Device for controlling a flow of coolant and/or lubricating oil

A technology of lubricating oil flow and lubricating oil, applied in the direction of valve operation/release device, valve device, fluid-driven clutch, etc., can solve the problems of increased traction torque, transmission efficiency burden, etc., to avoid friction loss and avoid friction loss and leakage loss, avoiding the effect of plug connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

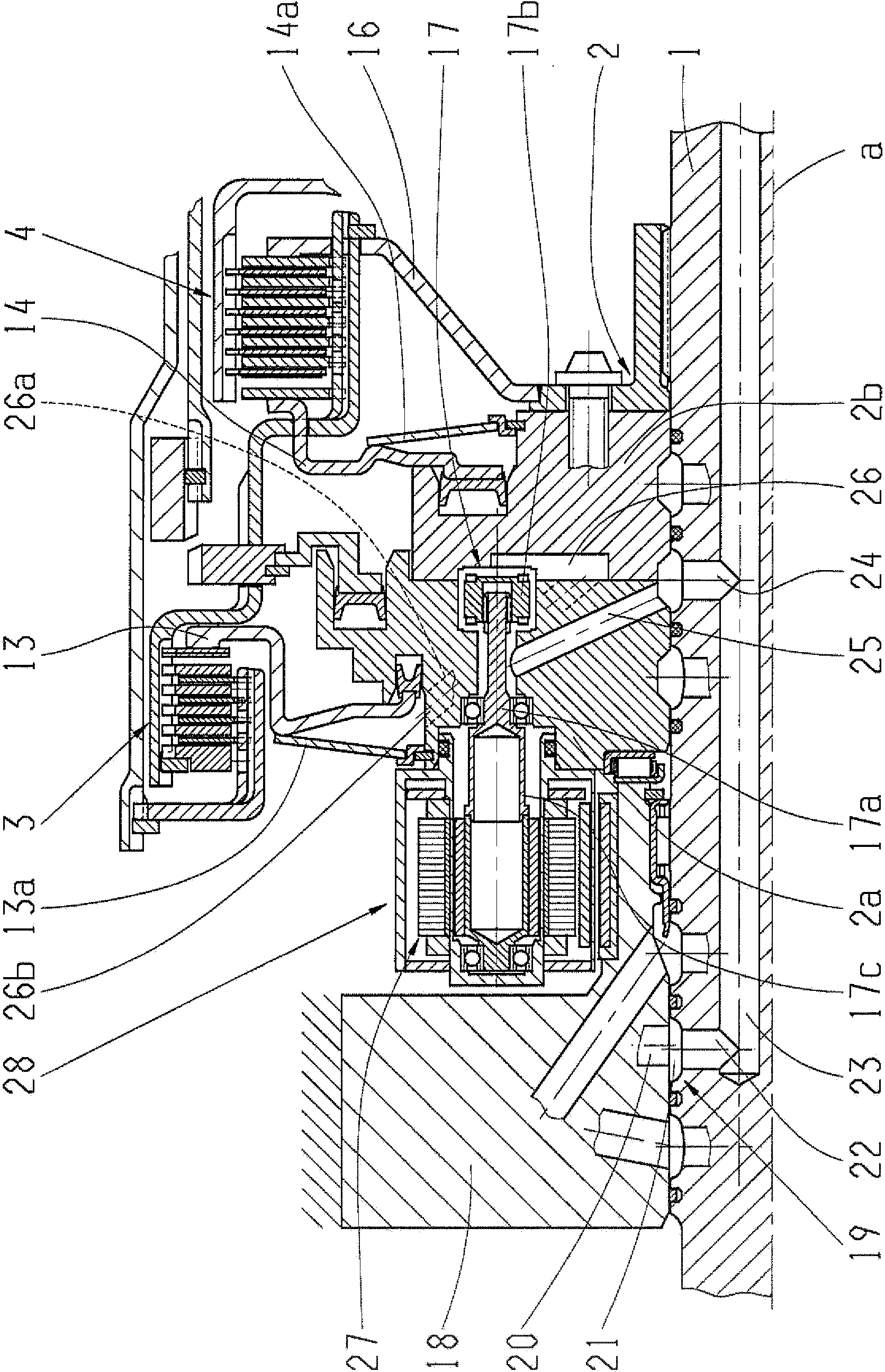

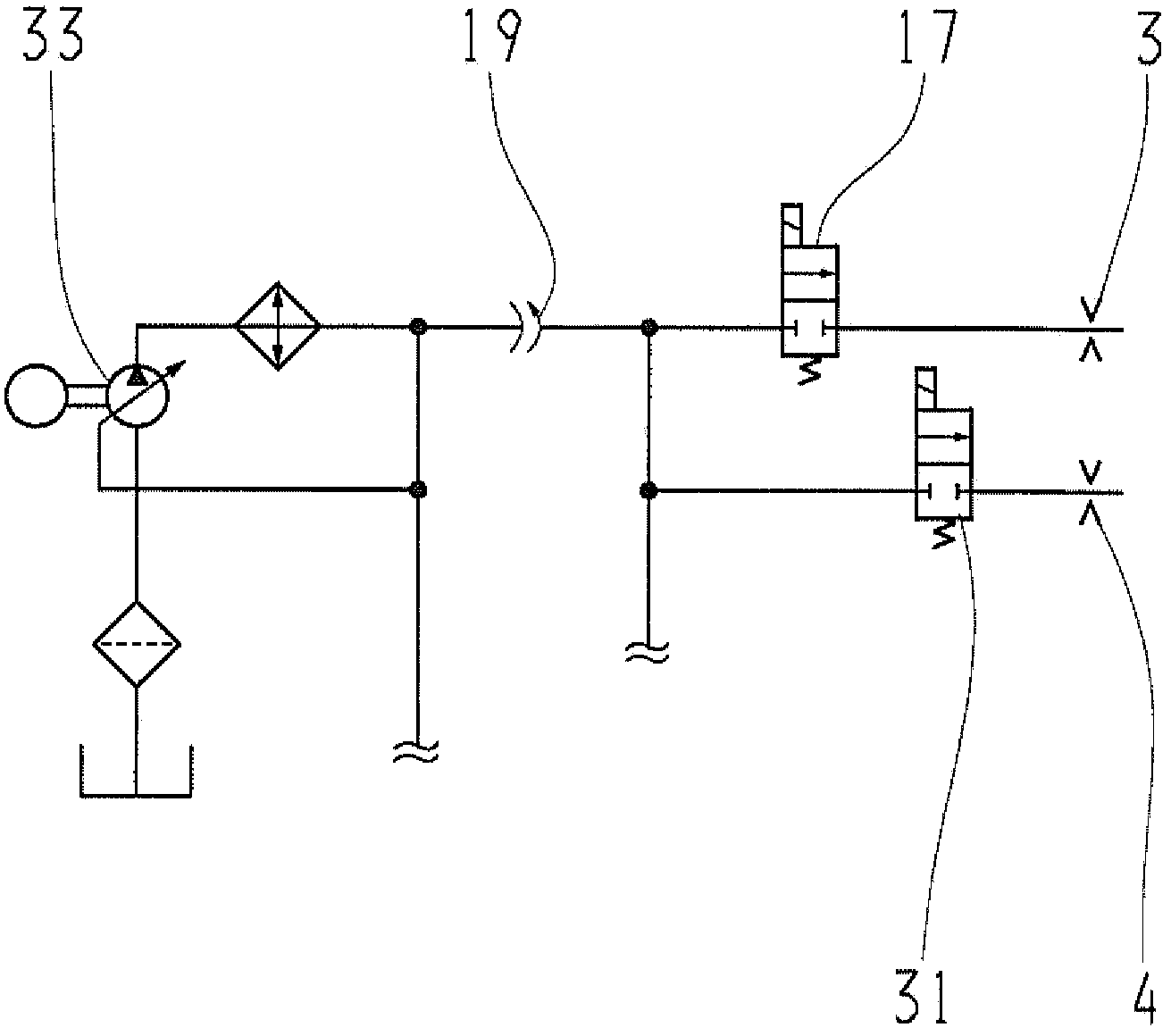

