Y-shaped centripetal bidirectional sealing leather ring

A two-way sealing and apron technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of non-radial outward compression, O-ring sealing reliability, and poor durability, so as to avoid movement being blocked, The effect of effective and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

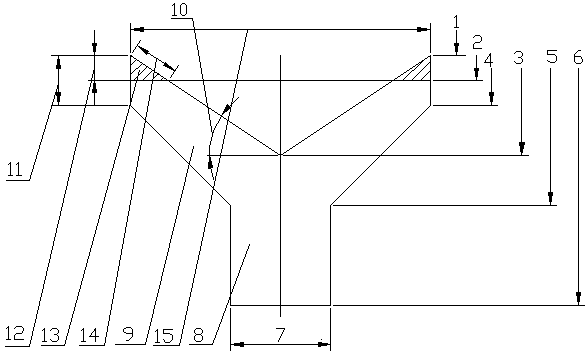

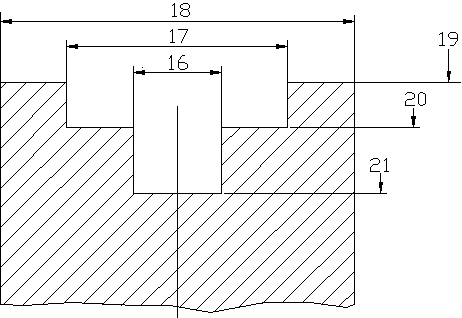

[0017]The preferred embodiment of the present invention is such, with reference to accompanying drawing, after apron is installed in the annular groove of housing, the aperture of its solid part is greater than plunger diameter, and solid part does not contact with plunger to reduce movement resistance, The gaps can store oil to keep lubricated. The radius R6 (6) of the outer end of the apron is slightly larger than the radius R9 (21) of the groove bottom of the T-shaped centripetal ring. The interference fit of this part plays a major role in the sealing between the apron and the shell. The pressure also makes the side of the handle of the apron close to the compressed side of the apron groove, thereby assisting the sealing between the apron and the housing. The cooperation of the thickness of the handle of the apron (7) and the width of the handle of the T-shaped centripetal ring groove (18) plays a role in stabilizing the positioning of the apron. The radius R1 (1) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com