Patents

Literature

151results about How to "High sealing pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

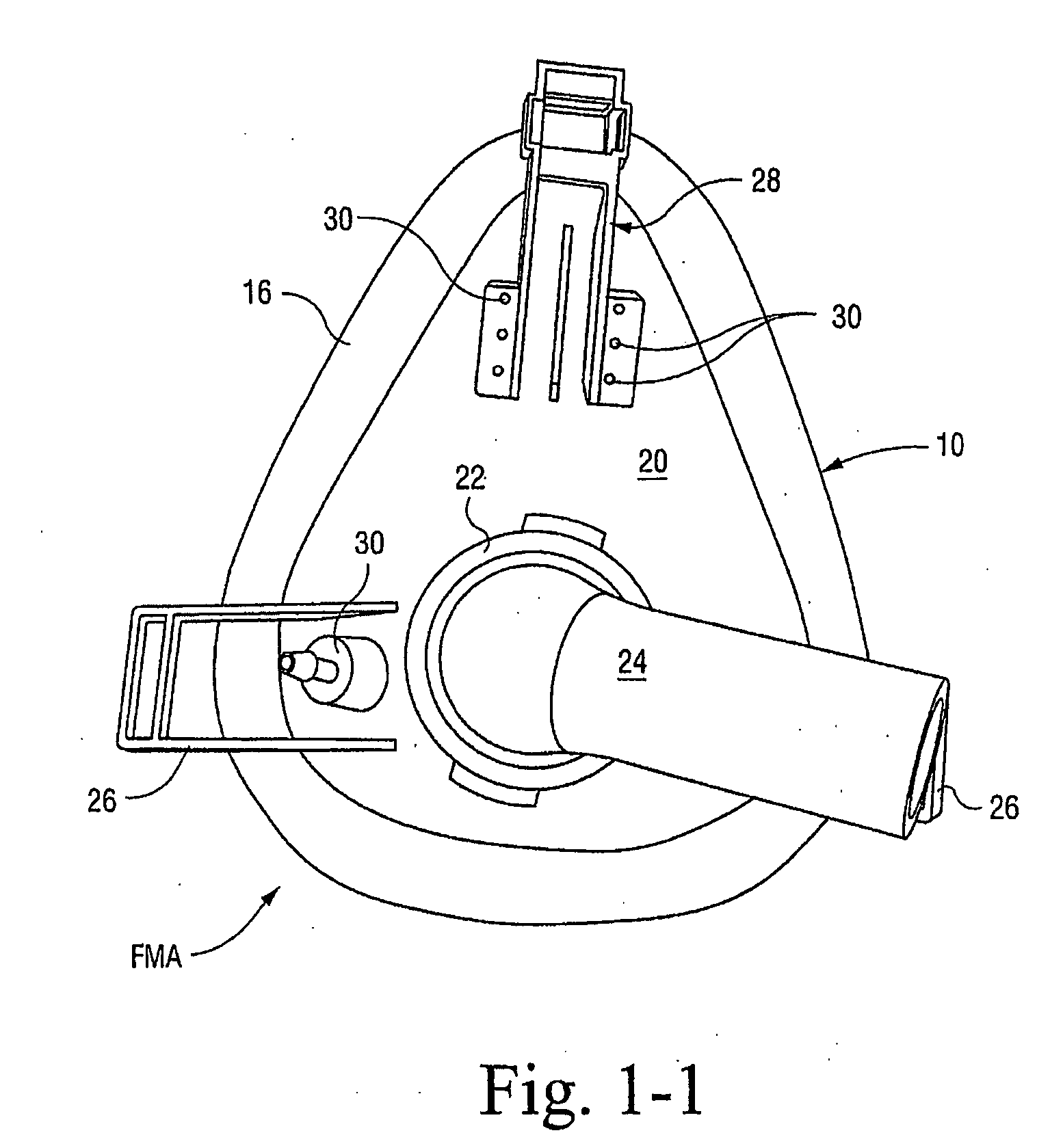

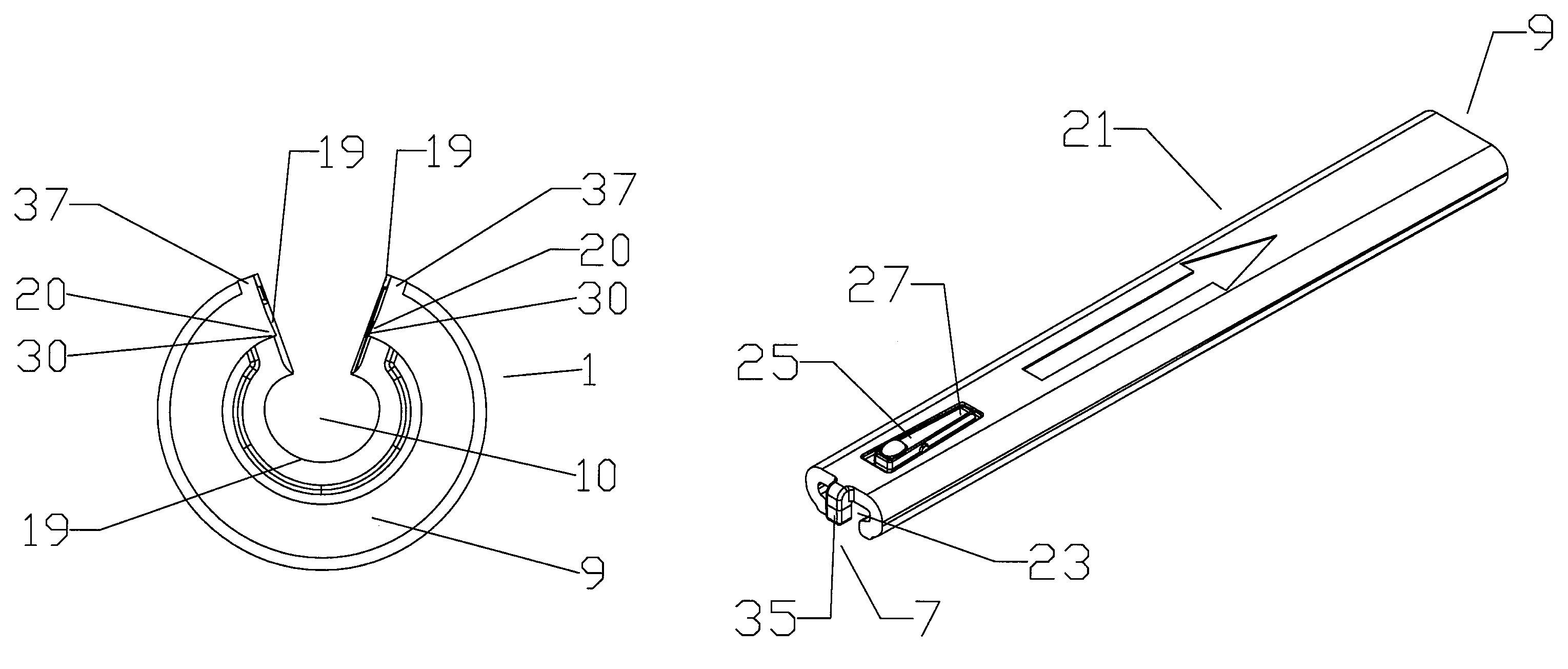

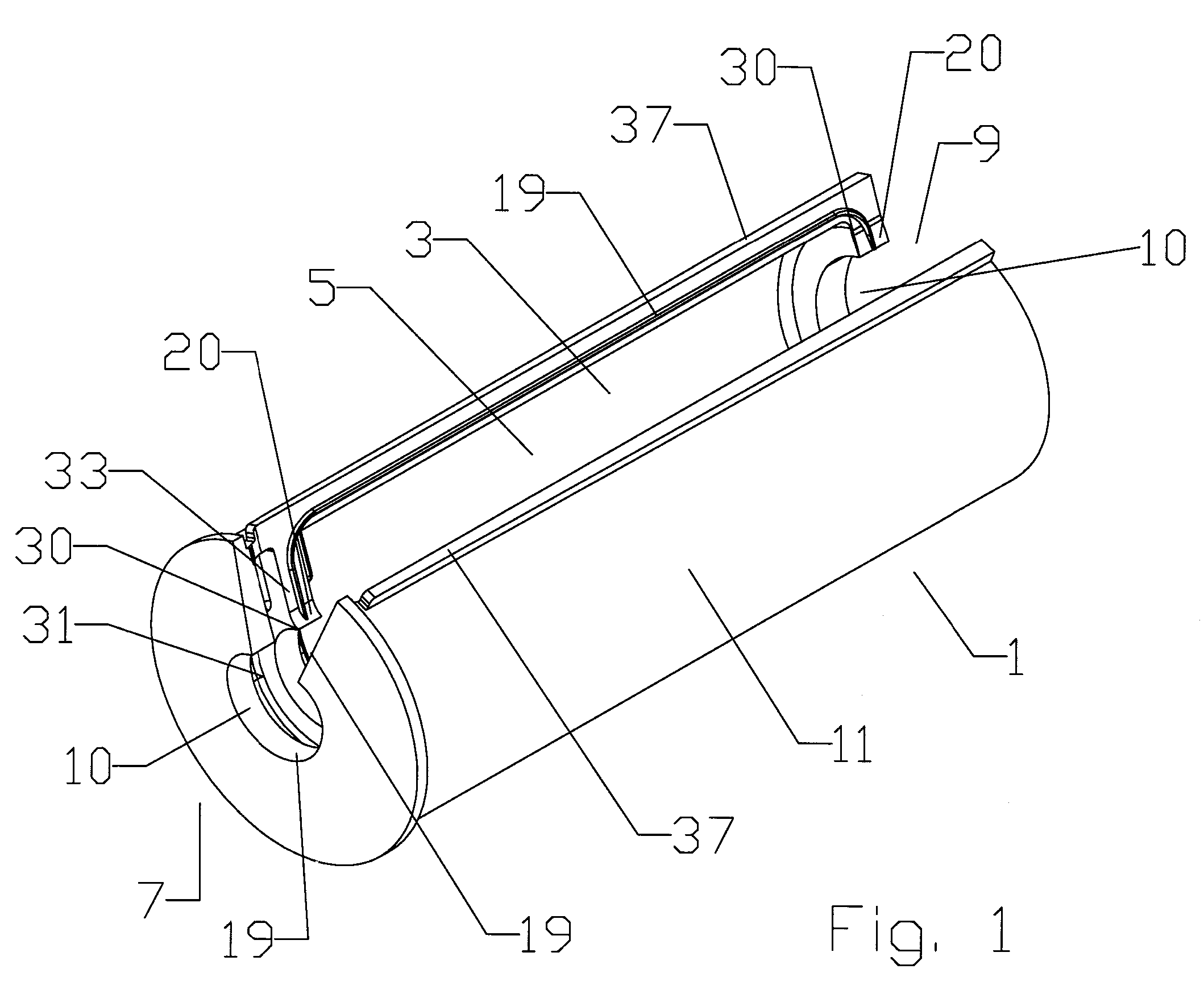

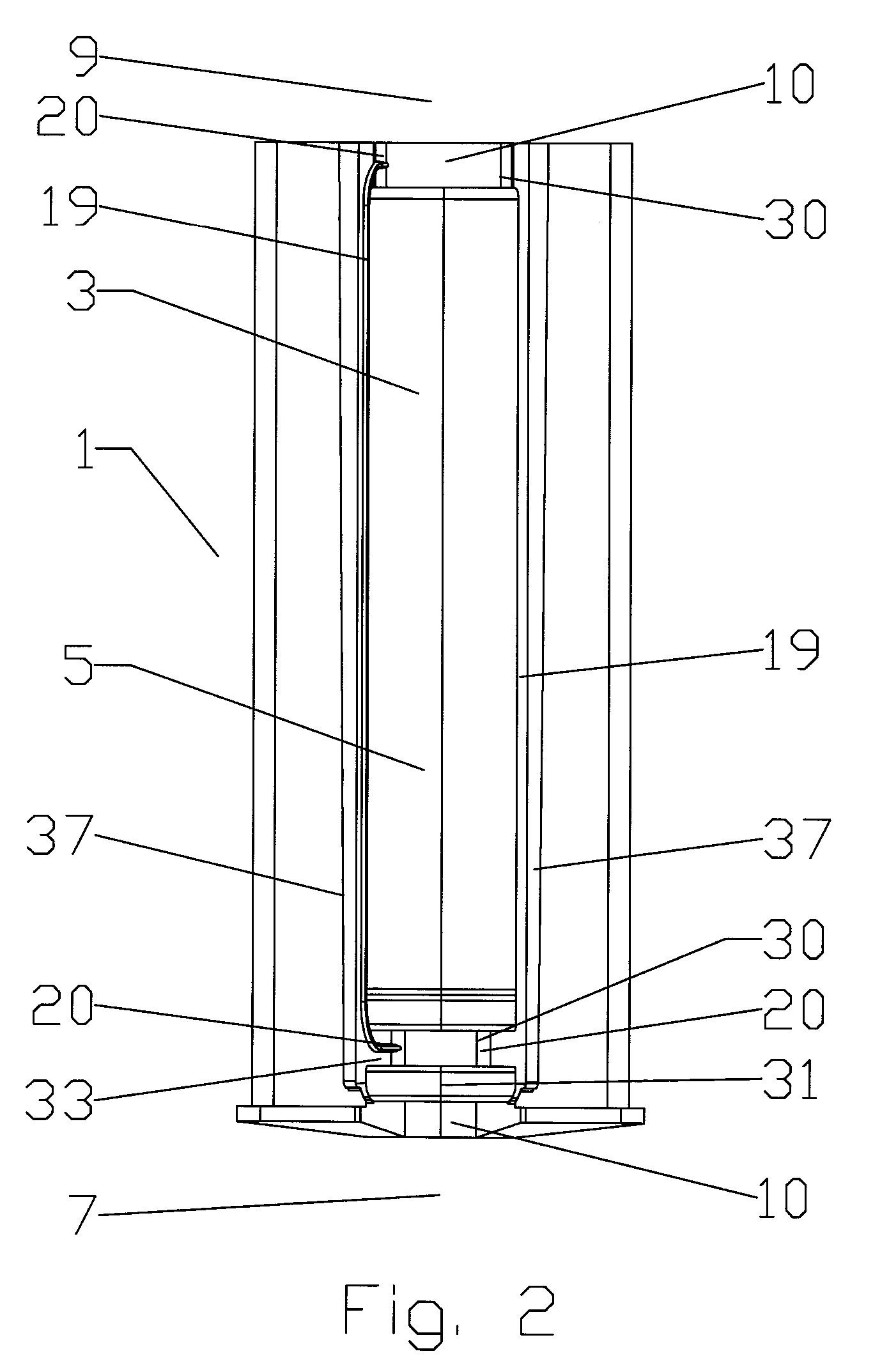

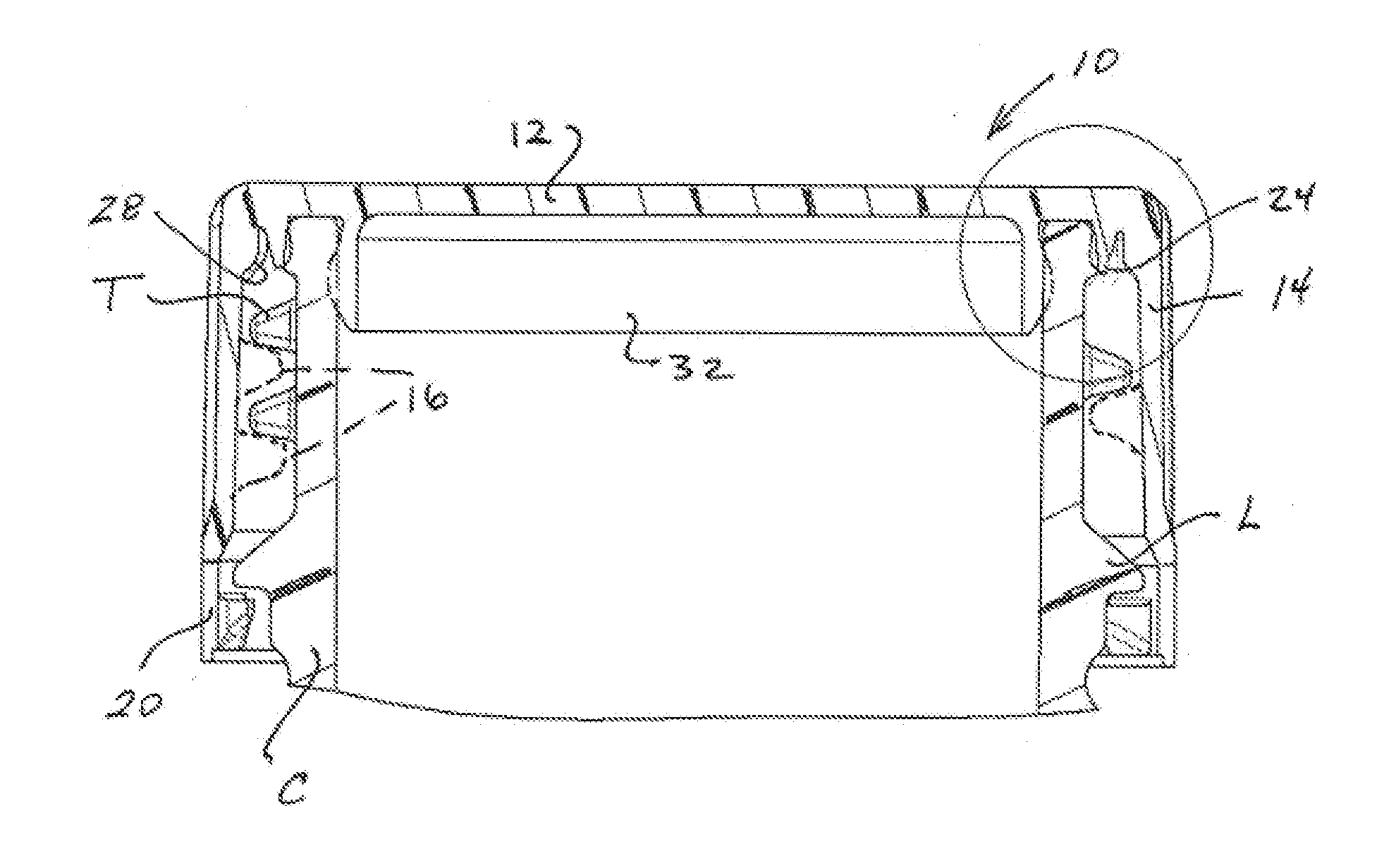

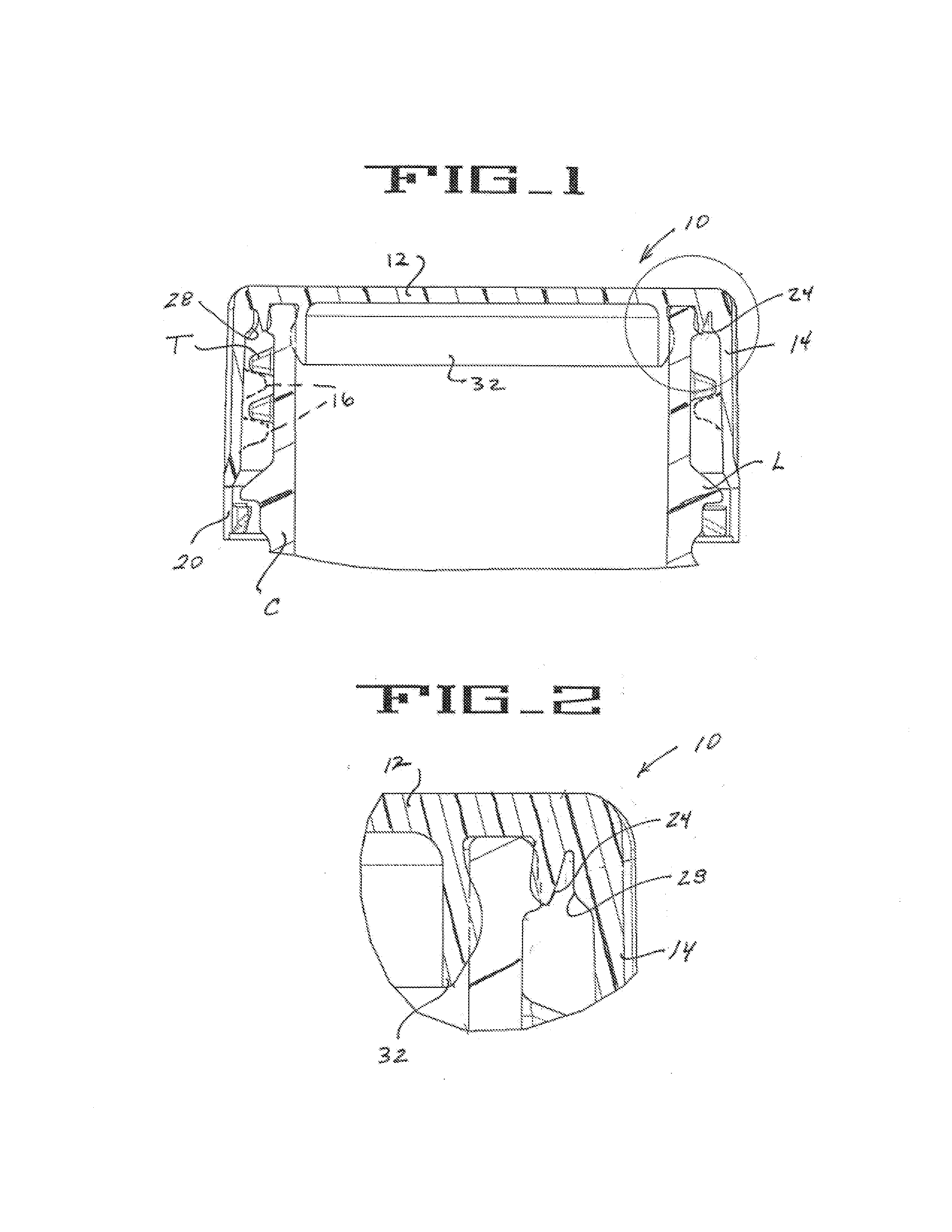

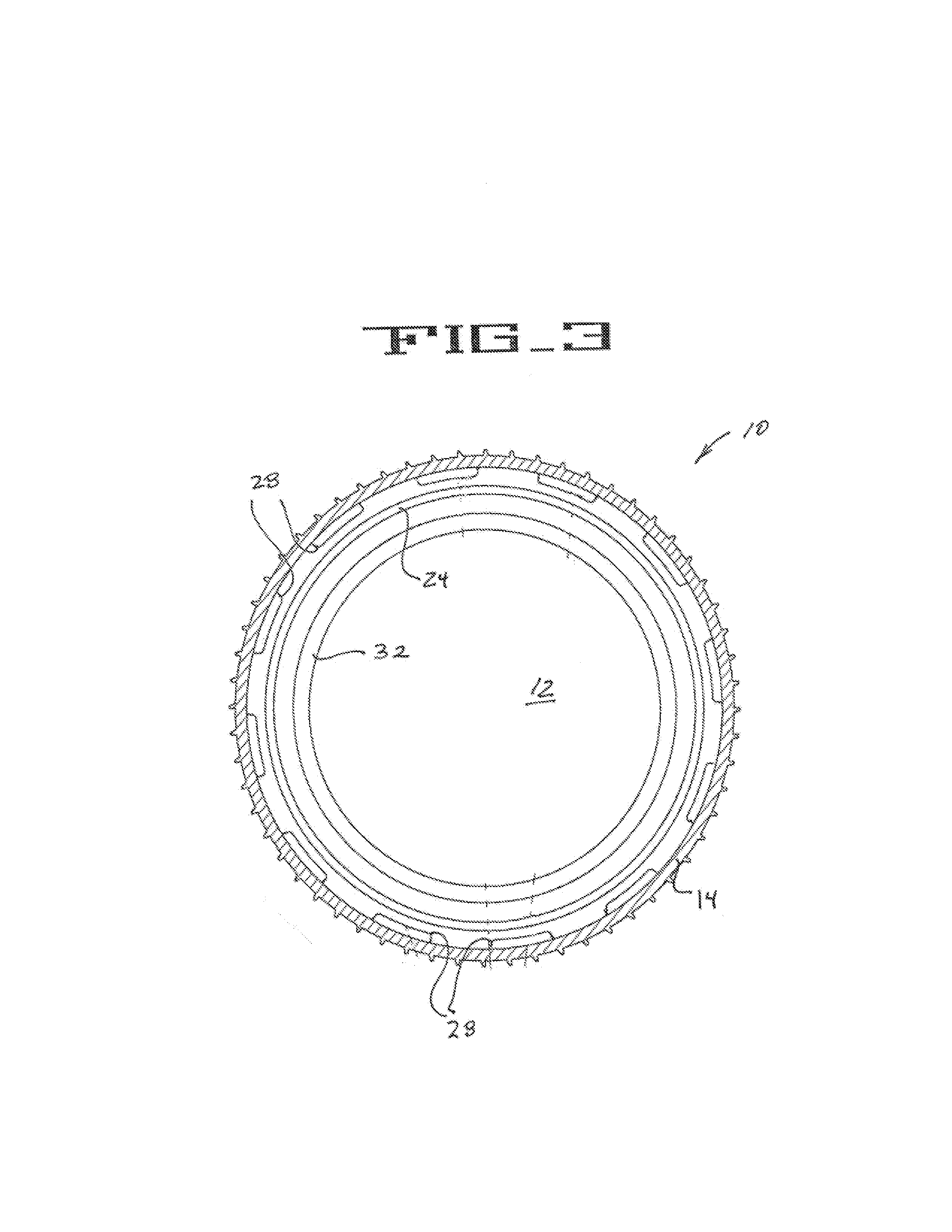

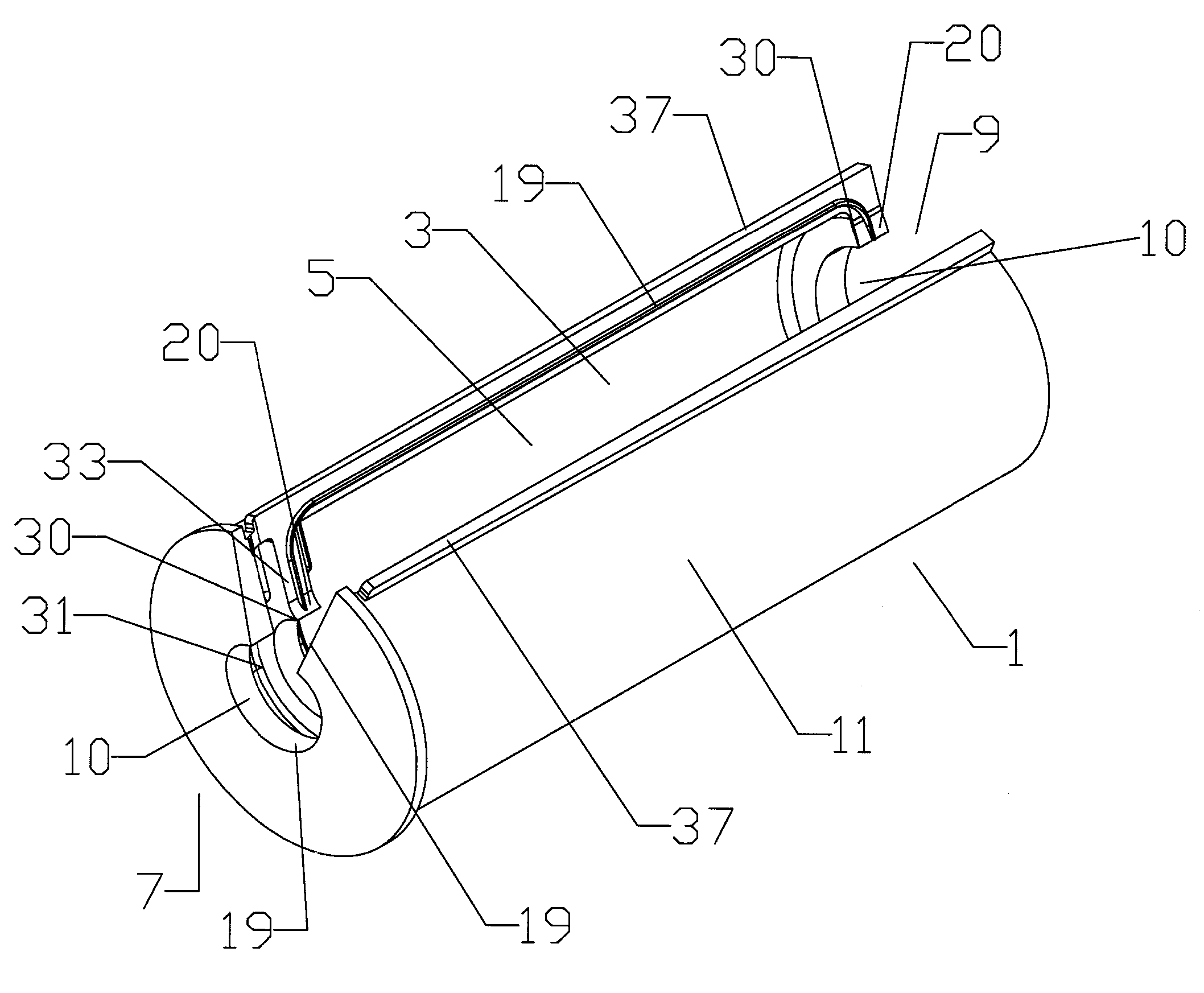

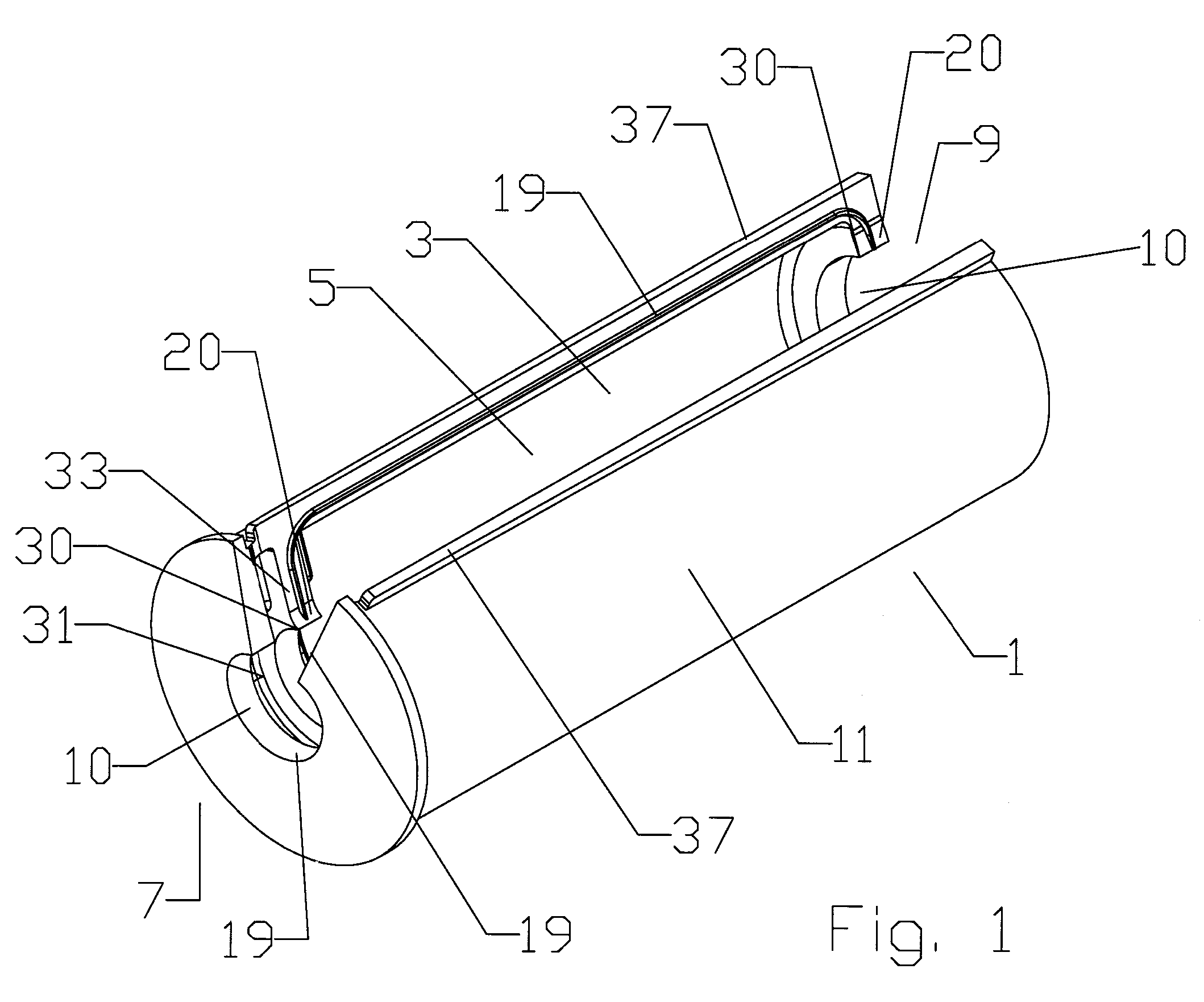

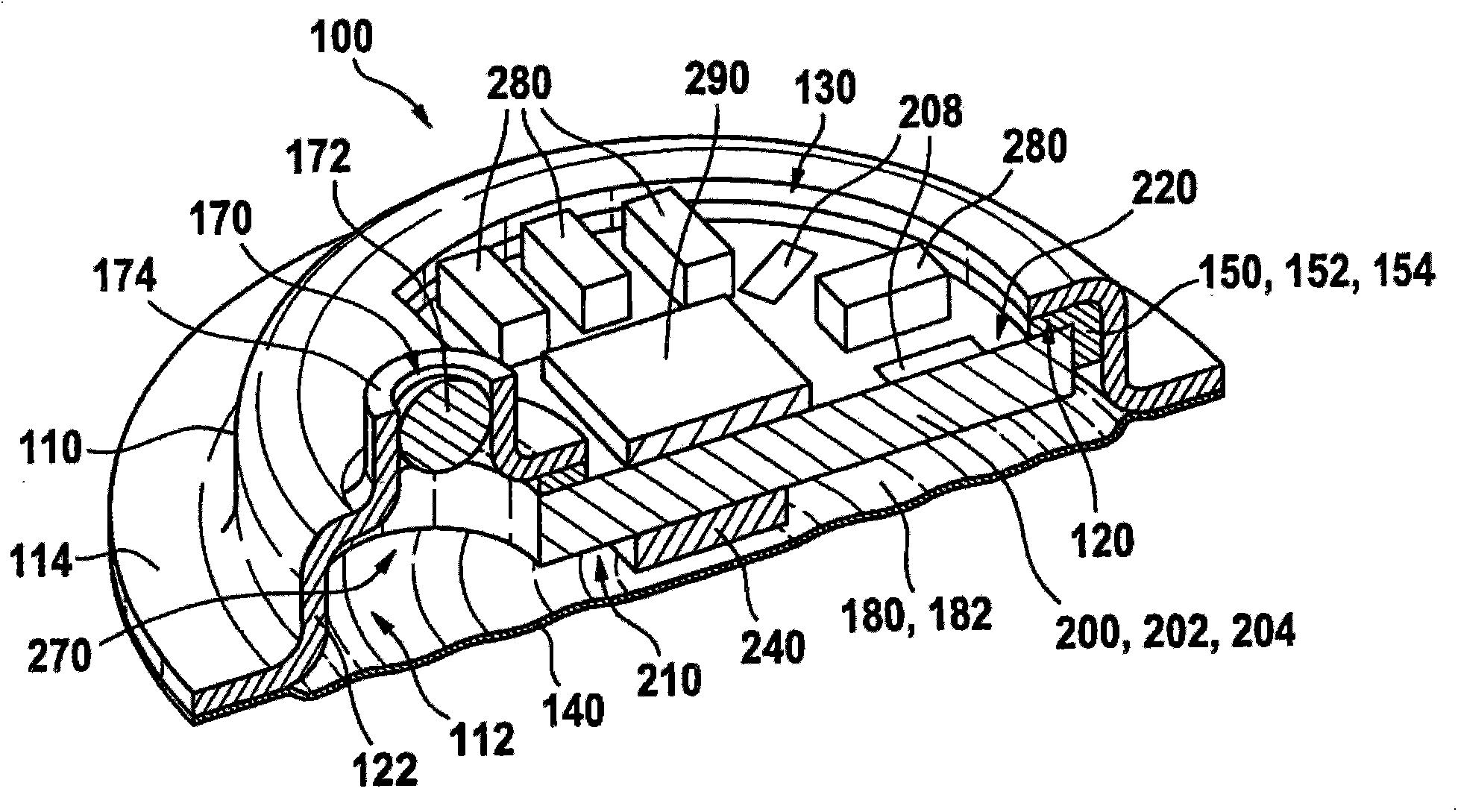

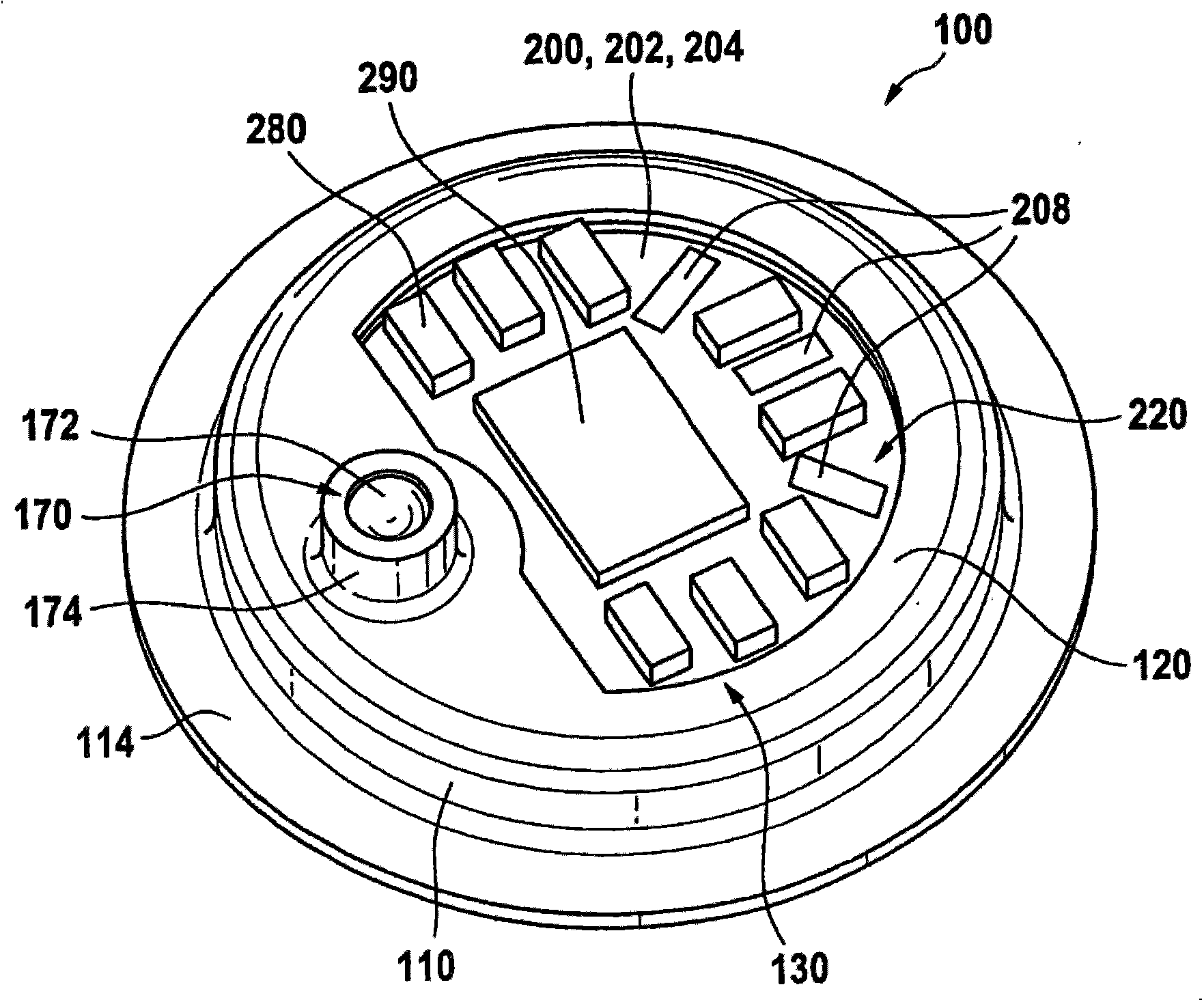

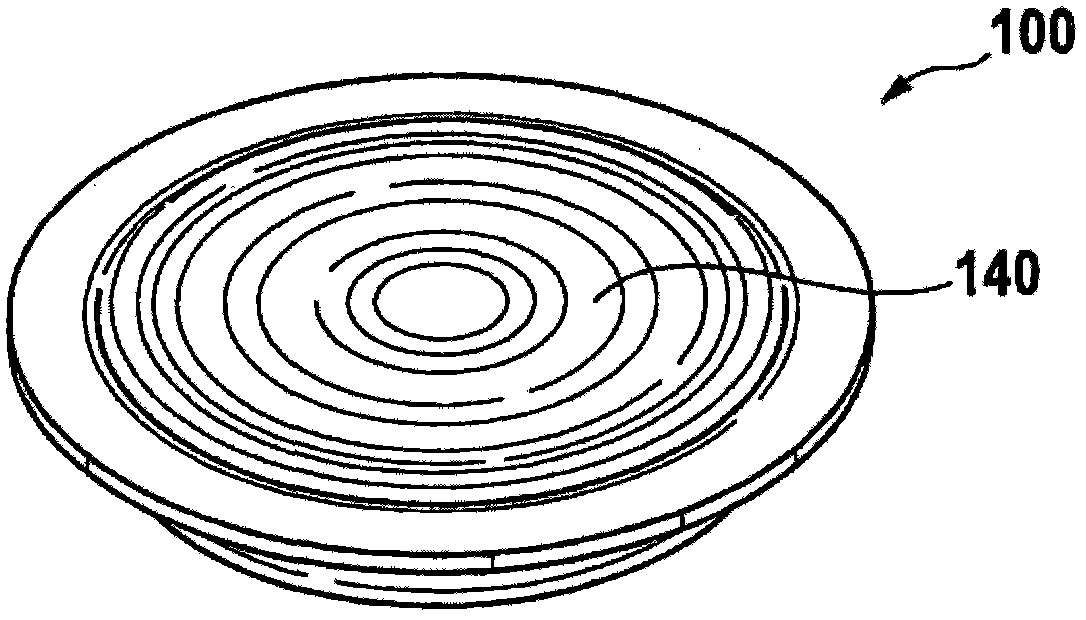

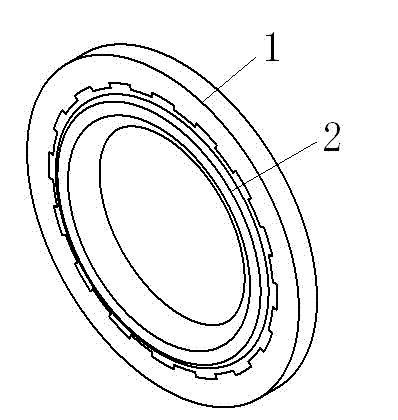

Respiratory masks with gusseted cushions

ActiveUS8297283B2Level of comfortEnsure integrityRespiratory masksBreathing masksEngineeringRespiratory mask

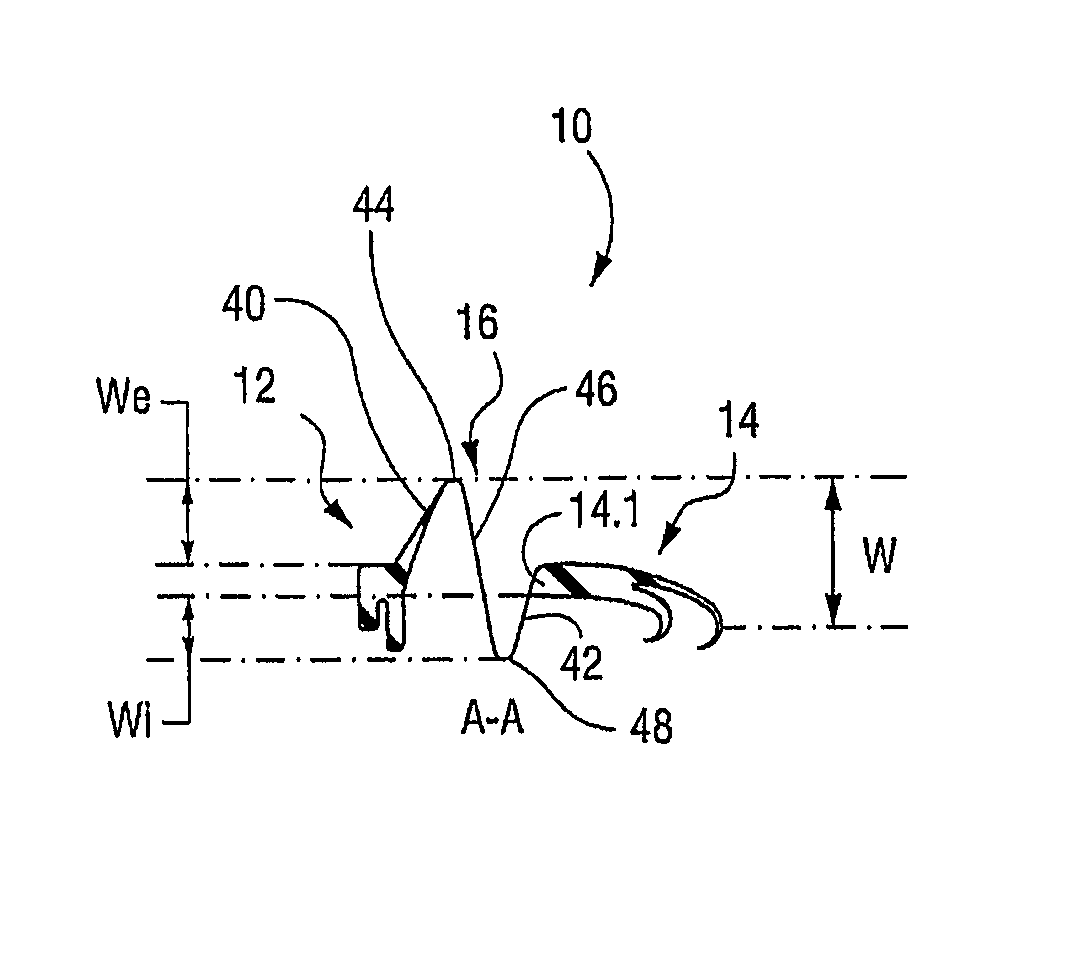

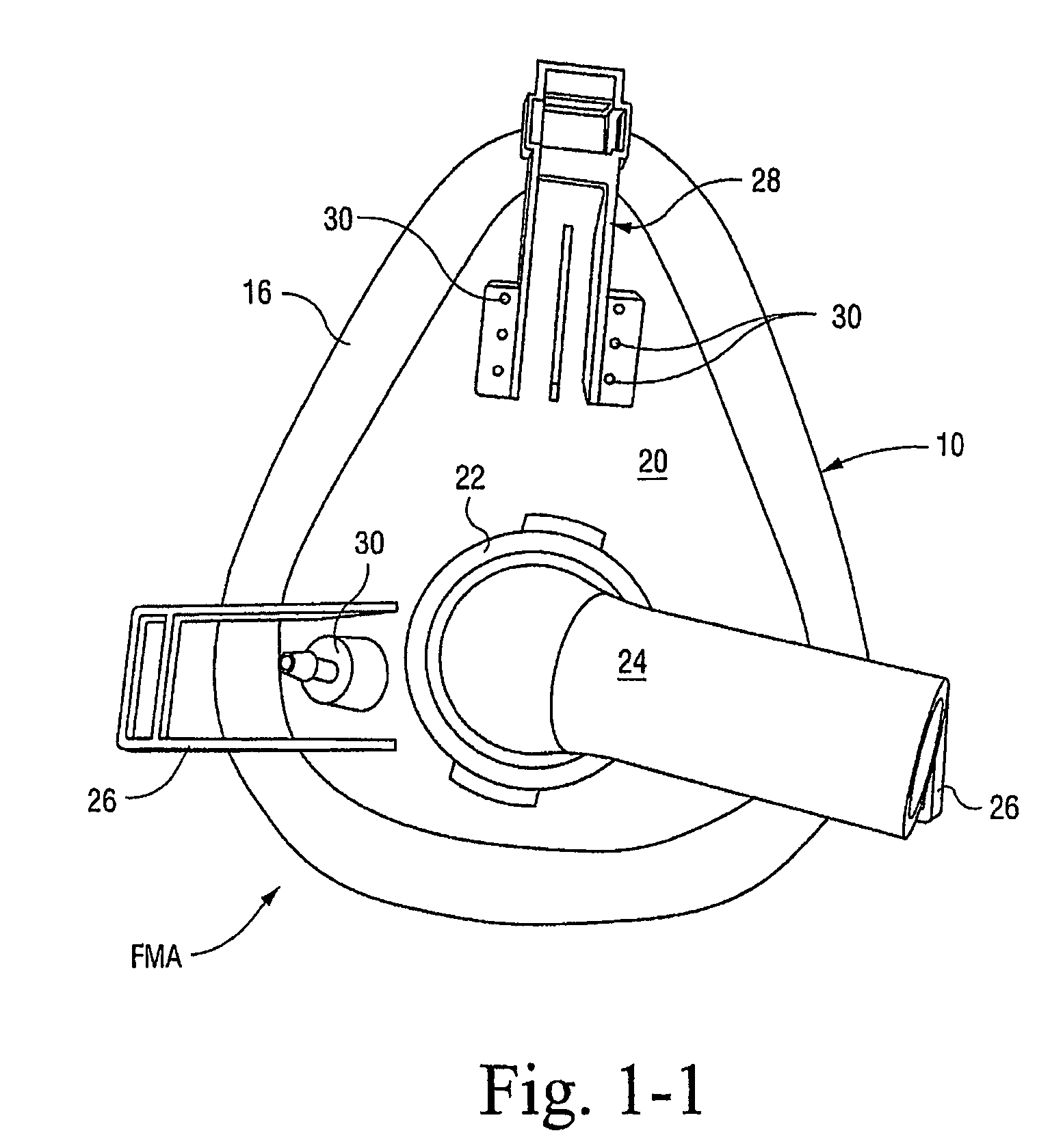

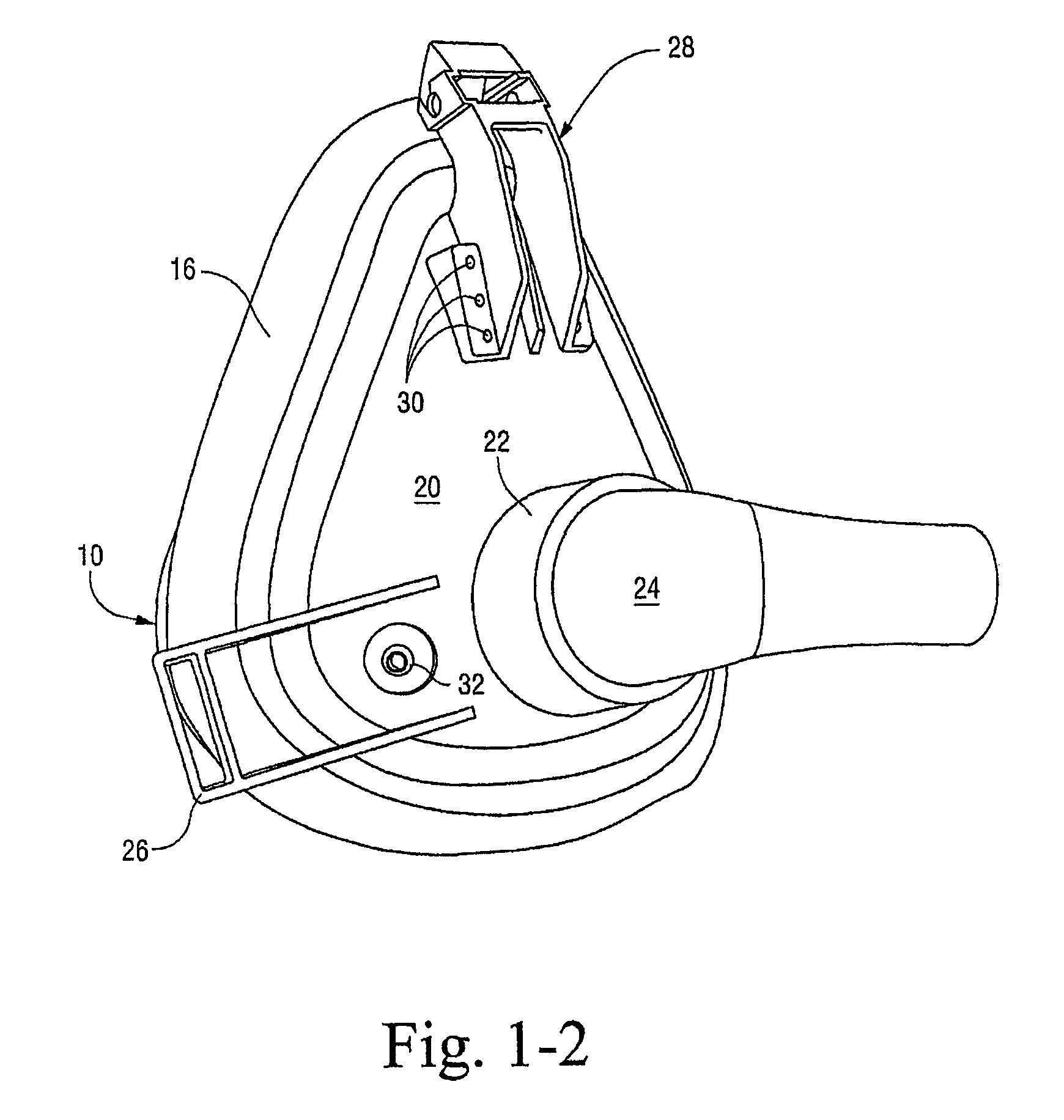

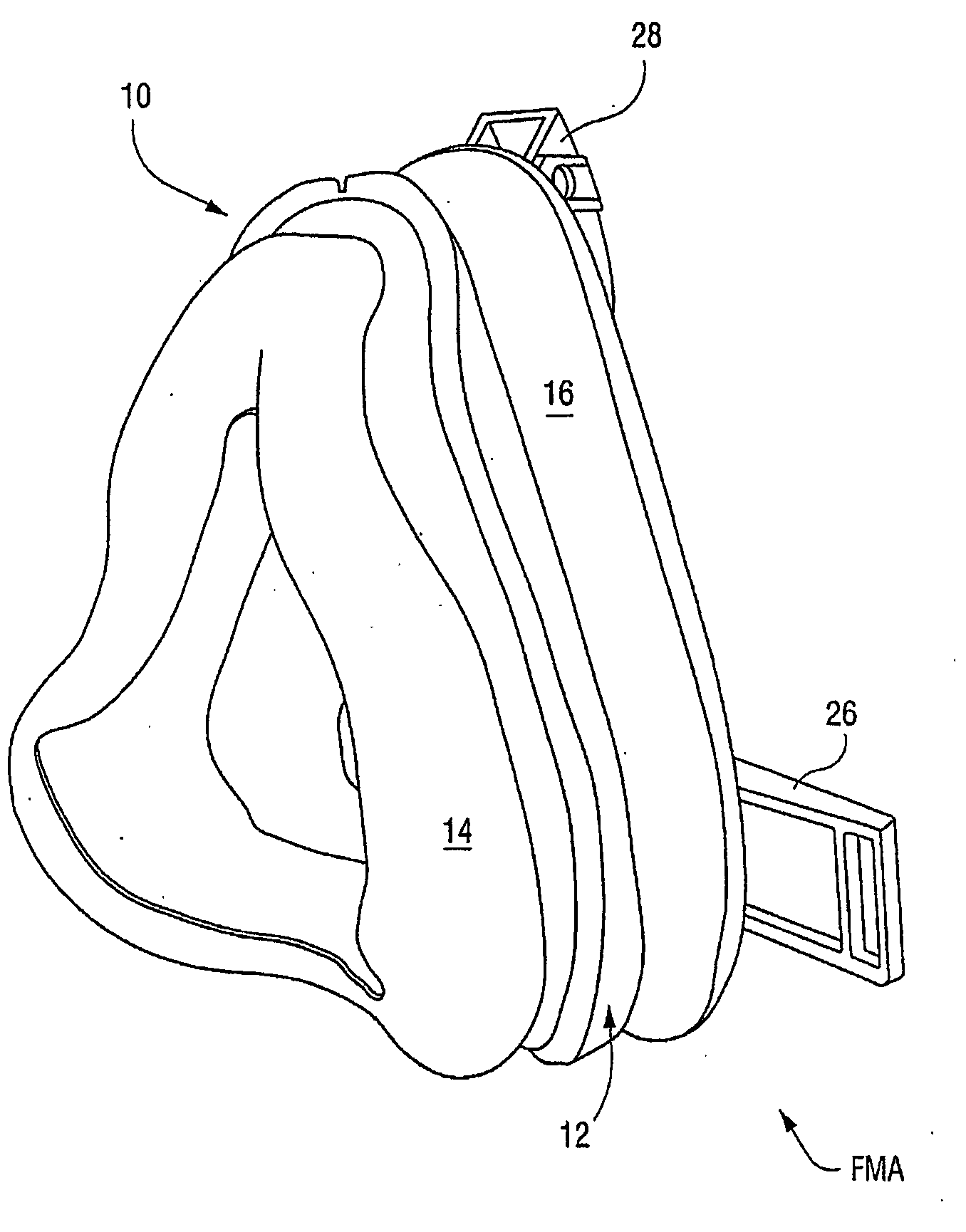

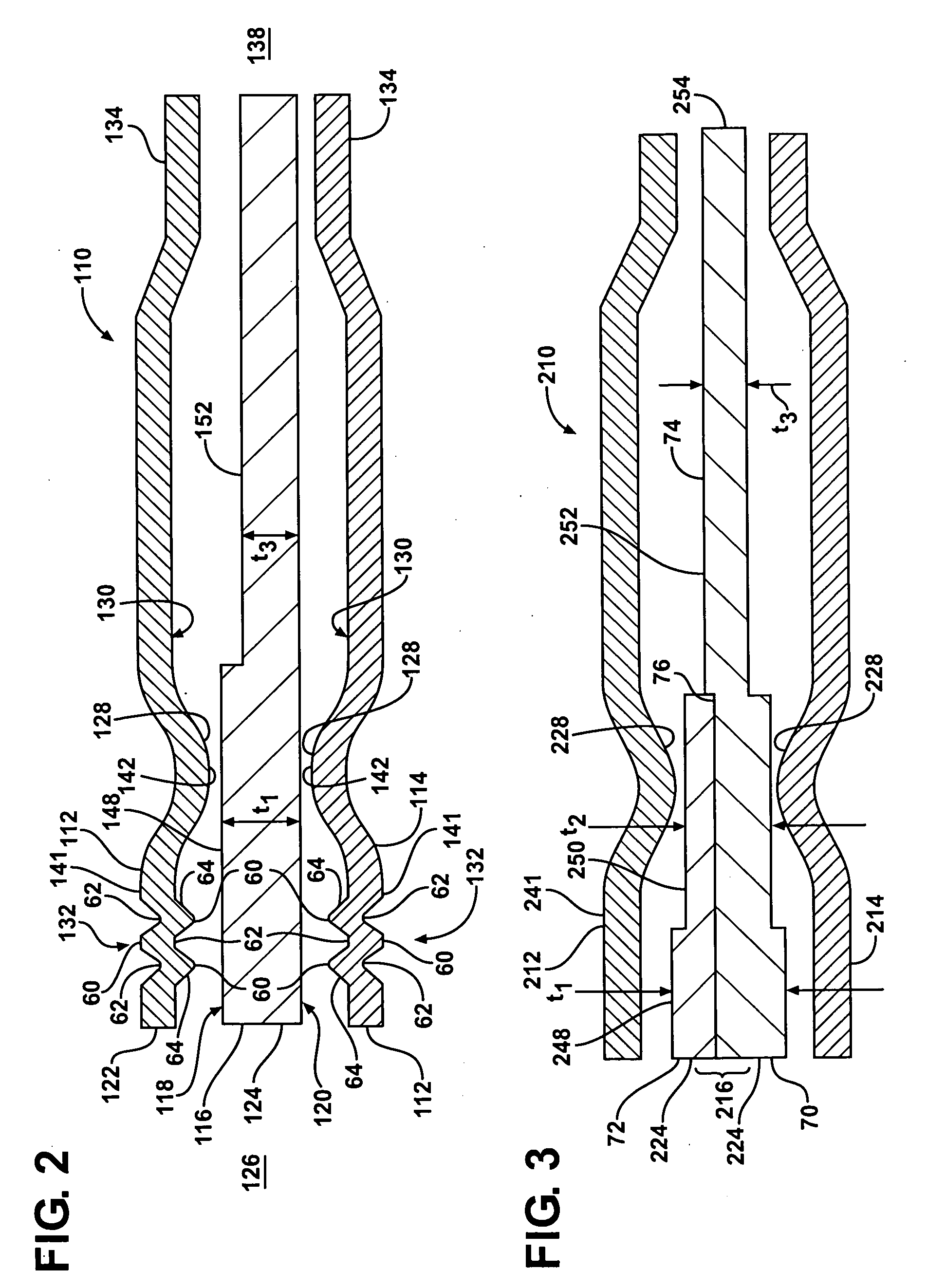

Cushions for respiratory face masks have a frame-connecting portion, a face-contacting portion, and a gusset portion disposed between and joining the frame-connecting and face-contacting portions. The gusset portion preferably includes at least one perimetrical region which having a laterally projecting exterior gusset section and a laterally projecting interior gusset section. According to one aspect, the laterally projecting exterior and interior gusset sections are disposed about the entire perimeter to the gusset portion so as to establish a substantially constant widthwise dimension thereof about the gusset's entire perimeter.

Owner:RESMED LTD

Respiratory Masks With Gusseted Cushions

ActiveUS20090095301A1Level of comfortEnsure integrityRespiratory masksBreathing masksRespiratory maskCushion

Cushions for respiratory face masks have a frame-connecting portion, a face-contacting portion, and a gusset portion disposed between and joining the frame-connecting and face-contacting portions. The gusset portion preferably includes at least one perimetrical region which having a laterally projecting exterior gusset section and a laterally projecting interior gusset section. According to one aspect, the laterally projecting exterior and interior gusset sections are disposed about the entire perimeter to the gusset portion so as to establish a substantially constant widthwise dimension thereof about the gusset's entire perimeter.

