Patents

Literature

239 results about "Oil terminal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil depot (sometimes called a tank farm, tankfarm, installation or oil terminal) is an industrial facility for the storage of oil and/or petrochemical products and from which these products are usually transported to end users or further storage facilities. An oil depot typically has tankage, either above ground or below ground, and gantries (framework) for the discharge of products into road tankers or other vehicles (such as barges) or pipelines.

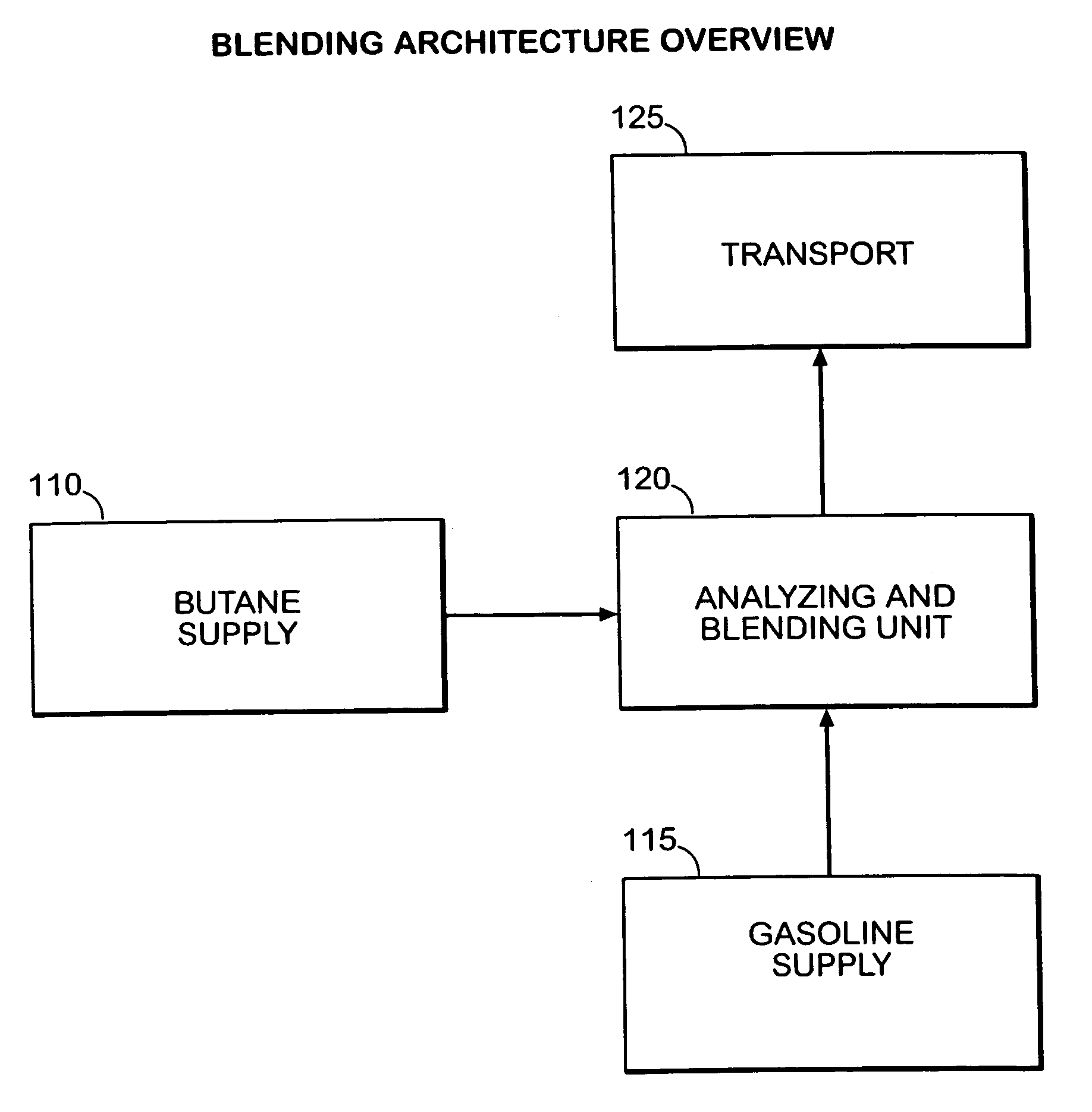

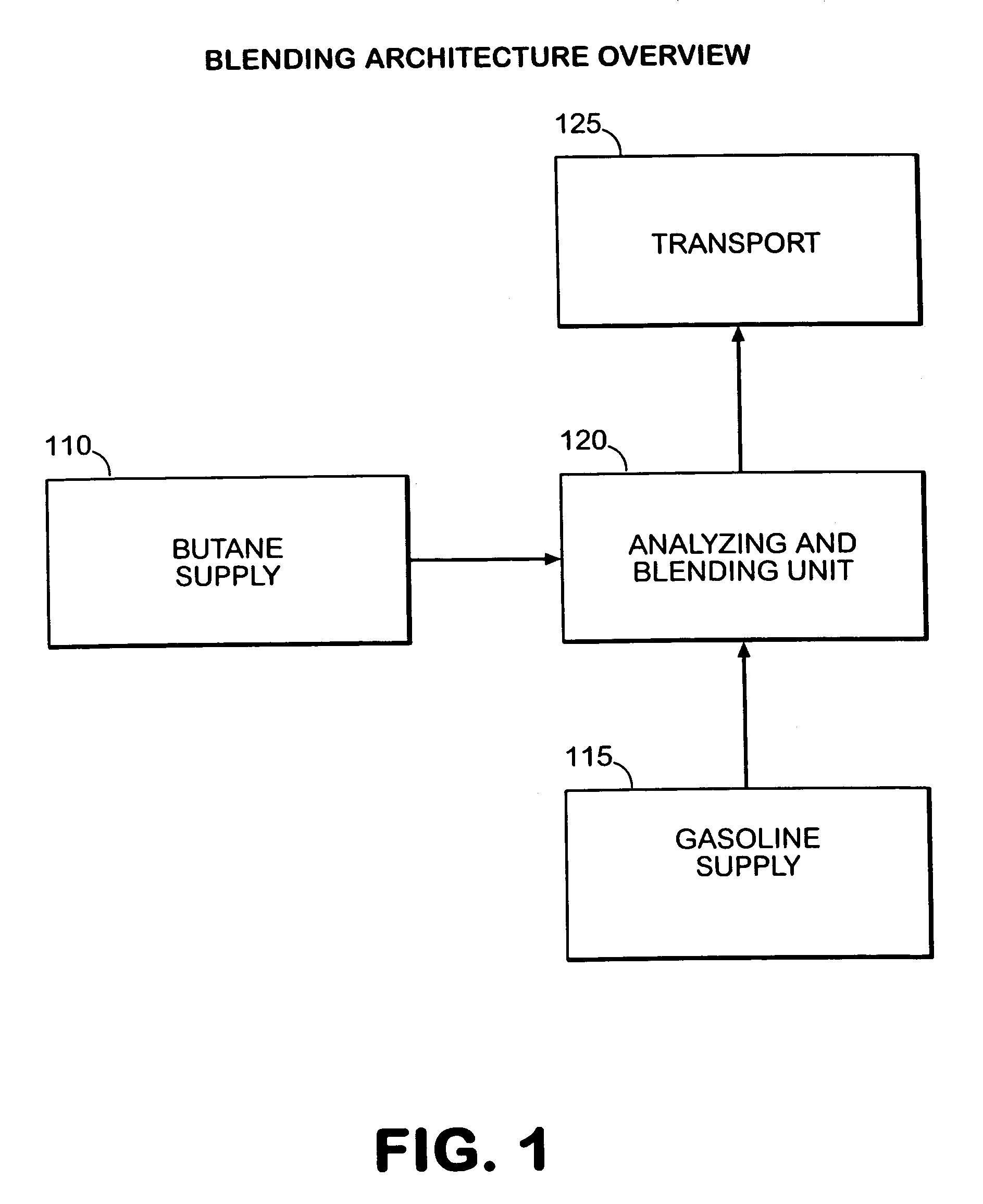

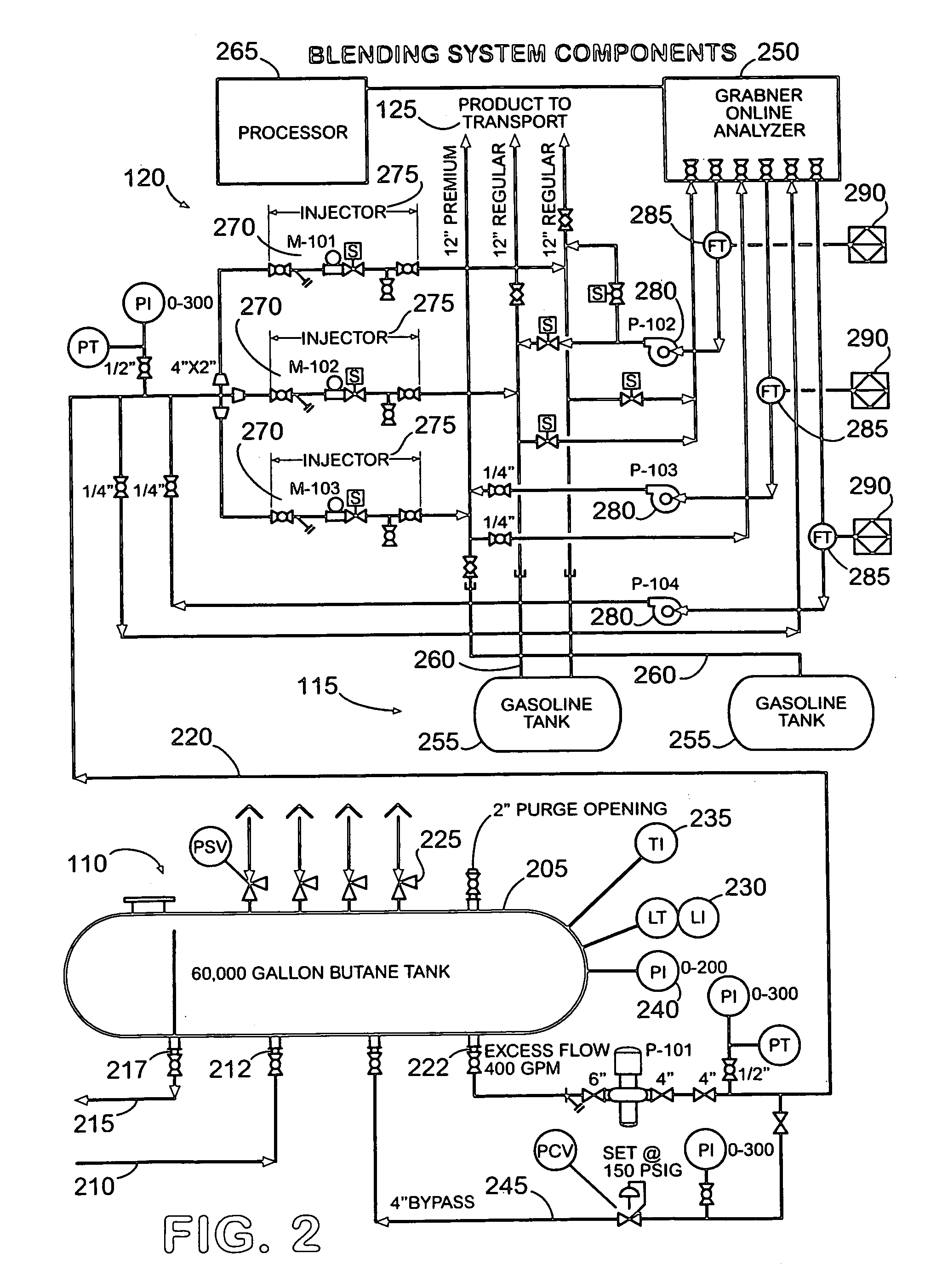

Method and system for blending gasoline and butane at the point of distribution

InactiveUS7032629B1Quantity maximizationMinimize their cost basisLiquid fillingOperating means/releasing devices for valvesEnvironmental regulationGasoline

A system and method is provided for blending butane with gasoline at petroleum tank farms, immediately before distribution to tanker trucks. The invention provides a method for blending gasoline and butane at a tank farm comprising: (a) drawing a gasoline stream from a tank of gasoline; (b) drawing a butane stream from a tank of butane; (c) blending the butane and gasoline streams to form a blend; and (d) dispensing the blend. The blending process can be controlled to ensure that the vapor pressure of the blended gasoline meets vapor pressure requirements of environmental regulations. Information generated by the blending process can be used to efficiently forecast butane purchasing requirements, and to generate regulatory reports.

