Cable and apparatus interface security device

a security device and cable technology, applied in the direction of securing/insulating coupling contact members, coupling device connections, cable inlet sealing means, etc., can solve the problems of affecting the sealing system of the sealing system using gel near the maximum specified temperature, electrical interconnections subject to degradation, and gel sealing compositions are typically limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

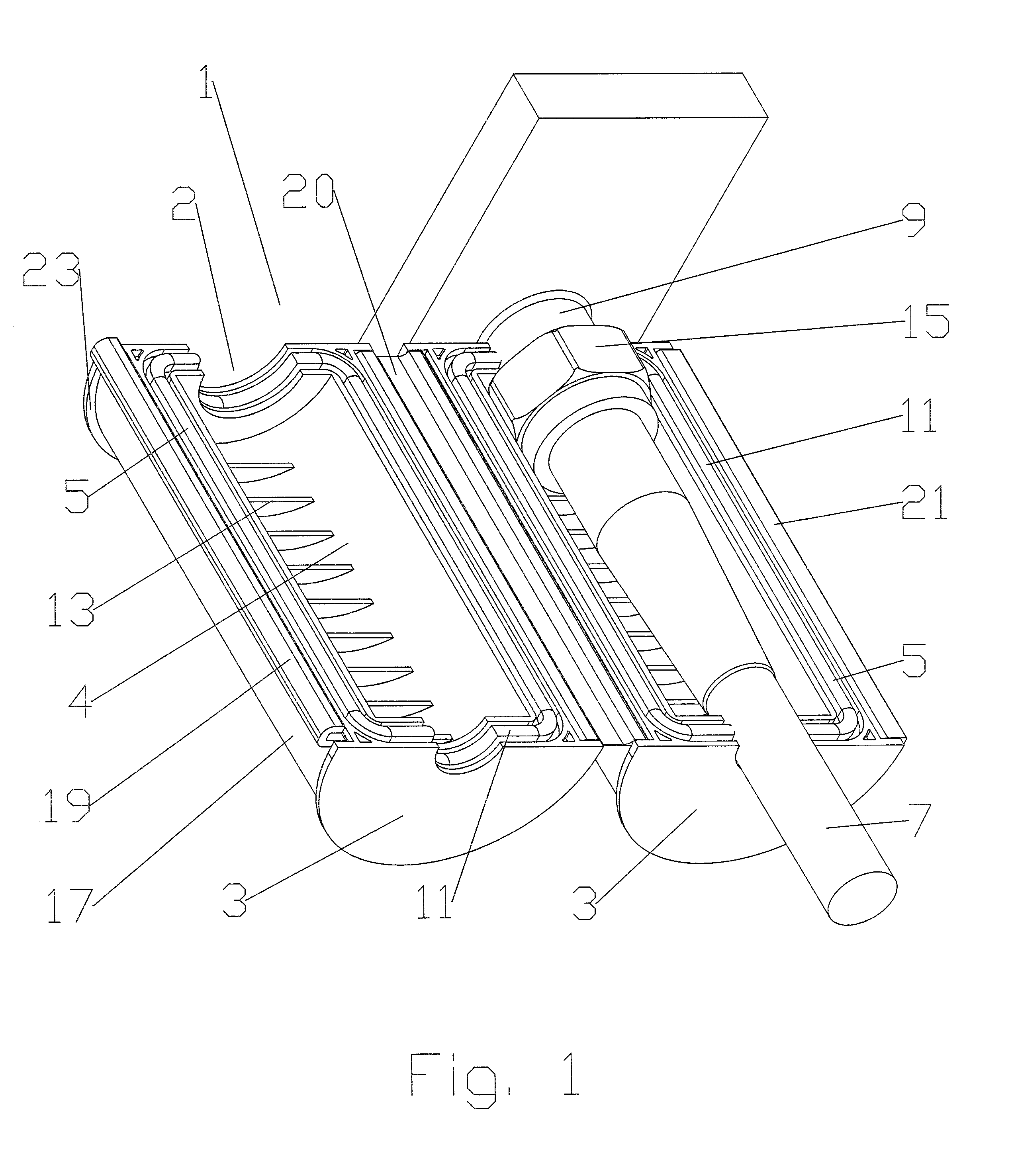

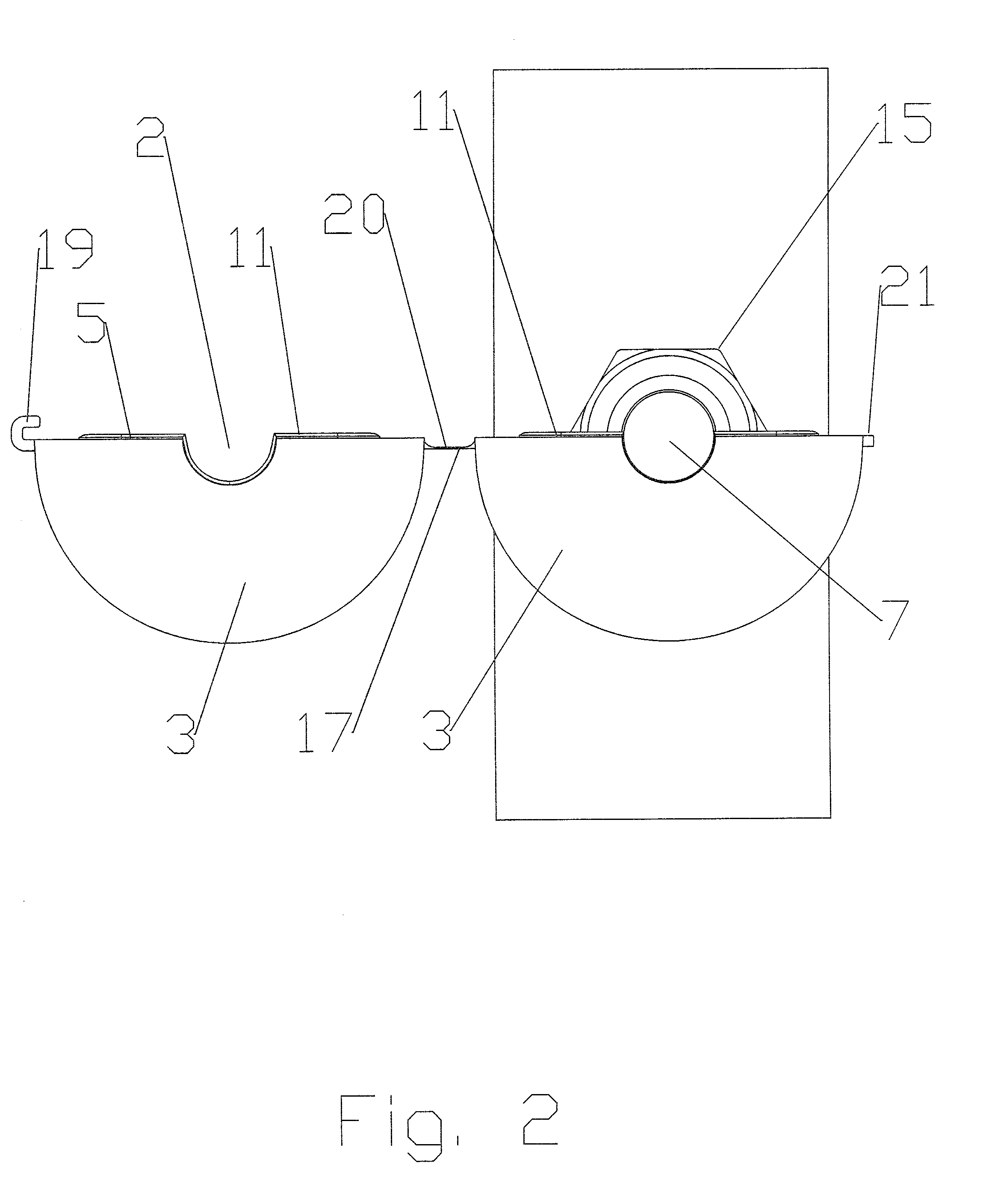

[0024] As shown for example by FIGS. 1-6, a sealing assembly 1 according to the invention has internal shell 3 halves adapted to seal against each other and around a desired interconnection space 4. The shell 3 halves may be formed, for example, from an impact resistant plastic using injection molding.

[0025] The mating surface(s) 5 of the shell 3 halves are adapted to mate with each other and around opening(s) 2 formed between the shell(s) 3 dimensioned to accept the outer diameter of the cable 7 and or apparatus connector body 9 at a cable end 6 and an apparatus end 8, respectively.

