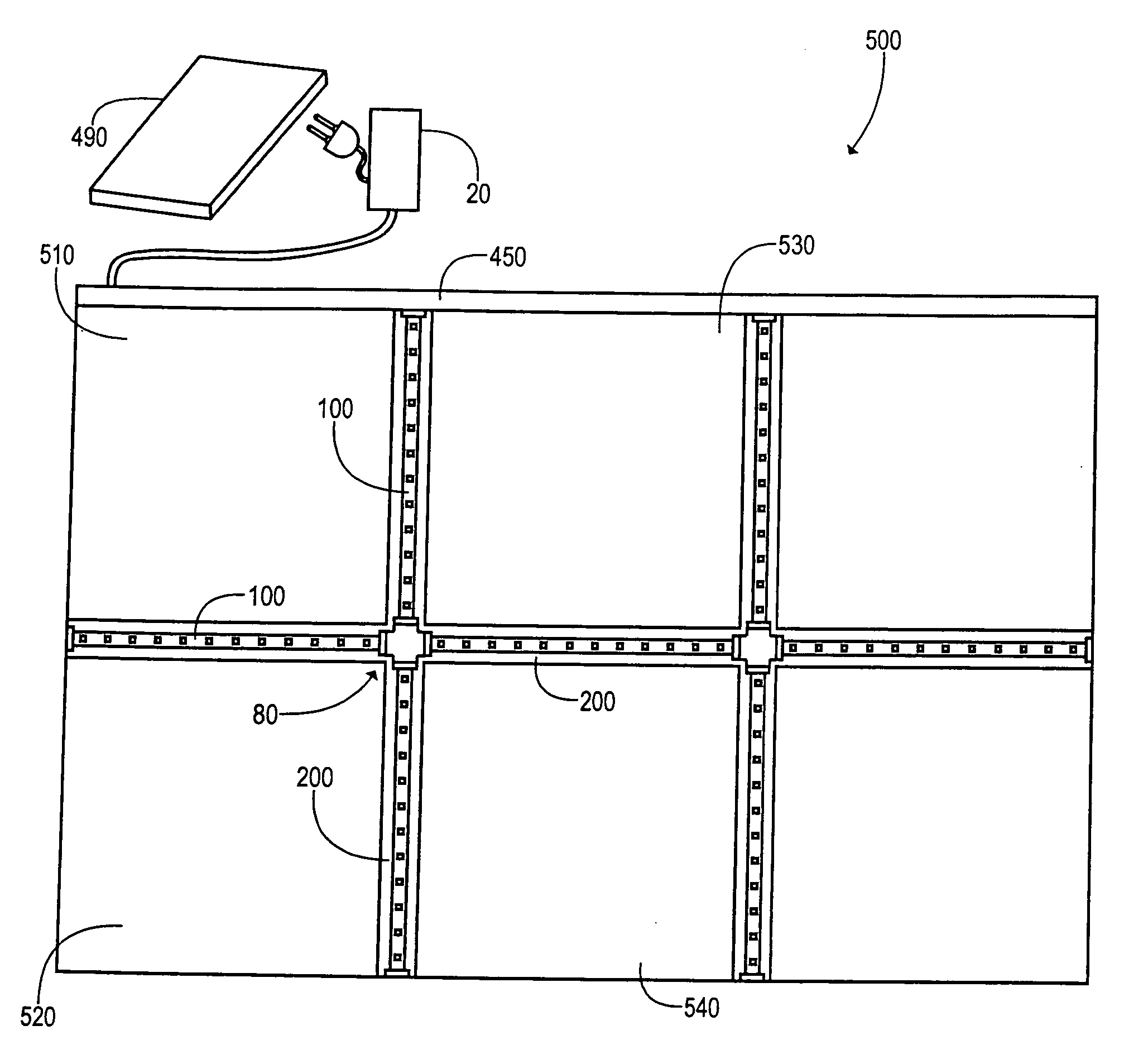

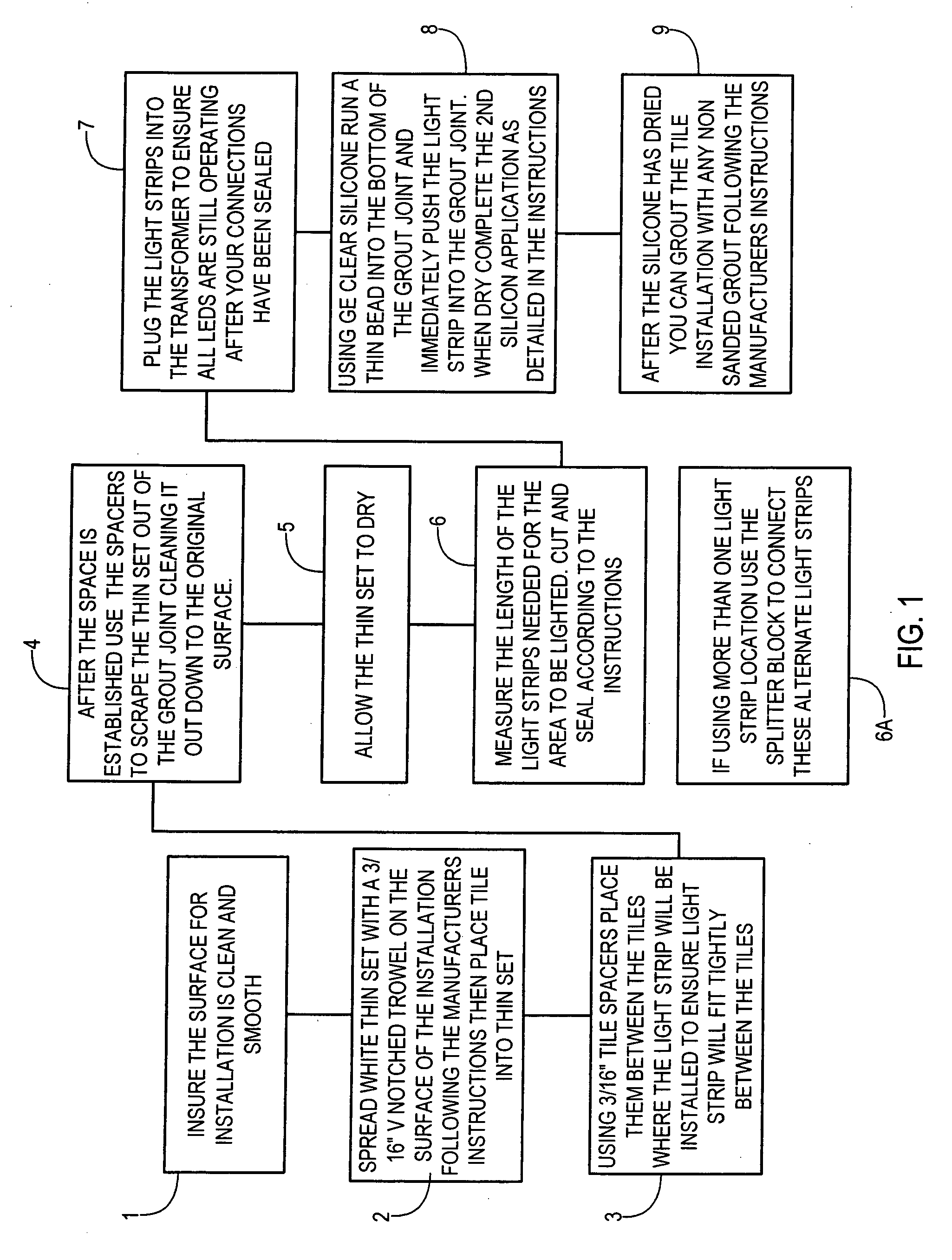

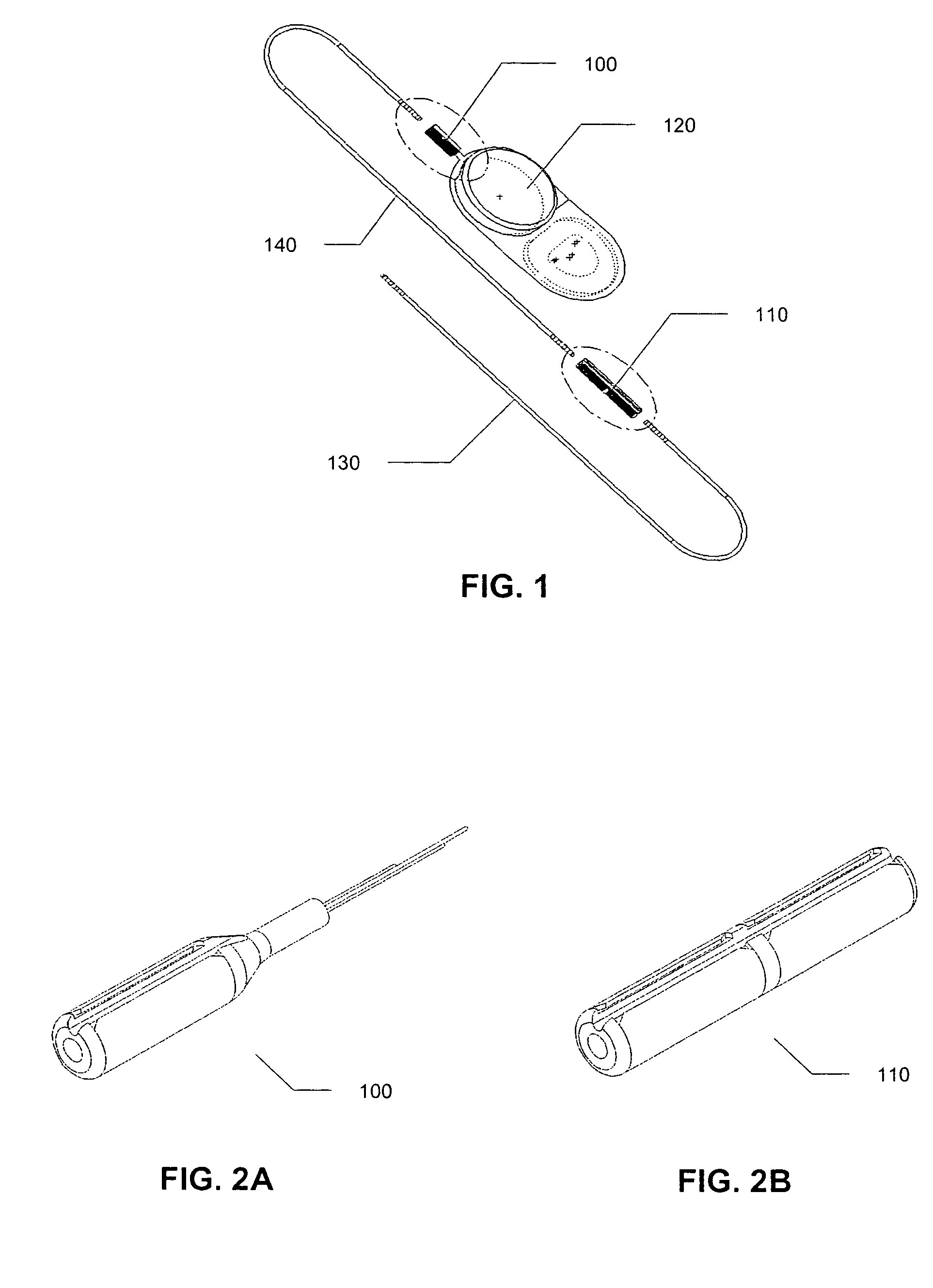

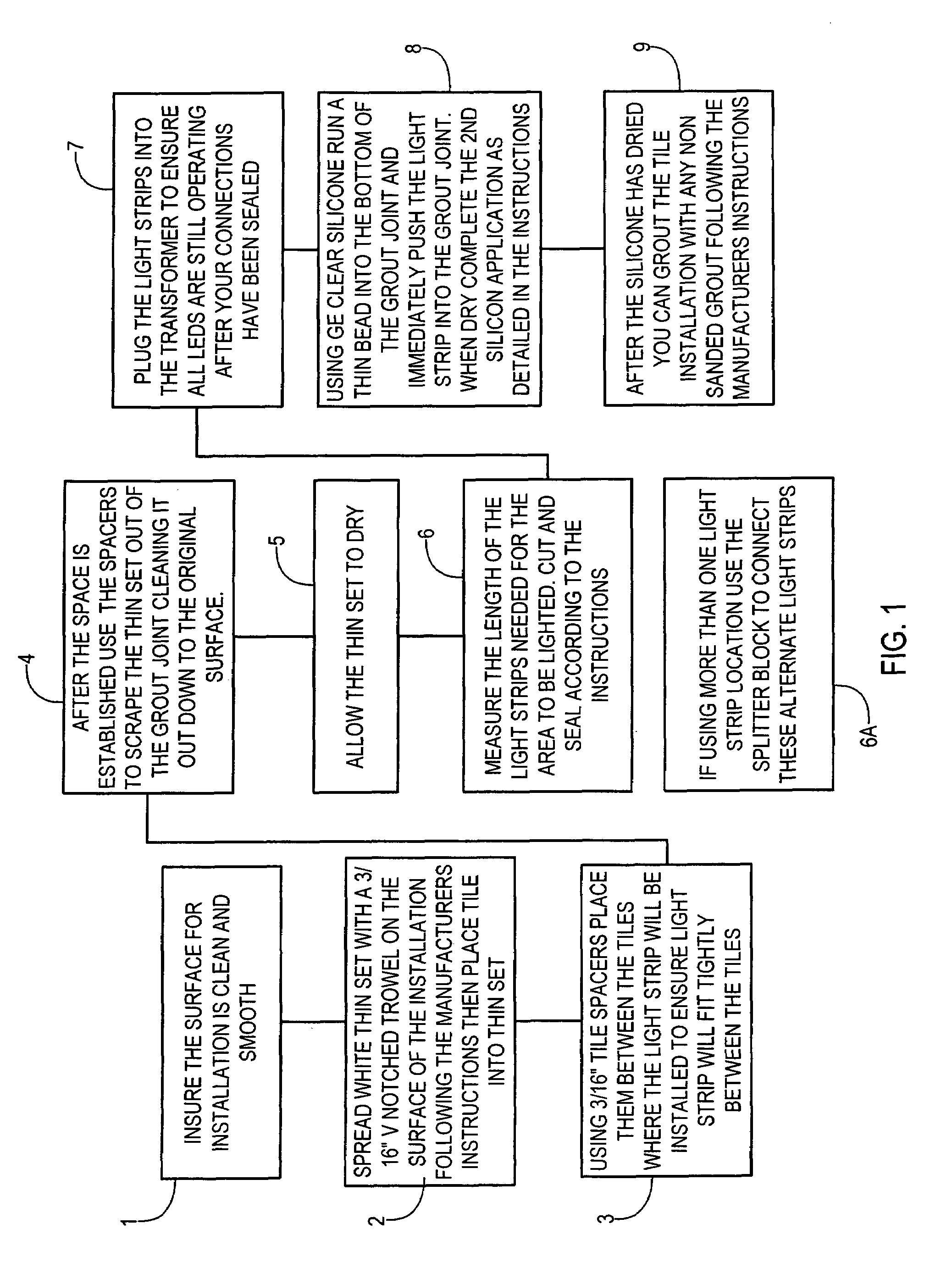

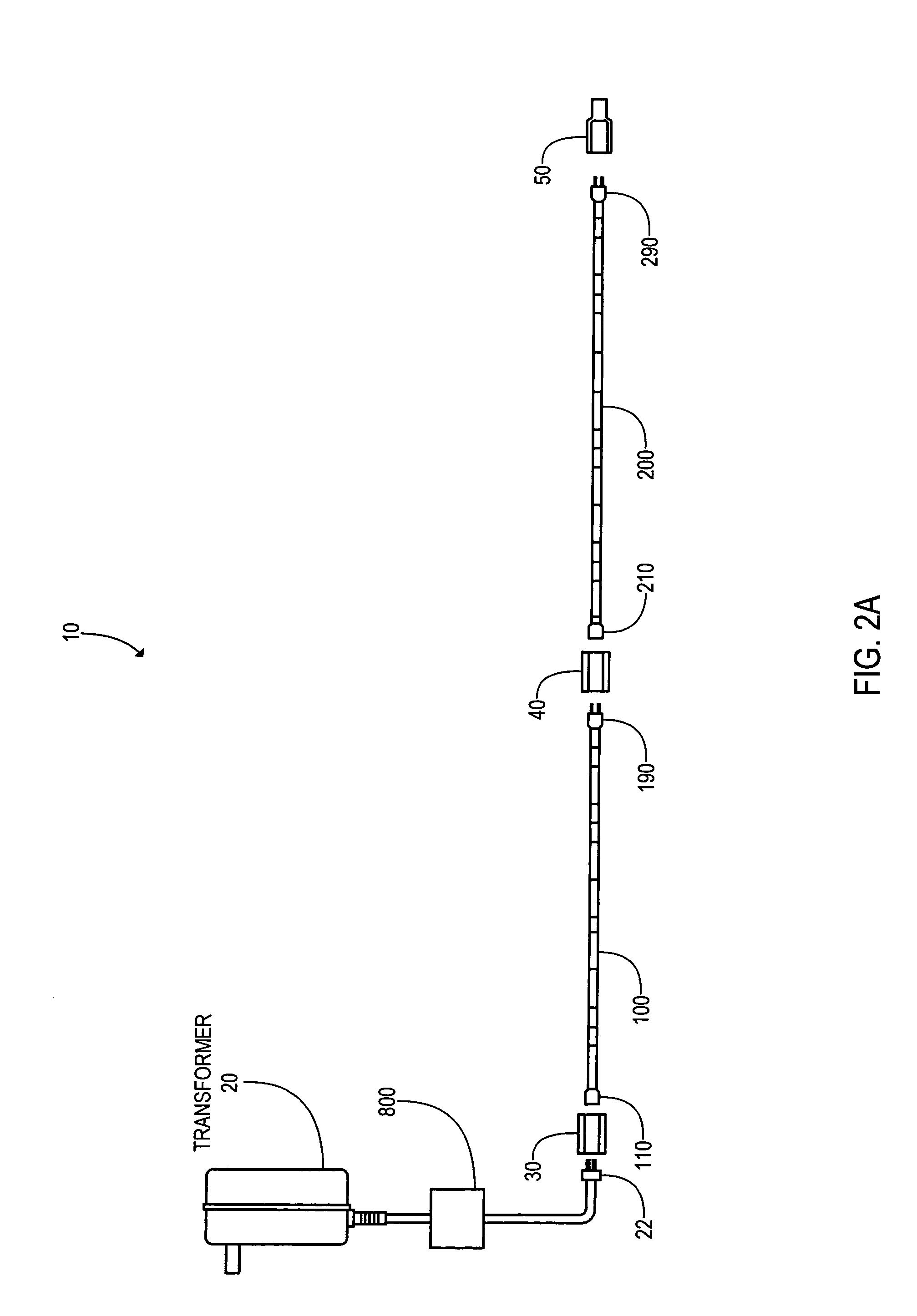

LED lighting for glass tiles

InactiveUS20090147504A1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceBrickSurface layer

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

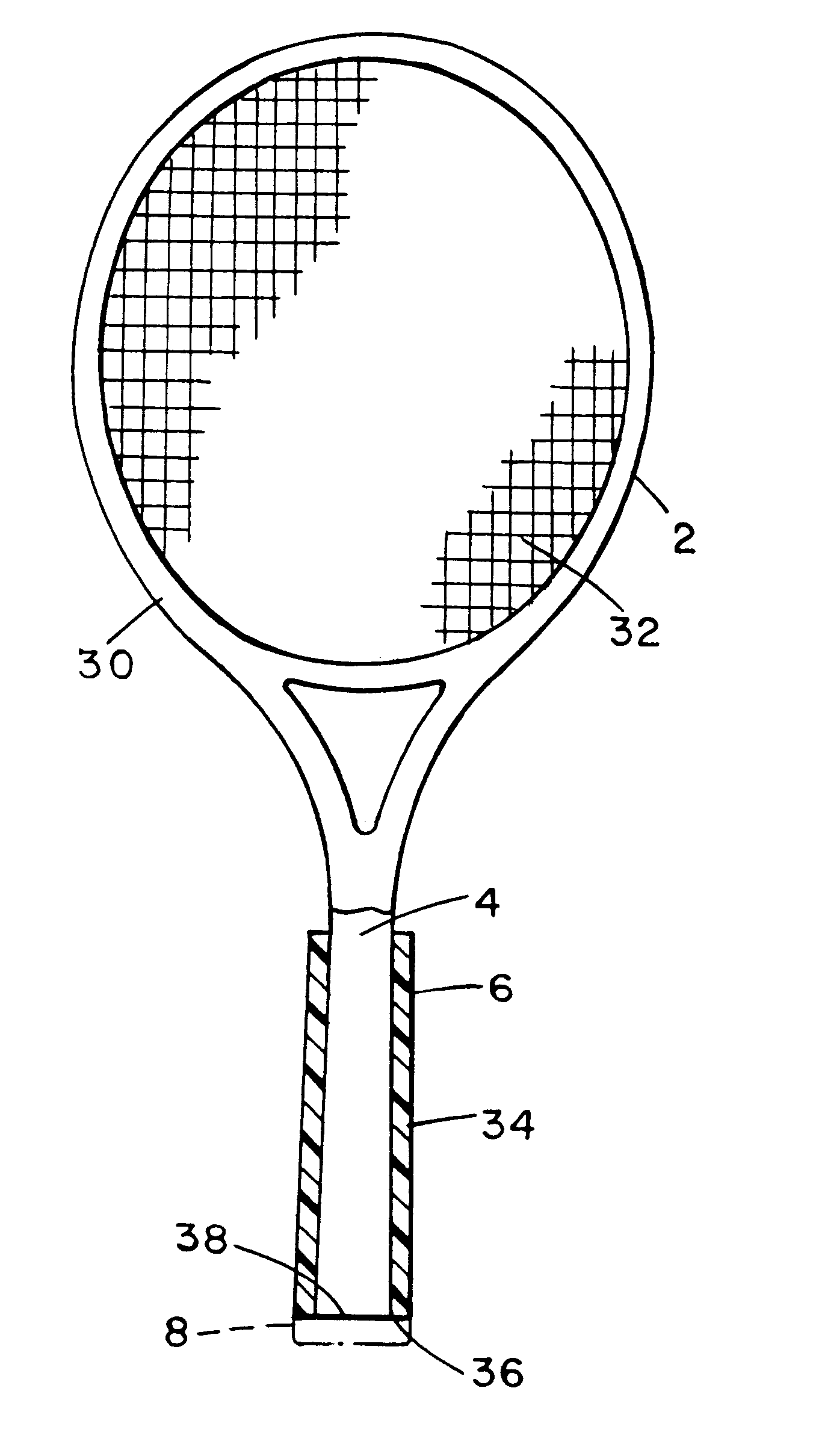

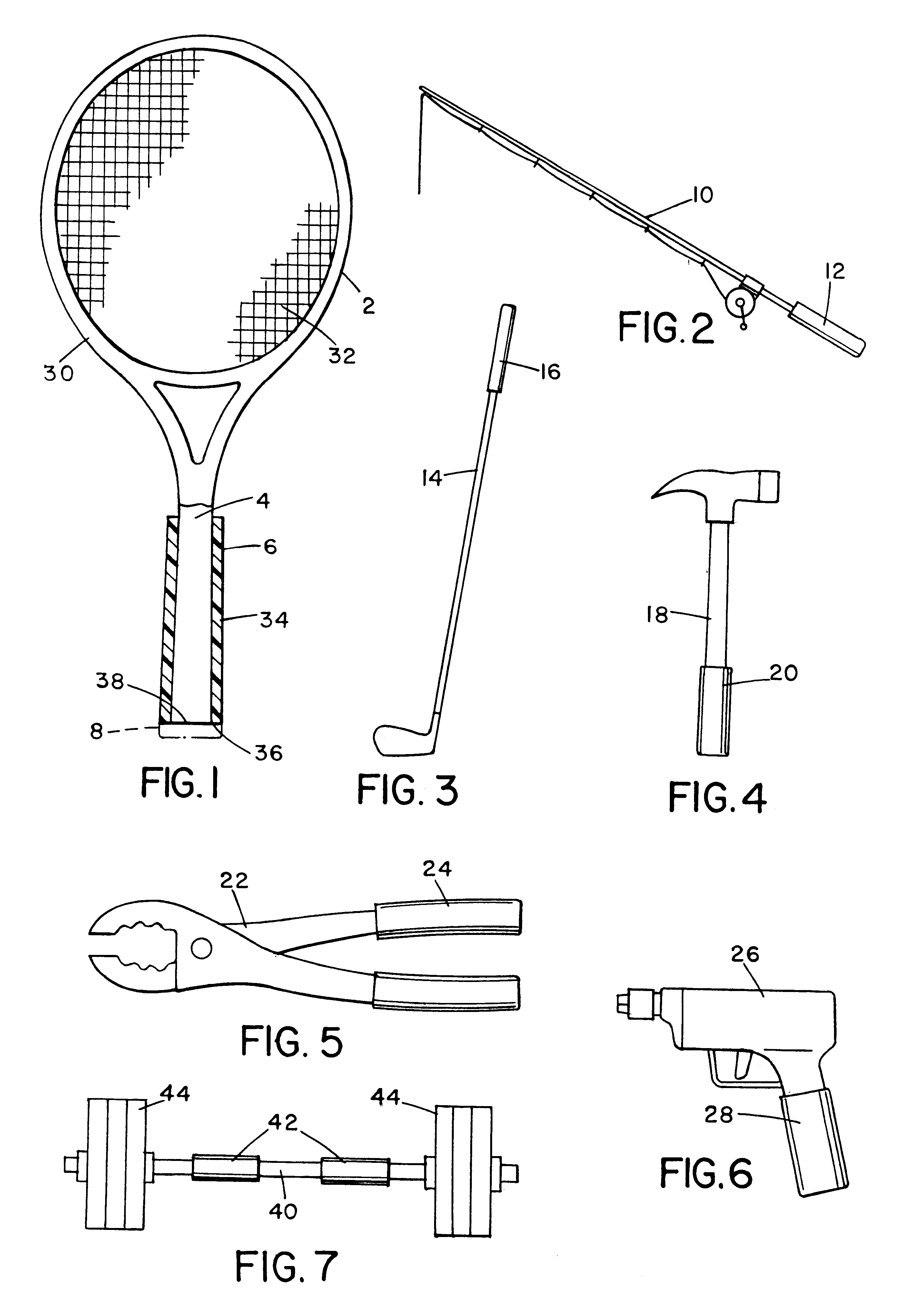

Low-odor single element equipment grip

A low odor grip is disclosed for a handle of a hand-held implement such as a sports implement or a manual or electric tool which is essentially free of disagreeable odors, which can be installed and quickly shrunk into a tight vapor resistant grip within a matter of a few minutes rather than requiring extended periods of time, and can be installed without the need for any application of heat or use of special tools, equipment or materials. The present device is therefore easy to install, merely sliding over the handle while in dilated state and then allowed to shrink and set by evaporation of the solvent, and thus can be satisfactorily installed in both fabrication facilities and in the field either as an original or replacement grip. The invention also includes an implement fitted with such grip. Representative implements include sports implements such as golf clubs, tennis racquets, weight bars and fishing poles, as well as tools such as hammers, drills, pliers, shovels, axes, and the like. The grip is preferable made of a swellable elastomeric material, preferably a natural or synthetic rubber. Suitable rubbers include EPDM rubber, neoprene or chlorosulfonate polyethylene (Hypalon(TM)) rubber, of which EPDM rubber is preferred.

Owner:JONES MICHAEL G

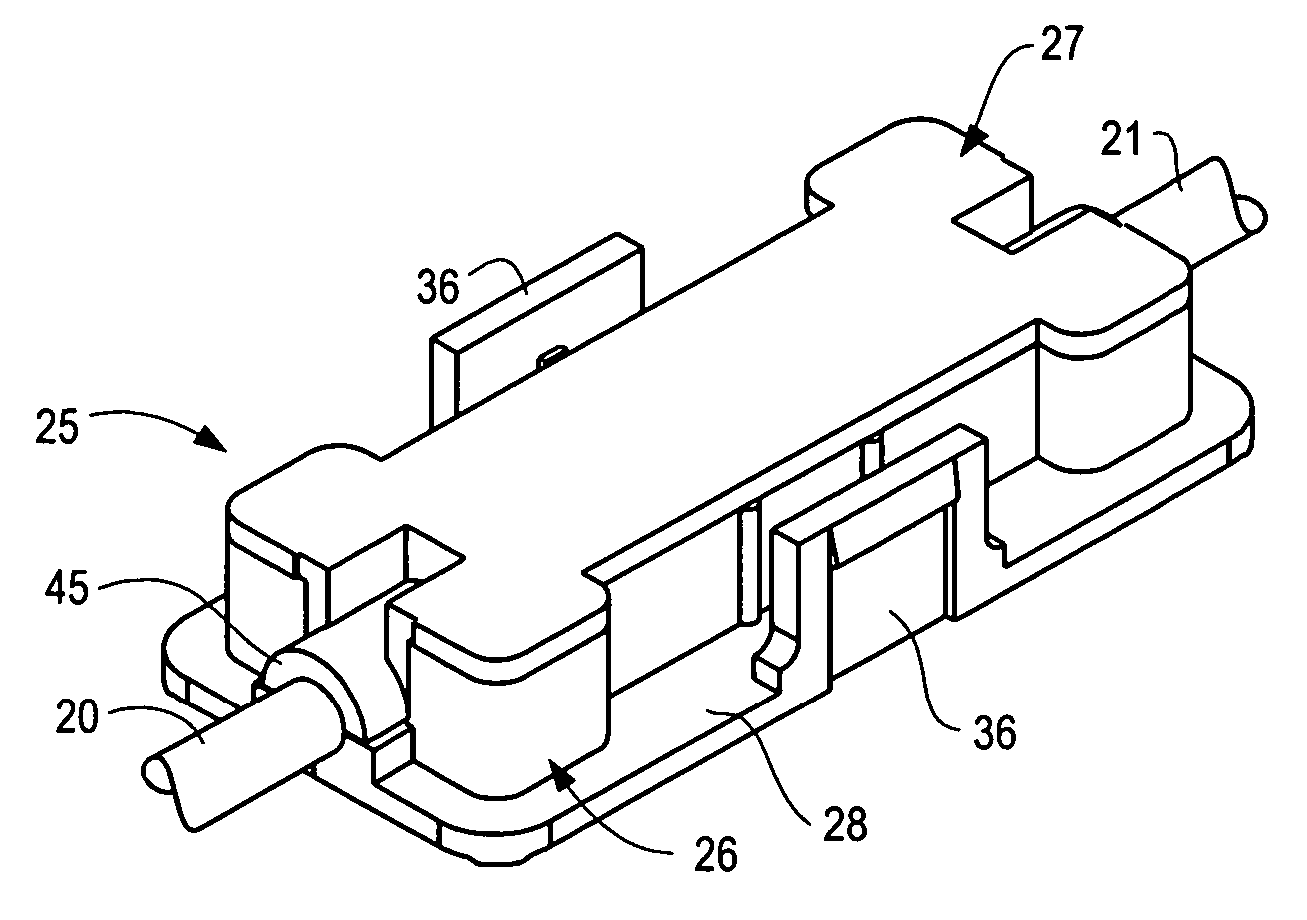

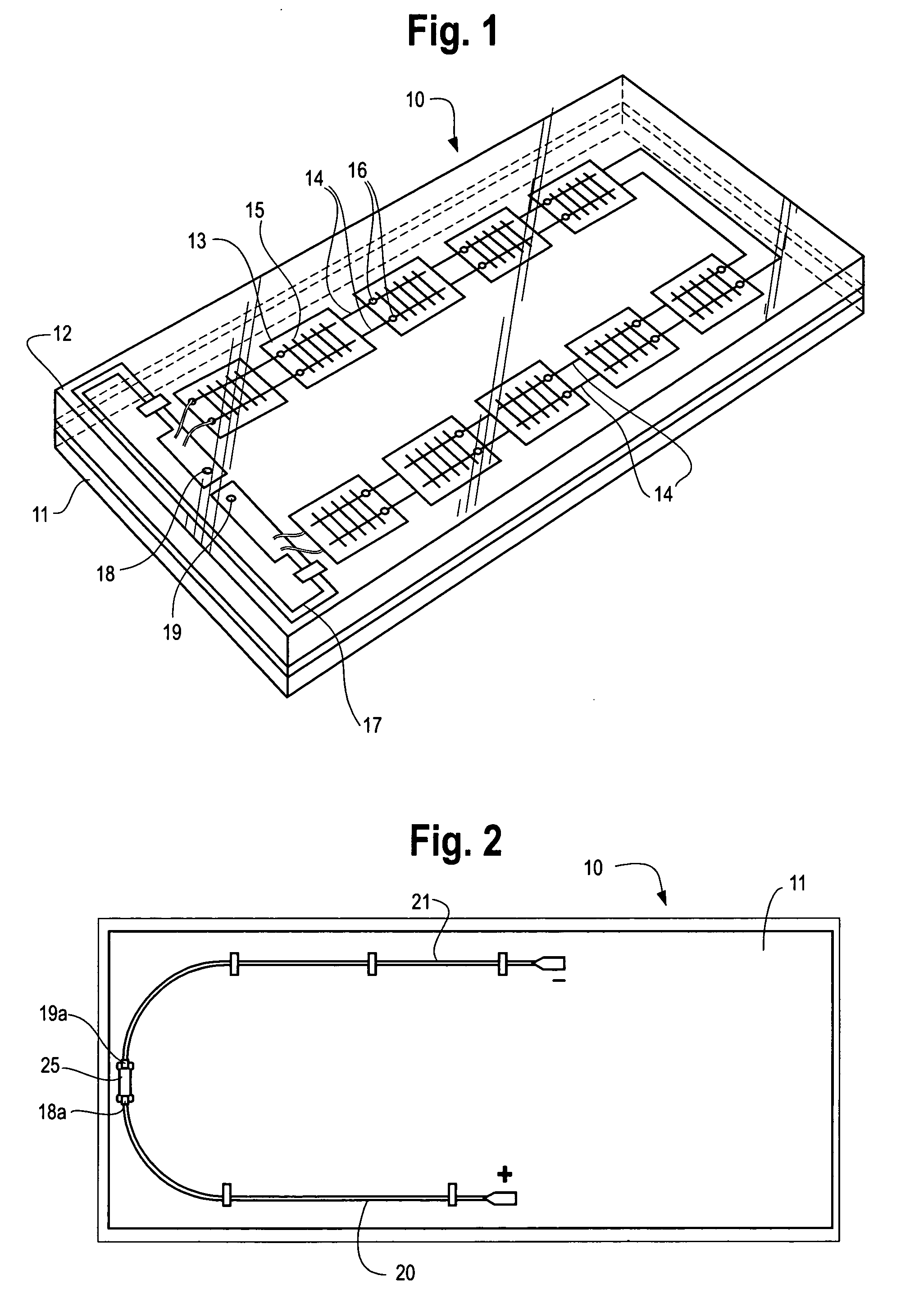

Junction box for output wiring from solar module and method of installing same

InactiveUS20060180196A1Easy to installReduce manufacturing costPV power plantsCoupling device detailsElectrical connectionEngineering

A junction box adapted to protect soldered electrical connections between outputs and cables wherein the connections are on a flat surface (e.g. the backing sheet of a solar module) and a method for installing the box over the connections. The junction box can have a split housing that can be spread to fit over the cables before filling the housing with a sealant which, in turn, covers and protects the connections. A separate cover is then latched onto the housing.