Owner:SUNOCO PARTNERS MARKETING & TERMINALS LP

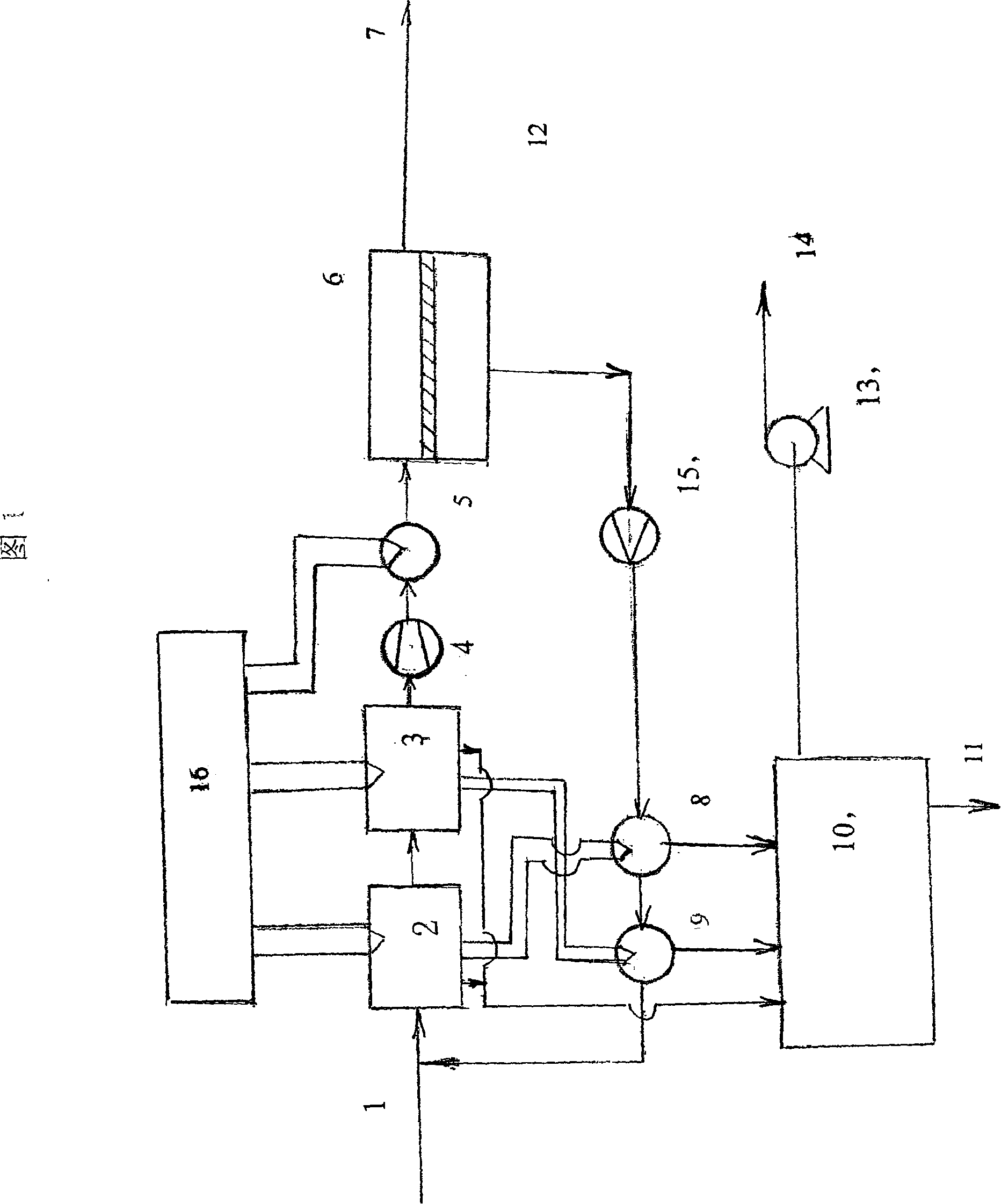

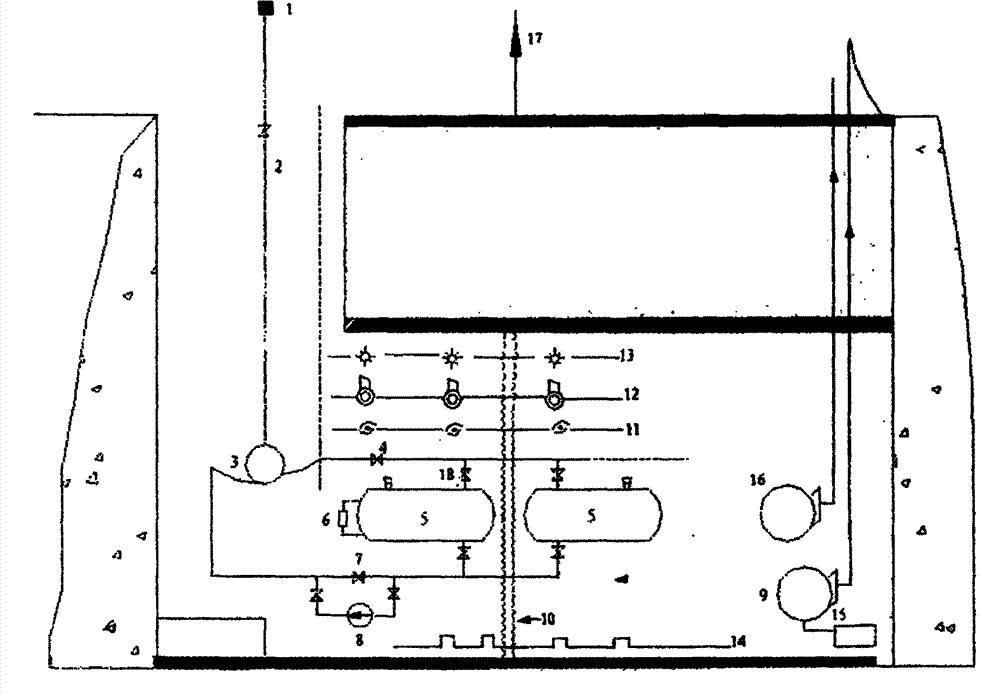

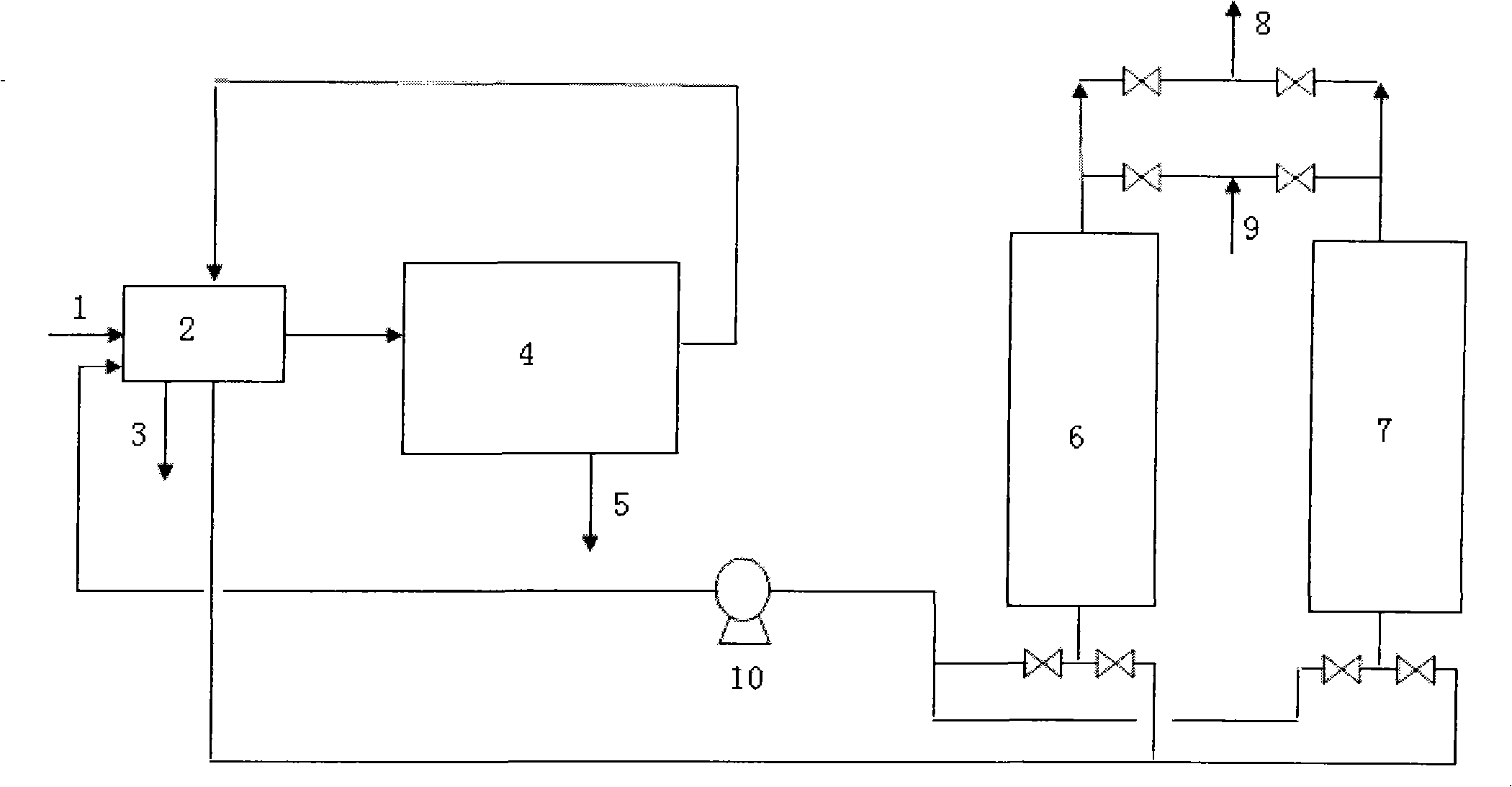

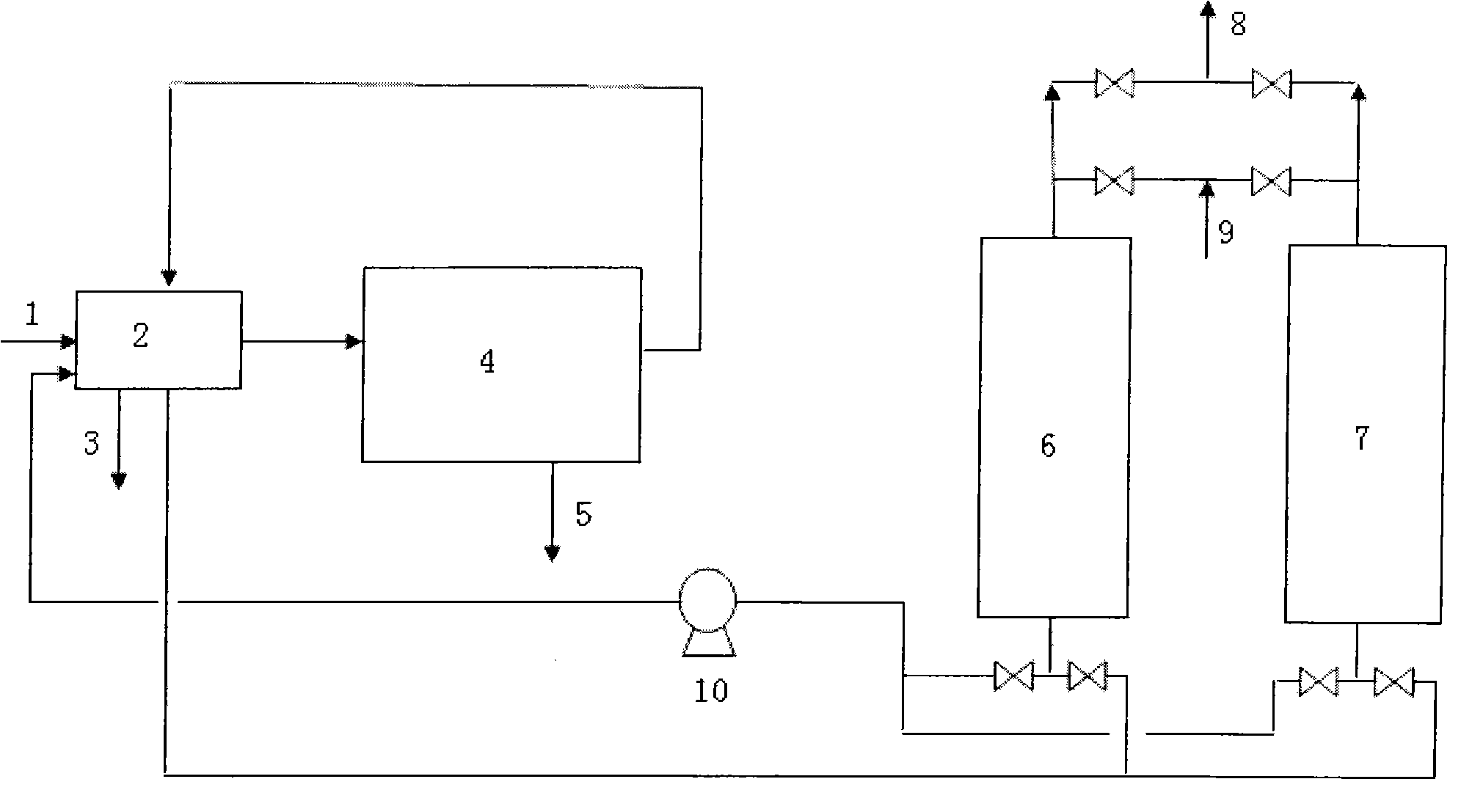

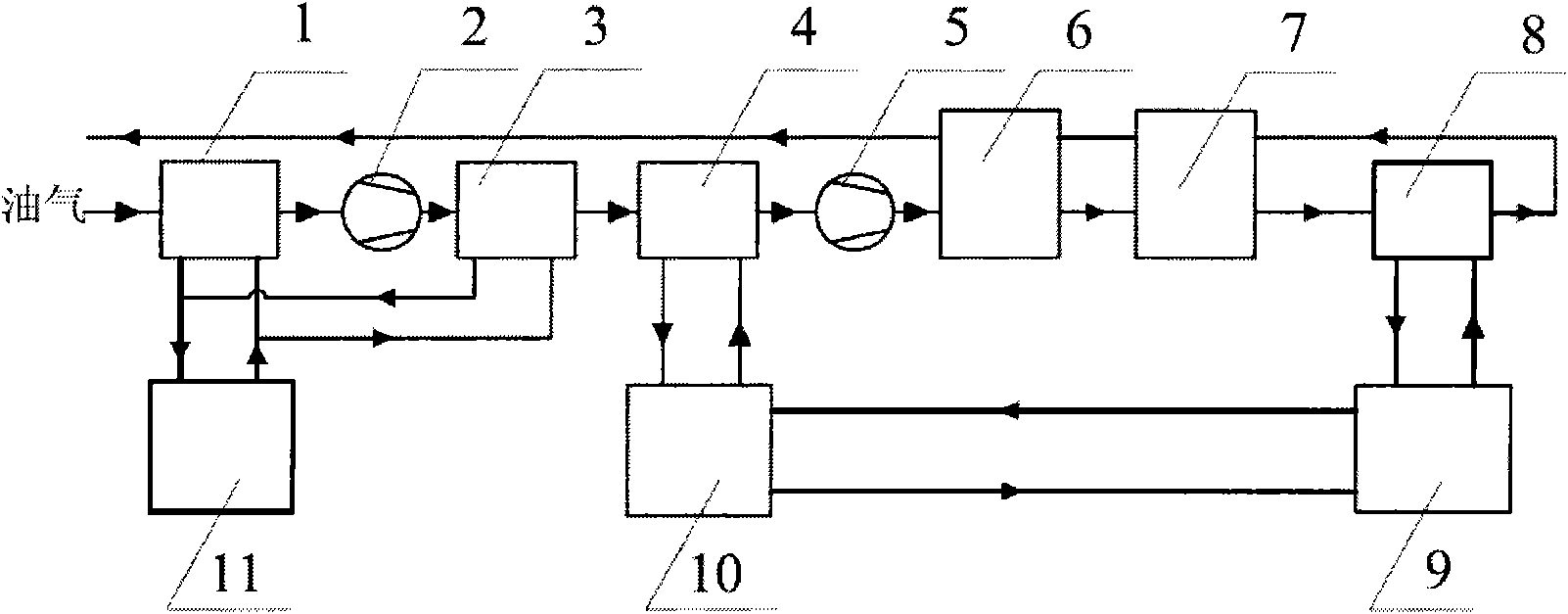

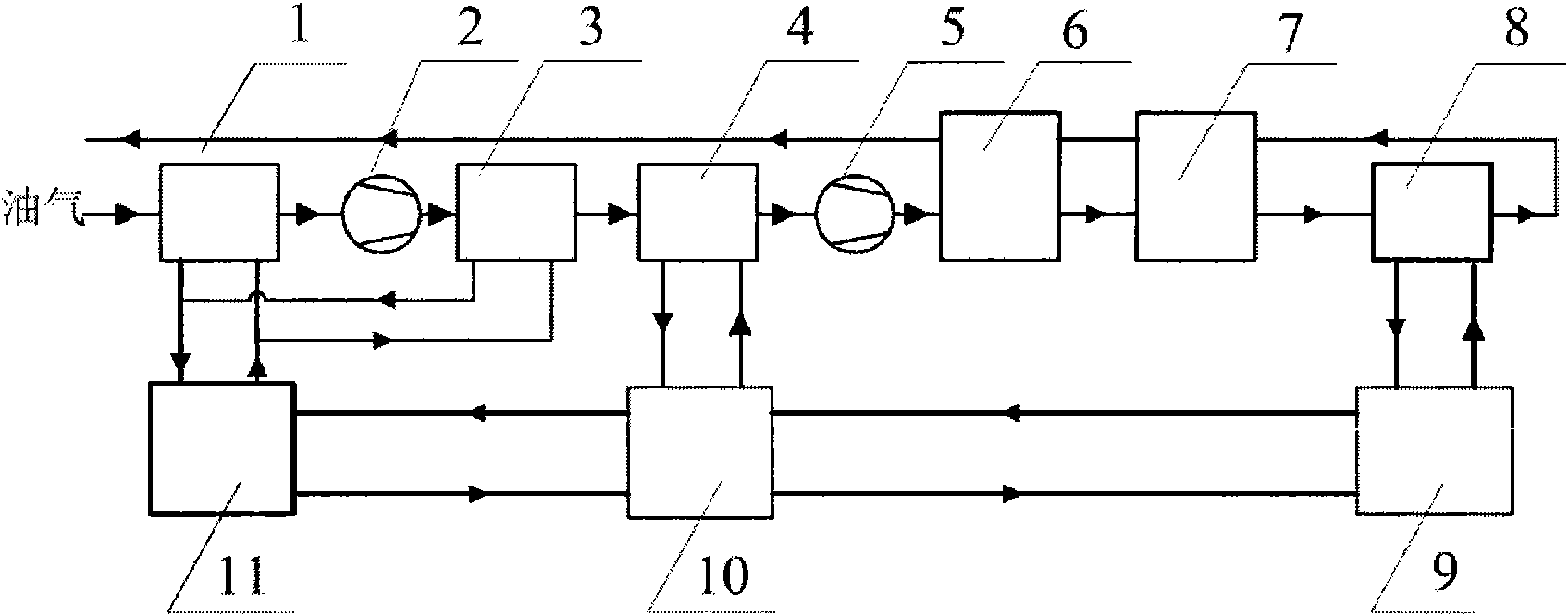

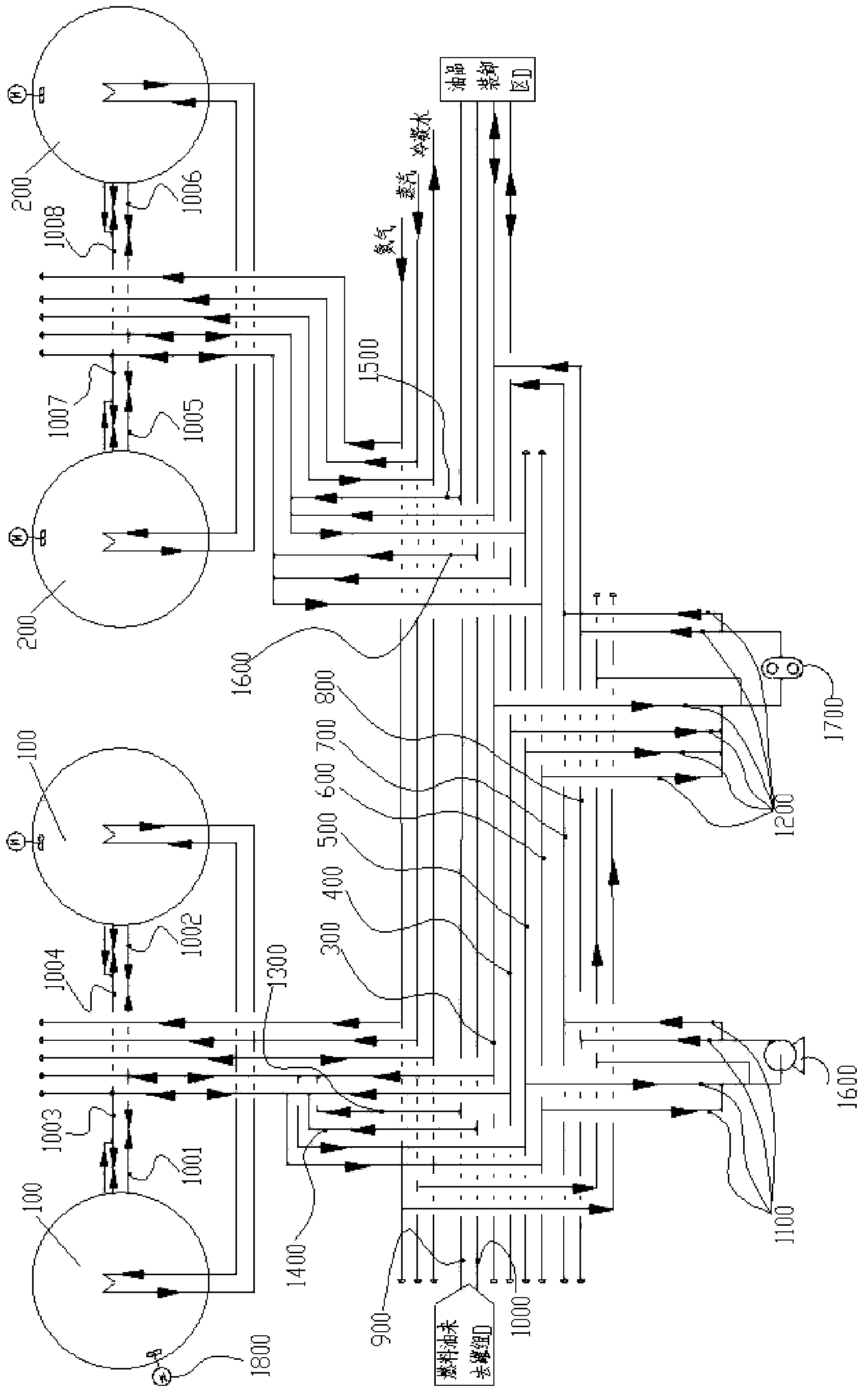

Condensing and membrane separation combined type oil gas reclaiming technical technology

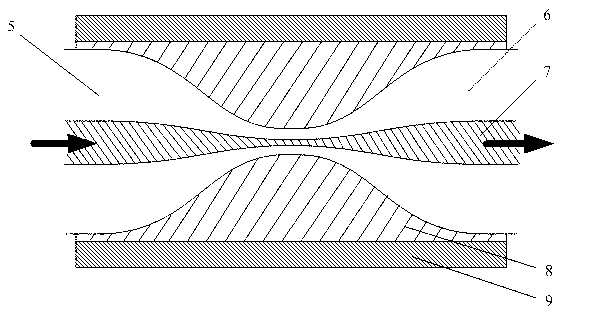

InactiveCN101161590ALiquid hydrocarbon mixture recoveryVapor condensationSeparation technologyCombined method

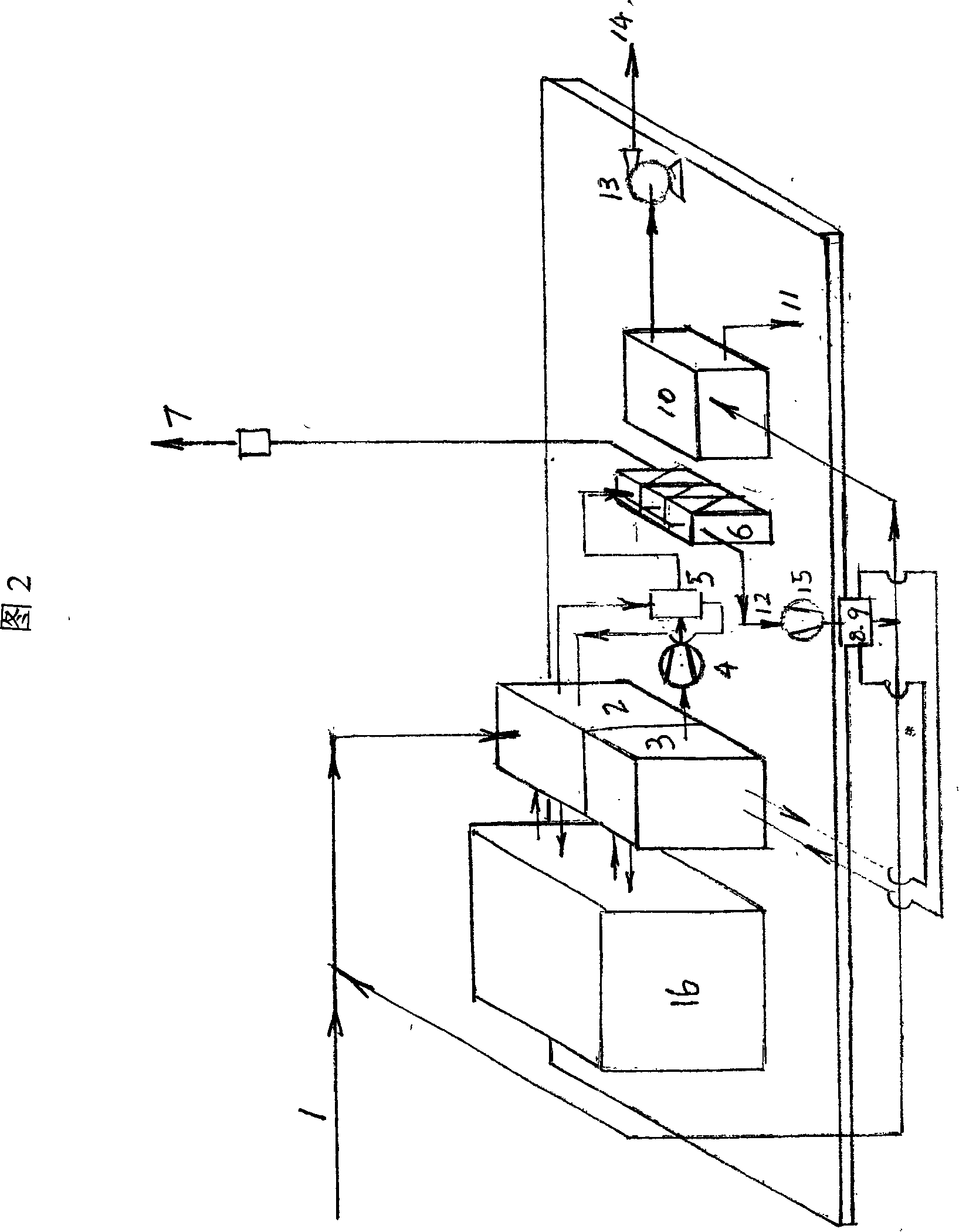

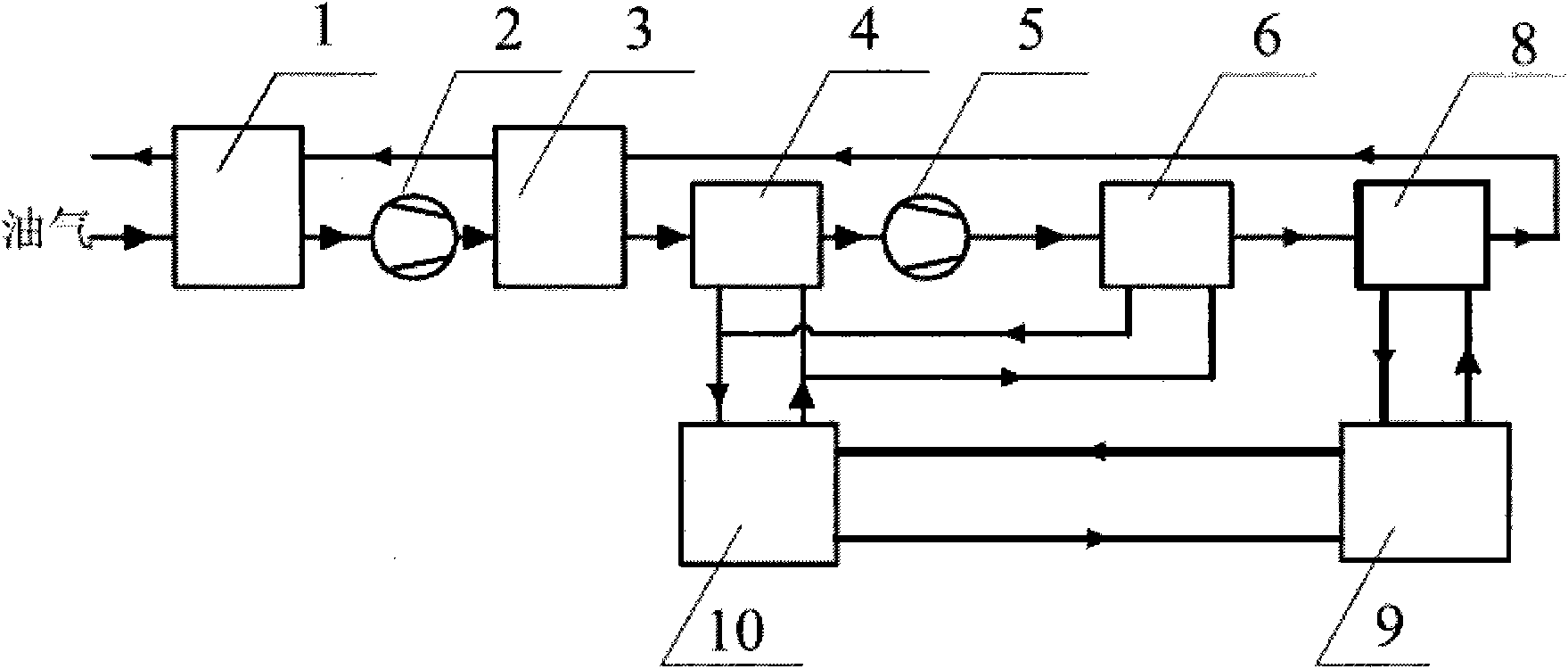

The invention relates to a condensation and film separation combination type oil gas recycling art technique which is an improvement of condensation type oil gas art technique. The invention adopts the combined method of condensation technique and film separating technique to reach discharging standards. The problem that the temperature of single condensation type oil gas recycling reaches lowers than 95 DEG C below zero is overcome. The invention belongs to the oil gas recycling technical field, and is mainly used for the oil gas recycling of oil house, city transfer oil house, gasoline and light weight oil loading and unloading process. The invention consists of a refrigeration machine set 16, a pre-cooling box 2, a middle cooling box 3, a liquid ring type compressor 4, a switch 5, a membrane module 6, a vacuum pump 15, a switch 8, a switch 9, an oil water separator 10 and an oil pump 13. According to the art flow sequence in the attached drawing 1, the refrigeration machine set 16, the pre-cooling box 2, the middle cooling box 3, the liquid ring type compressor 4, the switch 5, the membrane module 6, the vacuum pump 15, the switch 8, the switch 9, the oil water separator 10 and the oil pump 13 are connected together and are arranged on a base crowing. The construction is shown in the attached drawing 2. The three-dimensional graph of the modular structure is shown in the attached drawing 2.

