Blowout preventer ram

A technology of blowout preventer and ram, which is applied in the direction of wellbore/well components, earthwork drilling and production, sealing/packing, etc. It can solve the problems of spare parts occupying more space and affecting work efficiency, so as to reduce the operation process and improve work efficiency. Efficiency, Quantity Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

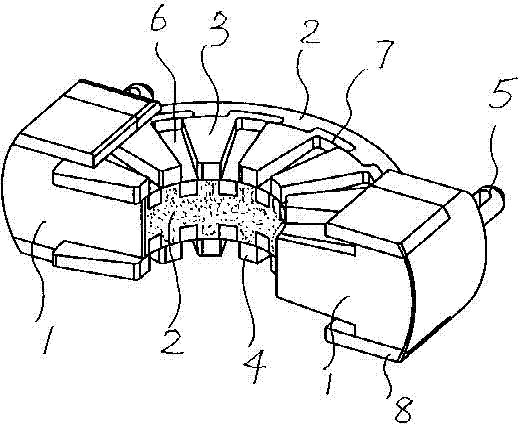

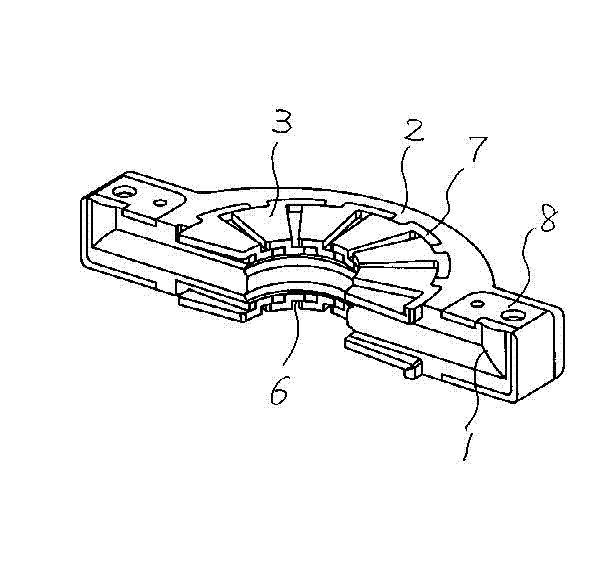

[0015] The structure and working principle of a blowout preventer ram provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, it is a structural schematic diagram of a blowout preventer ram that can be embedded in a casing to form a blowout preventer assembly provided by the present invention. Its structure includes an arc-shaped elastic sealing rubber body 2 with stoppers 1 at both ends, the sealing rubber body 2 can be fixed with the housing through the positioning pin 5 arranged on the stopper, and the elastic sealing rubber body Each of the upper and lower sides is provided with an exposed skeleton 4 composed of six fan-shaped metal plates 3 overlapped and combined with each other.

[0017] When in use, the above blowout preventer ram is fixed in the casing that can be fixed with the oil well head, and the two casings equipped with the ram correspond to enclose the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com