Complete process for treating coated industrial waste water

An industrial wastewater, complete set of treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effects of stable and reliable effluent quality, efficient degradation of organic matter, and good nitrification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

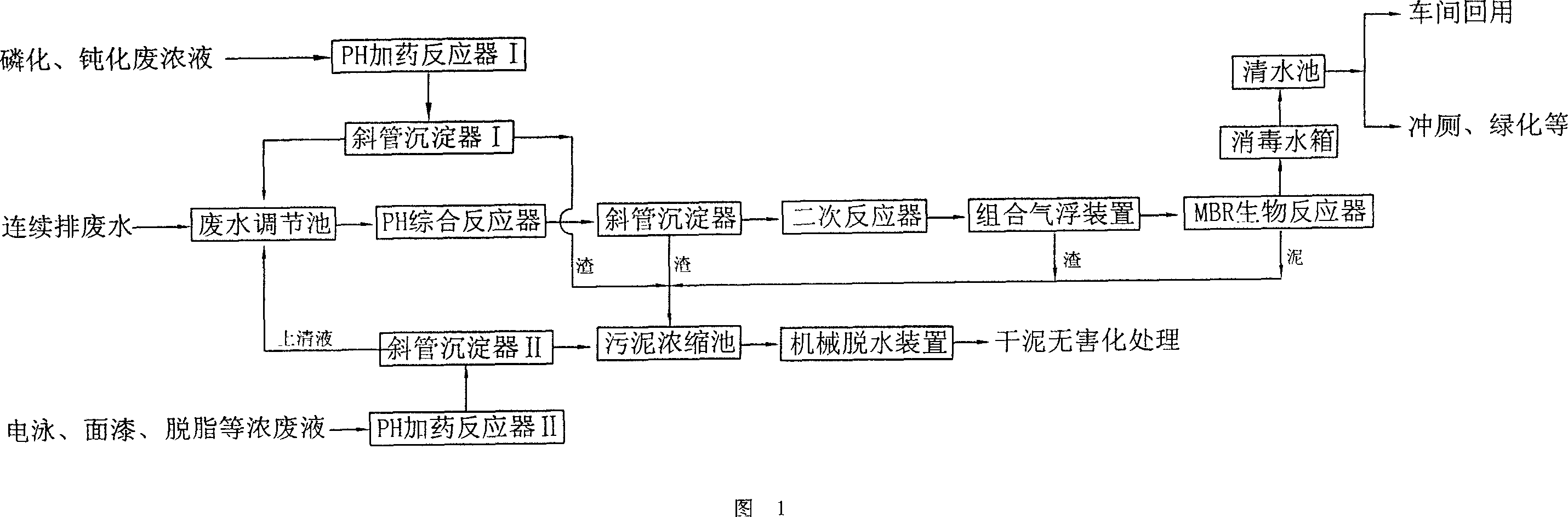

[0029] As shown in Figure 1:

[0030] 1. Pretreatment of waste liquid discharged from phosphating and passivation processes:

[0031] Add medicine to the waste liquid discharged from the phosphating and passivation process to precipitate phosphide, and use an inclined tube precipitator to separate the supernatant; mix the supernatant into the wastewater to be treated.

[0032] According to the different components of the phosphating and passivation waste liquid, lime milk can be added to the phosphating and passivation waste liquid to precipitate phosphide, or calcium chloride and sodium hydroxide can be added to precipitate phosphide.

[0033] 2. Pretreatment of waste liquid discharged from electrophoresis, topcoat and degreasing processes:

[0034] Add inorganic flocculant salts such as ferric chloride or aluminum chloride to the waste liquid discharged from the electrophoresis, topcoat, and degreasing processes to precipitate solid suspended matter and other heavy metal hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com