Owner:王建基 +1

System and method for recovering oil gas

InactiveCN102580463AFlexible selectionExtended operating cycleDispersed particle separationRecovery methodDesorption

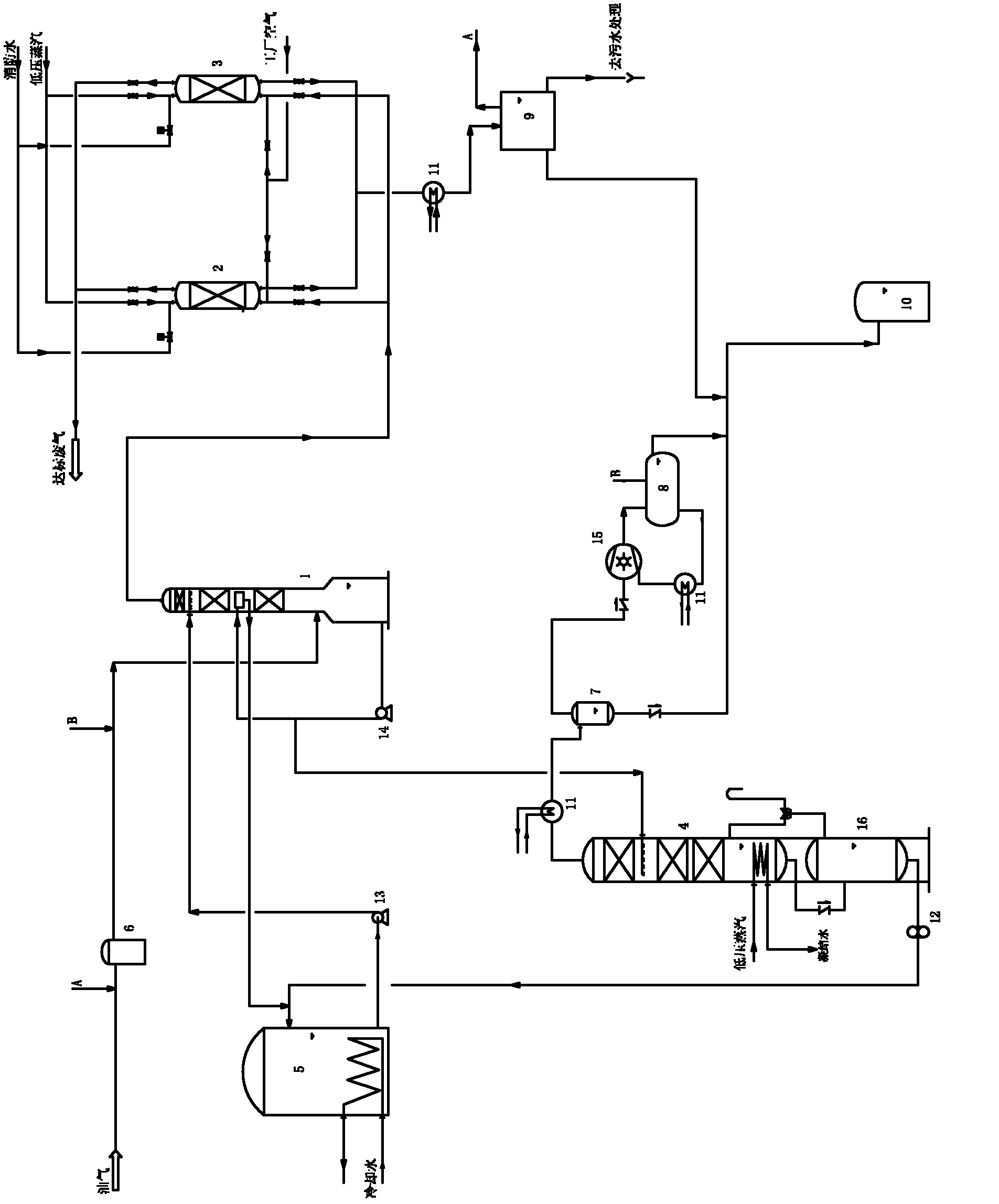

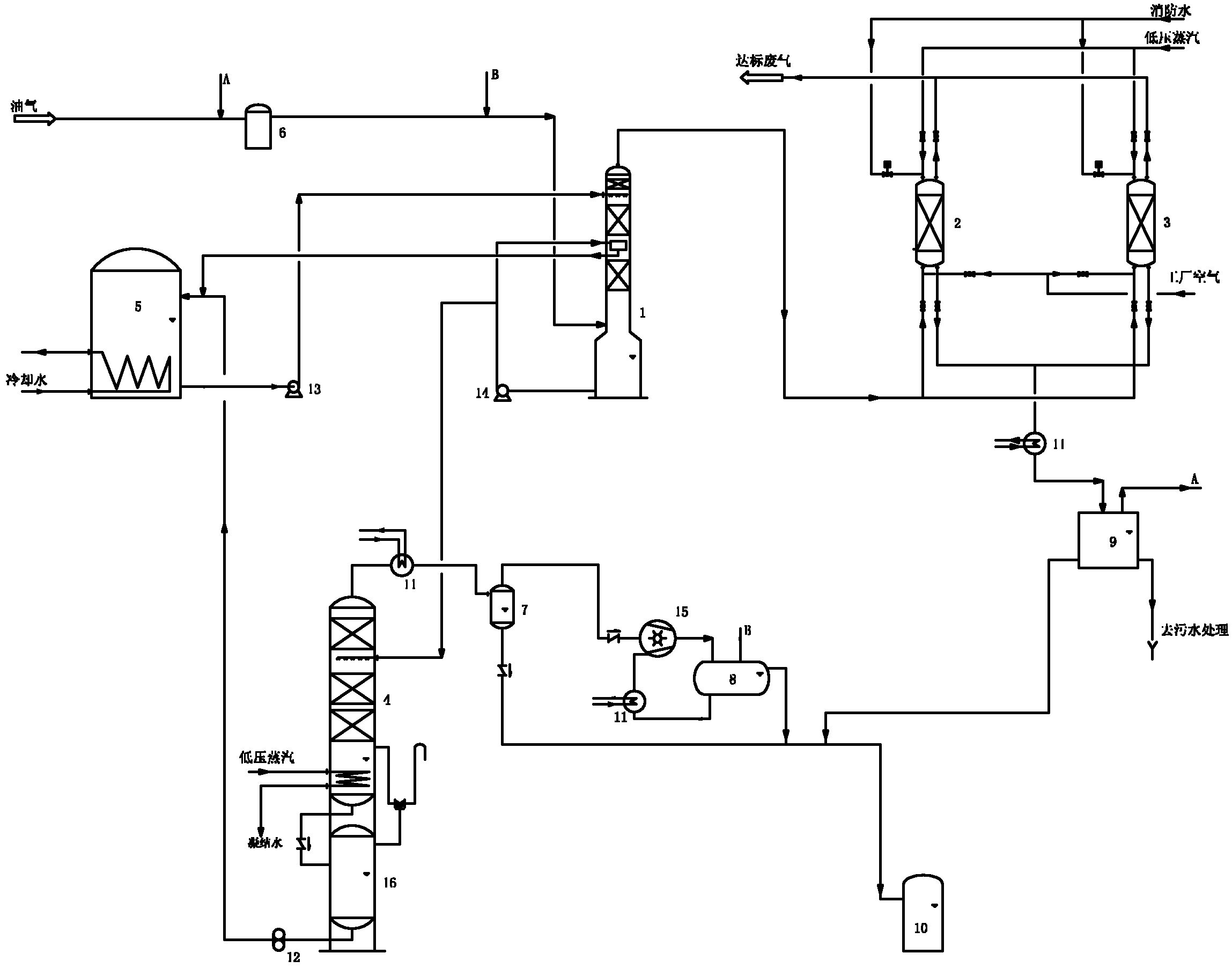

The invention relates to a recovering method and a recovering system for hydrocarbon and other volatile organic matters in refineries, chemical plants, large bulk plants, refuelling stations and the like. Oil gas is absorbed by two sections of stuffing in an absorption tower and then enters two activated carbon adsorption towers which run alternately; the oil gas reaches the standard after being absorbed by activated carbon, and then is discharged to the air; after the substance that is generated after desorption of the activated carbon is condensed and treated through oil-water separation, the obtained hydrocarbon liquid is conveyed to a storage tank, generated sewage is conveyed to a sewage treatment device to be treated, and a small amount of gas that is not condensed returns to the absorption tower; solvent that absorbs oil gas enters a desorption tower so as to desorb solvent and oil gas; and the hydrocarbon liquid is conveyed to the storage tank to be stored. The method and the system, which are provided by the invention, have the characteristics of smaller investment, longer operation period of equipment, high oil gas recovery rate and simple technological process.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

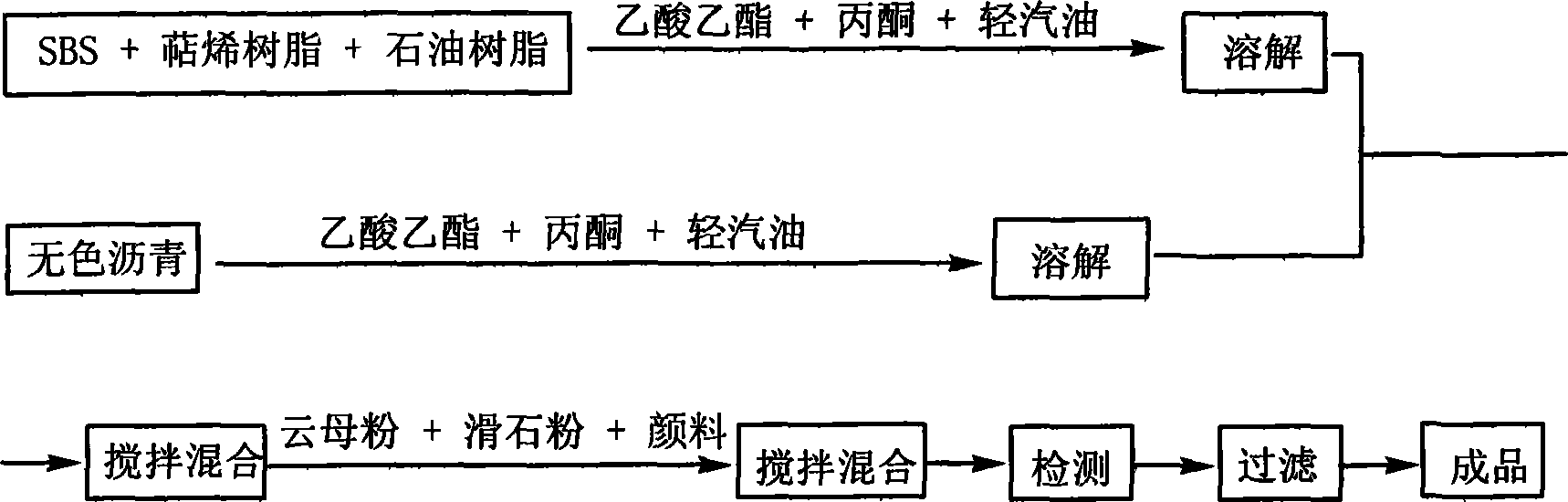

Color SBS modified waterproof asphalt material

InactiveCN101074345ASave energySimple and fast operationAntifouling/underwater paintsPaints with biocidesExtensibilityBituminous waterproofing

A color SBS modified asphalt waterproof coating with colorless asphalt as main filming substance is cheap and convenient. It adopts diamylene resin and petroleum resin as viscosity increaser and acetic ether as solvent. It saves resources, It's non-toxic, has no environmental pollution and excellent heat, freezing, ageing, water and weather resistances, has better extensibility and adhesive strength. It can be used for roof of architectures, toilet, gain depot, dam, oil depot, pipeline, swimming pool and tunnel.