Owner:RESMED LTD

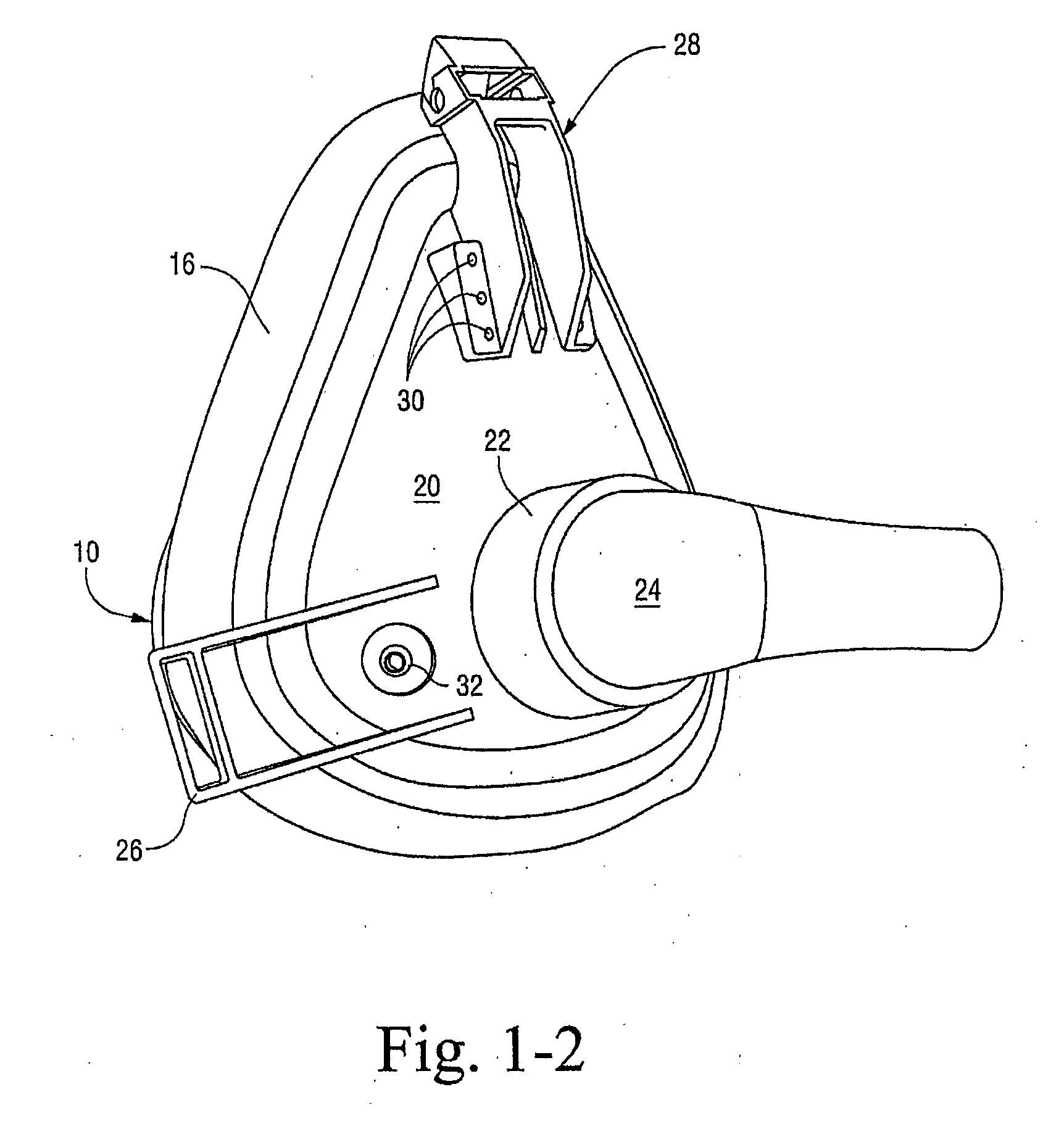

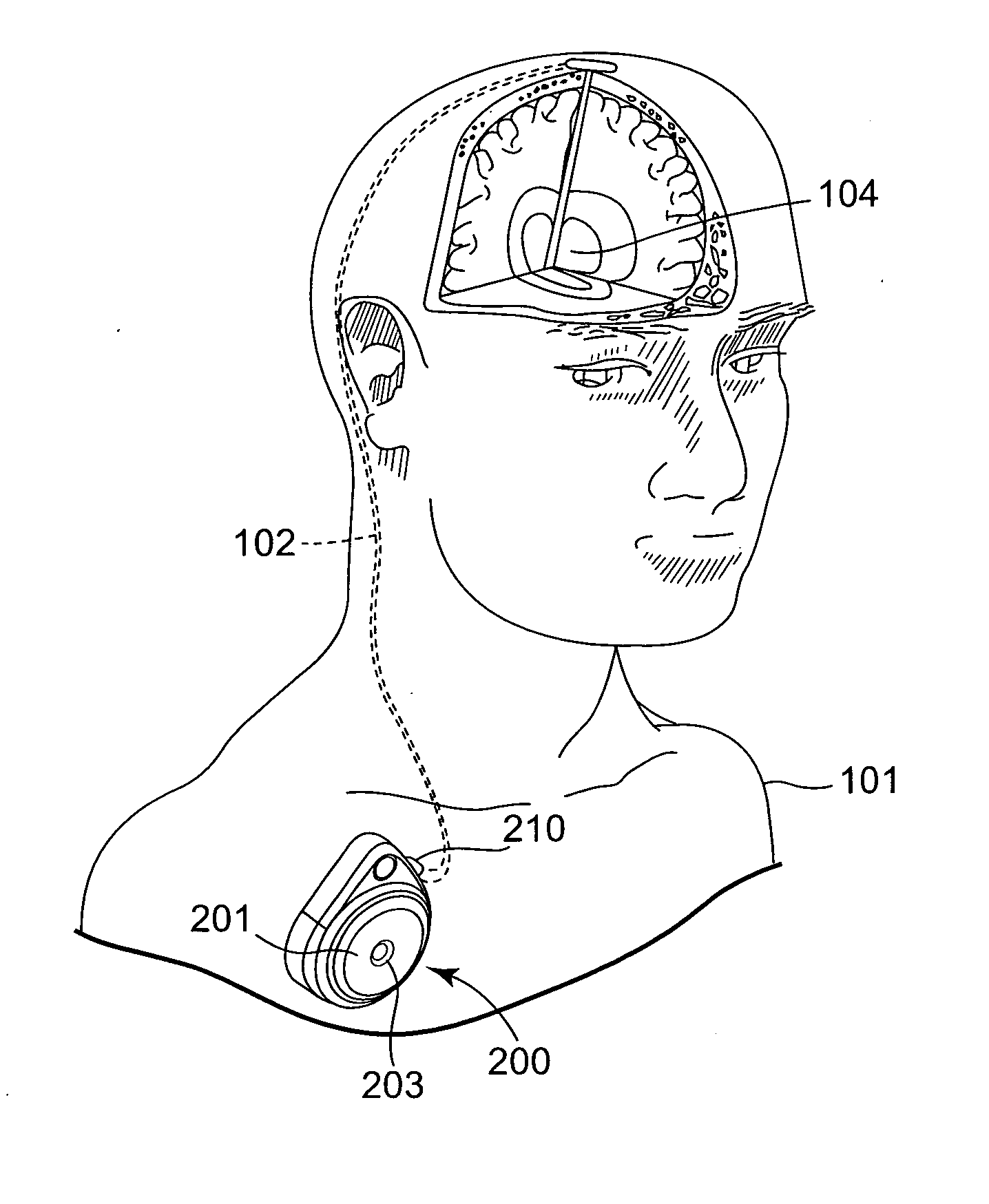

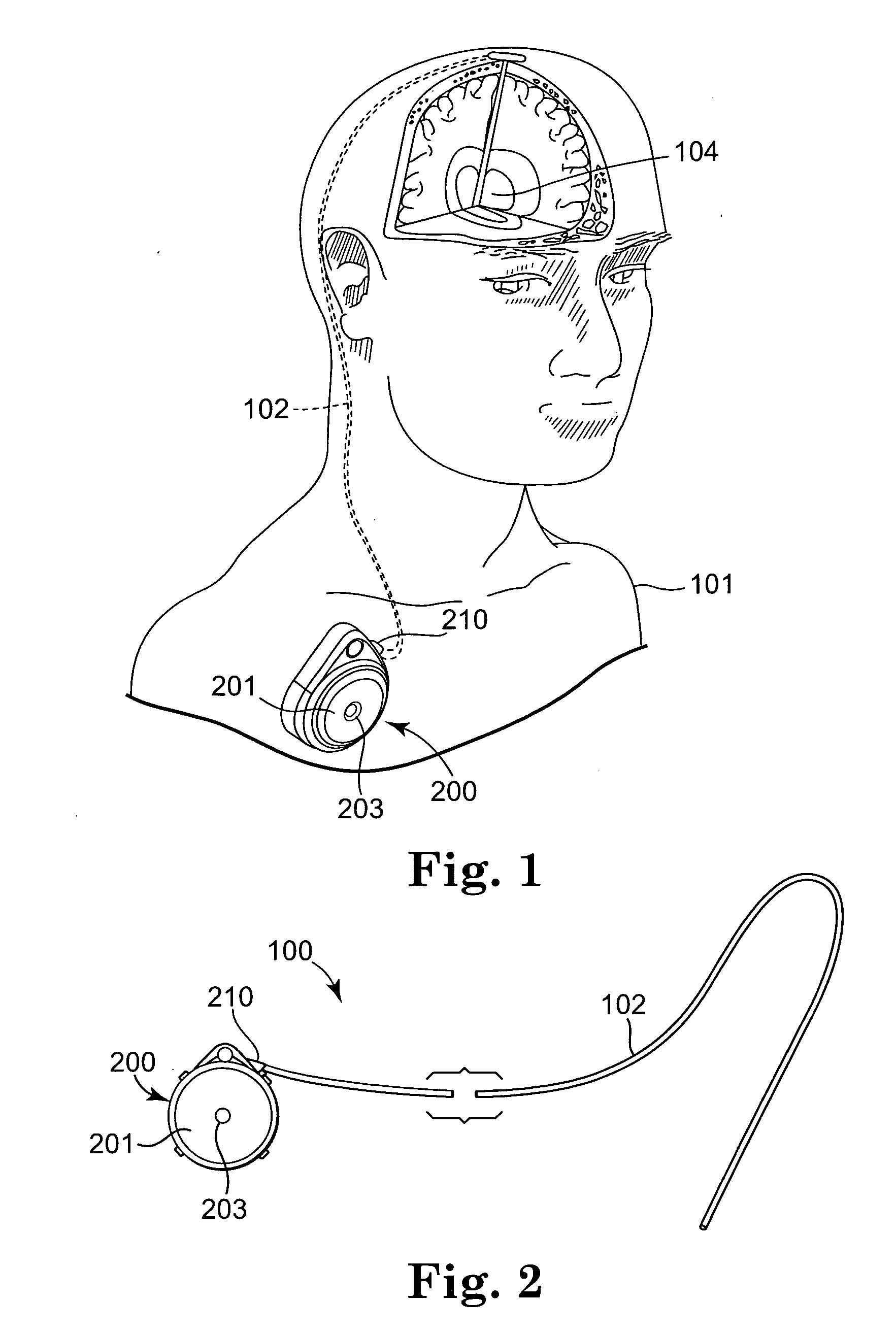

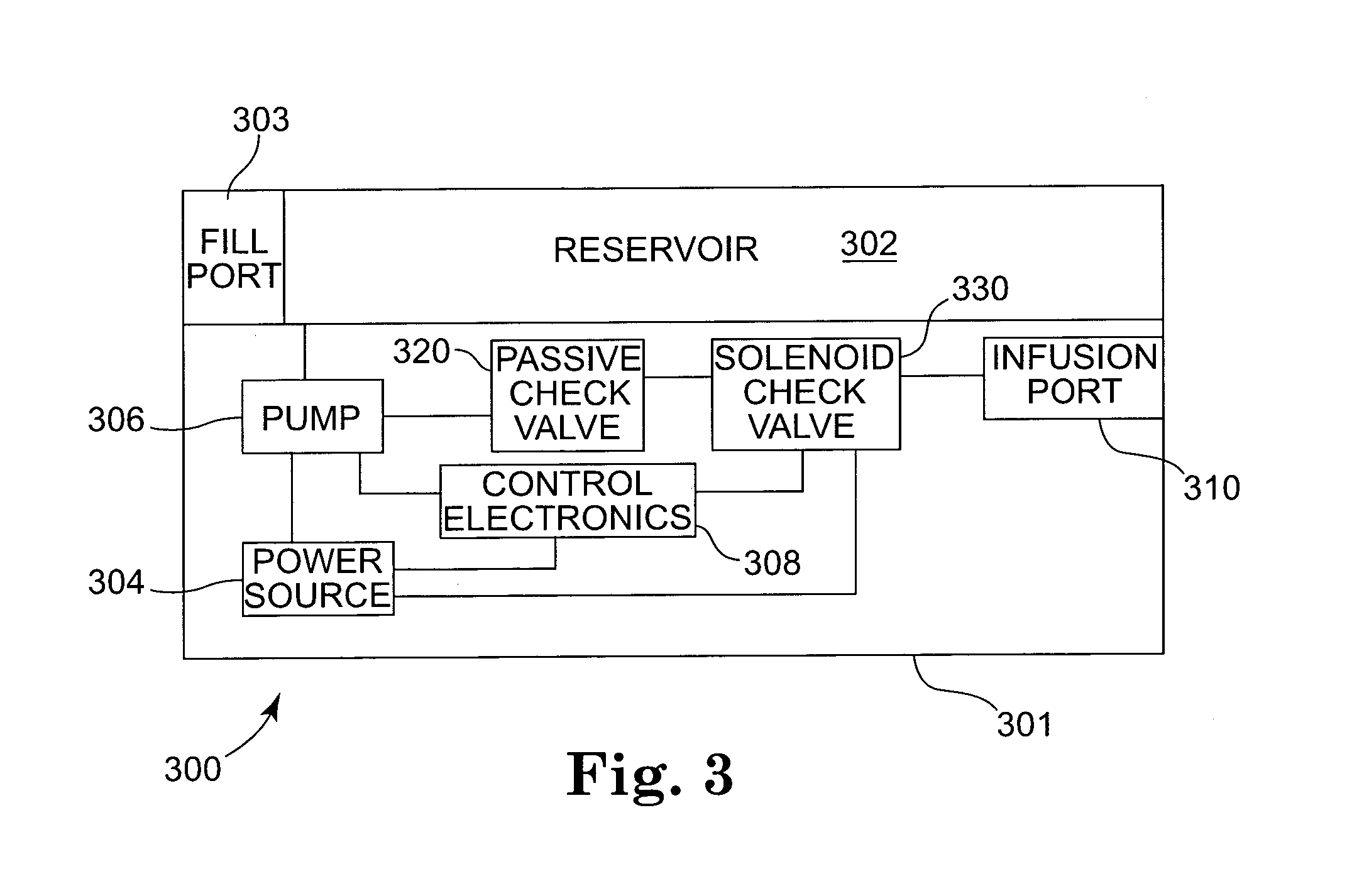

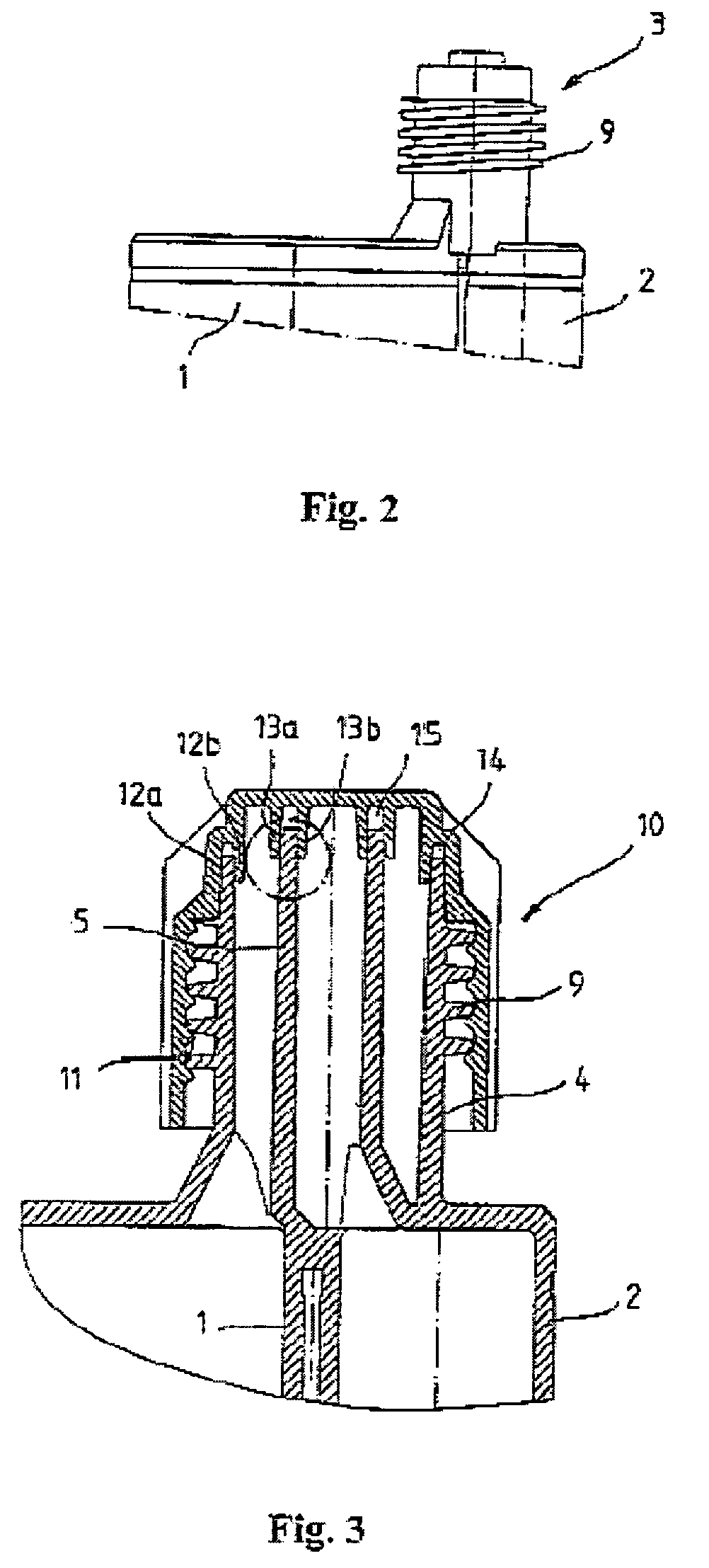

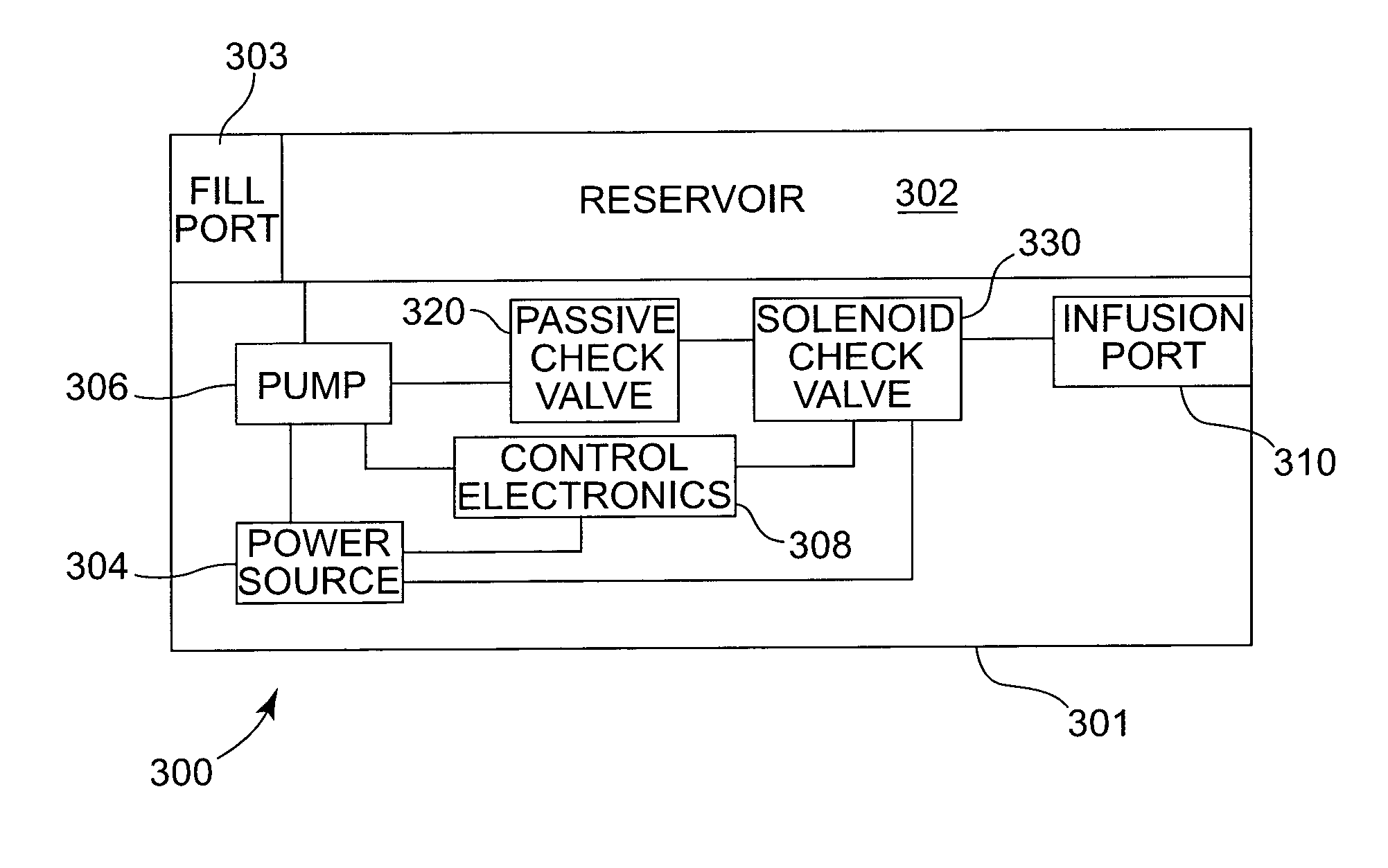

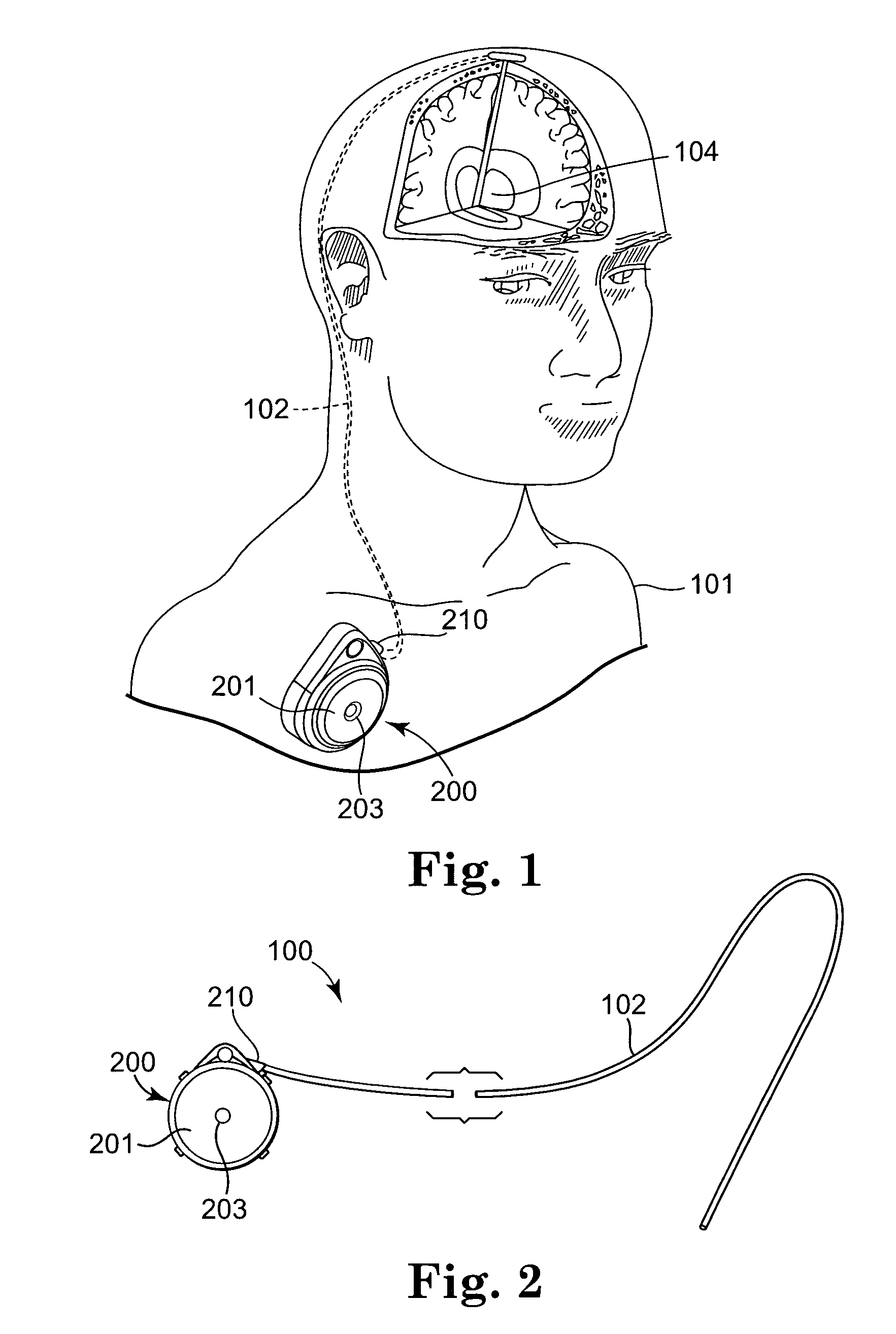

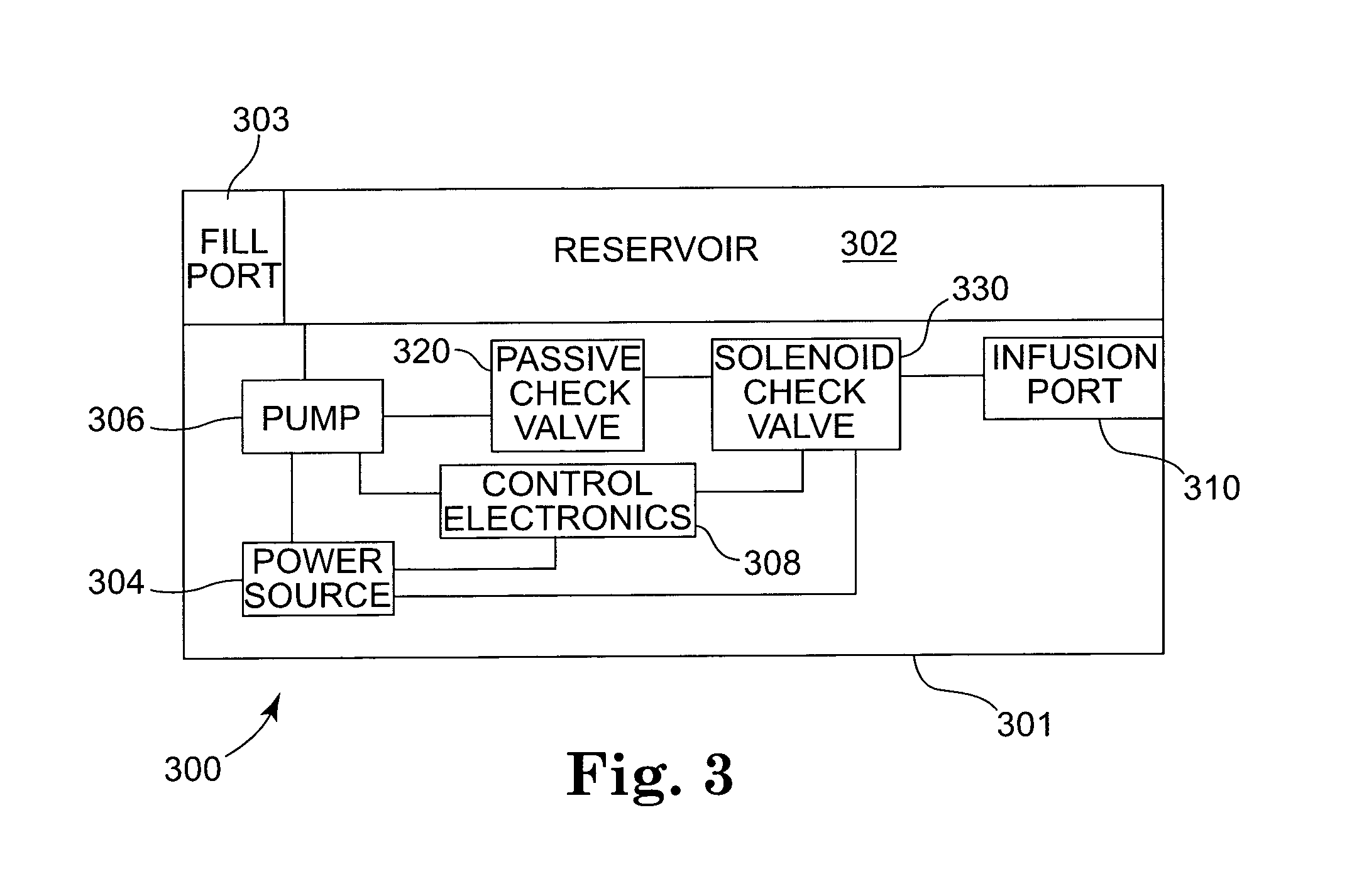

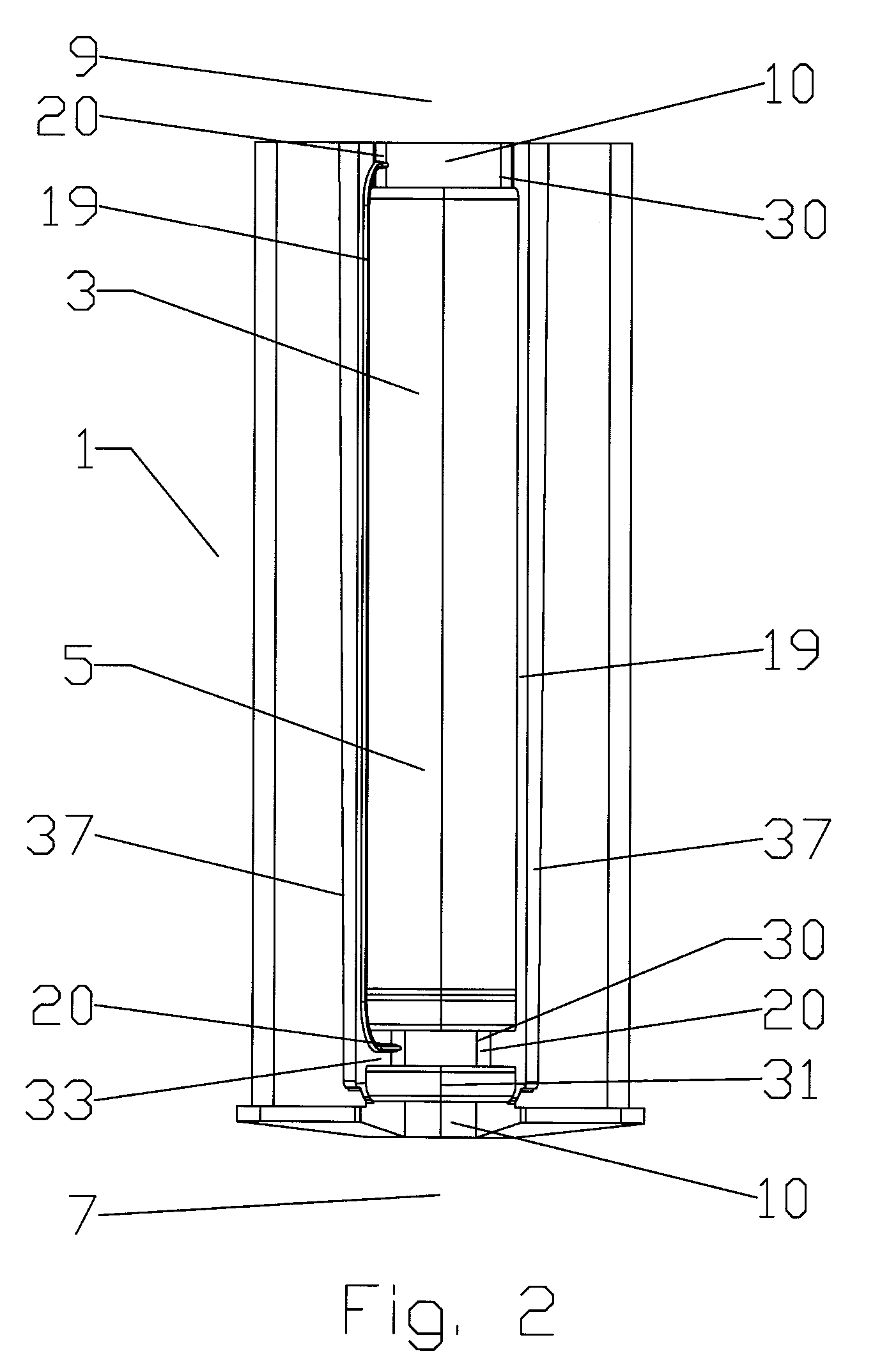

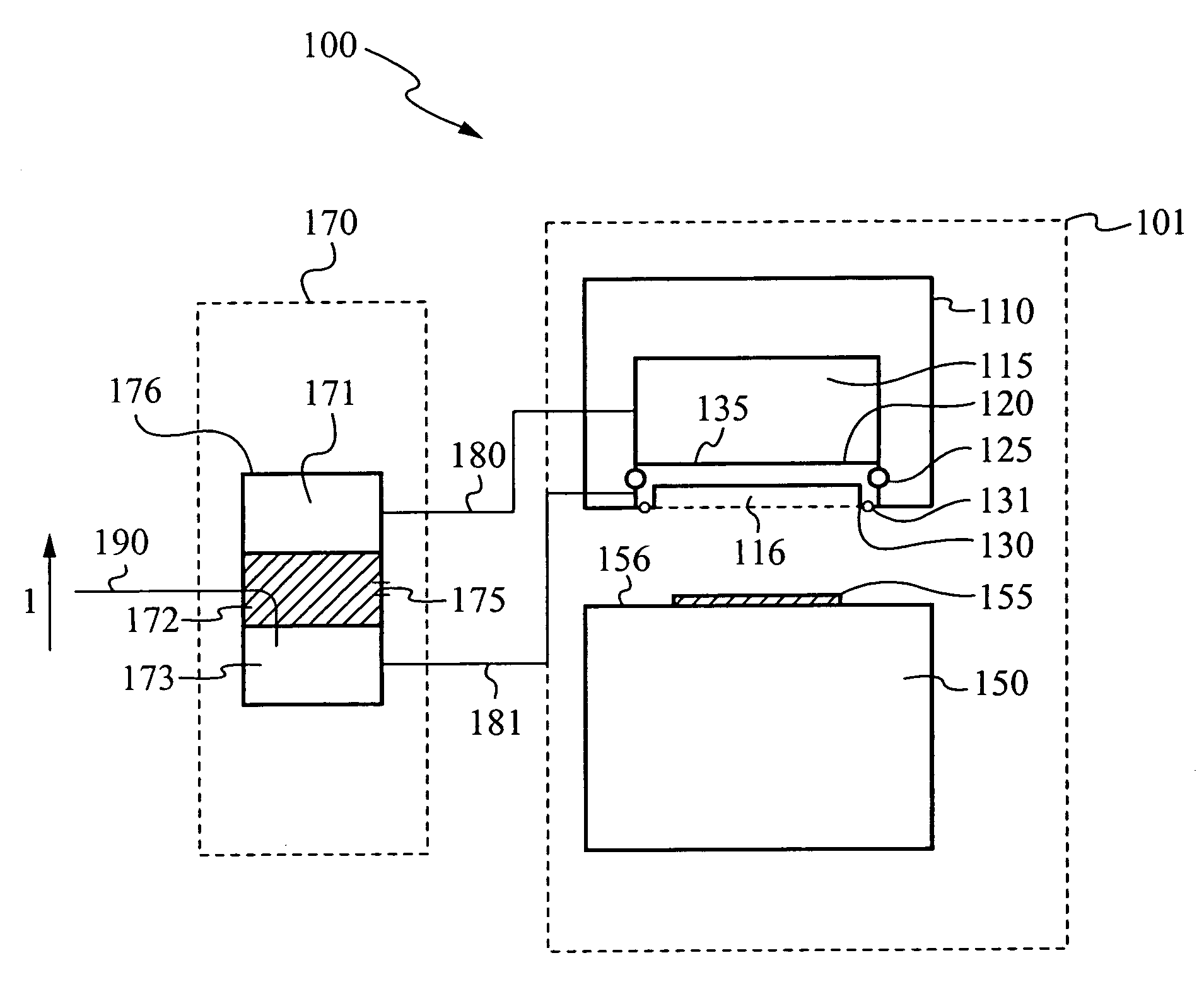

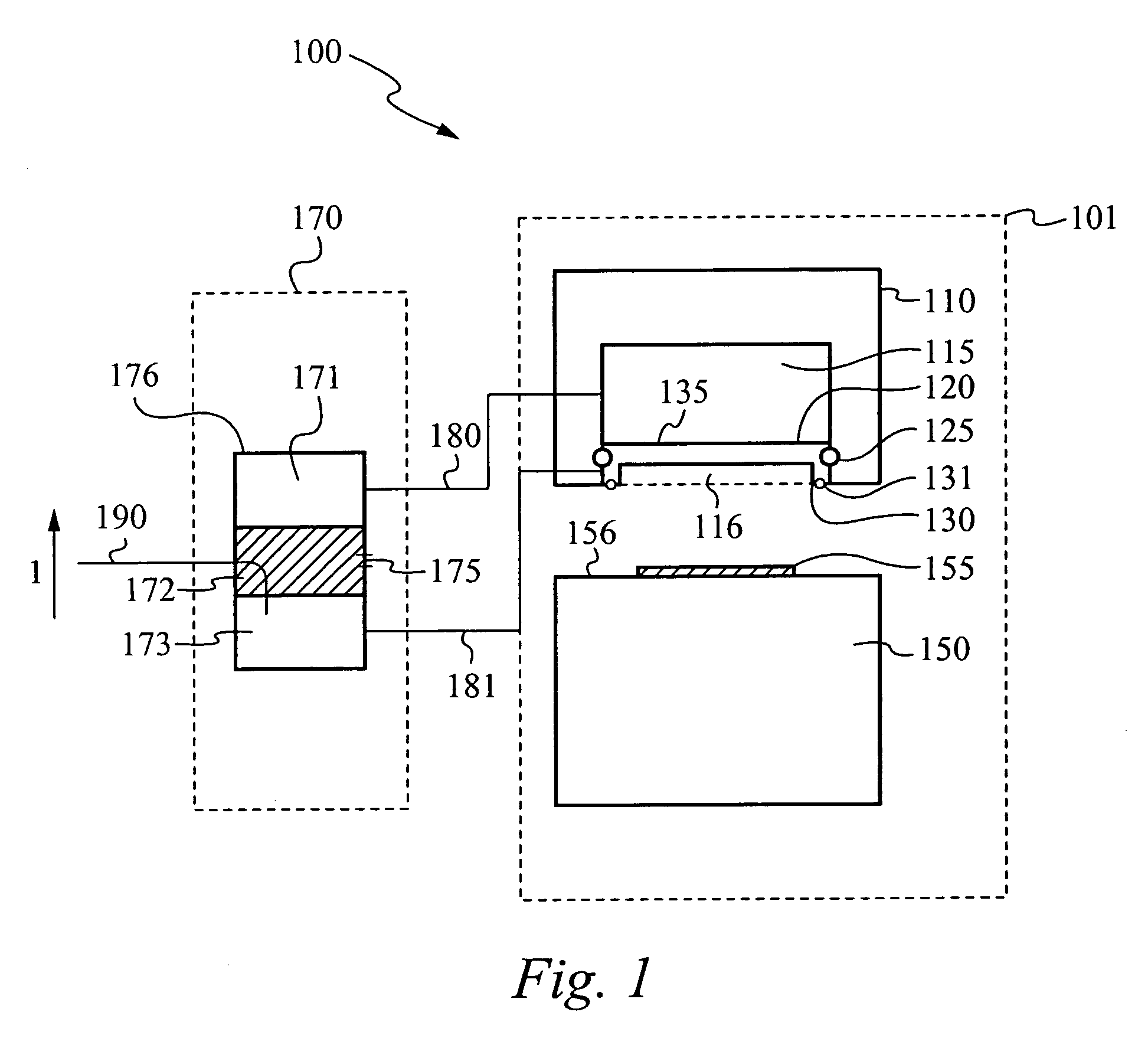

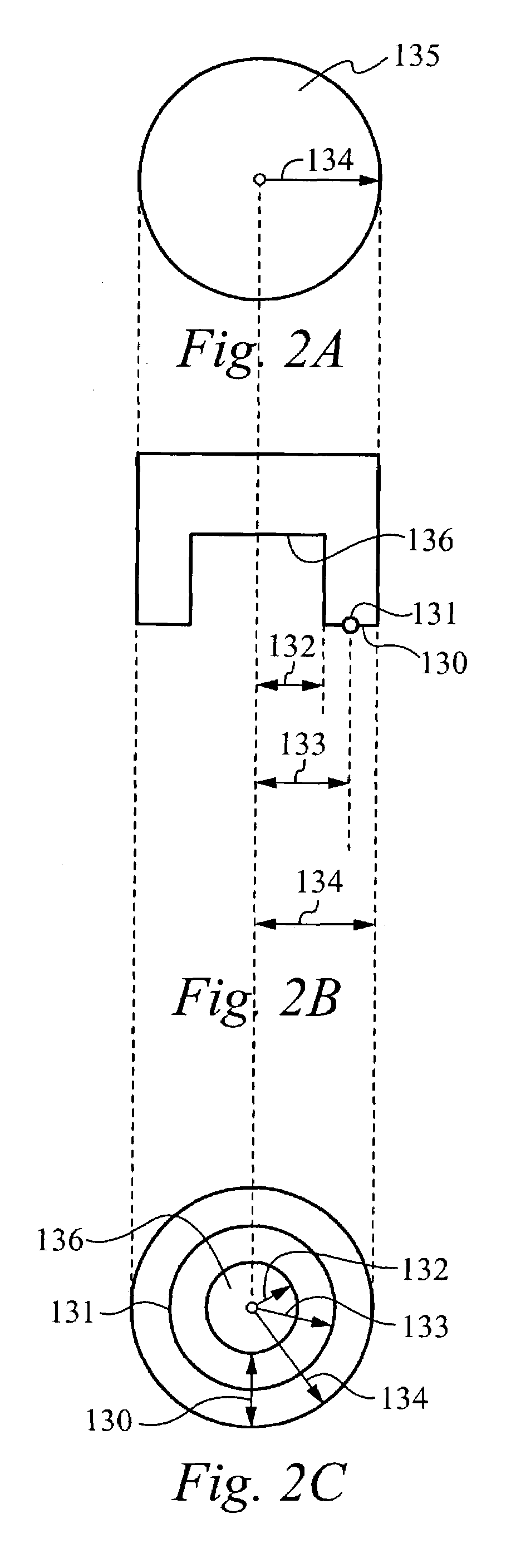

Infusion device with active and passive check valves

ActiveUS20070255261A1Avoid flowImprove energy efficiencyMedical devicesPharmaceutical delivery mechanismEngineeringCheck valve

An infusion system in which therapeutic substance from a reservoir is pumped by a bolus pump to an infusion port is disclosed. The therapeutic substance delivered by the bolus pump passes first through a passive check valve located downstream from the pump. The passive check valve opens in response to fluid pressure of the therapeutic substance. After passing through the passive check valve, the therapeutic substance passes through an active check valve located downstream from the passive check if the active check valve is actuated such that it is open. When not activated, the active check valve is closed and fluid flow through the active check valve in the downstream direction is prevented.

Owner:MEDTRONIC INC

Cable and apparatus interface security device

ActiveUS6955558B1Amplified equalizationHigh sealing pressureRelieving strain on wire connectionSecuring/insulating coupling contact membersInterconnectionSafety Equipment

A sealing assembly for a cable to apparatus interconnection formed bya plurality of shells adapted to mate together, surrounding the interconnection within an interconnection space. When mated together, the shells forming openings for the cable and the apparatus at an apparatus end and a cable end, respectively. A gasket mounted to each shell along a mating surface between the shells and along the openings environmentally seals the interconnection space. A locking rib projecting inward from the shell(s) may be applied to rotationally interlock a coupling nut of the interconnection with the sealing assembly. In a two shell embodiment, a locking band positioned around an outer diameter of the mated together shells with an end to end retaining means may be used to secure the shells together. Alternatively, if three shells are used, the shells may be hinged together and a retaining means applied to join the unhinged ends together.

