A large diameter and large gap magnetic liquid static sealing structure

A magnetic liquid, large gap technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficult processing of sealed components, poor sealing effect, uneven deformation, etc., to broaden the scope of use, long service life, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described with accompanying drawing as specific embodiment:

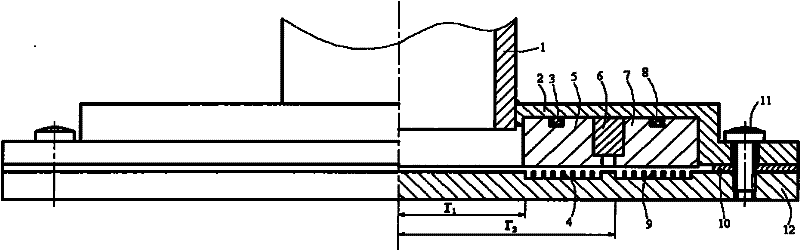

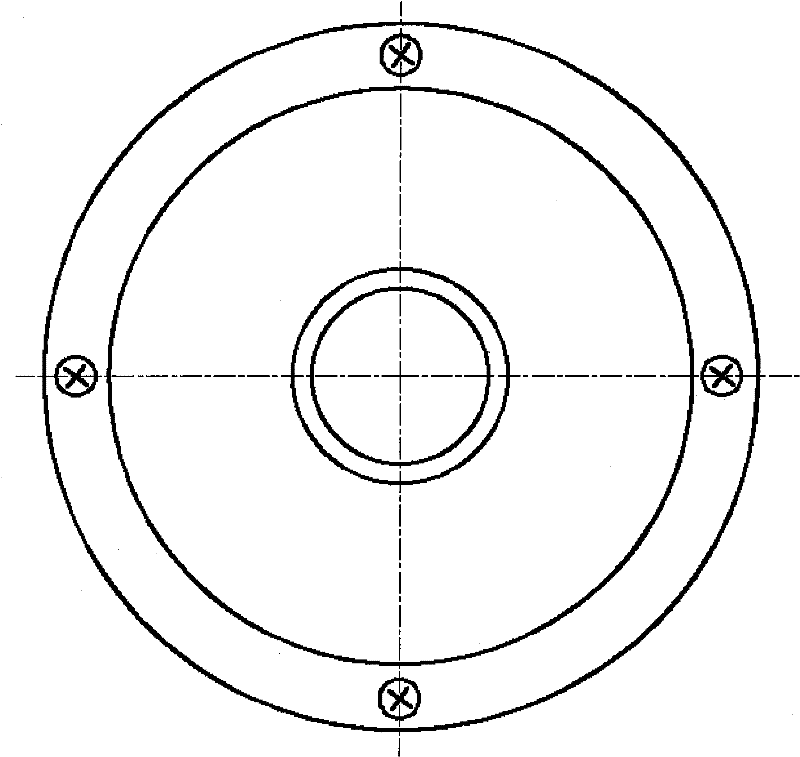

[0015] A large-diameter large-gap magnetic liquid static sealing structure, see figure 1 , 2 . The structure includes: a casing 2 , a sealing assembly, a magnetic fluid, and a chassis 12 .

[0016] The shell 2 is made of non-magnetic material, and is welded with the sealing body 1; the sealing assembly is placed in the groove of the shell 2, and the magnetic liquid is injected into the inner ring surface of the annular permanent magnet 6; there is a cushion between the chassis 12 and the shell 2 Gasket 10, the chassis 12, gasket 10 and shell 2 are fastened together with screws 11, and the thickness of the gasket 10 is adjusted to ensure the sealing gap;

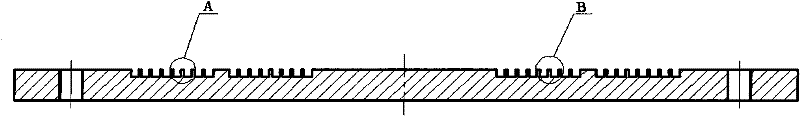

[0017] On the chassis 12, r from the centerline 1 and r 2 Start to make the inner sealing teeth 4 and the outer sealing teeth 9. The shape of the sealing teeth is rectangular, and the size of each tooth is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com