Owner:ZHENGZHOU UNIV

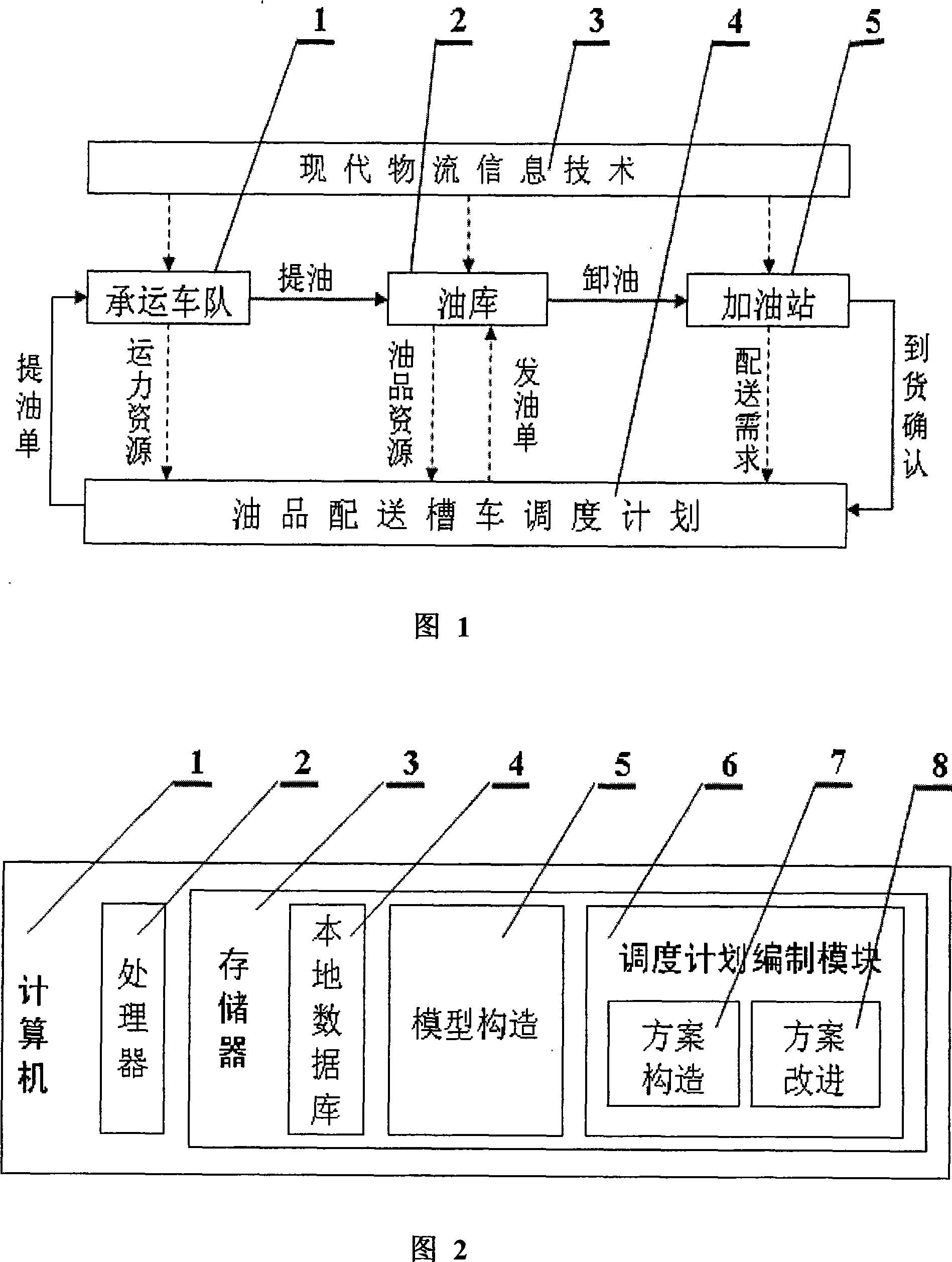

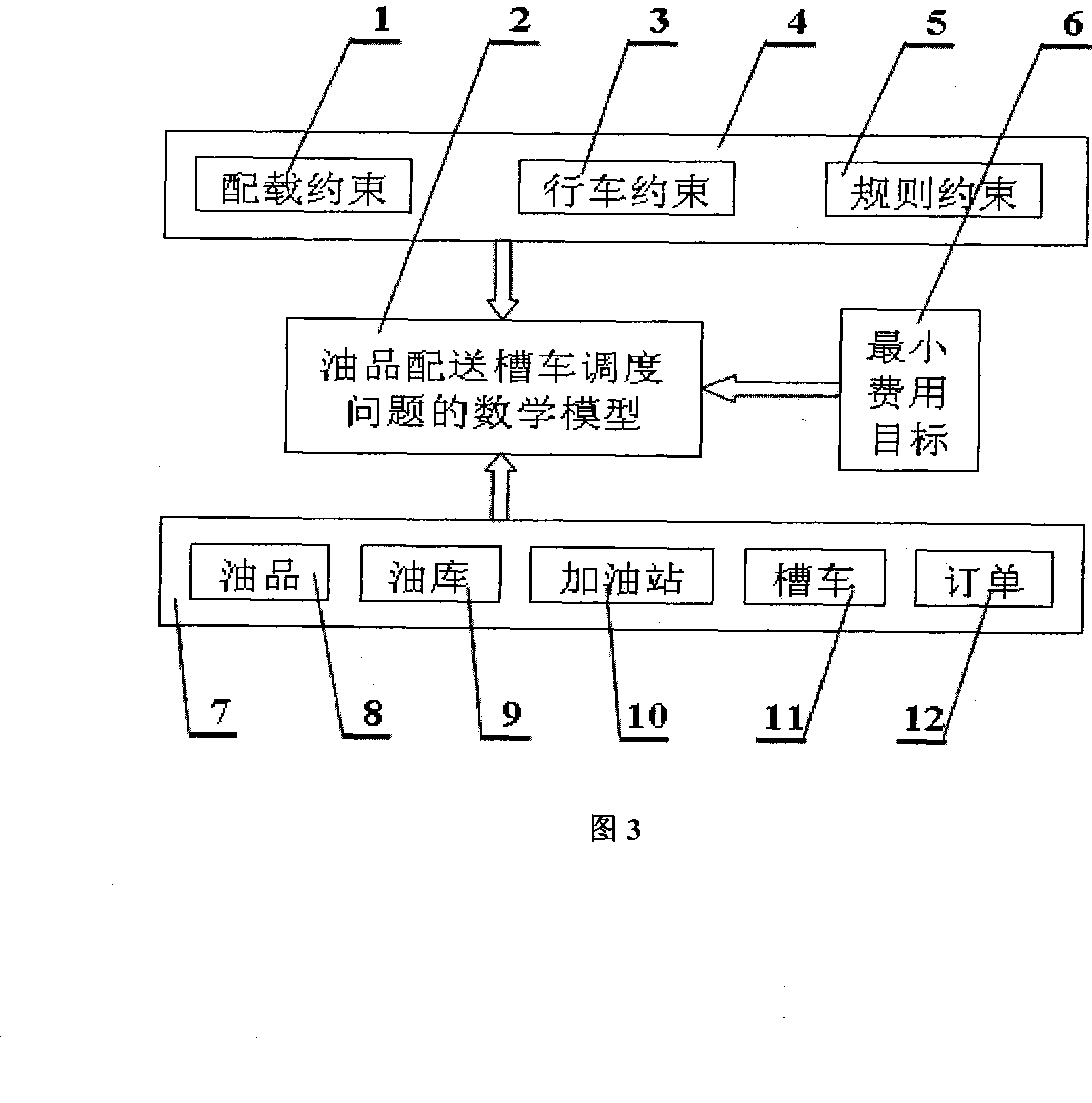

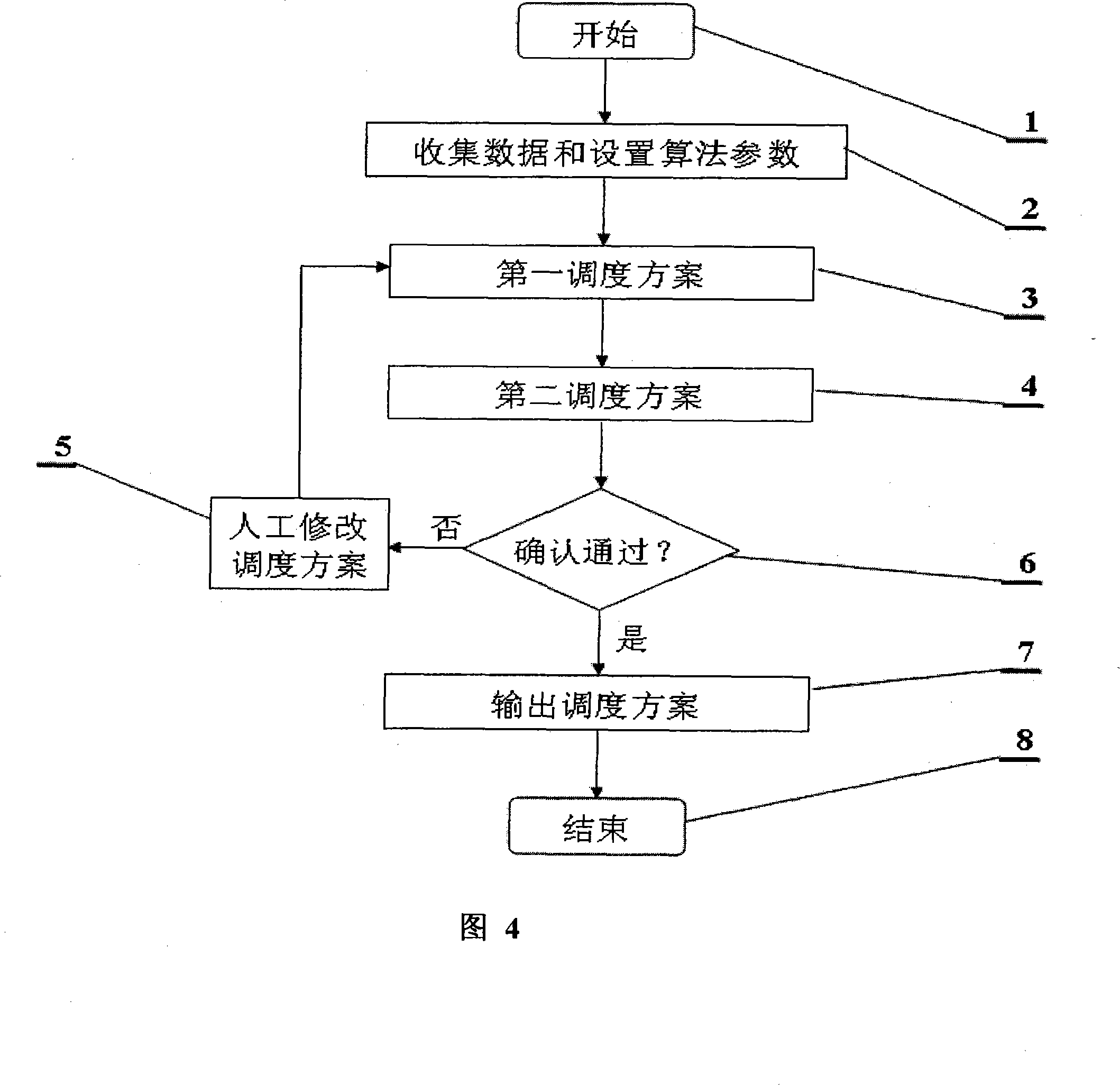

Oil products delivery cistern car scheduling system and method thereof

InactiveCN101159048AImprove the efficiency of scheduling decisionsImprove the level of flat centralized managementLogisticsLogistics managementMathematical model

The inventive method for scheduling oil product delivery receiver aims at oil product resource and transport resource; and includes scheduling a receiver, distributing cargo spaces, appointing oil-sending oil depot, scheduling the receiver running path. Socket communication mode is adopted and basic data is acquired via a materials stream information system; therefore a mathematical model, a first scheduling proposal for satisfying requirements, and a second scheduling proposal for performing optimization on the scheduling proposal are established to perform integral optimization and centralized dispatching. The advantage is that the method comprehensively considers parameters such as yards, receiver types, oil depots, oil products, cargo spaces, receiver running limits, load limits and working quantity to greatly reduce delivery cost, improve scheduling decision efficiency, promote rapid response level of the management, and delay dead-line of submitting an oil order form from a petrol filling station by 2 hours. The centralized optimization greatly increases flat centralized management level of a petrol sales company.