Owner:BP CORP NORTH AMERICA INC

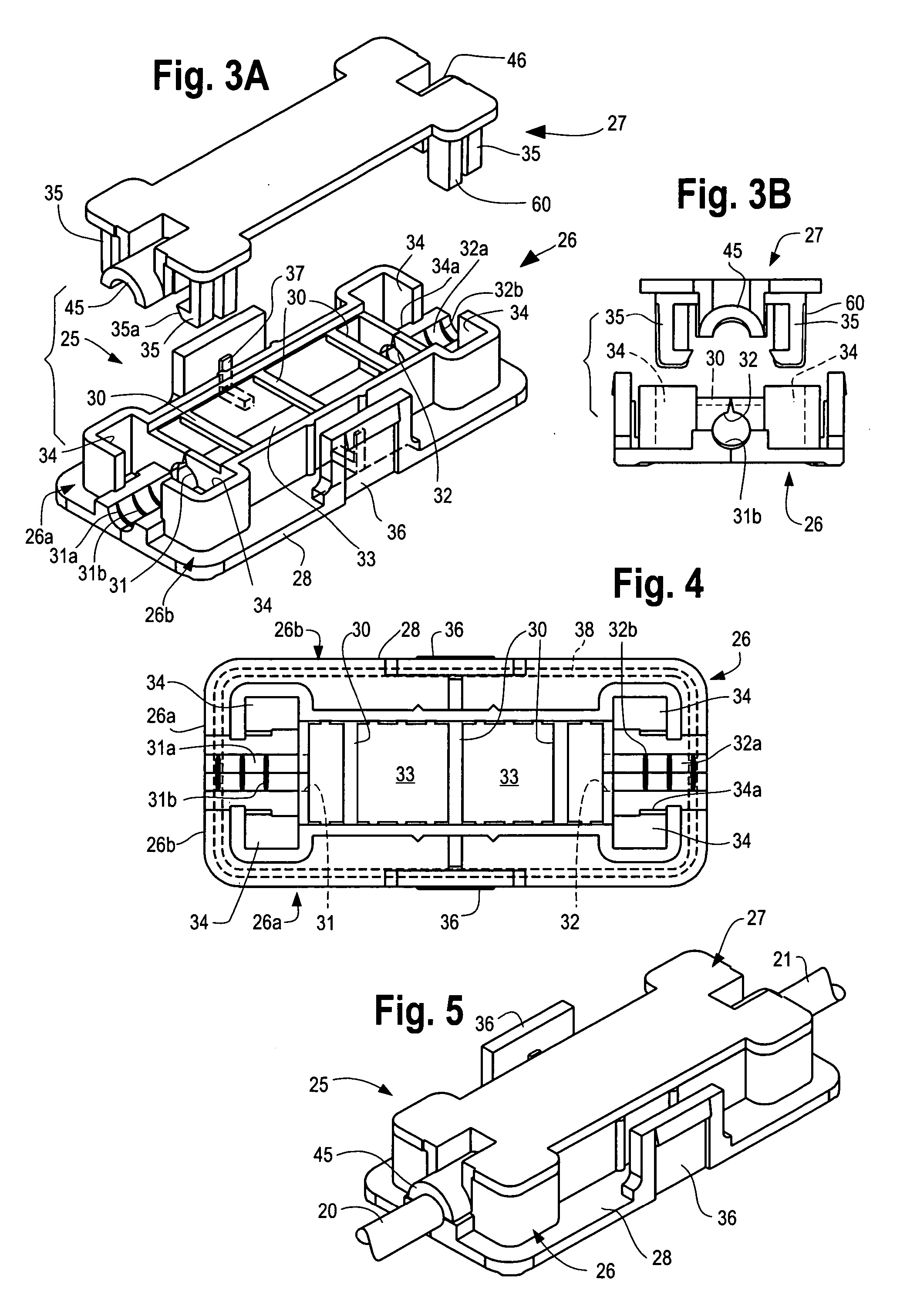

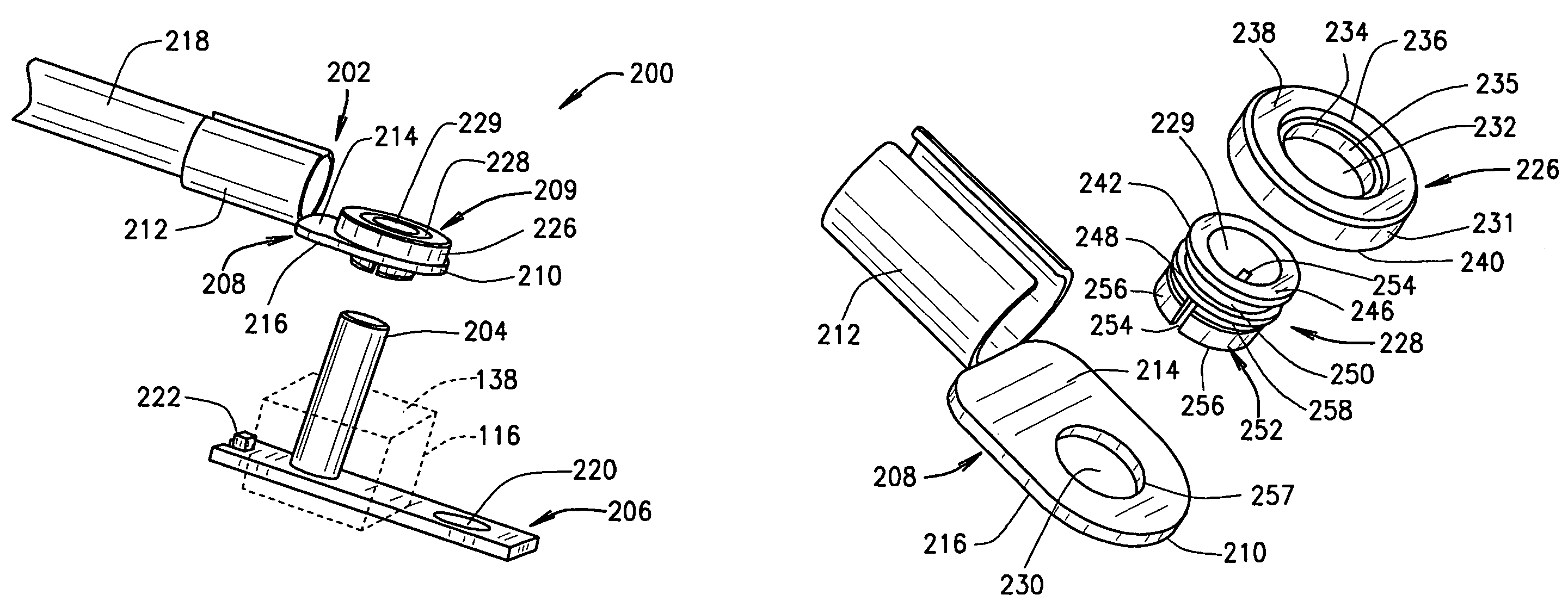

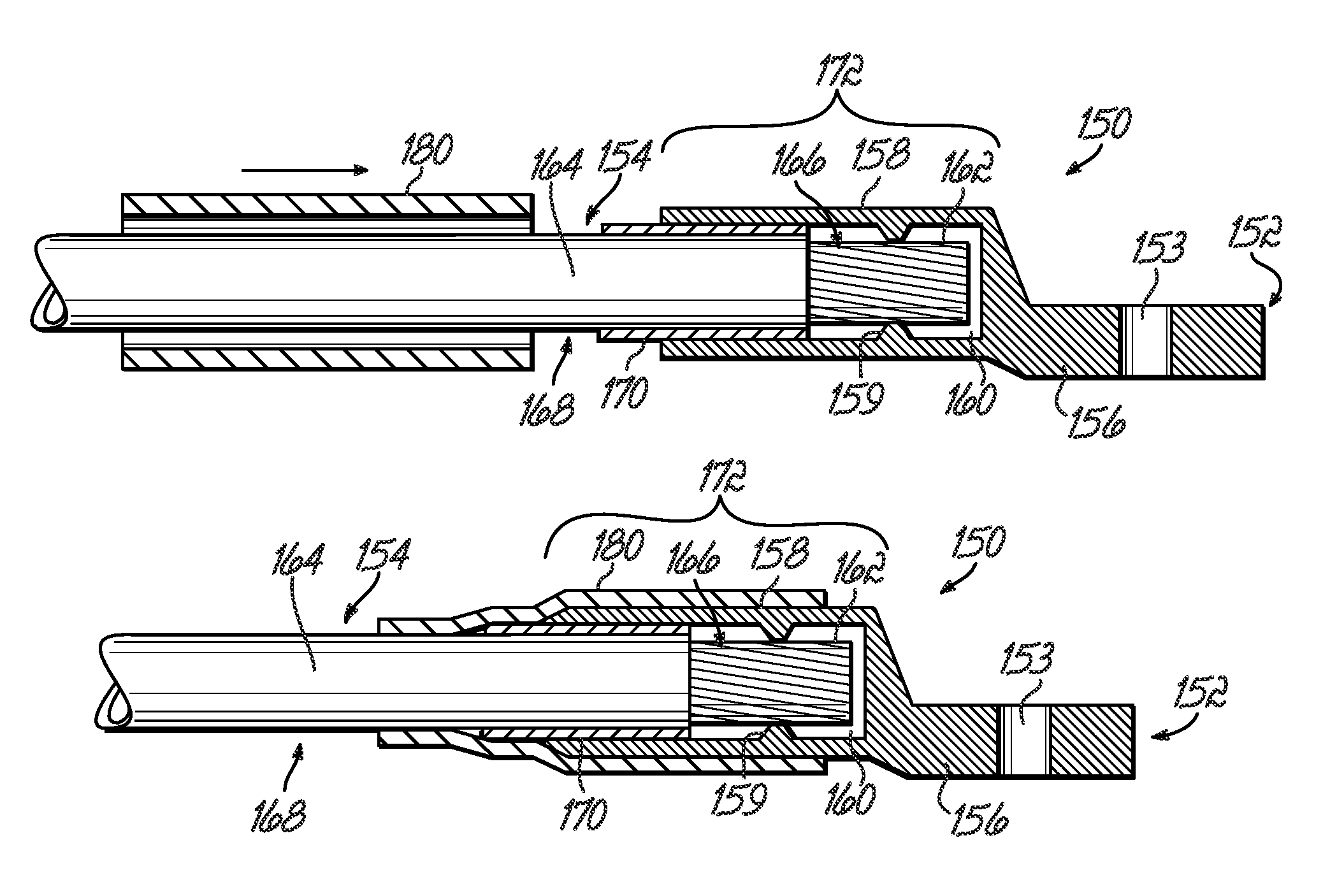

Lead connector, lead adapter, and lead insertion apparatus

InactiveUS7539542B1Minimizing IPG sizeSimple and quick procedureElectrotherapyCoupling device detailsMedical deviceBiomedical engineering

A connector and adapter engage leads with each other or with an implantable medical device when a wedge is removed from the spring-loaded connector or adapter assembly, thereby permitting the connector or adapter to compress around the lead connector. The connector and adapter assembly may include a body with at least one lumen, at least one contact exposed within the at least one lumen of the body, at least one wire electrically connected to the at least one contact, at least one clamp ring capable of compressing around the body, and at least one wedge or similar tool capable of opening and closing the at least one clamp ring.

Owner:BOSTON SCI NEUROMODULATION CORP

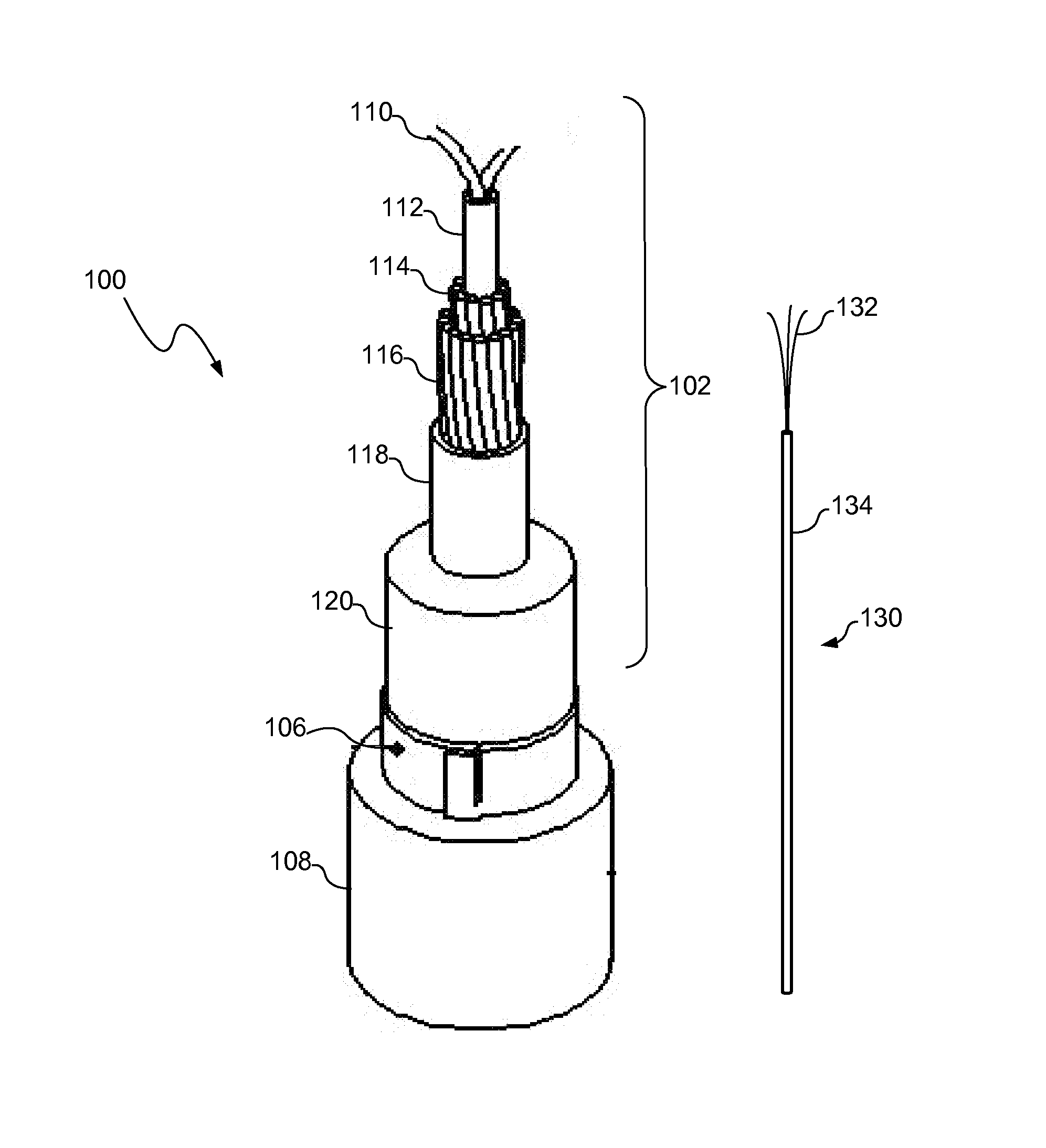

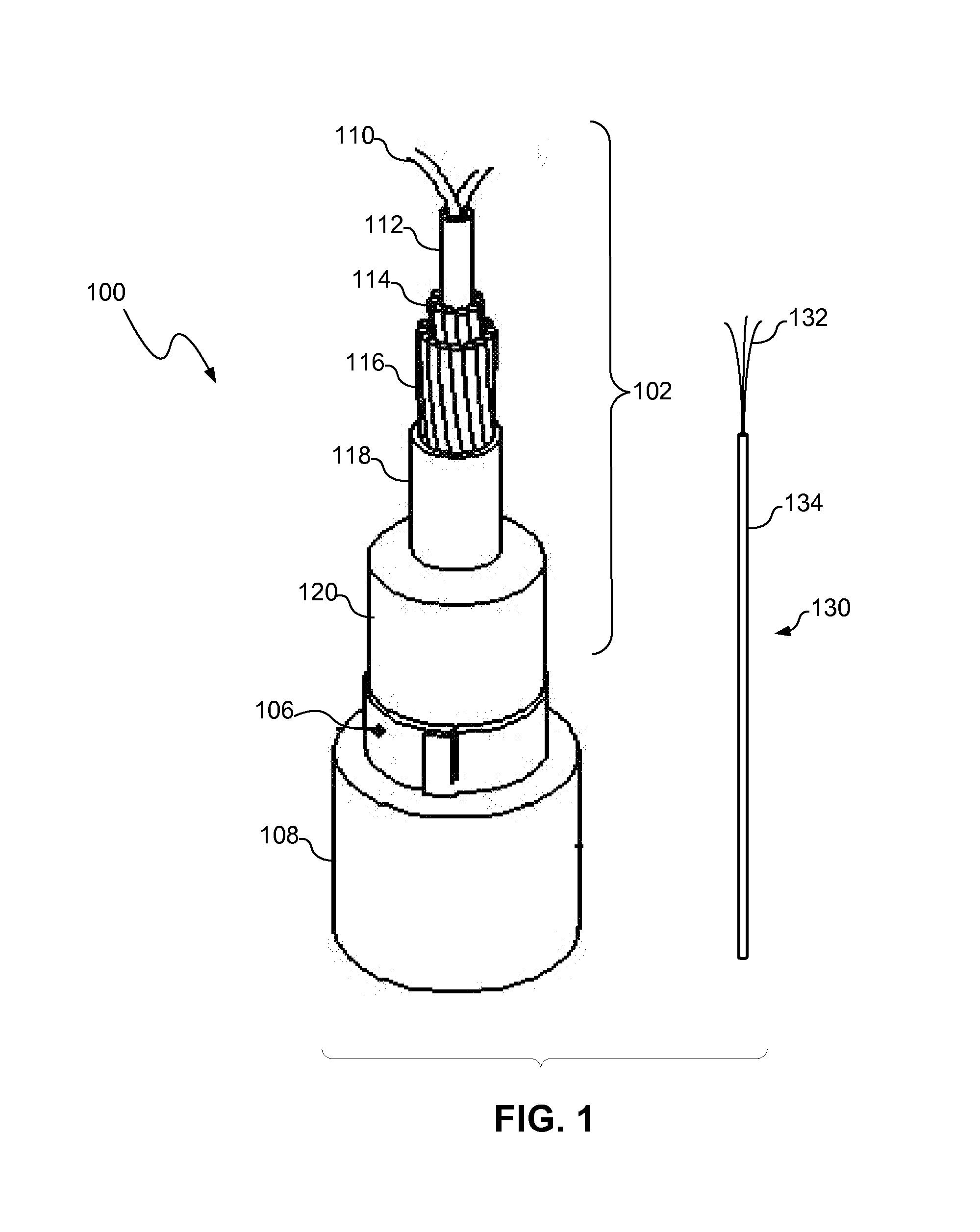

Optical cable shield layer connection

ActiveUS20070269169A1Coupling device detailsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectricityUniversal joint

An optical cable shield layer connection may include a wire electrically connected to a shield layer of an optical cable. The optical cable shield layer connection may also be sealed, for example, to prevent leak paths. The optical cable shield layer connection may be made when coupling the optical cable to a device or another cable, for example, using a universal joint such as the Millennia® Joint available from Tyco Telecommunications (US) Inc. The wire may provide a ground path from the shield layer or a continuity path from the shield layer to another optical cable.