Owner:COMMSCOPE TECH LLC

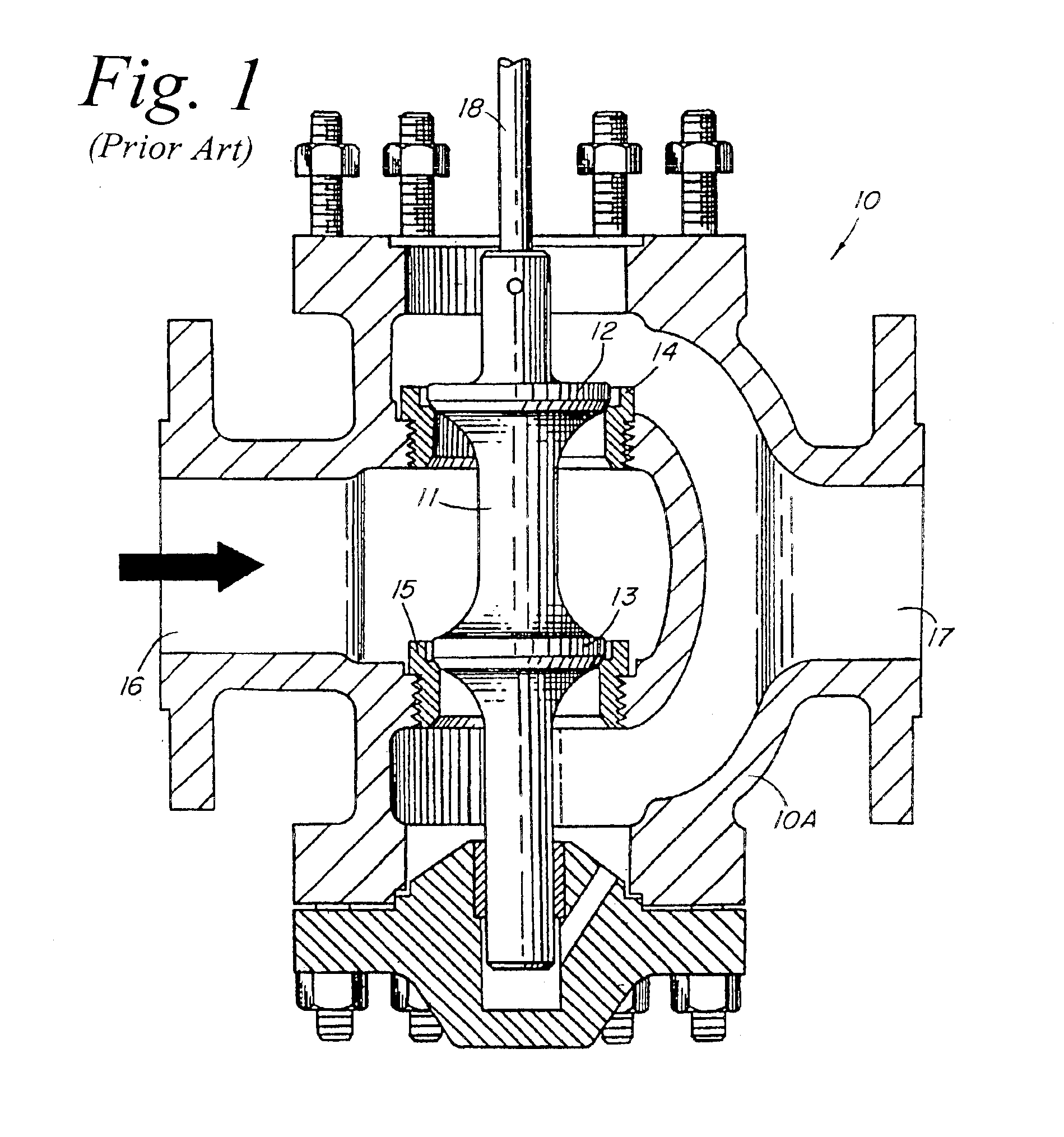

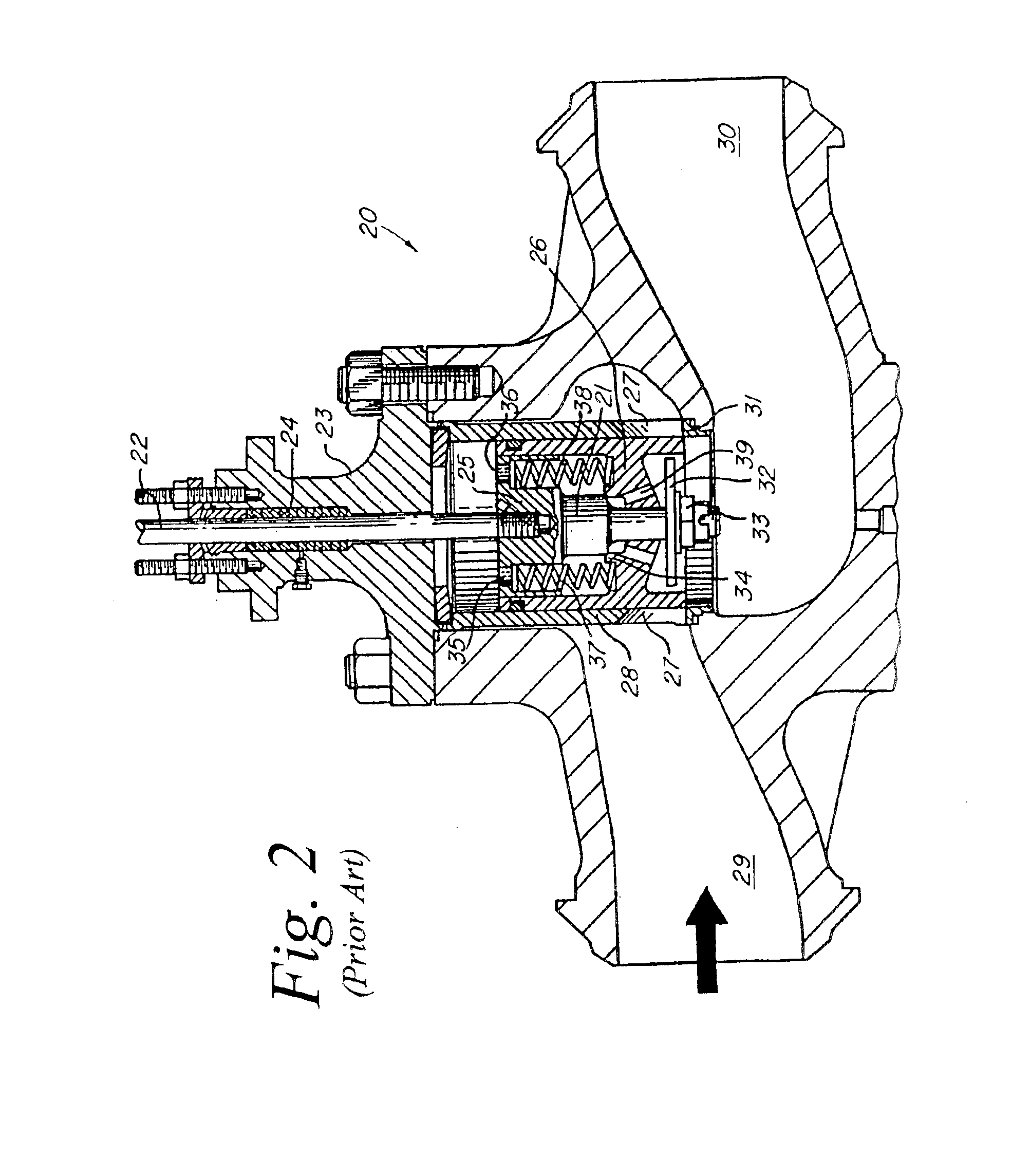

Control valve trim and bore seal

InactiveUS6851658B2Less stringent partReduced actuator forcePressure relieving devices on sealing facesValve members for absorbing fluid energyControl valvesActuator

An ANSI Leakage Class V control valve having consistent shut off characteristics with a reduced actuator force required to open and close the valve is provided. The trim arrangement of the control valve includes a valve cage having a multi-contoured inner surface. The multi-contoured inner surface can include a plurality of surfaces. The multi-contoured surface can include first, second, and third perimeter surfaces, and a first transition surface disposed between and coupling the first and second perimeter surfaces, and a second transition surface disposed between and coupling the second and third perimeter surfaces. The valve also includes a valve plug disposed at one end of a valve stem. The valve plug controls the fluid flow through the valve. The valve plug includes an opening through the plug for equalizing pressure across the valve plug. An annular channel is formed within a wall of the valve plug and is sized to accommodate a sealing ring. The sealing ring engages the second perimeter surface to form a fluid seal that substantially hinders fluid leakage through the valve.

Owner:FISHER CONTROLS INT LLC

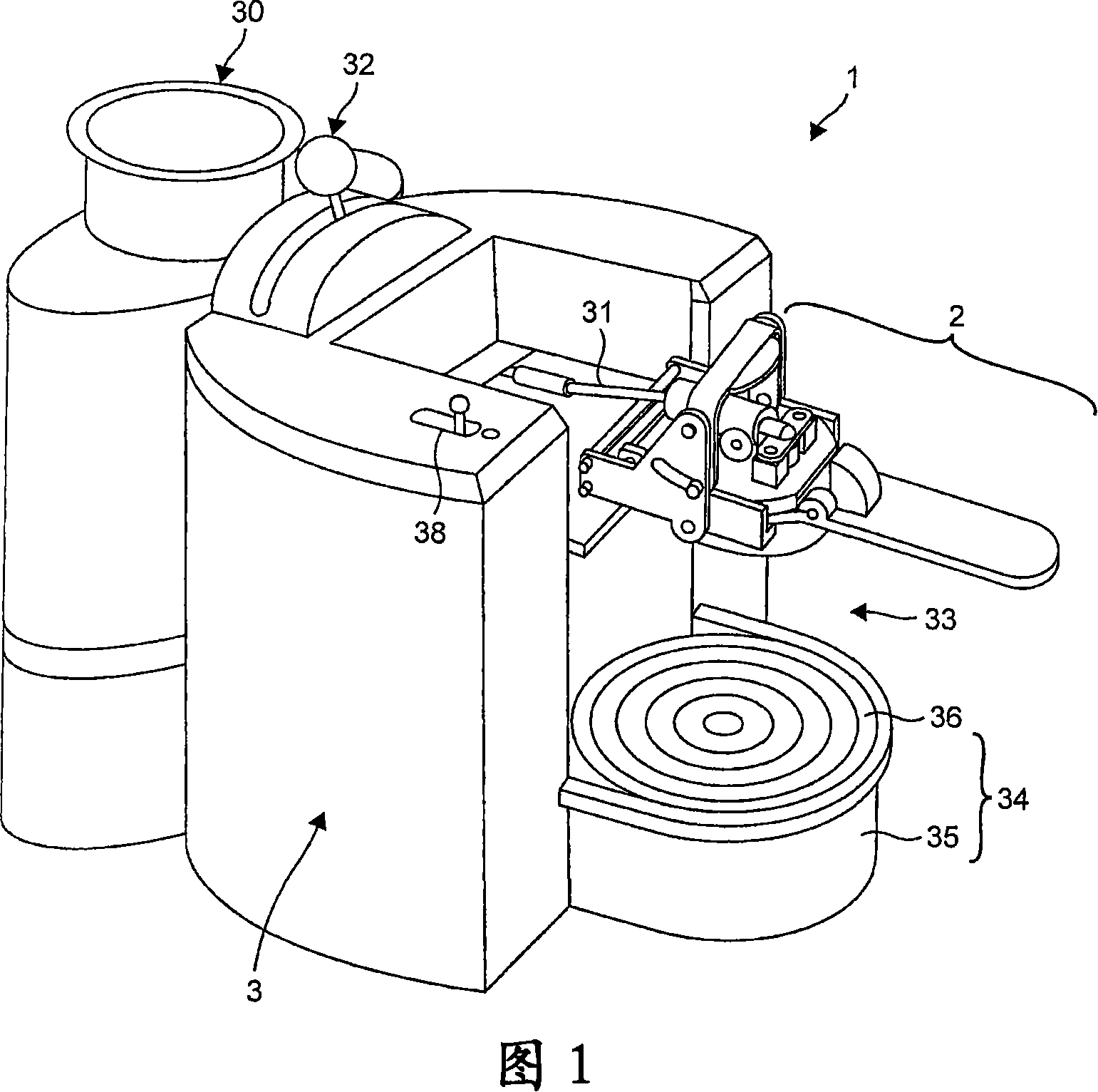

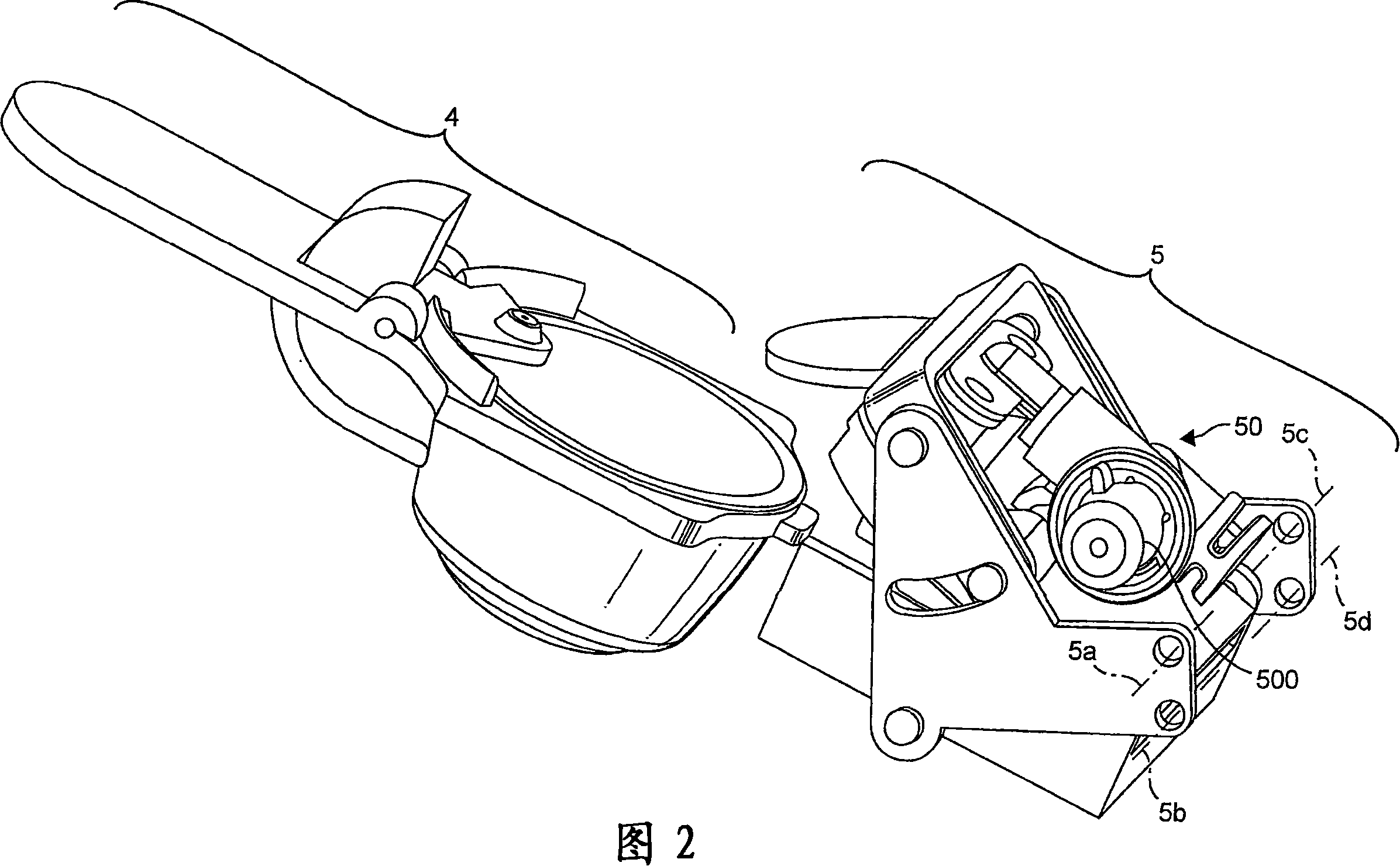

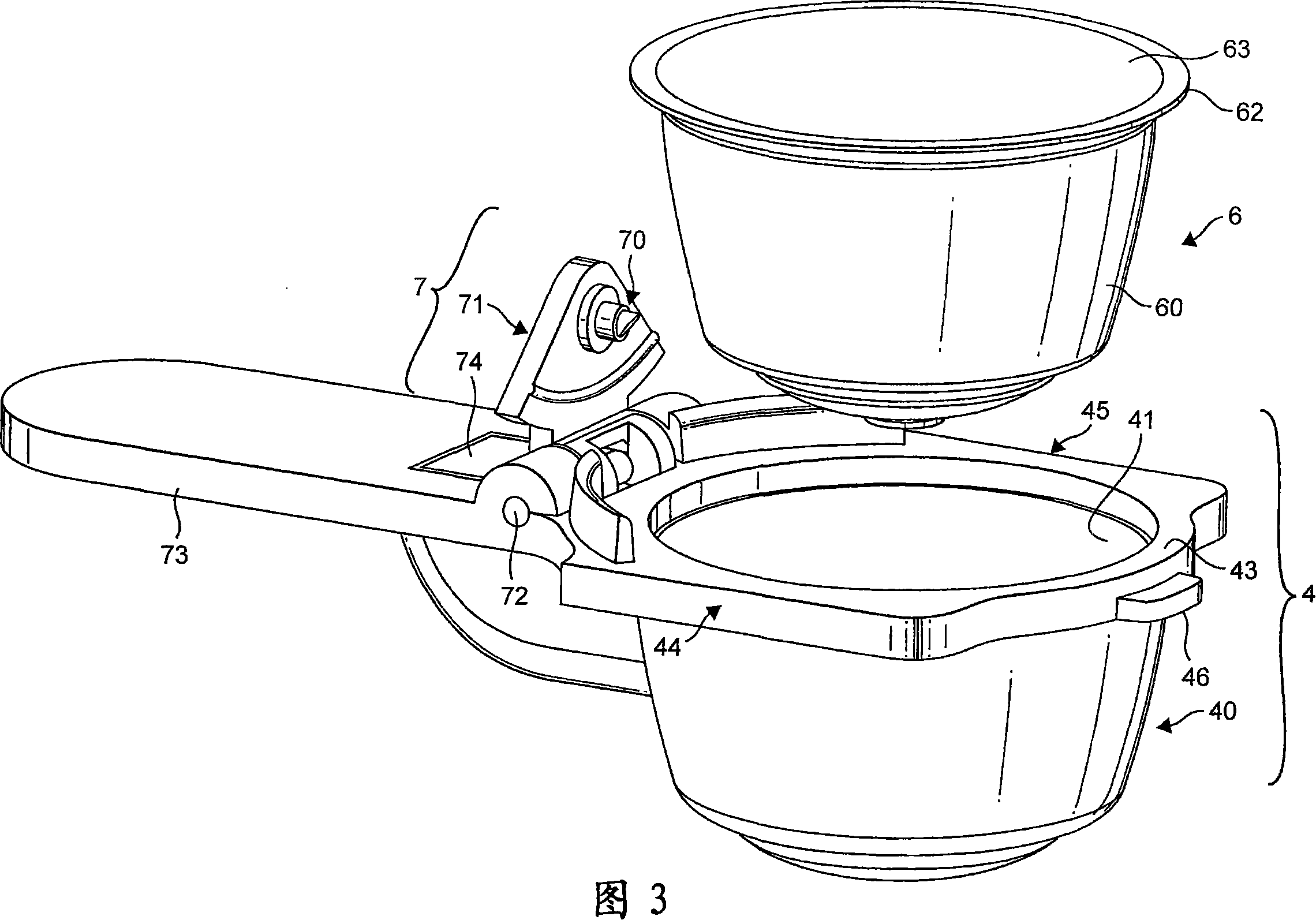

Device for preparing a drink from a capsule by injection of a pressurized fluid and capsule-holder adapted therefore

InactiveCN101115422AReduced risk of spillsStrong connectionBeverage vesselsBiomedical engineeringFluid supply

The device has a capsule holder (4) configured for receiving a capsule and detachable with respect to a pressurized fluid supply unit (5). An injector provided for injecting fluid in the capsule is separable from the fluid supply unit when the holder is detached. The holder and the injector are associated with each other. The holder has a cup with a housing that is complementary to that of body of the capsule. An independent claim is also included for a drink vending machine comprises a drink preparation device.

Owner:SOC DES PROD NESTLE SA

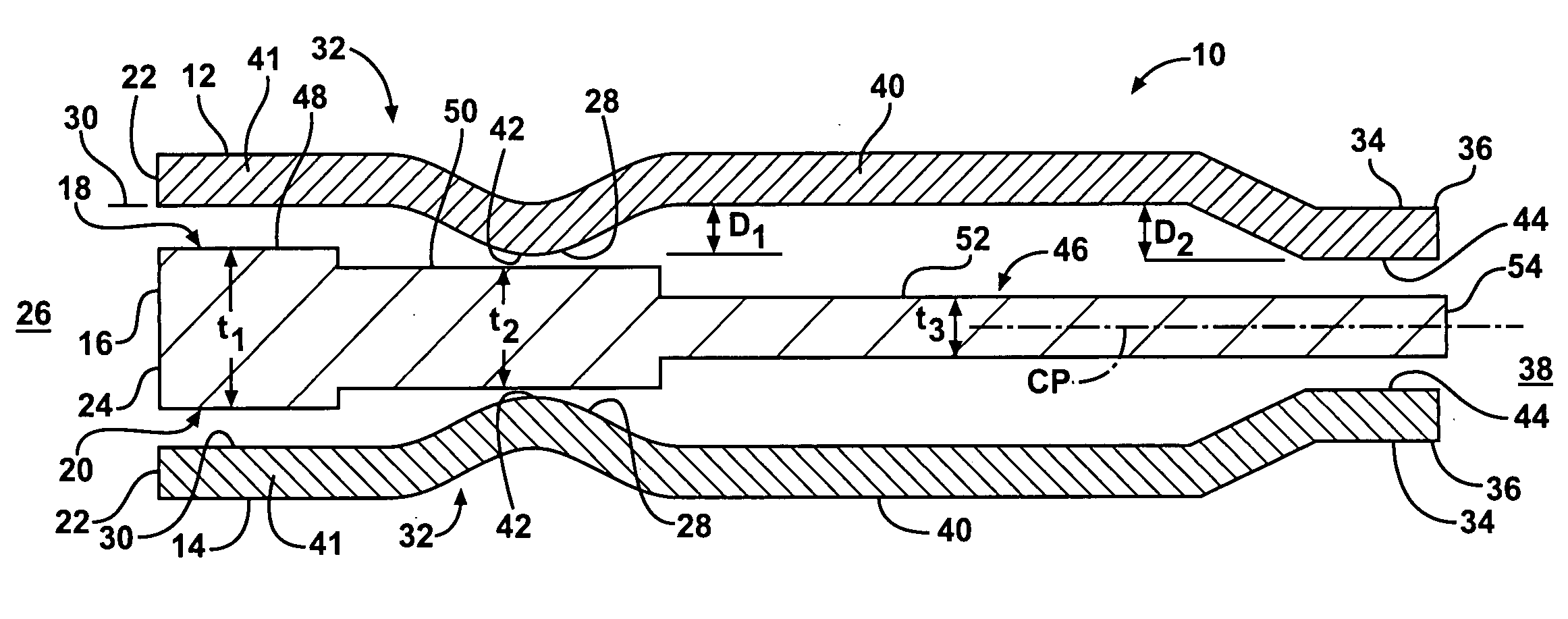

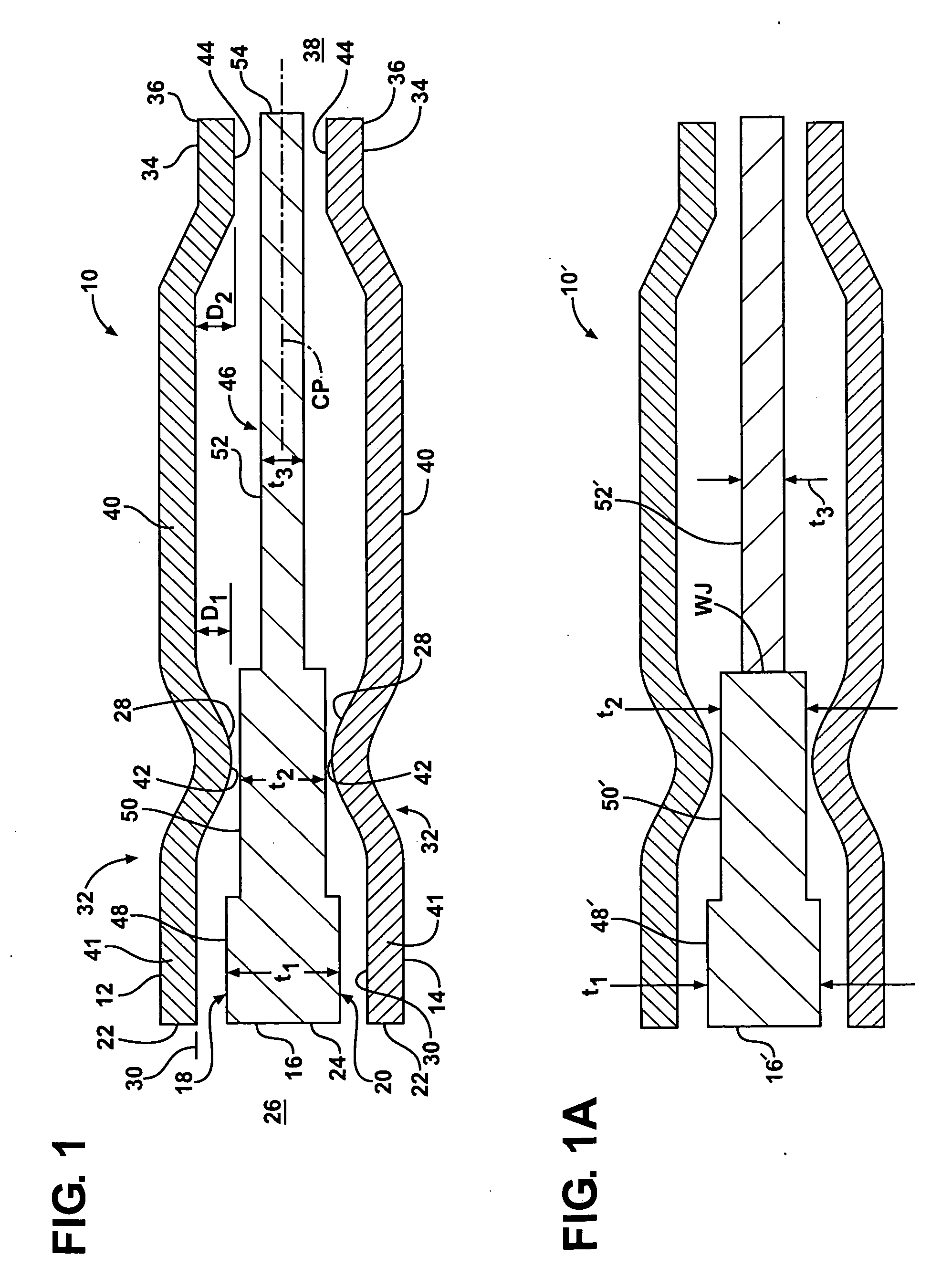

Multilayer static gasket with bead compression limiter

InactiveUS20090200752A1High sealing pressureReliable airEngine sealsSealing arrangements for enginesCylinder headEngineering

A multilayer static cylinder head gasket has at least one metal functional layer and a metal distance layer having registered openings. The functional layer has a full bead located radially outwardly from and extending about its opening. The opening in the distance layer is formed in a first portion having a first thickness. A second portion of the distance layer extends radially outwardly from the opening and the first portion, wherein the second portion has a second thickness that is less than the first thickness. A compression limiter is formed in at least one of the functional layer or the distance layer. The compression limiter prevents the full bead from being completely flattened, which in turn maintains the full bead in high sealing pressure against the distance layer relative to the remaining portion of the functional layer and also prevents premature fatigue cracks from forming in the full bead.

Owner:FEDERAL MOGUL MOTORPARTS LLC

Cable and apparatus interface security device

ActiveUS20050239324A1Amplified equalizationHigh sealing pressureRelieving strain on wire connectionSecuring/insulating coupling contact membersEngineeringInterconnection

