Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

A technology of blasting pressure relief and roof cutting pressure relief, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of roadside filling body fracturing and roadway retention failure, etc., so as to improve the stability of surrounding rock and reduce the The amount of excavation, the effect of the obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

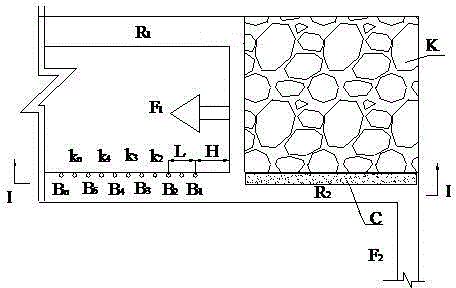

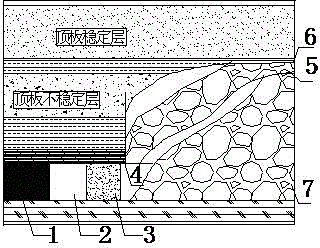

Embodiment 1

[0035] Example 2:

[0036] In the roadside filling method described in Example 1, the top-cutting blasting and pressure relief method of gob-side entry retaining, the first step is to determine the top-cutting method, drilling construction time and location, which are taken during the mining of the working face and the construction process of roadside filling. , a method for deep hole blasting to relieve pressure on the roof of the reserved roadway.

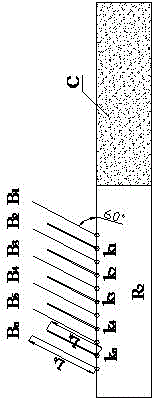

Embodiment 2

[0038] In the method for pressure relief of roadside filling and top-cutting blasting in gob-side entry retention described in Example 1, the second step to determine the drilling parameters of top-cutting pressure relief blasting is that the drilling position is close to the goaf side of the filling body, and the drilling angle Along the direction of the roadway, it is 40--60° from the roof. The drilling depth is 3 to 4 times the mining height of the working face. The depth of the charging hole is different from that of the control hole;

Embodiment 3

[0040] In the roadside filling method described in Example 1, the top-cutting blasting and pressure relief method of gob-side entry retention, the third step of setting up deep-hole blasting drilling and charging and sealing holes is to work in advance after the above-mentioned top-cutting drilling parameters are determined. After the drilling construction is completed, the mining distance of one round shift in the advance working face is about 10~15m for interval charging, the control hole is not charged, and the hole sealing operation is carried out after charging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com