Owner:SUBCOM LLC

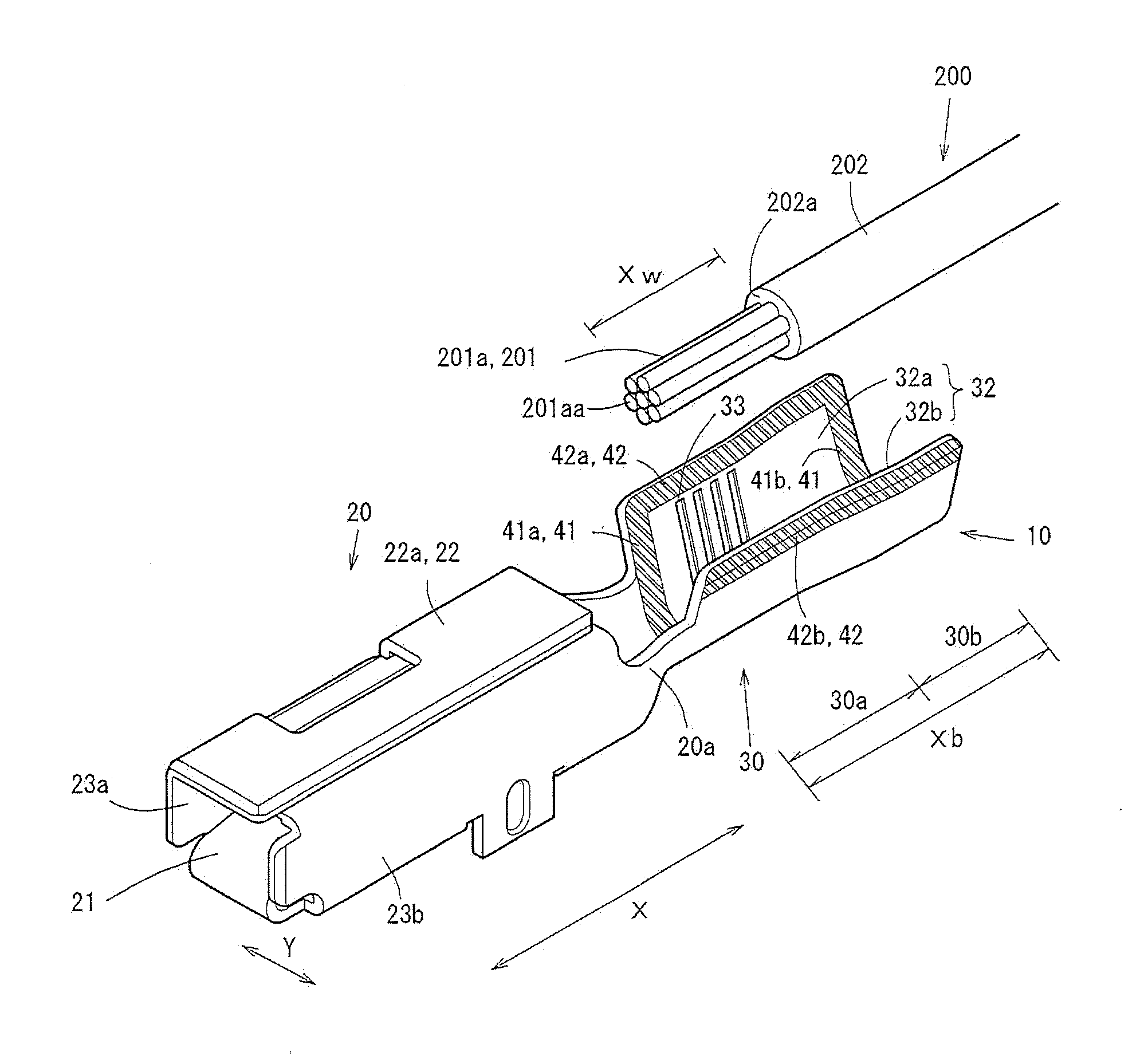

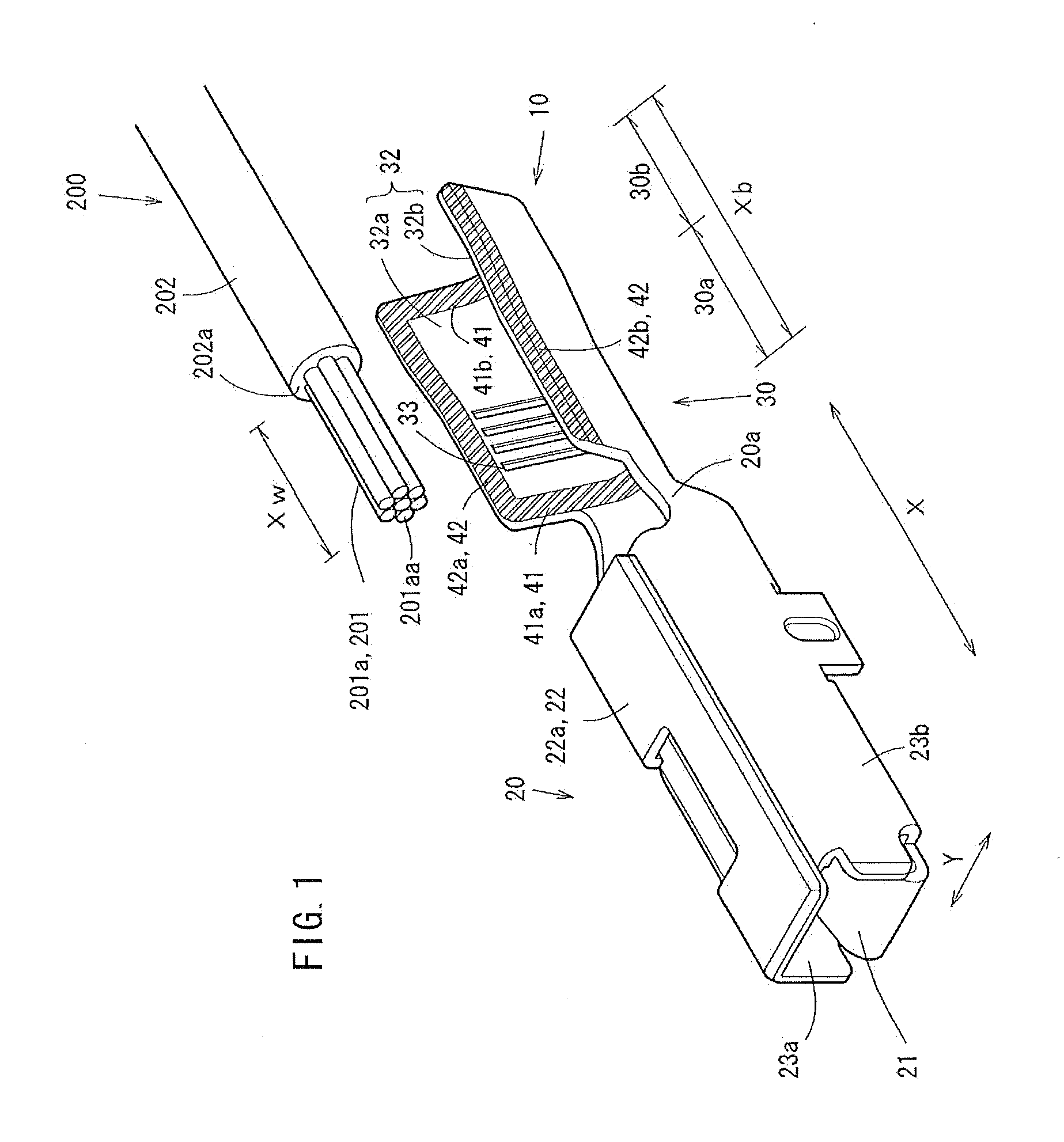

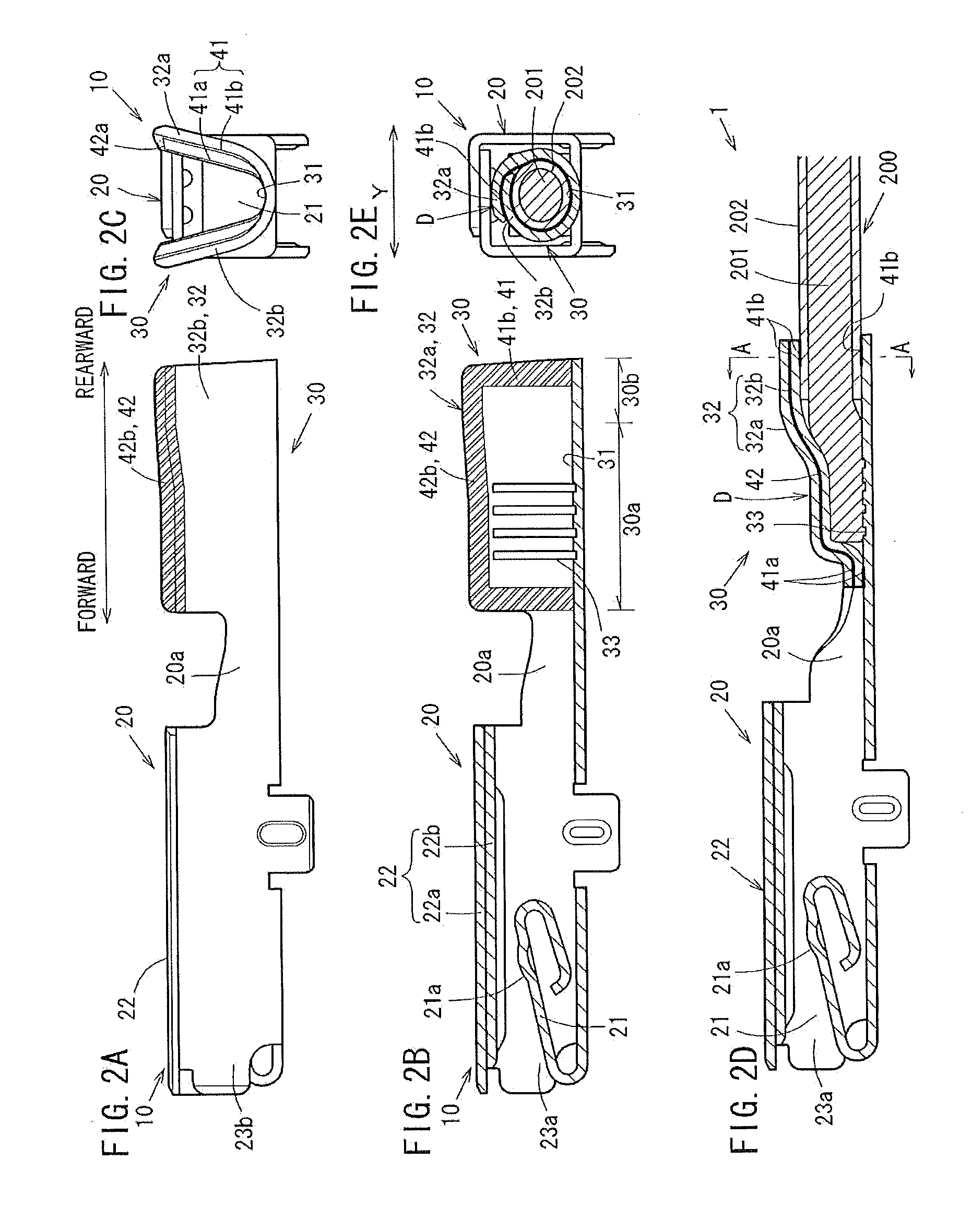

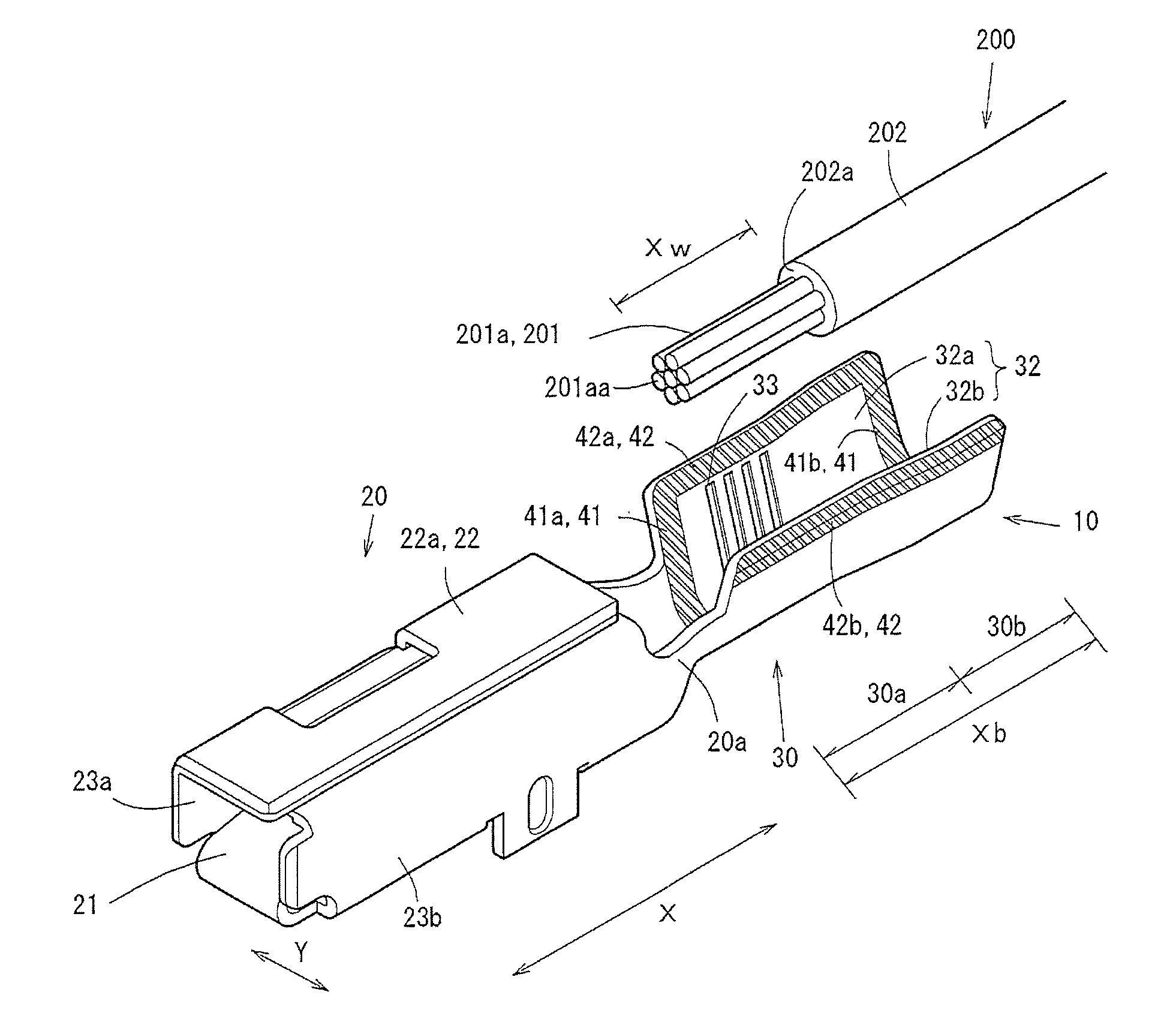

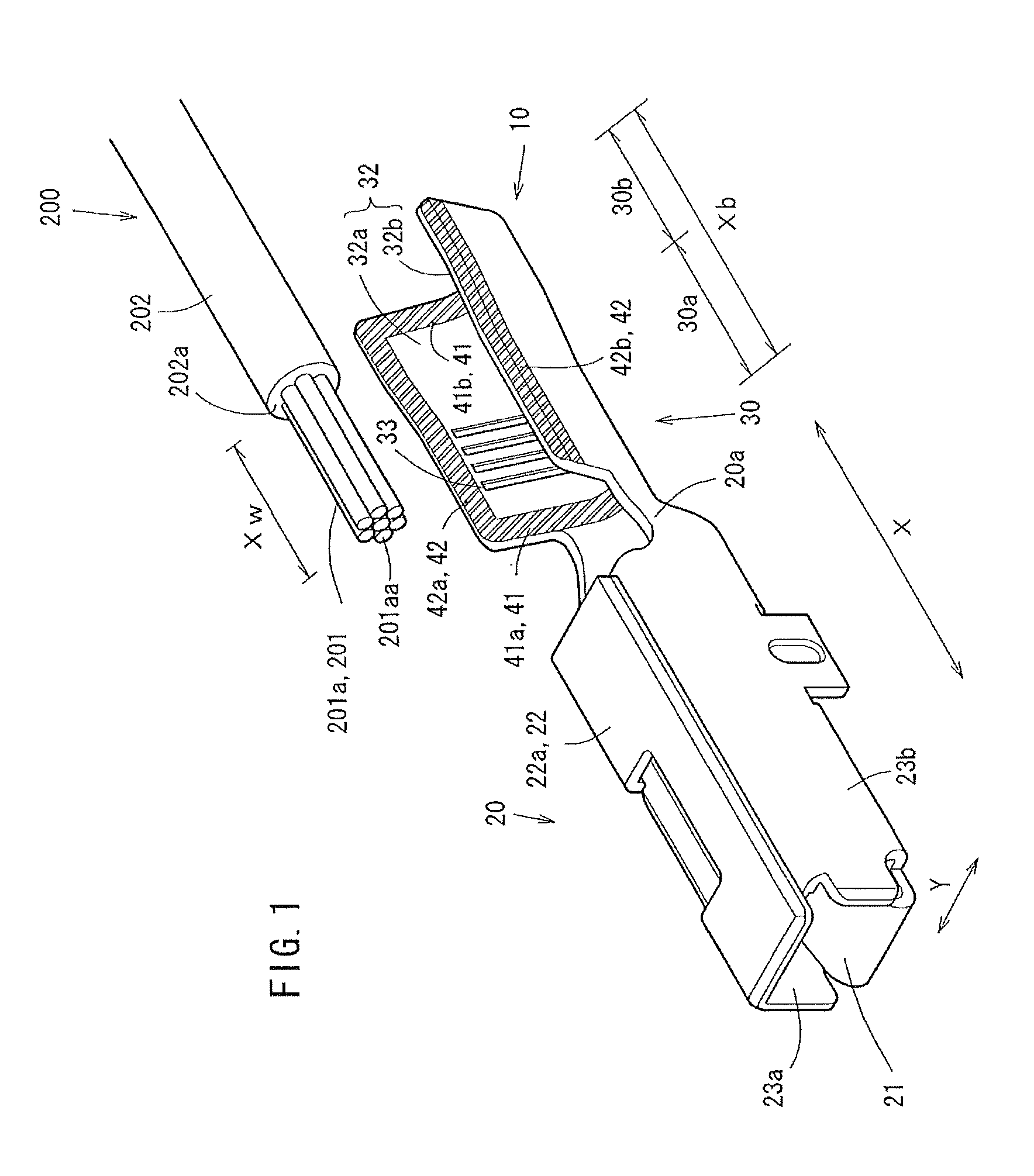

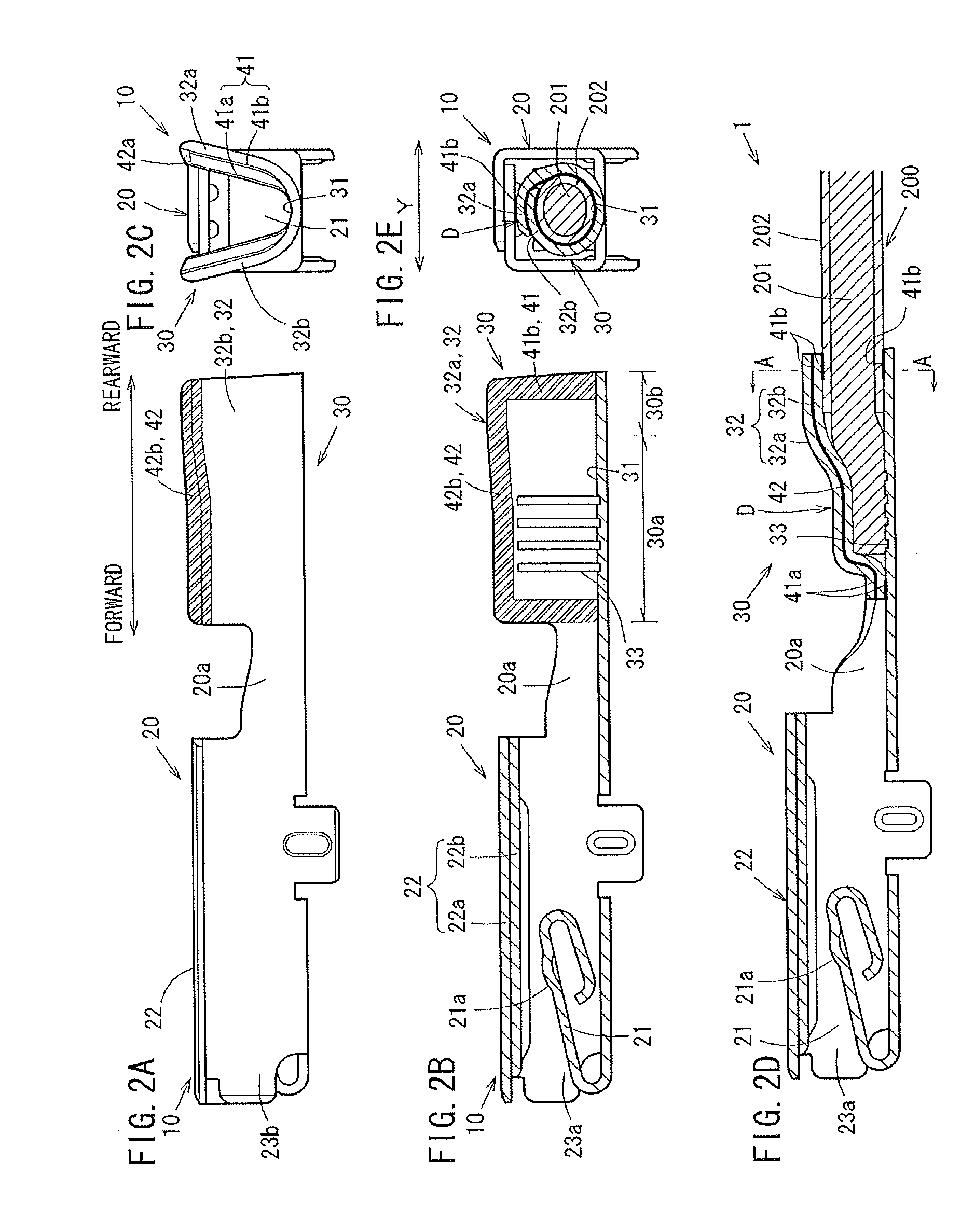

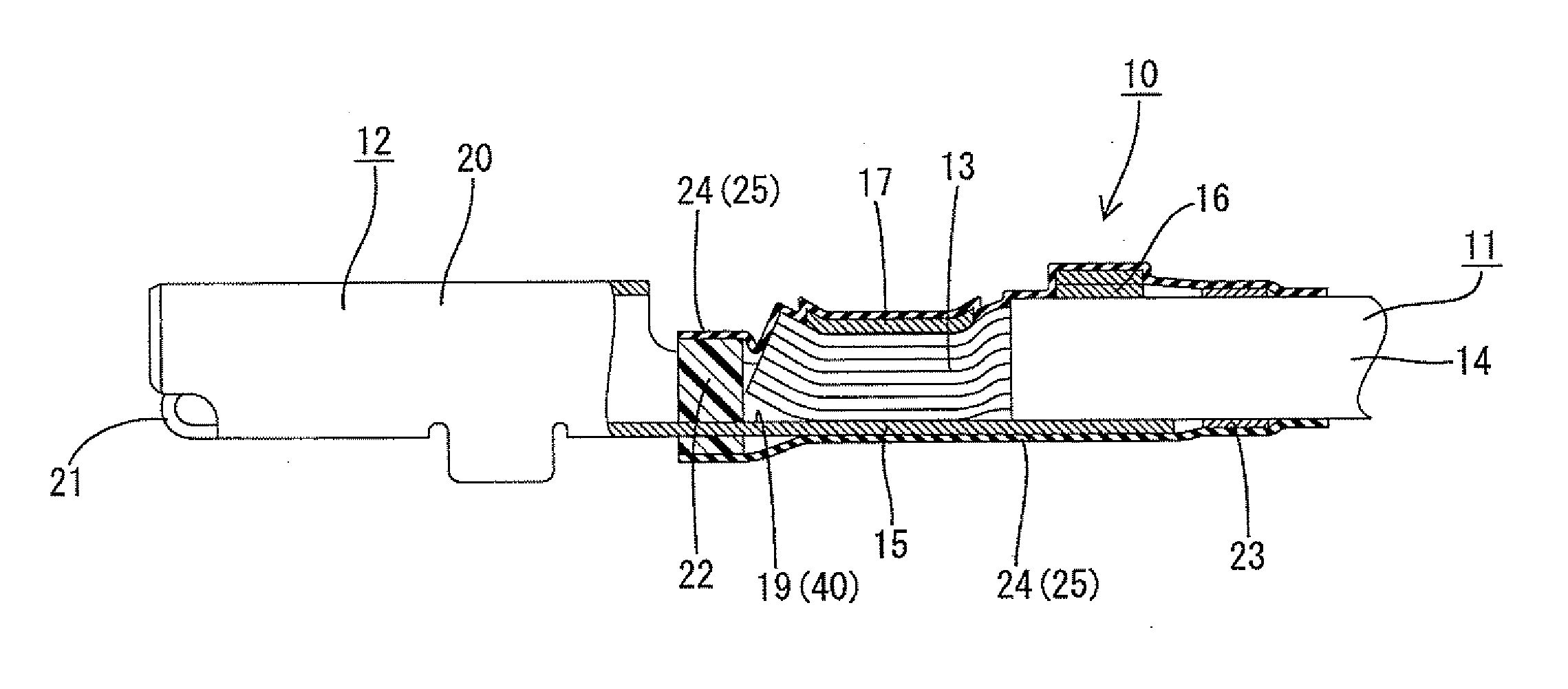

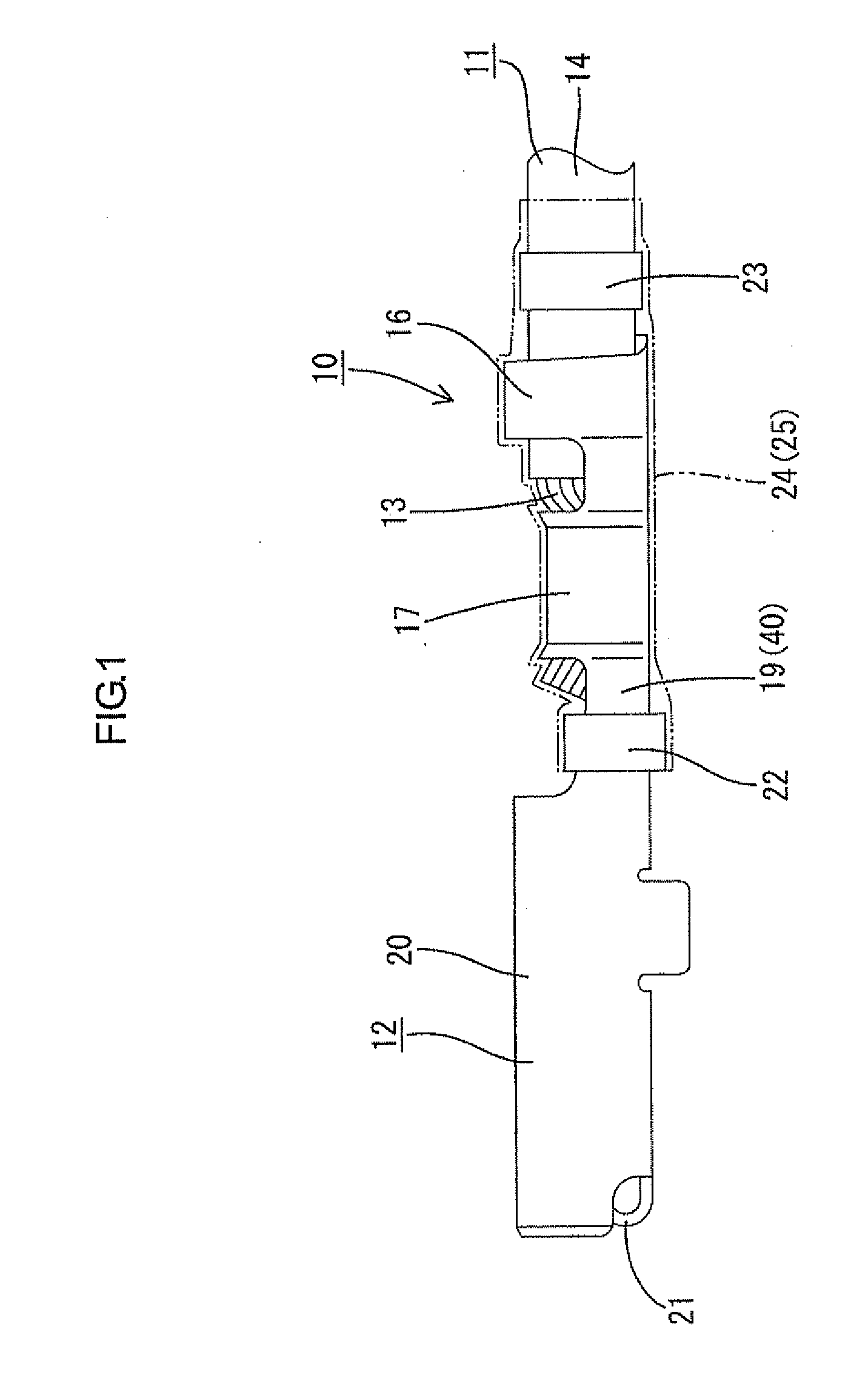

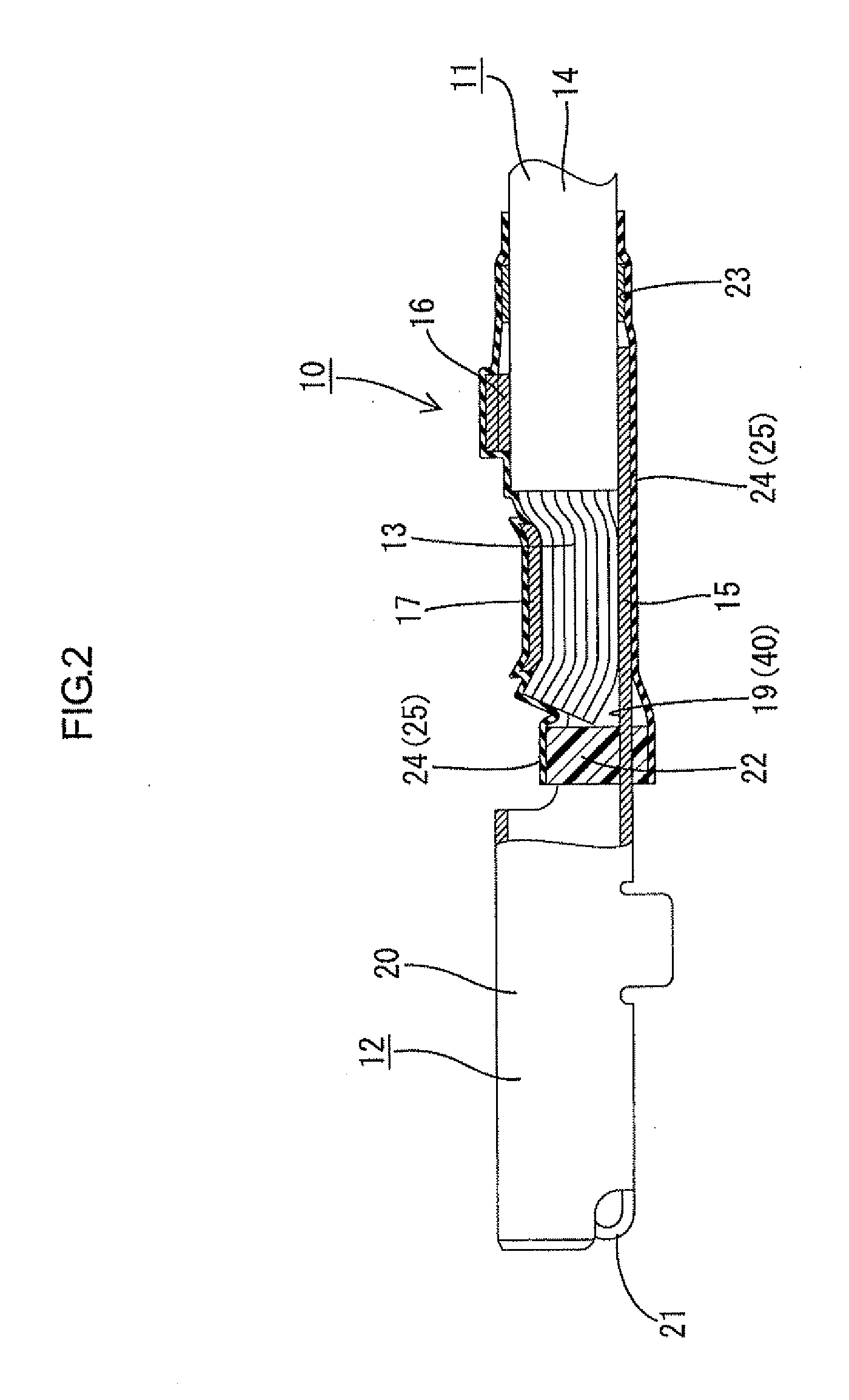

Crimp terminal, connection structural body and connector

ActiveUS20130095708A1Vehicle connectorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical conductorEngineering

A crimp terminal includes barrel pieces respectively on both of two sides in a width direction thereof. The barrel pieces are included in a pressure-bonding section for pressure-bonding an exposed part of an electric wire conductor of an insulated wire. The insulated wire includes the electric wire conductor and an insulating cover for covering an outer circumference of the electric wire conductor, and the exposed part is a part of the electric wire conductor which is exposed from a tip of the cover by a predetermined length. The barrel pieces have a length in a longitudinal direction which is longer than the length of the exposed part of the electric wire conductor. The pressure-bonding section pressure-bonds, by the barrel pieces, a continuous part from a tip of the electric wire conductor to a position rear to the tip of the cover.