Owner:COMMSCOPE TECH LLC

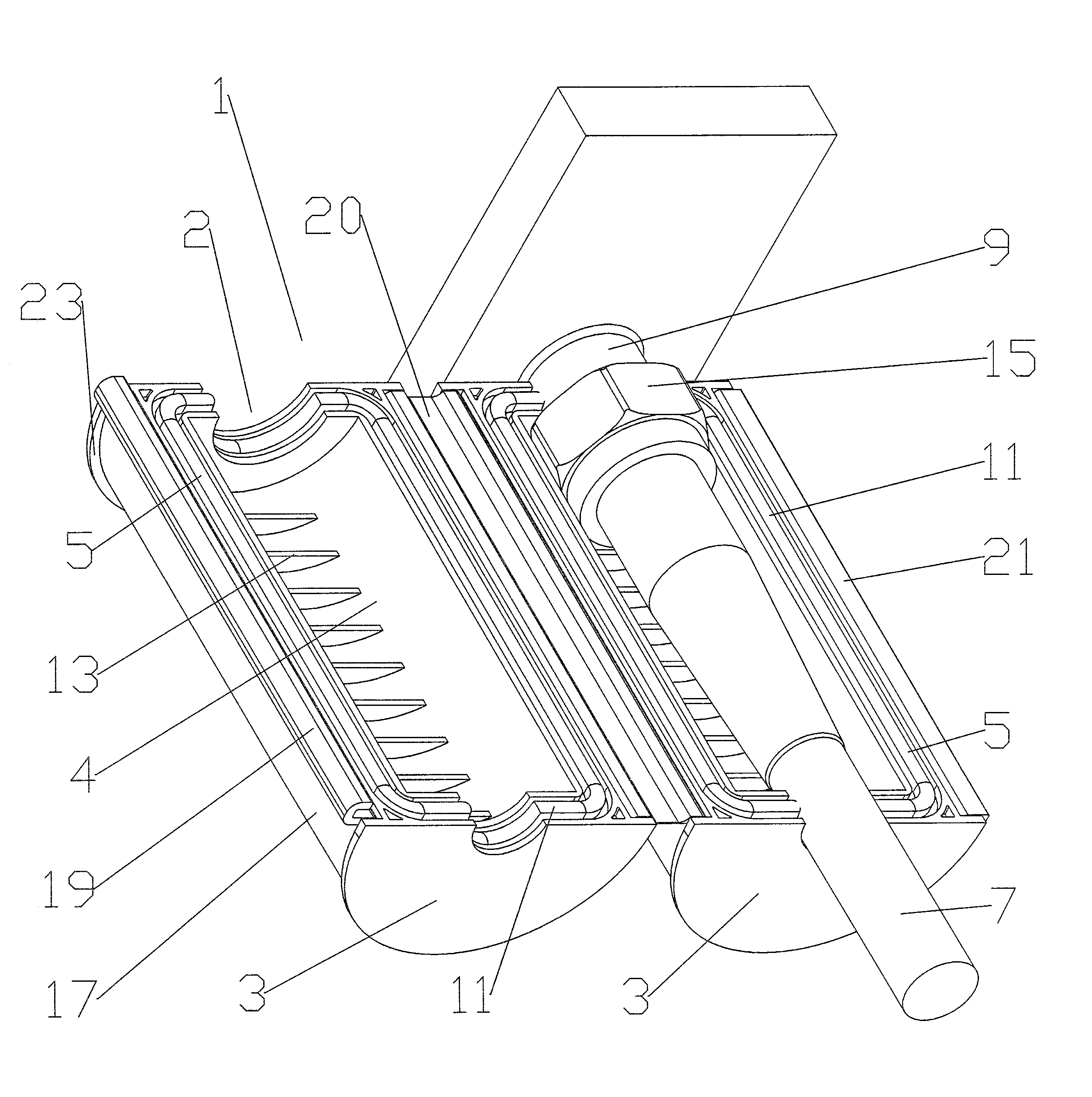

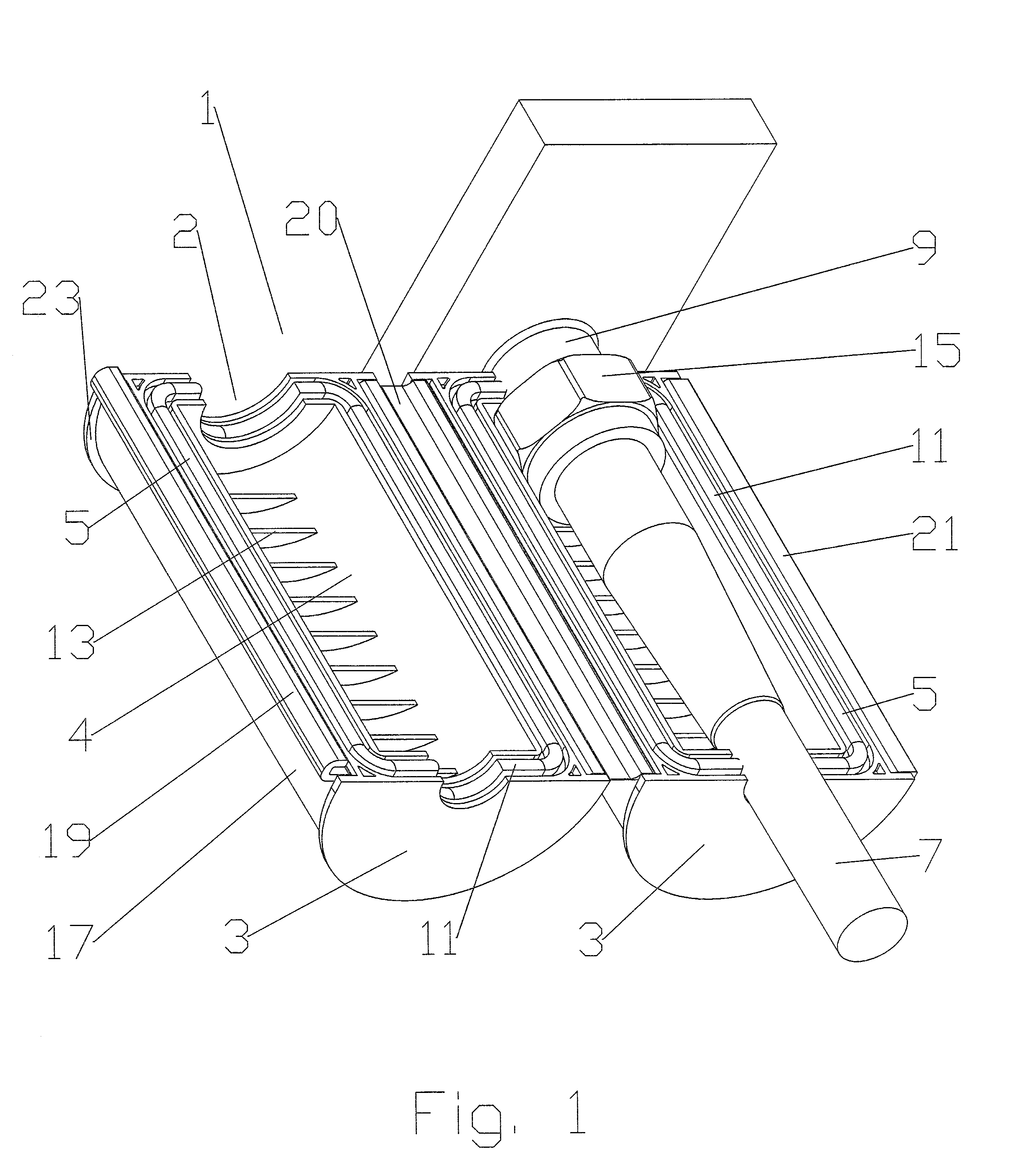

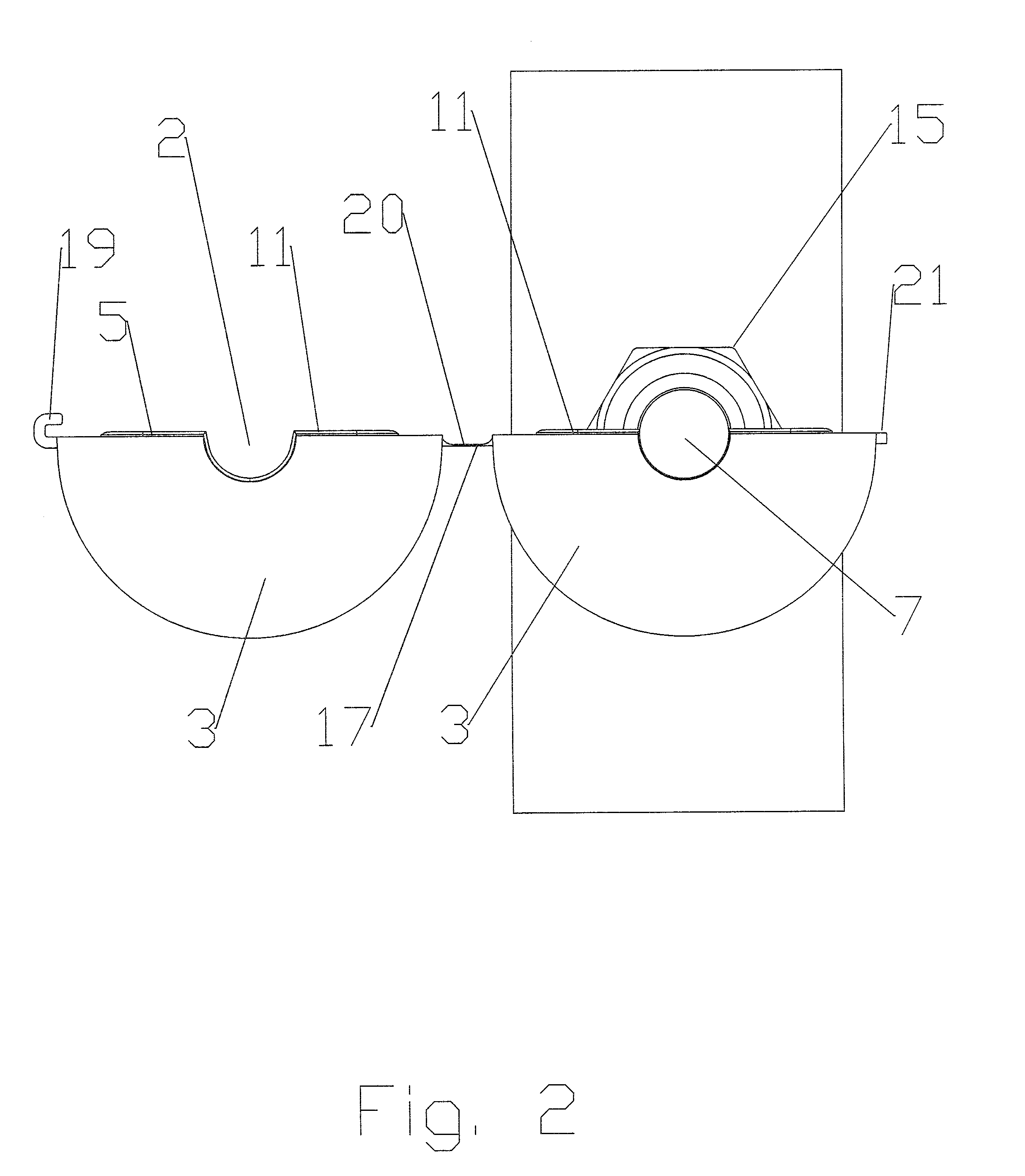

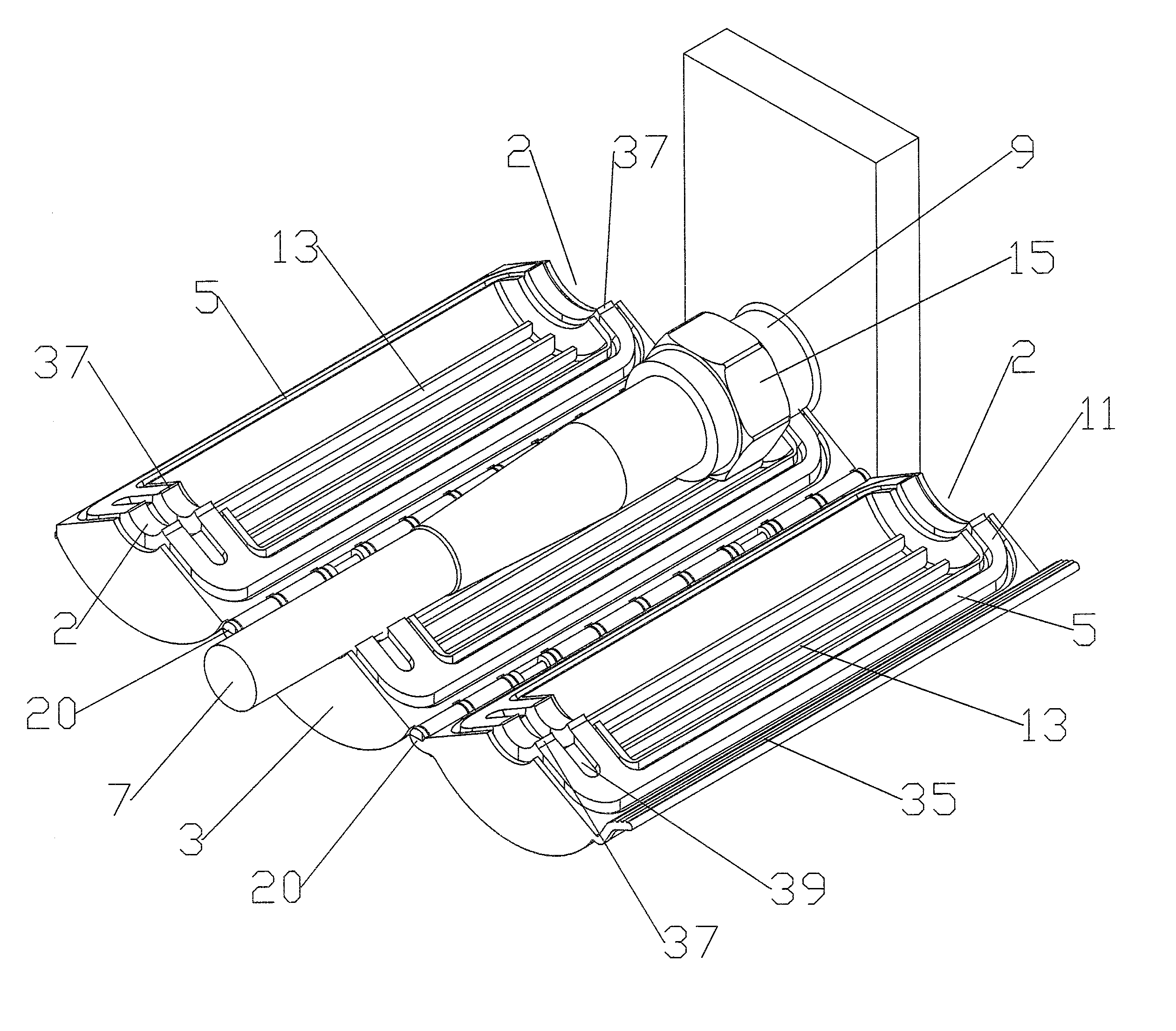

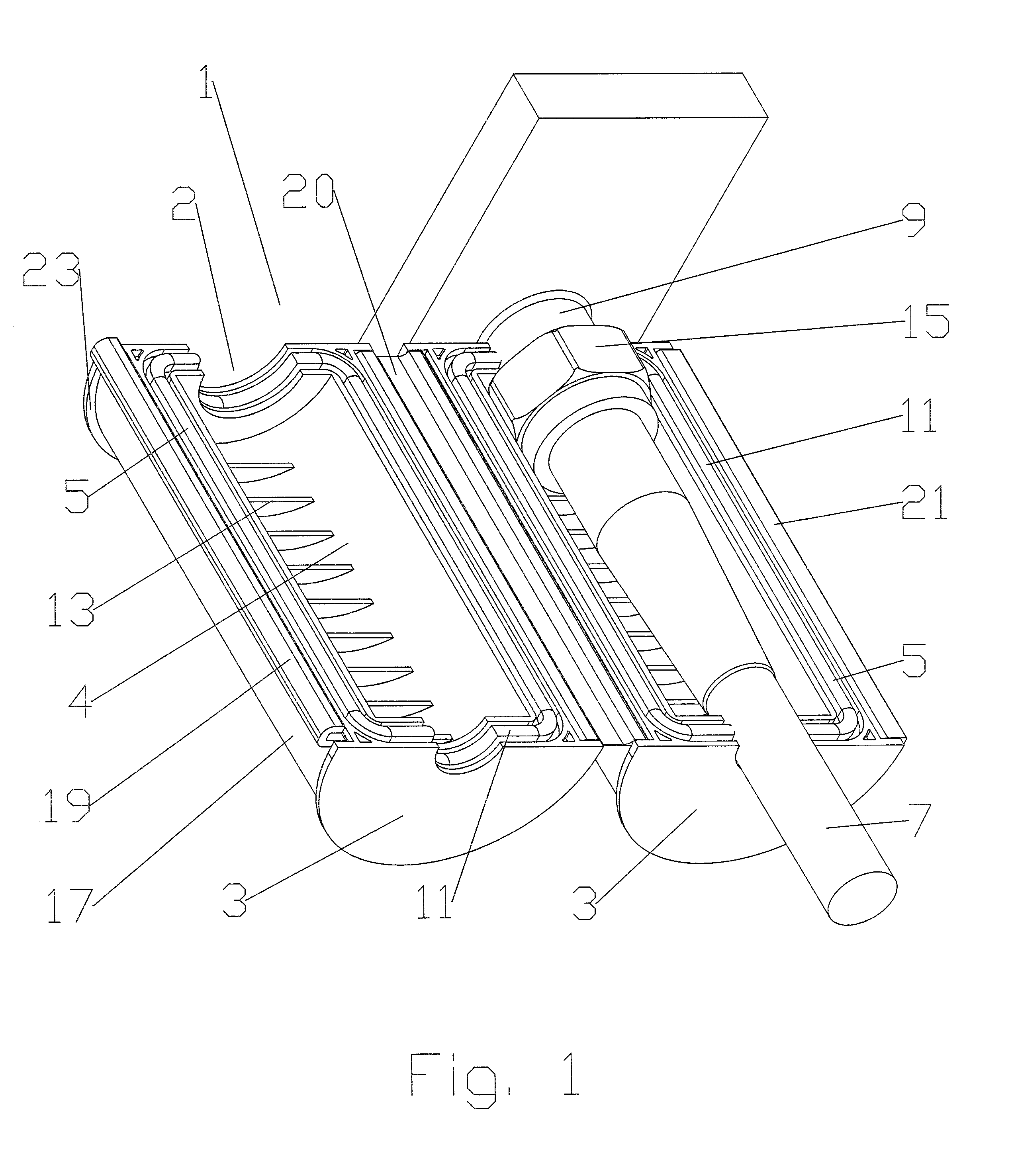

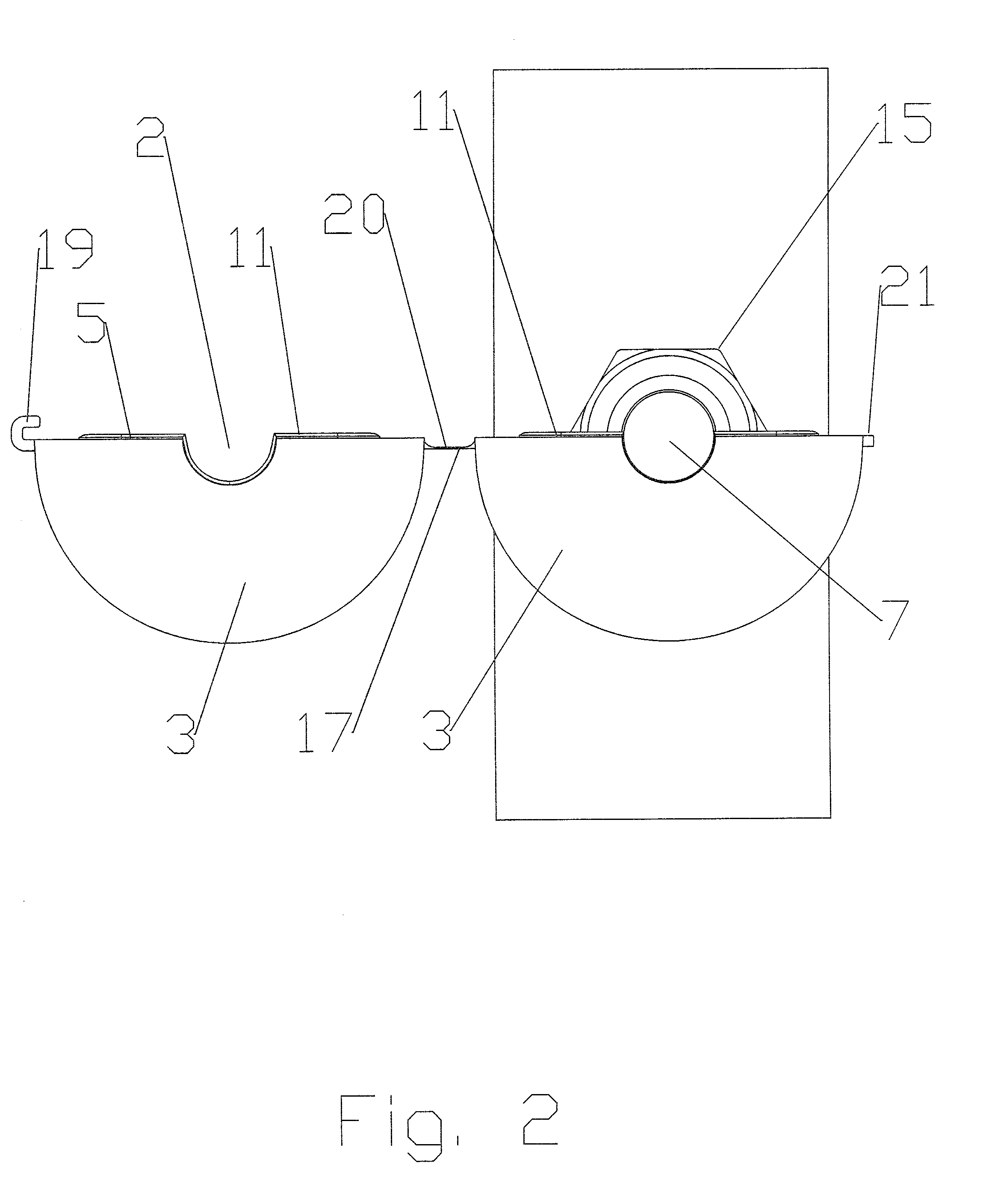

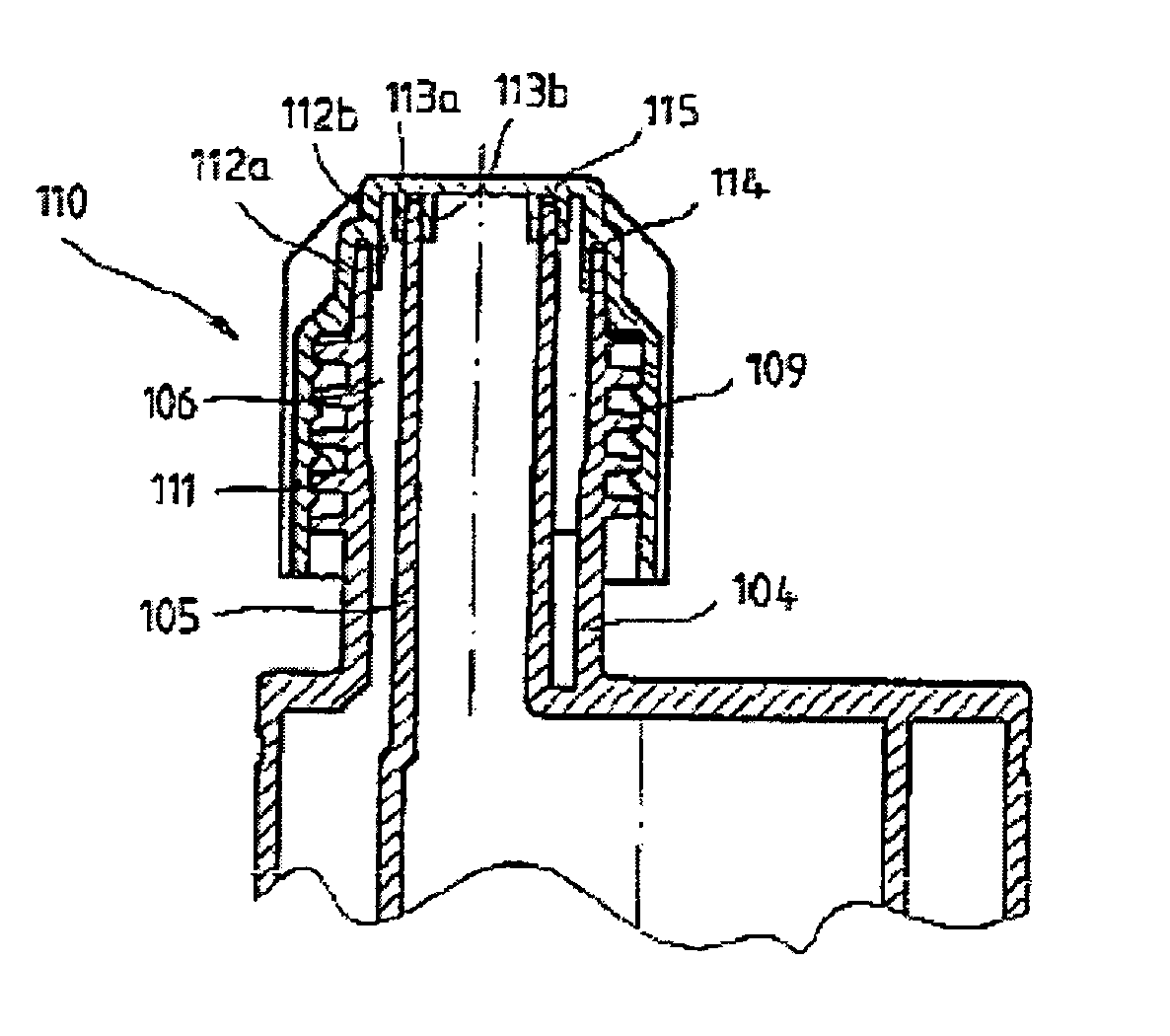

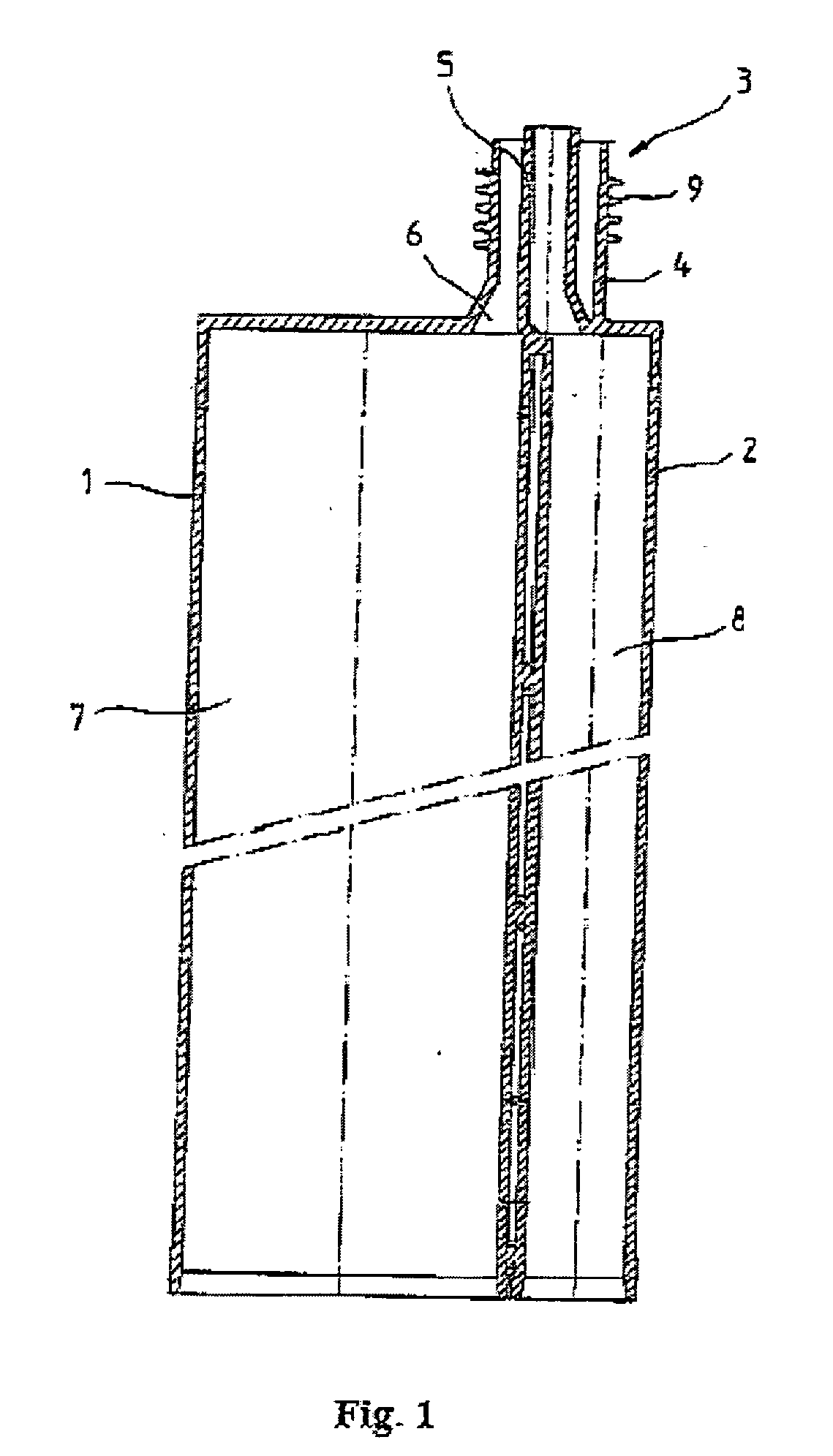

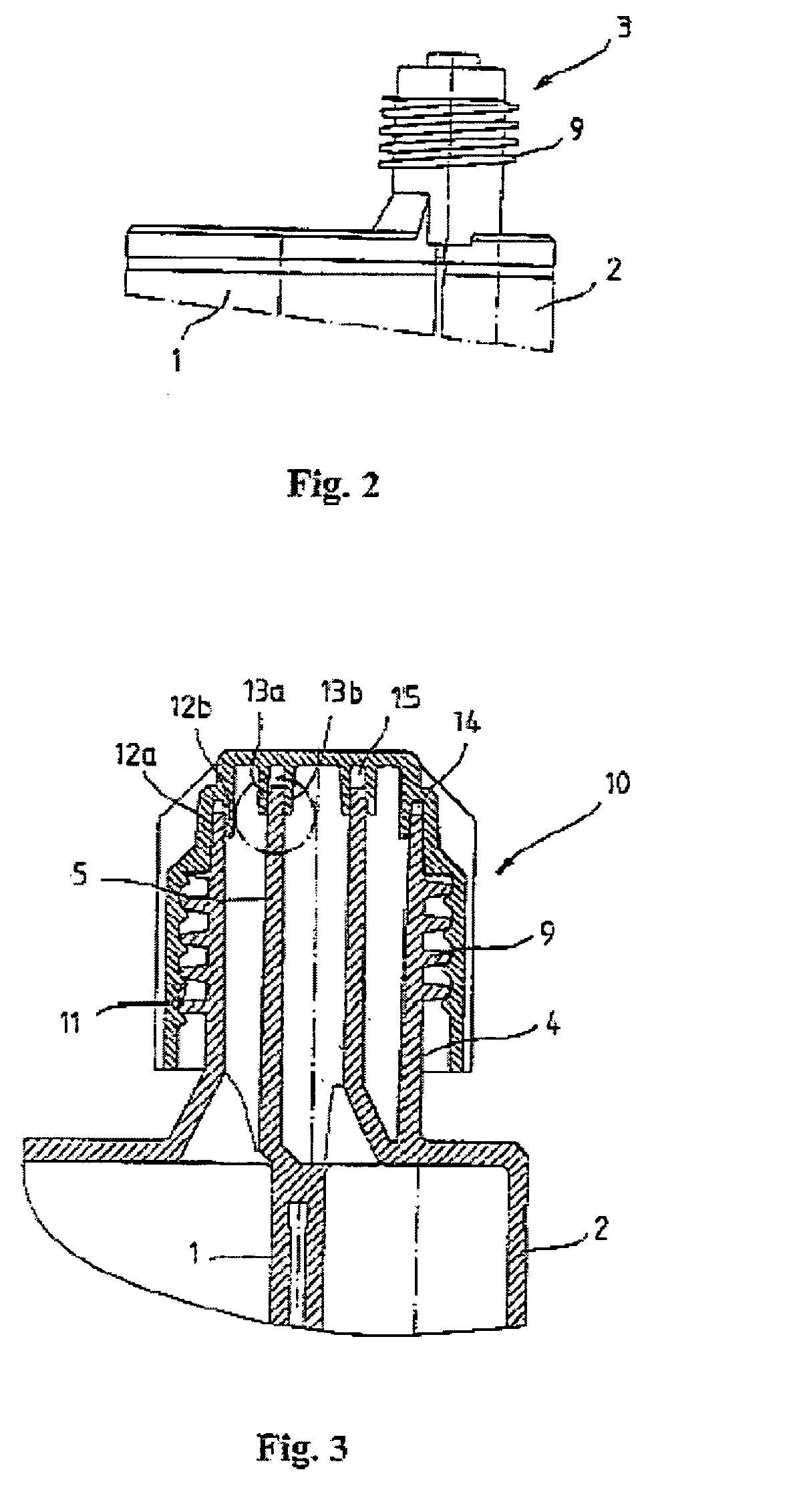

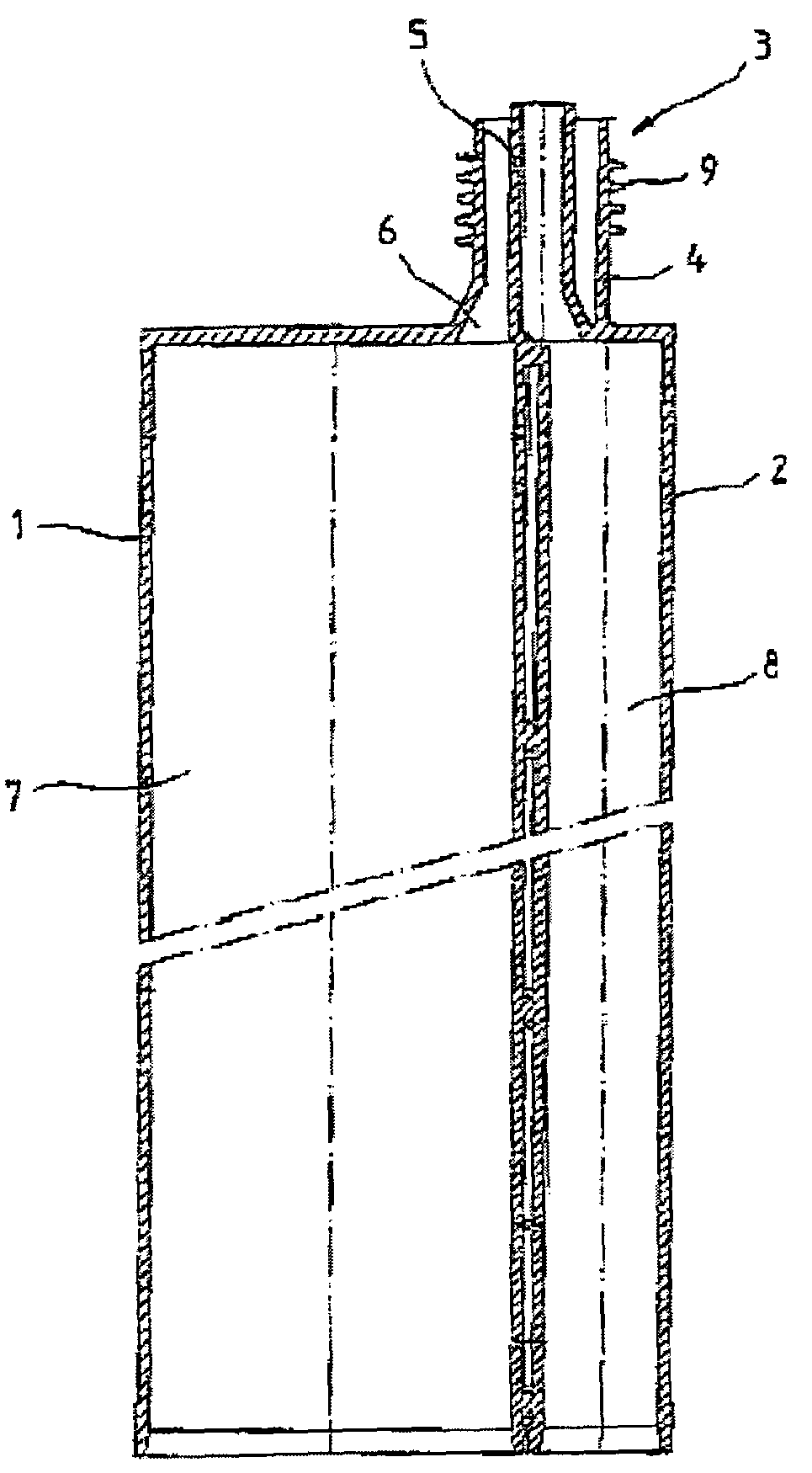

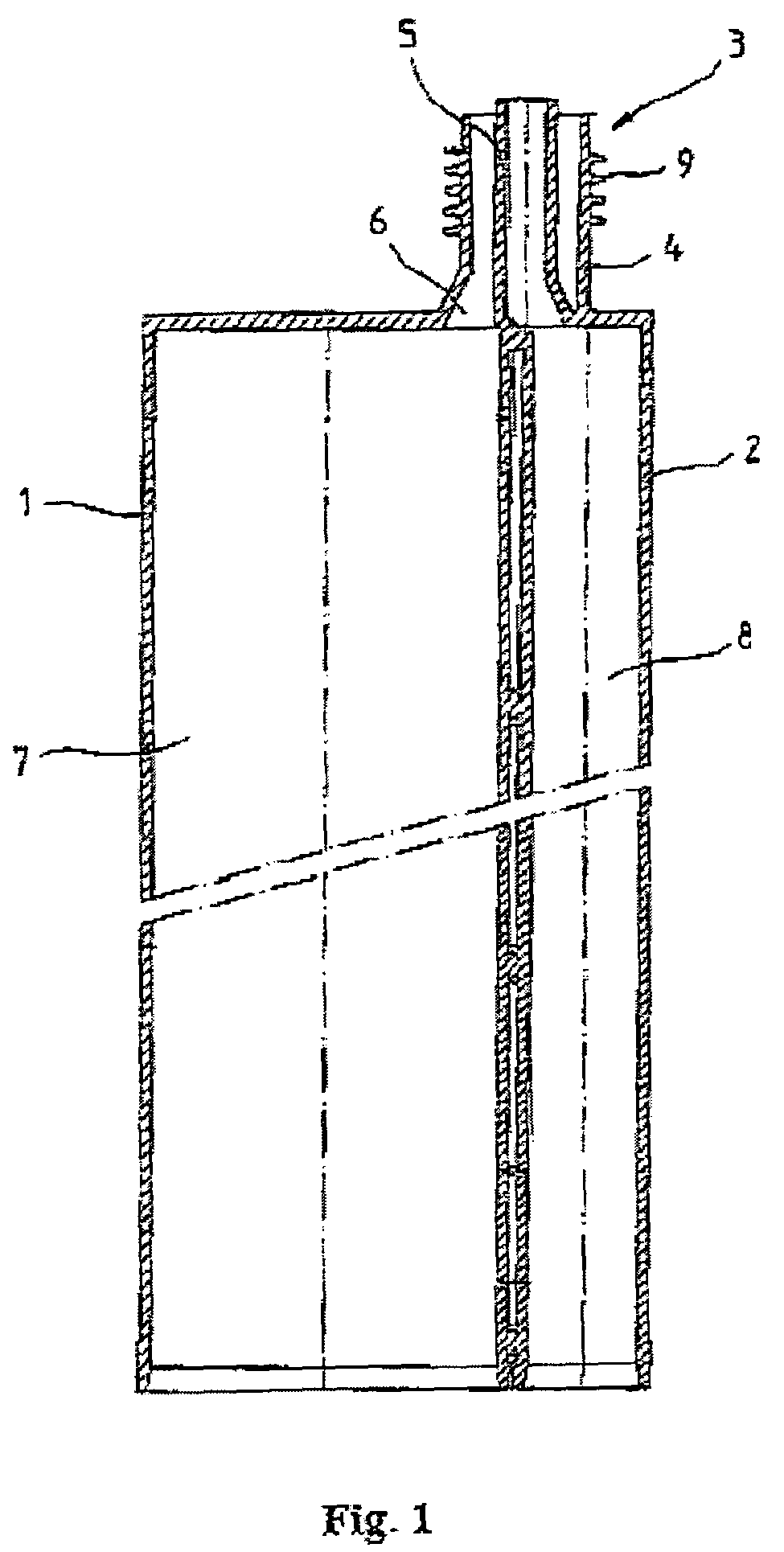

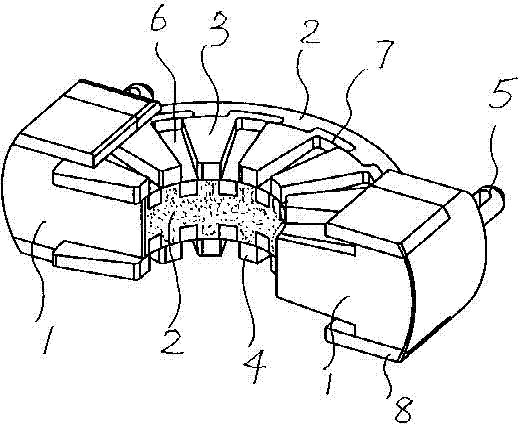

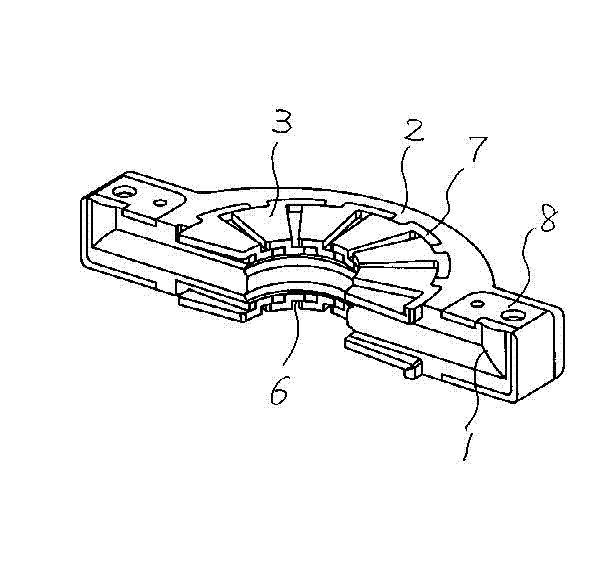

Multicomponent cartridge

ActiveUS20050051576A1Increase surface pressureHigh sealing pressureLiquid surface applicatorsInternal framesEngineeringFlange

A multicomponent cartridge, particularly a two-component cartridge, contains a coaxial outlet with an outer outlet tube and an inner outlet tube concentric to the outer tube. A cap detachably connected to the coaxial outlet. A seal with at least one seal flange is arranged on the cap for contact on the inner and / or outer outlet tube. A simplified and improved seal is thus enabled, such that the seal includes at least one laterally projecting sealing edge, which extends around the inner and / or outer side of the inner and / or outer outlet tube of the coaxial outlet and / or on the side of the one or more seal flanges facing the outer and / or inner side of the inner and / or outer outlet tube.