Owner:朱道立 +3

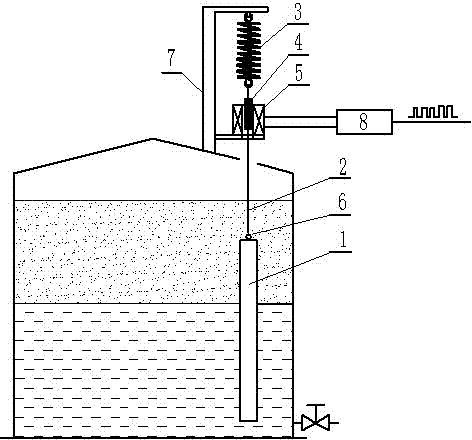

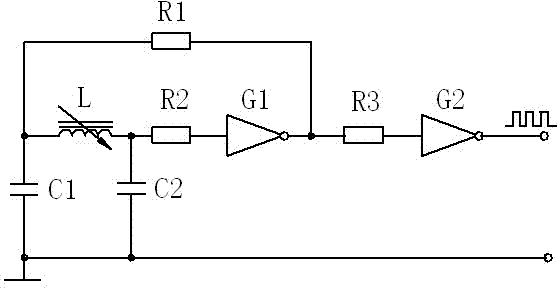

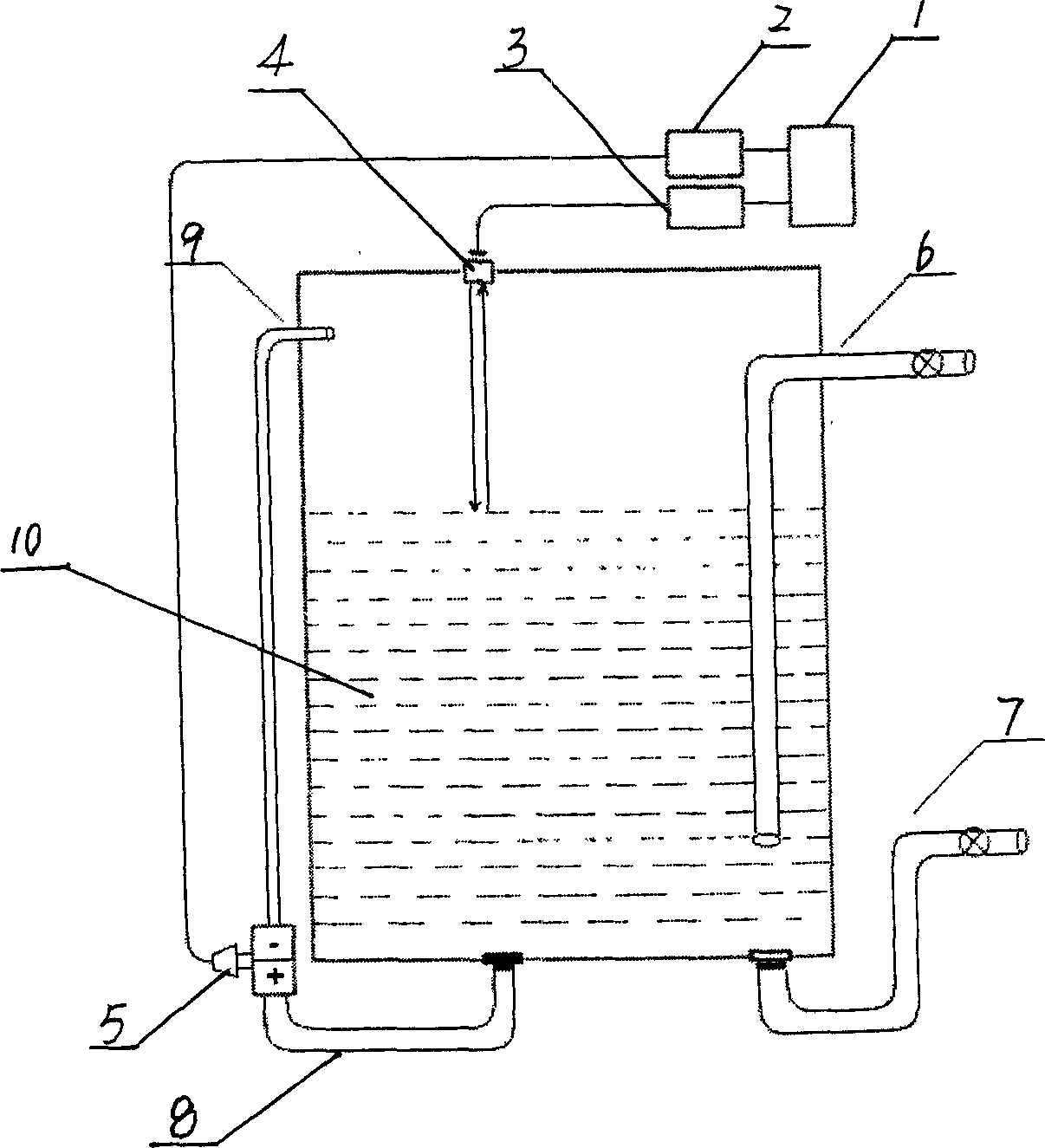

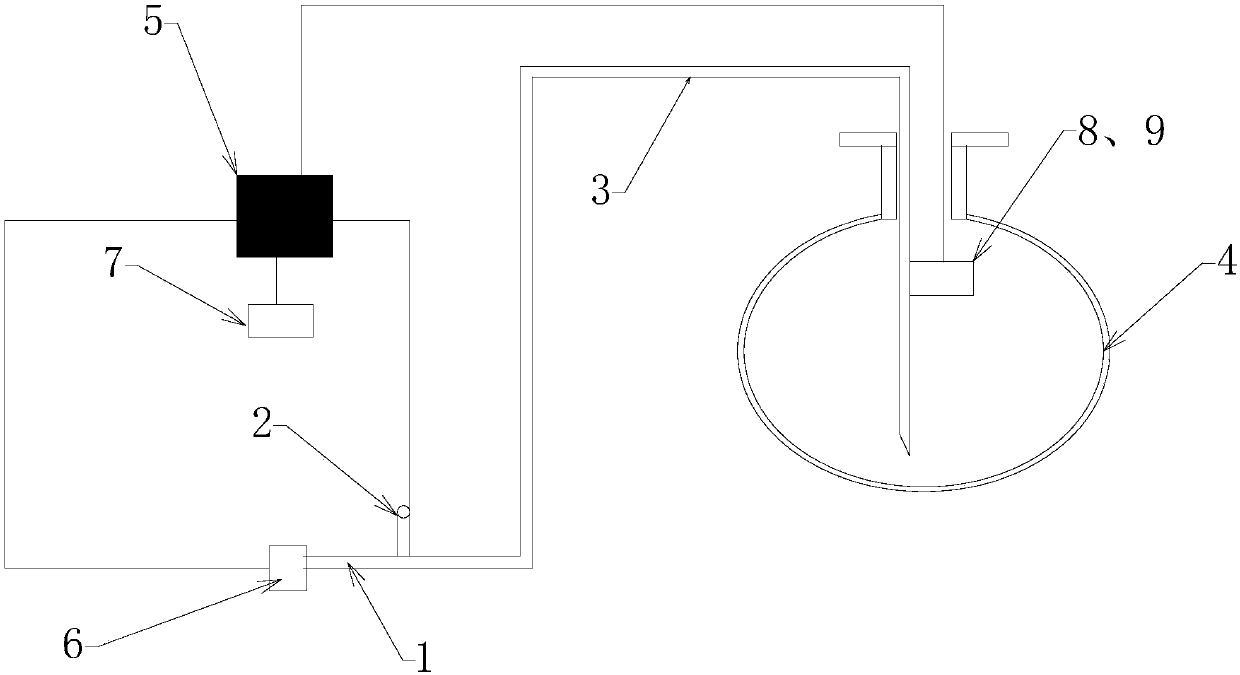

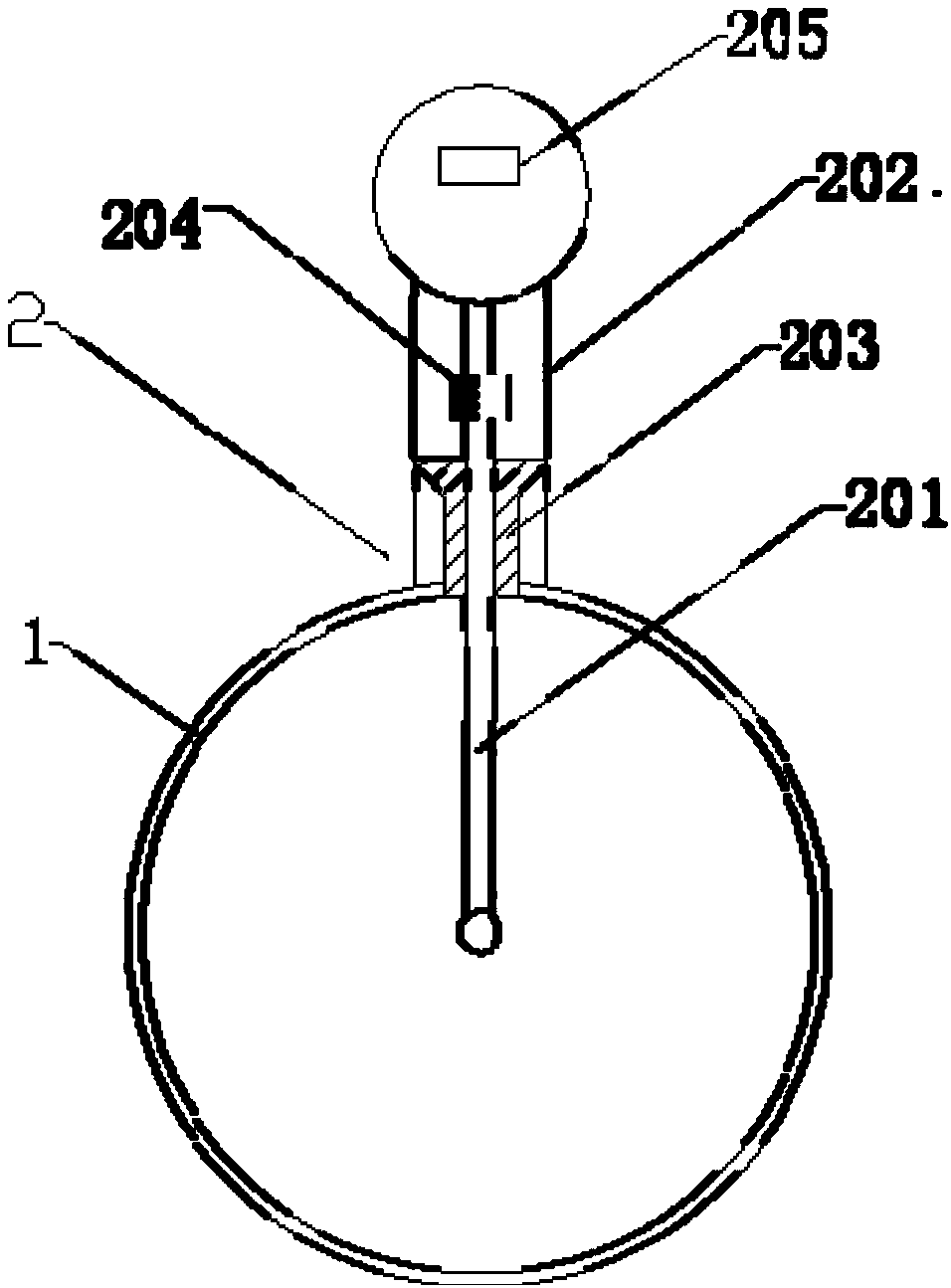

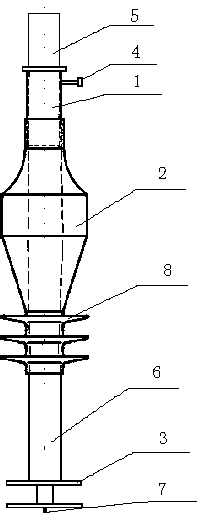

Digital oil water demarcation face height measurement sensor

The invention provides a digital oil water demarcation face height measurement sensor, and belongs to the technical field of measuring. The digital oil water demarcation face height measurement sensor is characterized in that a sensor special for measuring the height of the demarcation face of the oil and water level in an oil storage tank is provided, the entire sensor is composed of a traction mechanism, a displacement sensing unit, a float bowl and a transmitter 8, and is mainly applied to oil storage tanks of an oil refinery, a grease factory and an oil storage depot. A measuring range is the length L of the bowl body of the float bowel. The upper limit of the measuring range can not be higher than the top of the bowl body 1 of the float bowl, and the lower limit of the measuring range can not be lower than the bottom of the bowl body 1 of the float bowl. The top of the bowl body 1 of the float bowl has to be lower than the liquid level height of upper layer oil, and the float bowl is always in a submerged state. The digital oil water demarcation face height measurement sensor has the advantages that digital pulse signals are output directly, the measuring precision is high, the anti-interference capacity is strong, and the manufacturing cost is low.

Owner:TAIYUAN UNIV OF TECH

Preparing for protein foam fire-extinguisher by active sludge protein

InactiveCN1456372AReduce secondary pollutionTo overcome the shortage of raw materialsFire extinguisherSludgePetrochemical

Owner:HUBEI UNIV +1

Safe and covert high-capacity oil depot arranged underground

InactiveCN102852367ALarge storage capacityLow costBulk storage containerOperational costsLight equipment

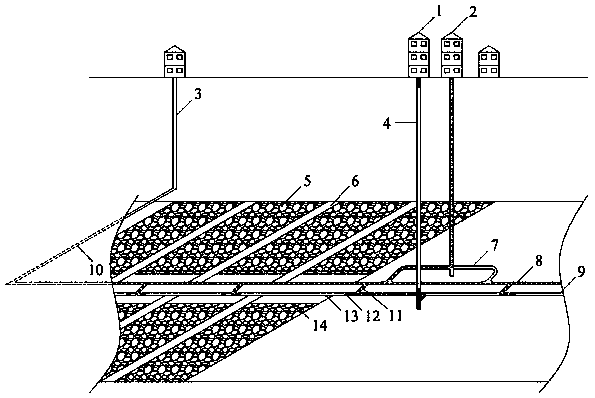

The invention discloses a technical method of a safe and covert high-capacity oil depot arranged underground. The safe and covert high-capacity oil depot arranged underground is characterized in that the oil depot is built in mines to be wasted or abandoned mines or idle tunnels, caves, cave dwellings and culverts. The oil depot is composed of a plurality of nonstandard single storage tanks, wherein the storage tanks are connected through pipelines, and tube valves are mutually communicated and isolated. An oil inlet tube and an oil outlet tube are respectively installed on the upper portion and the lower portion of a tank body and connected with an oil inlet and outlet main tube, the oil inlet tube and the oil outlet tube extend to the ground to be connected with an oil discharge device, and a buffer pump and an oil well pump are installed on the main tube. Inflaming retarding isolation protective screens are arranged among the storage tanks, and a pedestrian path is arranged on the side. Ventilation equipment, fire control equipment, lighting equipment and dewatering equipment are installed in the depot, and a camera shooting monitoring instrument and a gas automatic detecting instrument are installed. The safe and covert high-capacity oil depot arranged underground has functions of fire protection, thunder prevention, war prevention and man-made sabotage prevention, solves the problem that the prior art is large in land occupation, high in construction and operational cost, small in storage content, multiple in environmental factor influence, poor in elusive performance and poor in safety and reliability, and has safety risks on the periphery.

Owner:孔令先 +1

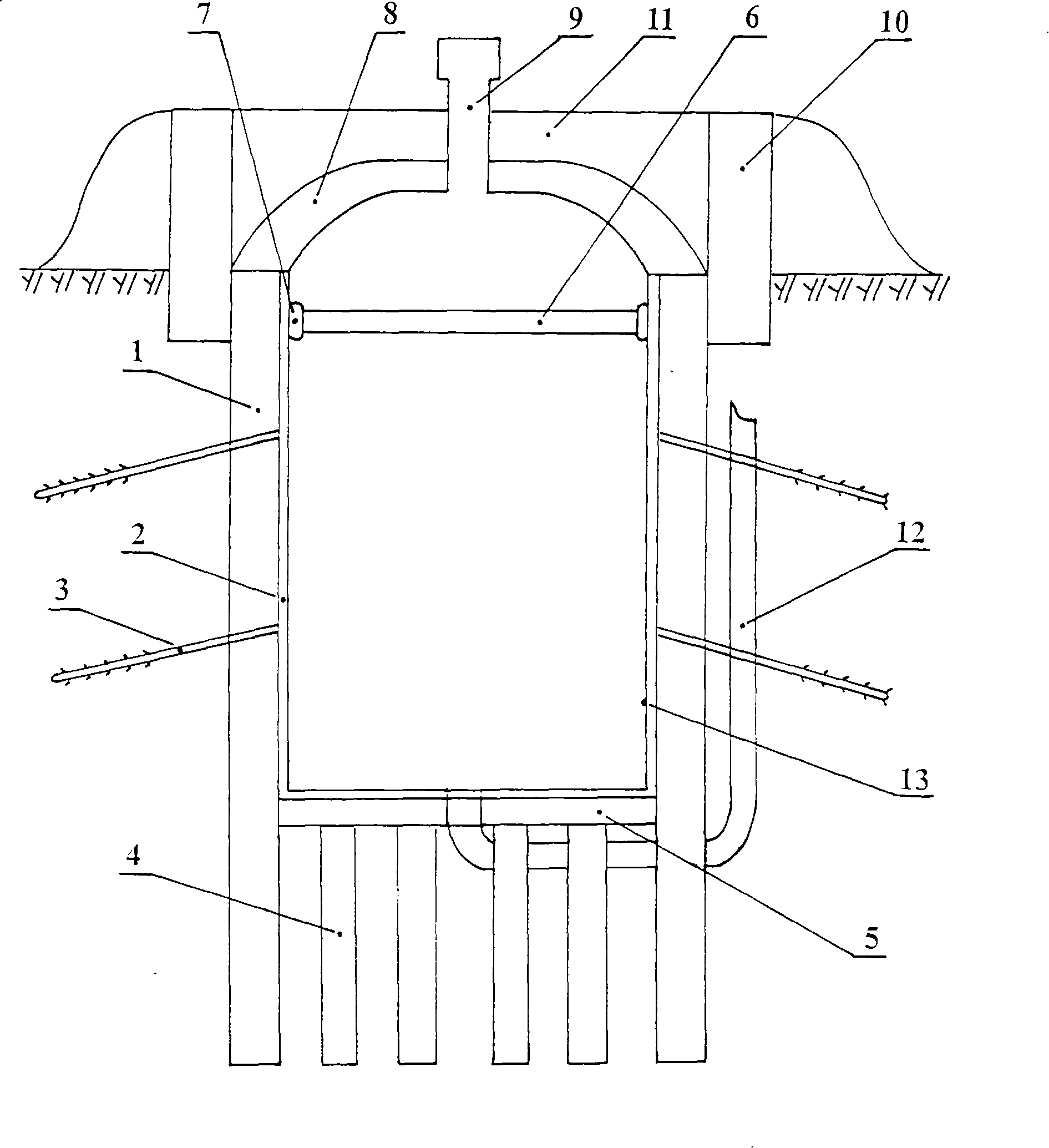

High capacity underground oil storage

InactiveCN101148951AImprove safety and reliabilityImprove reliabilityBulk storage containerSteel barSmall footprint

The great capacity underground oil reservoir has a cylindrical reservoir with floating roof and closed prestress dome structure; an integral foundation comprising a pile footing, anchor shafts, a concrete layer and a steel plate layer; a cylindrical wall comprising curtain piles, a concrete layer, a steel plate layer and anchor shafts; and a reservoir bottom comprising a pile footing, a reinforcing concrete floor and a steel plate layer. It has steady foundation, high integral strength, capacity as large as 400 kilo cubic meters, high safety, low construction cost and other advantages.