Owner:FURUKAWA ELECTRIC CO LTD +1

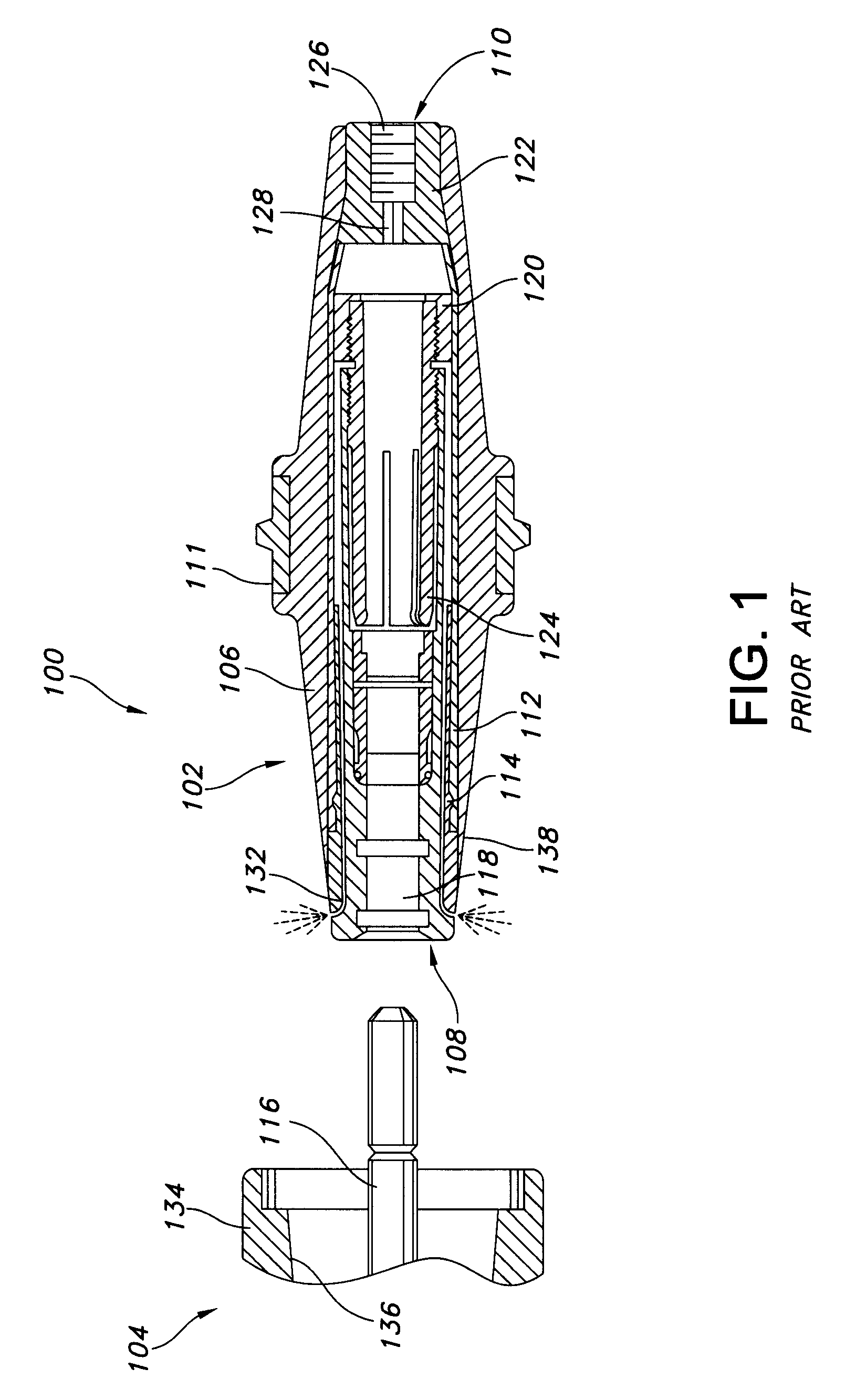

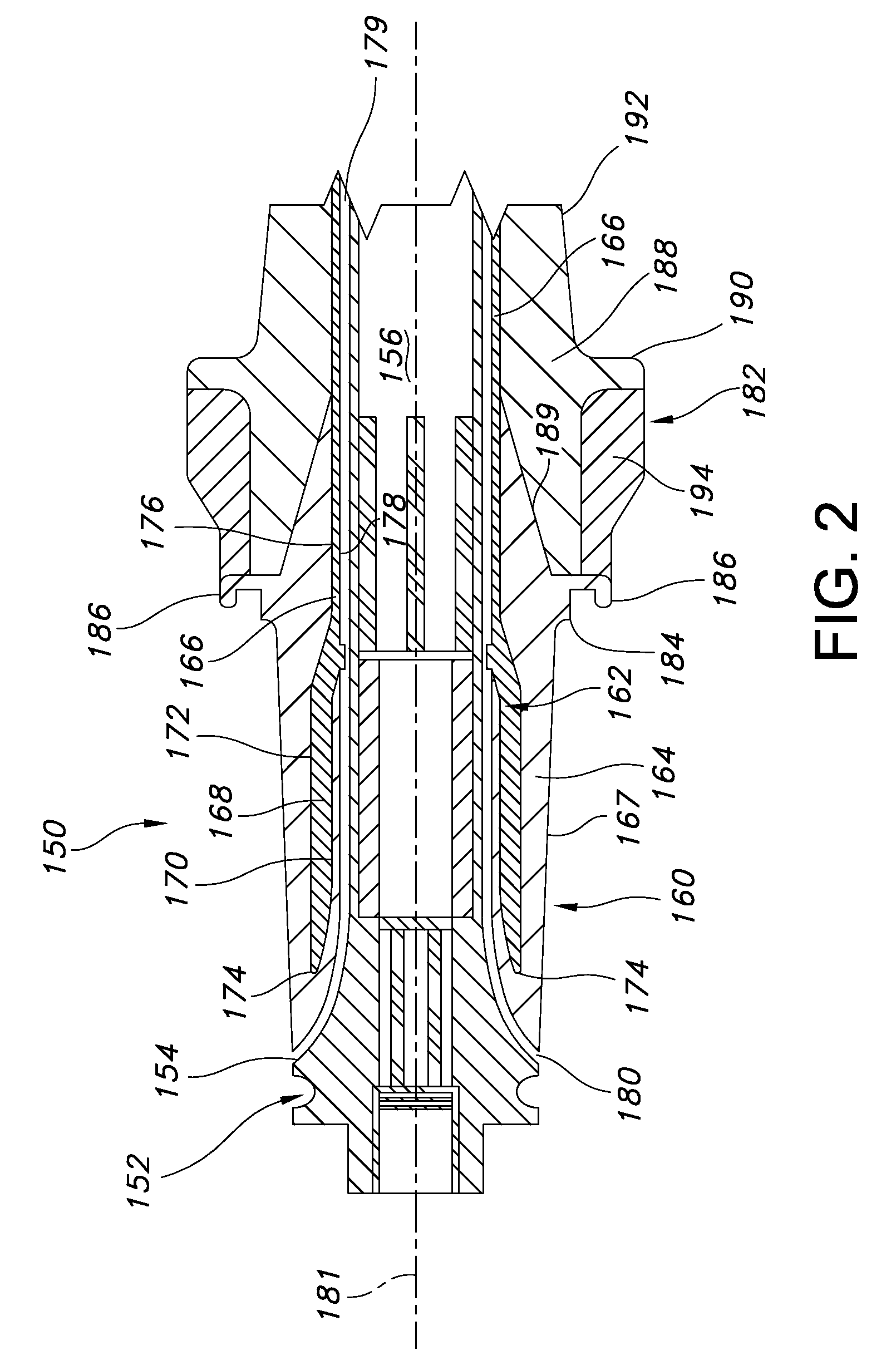

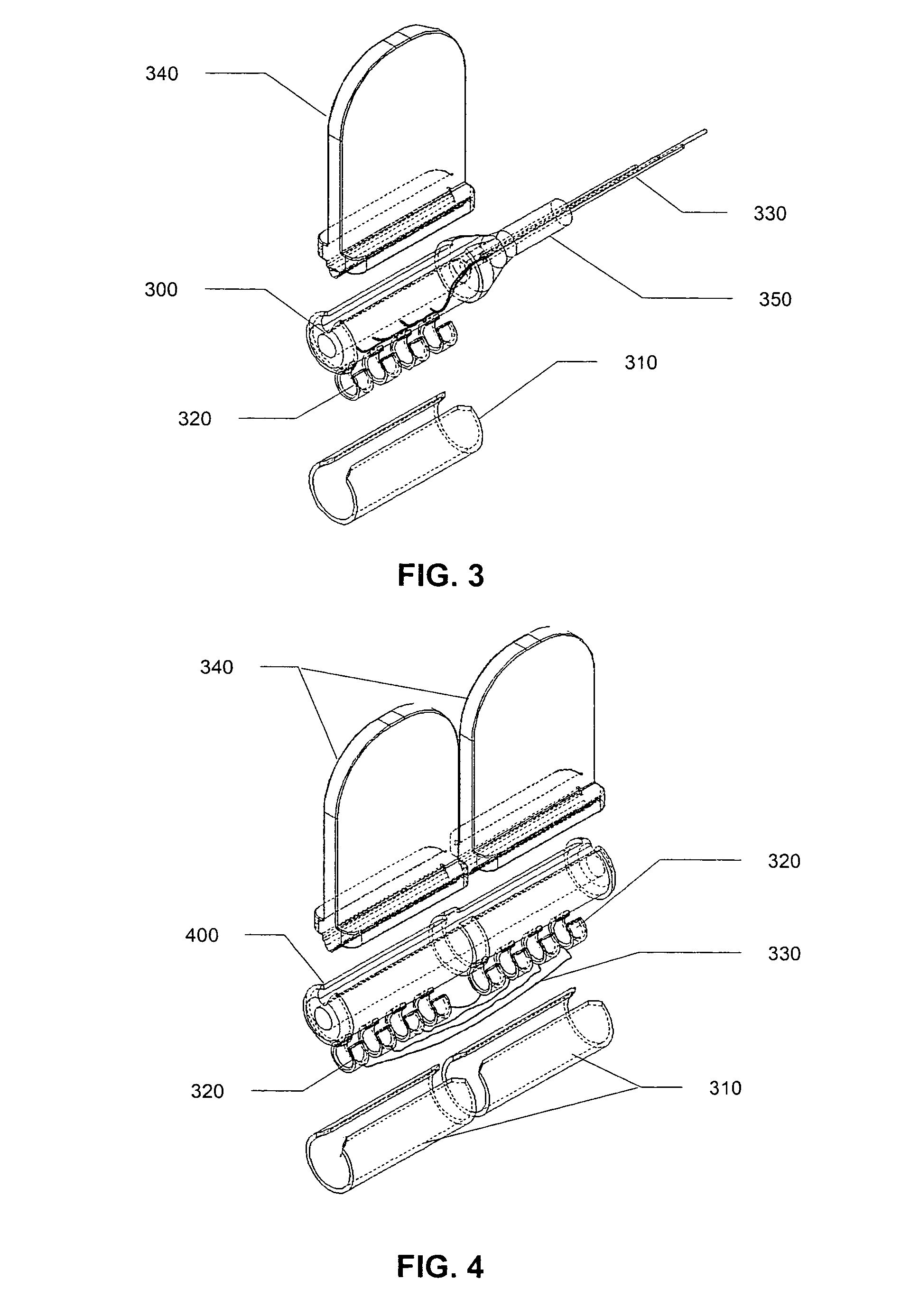

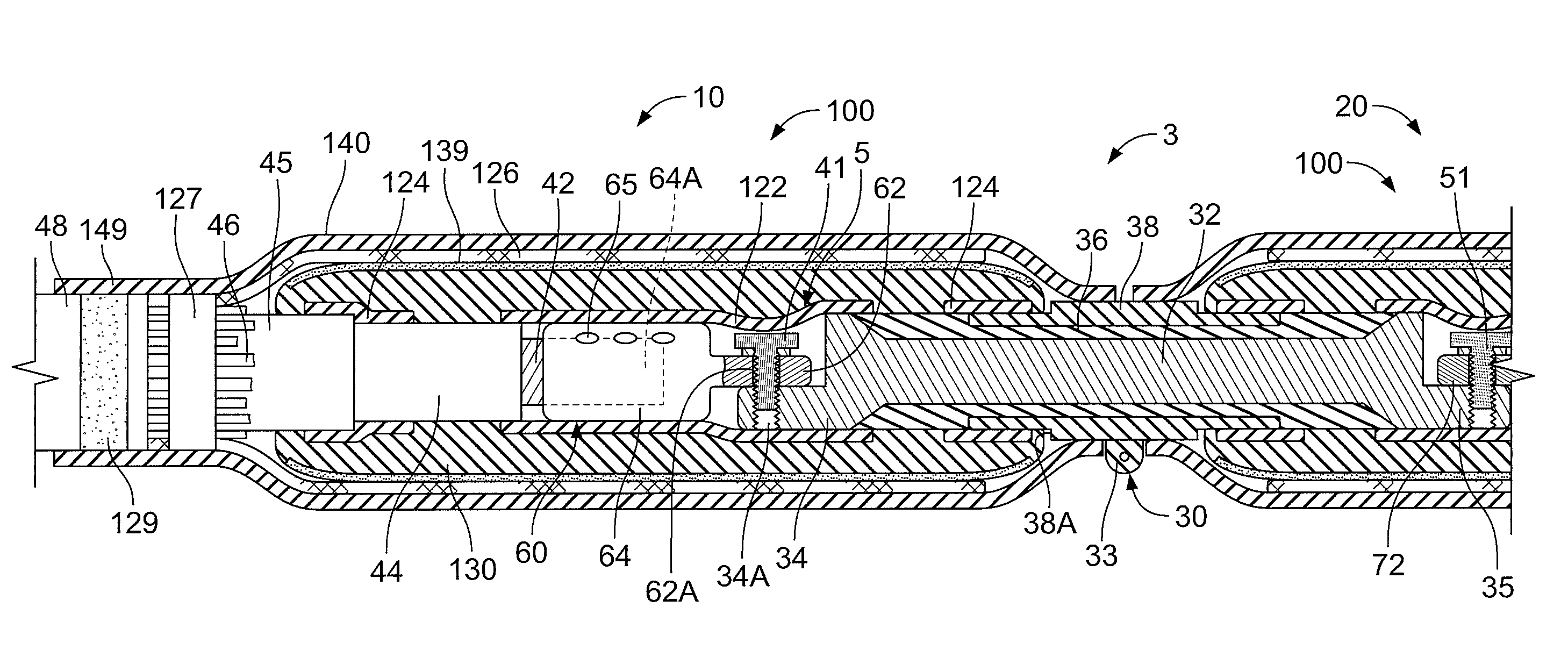

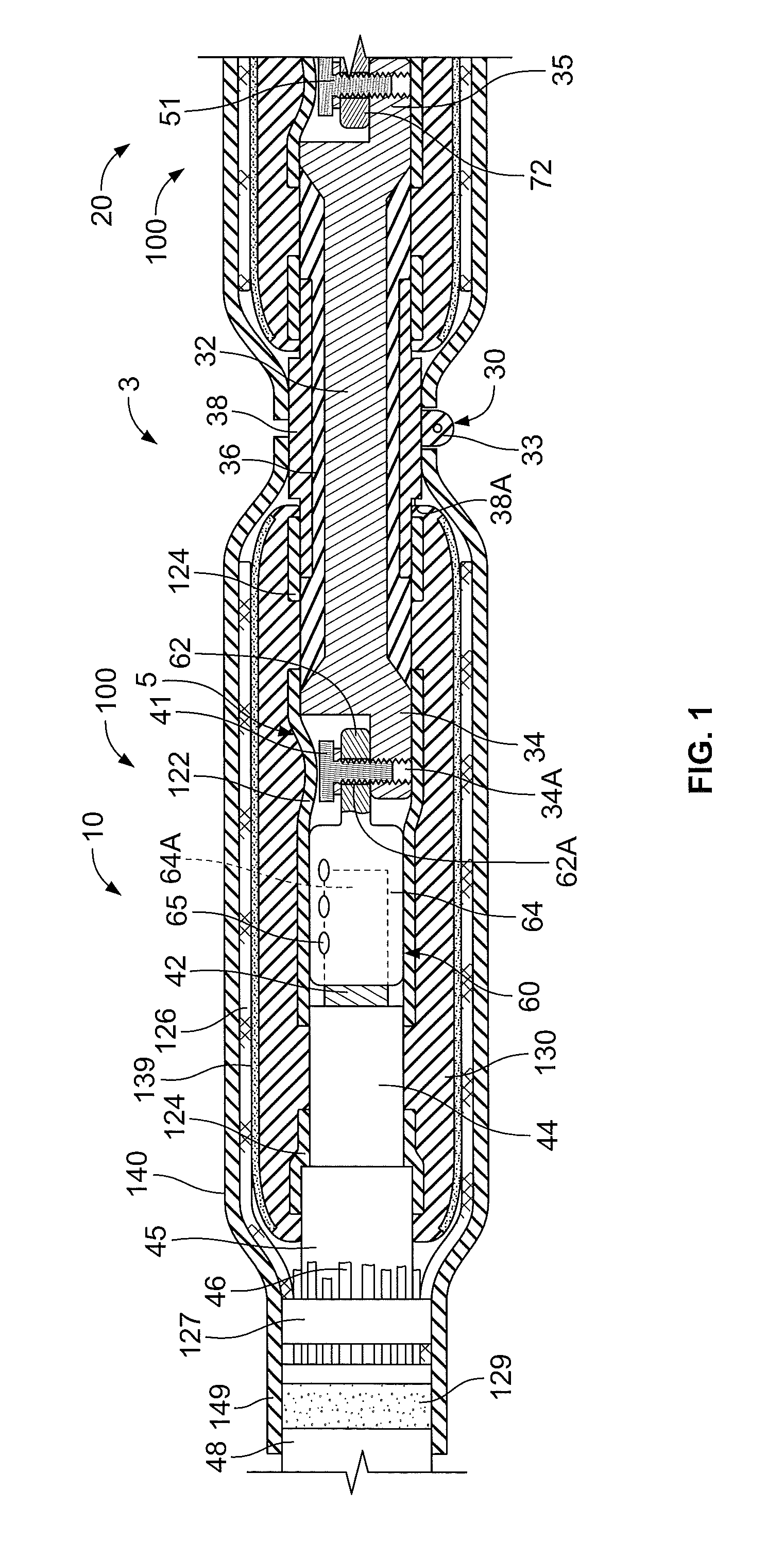

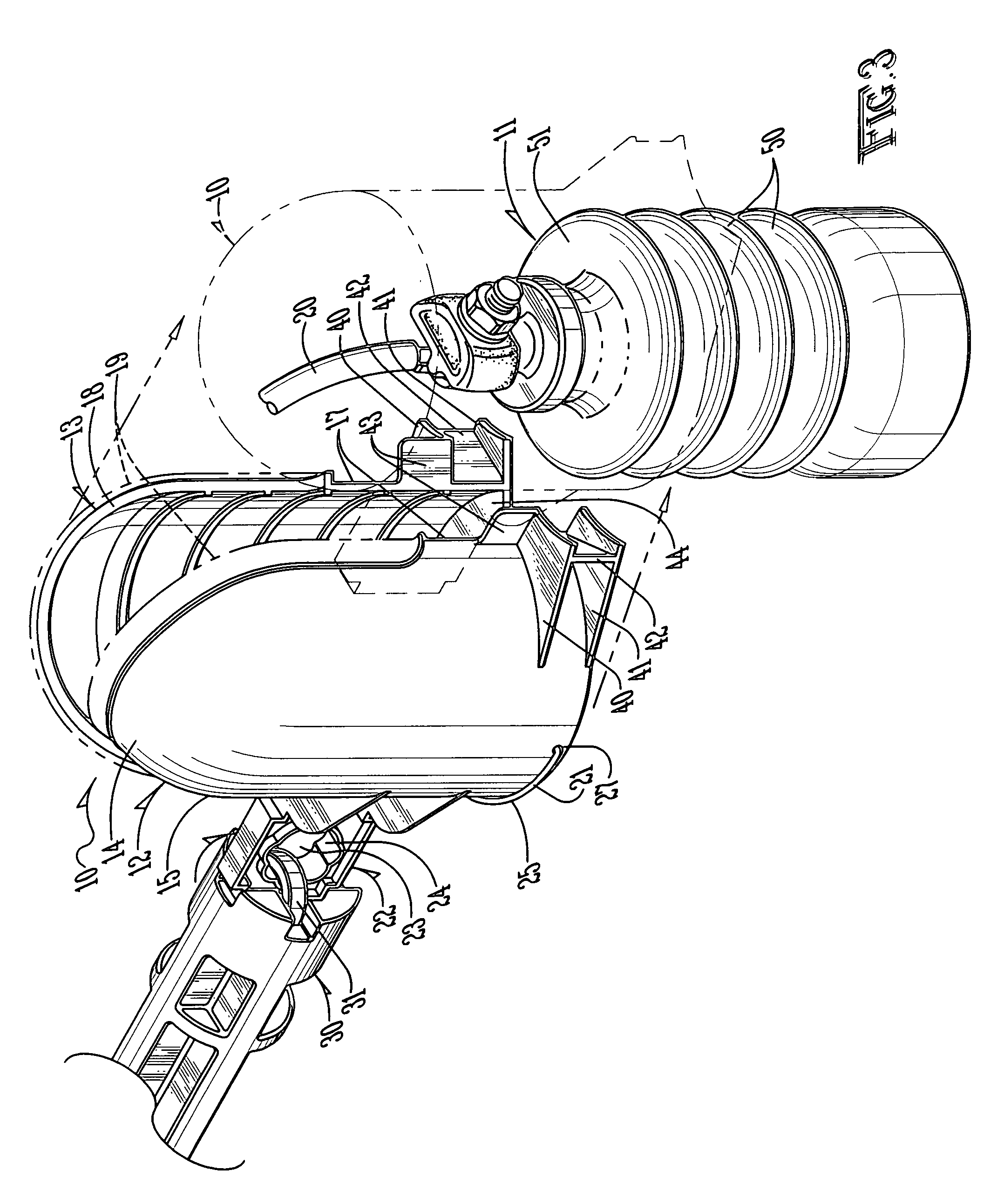

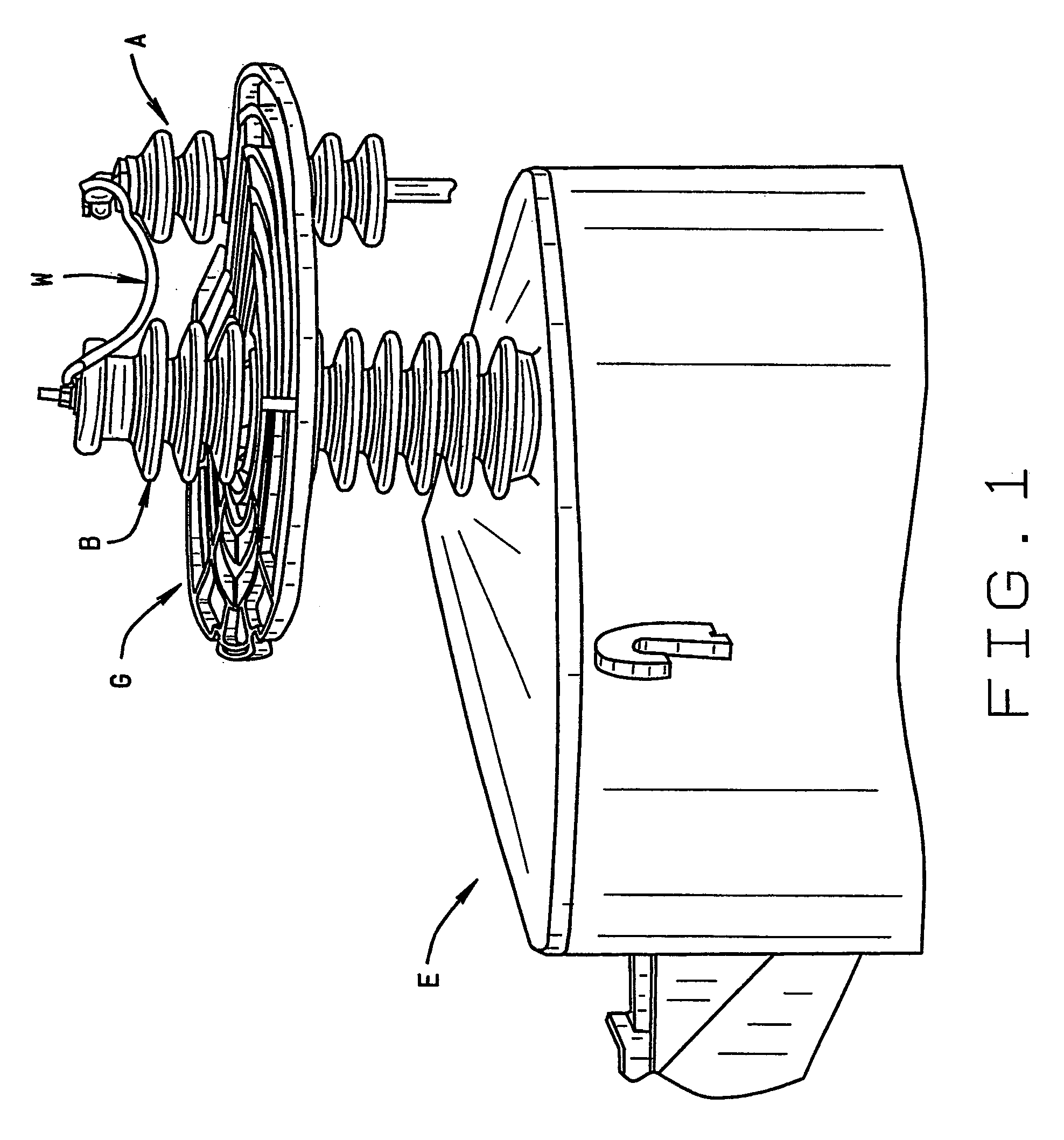

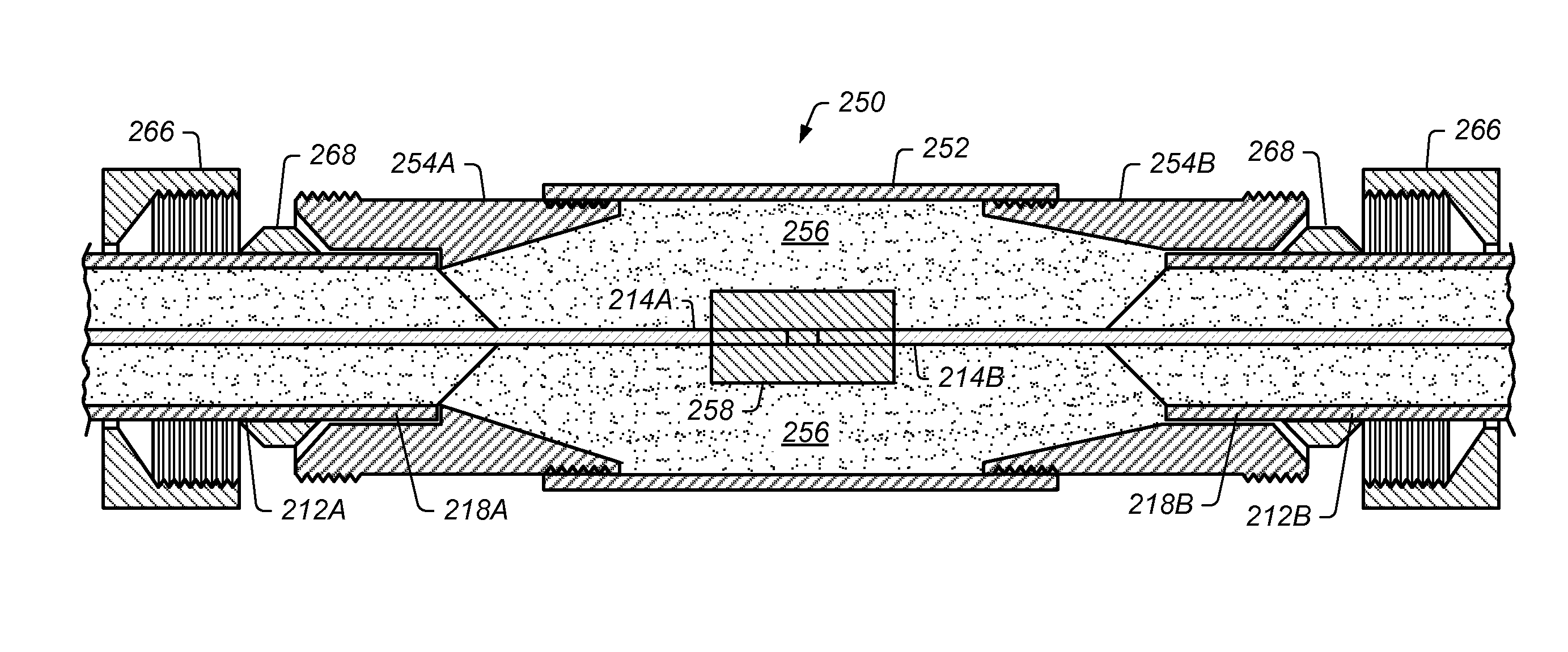

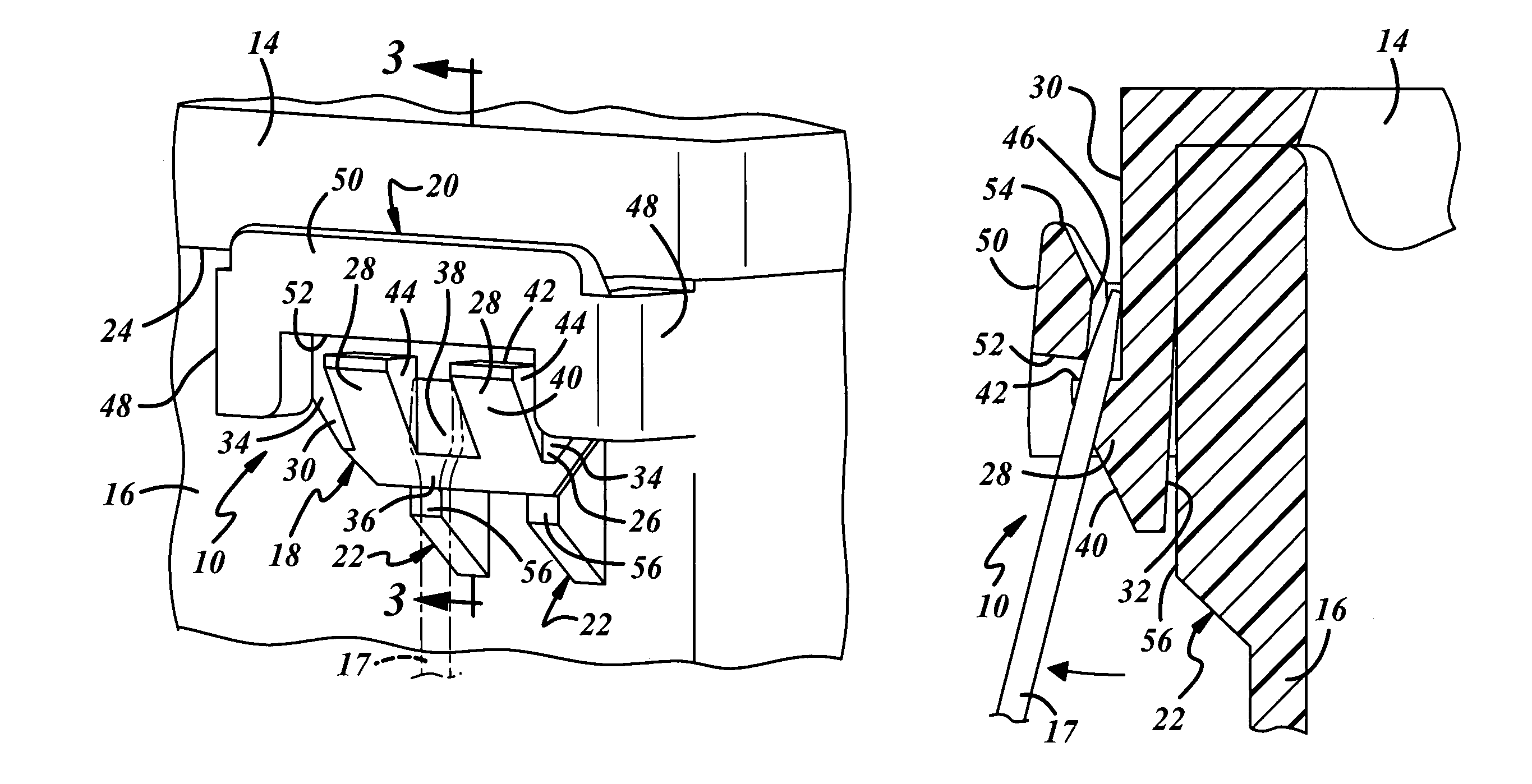

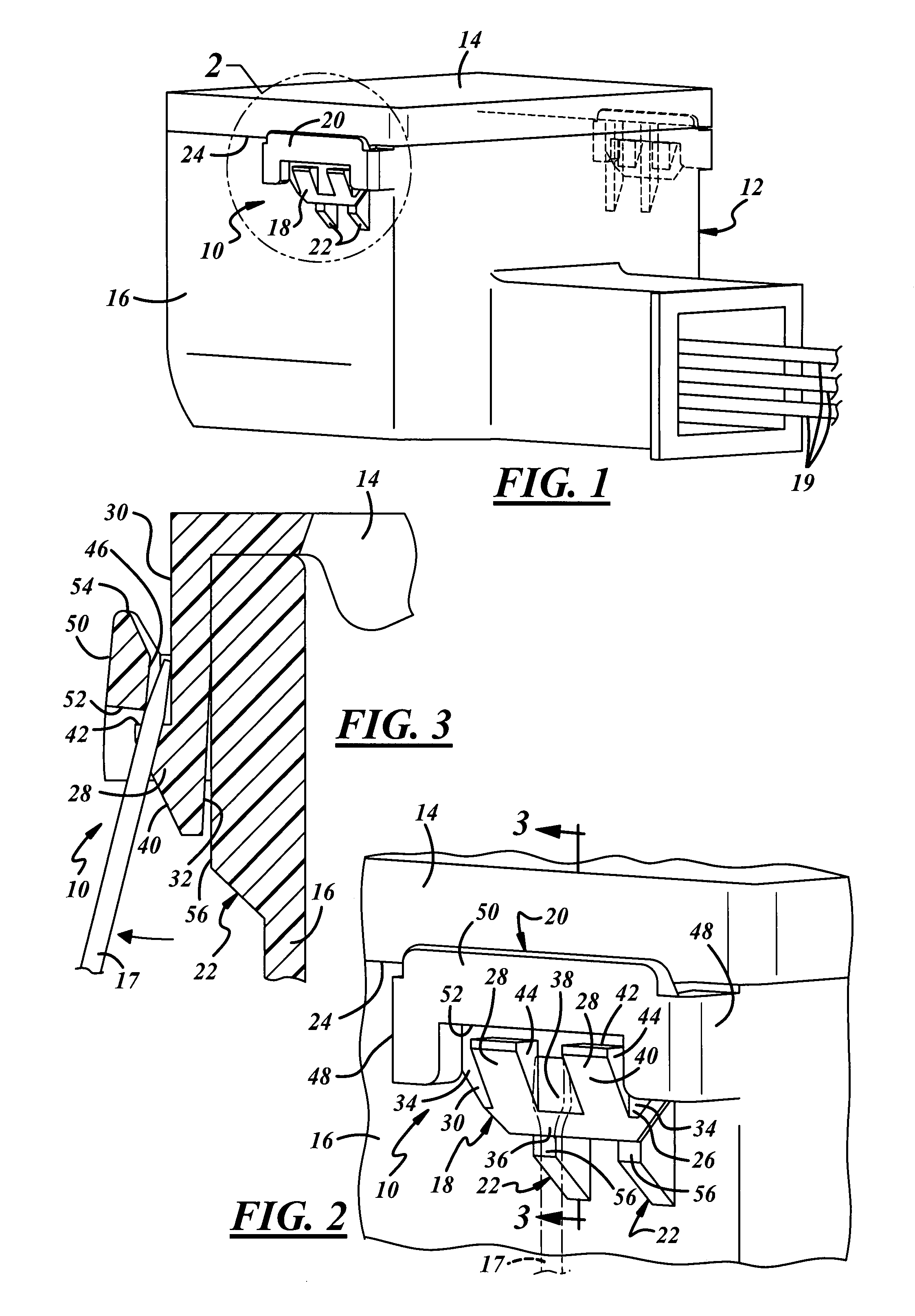

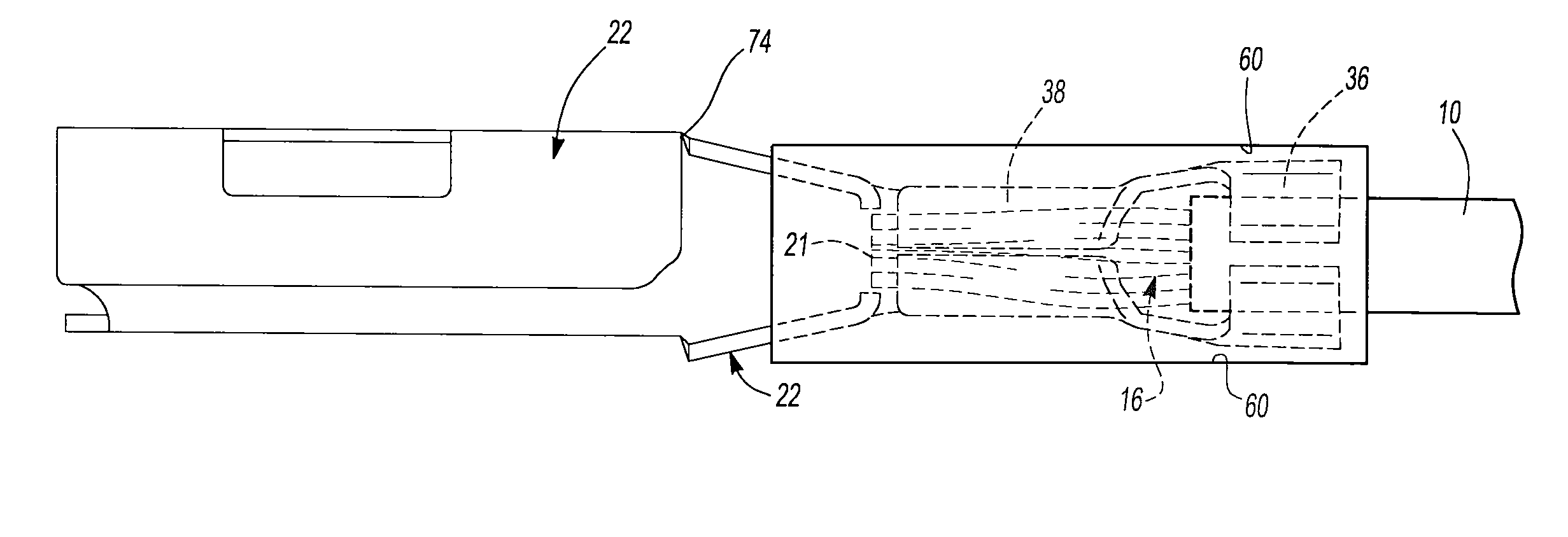

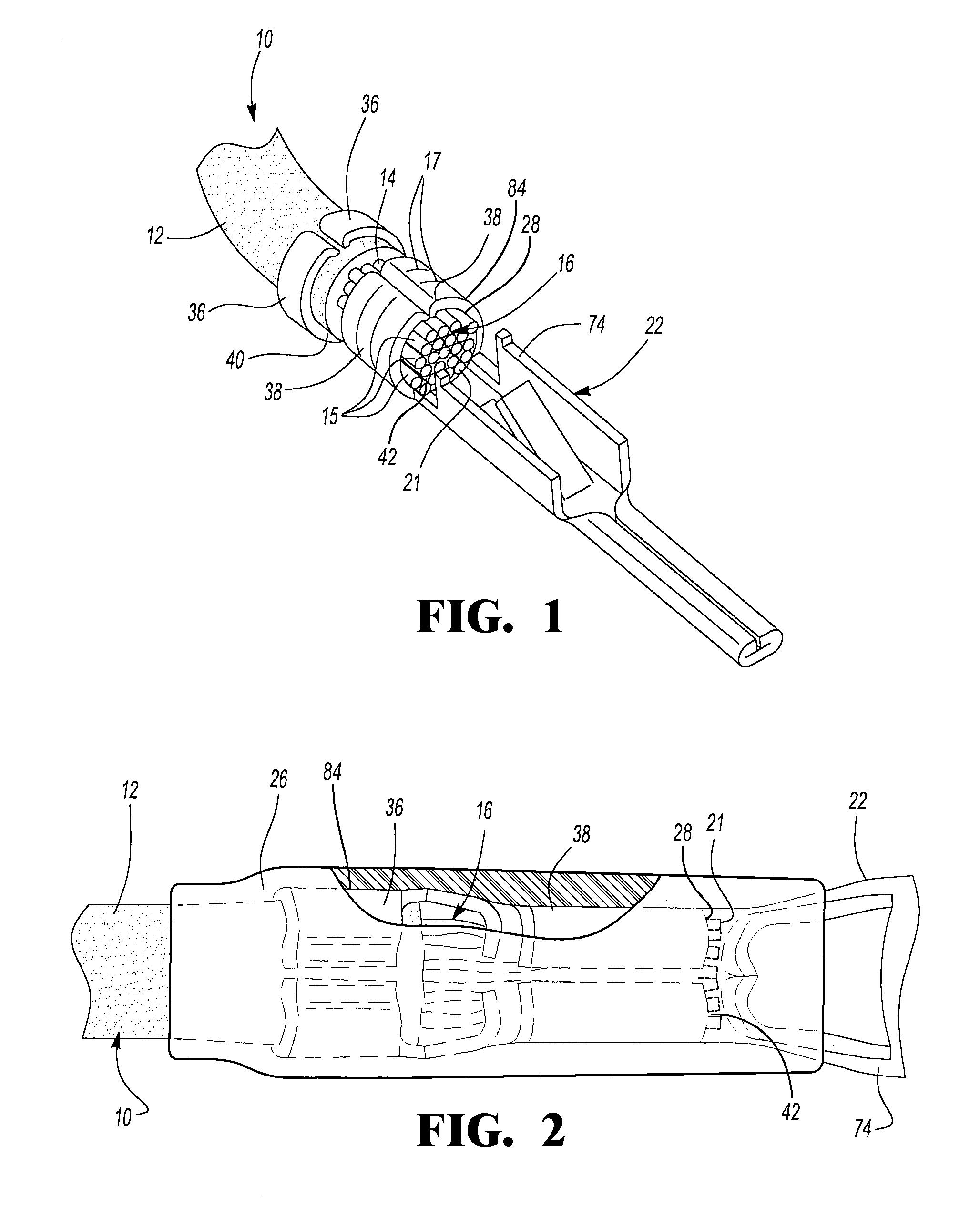

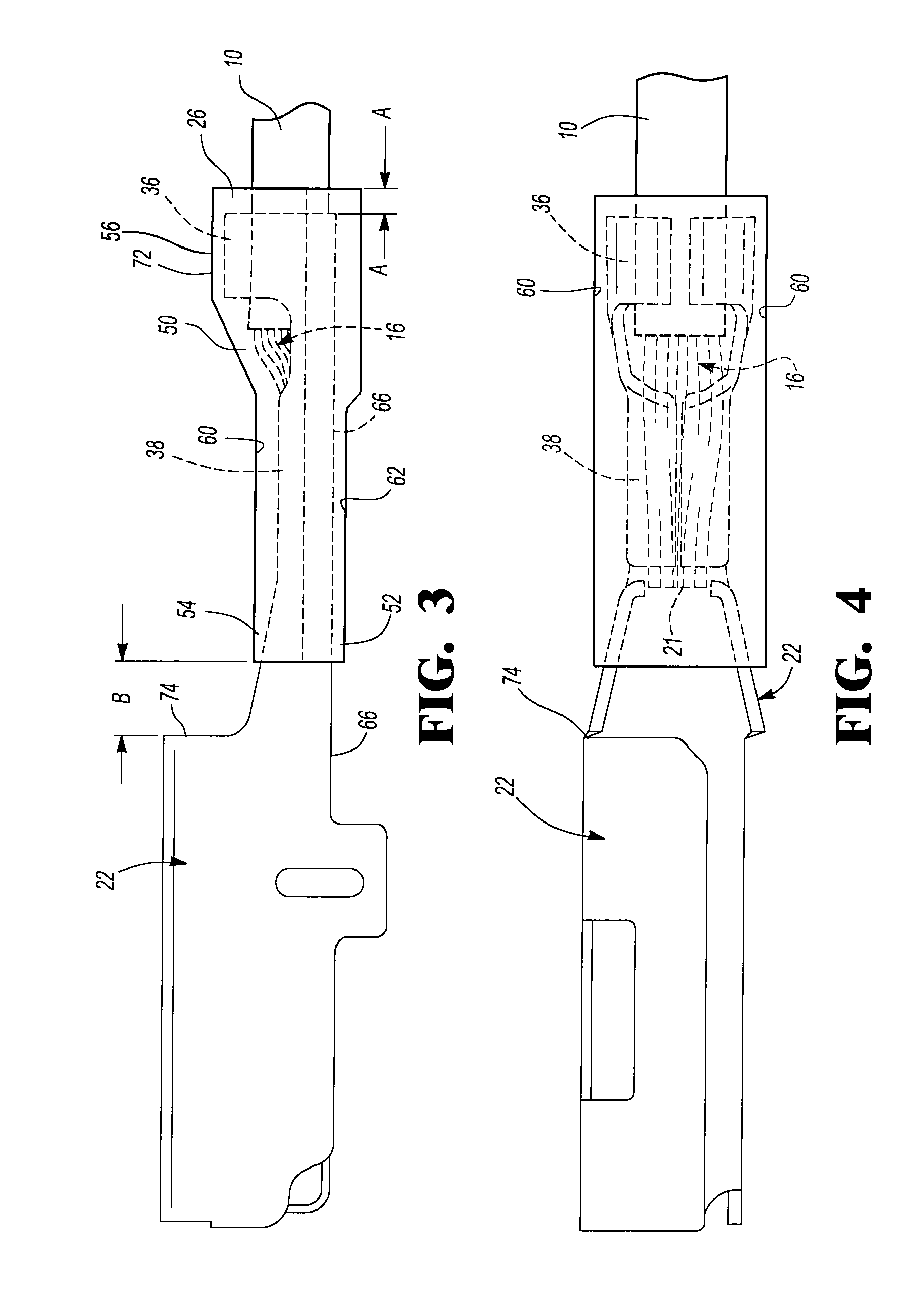

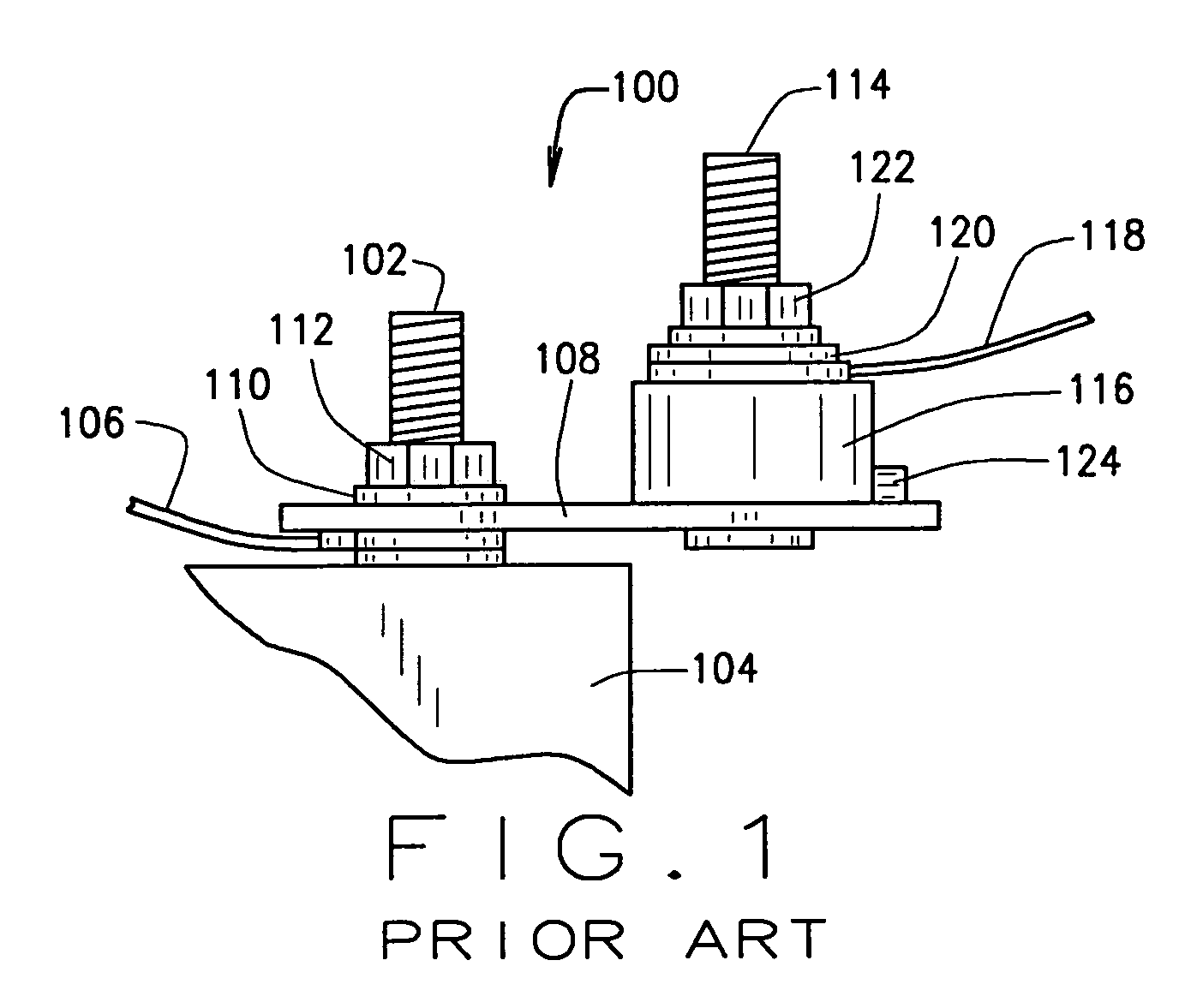

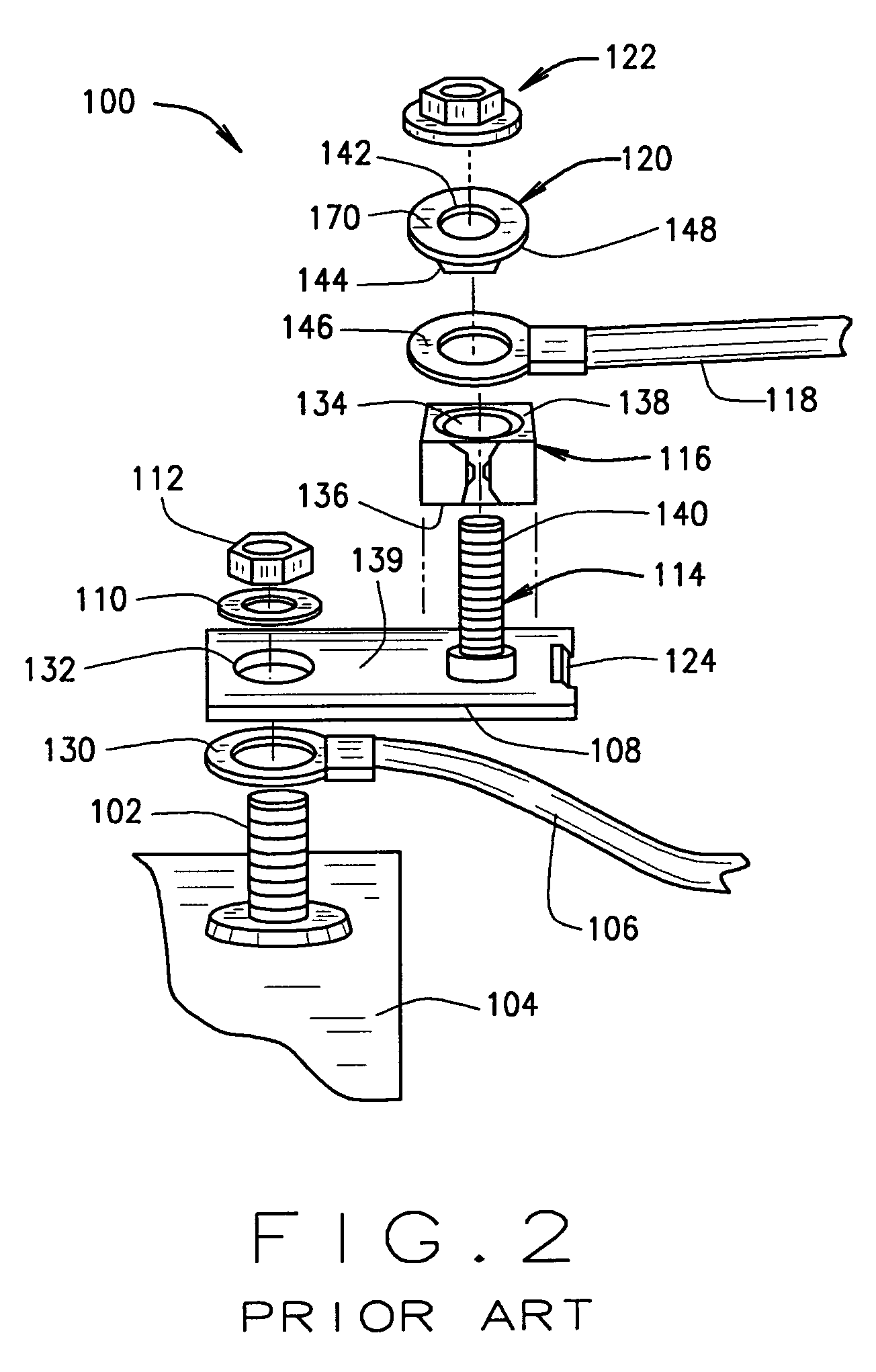

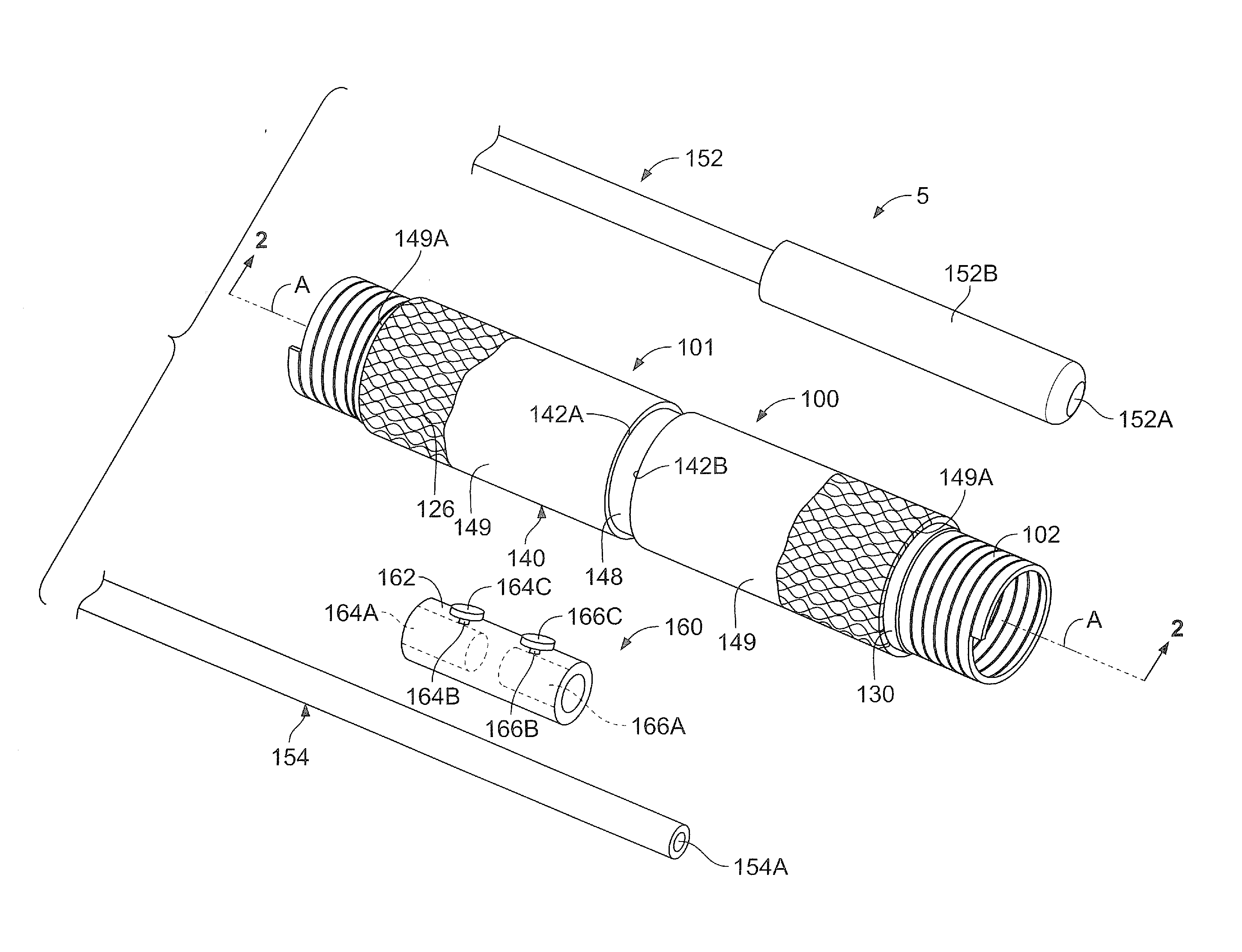

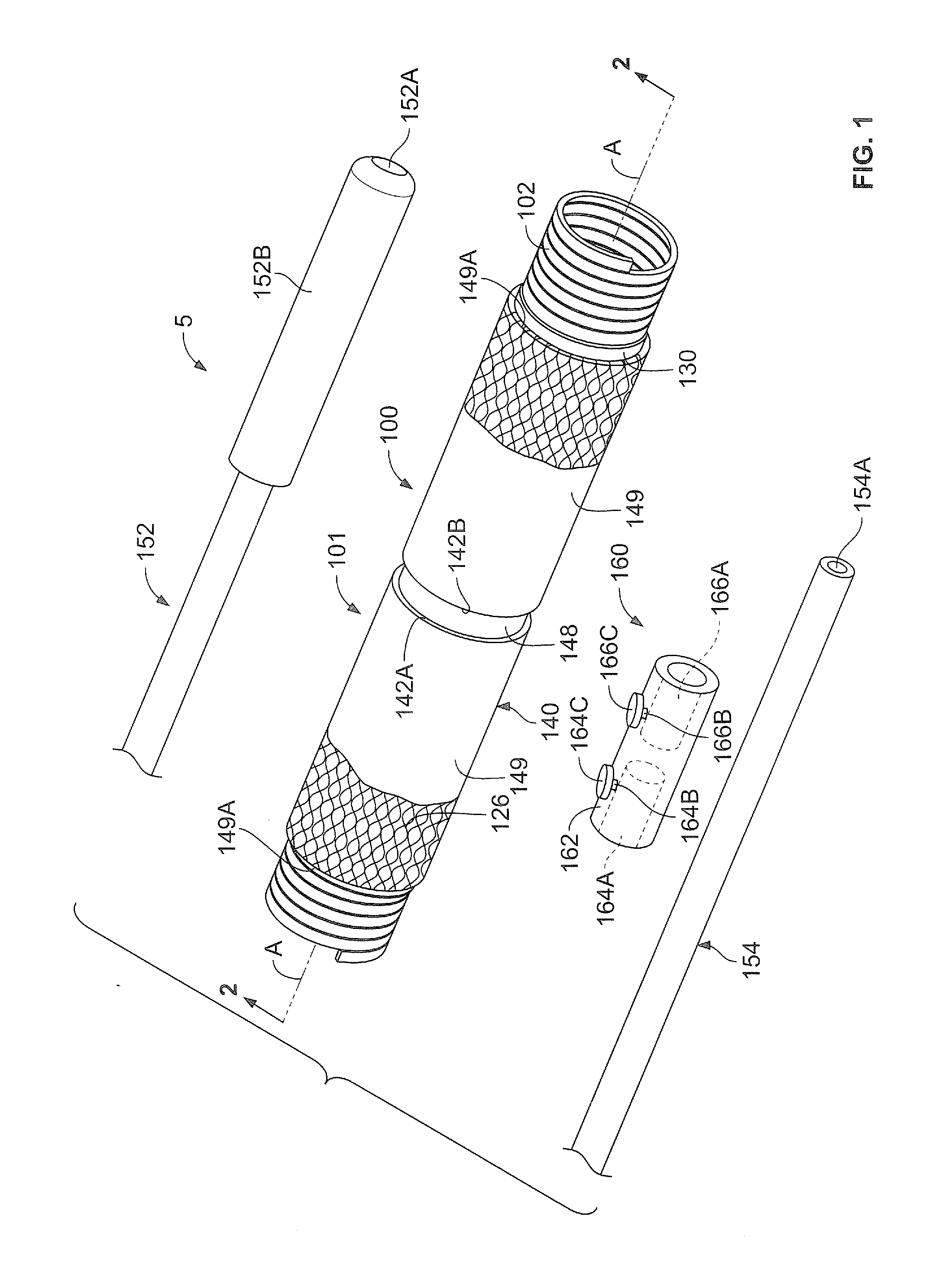

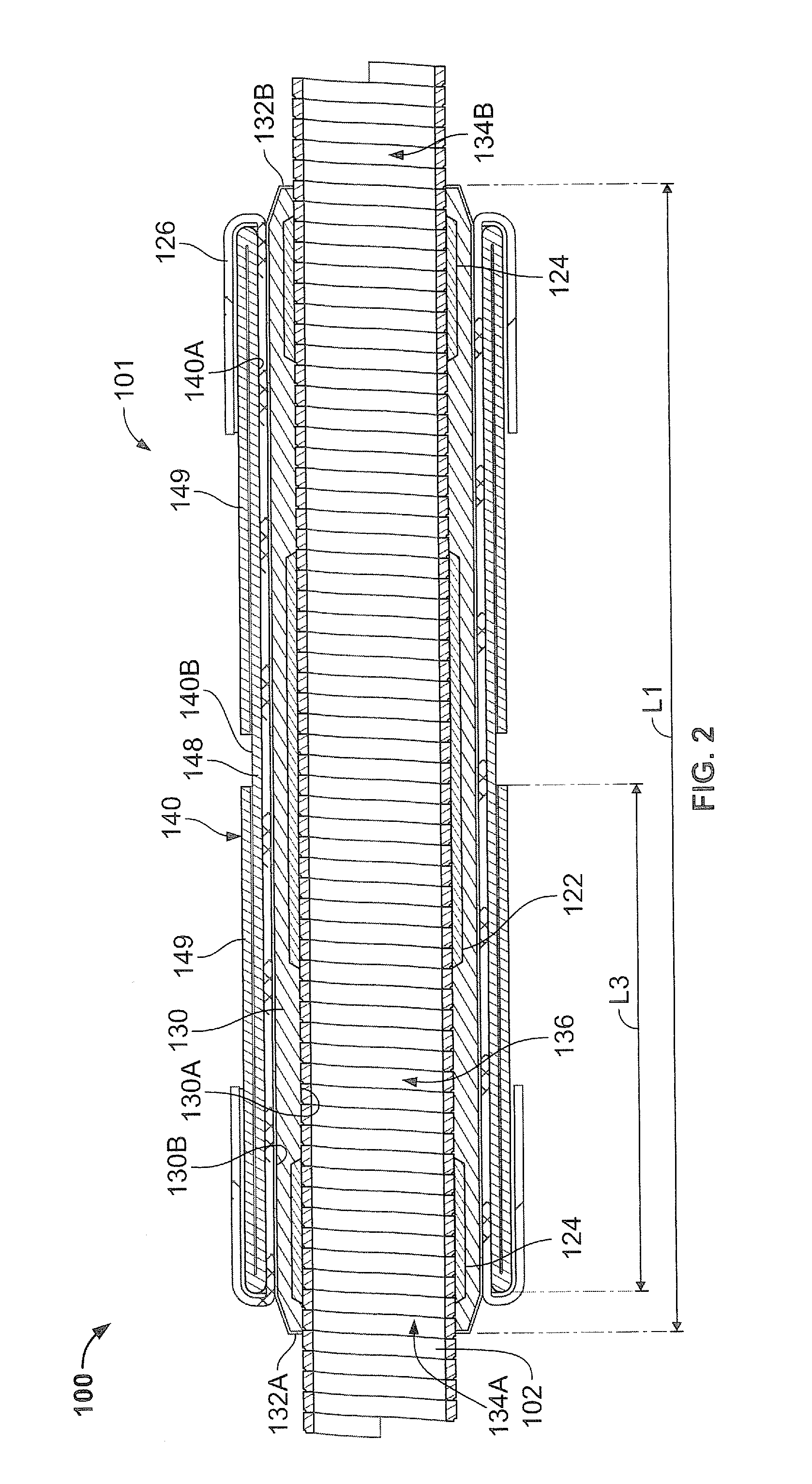

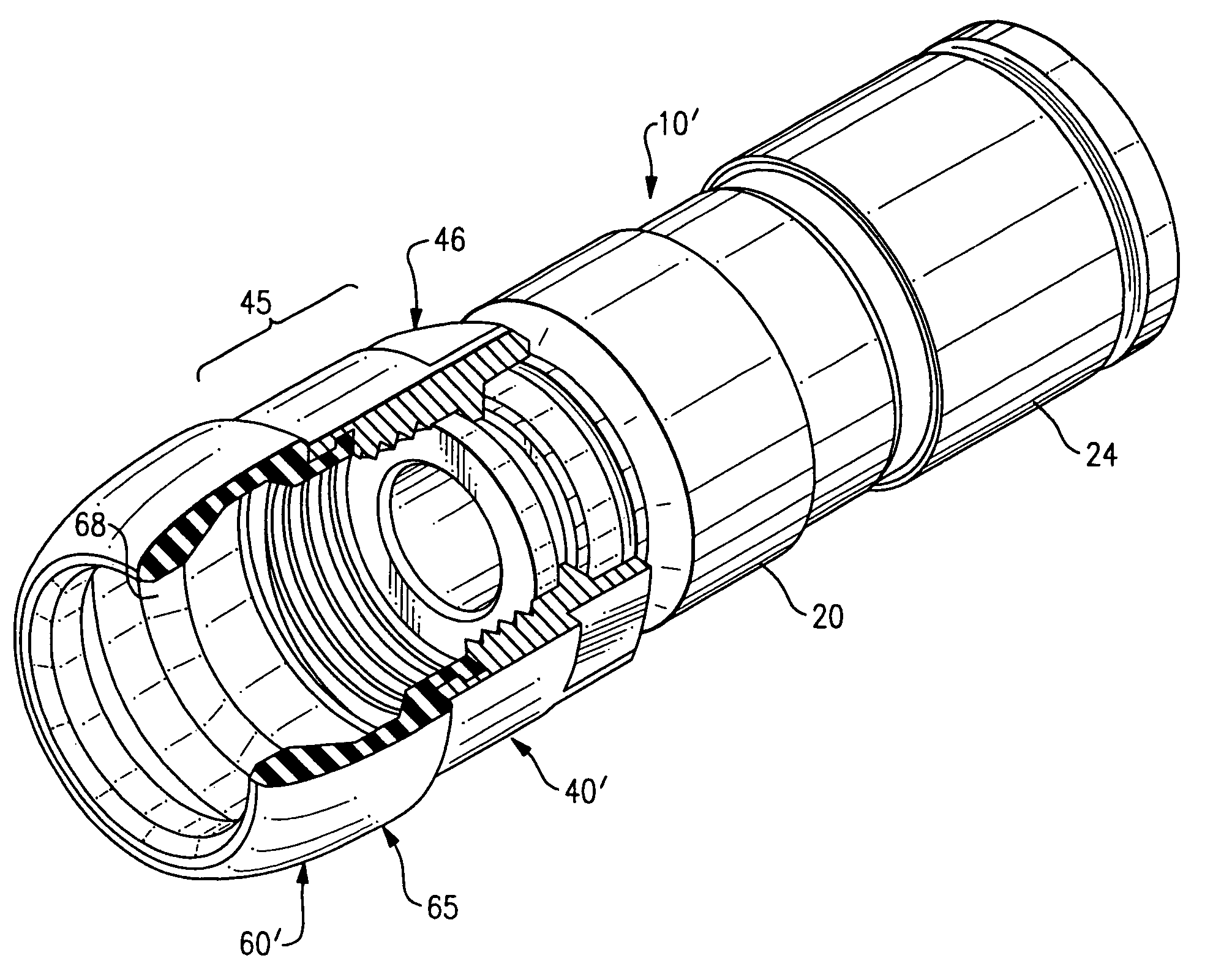

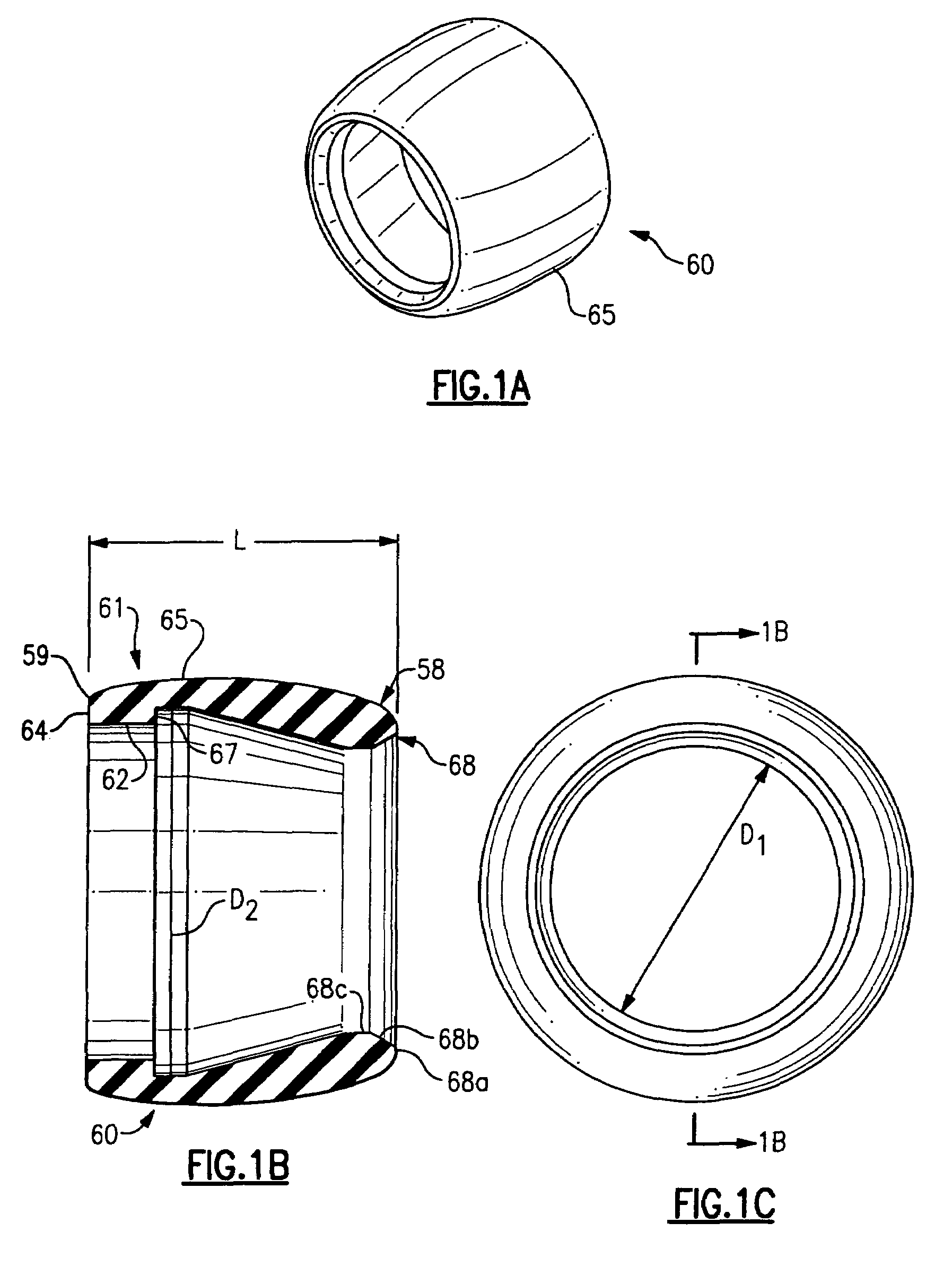

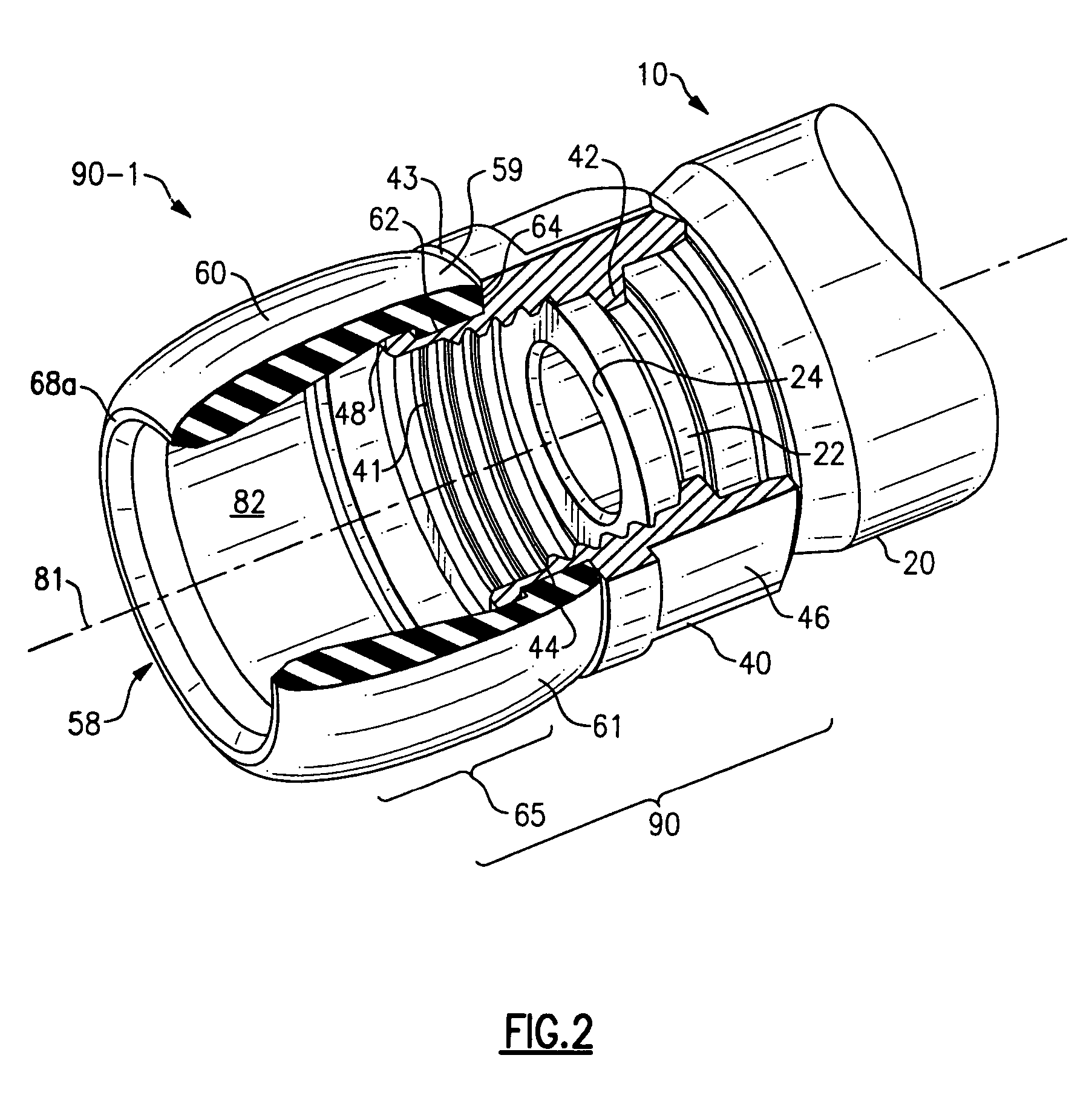

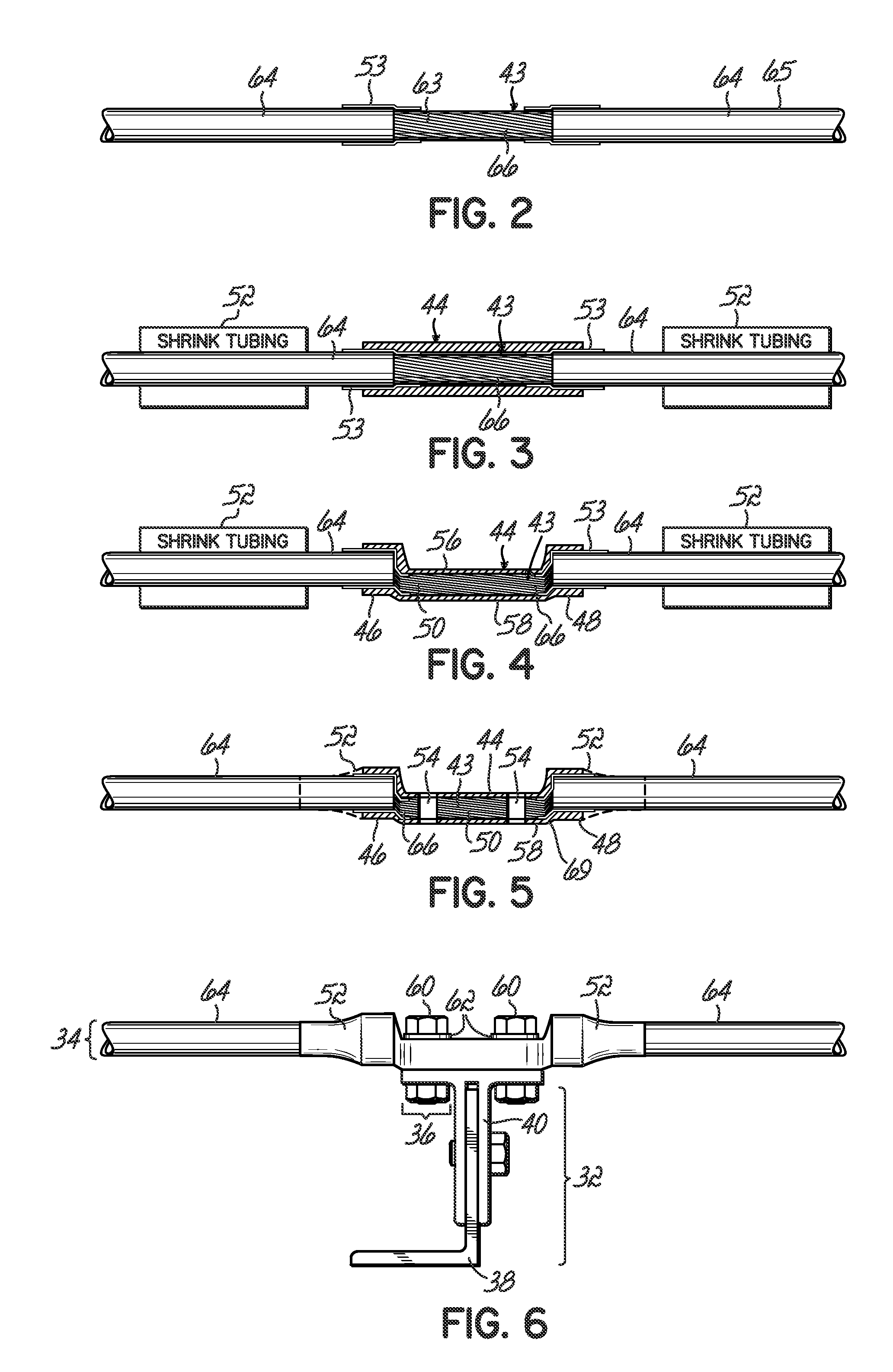

Methods and systems for forming a protected disconnectable joint assembly

InactiveUS7901243B1One pole connectionsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElastomerPower cable

A method for forming a protected disconnectable joint assembly includes providing a disconnectable joint assembly. The disconnectable joint assembly includes: an electrical transmission power cable including a conductor and a cable insulation layer covering the conductor, the conductor having a terminal end; an electrically conductive cable connector affixed to the terminal end of the power cable and having a connector coupling portion; a busbar including an electrically conductive busbar body, a busbar coupling portion extending from the busbar body, and a busbar insulation layer covering the busbar body; and a disconnectable coupling mechanism mechanically securing the cable coupling portion to the busbar coupling portion to provide a joint between the cable and the busbar. The disconnectable coupling mechanism is selectively operable to disconnect the cable connector from the busbar without severing the cable. The method further includes: providing a joint cover assembly including a tubular, elastomeric cold-shrinkable sleeve body; maintaining the joint cover assembly in an expanded state using a removable holdout device mounted within the sleeve body; mounting the joint cover assembly on the holdout over the joint between the cable and the busbar; and thereafter removing the holdout device from the joint cover assembly to release the sleeve body to contract onto the disconnectable joint assembly such that the sleeve body circumferentially surrounds the joint between the cable and the busbar, overlaps portions of the cable insulation layer and the busbar insulation layer adjacent the joint, and applies a persistent radially compressive load on the cable insulation layer and the busbar insulation layer.

Owner:TE CONNECTIVITY CORP

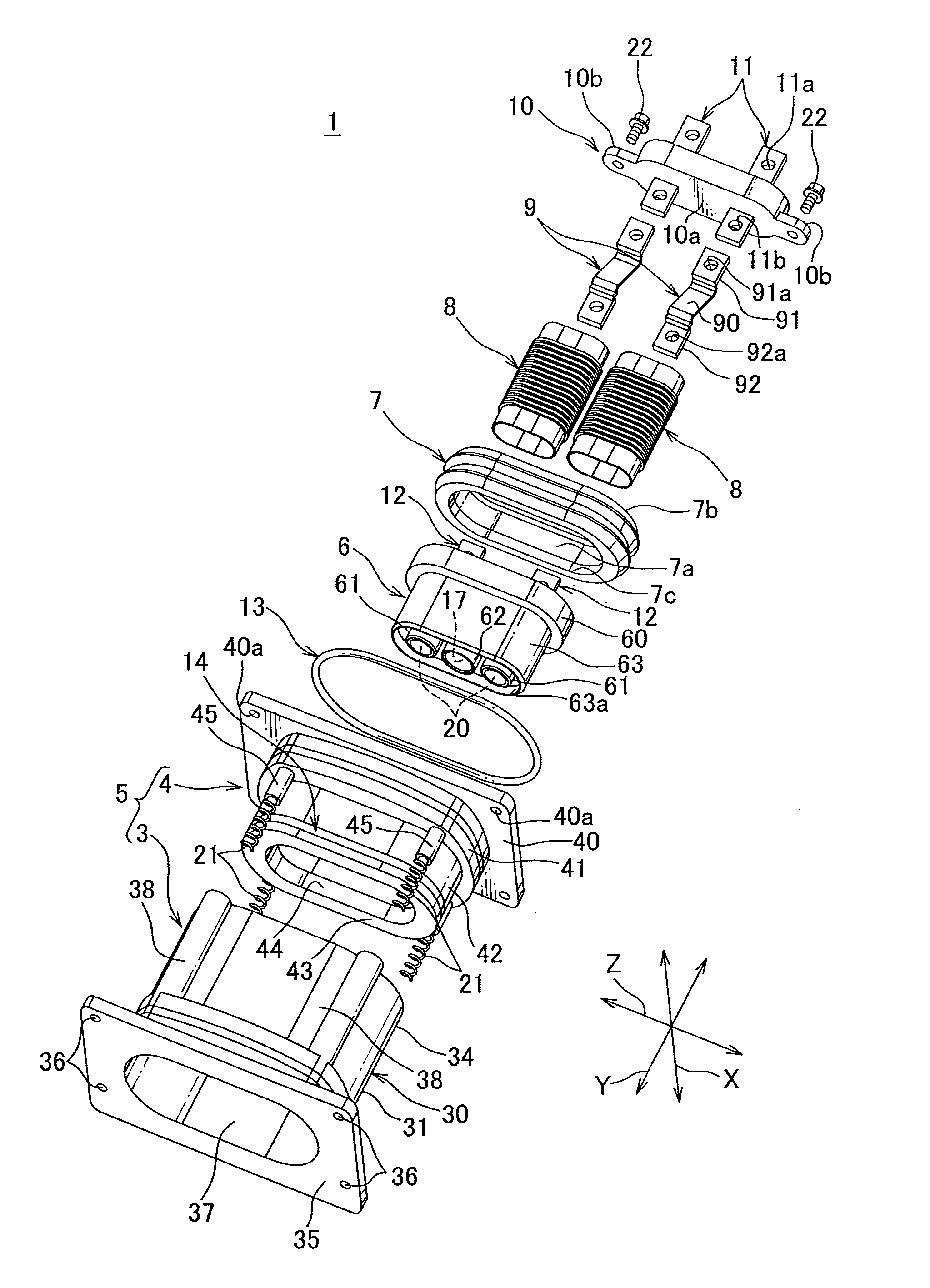

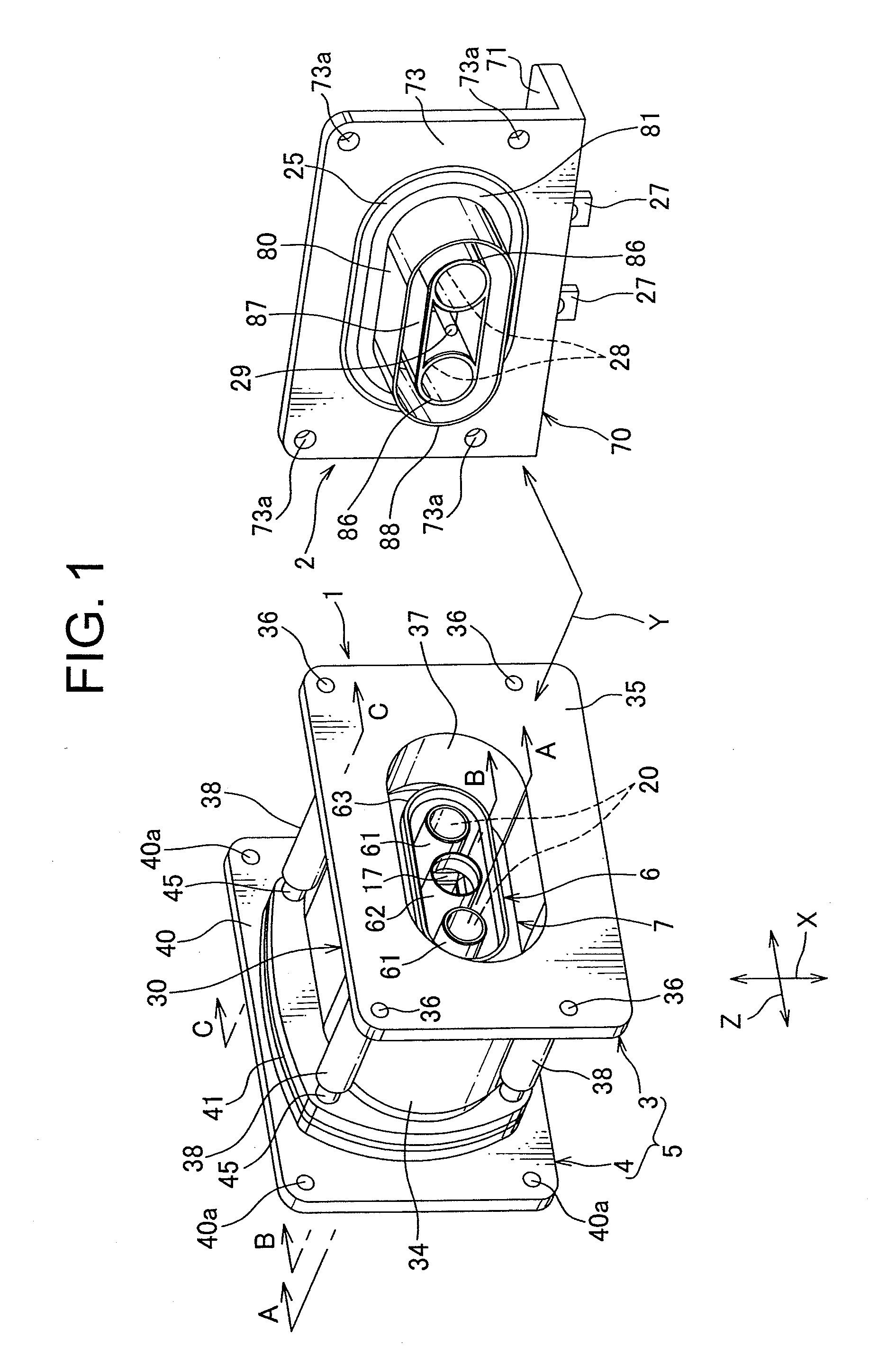

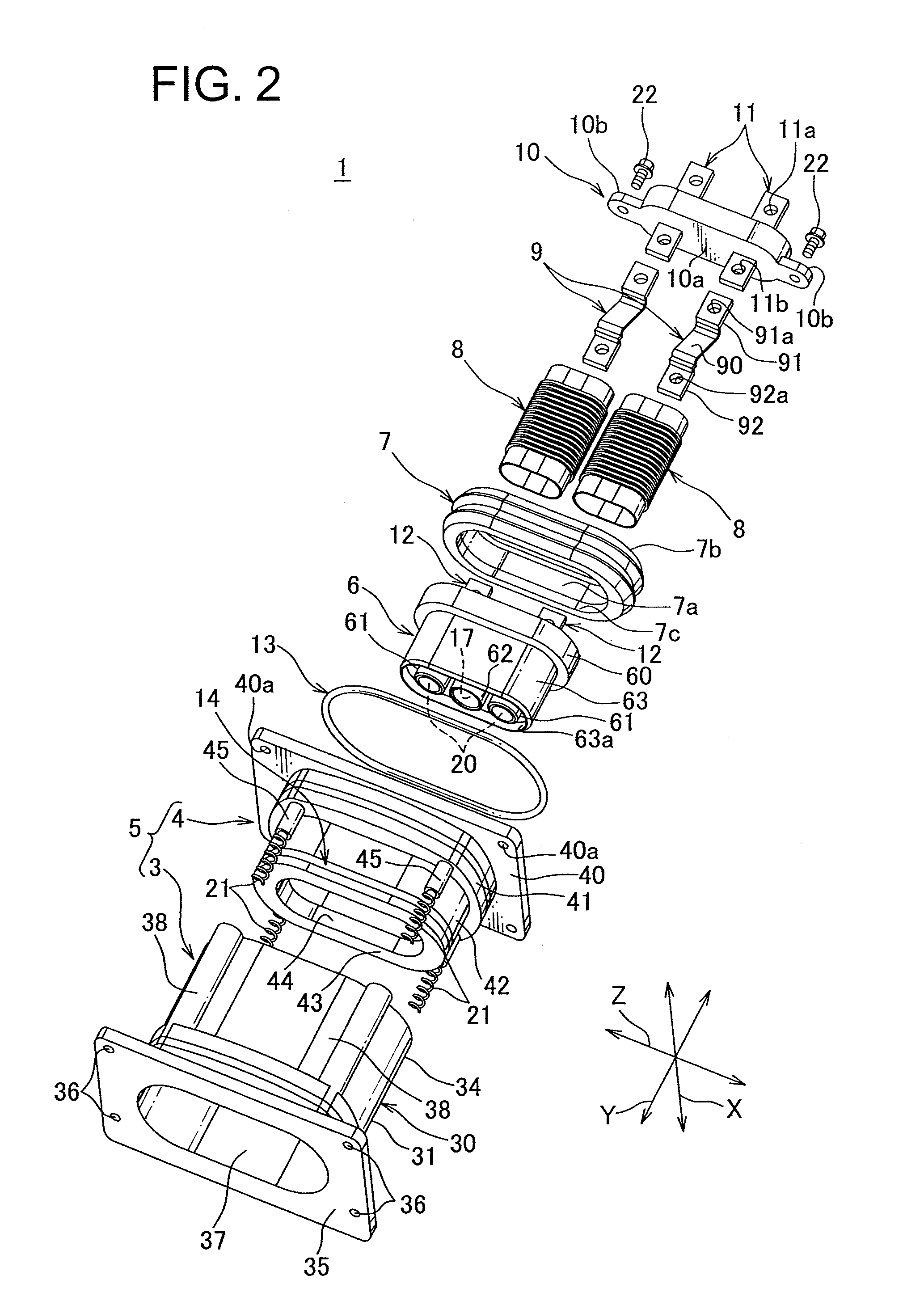

Floating connector with flexible conductive member