Owner:SULZER CHEMTECH AG

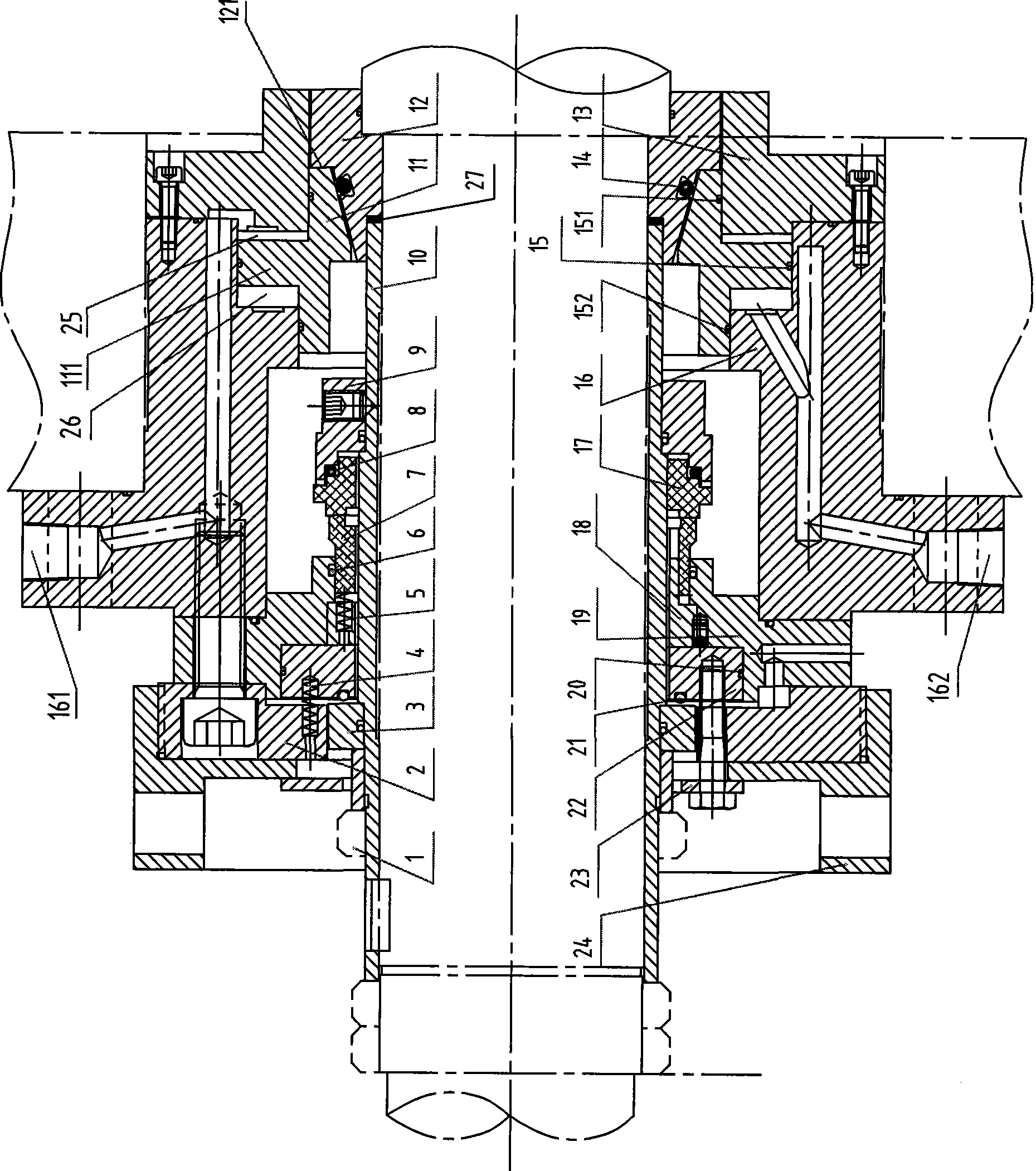

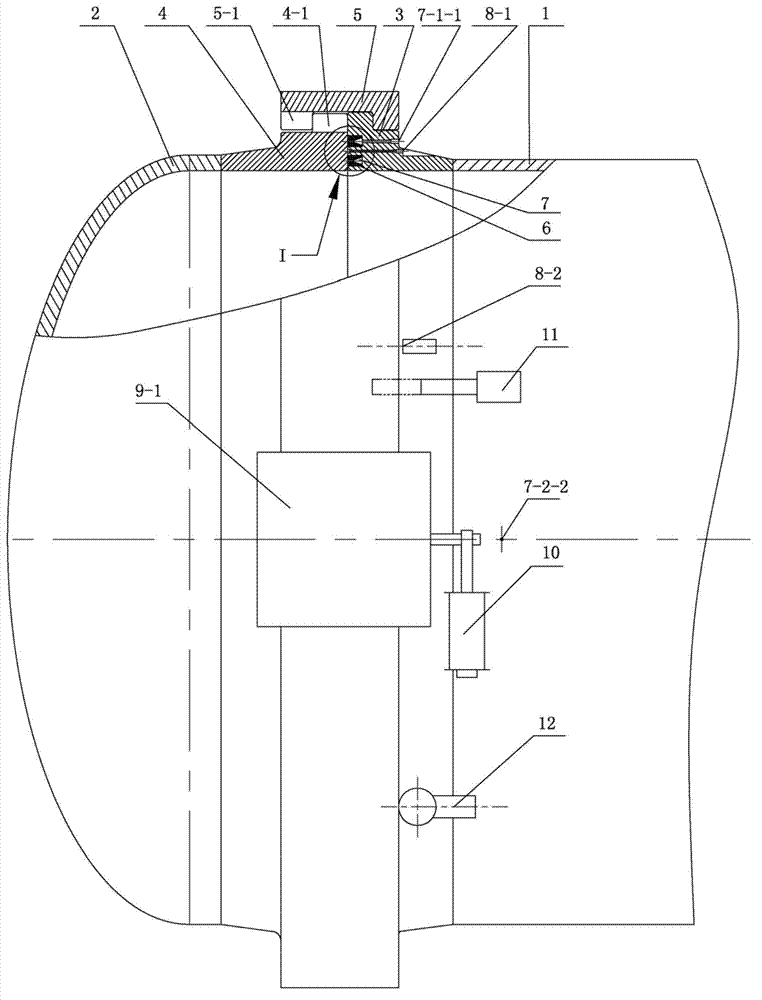

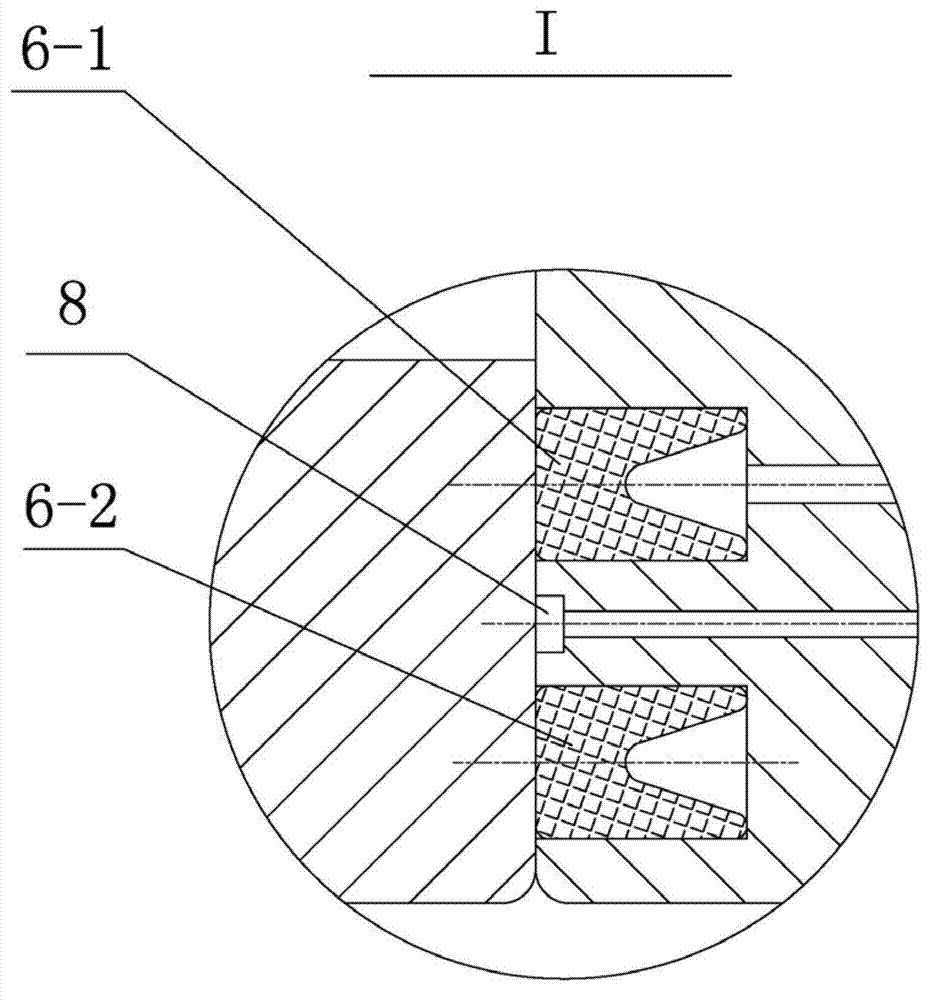

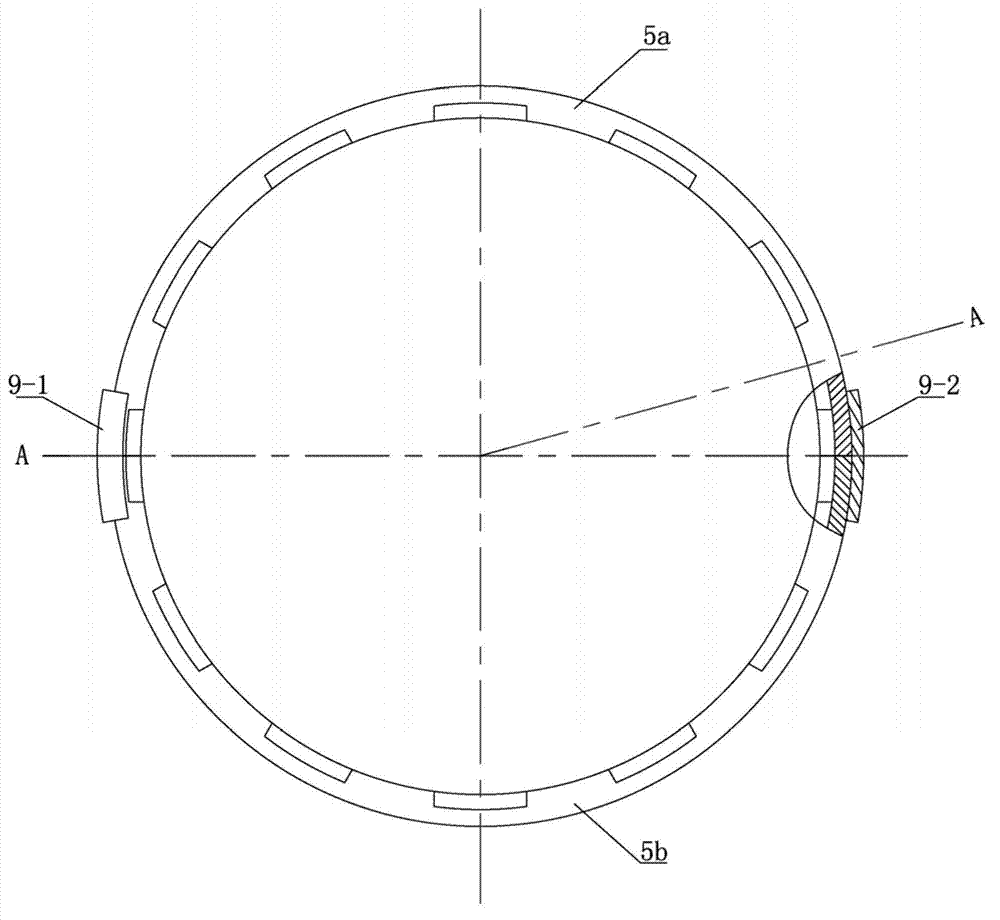

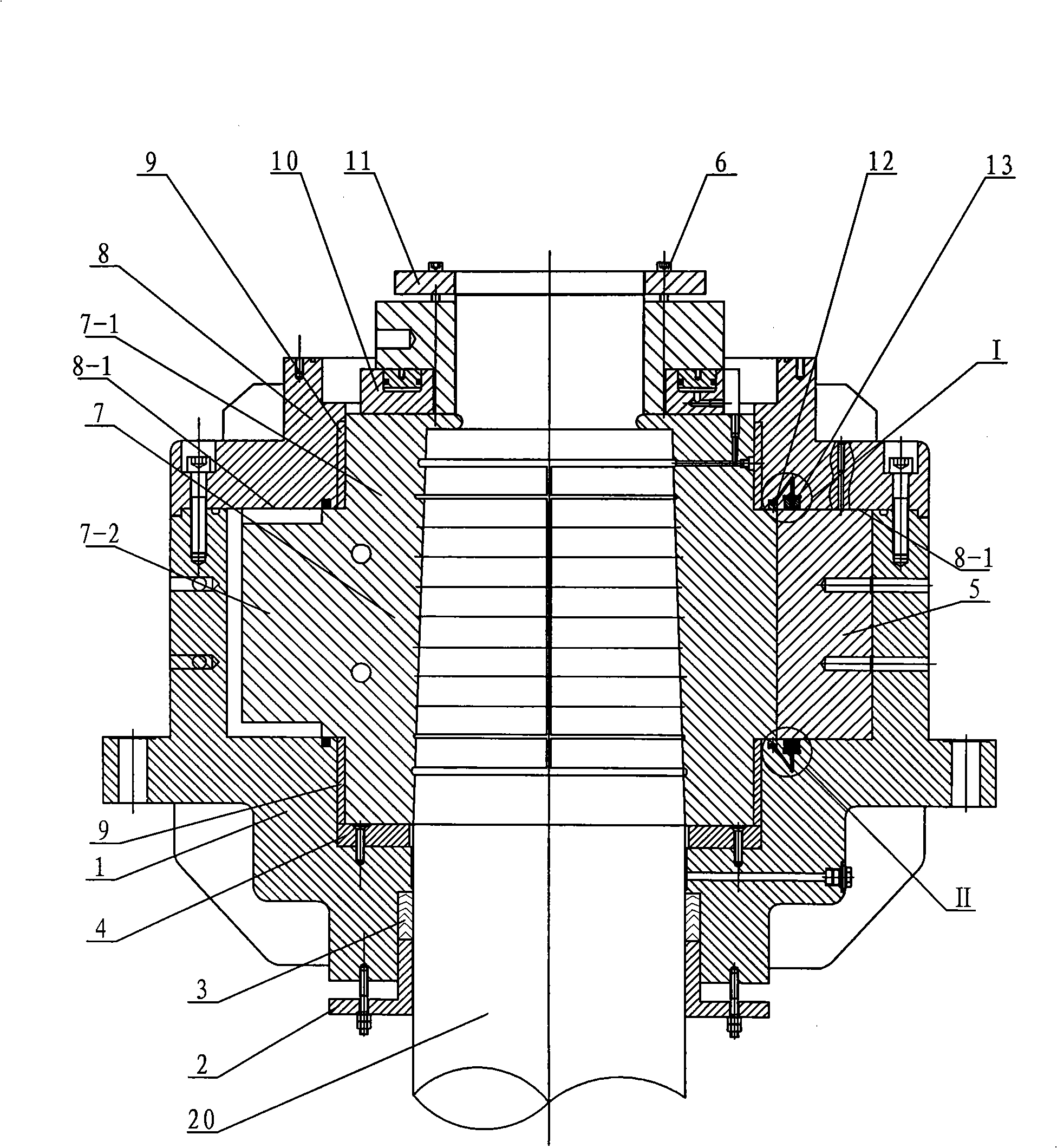

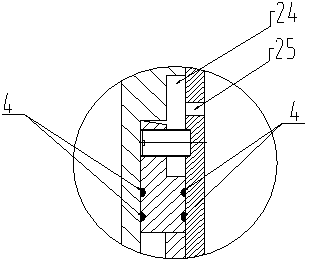

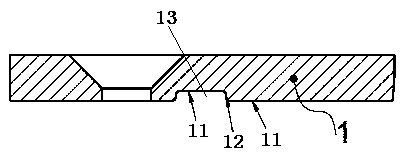

High-pressure controllable slide valve type mechanical combination sealing system

InactiveCN101463903AGuaranteed Replacement RepairAchieving a static sealEngine sealsEngineeringHigh pressure

The invention discloses a high-pressure controllable slide-valve type mechanical combined sealing system. The system comprises a controllable slide valve stationary seal assembly and a rotating mechanical seal assembly; the controllable slide valve stationary seal assemble comprises a slide valve gland (13), a slide valve (11) and a tapered shaft sleeve (12) sheathed on a shaft shoulder, the tapered shaft sleeve (12) is positioned inside the slide valve gland (13), the slide valve (11) which is partially positioned in a flange (16) is hermetically connected with the tapered shaft sleeve (12) in a sliding way, and the flange (16) is provided with a pressure source channel I (161) and a pressure source channel II (162) which are respectively used for controlling the slide valve (11) to slide leftwards or slide rightwards; the rotating mechanical seal assembly comprises a rotating seat (9) which is fixedly connected with a shaft sleeve (10), a rotating ring (17) and a stationary ring (7) which are closely jointed on a seal face and the like. The sealing system can help greatly reduce and avoid leakage of dangerous fluid and serious accidents.

Owner:ZHEJIANG UNIV

Cable and apparatus interconnection close quarters environmental seal

ActiveUS7453042B2High sealing pressureImprove sealingElectrically conductive connectionsCable junctionsInterconnectionC shaped

A sealing assembly for a cable to apparatus electrical interconnection. The assembly having a unitary cylindrical gasket, the outer diameter of the cylindrical gasket provided with an insertion opening to an interconnection cavity; the insertion opening having a generally circle sector shape at a cable end and an apparatus end, the insertion opening extending between the cable end and the apparatus end along the outer diameter. A generally C-shaped outer shell is dimensioned to seat along the outer diameter, the outer shell having outward protruding edge lips aligned with the insertion opening along the outer diameter. The edge lips movable towards one another to a closed position wherein the insertion opening is closed around the electrical interconnection; and means for retaining, such as a locking bar that fits over the edge lips.

Owner:COMMSCOPE TECH LLC

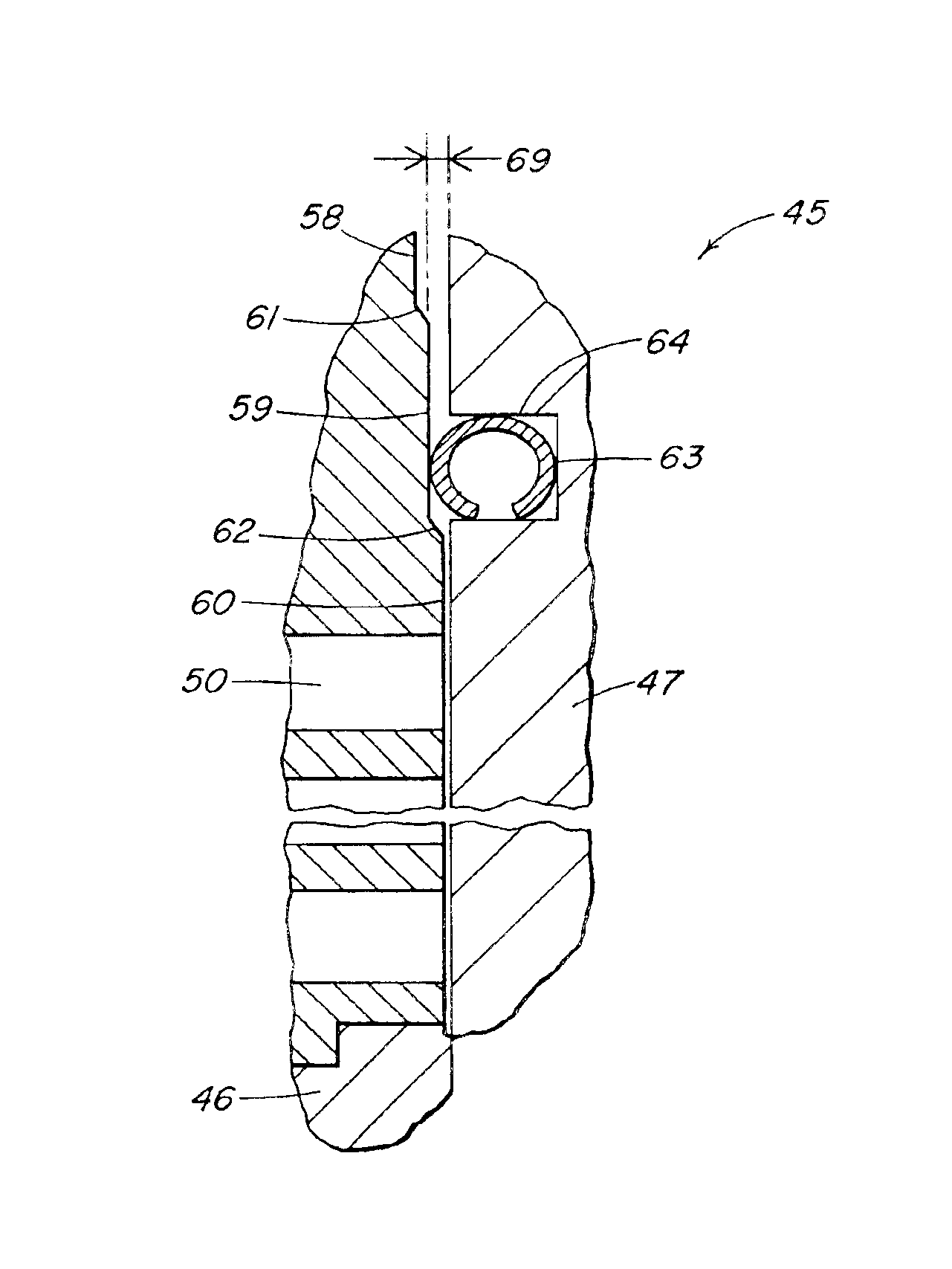

Multicomponent cartridge

ActiveUS7306126B2Simplified and improved sealIncrease surface pressureLiquid surface applicatorsInternal framesFlange

A multicomponent cartridge, particularly a two-component cartridge, contains a coaxial outlet with an outer outlet tube and an inner outlet tube concentric to the outer tube. A cap detachably connected to the coaxial outlet. A seal with at least one seal flange is arranged on the cap for contact on the inner and / or outer outlet tube. A simplified and improved seal is thus enabled, such that the seal includes at least one laterally projecting sealing edge, which extends around the inner and / or outer side of the inner and / or outer outlet tube of the coaxial outlet and / or on the side of the one or more seal flanges facing the outer and / or inner side of the inner and / or outer outlet tube.

Owner:SULZER CHEMTECH AG

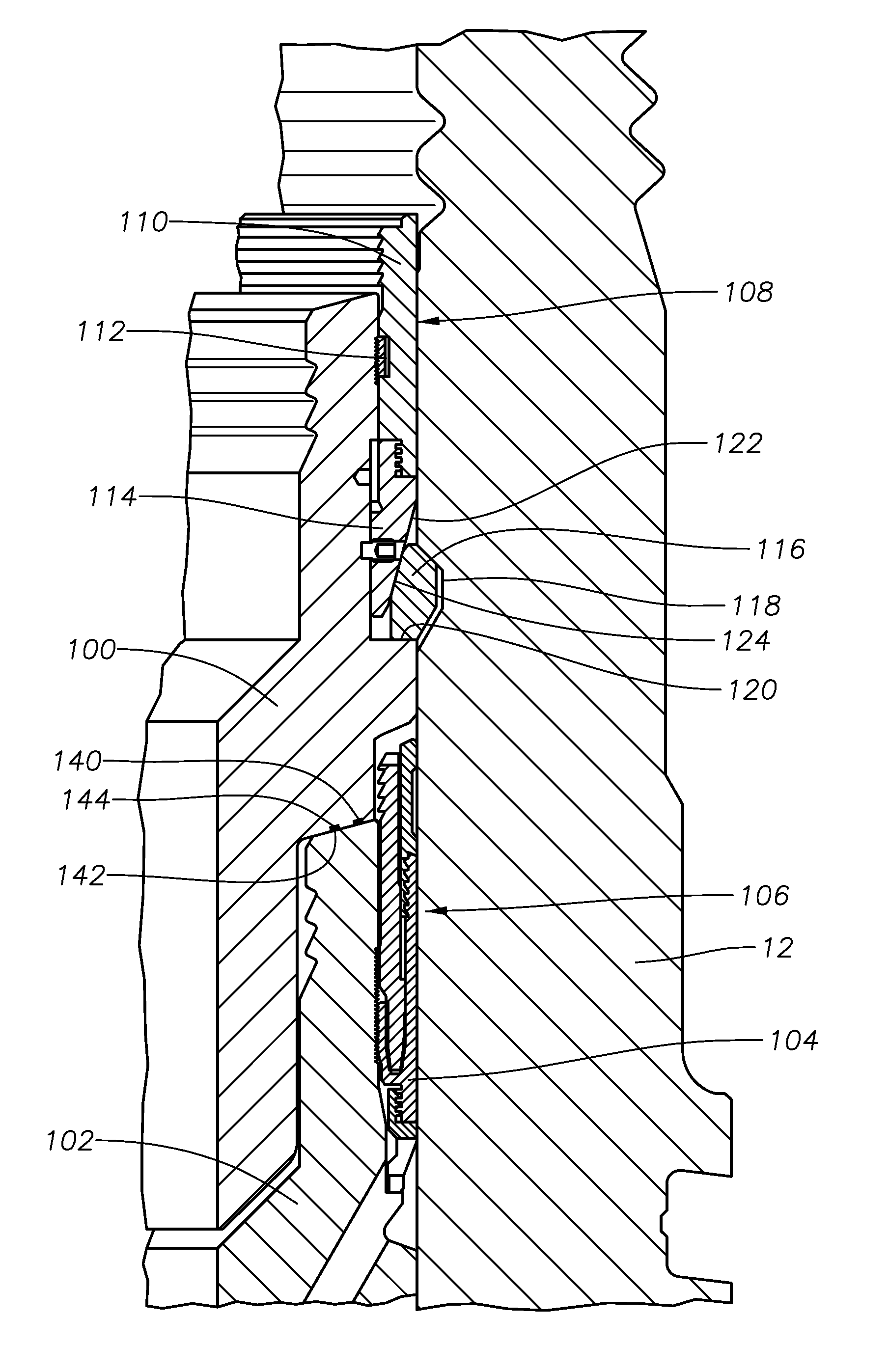

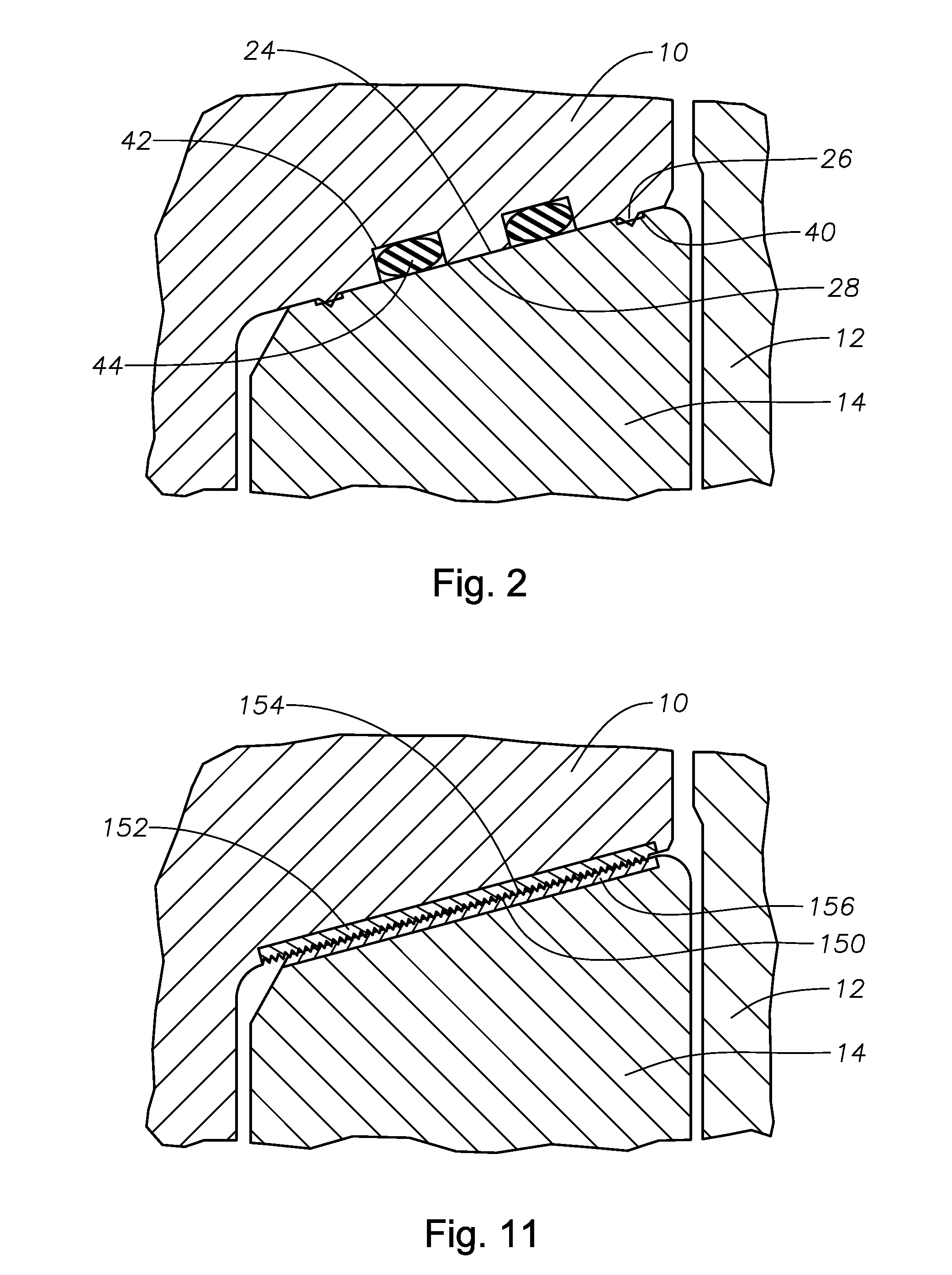

Wicker-Type Face Seal and Wellhead System Incorporating Same

InactiveUS20110316236A1Maintaining the integrity of the face sealMaintain integrityEngine sealsSealing/packingEngineeringCasing hanger

A wellhead seal assembly that forms a metal-to-metal seal between inner and outer wellhead members and a face seal between inner wellhead members. The face seal is created by two opposing sealing surfaces on inner wellhead members that sealingly engage each other. The inner wellhead members that interact to form a face seal may be a casing hanger, bridging hanger, or lockdown hanger. A wicker profile formed on one of the opposing seal surfaces bites into the opposing seal surface in response to a load. The face seal is designed such that well pressure enhances the face seal.

Owner:VETCO GRAY

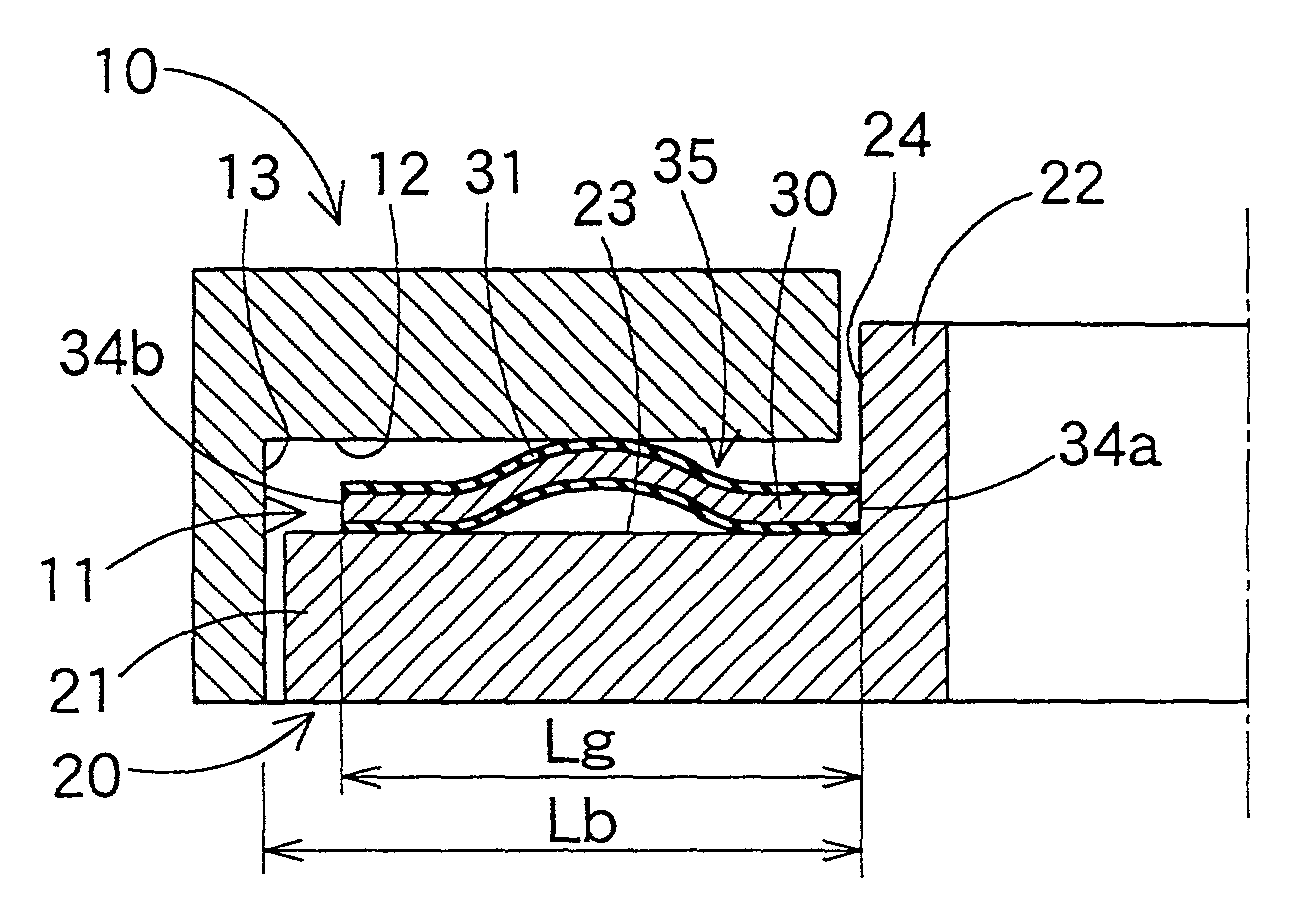

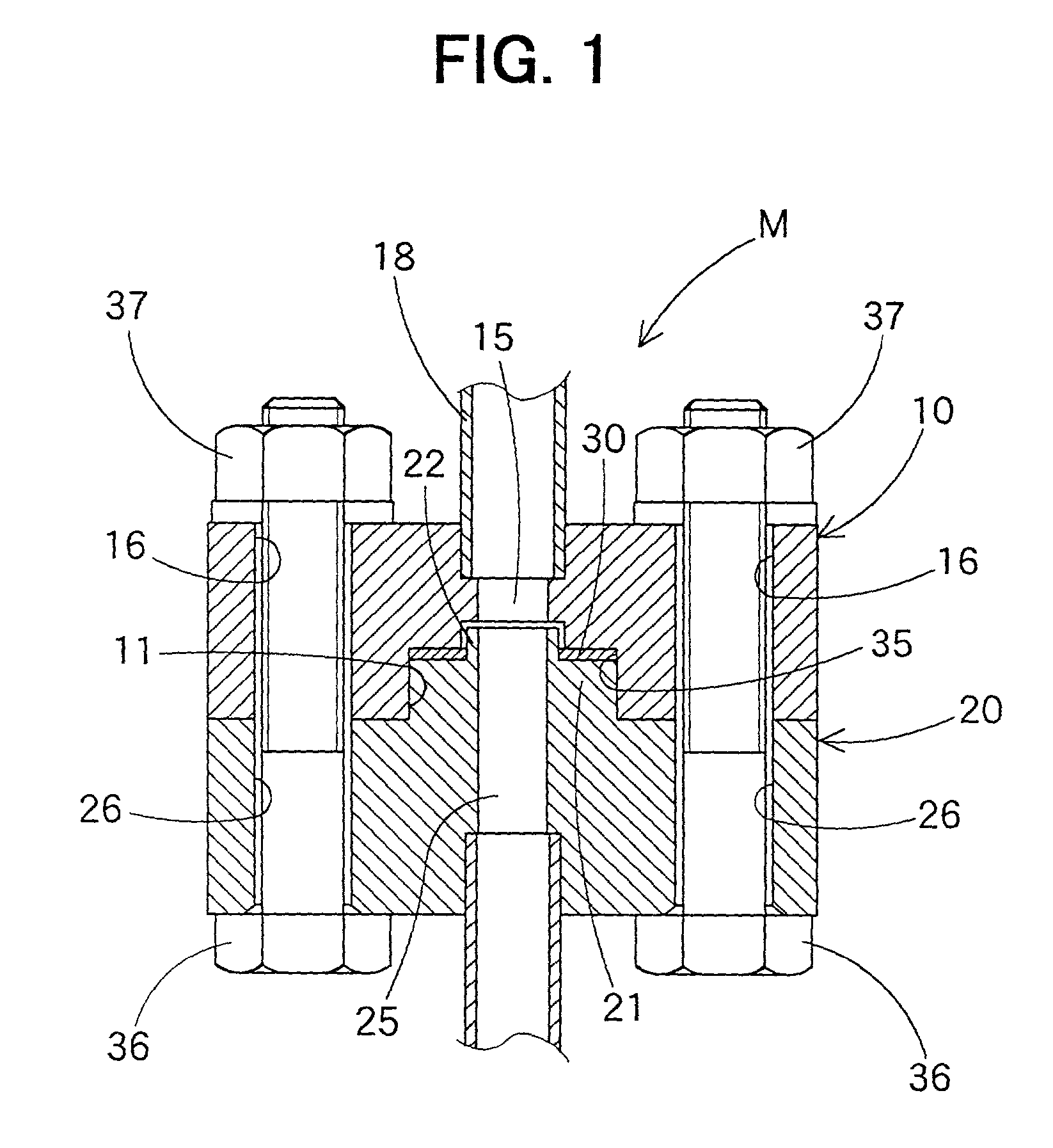

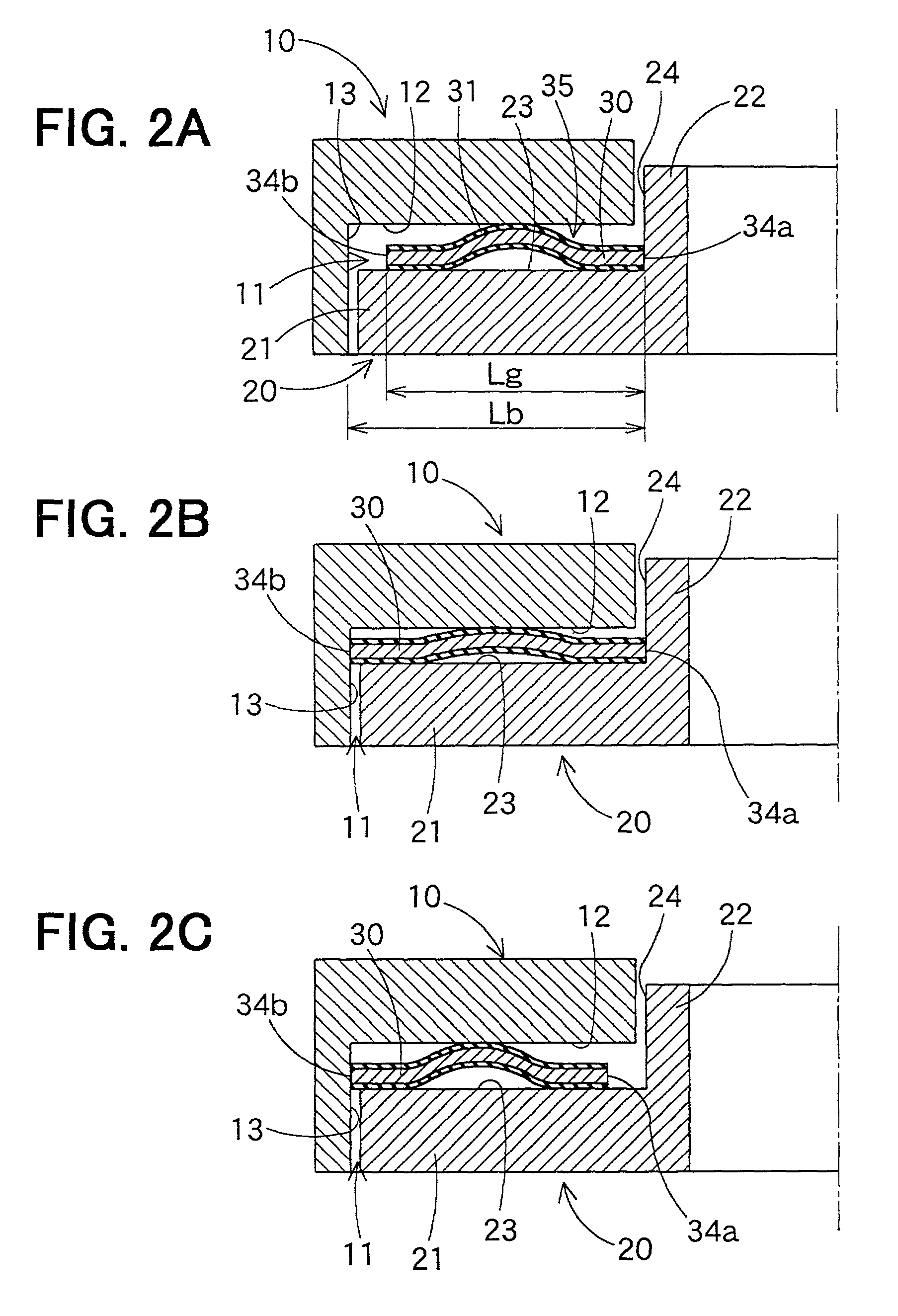

Gasket attachment structure for refrigerant-seal

InactiveUS20020000695A1Minimal leakageHigh sealing pressureEngine sealsFlanged jointsEngineeringRefrigerant

In an attachment structure of a gasket for a refrigerant-seal, both first and second connection members are disposed to define a seal space by first and second opposite surfaces and first and second wall surfaces, and the gasket having a beam portion is disposed in the seal space so that one end surface of the gasket is held on the first wall surface of the first connection member and the other end surface of the gasket is separated from the second wall surface of the second connection member by a predetermined clearance, before both the first and second connection members are fastened. After both the first and second connection members are fastened, the gasket extends, and the other end surface of the gasket press-contacts the second wall surface.

