A diesel storage device with blending function

A storage device and diesel technology, which is applied to containers with multiple items, packaging, petroleum industry, etc., can solve the problems of short use time and waste of resources, reduce equipment investment, ensure market supply, and save energy consumption for blending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

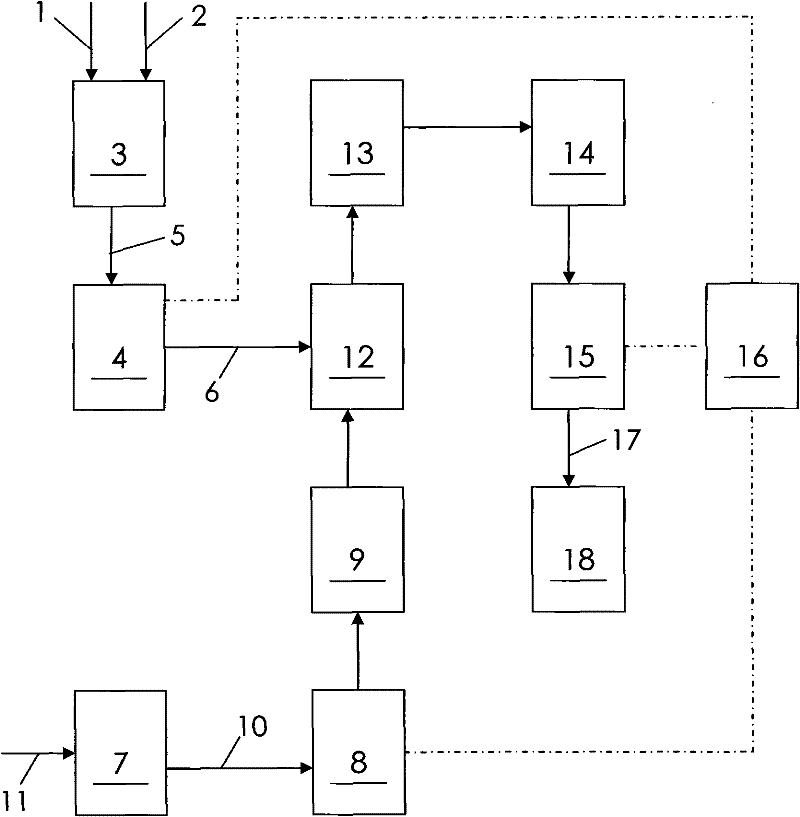

[0022] This example illustrates the situation where the device is used to blend -10# diesel oil with 0# diesel oil and pour point depressant as raw materials.

[0023] process such as figure 1 As shown, in the additive proportioning tank 3, the pour point depressant 1 is diluted with -35# diesel oil 2 at a volume ratio of 1:10, the dilution temperature is 40°C, and the diluted additive 5 is pumped into 0 by plunger pump 4. #Diesel oil pipeline 6, the oil in 0# diesel storage tank 7 is output by centrifugal pump 8 and measured by mass flow meter 9. The outlet pipeline 10 adopts electric heating and heat preservation, the temperature is 20-30°C, the flow rate of 0# diesel oil 11 and The flow rate of the additive diluent 5 is set according to a predetermined ratio. The additive diluent 5 and 0# diesel oil 11 are initially stirred by the centrifugal pump 12 and measured by the mass flow meter 13, and then enter the static mixer 14. After being fully mixed by the mixer 14, The col...

