Filter type spray nozzle for injection molding machine

A filter type, injection molding machine technology, applied in the direction of injection device, injection device, etc., can solve the problems of increased cost, troublesome, troublesome disassembly of the filter device, etc., to achieve the effect of convenient cleaning and cleaning, ensuring injection molding effect, and convenient replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

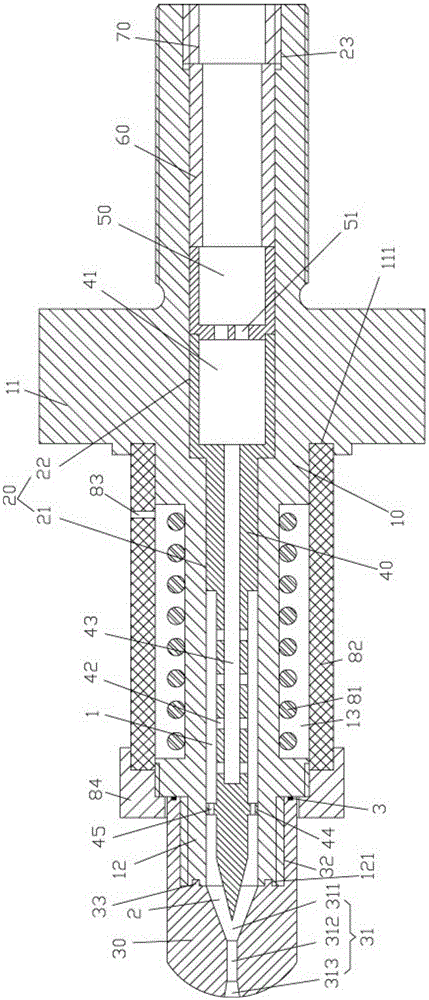

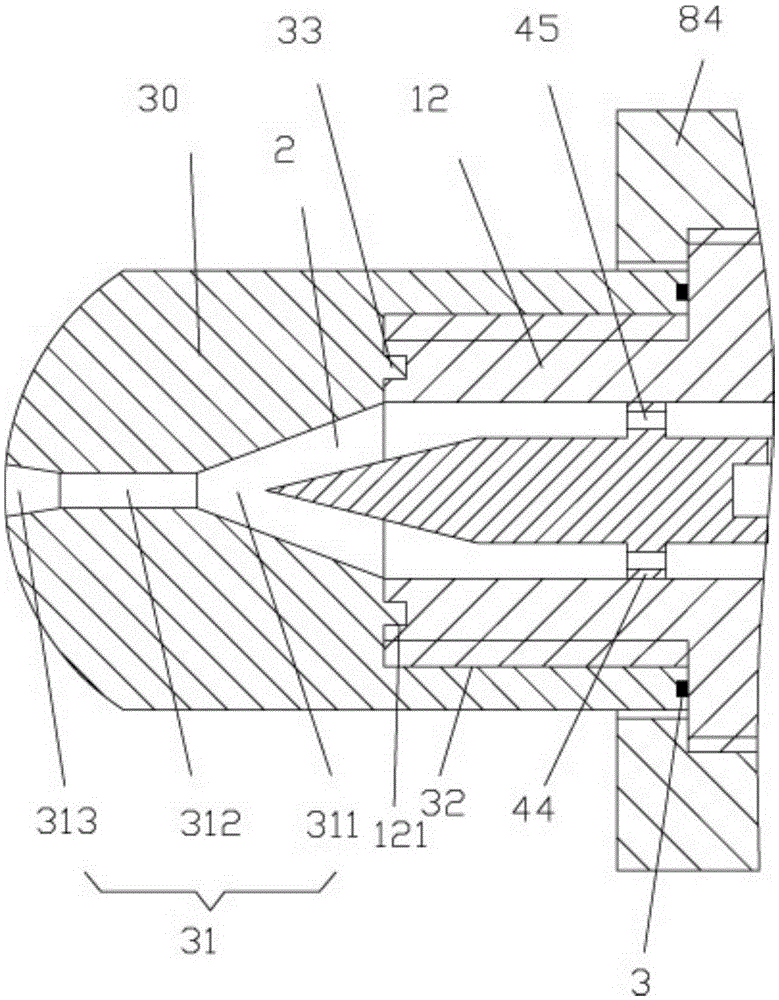

[0019] Examples, see e.g. Figure 1 to Figure 2 As shown, a filter nozzle for an injection molding machine includes a nozzle body 10, the nozzle body 10 has a stepped central through hole 20, and the rear outer wall of the nozzle body 10 has a limiting portion 11 extending radially outward, The middle part of the front end of the nozzle body 10 has a connecting part 12 extending axially forward, the outer wall of the connecting part 12 has an external thread, the nozzle head 30 is screwed on the connecting part 12, the middle part of the nozzle head 30 has a nozzle hole 31, and the nozzle hole 31 It communicates with the stepped central through hole 20, and the upper outer wall of the nozzle body 10 is provided with an electric heating device;

[0020] The front part of the stepped central through hole 20 is a small-diameter section 21, and the rear part is a large-diameter section 22. The rear part of the main filter sleeve 40 has a large-diameter connecting sleeve 41, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com