Device and method for sealing and locking liquid-cooled radiator nozzle

A locking device, heat sink technology, applied in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, sleeve/socket connection, etc., to avoid damage to components and protect them from being compressed bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

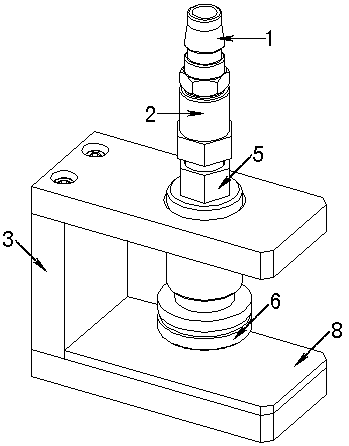

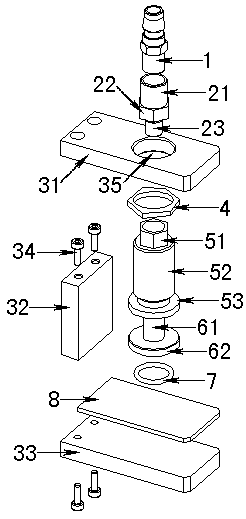

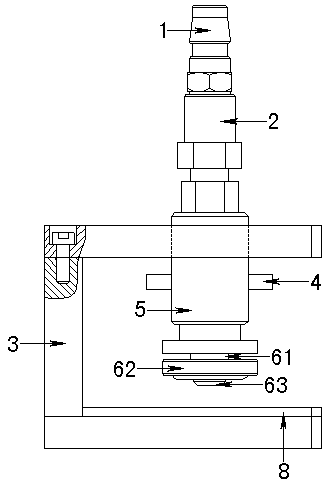

[0037] Such as figure 1 with figure 2 As shown, the fixed support 3 includes an upper guard plate 31 , a support block 32 and a base 33 , and the upper guard plate 31 is provided with a threaded hole 35 . The transition joint 2 connects the quick joint 1 and the sealing shaft 6 into a whole, and the fastening shaft 5 is sleeved on the whole, so that the whole can move up and down in the through hole in the middle of the fastening shaft 5 . The fastening shaft 5 is movably connected in the threaded hole 35 of the upper guard plate 31 of the fixed support 3 through threads, and the fastening shaft 5 can be moved downward by rotating the fastening shaft 5, so that the fastening chassis at the lower end of the fastening shaft 5 53 abuts on the shaft disc 62 of the sealing shaft 6, so that the shaft disc 62 also moves downwards.

[0038]The upper guard plate 31, the support block 32 and the base 33 are all cuboid, and one side of the upper guard plate 31 and the base 33 has moun...

Embodiment 2

[0049] Such as Figure 4 with Figure 5 As shown, the water nozzle 91 of the liquid cooling radiator 9 in the first embodiment is front, while the water nozzle 91 of the liquid cooling radiator 9 in the second embodiment is side. Since the structure of the liquid cooling radiator 9 and the orientation of the water nozzle 91 are different, the devices and methods for sealing and locking the water nozzle 91 of the radiator are also different.

[0050] Such as Figure 5 As shown, the locking screw 10 includes a screw head 101 and a locking head 102, and the upper guard plate 31 and the support block 32 of the fixed support 3 are provided with threaded holes 35, and the locking screw 10 is mounted on the fixed support through thread fit. In the threaded hole 35 of the upper guard plate 31 of 3, the fastening nut 51 is installed in the threaded hole 35 of the support block 32 of the fixed support 3 by the threads on the threaded pipe 52. The lower end of the locking screw 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com