Method of extracting succinic acid from microorganism fermentation liquor

A technology of microbial fermentation broth and succinic acid, which is applied in the separation/purification of carboxylic acid compounds, purification of alkali metal halides, organic chemistry, etc. The effect of low cost, high product purity and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

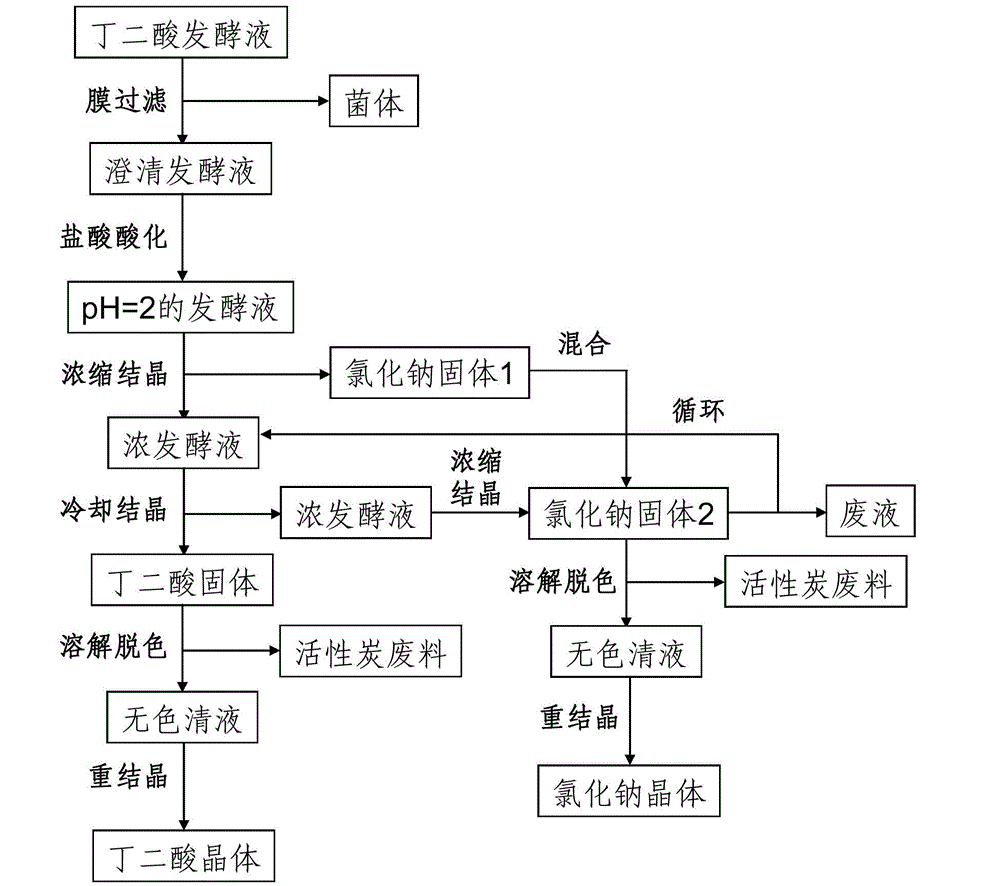

Image

Examples

Embodiment 1

[0030] Embodiment 1, extract succinic acid from microbial fermented liquid

[0031] 1) 2 L of fermented liquid containing 98 g / L sodium succinate obtained through microbial anaerobic fermentation was filtered through an ultrafiltration membrane (molecular weight cut-off of 0.02 μm) to remove bacteria and large proteins to obtain a clarified fermented liquid.

[0032] 2) Slowly add concentrated hydrochloric acid with a mass fraction of 35% to the above fermented liquid under stirring condition, and stop when the pH of the solution is 2 to obtain an acidified fermented liquid.

[0033] 3) Concentrate the acidified fermentation broth at 80° C. with a rotary evaporator until the concentration of succinic acid is 320 g / L, perform solid-liquid separation through a suction filtration tank, remove the solid sodium chloride, and collect the clarified filtrate.

[0034] 4) The filtrate obtained in step 3) was cooled and crystallized at 4° C. under agitation for 2 h, and solid-liquid sep...

Embodiment 2

[0038] Embodiment 2, extract succinic acid from microbial fermented liquid

[0039] 1) 2L of fermented liquid containing 98g / L sodium succinate obtained through microbial anaerobic fermentation was passed through an ultrafiltration membrane (molecular weight cut-off of 0.02 μm) to remove bacteria and large proteins to obtain clarified fermented liquid.

[0040] 2) Under stirring conditions, gradually add concentrated hydrochloric acid with a mass fraction of 35% to the above fermentation broth for acidification, stop when the pH of the solution is 2, and obtain an acidified fermentation broth.

[0041] 3) Concentrate the acidified fermentation broth at 90°C with a rotary evaporator until the concentration of succinic acid is 350g / L, perform solid-liquid separation through a suction filtration tank, remove the solid sodium chloride, and collect the clarified filtrate.

[0042]4) The filtrate obtained in step 3) was cooled and crystallized at 4° C. under stirring conditions for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com