Suppressing fluid communication to or from a wellbore

A fluid communication, wellbore technology, applied in the direction of production fluids, wellbore/well components, drilling composition, etc., can solve the problems of complex and expensive completions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

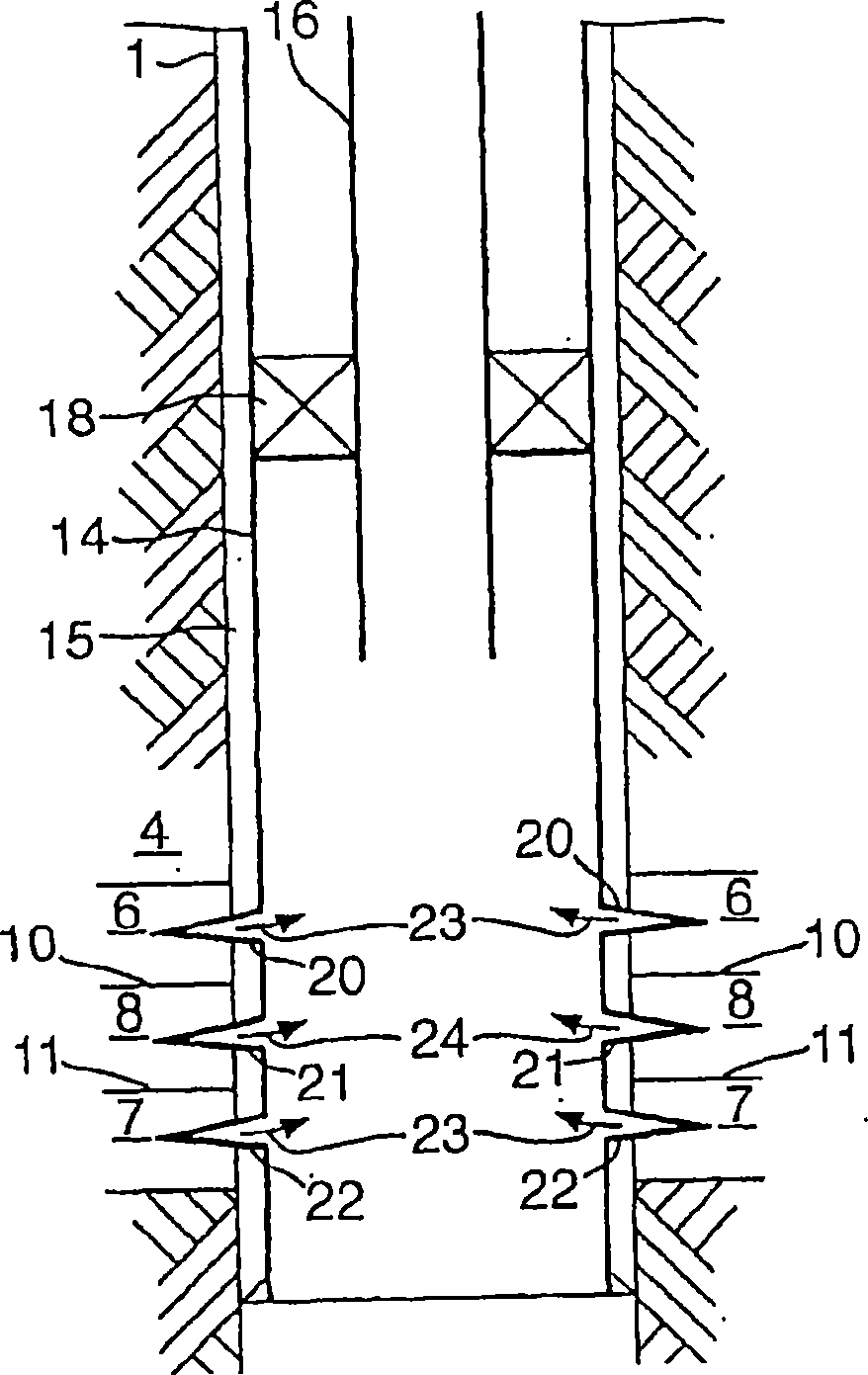

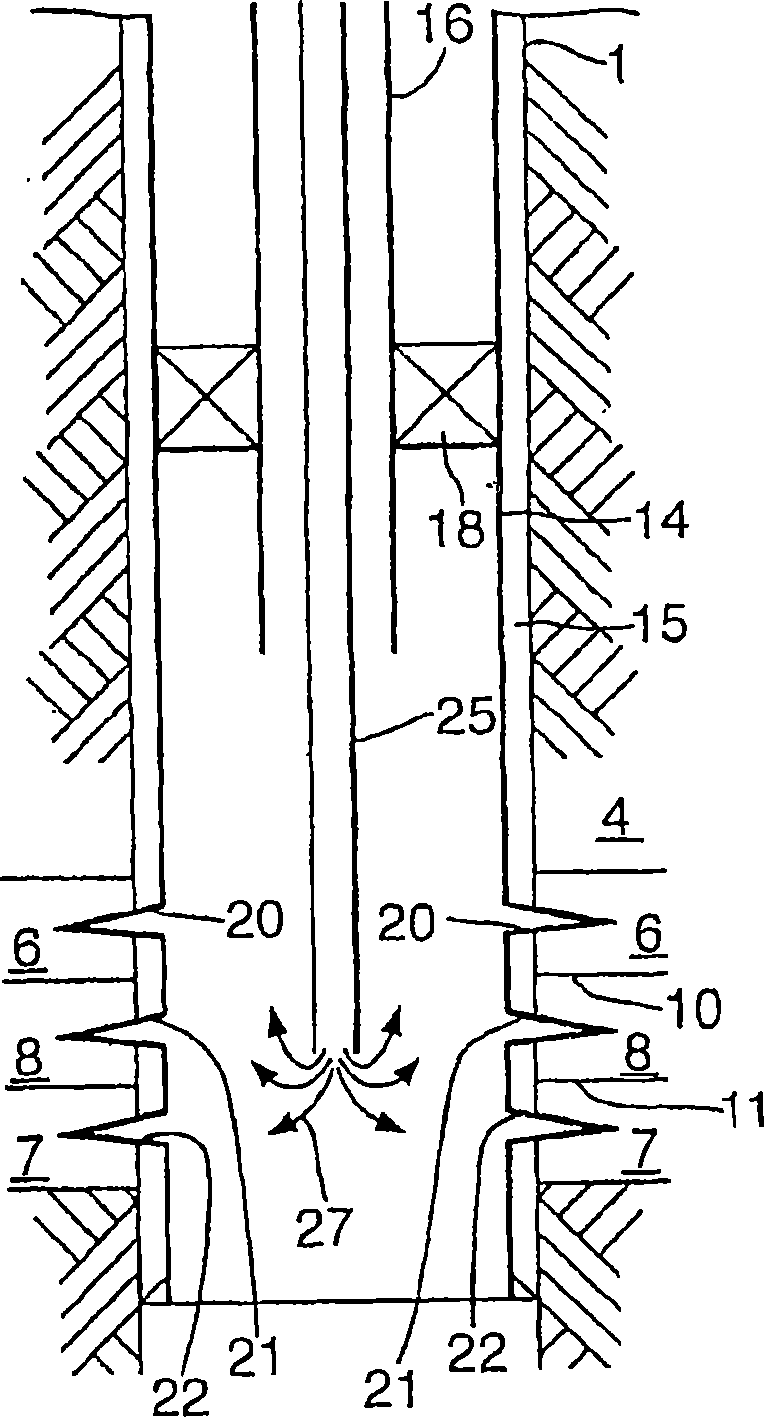

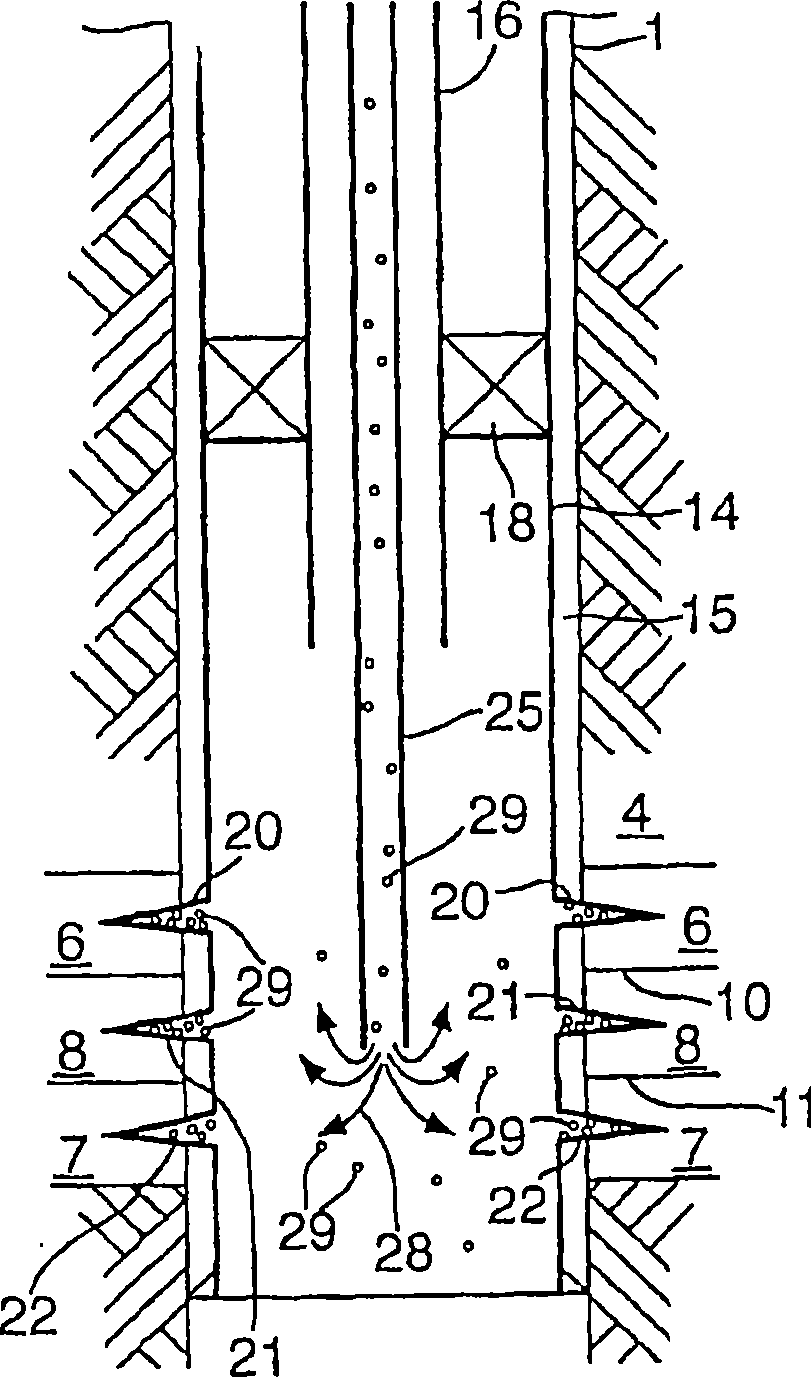

[0038] see figure 1 , figure 1 The lower portion of the wellbore 1 extending from the surface (not shown) into the formation 4 is shown. In this example the strata are stratified. Layers 6 and 7 contain hydrocarbon oil and layer 8 contains water. Layers 6, 7, 8 are separated by boundary or impermeable layers 10, 11 . The wellbore 1 has a casing 14 consisting of a metal casing string, and the annulus 15 between the casing 14 and the wall of the wellbore 1 is filled with cement. The downhole completion is marked by tubing 16 and packers 18 extending to the surface.

[0039] The fluid enters the wellbore 1 from the layers 6, 7, 8 through the perforated holes 20, 21, 22 in the directions indicated by the arrows and is produced to the surface through the tubing 16. This fluid contains oil 23 and a large amount of water 24 which flows from layer 8 . There is a need to seal off the water flowing out of the aquifer 8, in particular through the perforations 21 formed at the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com