High-pressure controllable slide valve type mechanical combination sealing system

A combined sealing and sliding valve technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve high-pressure reliable sealing and sealing components that cannot meet the requirements of hazardous chemical media Problems such as poor operability and reduced dynamic stability of the rotating spindle can reduce and avoid major accidents, facilitate quick disassembly and replacement, and improve maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

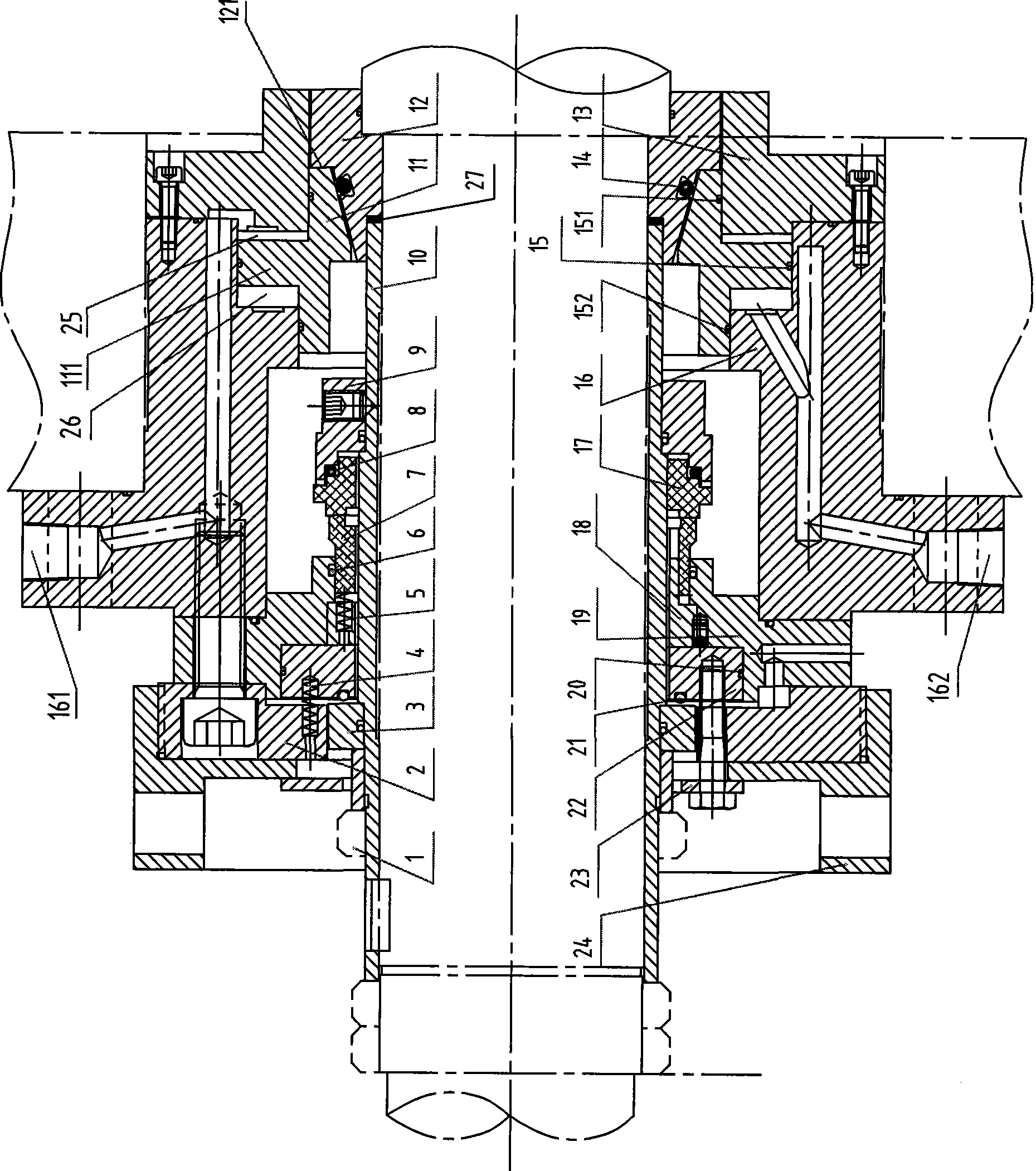

[0028] figure 1 A high-pressure controllable slide valve mechanical combined sealing system is presented, which consists of the following three parts arranged from right to left: controllable slide valve static seal assembly, rotating mechanical seal assembly and emergency seal assembly.

[0029] The static seal assembly of the controllable spool valve includes a tapered bushing 12 for fitting on the shaft shoulder. The tapered bushing 12 is located in the spool valve gland 13. The tapered bushing 12 consists of a hollow cylindrical section and a hollow cone The outer surface of the hollow cylindrical section and the inner surface of the slide valve gland 13 form a certain gap, the gap is generally 0.5 ~ 1mm; the outer surface of the hollow conical section of the tapered sleeve 12 is provided with a dovetail groove, The main sealing ring 14 is placed in the dovetail groove, and the main sealing ring 14 can be an O-shaped rubber ring.

[0030] The inner surface of the spool va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com