ActiveUS20120040553A1Reduced connection reliabilitySavesVehicle connectorsElectric discharge tubesMating connectionEngineering

There is provided a connector 1 connected to a mating connector, fixed in a case of a motor, comprising: an outer housing 5 attached to the case; a first inner housing 6 accommodating a first terminal 20 engaging to the mating connector, being accommodated in the outer housing 5 movably in the engaging direction Y of the first terminal 20 and in the intersectional direction of the engaging direction Y; a first inner connector 6 engaging to the mating connector; a second inner housing 10 accommodating a second terminal 11 electrically connected to a electric circuit in the case and being fixed in the outer housing 5 and a braided wire 90, and further including a connection portion 9 connecting the first terminal 20 and the second terminal 11 and a packing 7 attached to the first inner housing.

Owner:YAZAKI CORP

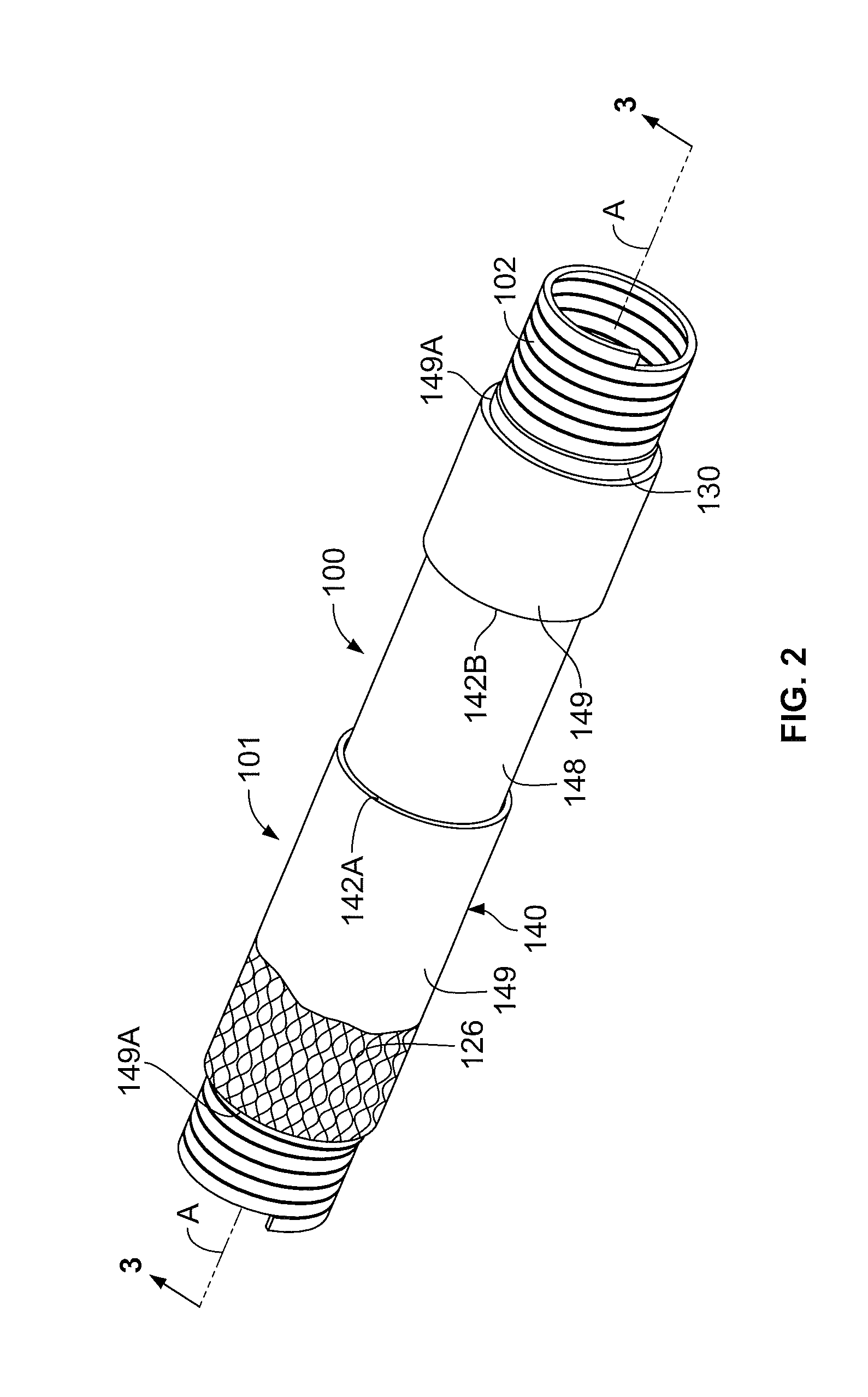

Cover for cable connectors

ActiveUS7838775B2Quick installation and removalKeep tightTwo pole connectionsCouplings bases/casesEngineeringTower

A cover / boot and a system of covers / boots for placement in sealed relation over a connector or pair of connectors that is or are adapted to terminate a cable or splice together a pair of cables, preferably cables that carry signals received by a receiving apparatus on a cell tower. The covers include a cable end that sealingly receives a cable therein, an elongated body that provides secure cover to a cable connector, and an end that abuts a bulkhead or sealingly engages with a second cover when used in a splicing application.

Owner:JOHN MEZZALINGUA ASSOC INC

Crimp terminal, connection structural body and connector

ActiveUS8974258B2Vehicle connectorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical conductorEngineering

A crimp terminal includes barrel pieces respectively on both of two sides in a width direction thereof. The barrel pieces are included in a pressure-bonding section for pressure-bonding an exposed part of an electric wire conductor of an insulated wire. The insulated wire includes the electric wire conductor and an insulating cover for covering an outer circumference of the electric wire conductor, and the exposed part is a part of the electric wire conductor which is exposed from a tip of the cover by a predetermined length. The barrel pieces have a length in a longitudinal direction which is longer than the length of the exposed part of the electric wire conductor. The pressure-bonding section pressure-bonds, by the barrel pieces, a continuous part from a tip of the electric wire conductor to a position rear to the tip of the cover.

Owner:FURUKAWA ELECTRIC CO LTD +1

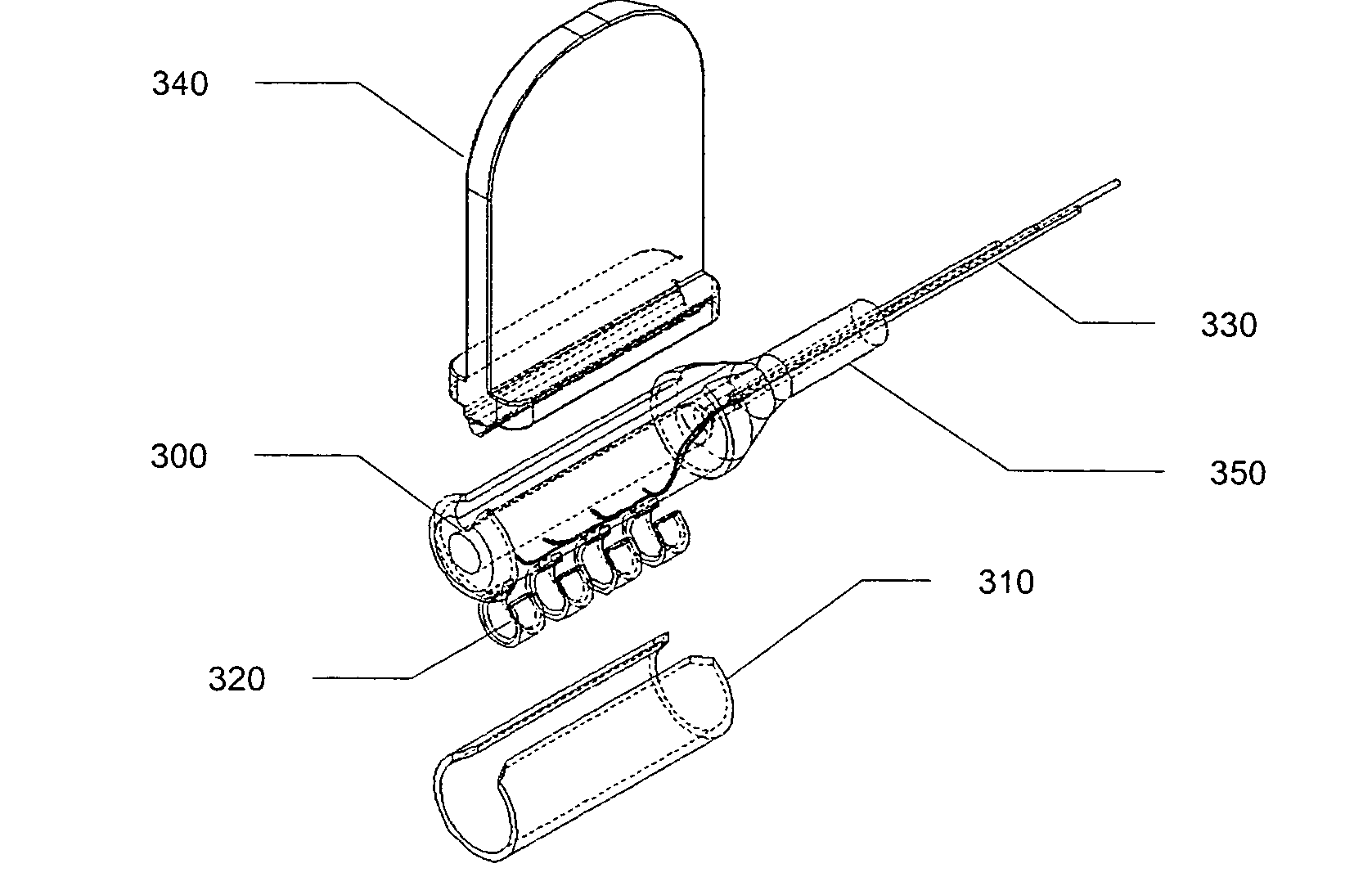

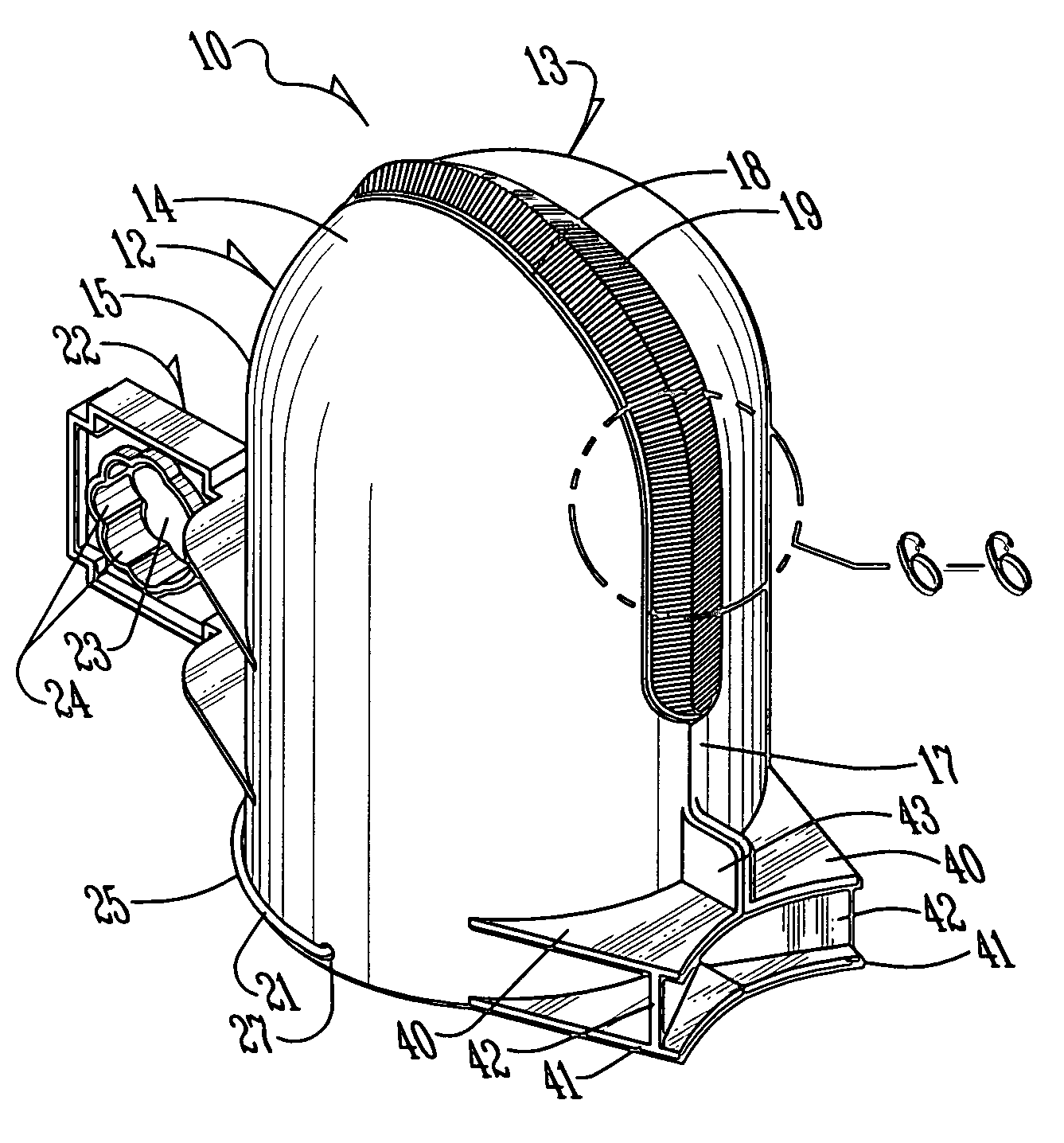

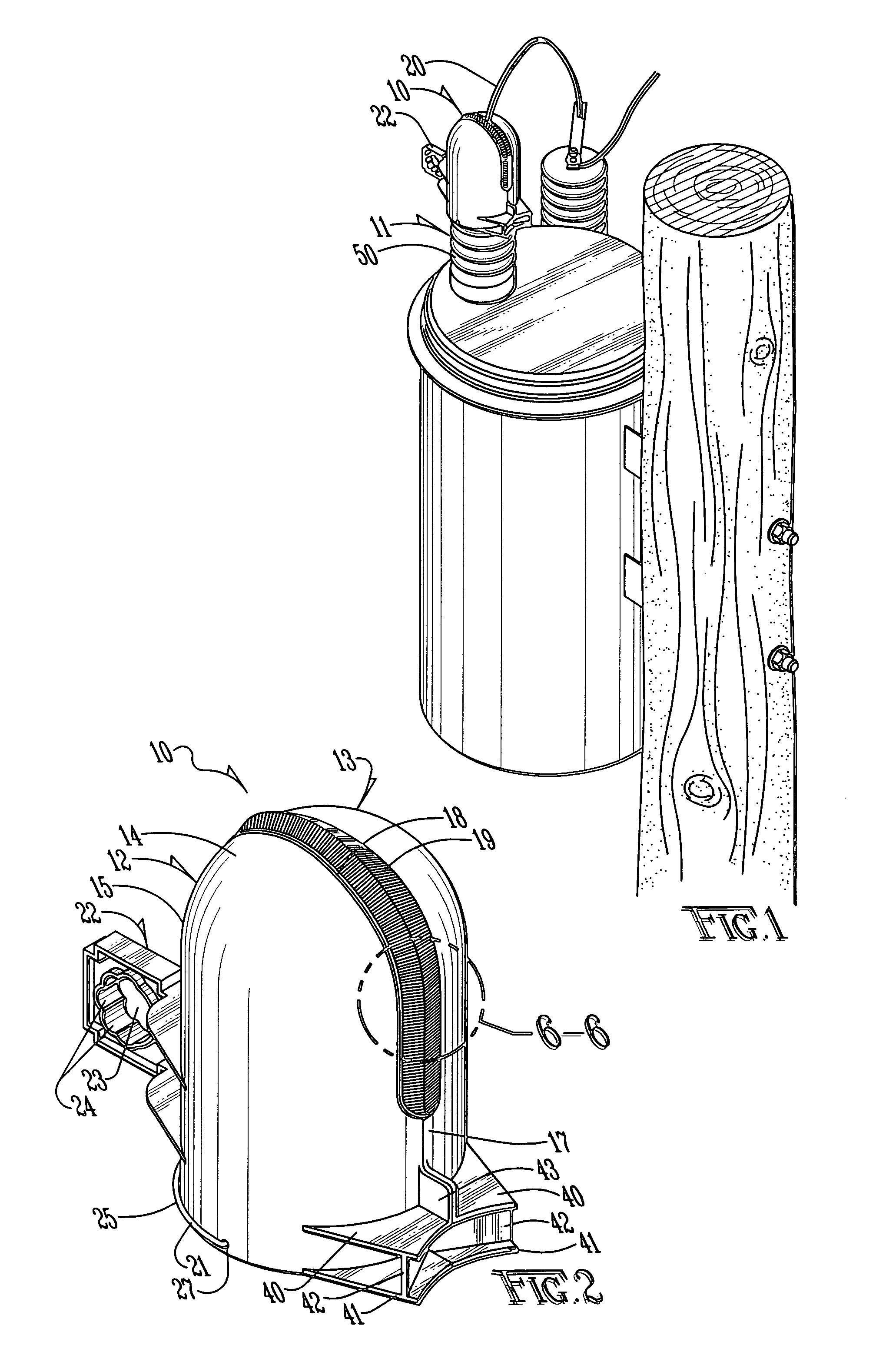

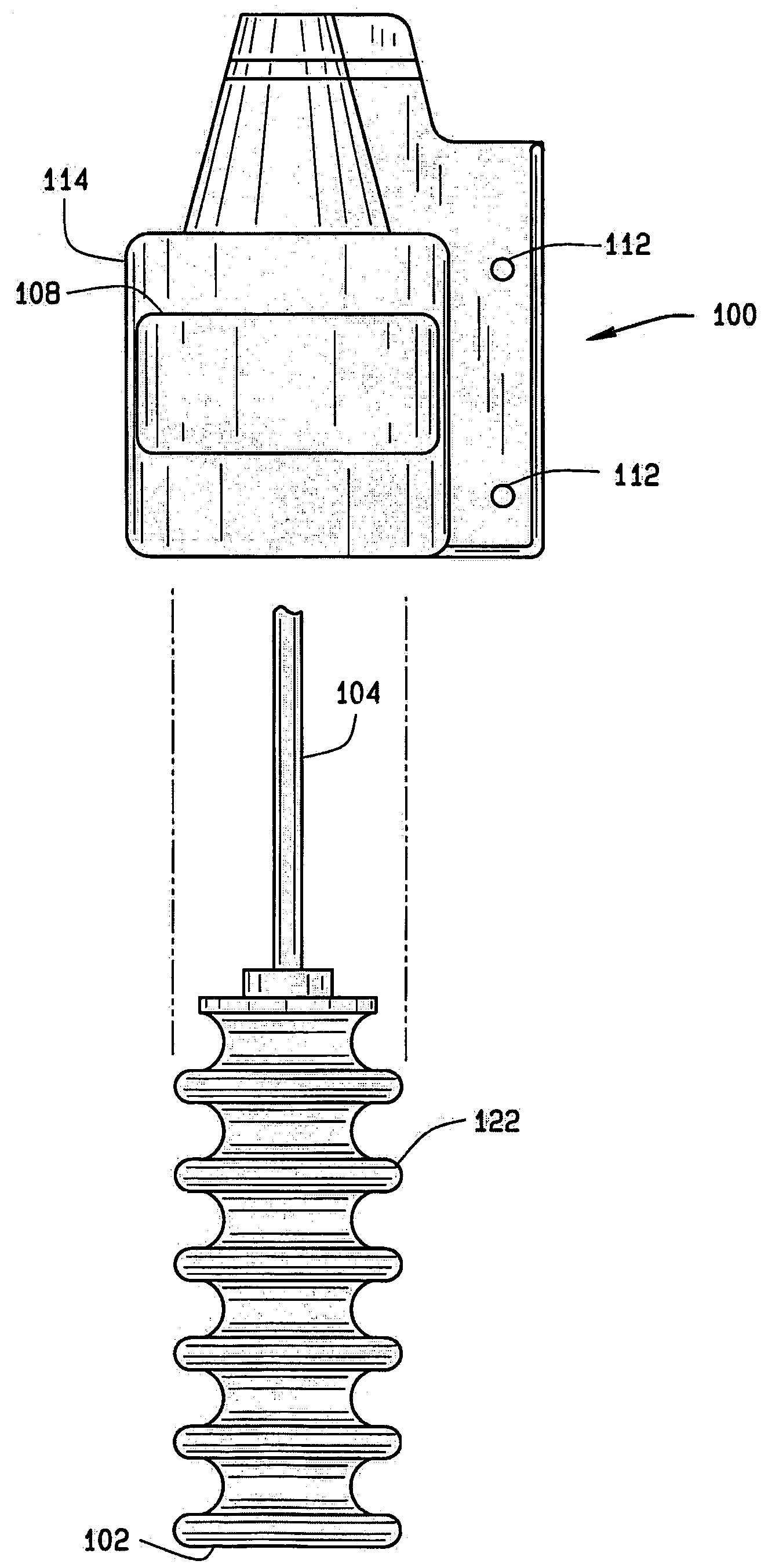

Insulator bushing wildlife guard

ActiveUS6995313B1Easy to grasp and manipulateEasy alignmentSuspension arrangements for electric cablesInsulatorsWildlifeElectrical conductor