Owner:DENSO CORP

Linerless closure

Owner:CLOSURE SYST INT INC

Infusion device with active and passive check valves

ActiveUS8323267B2Avoid flowImprove energy efficiencyPharmaceutical delivery mechanismMedical devicesEngineeringCheck valve

An infusion system in which therapeutic substance from a reservoir is pumped by a bolus pump to an infusion port is disclosed. The therapeutic substance delivered by the bolus pump passes first through a passive check valve located downstream from the pump. The passive check valve opens in response to fluid pressure of the therapeutic substance. After passing through the passive check valve, the therapeutic substance passes through an active check valve located downstream from the passive check if the active check valve is actuated such that it is open. When not activated, the active check valve is closed and fluid flow through the active check valve in the downstream direction is prevented.

Owner:MEDTRONIC INC

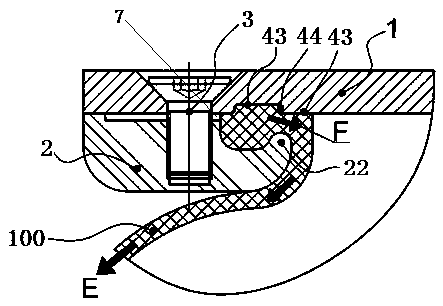

Pressure vessel door quickly-opened device with leakage on-line detection function

ActiveCN102818021AEasy to assemble and disassembleReduce processEngine sealsPressure vesselsVessel sealingEngineering

The invention relates to the field of pressure vessels, and aims to provide a pressure vessel door quickly-opened device with a leakage on-line detection function. The device comprises a barrel flange, a cover flange and a locking clamp, wherein the barrel flange is welded with a vessel barrel, the cover flange is welded with a cover, and the locking clamp is used for fixedly connecting the barrel flange and the cover flange; the flange surface of the barrel flange is provided with three circles of grooves which sequentially include a first sealing groove, a gas detecting groove and a second sealing groove from outside to inside, and a lip-type sealing ring is respectively placed in the first sealing groove and the second sealing groove; and the barrel flange is provided with a gas inlet and a medium sensor, wherein the gas inlet is respectively connected to the first sealing groove and the second sealing groove and used for importing sealing gas, and the medium sensor is communicated to the gas detecting groove. The device disclosed by the invention is convenient to assemble and disassemble, saves the cost, prolongs the service life, and ensures the success rate of vessel sealing; the gas detecting groove can detect the gas leakage of the insides of vessels; and the economic loss caused by suddenly stopping the operation of the vessels can be avoided.

Owner:ZHEJIANG UNIV

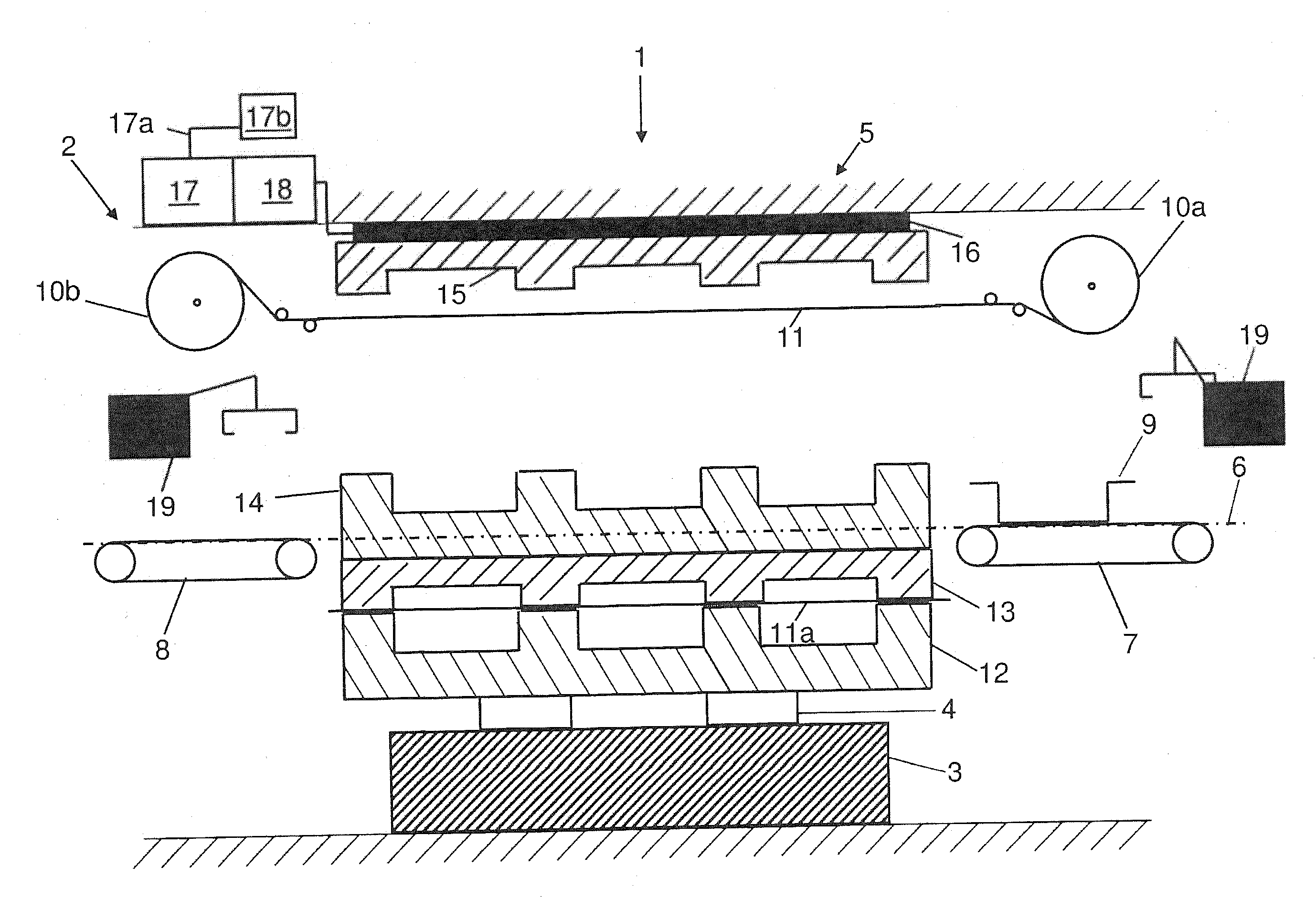

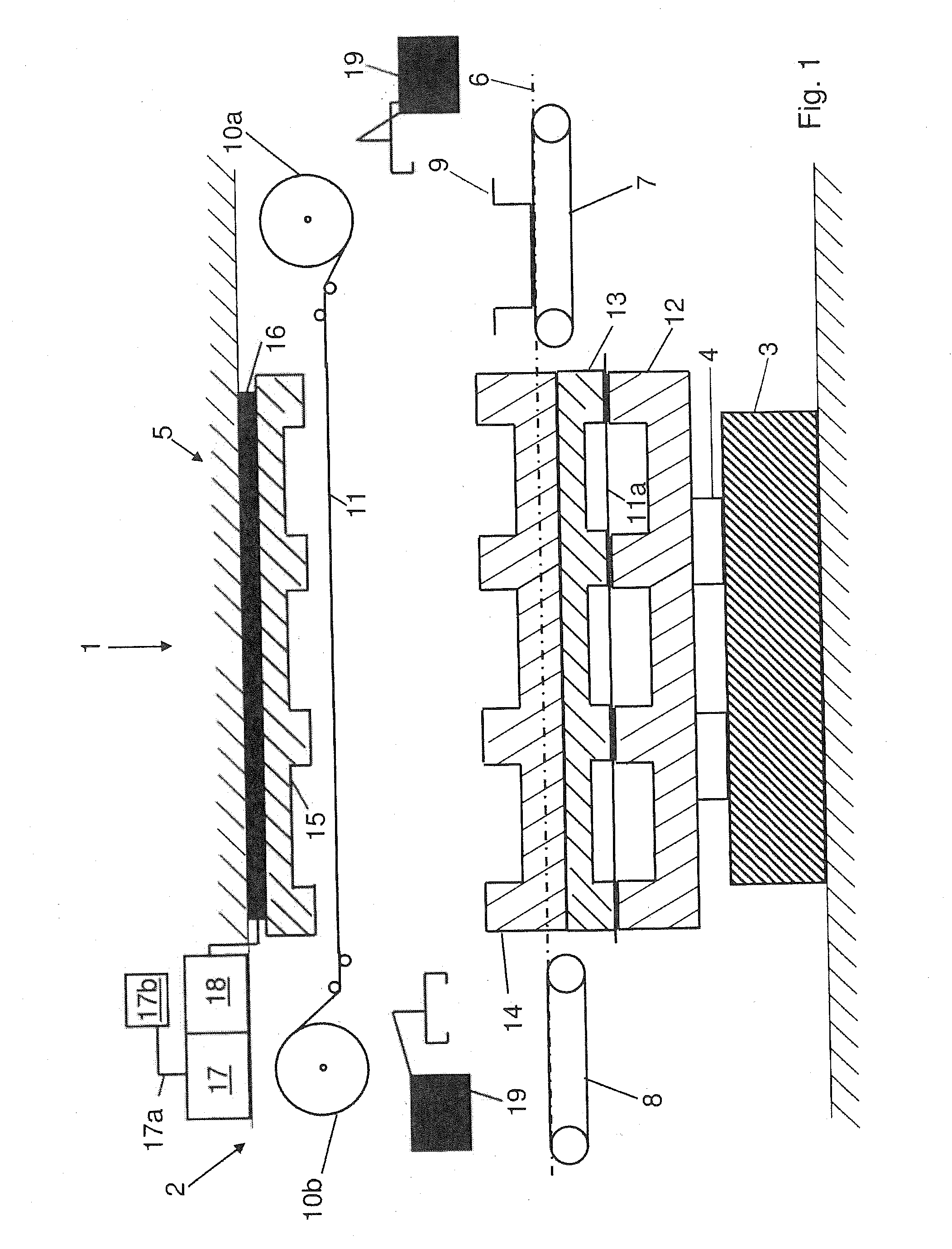

Sealing station and method for its operation

InactiveUS20130055688A1Improve sealingEffective surface is reducedOpening closed containersCapsEngineeringPackaging machine

A sealing station for a packaging machine for sealing a foil on to a packaging tray is provided. The sealing station comprises a sealing tool whereby the sealing tool is configured to apply a sealing force for sealing on to the foil and the packaging tray. The sealing tool includes an upper tray holding fixture and a lower tray holding fixture that are arranged at different heights, whereby each is configured for holding at least one packaging tray.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Cable and apparatus interconnection close quarters environmental seal

ActiveUS20080245547A1High sealing pressureImprove sealingElectrically conductive connectionsCable junctionsEngineeringInterconnection

A sealing assembly for a cable to apparatus electrical interconnection. The assembly having a unitary cylindrical gasket, the outer diameter of the cylindrical gasket provided with an insertion opening to an interconnection cavity; the insertion opening having a generally circle sector shape at a cable end and an apparatus end, the insertion opening extending between the cable end and the apparatus end along the outer diameter. A generally C-shaped outer shell is dimensioned to seat along the outer diameter, the outer shell having outward protruding edge lips aligned with the insertion opening along the outer diameter. The edge lips movable towards one another to a closed position wherein the insertion opening is closed around the electrical interconnection; and means for retaining, such as a locking bar that fits over the edge lips.

Owner:COMMSCOPE TECH LLC

High-pressure processing chamber for a semiconductor wafer

InactiveUS7077917B2Improve sealingLarge forceElectrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringHigh pressure

A processing chamber having an improved sealing means is disclosed. The processing chamber comprises a lower element, an upper element, and a sealing means that tightly holds the lower element to the upper element to define a processing volume that is maintained using the minimum pressure necessary. The processing chamber comprises a plate having a first face that forms the processing volume and a second, opposing face that forms a seal-energizing cavity. In one embodiment, a surface area of the first face is smaller than a surface area of the second face. When the same pressure is applied against both the first face and the second face, the force on the second face is greater than the force on the first face, resulting in a sealing force exceeding a processing force generated within the processing volume.

Owner:TOKYO ELECTRON LTD

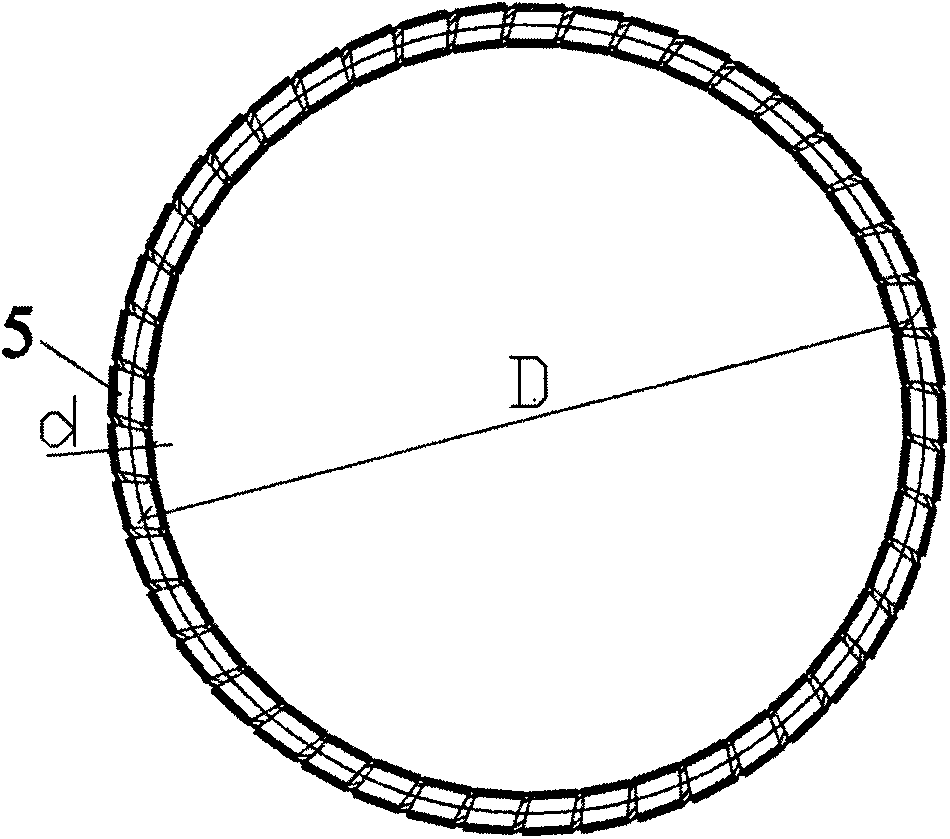

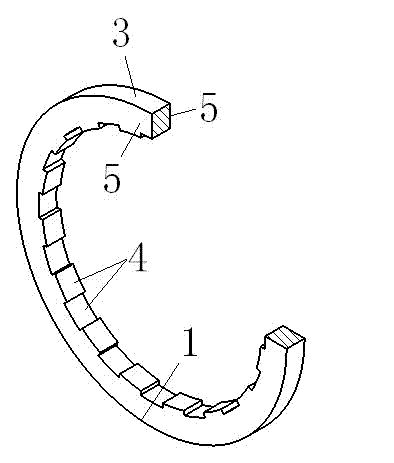

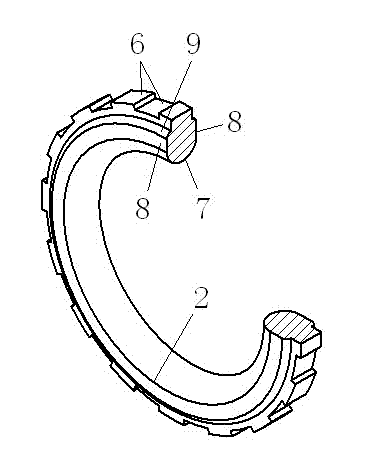

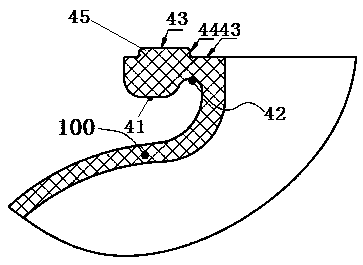

Blowout preventer ram

The invention belongs to the technical field of petroleum drilling support equipment, and discloses a blowout preventer ram. According to the technical scheme, the blowout preventer ram comprises a circular-arc elastic sealing rubber body with baffle plates at two ends, wherein the sealing rubber body can be fixed to a shell through positioning pins on the baffle plates; and the upper and lower sides of the elastic sealing rubber body are respectively provided with an exposed framework formed by lapping six sector metal plates. The sealing diameter of the blowout preventer ram is variable within a certain range, so that drill rods with different specifications and dimensions can be sealed by one pair of rams with diameter varying functions, the number of used rams is reduced, the operation process of replacing rams is omitted, and the working efficiency is improved.

Owner:HENGSHUI YIDE RUBBER PLASTIC PROD

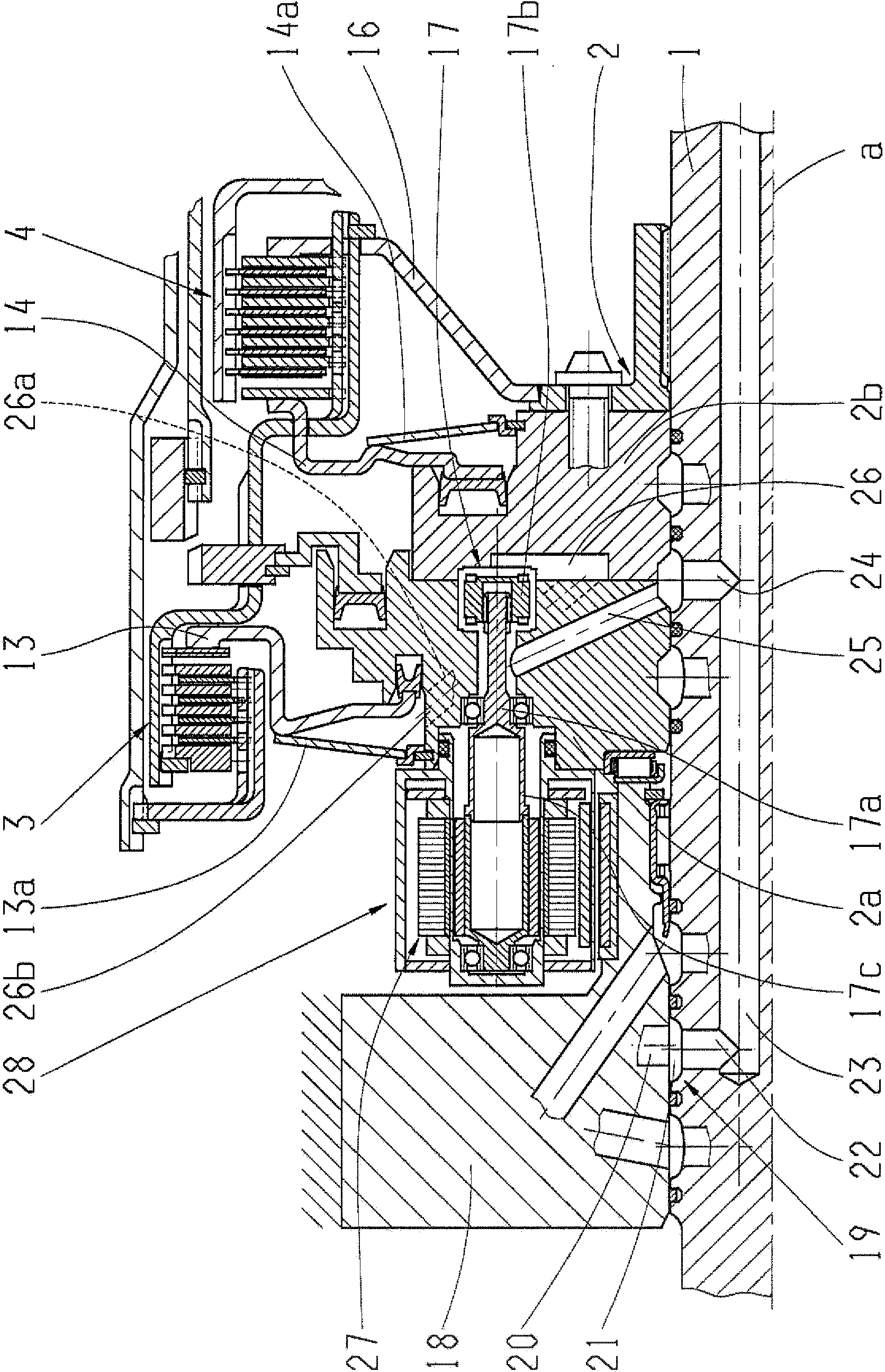

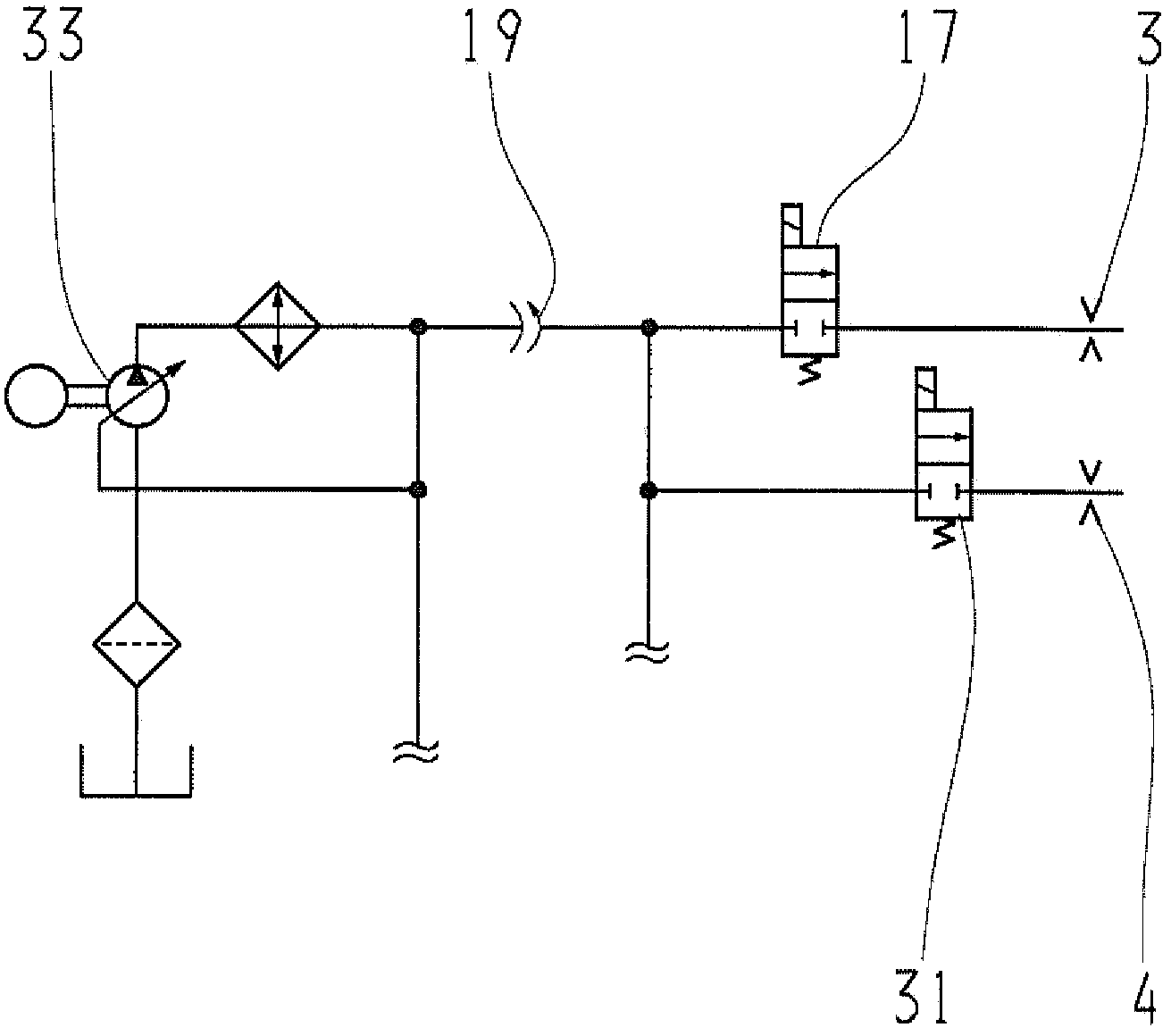

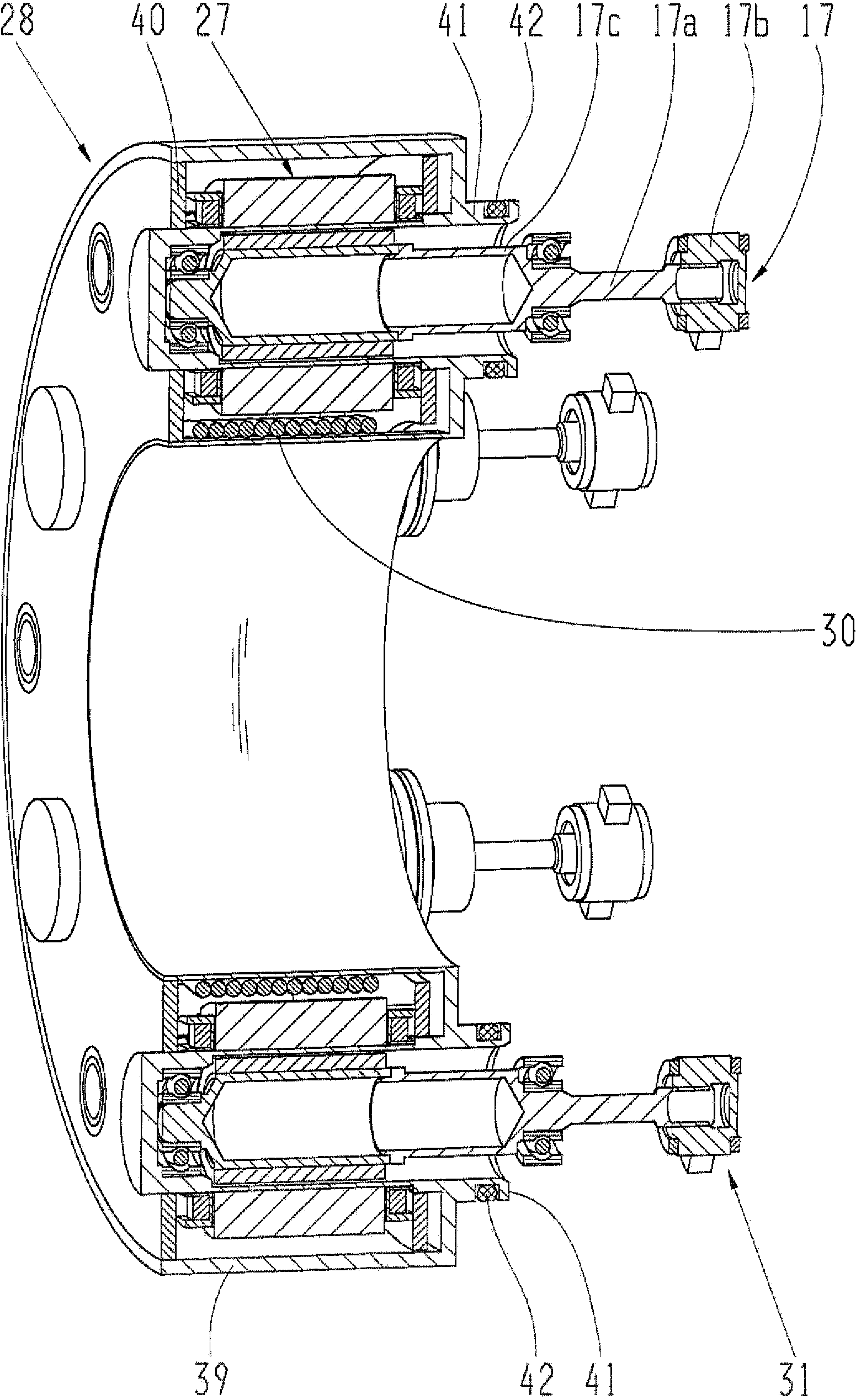

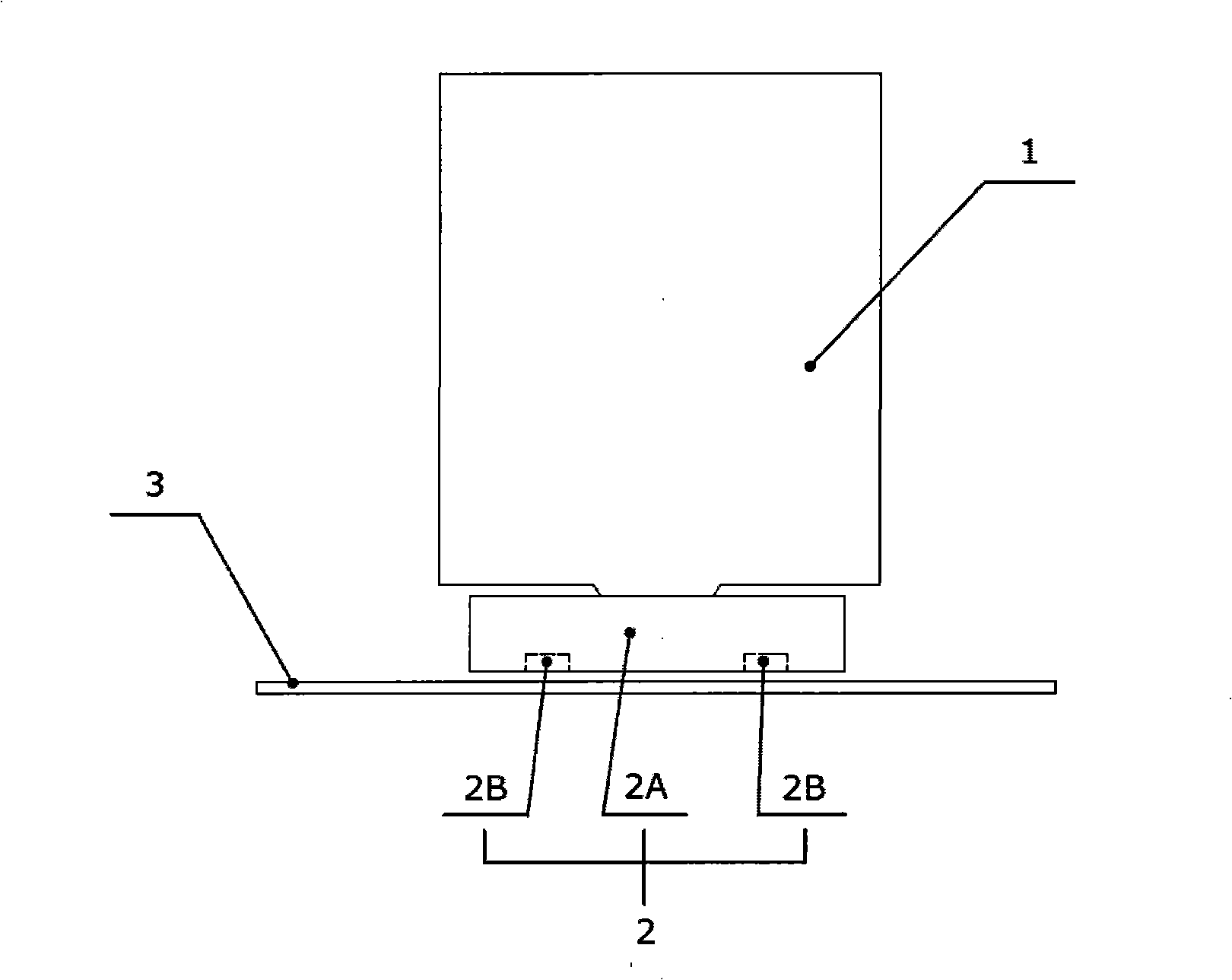

Device for controlling a flow of coolant and/or lubricating oil

InactiveCN103890434AAvoid friction lossReduce traction torqueOperating means/releasing devices for valvesFluid actuated clutchesEngineeringElectric energy

The invention relates to a device for controlling at least one flow of coolant and / or lubricating oil by at least one valve (17) for at least one cooling and / or lubricating point (3, 4) connected to a shaft (1). According to the invention, the valve (17) can be electrically actuated and is connected to the at least one cooling and / or lubricating point (3, 4) in a rotationally fixed manner, and the electrical energy for actuating the valve (17) can be supplied in a contactless manner.