Embodiment 2

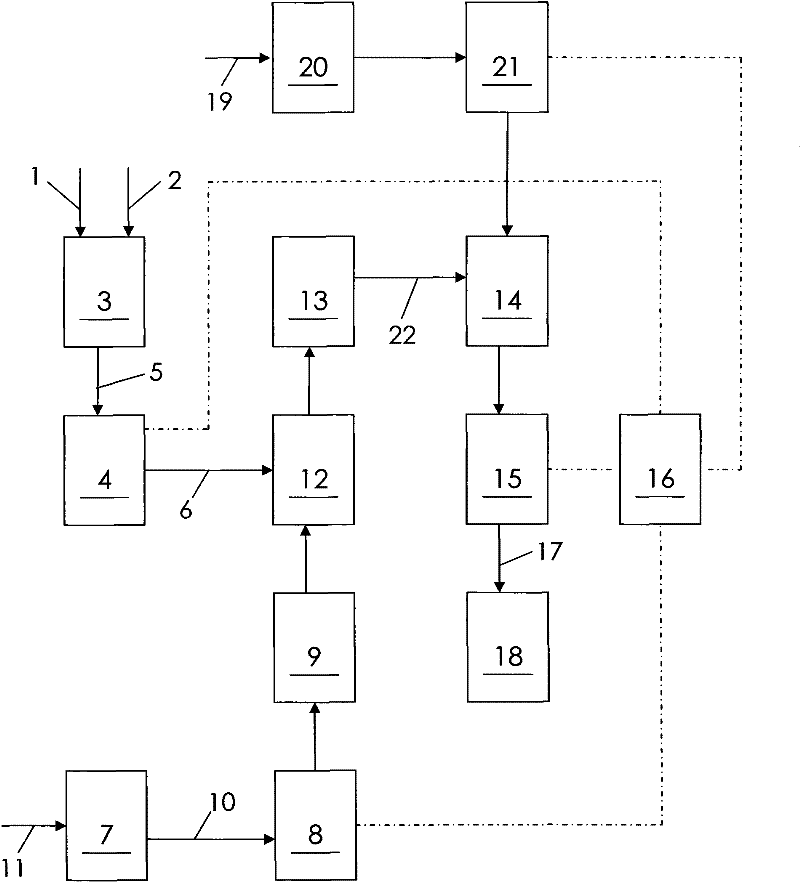

[0028] This example illustrates that the device is used to blend -20# oil with 0# oil, -35# oil and pour point depressant as raw materials.

[0029] process such as figure 2 As shown, in the additive proportioning tank 3, the pour point depressant 1 is diluted with -35# diesel oil 2 at a volume ratio of 1:10, the dilution temperature is 40°C, and the diluted additive 5 is pumped into 0 by plunger pump 4. #Oil oil pipeline 6, the oil product 11 in 0# oil storage tank 7 is output by centrifugal pump 8, measured by mass flow meter 9, additive dilution 5 and 0# oil 11 are first stirred by centrifugal pump 12, mass flow meter 13 Metering, the outlet pipeline 10 adopts electric heating and heat preservation, the temperature is 20-30°C, -35# oil 19 is output by centrifugal pump 20, and is measured by mass flow meter 21, the flow rate of -35# oil 19 and 0# oil containing additive diluent 22 The flow rate is set according to a predetermined ratio. After being fully mixed by the mixer...

Embodiment 3

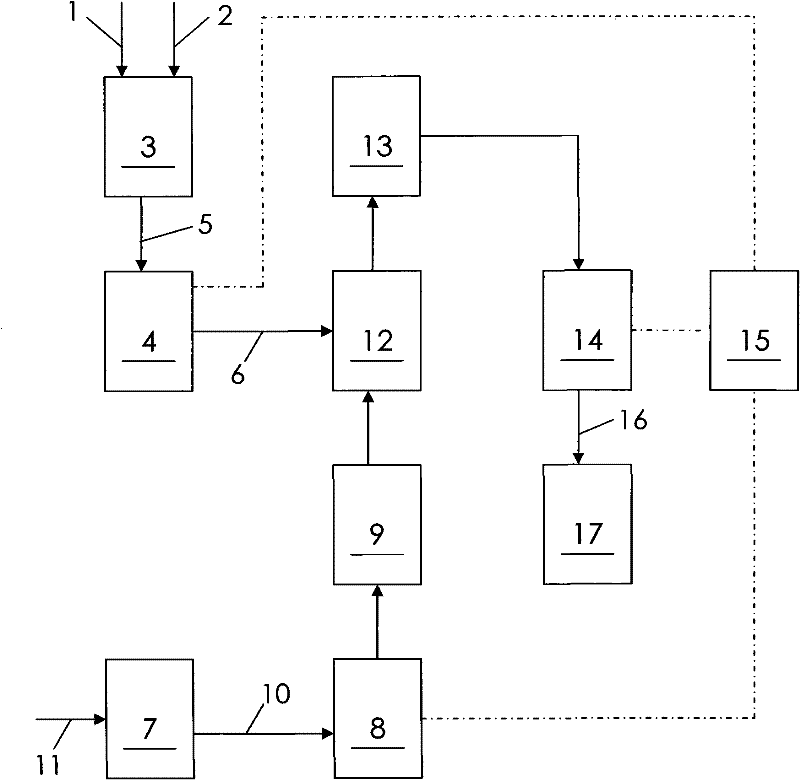

[0034] This embodiment illustrates the situation when the device is used to improve the indicators of oil products with quality changes.

[0035] process such as image 3 As shown, the unqualified 0# oil product 11 in the 0# oil storage tank 7 is output by the centrifugal pump (8), measured by the mass flow meter 9, and the outlet pipeline 10 adopts electric heating and insulation, and the temperature is 20-30°C , Additive 1 is diluted with -35# diesel oil 2 in the additive proportioning tank 3, and the released liquid 5 is mixed with 0# oil 11 for the first time by centrifugal pump 12, metered by metering pump 13, fully mixed by static mixer 14, and online analysis instrument 15 Measure the inspection index of the oil product 16 after blending, and the computer control system randomly adjusts the ratio of the flow rate of 0# oil 11 and additive diluent 6 until the evaluation index after blending is within the set range. The blended oil product goes to the storage tank 17 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com