[0026] A gasket 11 lines each mating surface 5 to seal the interconnection of each shell 3 half with the other and around the outer diameter of the cable 7 and the apparatus connector body 9. The gasket 11 may be formed from, for example, liquid injection molded / liquid silicone rubber, thermoplastic elastomers, molded closed-cell foam or the like having suitable sealing and environmental resistance and ...

second embodiment

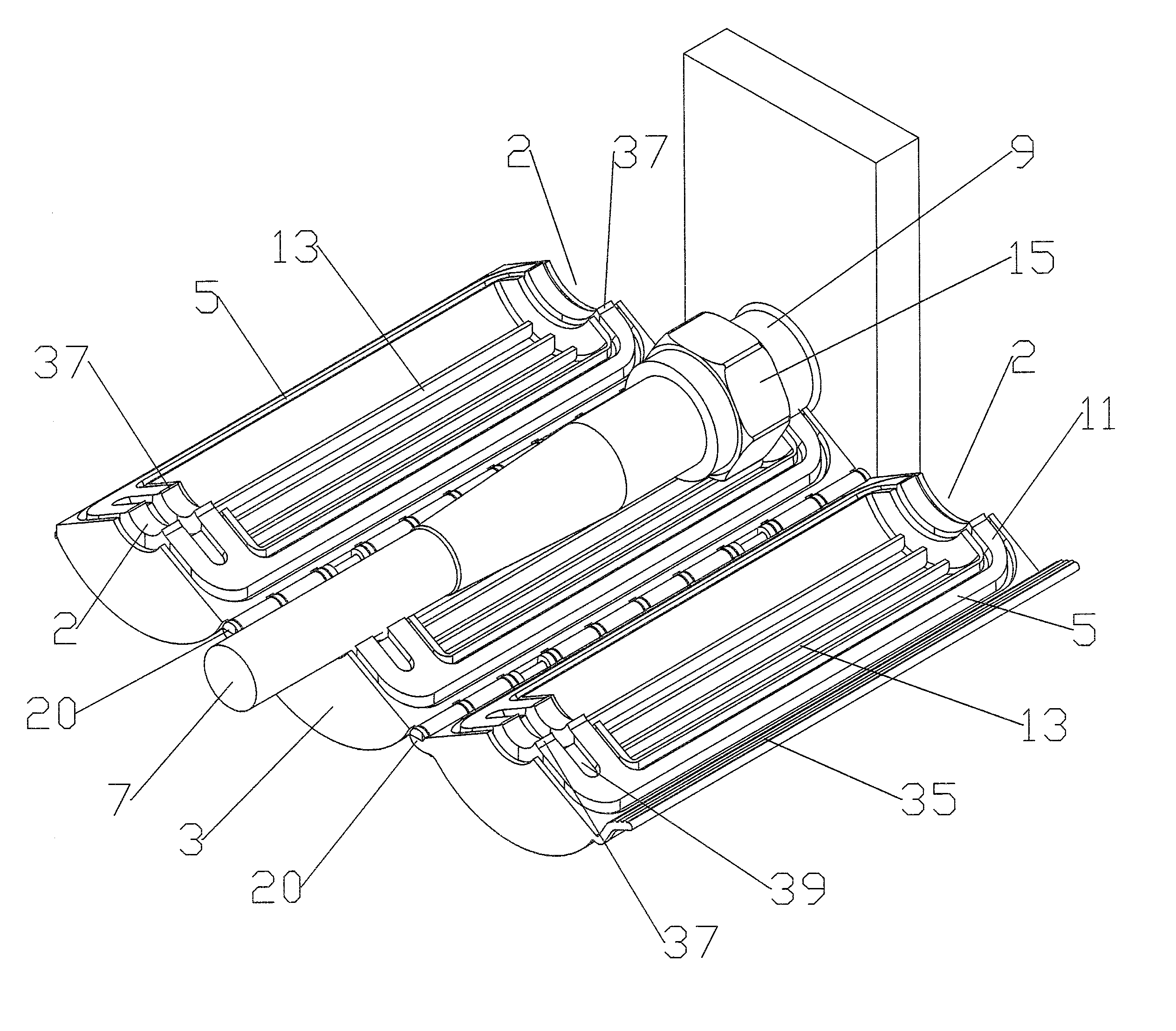

[0033] Because the shell 3 wedges section the circumference of the sealing assembly 1 into thirds, the opportunity for pinching of the gasket(s) 11 during closure is reduced. The locking band may be omitted because when closed, the shell 3 wedge geometry of the second embodiment improves equalization of the pressure between adjacent gasket 11 surfaces and inwards towards the cable 7 and apparatus connector body 9. To form an improved seal at the junction between each adjacent gasket 11 and the cable 7 or apparatus connector body 9, protruding compensation spike(s) 37 as shown for example in FIG. 10 may be formed in the gasket 11. The increased gasket material added via the compensation spike(s) 37 increases the sealing pressure between the gasket(s) 11 and also against the cable 7 or connector body 9.

[0034] As demonstrated in the second embodiment, the gasket(s) 11 may be adapted to have increased contact area via an increased width along the longitudinal axis of the cable 7 to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com