Owner:ZF FRIEDRICHSHAFEN AG

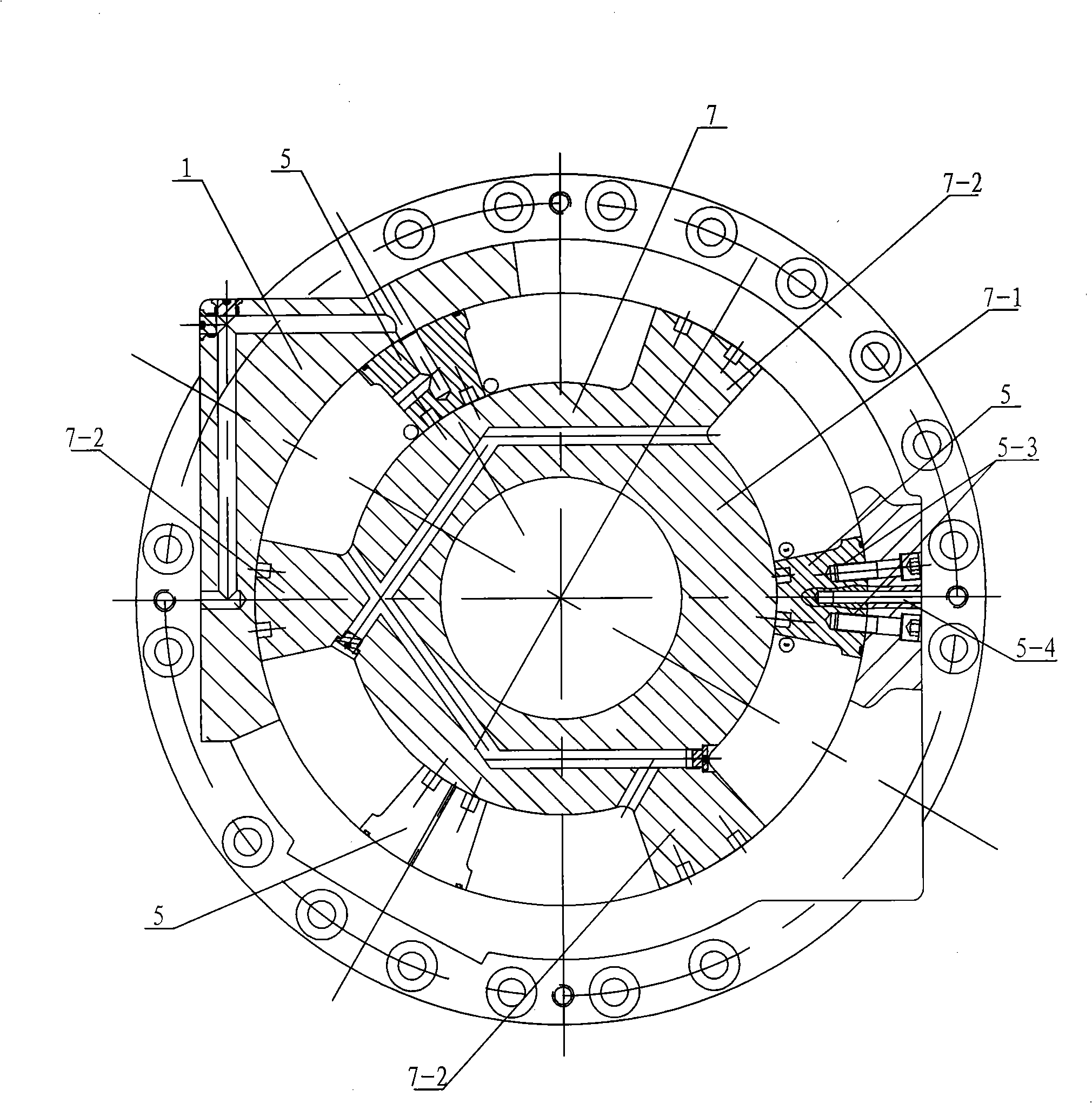

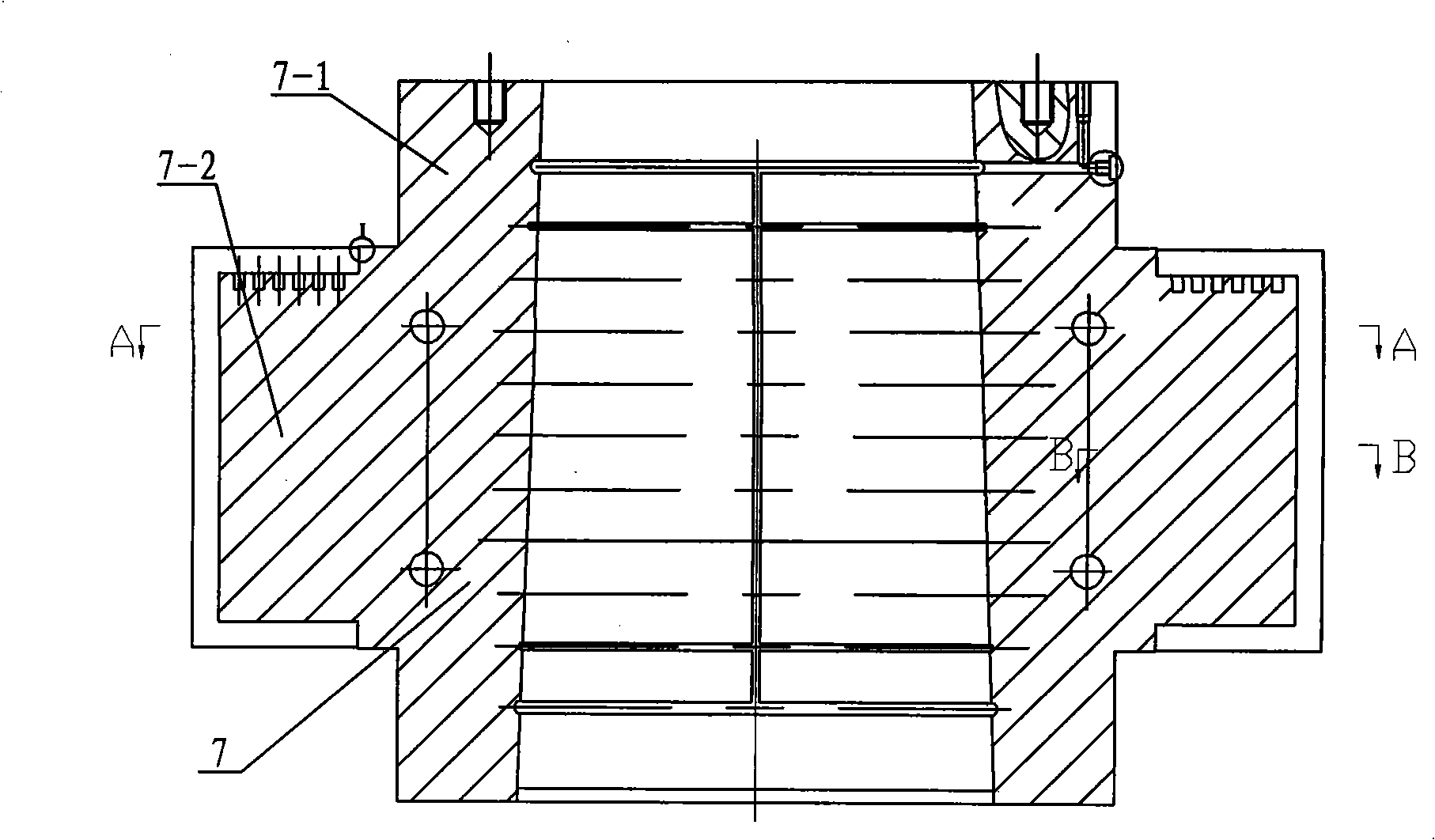

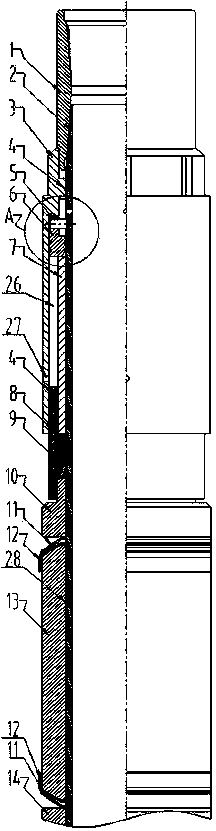

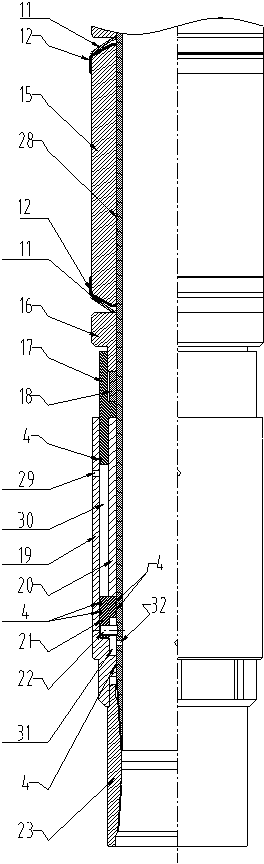

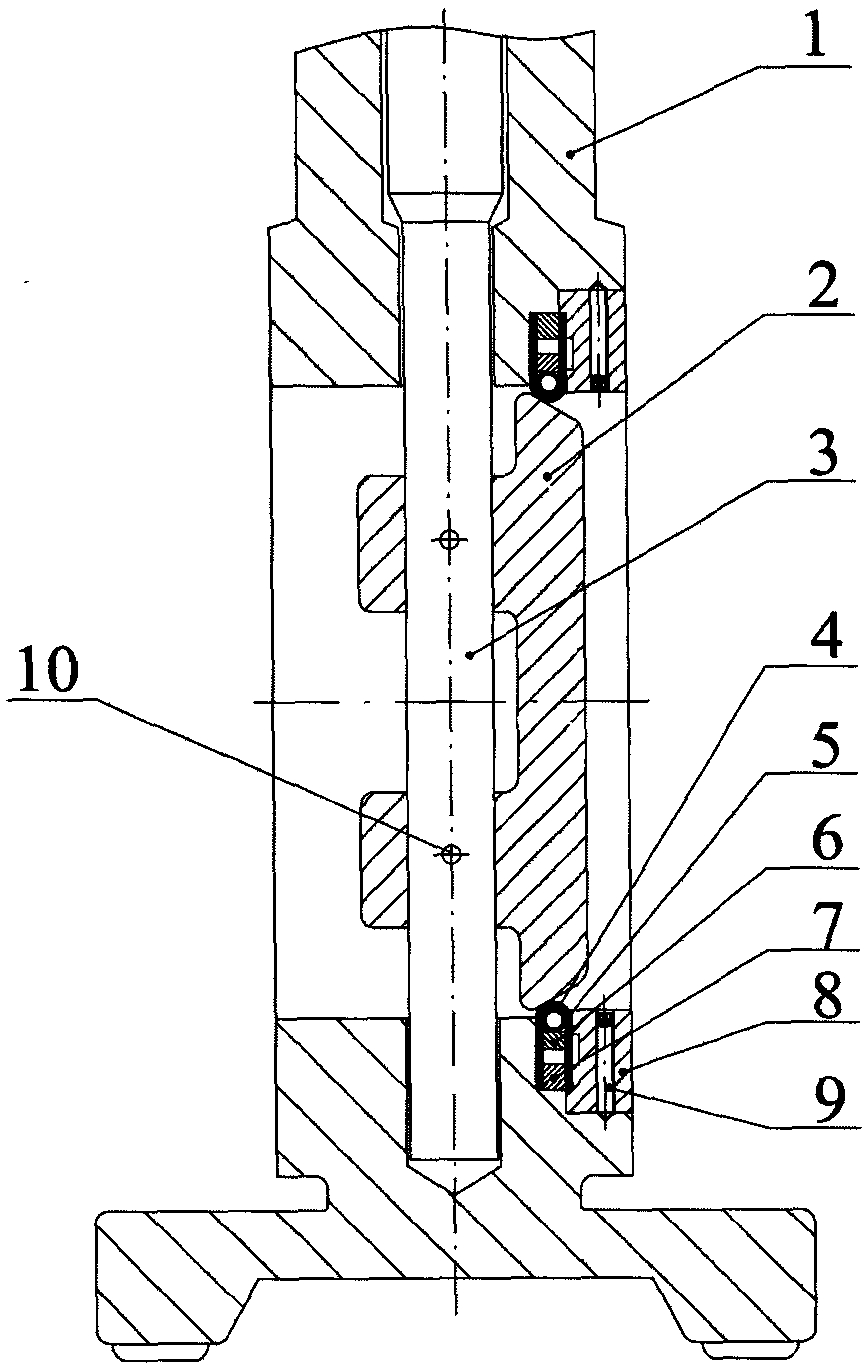

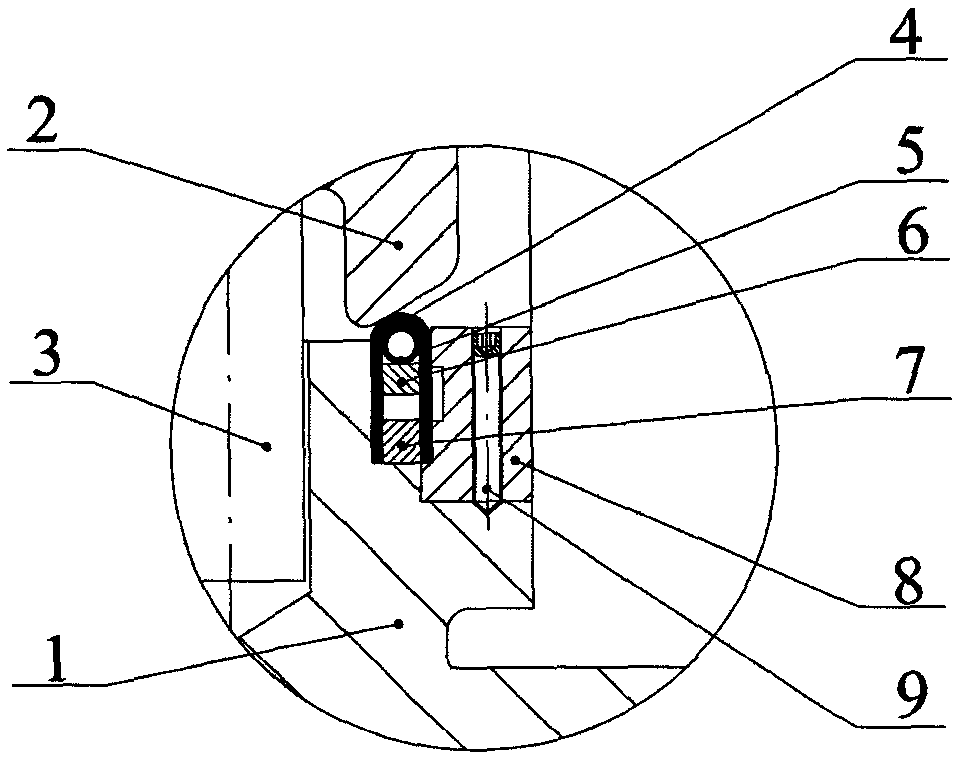

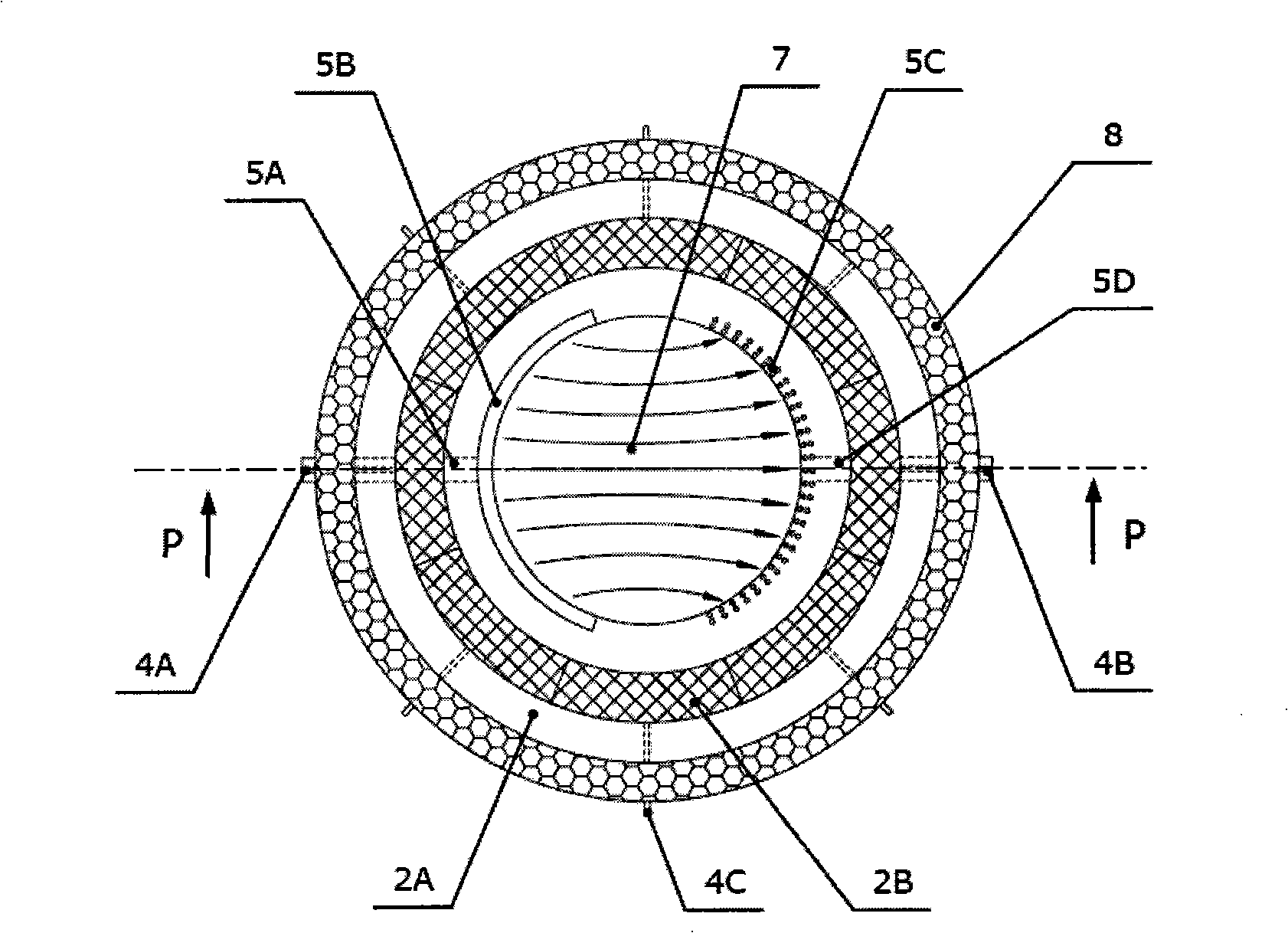

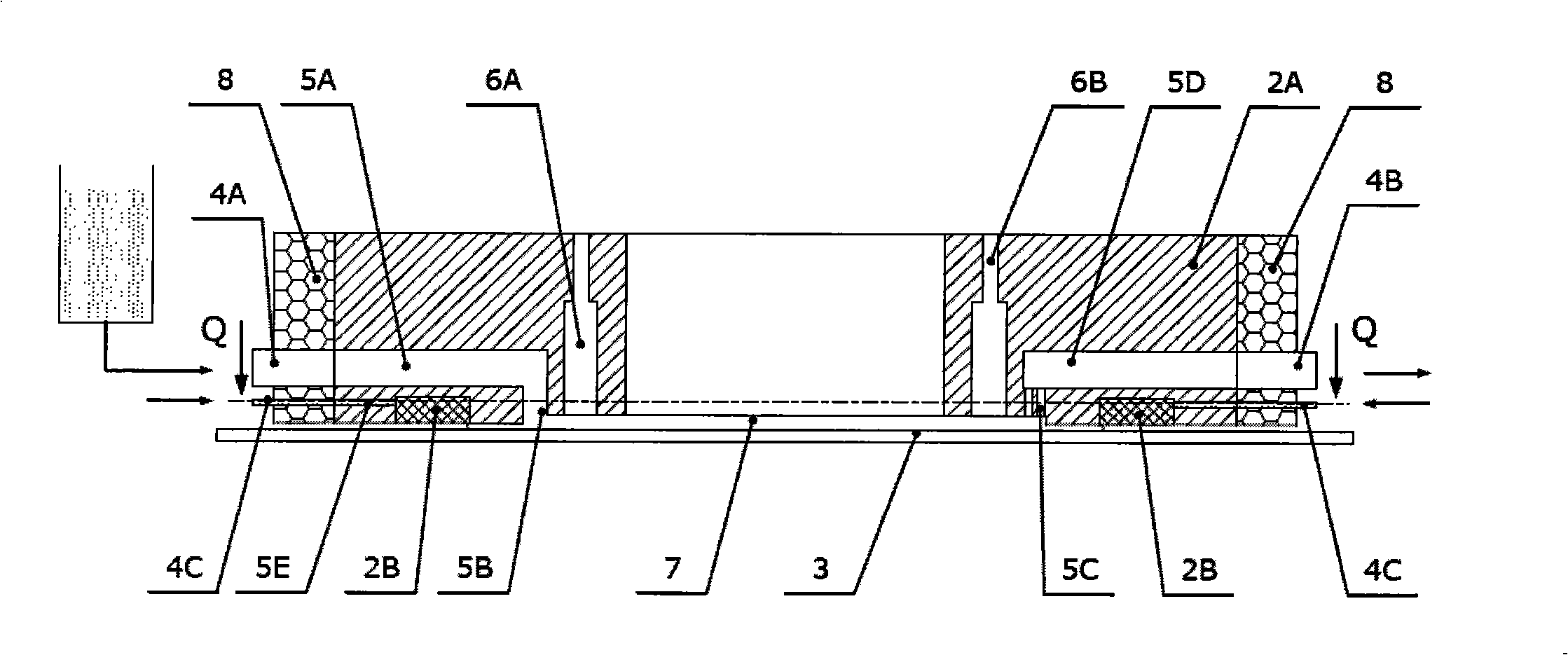

Low friction high-pressure blade rotating motor based on self-compensation compound seal technique

InactiveCN101328858AImprove sealingHigh sealing pressureRotary piston pumpsFluid-pressure actuatorsThrust bearingSelf compensation

A low-friction high-voltage rotary vane motor based on the self-compensation composite sealing technology relates to a rotary vane motor. The rotary vane motor solves the problems of the prior rotary vane motor that: sealing between a moving vane and a stator and between the stator and a casing is realized through cast iron sealing strips, thereby resulting in poor sealing performance and small sealing pressure and restricting the application of rotary vane motor in highpower steering engine. The rotary vane motor comprises the following structure that: two one-way group valves are respectively arranged inside two first valve spools at both side faces of a moving vane; two sealing strips are respectively arranged inside two first straight grooves; a rotor body and a component of a sliding bearing are arranged on a thrust bearing inside a casing; one side of a stator is fixed on the inner side wall of the casing, while the other side is adhered to a rotor shaft; a lower end cap is arranged on the lower end face of the casing; the two one-way group valves are respectively arranged inside two valve spools on both side faces of the stator; and the two sealing strips are respectively arranged inside two second straight grooves. The low-friction high-voltage rotary vane motor adopts the one-way group valves and the sealing strips to realize radial seal, and has reliable sealing property and greater pressure, thereby enlarging the application range of rotary vane motor.

Owner:HARBIN INST OF TECH

Double-cylinder compression packer

The invention discloses a double-cylinder compression packer. The double-cylinder compression packer comprises a center pipe. The center pipe is sequentially sleeved with an upper connector, an upper hydraulic cylinder, an upper starter, an upper piston, an upper impelling ring, an upper moving ring, an upper pressing ring, an upper rubber barrel, a spacer ring, a lower rubber barrel, a lower pressing ring, a lower moving ring, a lower impelling ring, a lower piston, a lower starter, a lower hydraulic cylinder and a lower connector from top to bottom. Instant impact force in the setting process of the compression packer is buffered by arranging end portion copper rings and elastic steel rings at the two ends of the upper rubber barrel and the two ends of the lower rubber barrel to prevent parts of the compression packer from being damaged by the instant impact force so that sealing pressure of the upper rubber barrel and the lower rubber barrel on a casing pipe is more even, and the service life of the compression packer is prolonged. Because a saw-tooth-shaped structure is arranged on the center pipe, the upper rubber barrel and the lower rubber barrel can be effectively prevented from wriggling in the working process. Rubber barrel frameworks are arranged on the upper rubber barrel and the lower rubber barrel in a sulfuration mode and are provided with saw-tooth-shaped structures, so that the upper rubber barrel and the lower rubber barrel are prevented from being damaged in the setting and sealing processes of the compression packer, and the elastic restoring force of the upper rubber barrel and the elastic restoring force of the lower rubber barrel are increased in the release process of the compression packer.

Owner:齐齐哈尔亚盛机械制造有限公司

Pressure detection module and pressure sensor device having such a pressure detection module

ActiveCN103512701AAchieve airtight fixationSave construction spaceFluid pressure measurement by electric/magnetic elementsMechanical engineeringStress sensors

The invention relates to a pressure detection module. The pressure detection module includes a receptacle part for receiving a carrier substrate. A first side of the carrier substrate is provided with a pressure detection unit; and the carrier substrate is inserted into the receptacle part by virtue of a second side facing away from the first side; and the carrier substrate is fixed on the bottom of a receptacle groove by virtue of the second side facing away from the first side. In order to construct the pressure detection module as small as possible, and to manufacture it in a cost-effective way, the receptacle part, the receptacle groove and a peripheral flange around the receptacle groove are, for example, provided with a plate-shaped design. The bottom has a contacting opening, through which contact surfaces of the carrier substrate, which are exposed at the contacting opening, are electrically contactable. Besides, the invention also relates to a pressure sensor device having such a pressure detection module.

Owner:ROBERT BOSCH GMBH

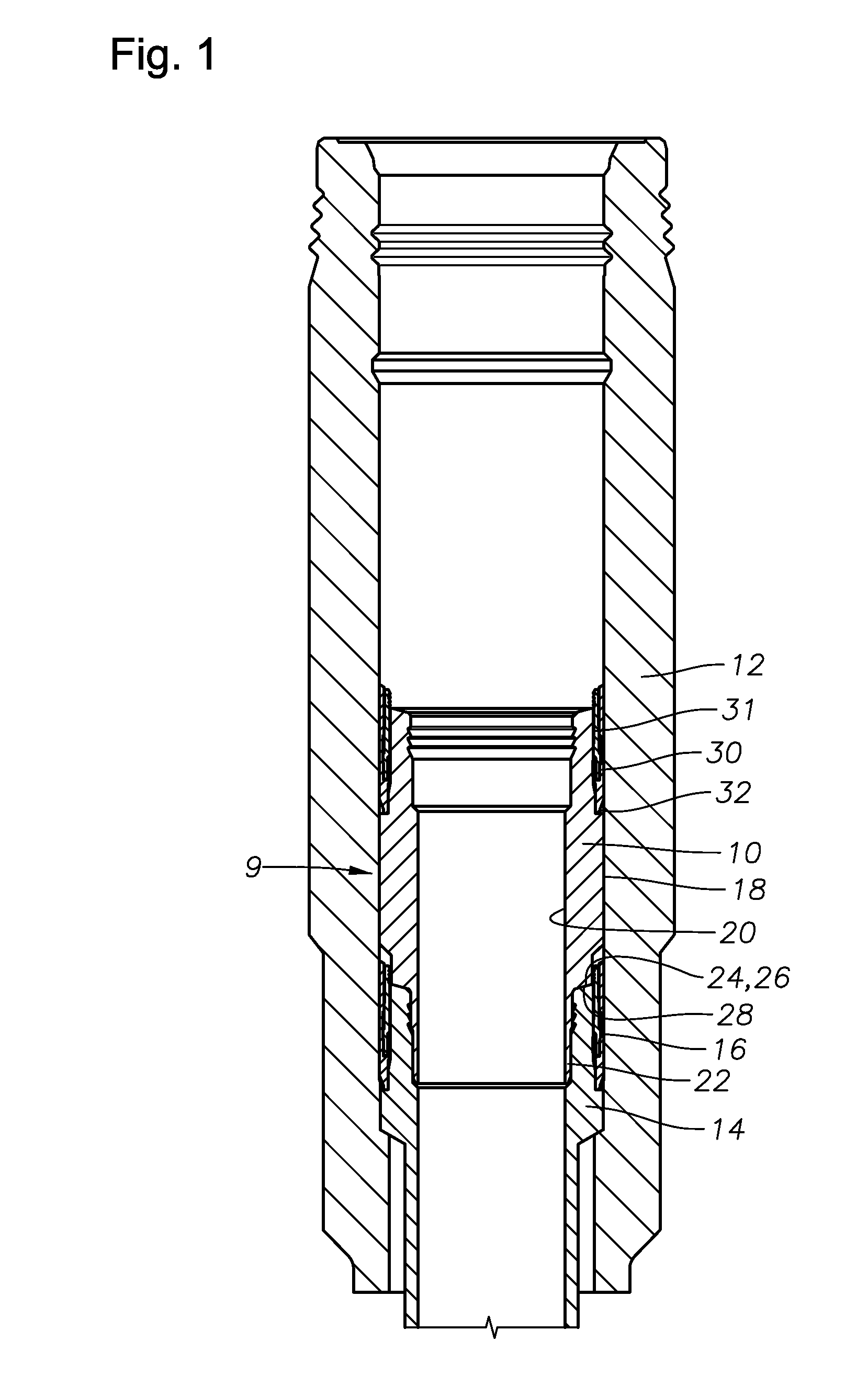

Low temperature resistant butterfly valve

ActiveCN103644309AOvercoming cold flow and stress relaxationEffective and reliable sealingLift valveEngineeringFluid control

The invention relates to a low temperature resistant butterfly valve and belongs to the technical field of fluid control valves. The low temperature resistant butterfly valve comprises a valve body (1); a butterfly plate (2) is arranged on the valve body (1) in a bias mode through a valve rod (3); the butterfly plate comprises a flow channel opening device and a flow channel closing device which deflect around the axis of the valve rod; one end of the butterfly plate, which is far away from the valve rod, comprises a peripheral chamfer; the position of the peripheral chamfer of a flow channel, which is corresponding to the closed position of the butterfly plate, comprises a sealing clamping groove; a U-shaped cross section of low temperature resistant non-metal sealing ring (4) with the circular arc end adhered to the chamfering surface of the butterfly plate of the low temperature resistant butterfly valve is inserted into the sealing clamping groove; a spring ring (5) and a supporting ring (7) are embedded into the non-metal sealing ring; the trend that the circular arc end is adhered to the chamfering surface is kept due to the spring ring (5); the two outer sides of the U-shaped cross section are adhered to the wall of the sealing groove due to the supporting ring (7). According to the low temperature resistant butterfly valve, the sealing ring is adhered to the butterfly plate in a sealing mode under the action of contraction of the spring ring and accordingly the reliable effective sealing under the ultra-low temperature conditions can be ensured.

Owner:JIANGSU EVALVE GRP

Immersion self-adapting seal control device used for photo-etching machine

InactiveCN101403861APrevent flow field fluctuationsAvoid interferencePhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

The invention discloses an immersion self-adaptive sealing control device used in a lithography machine. The immersion self-adaptive sealing control device is arranged between a projection lens set and a substrate, and consists of a sealing element and a self-adaptive sealing member. When liquid forms the impact on the self-adaptive sealing member due to traction of the substrate, the device can absorb the impact formed by the high-speed moving liquid and converts the impact into power enhancing sealing; on the contrary, when the substrate draws the liquid away from the self-adaptive sealing member, the liquid prestored inside the device follows to enter a slit flow field to avoid gas bubble entrainment owing to the loss of the liquid at the boundary, meanwhile, the reduction of the liquid prestored inside the device reduces the sealing power of the self-adaptive sealing member, and the leaked liquid flows back to the inside of the slit flow field along with the substrate due to the reduction of obstruction. The liquid transmission mode of the immersion self-adaptive sealing control device adopts negative pressure recovery and free flow of a fluid injection end, which avoids the flow field fluctuation caused by the in-coordination between the injected fluid and the recovery pressure.

Owner:ZHEJIANG UNIV

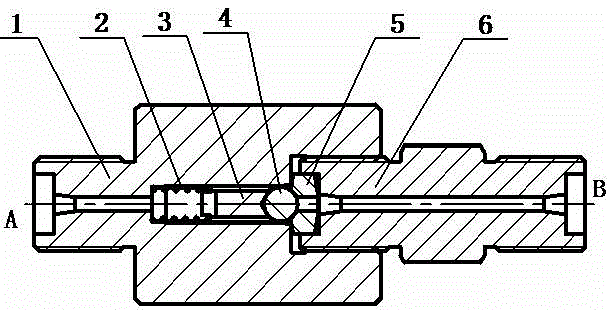

Ultrahigh pressure check valve

InactiveCN104455581AEasy installation and designEasy to use and maintainServomotor componentsCheck valvesUltra high pressureEngineering

The invention discloses an ultrahigh pressure check valve which comprises a reset spring and a steel ball, the reset spring and the steel ball are arranged in a valve body hole fluid channel and connected with a valve element, wherein the reset spring (2) is clamped on a step hole of an assembly channel of the valve body (1), one end of the valve element (3) jacks to the reset spring (2), a spherical groove in one end presses the steel ball (4), a step threaded hole of a threaded connection inlet connector (6) is formed in the valve body at the rear end of the steel ball (4), a medium flow pass stop block (5) which protrudes out of an end surface is arranged at a shaft end of the inlet connector (6), and the steel ball (4) presses into a groove in a front end outlet of the medium flow pass stop block (5). According to the ultrahigh pressure check valve, the steel ball presses a conical cushion groove so as to realize a one-way sealing effect. The ultrahigh pressure check valve can be mounted on an ultrahigh pressure pipeline alone, and the problems that the size is larger and the reliability, the maintainability, the safety and the sealing performance are poor and universal in integrated valve groups are solved.

Owner:SICHUAN AVIATION IND CHUANXI MACHINE

High-pressure sealing method and sealing ring

The invention discloses a method for arranging a shock-absorbing convenient-to-install self-locking nut on a thin-walled plate and a nut assembly. The method is characterized in that one or more than one pressing groove is punched on the external sides of bent parts of a right-angle supporting plate before the right-angle supporting plate is bent, the microstructure of the bent parts of the right-angle supporting plate is enabled to be finer due to the pressing groove, the problems of loose material and internal stress increase caused during the bending of the right-angle supporting plate are reduced, and the material resilience and deformation caused after the right-angle supporting plate is bent can be effectively controlled. The nut assembly comprises the right-angle supporting plate (1) and the self-locking nut (2) which is connected with the right-angle supporting plate (1). One or more than one pressing groove (3) is arranged on the external sides of the bent parts of the right-angle supporting plate (1). By adopting the method, the antifatigue performance is improved and the problem that the self-locking nut cannot be used on thin-walled parts, narrow parts which are hard to approach or non-open structures of airplanes is solved. The method and the nut assembly provided by the invention have the advantages that not only can the manufacturing difficulty of bearing and connecting components be reduced, but also the weight can be reduced, the production process becomes rapid and simple, the safety and the reliability are high and the maintenance is convenient to conduct.

Owner:AEROSPACE PRECISION PROD INC LTD

Low-temperature-resistant air spring upper seam allowance sealing structure, method and product

PendingCN109944894AMeet sealing requirementsImproves sealing reliabilitySpringsGas based dampersAir springAir suspension

The invention discloses a low-temperature-resistant air spring upper seam allowance sealing structure. The sealing structure comprises an upper cover plate, a buckle ring, a connecting bolt and an upper seam allowance; the upper seam allowance is compressed between the upper cover plate and the buckle ring, the buckle ring and the connecting bolt are arranged on the radial outer side of the upperseam allowance, a bag body below the upper seam allowance is attached to the inner wall of the buckle ring and is attached to the bottom surface of the buckle ring downwards; a sealing structure formed by radial sealing and axial seal which are arranged alternately and connected in sequence is adopted between the upper cover plate and the upper seam allowance and between the upper seam allowance and the buckle ring, the sealing pressure of at least one axial sealing surface of the upper seam allowance to the upper cover plate faces the inner direction which is away from the connecting bolt, and the sealing pressure and the compression amount of the upper seam allowance are increased along with the loading and the displacement of the air spring. The sealing reliability of the upper seam allowance of the air spring in the loading process is guaranteed, effective sealing of the upper seam allowance in a low-temperature state is realized, and the sealing requirement of the air spring underthe low-temperature state is met. The invention further provides a low-temperature-resistant air spring upper seam allowance sealing method and a low-temperature-resistant air spring.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com