An insulator bushing wildlife guard having features for easier alignment and installation of the guard on the bushing. The guard has two hinged body sections of insulating material. An outer edge of each body section is provided with a plurality of flexible fingers that allow conductors to pass through from the interior to the exterior of the enclosure when the two portions of the guard are engaged. In one embodiment, the guard is spring biased toward a closed position. A handle on the back has inner grooves to make it easier to grasp and manipulate the guard using a shotgun stick. On a lower front side of each portion of the guard, spaced-apart, curved, horizontal upper and lower flanges help align the guard with the topmost skirt of a bushing. Medial walls having a curved, sloped, concave or otherwise inwardly-directed configuration between the two flanges facilitate forcing the guard open by pushing it against the bushing. An external tab limiter, disposed above the upper flange, makes it difficult to install the guard over any part of the bushing other than the topmost skirt of the bushing. An alternative version of the guard has a releasable trigger, which is used to hold the two portions in an open position until the bushing or power line displaces the trigger and allows the biasing spring to close the two cover portions. The guard is provided with a handle for grasping by a manipulator tool. In one embodiment the handle is provided with inner grooves for grasping by a shotgun stick. In another embodiment, an adapter releasably engages the handle and provides means for attachment to a hotstick.

Owner:CENT MOLONEY

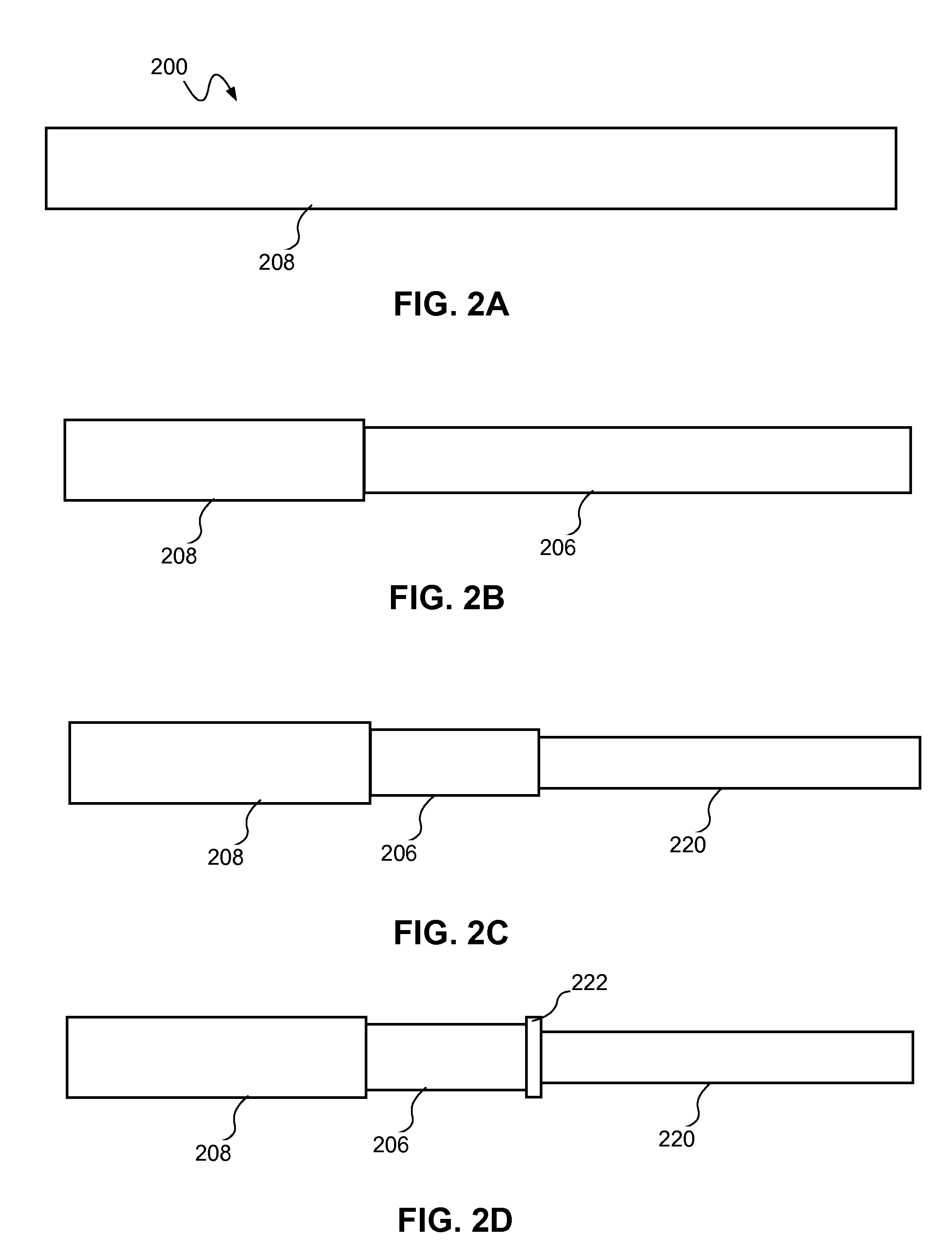

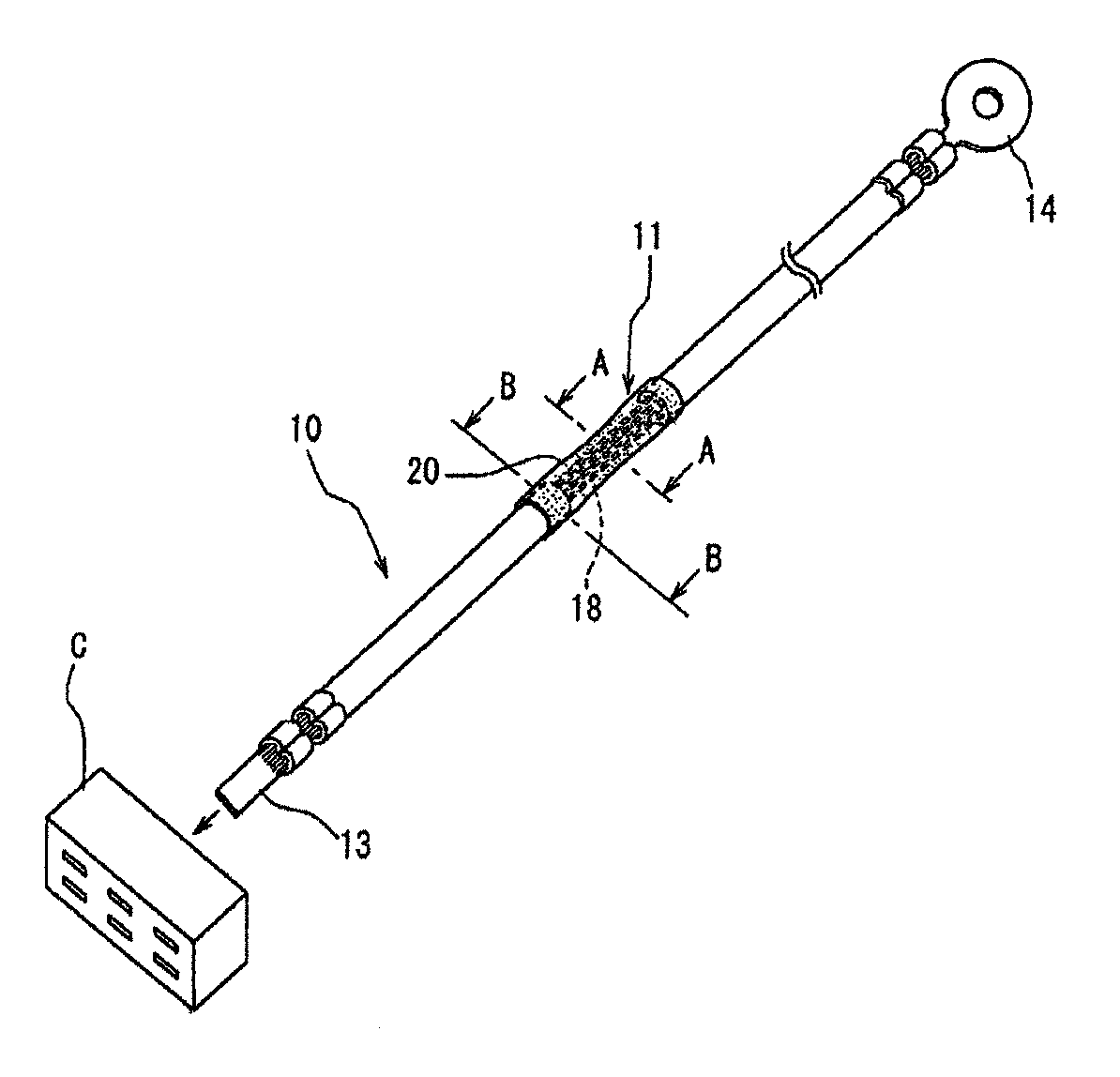

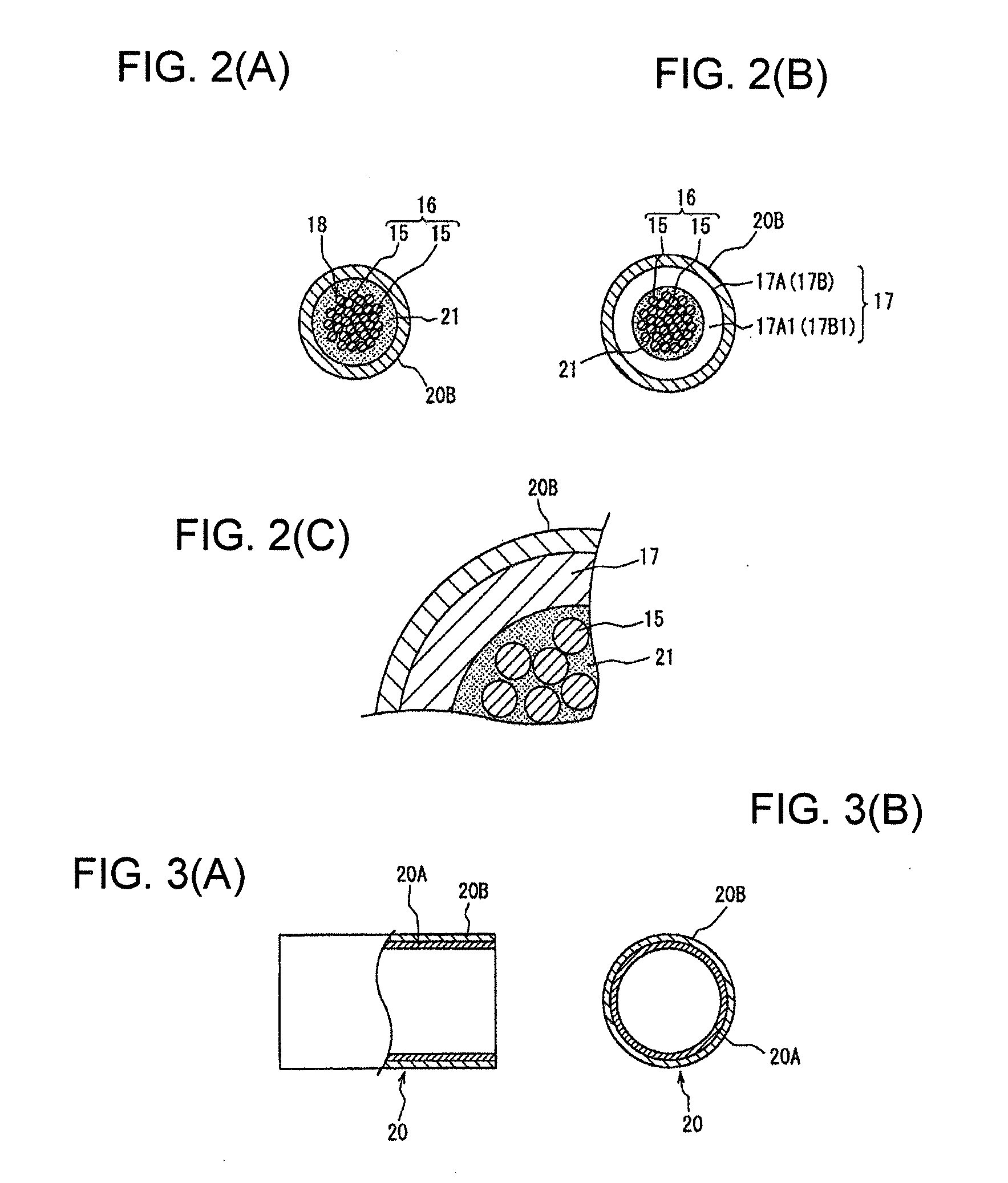

Waterproofing method for wire and wire having waterproof part formed by the waterproofing method

InactiveUS20110048762A1Water penetration into a connector can be more reliably preventedPrevent water penetrationSoldering apparatusInsulated cablesEngineeringHot melt

A waterproofing method is provided for a wire to be arranged in a water susceptible area of a vehicle. An insulating coating layer is removed in a lengthwise intermediate part of the wire to expose a core. A heat shrinkable tube with an inner layer made of a hot-melt waterproofing agent is mounted on the exposed core section and parts of the insulating coating layer adjacent to the exposed core section and heated. As a result, the hot-melt waterproofing agent of the inner layer is melted and infiltrates into clearances between strands of the exposed core section. In addition, negative pressure is introduced into the inside of the insulating coating layer from an end of the wire, thereby sucking the waterproofing agent into the inside of the insulating coating layer to infiltrate the waterproofing agent also between the strands of the core inside the insulating coating layer.

Owner:SUMITOMO WIRING SYST LTD

Wildlife guard for electrical power distribution and substation facilities

The present disclosure provides a wildlife guard for electrical power equipment including a disc having a central opening for fitting onto the equipment. The disc includes an electrically insulating material with a conductive filler material in quantity sufficient for the disc to maintain an electrostatic charge. The disc has an insertion slot extending from an outer portion to the central opening for movement of the disc onto the equipment. The present disclosure also provides a wildlife guard for an electrical insulator bushing having an electrical conductor extending outwardly therefrom. The wildlife guard includes an electrically nonconductive cover for covering at least a portion of the electrical conductor, the cover being adapted to mount upon the bushing and a conductive panel attached to the cover.

Owner:NAT SAFETY APPL INC

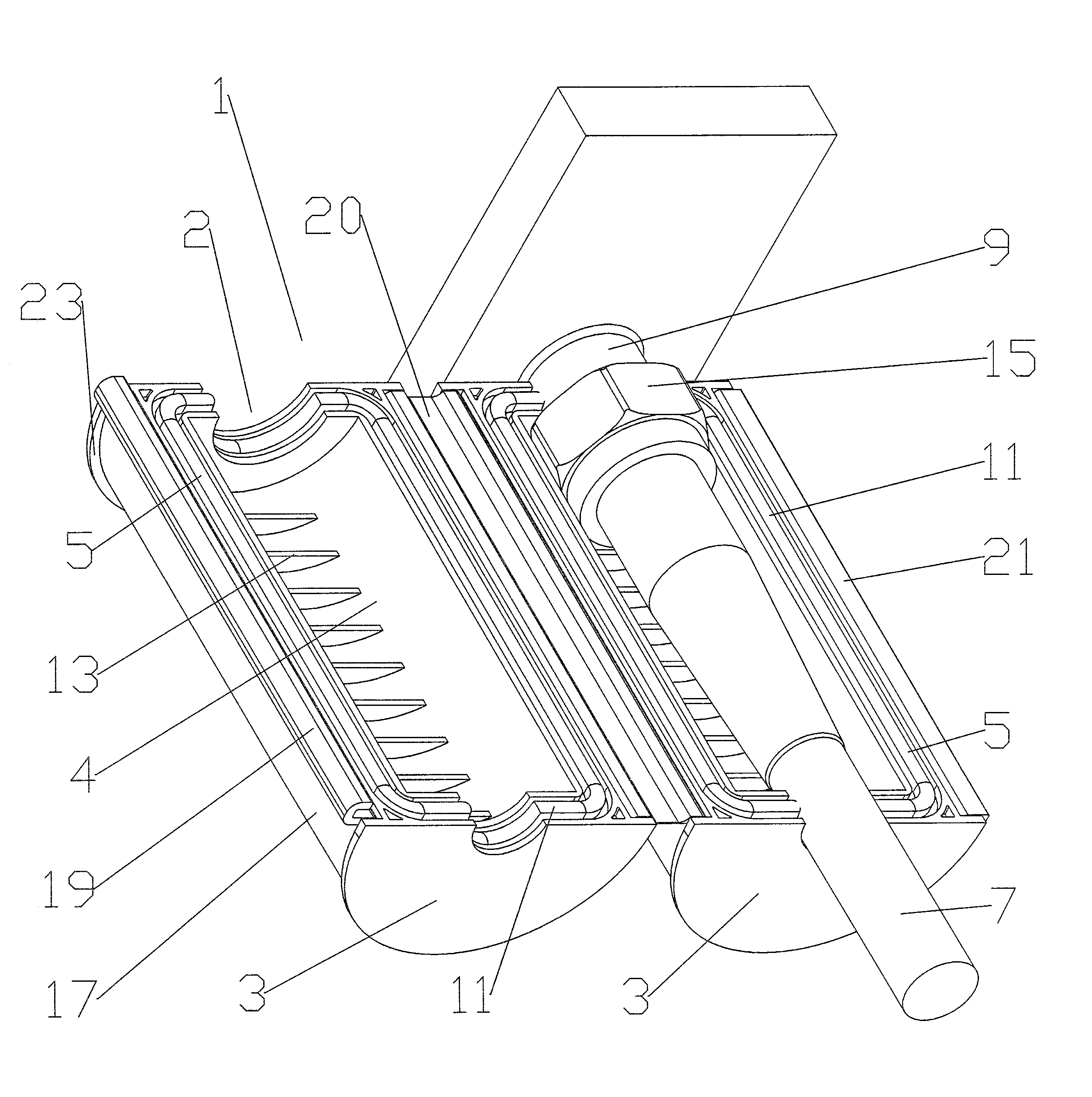

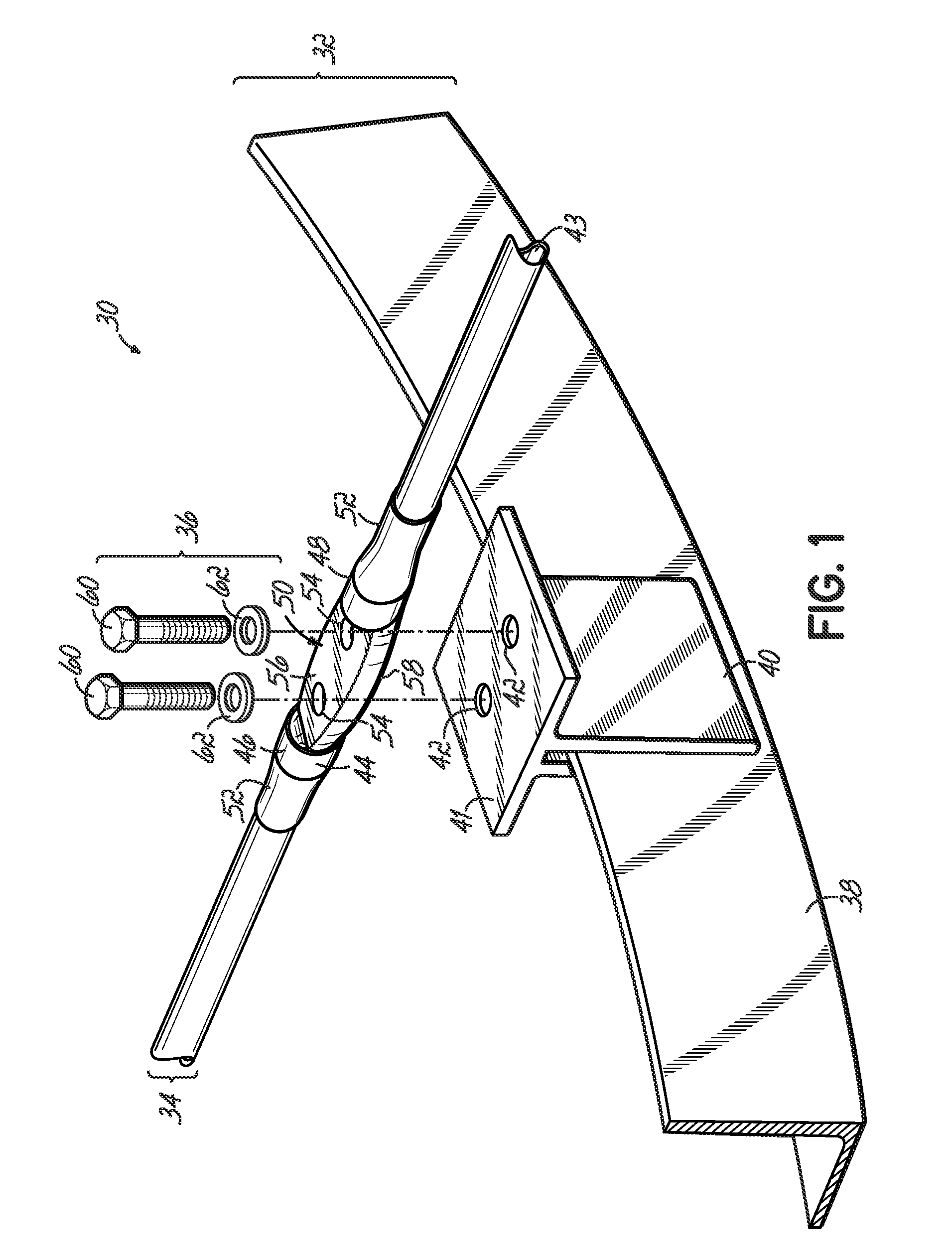

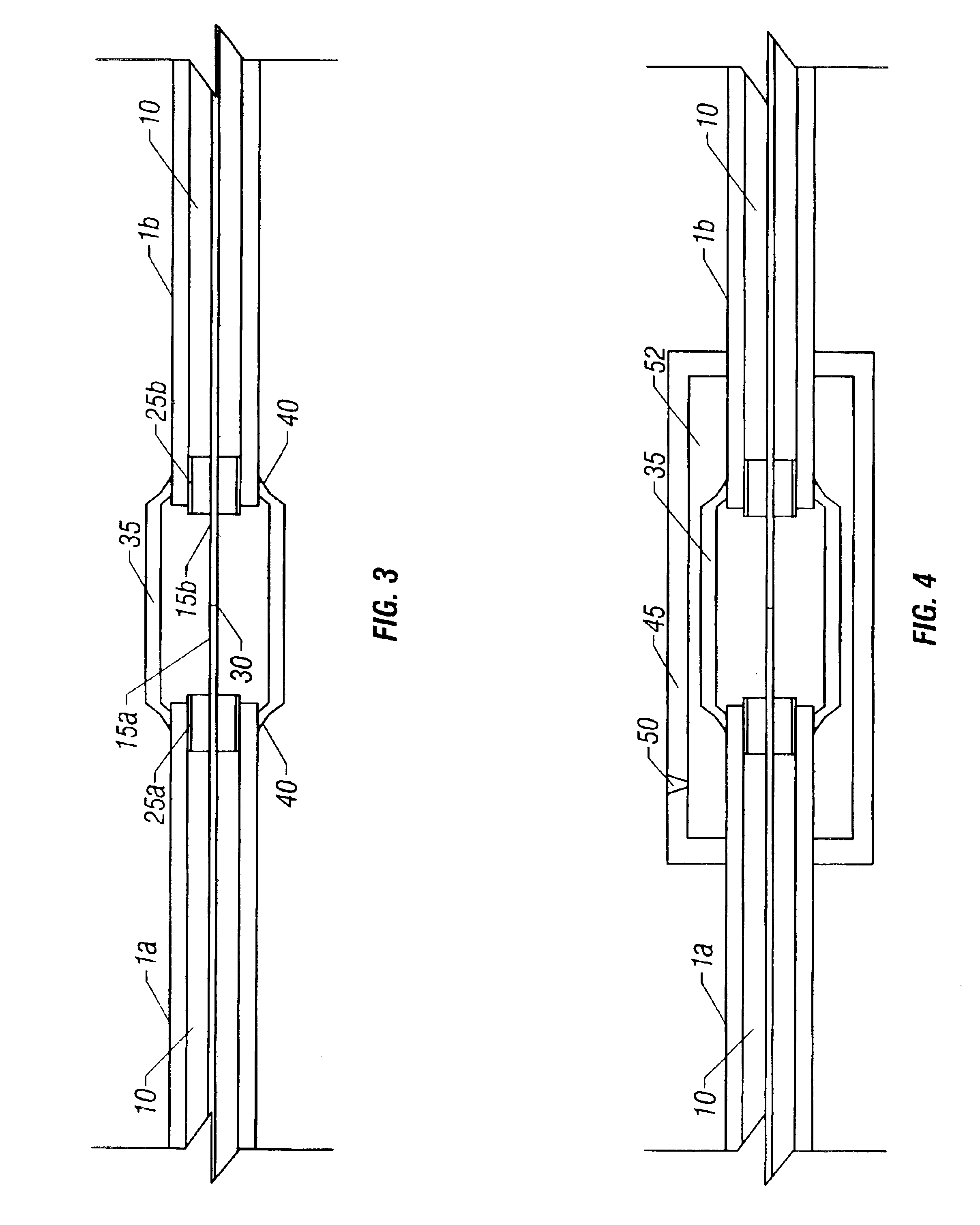

Parallelogram coupling joint for coupling insulated conductors

A fitting for coupling ends of insulated conductors includes a sleeve to couple an end of a jacket of a first insulated conductor to an end of a jacket of a second insulated conductor. The sleeve is located between end portions of the insulated conductors. At least one of the ends of the sleeve is angled relative to the longitudinal axis of the sleeve. The sleeve has a longitudinal opening that extends along the length of the sleeve substantially the distance between end portions of the jackets of the insulated conductors. The longitudinal opening allows electrically insulating material to be filled into the sleeve.

Owner:SALAMANDER IP HLDG LLC

Cable and apparatus interface security device

ActiveUS6955558B1Amplified equalizationHigh sealing pressureRelieving strain on wire connectionSecuring/insulating coupling contact membersInterconnectionSafety Equipment

A sealing assembly for a cable to apparatus interconnection formed bya plurality of shells adapted to mate together, surrounding the interconnection within an interconnection space. When mated together, the shells forming openings for the cable and the apparatus at an apparatus end and a cable end, respectively. A gasket mounted to each shell along a mating surface between the shells and along the openings environmentally seals the interconnection space. A locking rib projecting inward from the shell(s) may be applied to rotationally interlock a coupling nut of the interconnection with the sealing assembly. In a two shell embodiment, a locking band positioned around an outer diameter of the mated together shells with an end to end retaining means may be used to secure the shells together. Alternatively, if three shells are used, the shells may be hinged together and a retaining means applied to join the unhinged ends together.

Owner:COMMSCOPE TECH LLC

Cover lock

An electrical housing has a first member and a second member that can be locked and unlocked with a cover lock. The cover lock itself can include a male member disposed on one of the members, and a female member disposed on the other of the members for mating with the male member. A rib can also be provided on either the first or second member to help mate the male member with the female member.

Owner:APTIV TECH LTD

Electrical terminal connection with molded seal

InactiveUS20110070770A1Curb bendingImprove sealingContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectricityElectrical connection

A corrosion resistant electrical connection structure has an electrically conductive cable with an electrically conductive core and an insulative outer cover. An electrically conductive terminal is electrically connected to a lead of the core that extends beyond the insulative outer cover. A molded hot melt seal seals the lead of the core and the terminal interface section from ambient electrolytes. In an exemplary embodiment, the core is made from aluminum or an aluminum alloy and the terminal is made from a copper alloy.

Owner:APTIV TECH LTD

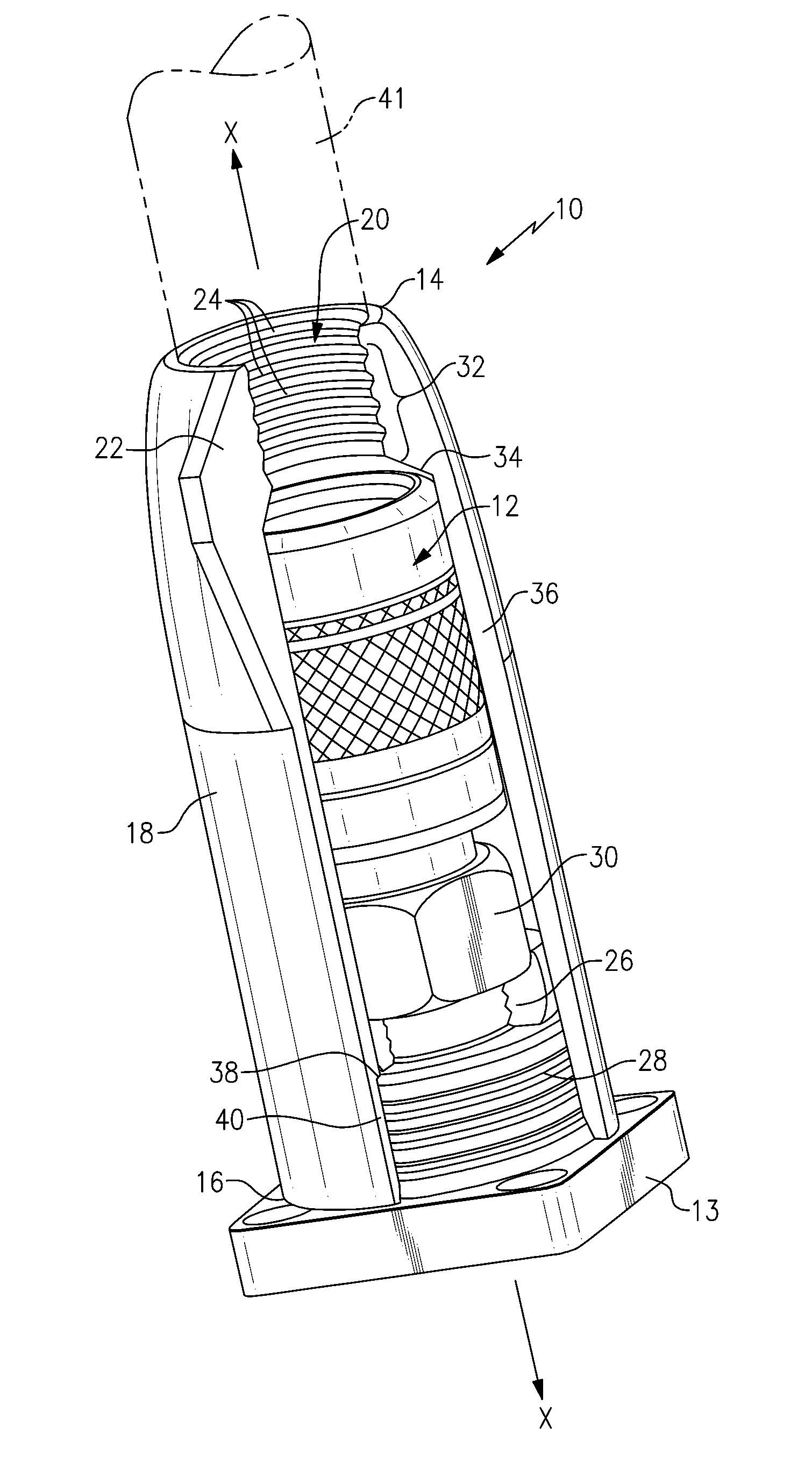

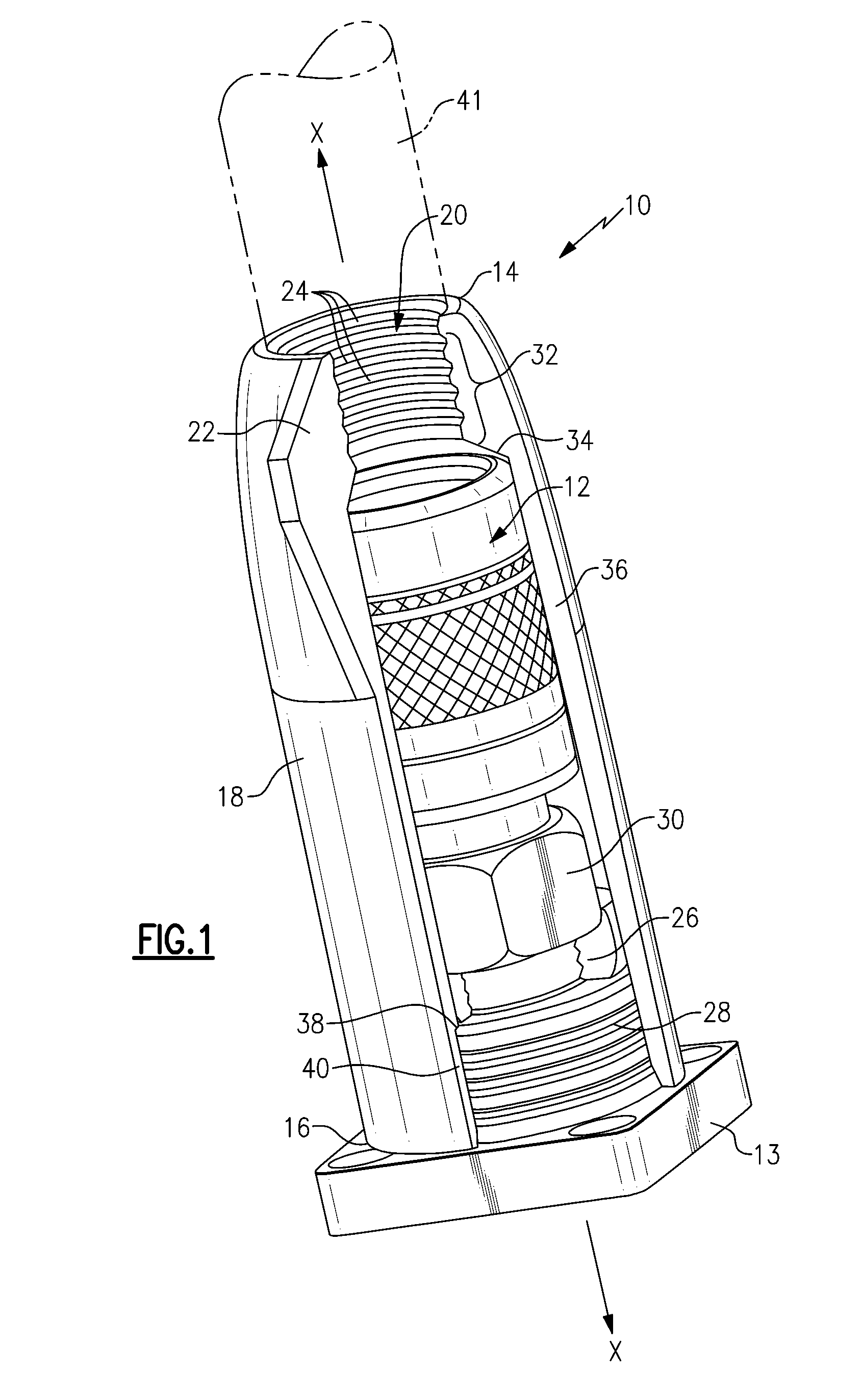

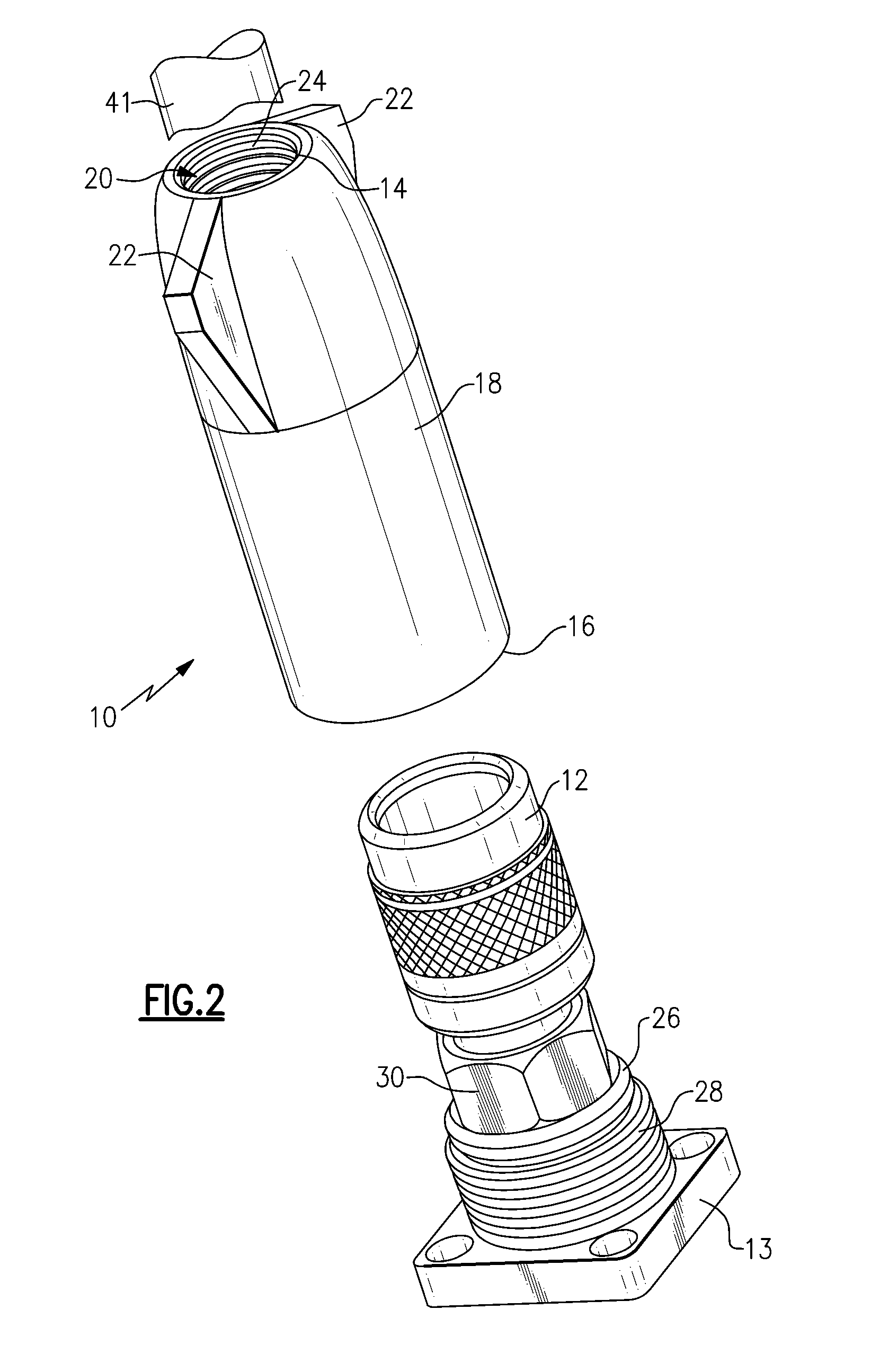

Insulated cable termination assembly and method of fabrication

ActiveUS7192319B1Avoid flowPrevents damaging current flowConnection end capsClamped/spring connectionsEngineeringElectrical and Electronics engineering

Owner:EATON INTELLIGENT POWER LIMITED

Cross talk reduction for high speed electrical connectors

ActiveCN101960674ATwo-part coupling devicesCoupling protective earth/shielding arrangementsGround contactElectricity

Example electpcal connectors are provided including a plurality of electrical contacts configured to communicate between electrical devices. The plurality of electrical contacts includes a plurality of ground contacts. A ground coupling assembly is configured to electrically connect ground contacts of an electrical connector to adjust a performance characteristic of the electrical connector as desired.

