Pressure vessel door quickly-opened device with leakage on-line detection function

A technology for door opening device and pressure vessel, which is used in pressure vessels, engine sealing, fixed capacity gas storage tanks, etc., can solve the problems of inability to detect in time, reduce structural strength, loss of life and property, etc., and achieve convenient assembly and disassembly and extended use. Longevity, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Structure introduction

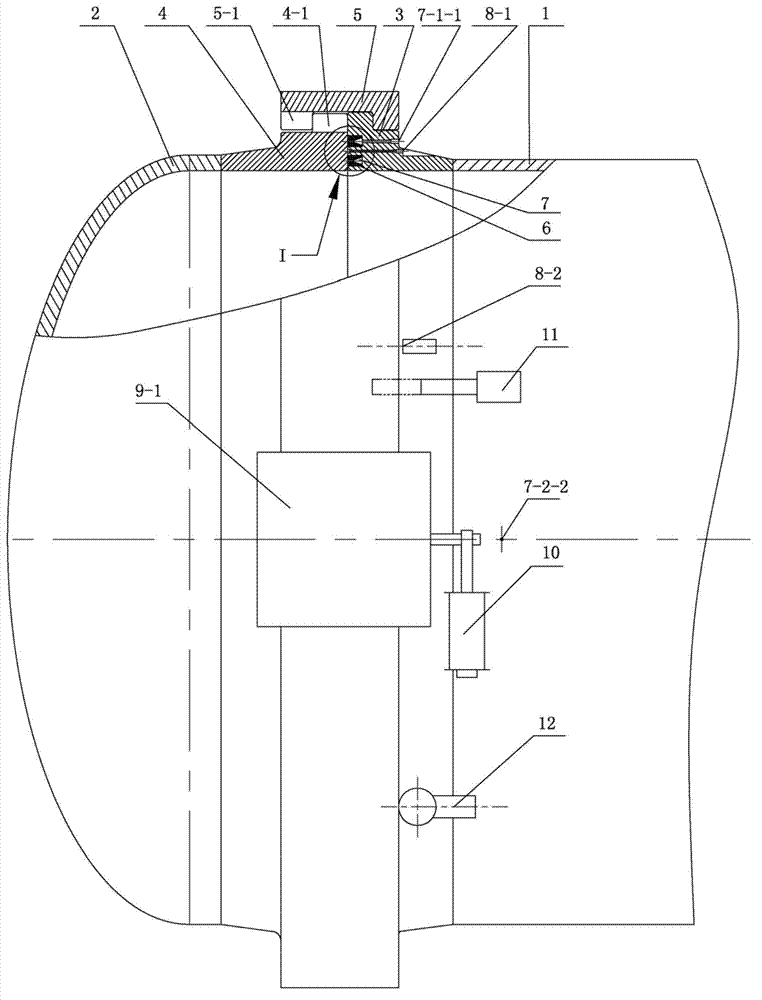

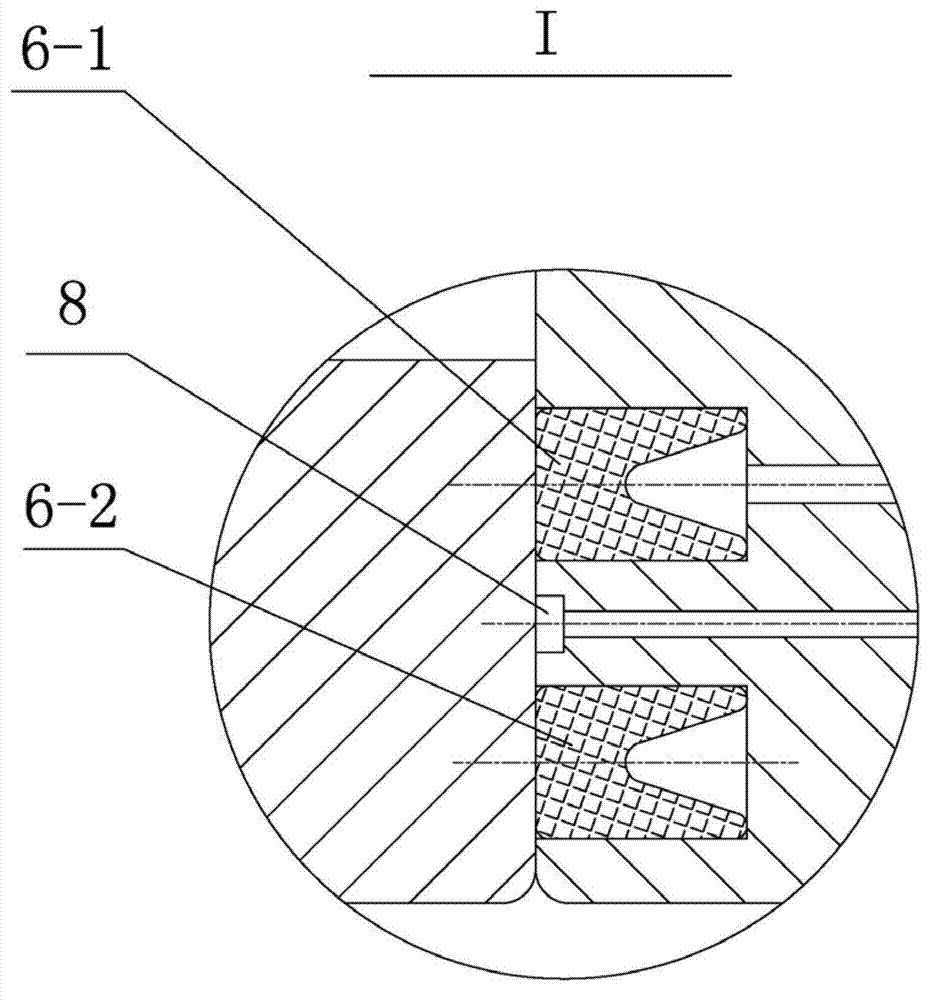

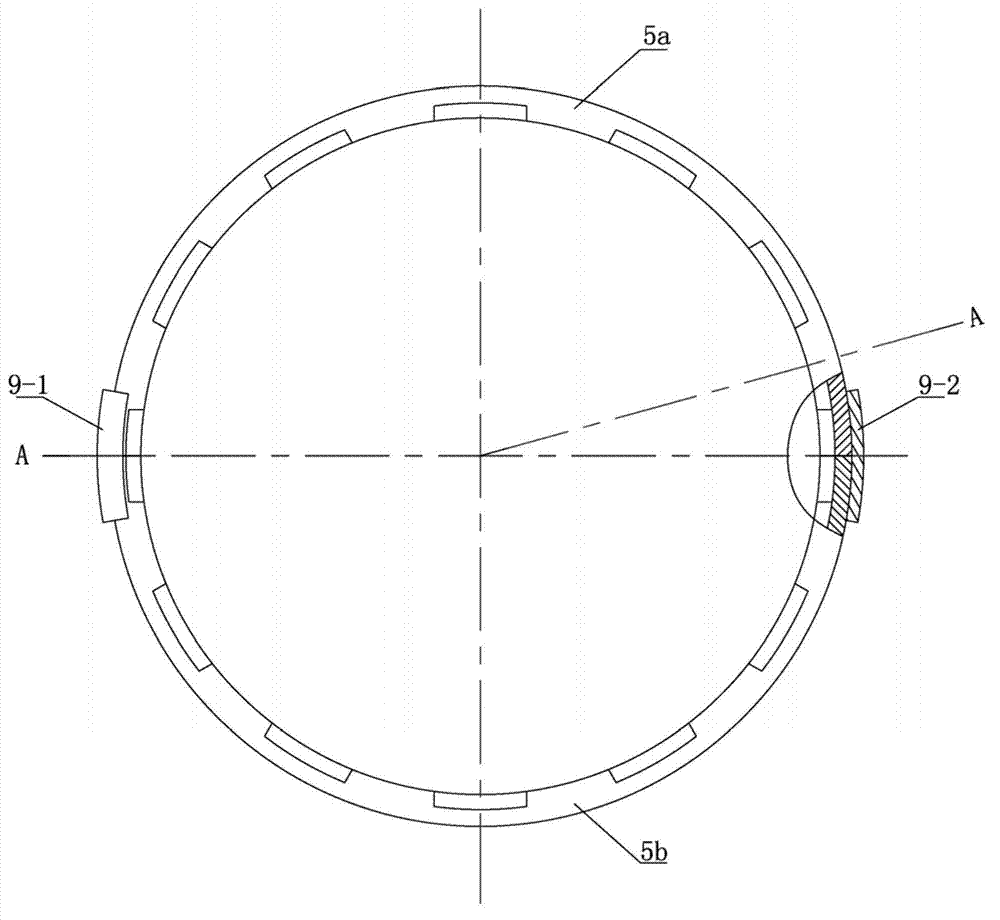

[0039] See Figure 1-12 In this embodiment, the pressure vessel quick-opening device with online leakage detection function includes a cylinder flange 3 welded to the cylinder body 1, a head flange 4 welded to the head 2, and the head flange is far away from the head The outer end of one side is evenly equipped with locking teeth 4-1, while the flange of the cylinder is not toothed, so that on the basis of ensuring the strength, it can avoid reducing the thickness of the flange edge of the cylinder due to the weakening of the strength caused by toothing, and achieve The purpose of cost saving. The cylinder flange 3 and the head flange 4 are connected or loosened through the locking clip 5 . The locking clip 5 is formed by connecting two semicircular clips (5a, 5b) by splicing plates 9 (two, respectively 9-1, 9-2). The inner side of the locking clip 5 close to the end of the head is evenly processed with a number of clip teeth 5-1 correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com