Owner:曾建军

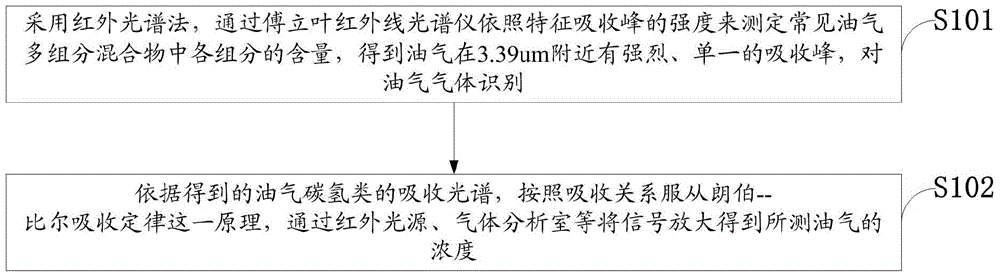

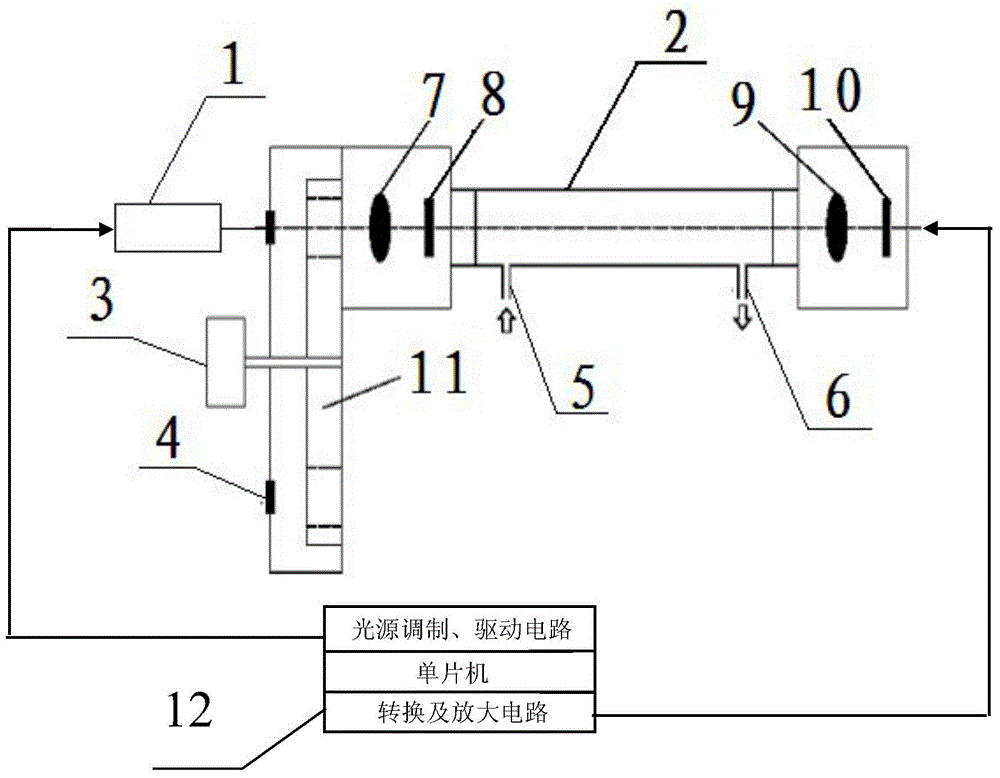

Infrared spectrum-based detection method of large-space oil gas concentration of oil house

The invention discloses an infrared spectrum-based detection method of the large-space oil gas concentration of an oil house. An infrared spectroscopy is adopted, the content of each component of a common oil gas multicomponent mixture (gasoline, diesel oil, kerosene and the like) is determined by a fourier transform infrared spectrometer according to the intensity of a characteristic absorption peak, an obtained absorption spectrum of oil gas hydrocarbons follows a lambert-bill absorption law according to an absorption relation, and a signal is amplified by virtue of an infrared light source, a gas analysis chamber, a circuit system and the like, so as to obtain the detected oil gas concentration. According to the detection method, the fourier transform infrared spectrometer is sent into a test analysis unit in an active extraction mode, and an explosion-proof analyzer can be installed in a safe area out of an oil can by adopting onsite pipeline suction on sampling, and thereby the risk of the oil gas analysis is greatly reduced, the condition that no circuit system is within a hazard source is guaranteed and the ignition caused by measurement is avoided.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

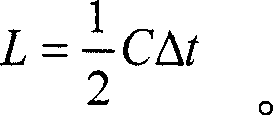

Finished oil water ratio on-line real time measuring method and apparatus

InactiveCN1811404ASimple compositionAnalysing fluids using sonic/ultrasonic/infrasonic wavesSpecific gravity by measuring pressure differencesMeasurement deviceDifferential pressure

The present invention discloses an on-line real-time measurement method of finished oil water content and its measurement equipment. Said measurement equipment includes the following several portions: tank dome, ultrasonic probe, ultrasonic level measuring device, liquid pressure intensity pressure-guiding pipe, air pressure intensity pressure-guiding pipe, pressure difference sensor, differential pressure measuring device and computer. Said invention also provides its working principle and its operation method and steps.

Owner:SOUTHEAST UNIV +1

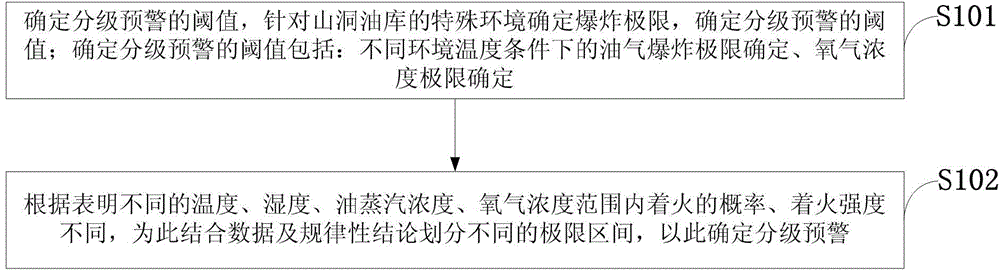

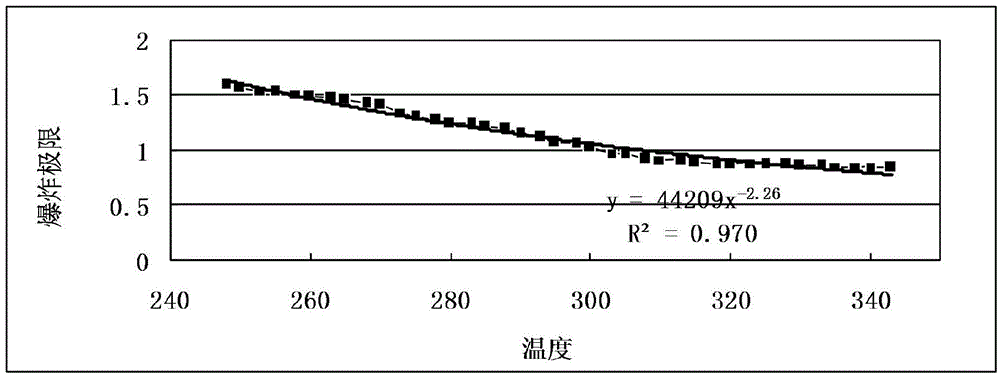

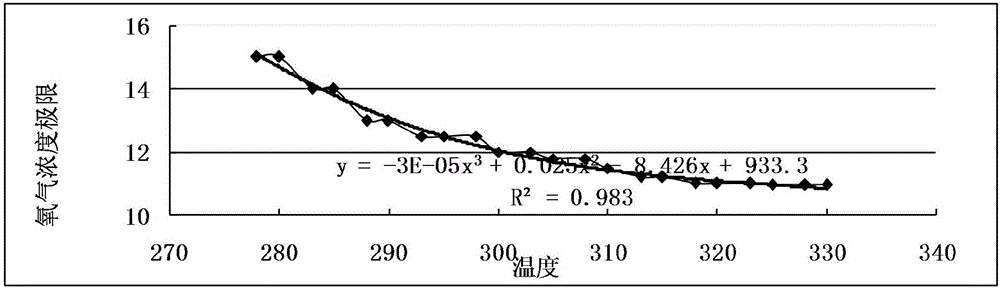

Grading early warning method of oil gas hazard source of oil house in cave

InactiveCN104090089ASimple methodEasy to operateMaterial testing goodsOxygenUltimate tensile strength

The invention discloses a grading early warning method of an oil gas hazard source of an oil house in a cave. The method comprises the steps: determining grading early warning thresholds expressing different firing probability values and firing intensity values within different temperature ranges, humidity ranges, oil vapor concentration ranges and oxygen concentration ranges, and dividing different limit intervals by combining experimental data and regular conclusions, so as to determine grading early warning, so that the grading early warning which aims at the oil gas hazard source of the oil house in the cave is realized. The grading early warning method has the advantages of simplicity and convenience in operation, the blank that the grading early warning method of the oil gas hazard source of the oil house in the cave is in shortage at home is made up, and reference data are provided for the oil storage of the oil house in the cave.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Oil gas recovery method

ActiveCN101342427BHigh recovery rateMeet stringent environmental requirementsDispersed particle separationVapor condensationEmission standardOil terminal

The present invention relates to an oil gas recovery method. The oil gas recovery method adopts an oil gas-reclaiming technique including cooling, condensing, adsorption, vacuum regeneration and regenerated gas circulation, and the cooling medium used by the cooling step adopts the condensed oil gas. Compared with the prior art, the oil gas-reclaiming method has the advantages of high oil gas recovery rate, low energy consumption, no potential safety hazards, etc., and the tail gas can measure up to the emission standard. The oil gas recovery method is applicable to the oil gas recovery in cases such as oil loading and unloading on vehicles or boats, oil cut-off at crude oil depots and large and small tank breathing.