Owner:FRAMATOME CONNECTORS INT SA

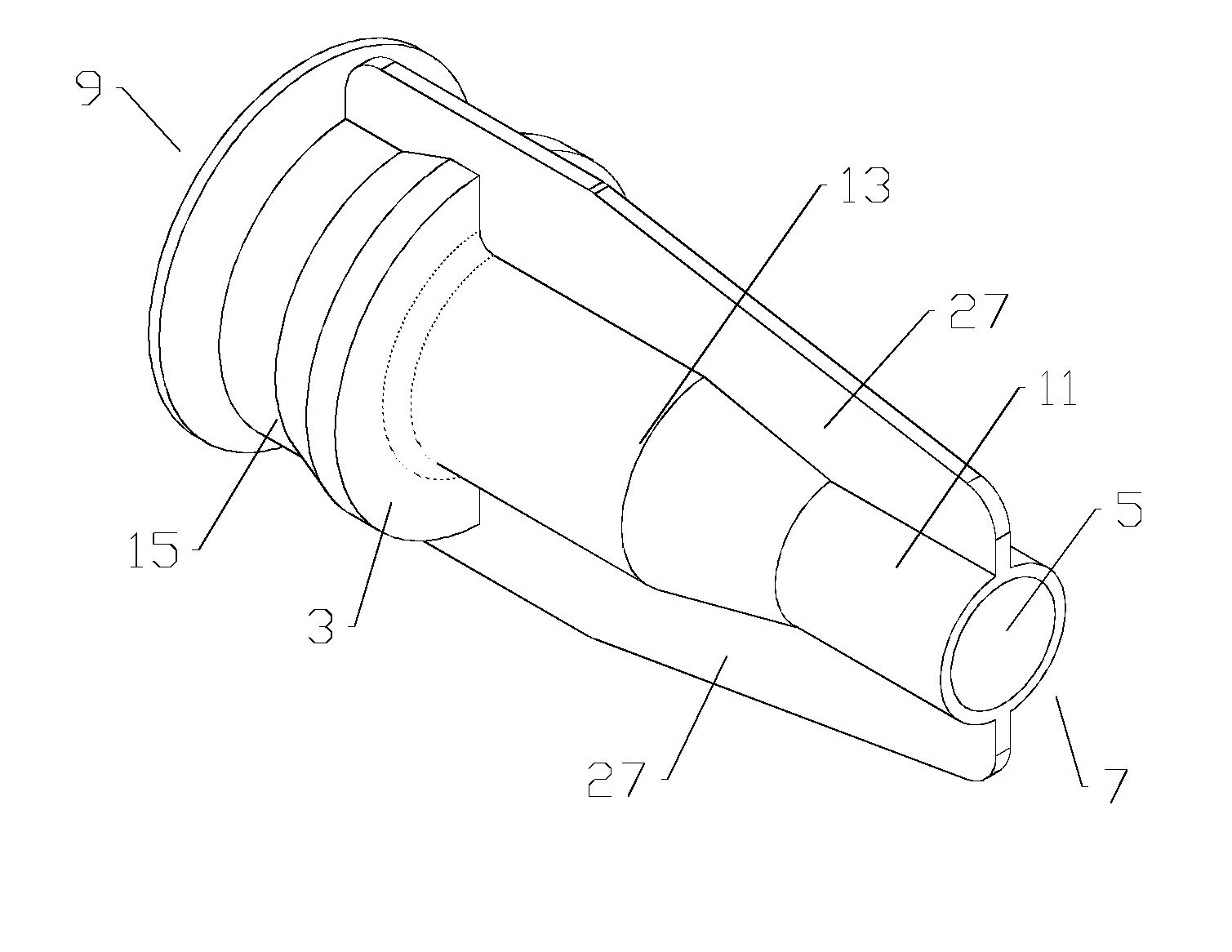

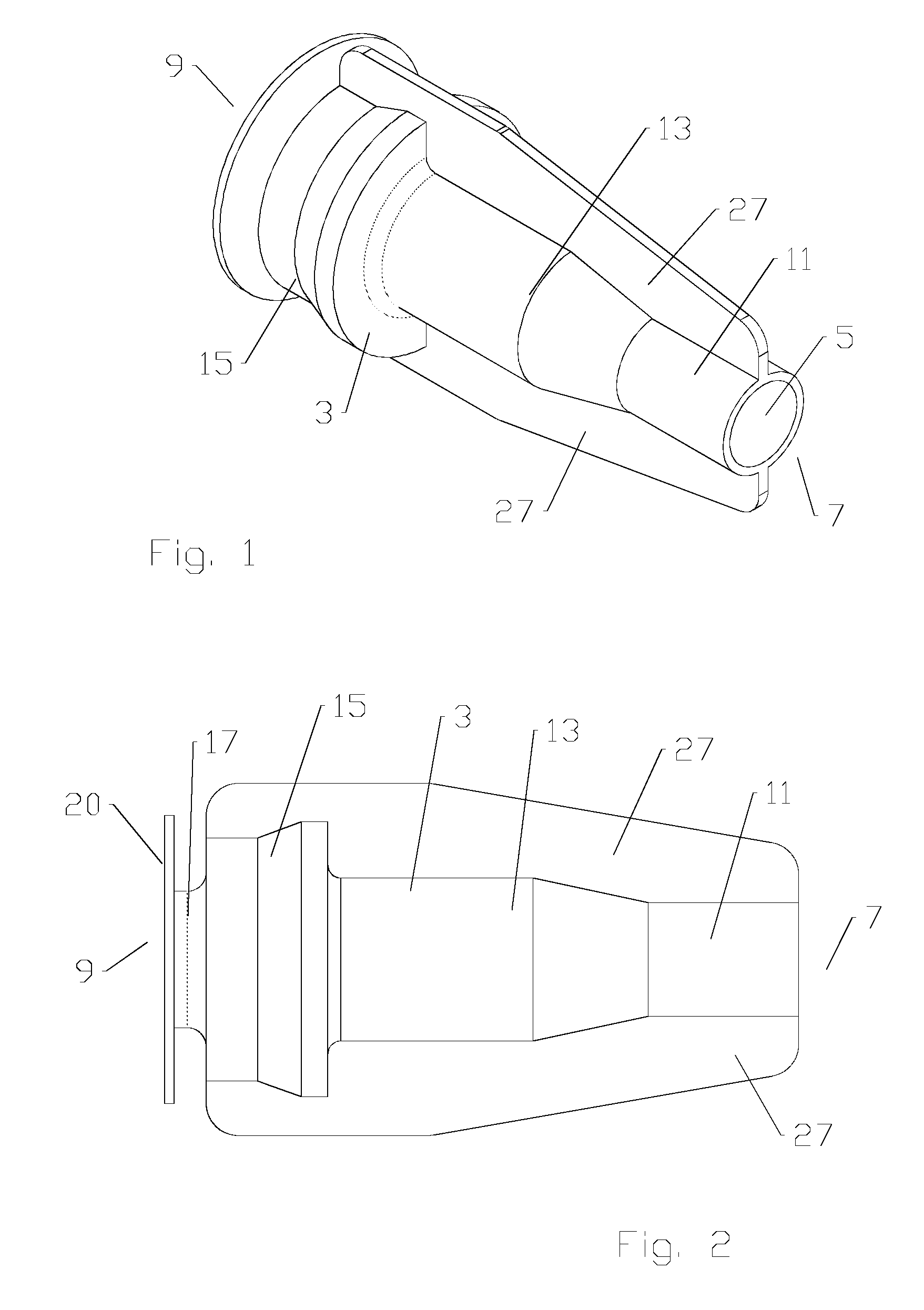

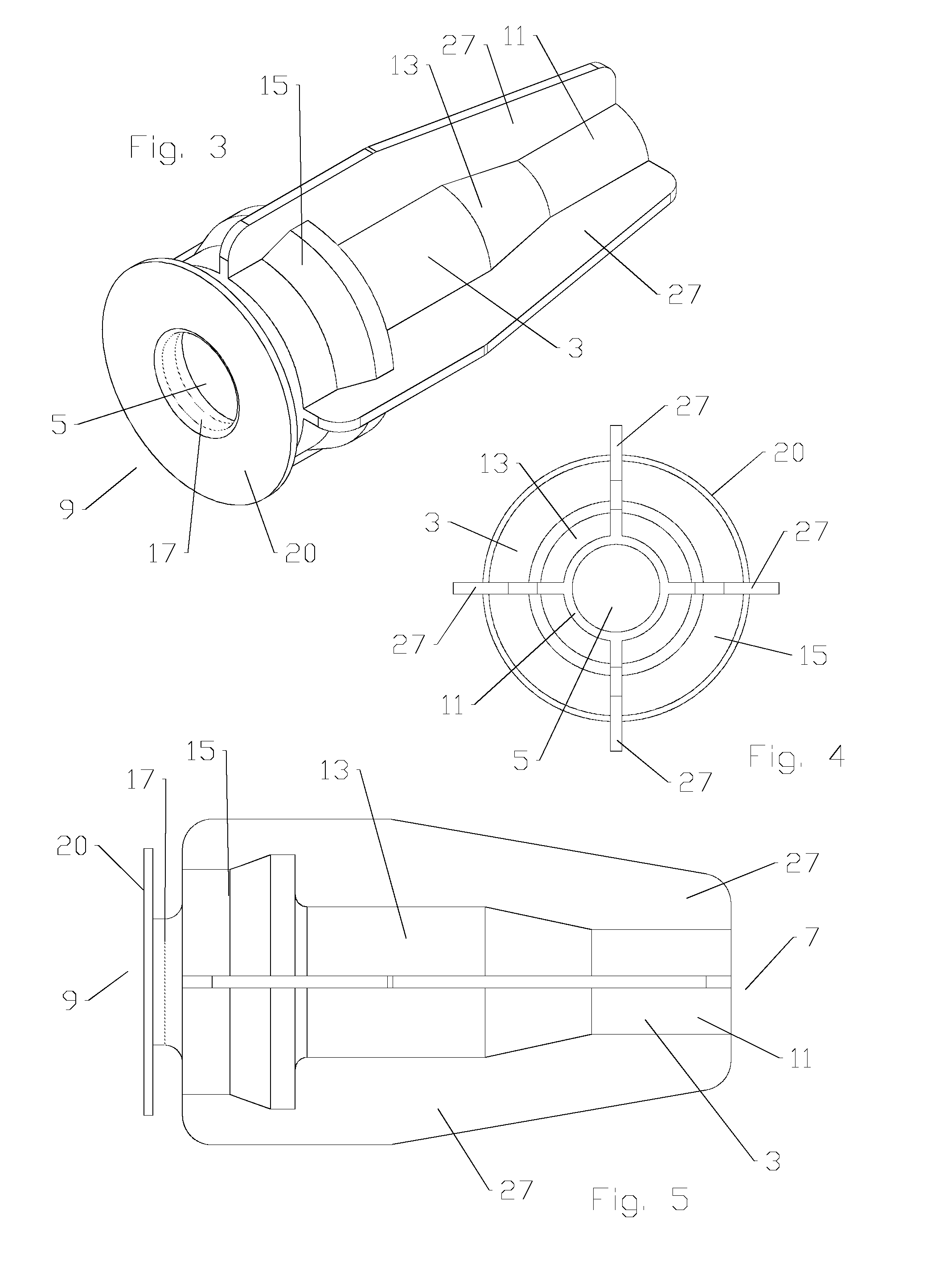

Interconnection seal

ActiveUS20150017827A1Improve sealingMinimize formationLine/current collector detailsCouplings bases/casesInterconnectionEngineering

A seal for a cable and connector interconnection includes a unitary elastic body with a bore therethrough. The bore is provided with a cable outer diameter seal portion at a cable end, the cable outer diameter seal portion adjacent a connector cavity portion, the connector cavity portion adjacent a coupling nut cavity portion, and the coupling nut cavity portion adjacent a connector neck seal portion with a bulkhead seal at a connector end. The coupling nut cavity portion is longitudinally aligned with a coupling nut of the connector and is provided with a greater inner diameter than the cable outer diameter seal portion and the connector neck seal portion. The bulk head seal is provided with an outer diameter greater than an outer diameter of the connector neck seal portion.

Owner:COMMSCOPE TECH LLC

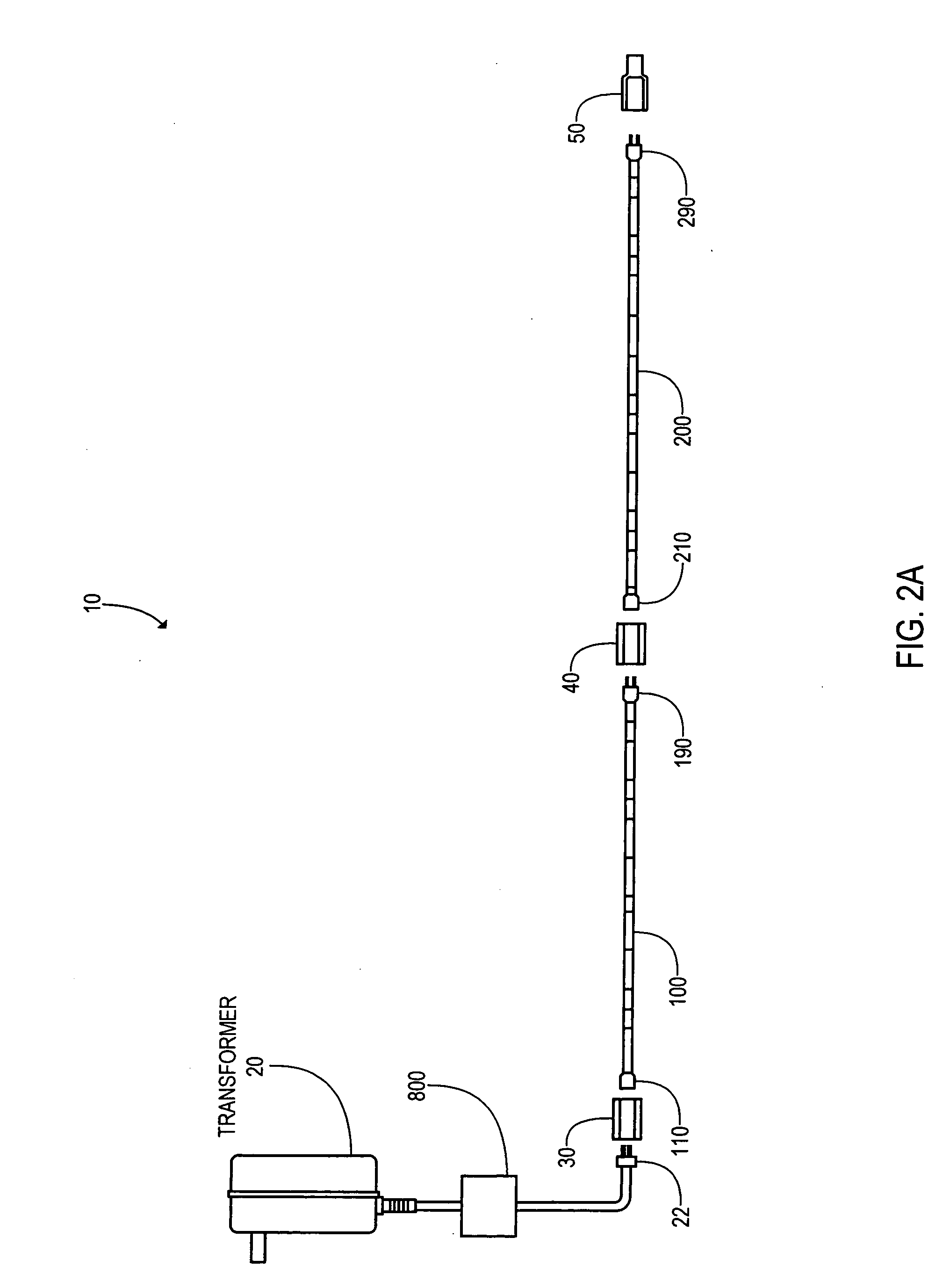

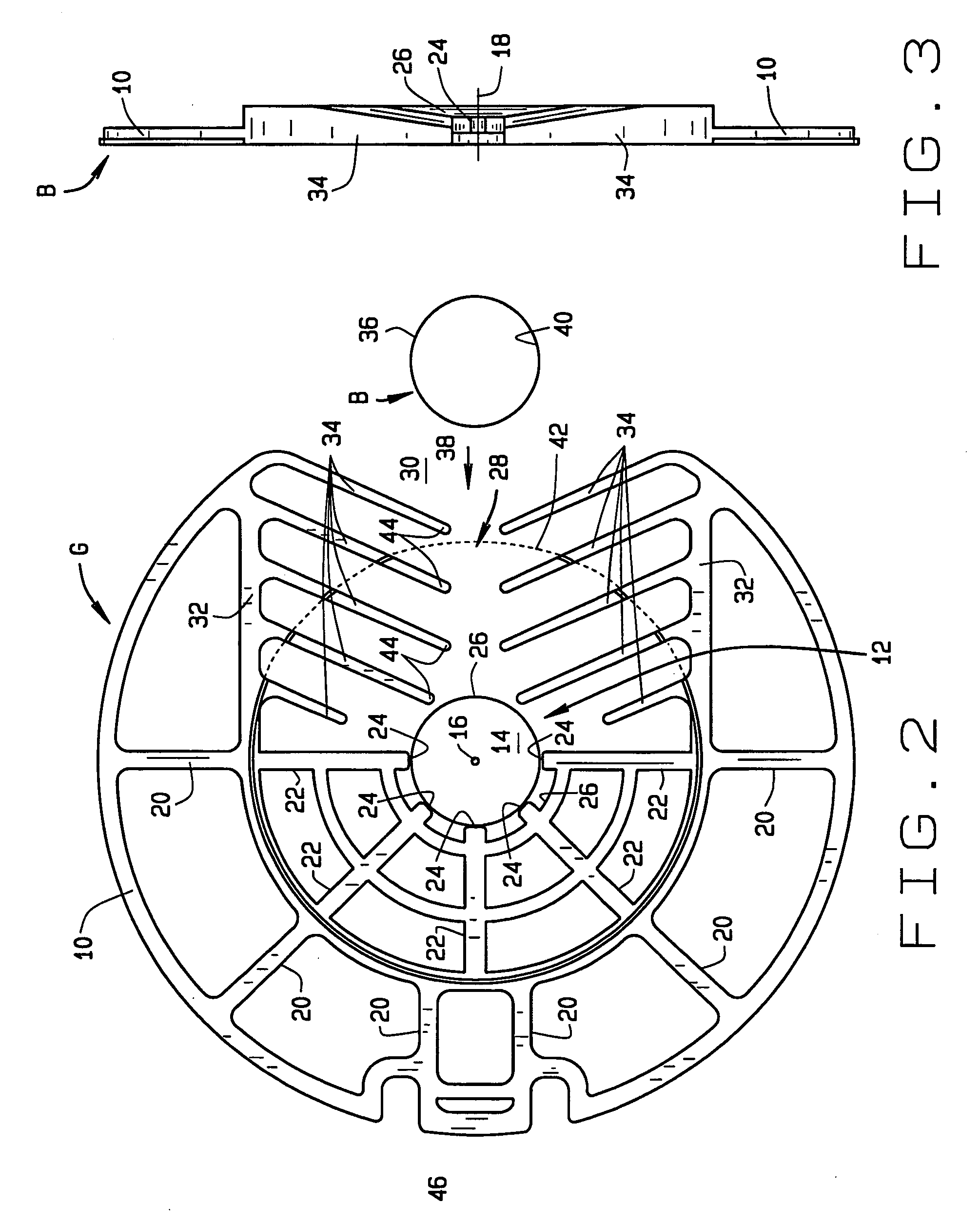

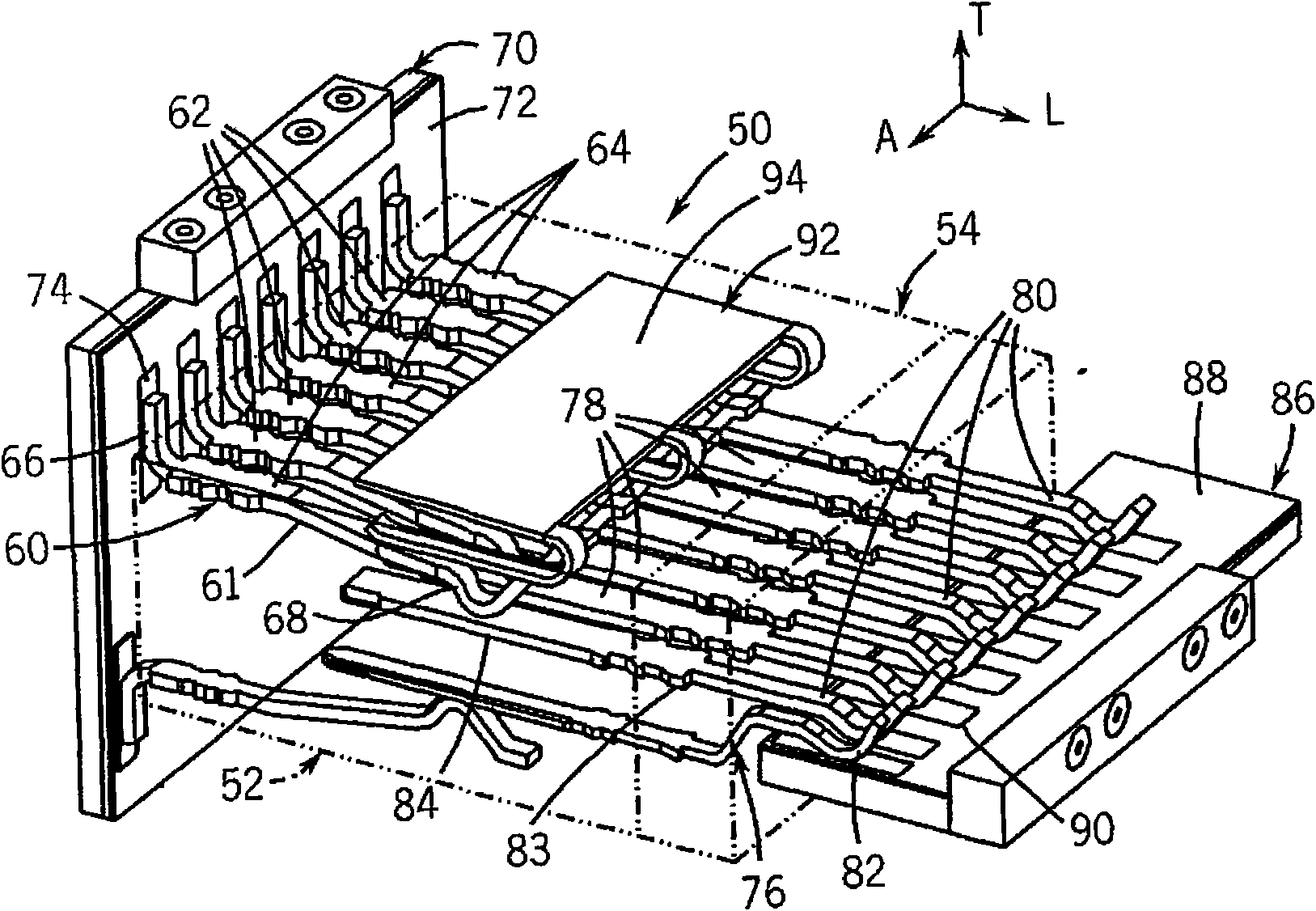

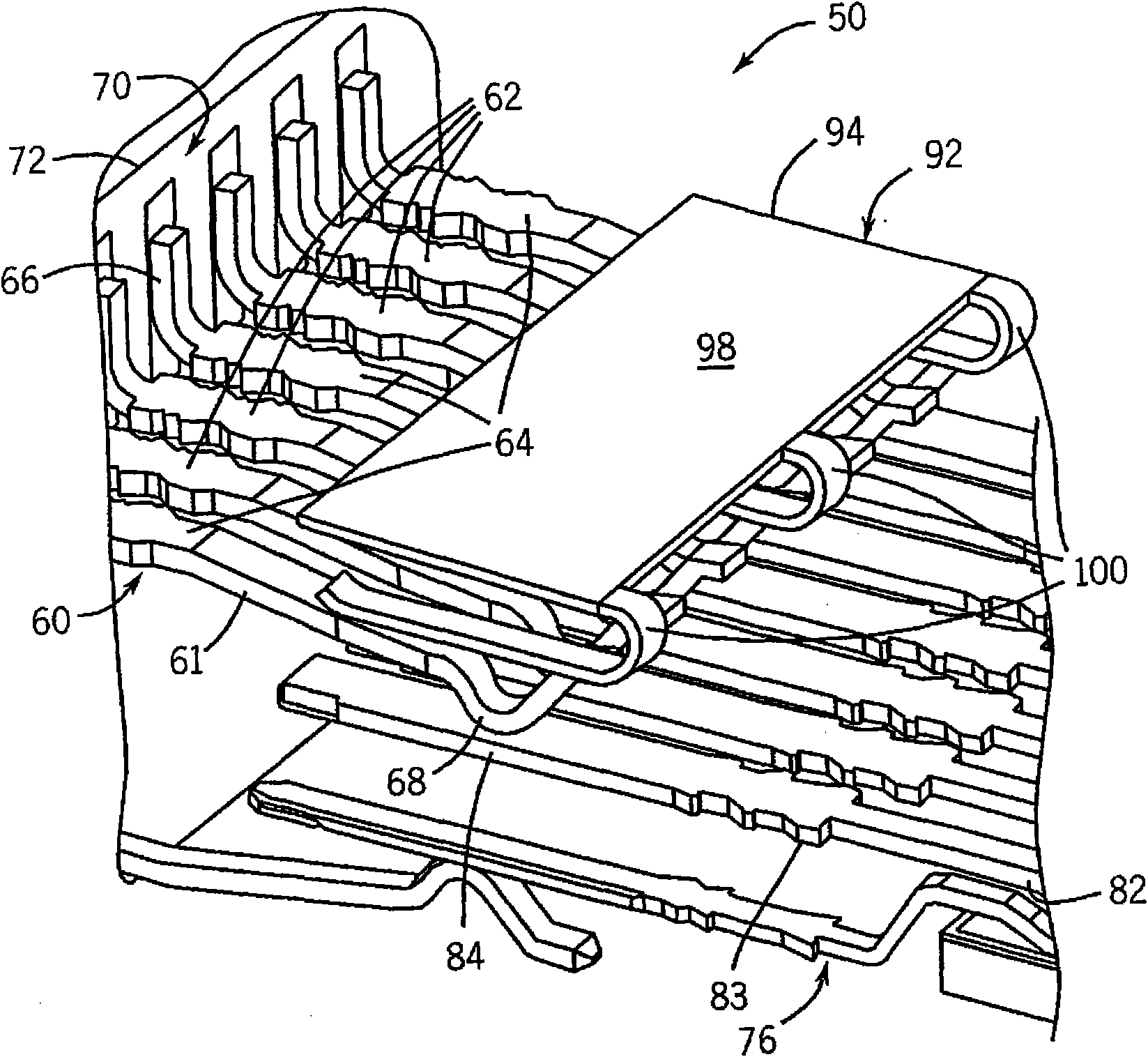

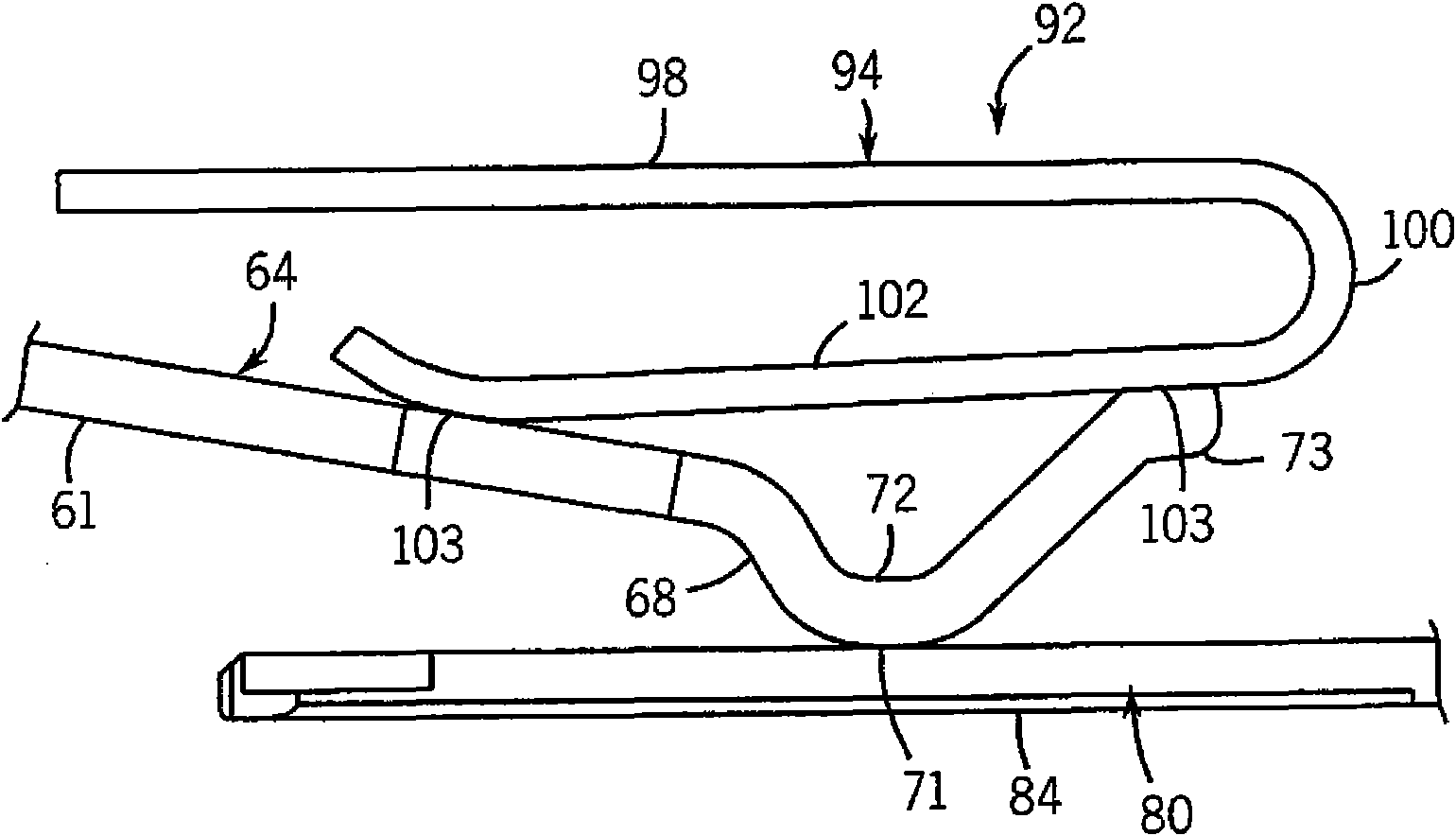

Methods and kits for covering electrical cables and connections

ActiveUS20100279542A1Wave amplification devicesCable fittingsElectrical conductorElectrical connection

A method for forming a connection assembly includes: forming an electrical connection between first and second electrical cables, the first cable including a first primary conductor and a first neutral conductor, the second cable including a second primary conductor and a second neutral conductor; and providing an integral, unitary cover assembly. The cover assembly includes: an inner elastomeric sleeve defining a cable passage to receive the electrical connection and the first and second primary conductors; and an outer elastomeric sleeve surrounding the inner sleeve. The method further includes: mounting the cover assembly on the cables such that the electrical connection and the first and second primary conductors extend through the cable passage; installing a first protective sleeve on a first neutral segment of the first neutral conductor; routing the first neutral segment and the first protective sleeve exteriorly of the outer sleeve to a second neutral segment of the second neutral conductor; and mechanically and electrically coupling the first and second neutral segments to thereby provide electrical continuity between the first neutral conductor and the second neutral conductor.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

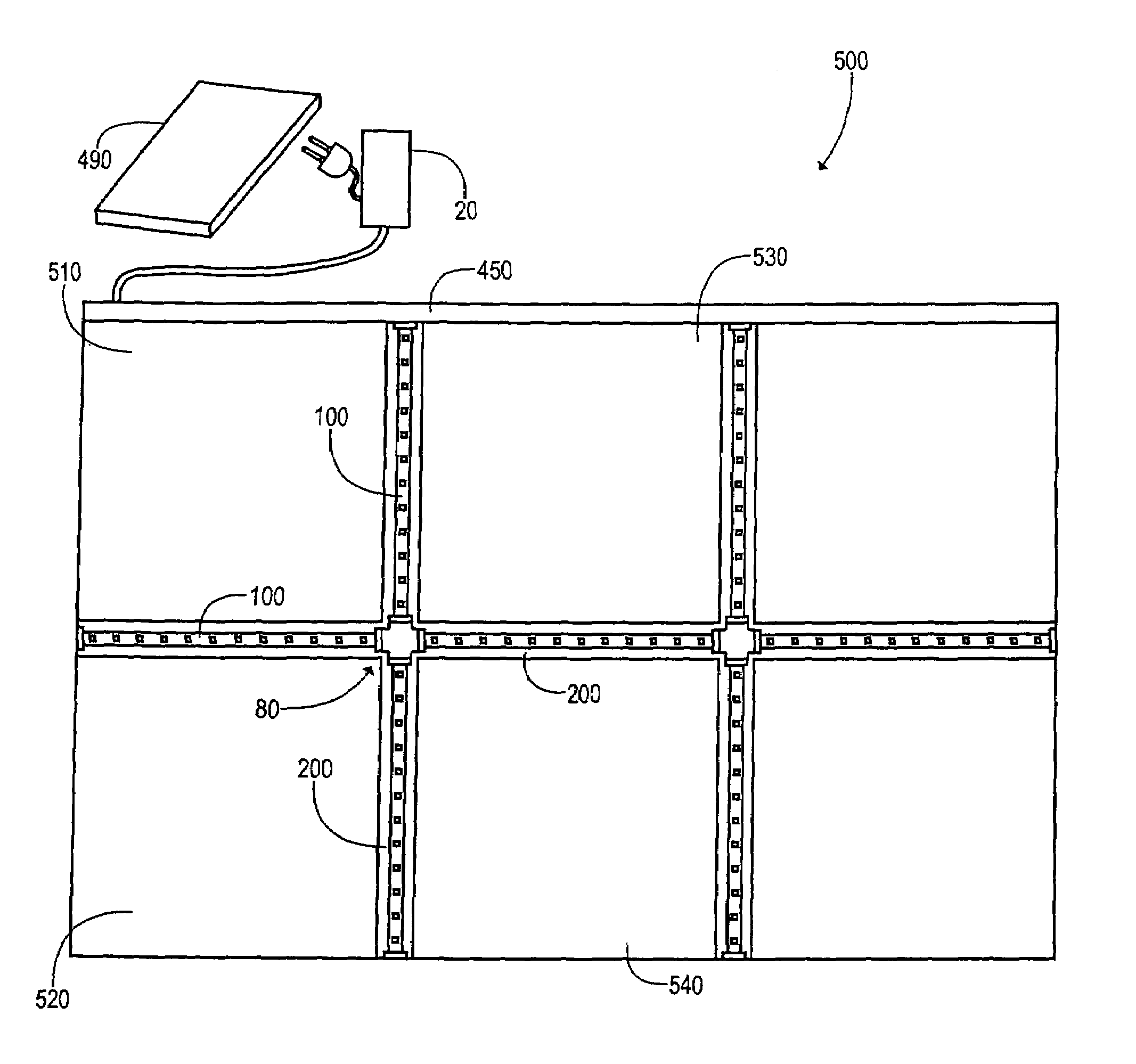

LED lighting for glass tiles

InactiveUS7549784B1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceInterconnectorBrick

