Infusion tube automatic production line

A technology for automatic production lines and infusion tubes, which is used in catheters, transportation and packaging, and liquid/vacuum measurement for liquid tightness. It can solve the problems of high labor intensity, low production efficiency, and difficulty in improving efficiency. Strength, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and following embodiment is illustrative only, does not constitute the limitation of the present invention, and all modifications and distortions that do not deviate from the spirit essence of technical solution of the present invention do, all Belong to the protection scope of the present invention.

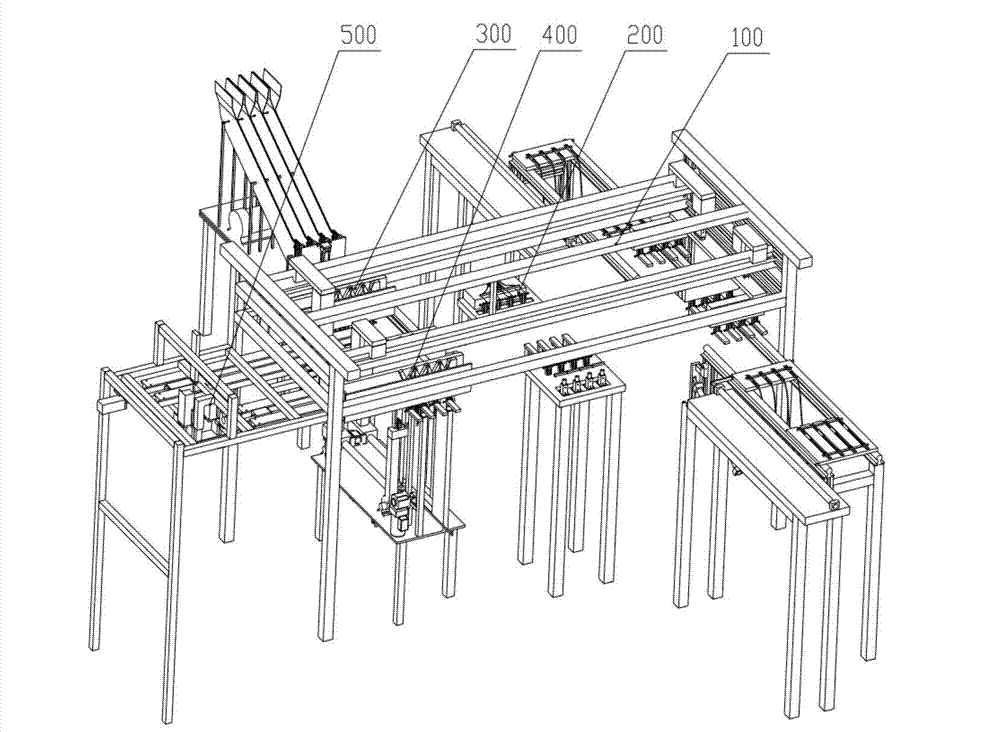

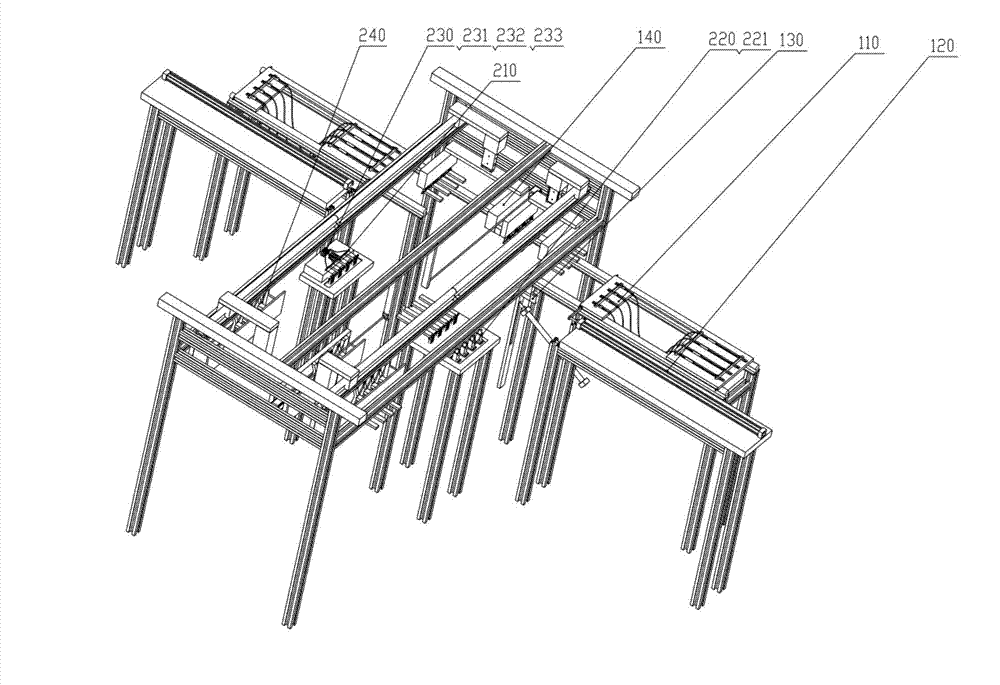

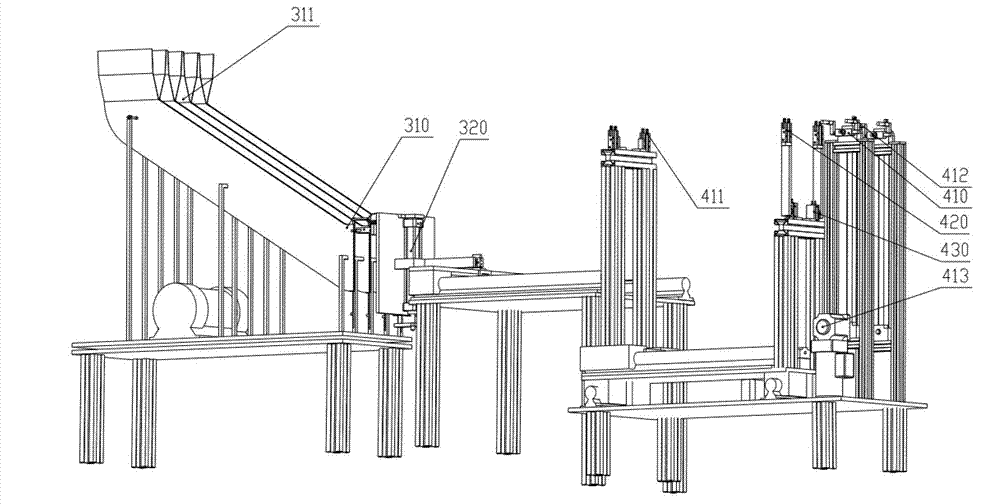

[0038] Such as figure 1 As shown, the production line of this embodiment includes a feeding mechanism 100 , an air leakage detection mechanism 200 , a scalp needle assembly mechanism 300 , a winding mechanism 400 , and a packaging sealing mechanism 500 arranged in sequence along the process. The feeding mechanism 100 is used to load and transport the raw material of the infusion tube body for feeding. It first transports the tube body to the air leakage detection mechanism 200. The body of the infusion tube is sent into the needle assembly mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com