Low temperature resistant butterfly valve

A technology of low temperature resistance and butterfly valves, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems that are difficult to meet this requirement, and achieve the effect of overcoming cold flow and stress relaxation, reliable and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

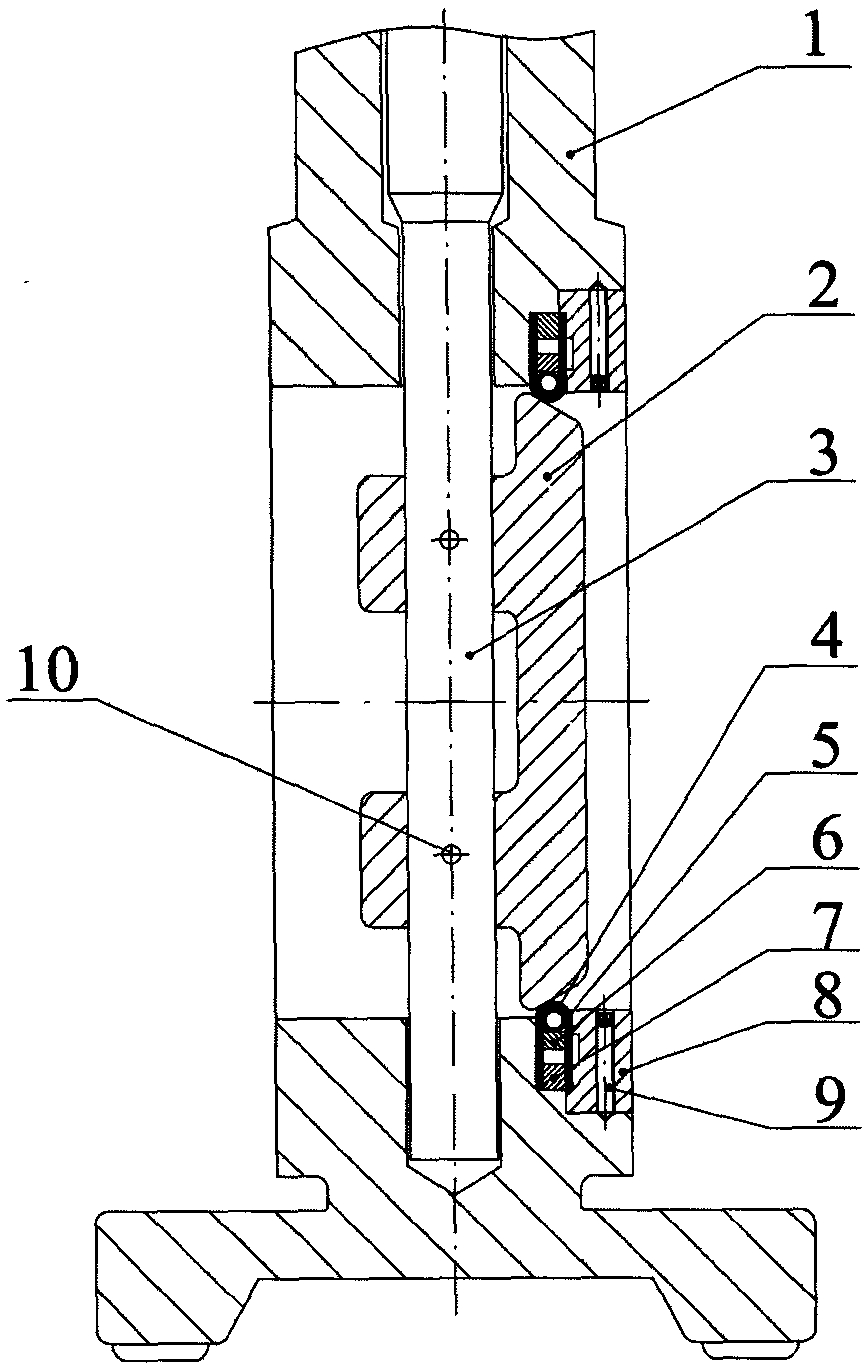

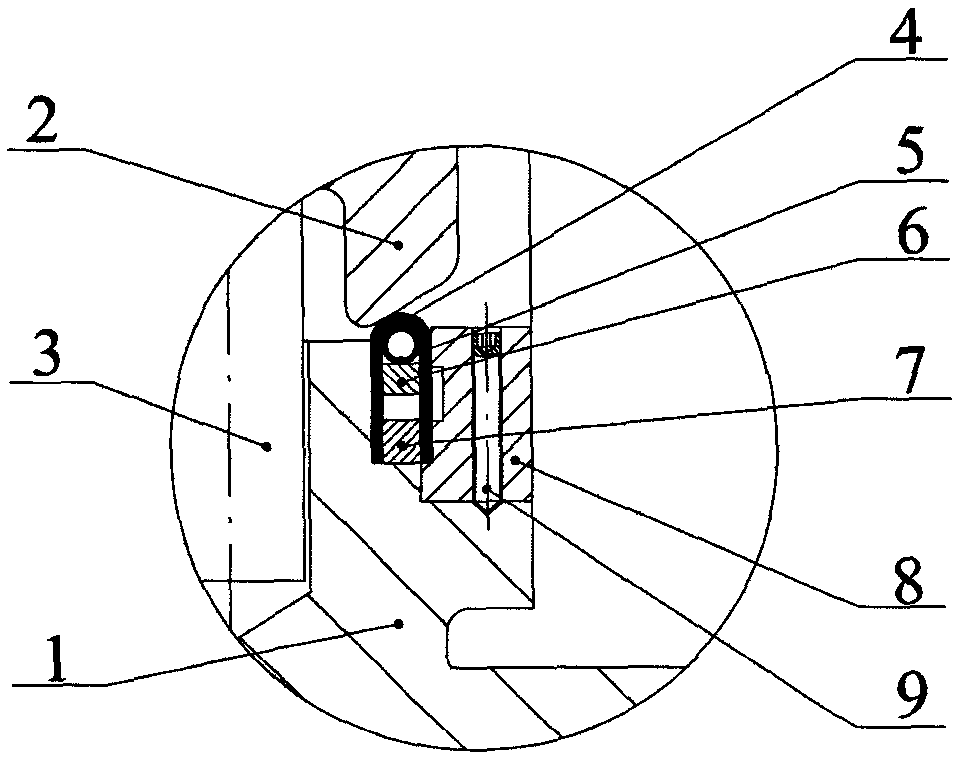

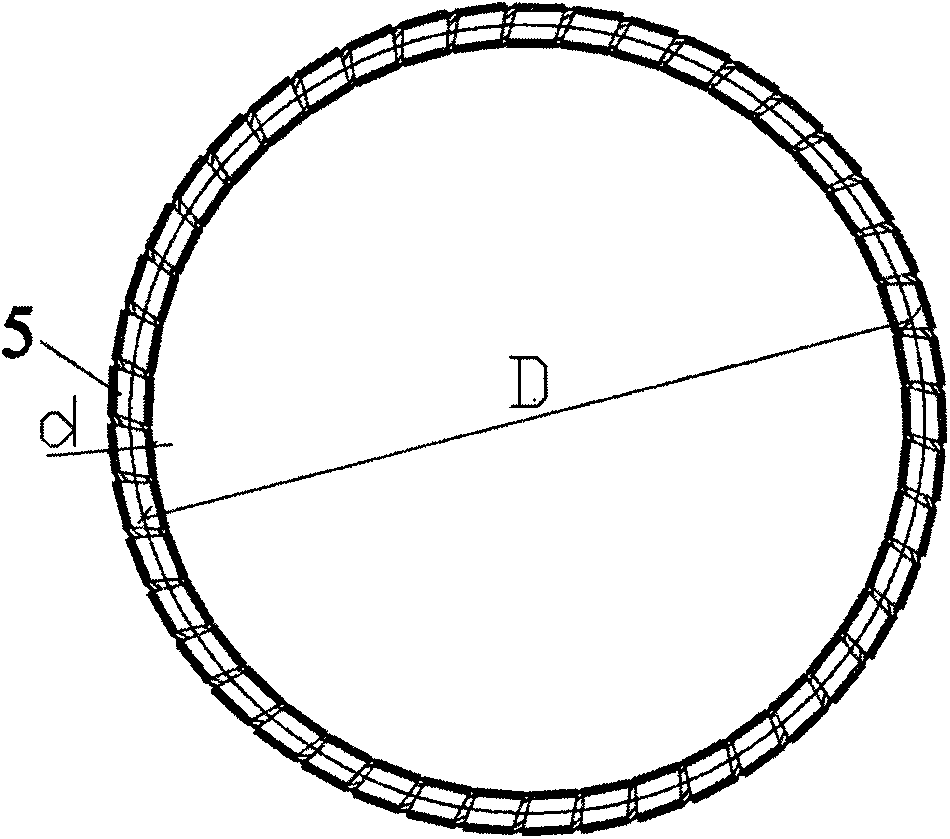

[0022] This embodiment is a highly reliable ultra-low temperature double eccentric butterfly valve based on shape memory alloy, and its structure is as figure 1 , figure 2 As shown, it includes a valve body 1, a circular butterfly plate 2, a valve stem 3, and a sealing ring 4, a spring ring 5, a pre-tightening ring 6, a support ring 7, a retaining ring 8 and a fixing screw 9 arranged in the valve body 1.

[0023] The two perforated protrusions of the circular butterfly plate 2 are fixedly connected to the valve stem 3 by the pins 10 and are biased and installed on the valve body 1 through the valve stem. The valve stem 3 can rotate in the valve body 1. The butterfly plate 2 has an open position of a circular flow channel deflected around the axis of the valve stem 3 ( Figure 4 Dotted line position) and closed position ( figure 1 ), its end away from the valve stem 3 has a peripheral chamfer. The circular flow channel has an annular sealing groove at the peripheral chamfer corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com