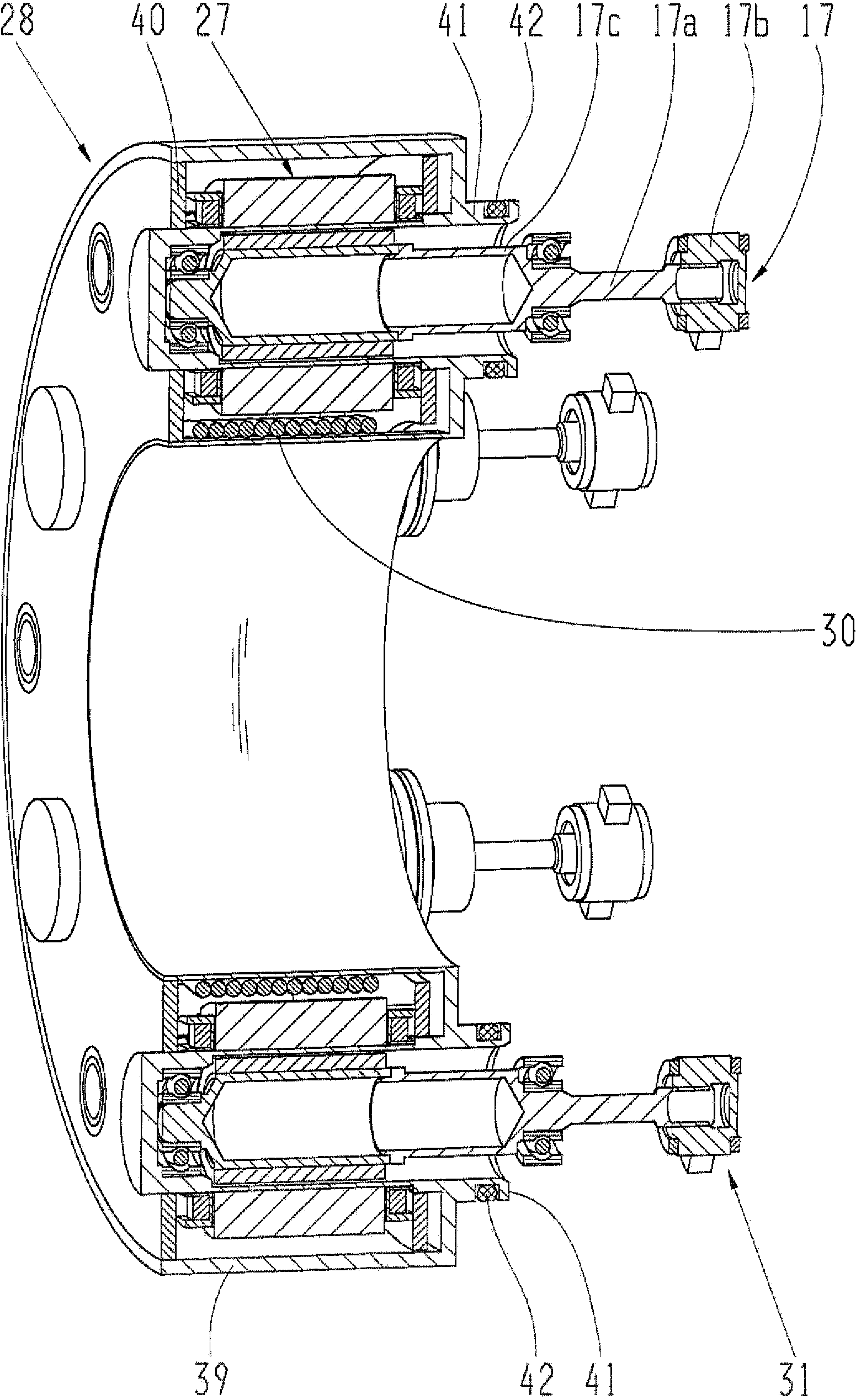

[0028] figure 1 A device for the control of cooling oil flow of an automatic transmission of a motor vehicle is shown. A so-called function carrier 2 with an axis of rotation a is arranged on the drive shaft 1 in a rotationally fixed manner. A first cooling point, which is designed as a multi-plate clutch 3 , and a second cooling point, which is designed as a multi-plate clutch 4 , are connected by means of the functional carrier 2 . The first multiplate clutch 3 is actuated by a first annular piston 13 and the second multiplate clutch 4 is actuated by a second annular piston 14 . Disk springs 13 a , 14 a supported on the functional carrier 2 are provided for restoring the annular pistons 13 , 14 . The drive sides of the shifting elements 3 , 4 are connected to the drive shaft 1 via the connecting element 16 and the functional carrier 2 . The functional carrier 2 is therefore also the carrier of the shifting elements 3 , 4 .

[0029]According to the invention, a valve 17 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com