Support mechanism and automatic lifting device with the mechanism

A support mechanism and automatic lifting technology, applied in the field of support mechanism, can solve the problems of complex structure, difficult installation, no buffer and vibration reduction of the support mechanism, and achieve the effects of avoiding hard mechanical contact, reducing production cost and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

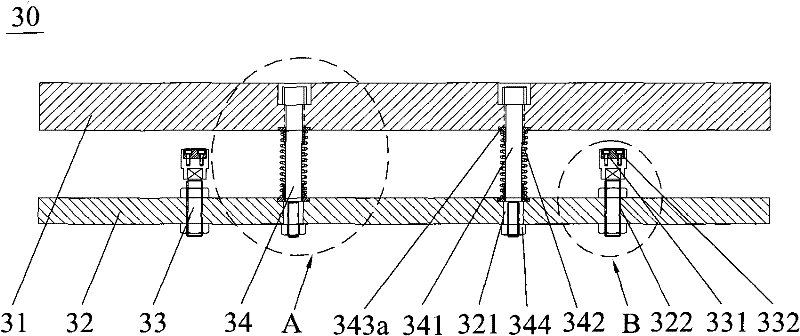

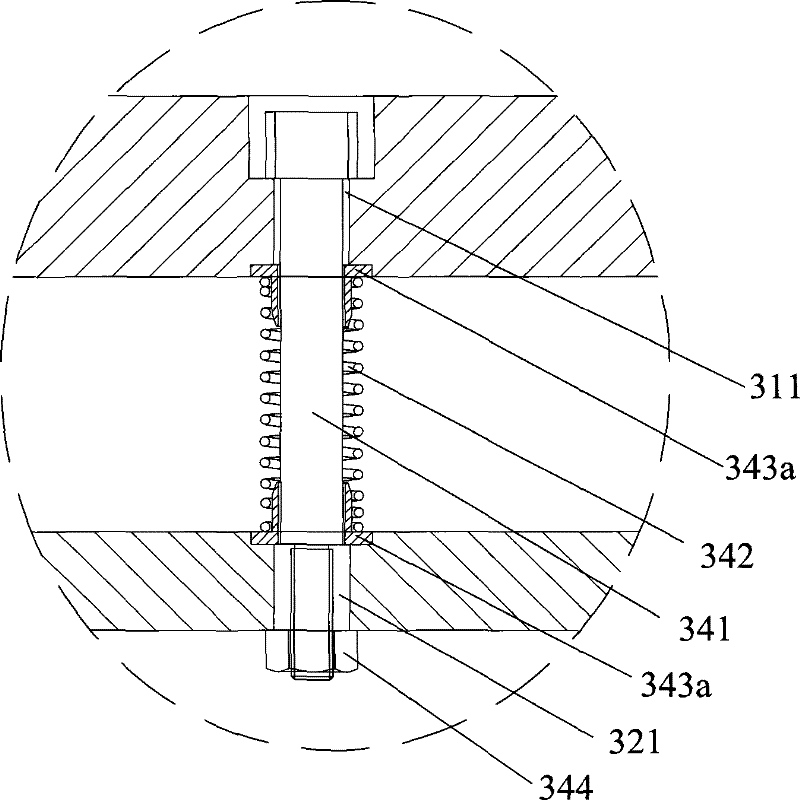

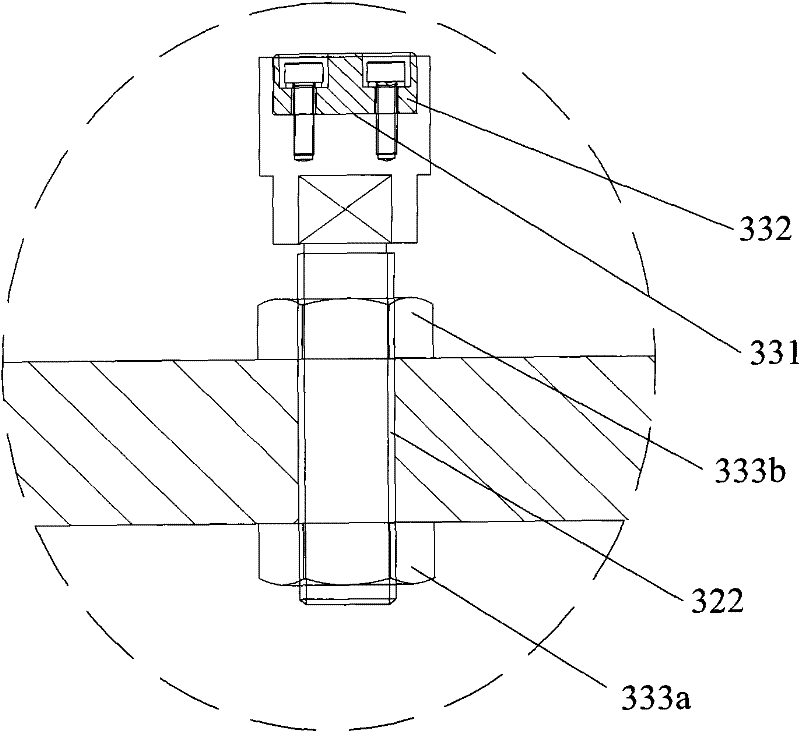

[0022] Such as Figure 1-Figure 3As shown, the supporting mechanism 30 of the present invention includes a mounting plate 32, a loading plate 31, a connecting piece 34 and a limiting piece 33, and the connecting piece 34 and the limiting piece 33 are connected between the installing plate 32 and the loading plate 31 in parallel with each other. Wherein, the connector 34 includes a connecting column 341 and an elastic element 342, the upper end of the connecting column 341 is movably connected with the bearing plate 31, the lower end of the connecting column 341 is movably connected with the mounting plate 32, and the elastic element 342 is sleeved on the connecting column in a compressed form. 341, and the upper end of the elastic element 342 is in conflict with the bearing plate 31, the lower end of the elastic element 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com