Microcarrier bioreactor tank inner and outer pipeline channel sealing connection device

A technology for bioreactors and connecting devices, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, enzymology/microbiology devices, etc., can solve problems such as wear failure, cell contamination, etc. To achieve the effect of simple structure, convenient insertion and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

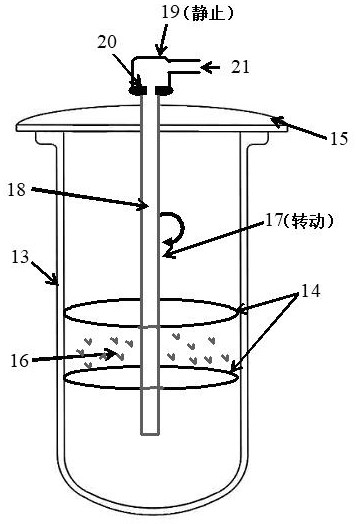

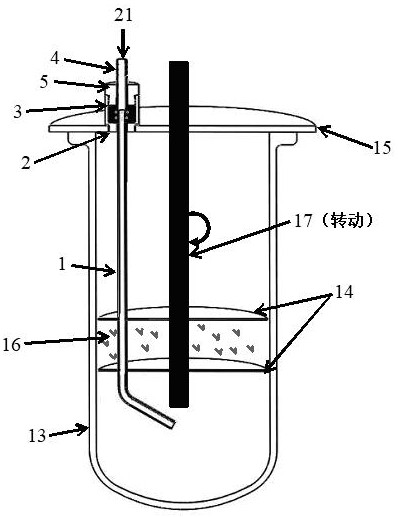

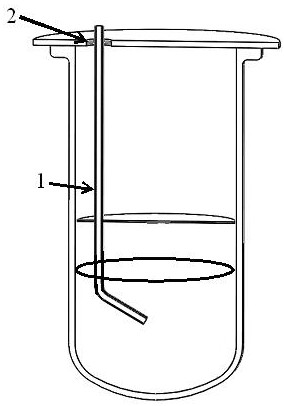

[0030] Such as Figure 2~12 As shown, a microcarrier bioreactor tank internal and external channel sealing connection device, the device includes a hard tube 1, a sealing connection seat 3, a sealing connection sleeve 4 and a compression nut 5. The hard tube 1 is fixed on the microcarrier frame 14 in the reaction tank 13, and one end passes through the top cover 15 of the reaction tank 13; the top cover 15 is provided with a threaded interface 2, and the threaded interface 2 is connected with the sealing connection seat 3; The sealing connection seat 3 is provided with a sealing connection sleeve 4 inserted on the hard pipe 1, and a compression nut 5 is pressed on the sealing connection sleeve 4; the compression nut 5 is connected with the sealing connection seat 3; the sealing connection seat 3 is connected with the Sealing rings 22 are arranged in the sealing connection sleeves 4 .

[0031] Wherein: the top of the hard tube 1 is the channel inlet 21, and its end extends int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com