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

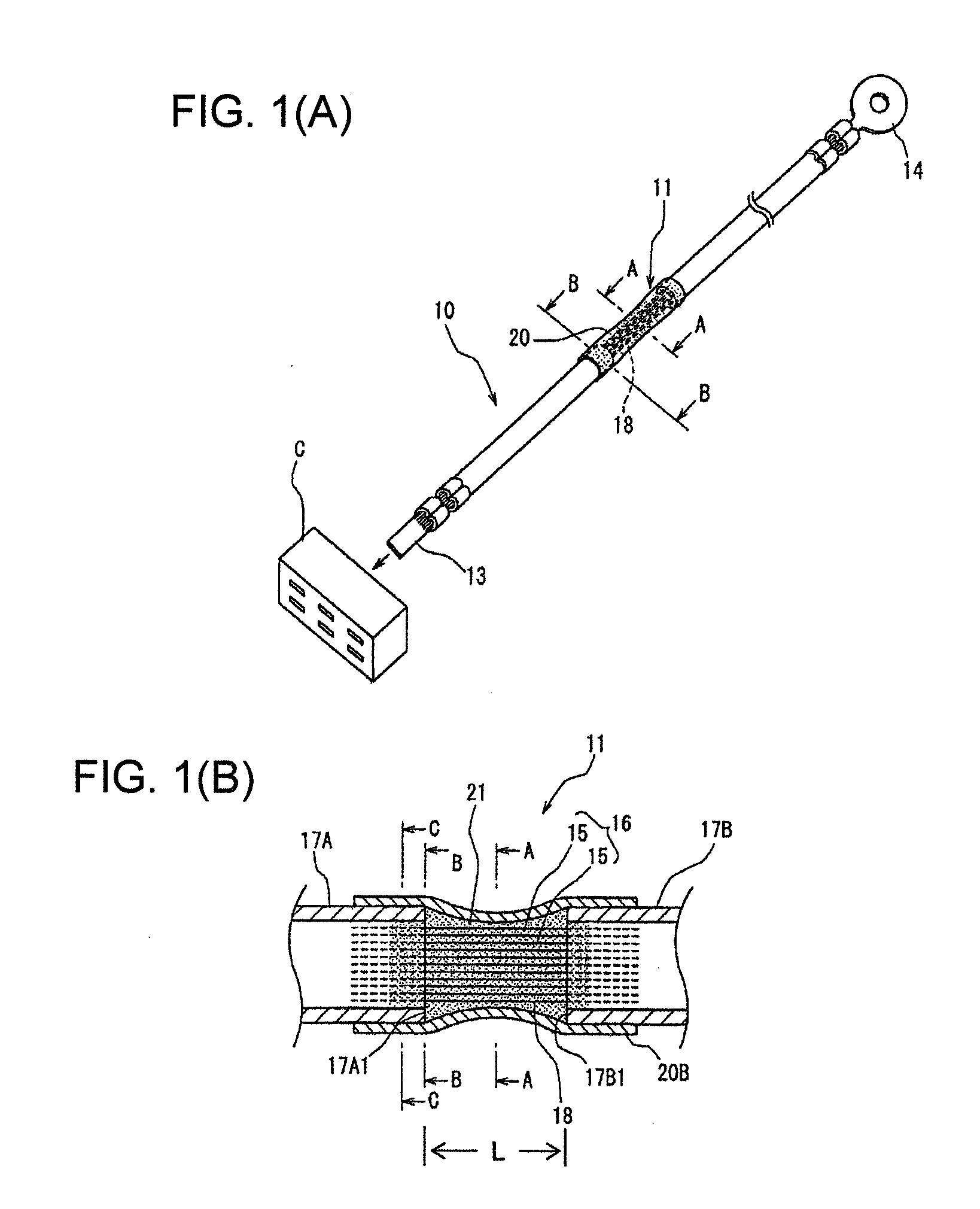

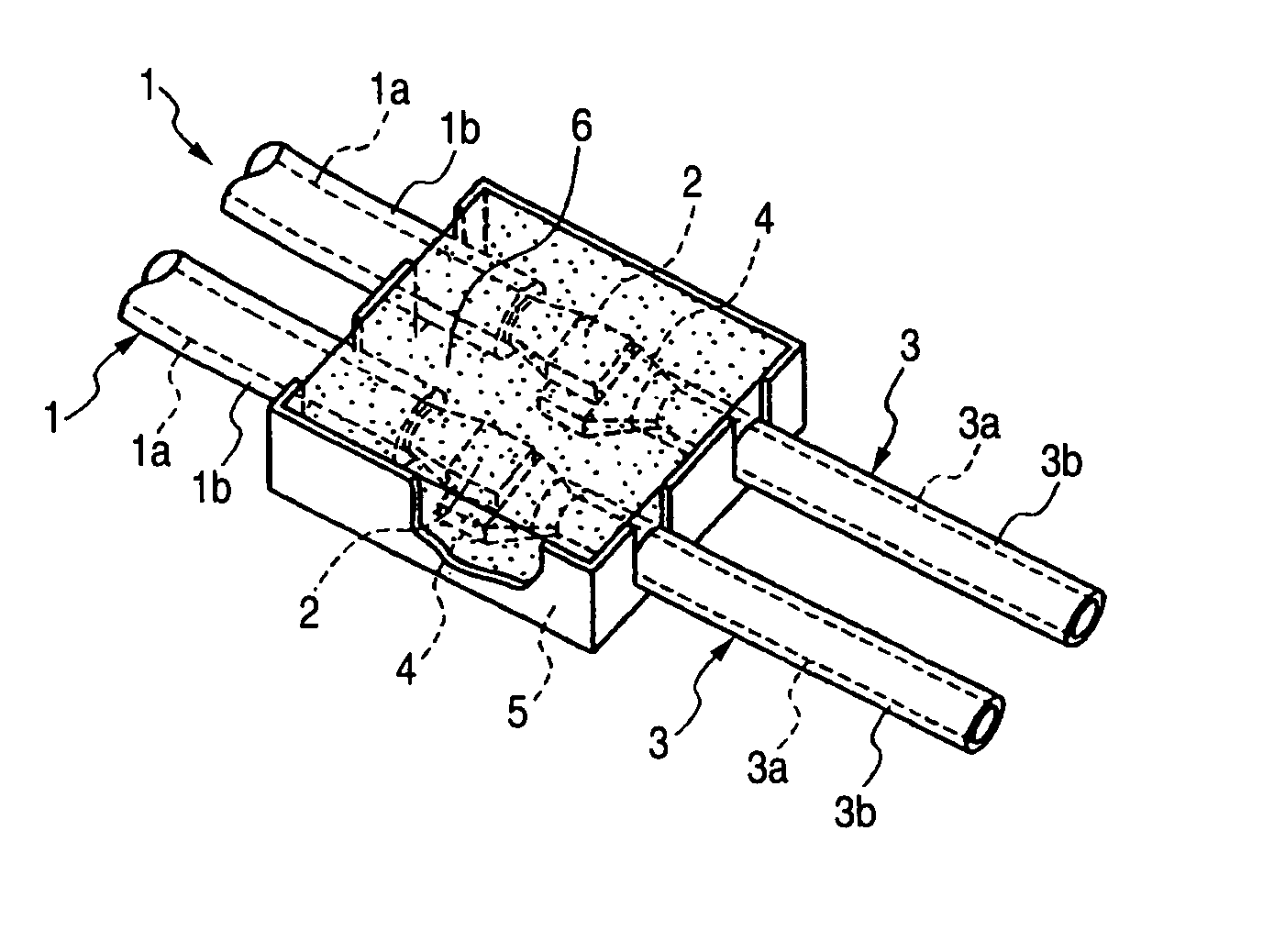

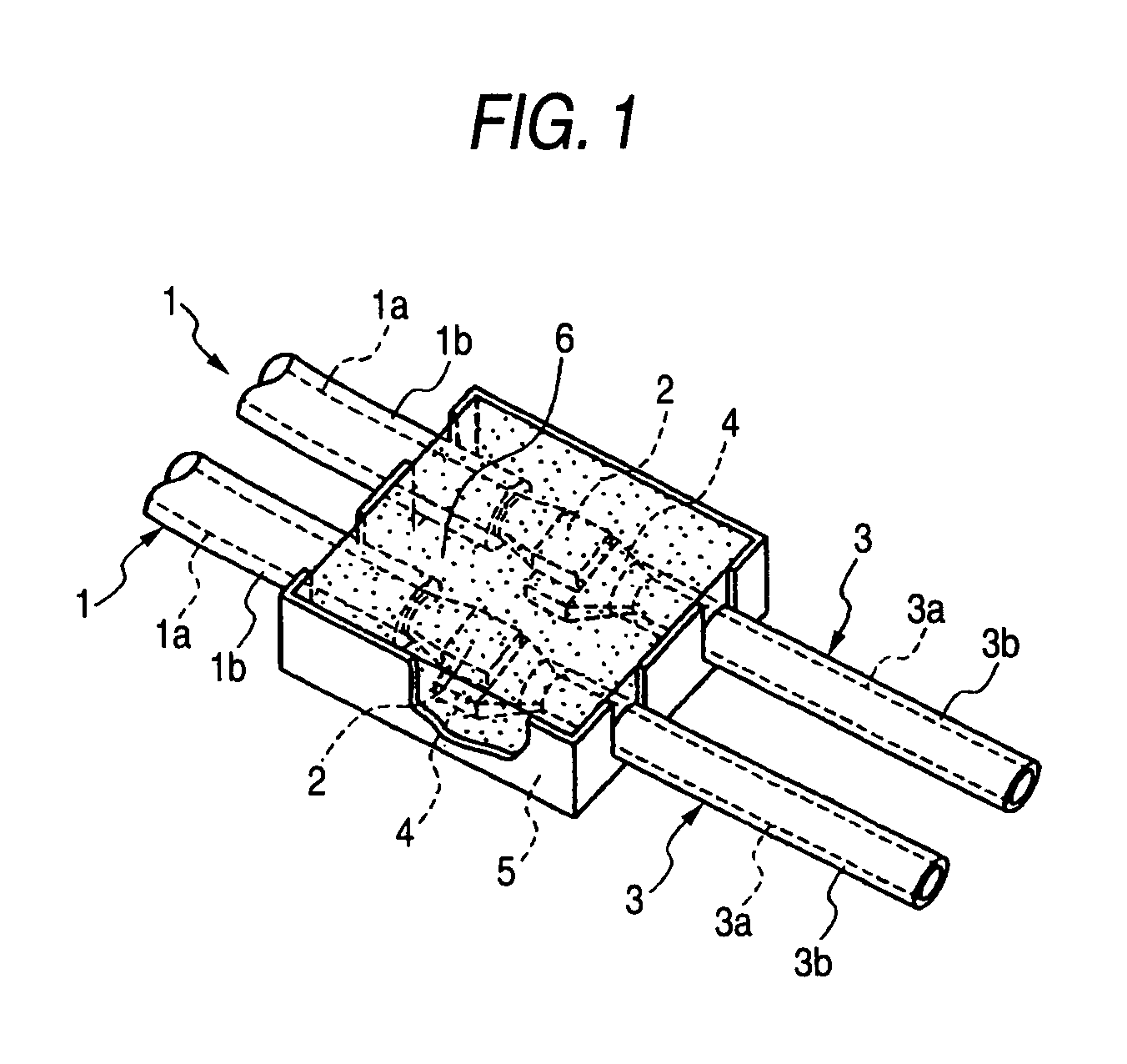

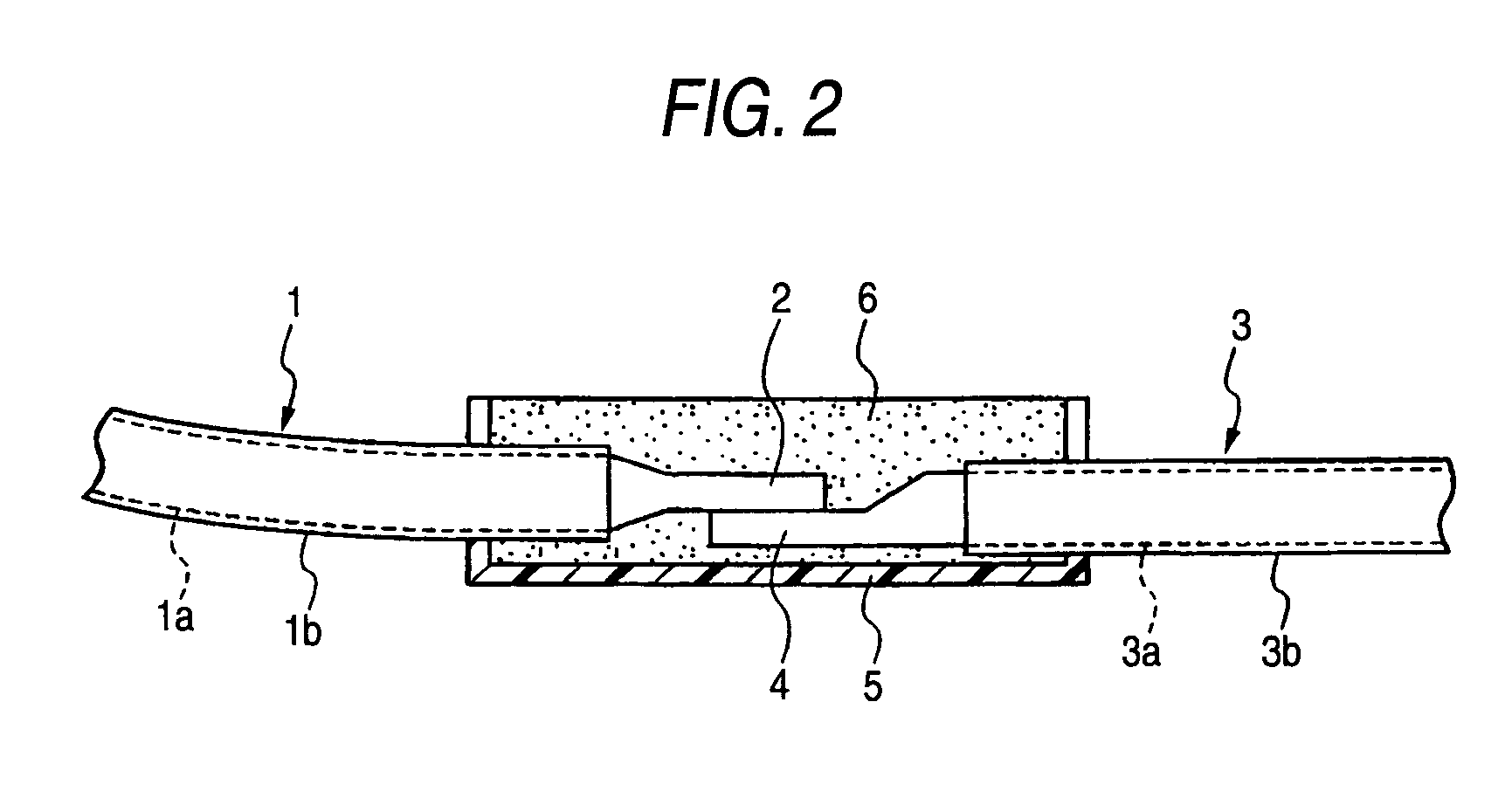

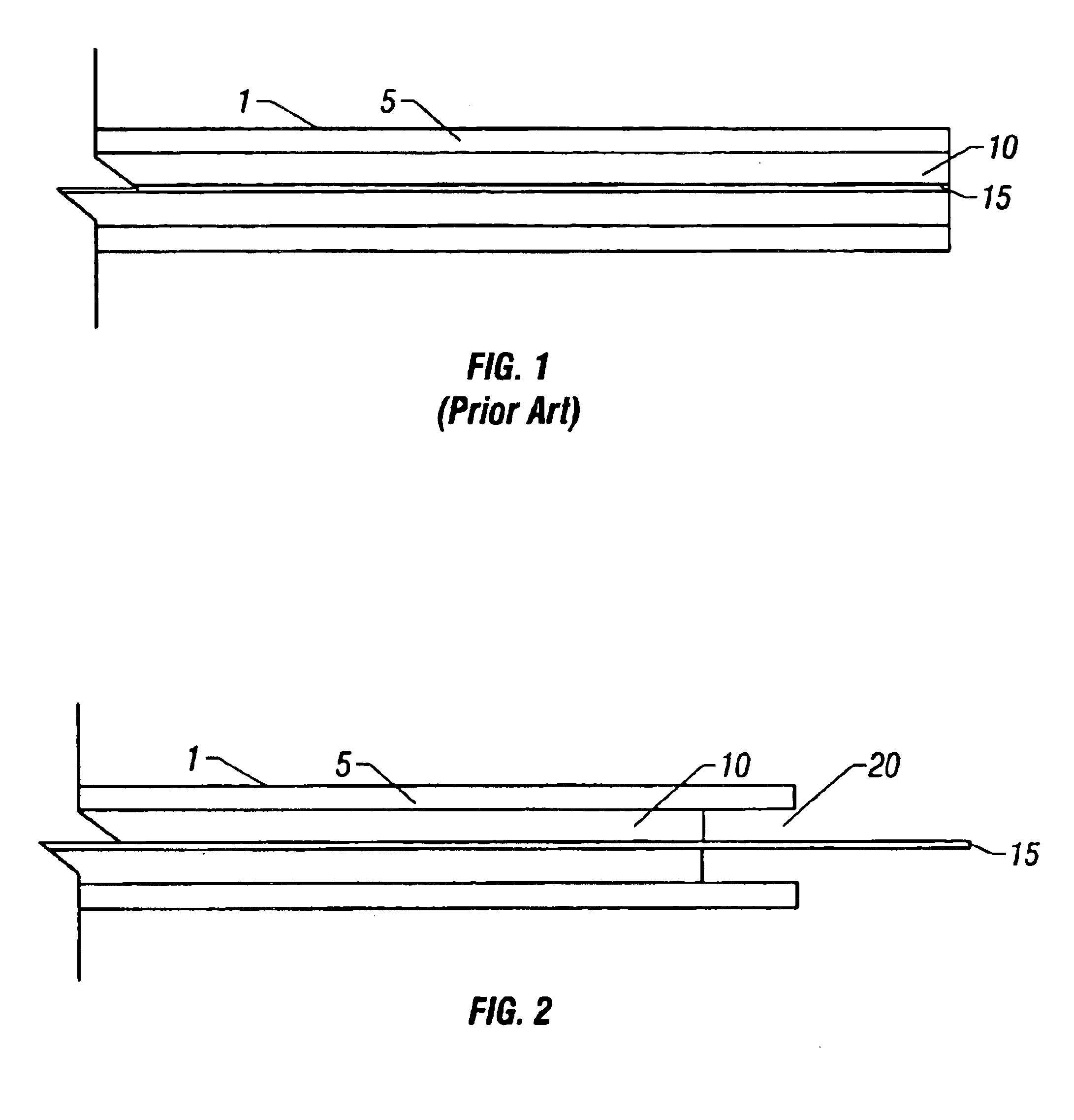

High-voltage wire connecting structure and high-voltage wire connecting method

InactiveUS20060121773A1Fast curingCouplings bases/casesSoldered/welded connectionsElectrical conductorEngineering

A portion of a conductor 1a of each high-voltage wire, exposed by removing an insulating sheath 1b, is formed into a flat plate-like terminal 2 of an integral construction. A portion of a conductor 3a of each of the other high-voltage wires 3, exposed from an insulating sheath 3b, is formed into a flat plate-like terminal 4. Each mating pair of flat plate-like terminals 2 and 4 are connected together by welding or melt adhesion, and are received within an insulating casing 5, and are sealed by a hot-melt adhesive 6 filled in the insulating casing 5.

Owner:YAZAKI CORP

Electric wire with terminal and connector

InactiveUS20130126234A1Waterproofness can be improvedAvoid stickingCable junctionsCable terminationsEngineeringWater block

An electric wire with terminal includes an electric wire covering an outer periphery of a core wire with an insulating coating and a female terminal. The female terminal includes: a wire barrel having a bottom plate on which the core wire is placed and crimped onto the core wire; a groove portion extending from the bottom plate in a direction in which the core wire extends and whose surface on the side where the core wire is placed is bent into a concave shape. The groove portion has a water blocking wall molded by synthetic resin. The water blocking wall is provided to fill the inside of the groove portion. A region extending from the water blocking wall to the end of the insulating coating is covered with a water blocking coating, and the inner surface of the water blocking coating is in close contact with the water blocking wall.

Owner:AUTONETWORKS TECH LTD +2

Nut seal assembly for coaxial cable system components

ActiveUS7500874B2Two pole connectionsSecuring/insulating coupling contact membersCoaxial cableEngineering

An integrated seal assembly and a coaxial cable system component incorporating the seal assembly with a connector for coupling to an externally threaded port. The seal assembly includes a bellows-type seal having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces is made to engage a corresponding surface of an internally threaded nut or housing. The component is engagable with an externally threaded port via the internally threaded connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector of a system component on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

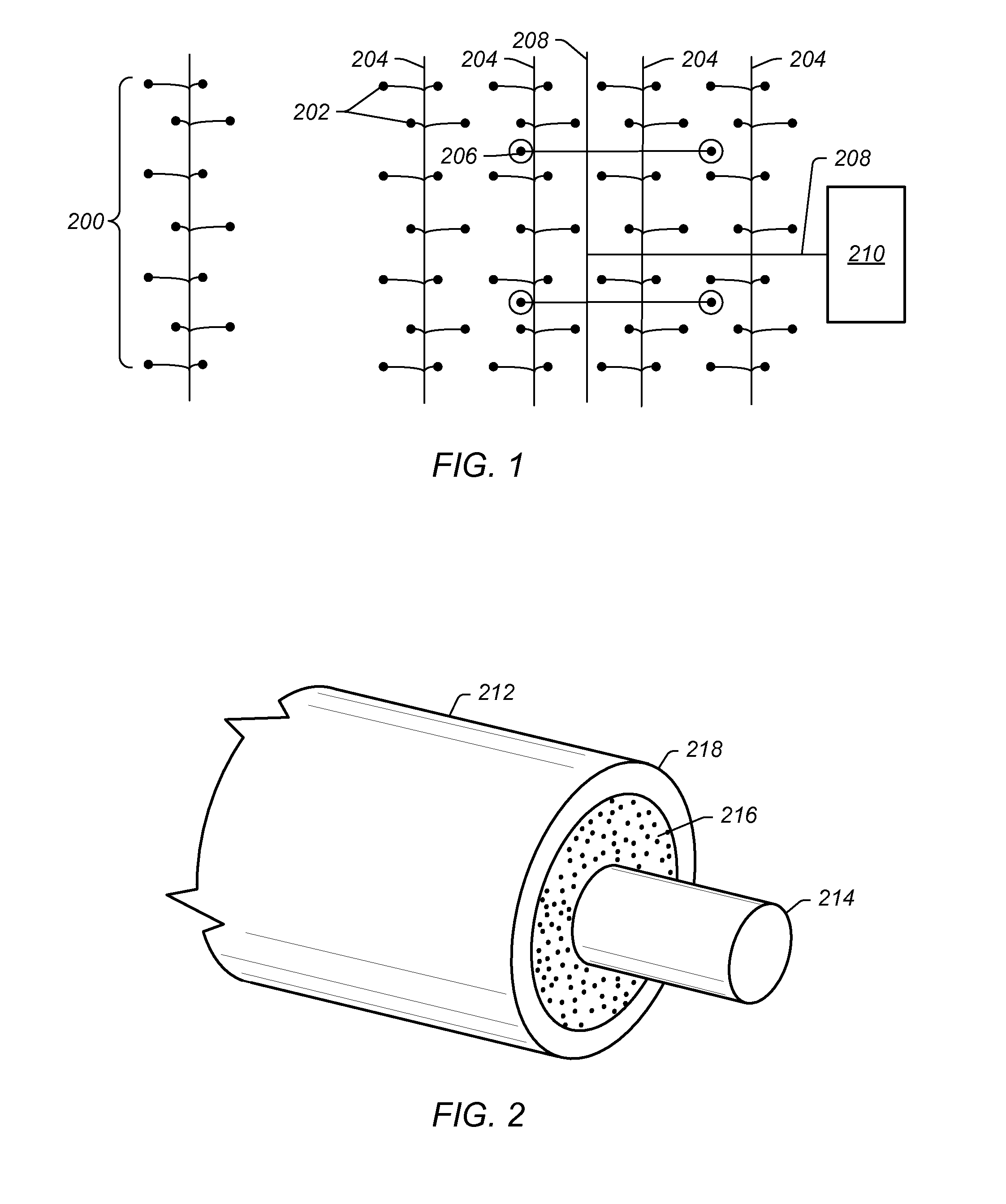

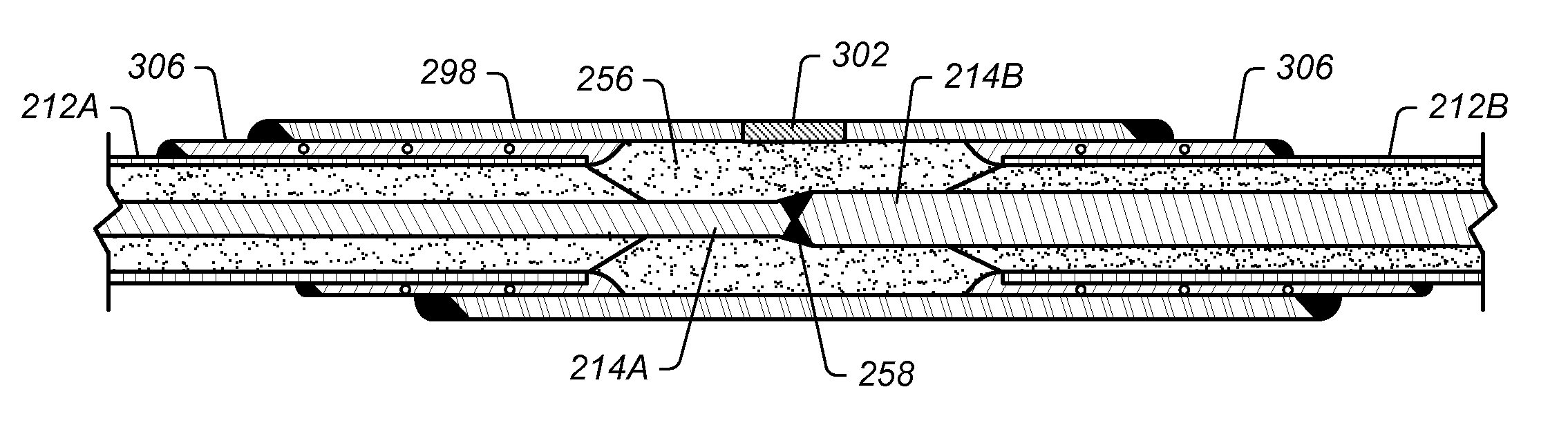

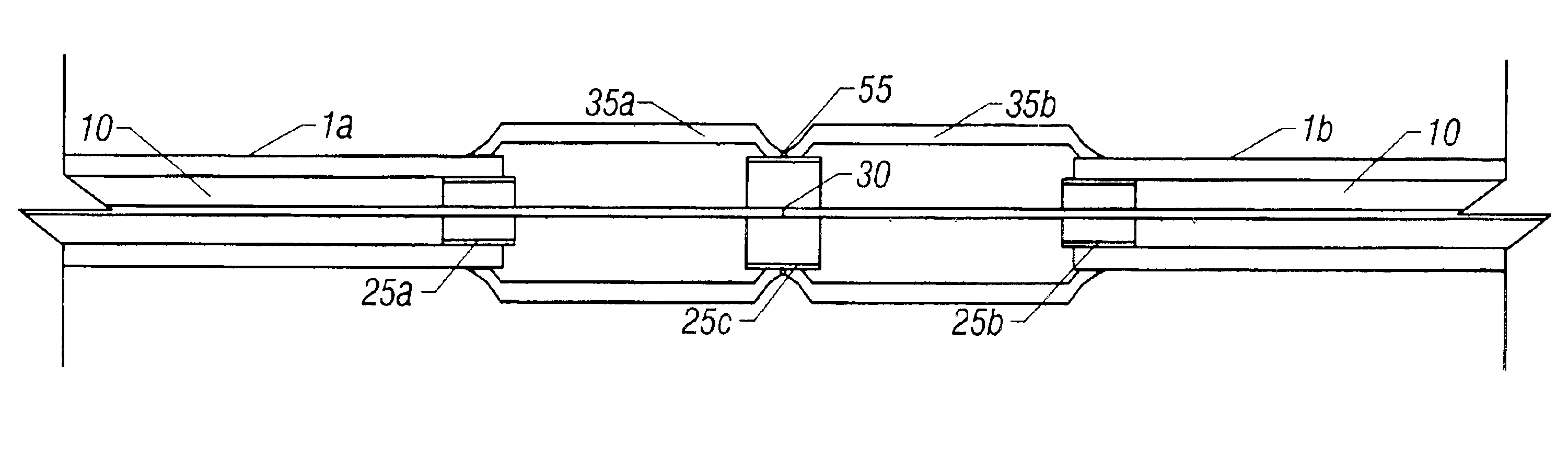

Press-fit coupling joint for joining insulated conductors

ActiveUS8257112B2Line/current collector detailsSecuring/insulating coupling contact membersElectrical conductorCoupling

A fitting for coupling an end of a first insulated conductor to an end of a second insulated conductor is described. The fitting includes a sleeve placed over the end of the first insulated conductor and the end of the second insulated conductor and a core coupling located inside the sleeve. The core coupling fits around an end of a core of the first insulated conductor and an end of a core of the second insulated conductor. An interior volume of the sleeve is at least partially filled with electrically insulating material. The electrically insulating material is compressed with an end portion of an electrical insulator in the first insulated conductor and an end portion of an electrical insulator in the second insulated conductor when the fitting is coupled to the insulated conductors.

Owner:SALAMANDER IP HLDG LLC

Integral bonding attachment

ActiveUS7896712B2Couplings bases/casesConnections effected by permanent deformationEngineeringElectrical and Electronics engineering

Owner:CARLISLE INTERCONNECT TECH

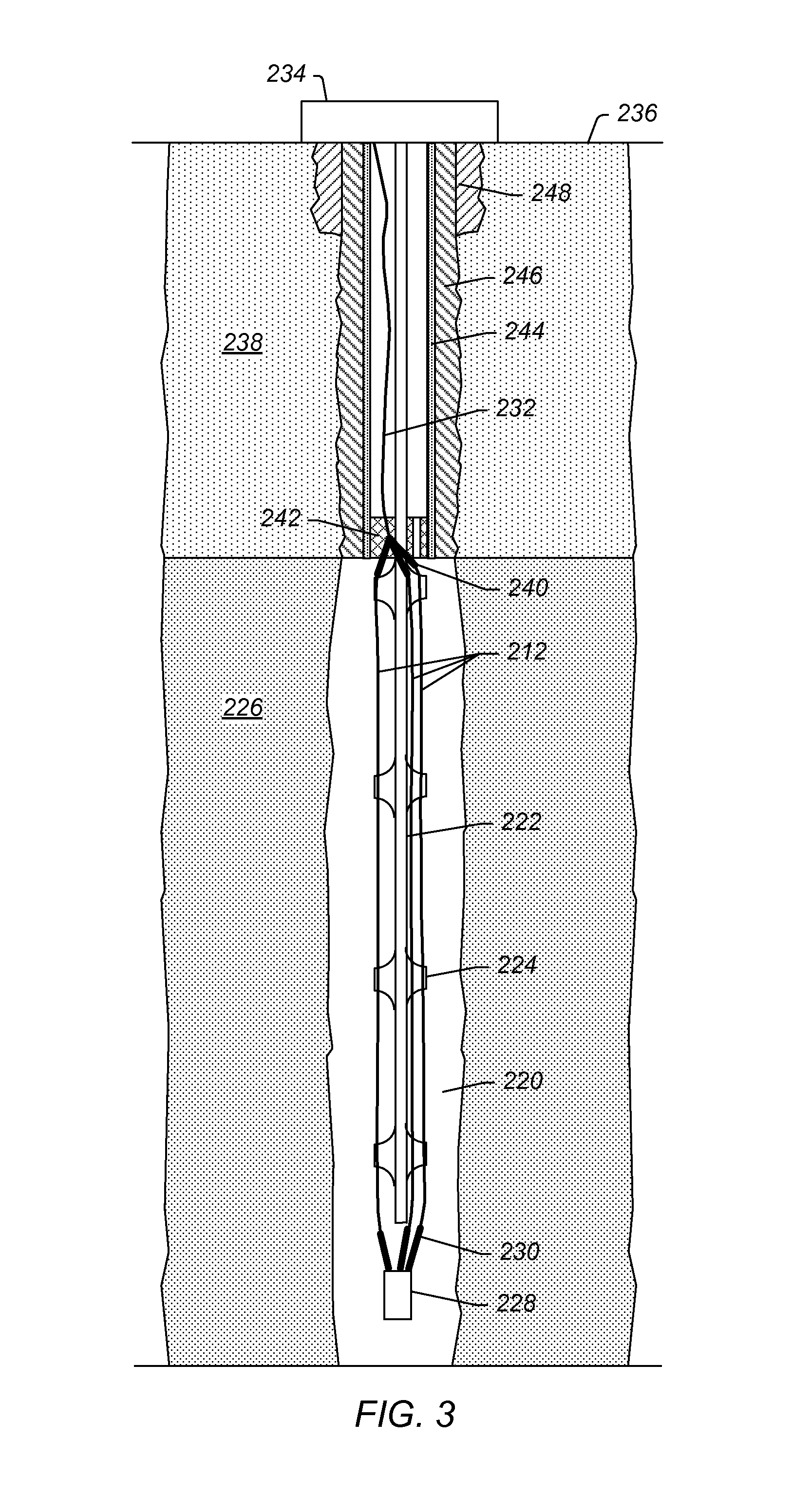

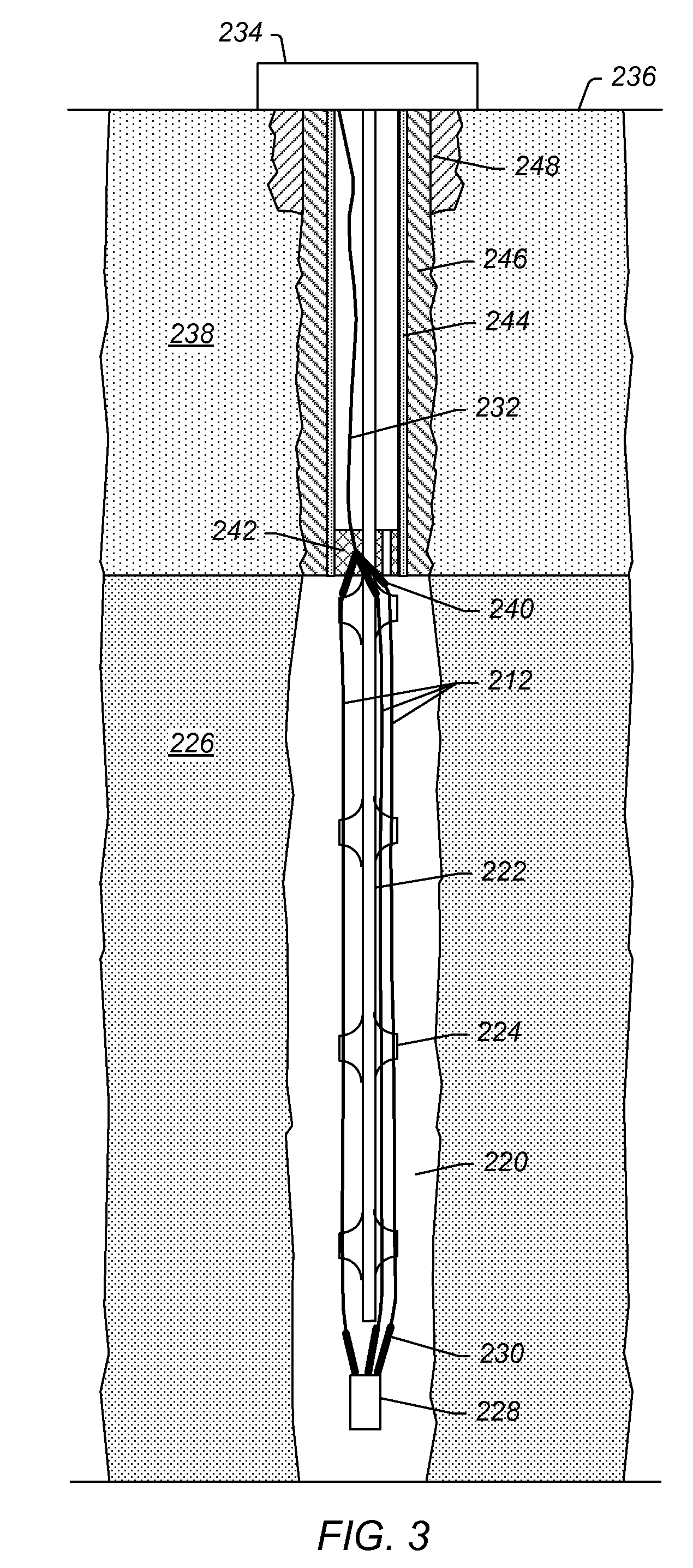

Field weldable connections

The present invention provides a field weldable connection. In one embodiment, the field weldable connection is a downhole connector assembly for sealingly attaching a first and a second segment of a control line. The control line has an outer housing that encapsulates a polymeric secondary housing. A communication line runs therethrough the secondary housing. The connector further comprises a weld coupling welded to the outer housing of the first and second segments of the control line. To protect the communication line from the thermal radiation and heat generated during the welding process, at least one reflective sleeve replaces a portion of the secondary housing at a location intermediate the communication line and the welds of the coupling.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com