Owner:CHINA PETROLEUM & CHEM CORP +1

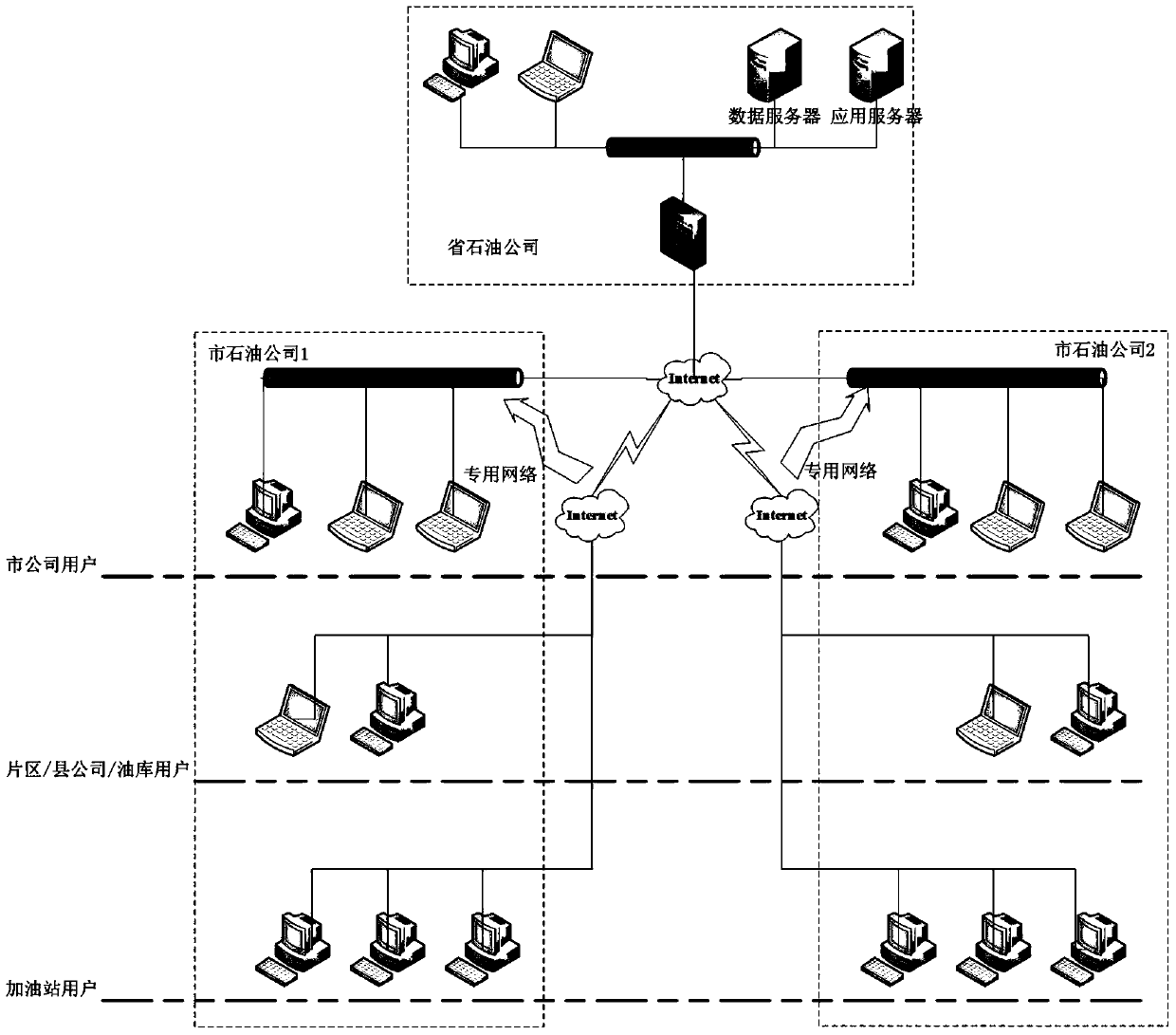

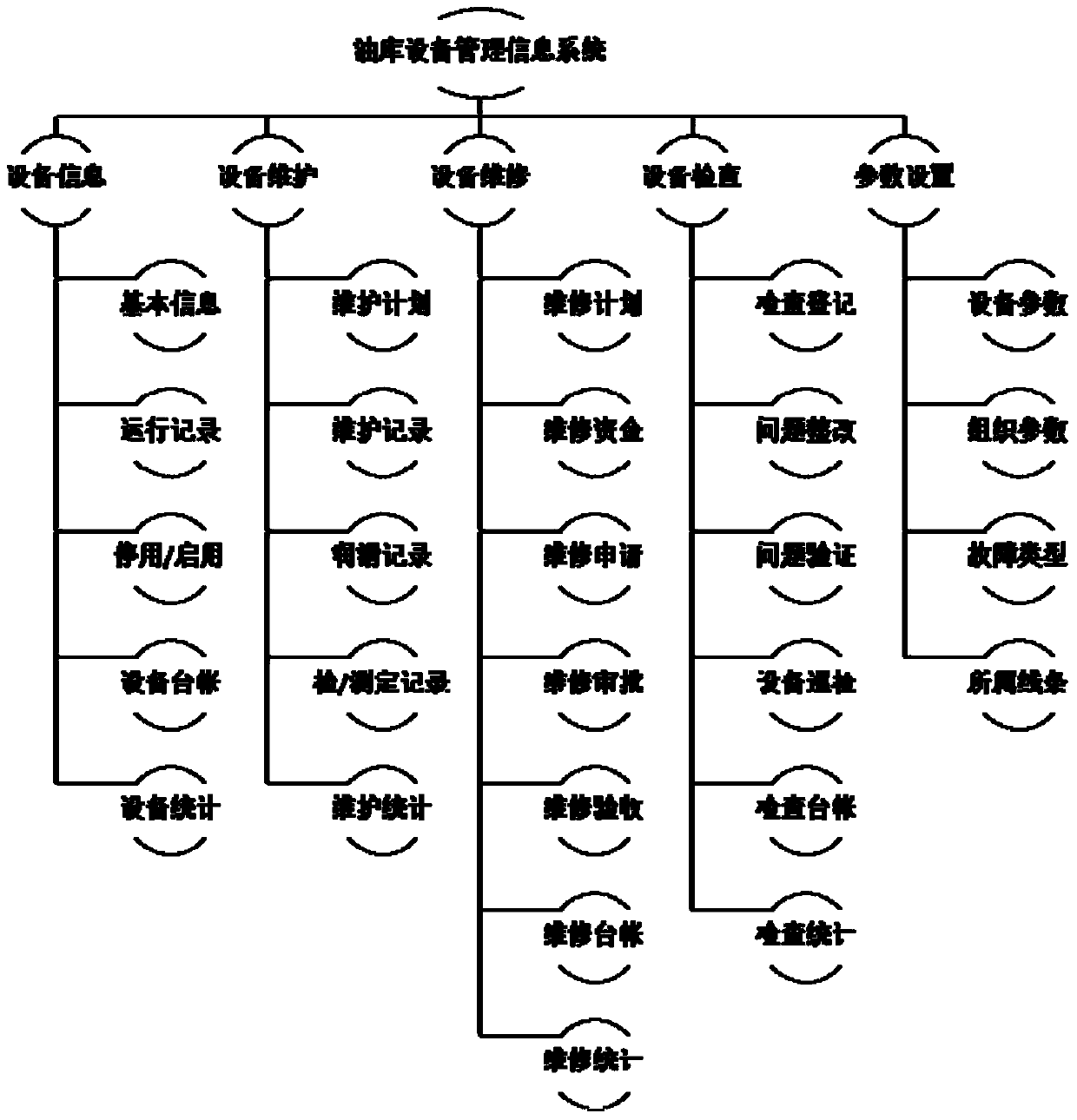

Safety management method for equipment in oil depot and gas station

InactiveCN104200307AImprove safety management levelGuaranteed uptimeResourcesStatistical analysisThe Internet

The invention relates to a safety management method for equipment in an oil depot and a gas station. The safety management method mainly solves the problems that the administrative department cannot obtain dynamic information of the equipment in the oil depot and the gas station in time in the prior art, the position of the equipment is difficult to trace after being migrated and changed, the setting of equipment maintenance plane is a rule of thumb, the maintenance cost management cannot be controlled accurately and comprehensive statistic analysis for the equipment condition cannot be performed. By adopting the safety management method for the equipment in the oil depot and the gas station, a user logs in a safety management platform for the equipment in the oil depot and the gas station through the Internet or an enterprise private network, so that the safety management for the equipment is completed; the safety management platform for the equipment in the oil depot and the gas station comprises a hardware part and a software part, a technical scheme composed of the gas station, the oil depot and a superior oil company solves the problems better, and the method can be used in the safety management for the equipment in the oil depot and the gas station.

Owner:CHINA PETROLEUM & CHEM CORP +1

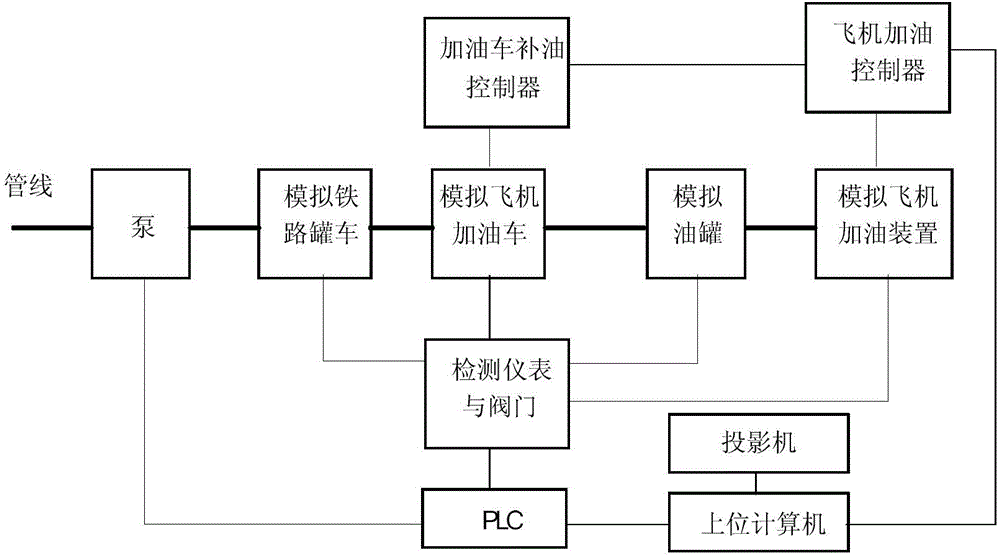

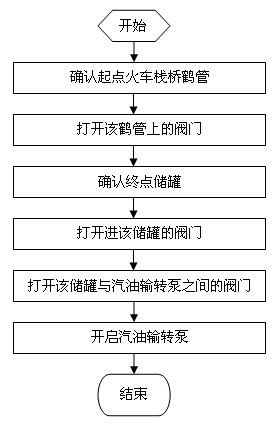

Airport oil depot work simulating and training system

InactiveCN104157176AEasy to analyze operation rationalityImprove operational efficiencyCosmonautic condition simulationsSimulatorsWork functionSimulation

The present invention discloses an airport oil depot work simulating and training system. The airport oil depot work simulating and training system comprises an airport oil depot technical process simulator, an airport oil depot work process simulator, an airport oil depot fault simulator, an airport oil depot automated work simulator and an airport oil depot automated work function simulator. The beneficial effects are that: firstly, the system can simulate the airport oil depot manual and automated work flows, train the manual operation and automated operation programs, and display the change cases of the technical processes and the process parameters visually by utilizing a water medium and by the transparent pipelines, tanks, instrument and pipeline accessories; secondly, the system can train the emergency processing capability of the students by setting various faults; finally, the system can record and reproduce the operation steps and parameter setting of the students by a computer system, is convenient to analyze the operation rationality of the students, and enables the operation efficiency to be improved.

Owner:中国人民解放军空军勤务学院

Condensation method for oil gas recovery

ActiveCN101793456ARaise the minimum condensing temperatureImprove the shortcomings of low energy efficiency ratioSolidificationLiquefactionRecovery methodGasoline

The invention relates to a condensation method for oil gas recovery, belonging to the technical field of energy utilization, environment safety, environment protection, and the like. The invention adopts an oil gas recovery method of multi-stage condensation, interstage pressurization and low-temperature tail gas cooling capacity recovery and realizes the recovery of volatile oil gas. The method has the high recovery efficiency, and can effectively save the energy source, and a system used in the method has low cost, simple structure, long service life and easy operation. The invention can be applied to recovery of volatile oil gas of crude oil, gasoline and the like with lower carbon content in the occasions of gas stations, oil storages, oil fields and the like.

Owner:TSINGHUA UNIV +1

Method for building underground oil depot by utilizing abandoned coal mine well lane

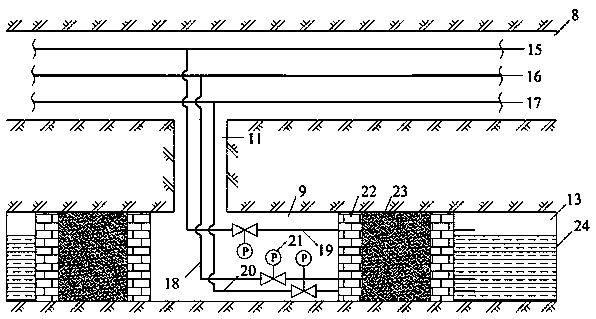

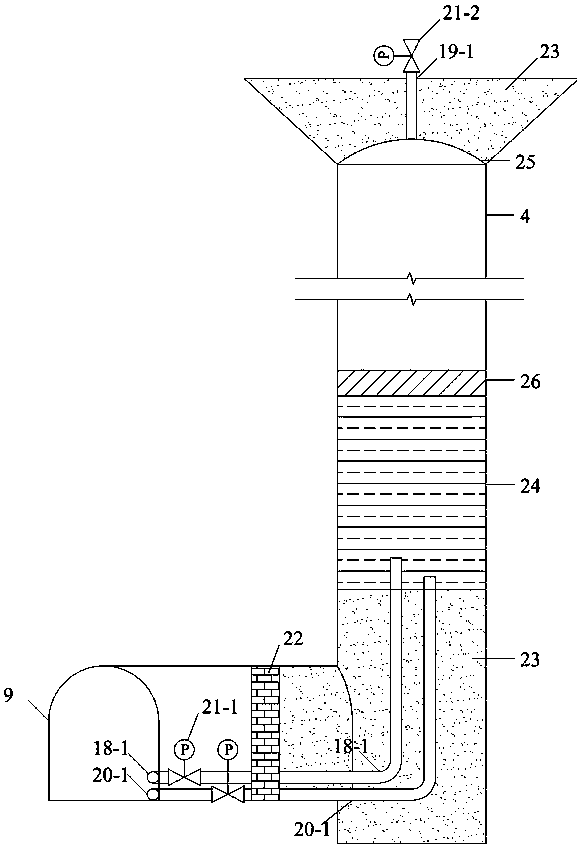

The invention discloses a method for building an underground oil depot by utilizing an abandoned coal mine well lane. The method for building the underground oil depot by utilizing the abandoned coalmine well lane comprises the steps of collecting geological data in the period of coal geology exploration, laneway exploiting and coal mining, and determining distribution characteristics of rock stratums, faults and fractures in a shaft and a laneway; determining oil permeability characteristics of the shaft and the laneway penetrating through the rock stratums with different lithology, and judging whether the rock stratums has oil storage conditions or not; carrying out leaking stoppage on the faults, the fractures and the high-permeability coal rock stratums, and preventing stored oil leakage; building a sealed space in a rubber belt main laneway, and isolating the rubber belt main laneway into oil depot chambers with different lengths ranging from 200 to 300m; through reconstructing the bottom part and a wellhead of a main well, enabling the main well to become a complete oil depot well; and reconstructing a power supply system, a ventilating system and a drainage system in an abandoned mine well, and meeting the demands of firefighting, ventilating and water supplying and draining functions of the oil depot. According to the method for building the underground oil depot by utilizing the abandoned coal mine well lane provided by the invention, the underground space resources of the abandoned mine well are fully utilized, and the built underground oil depot has the characteristics of concealment, safety and strategic performance.

Owner:ANYANG INST OF TECH

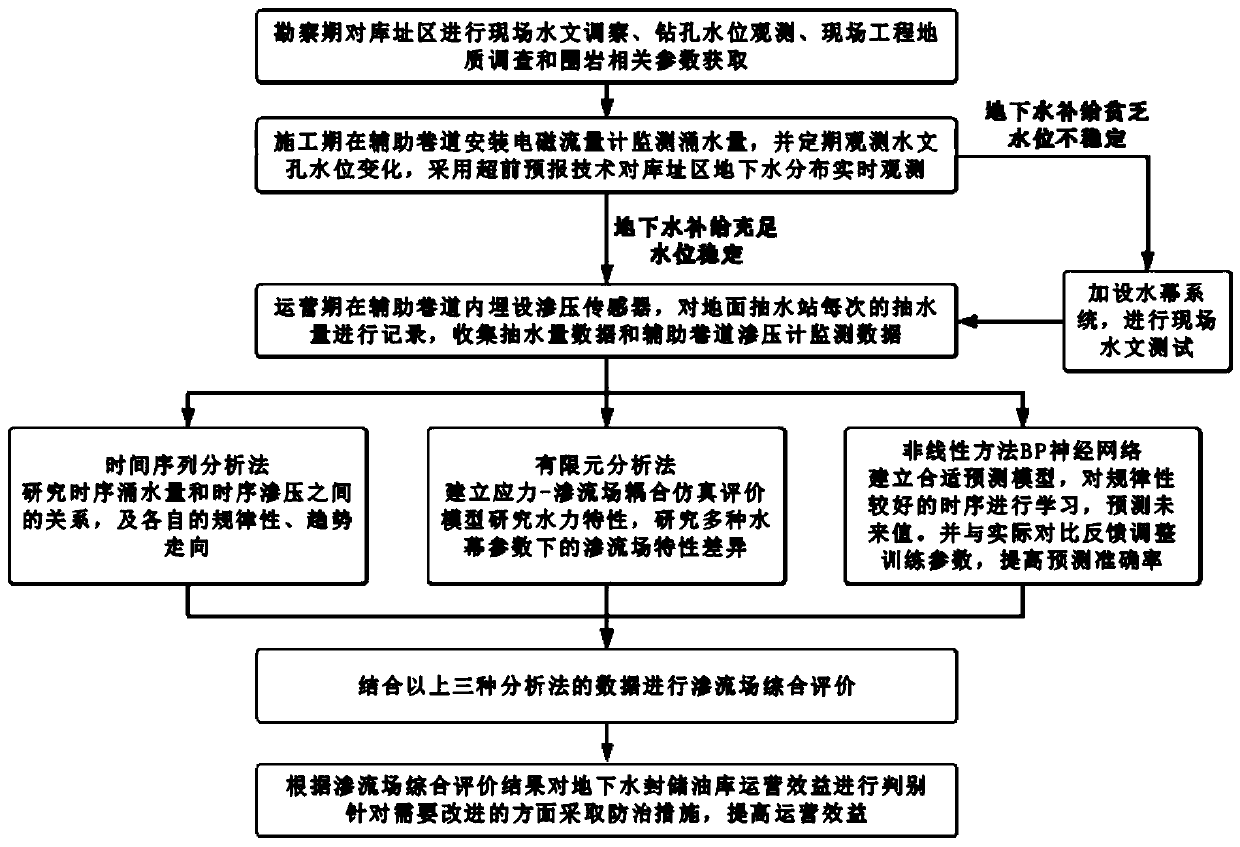

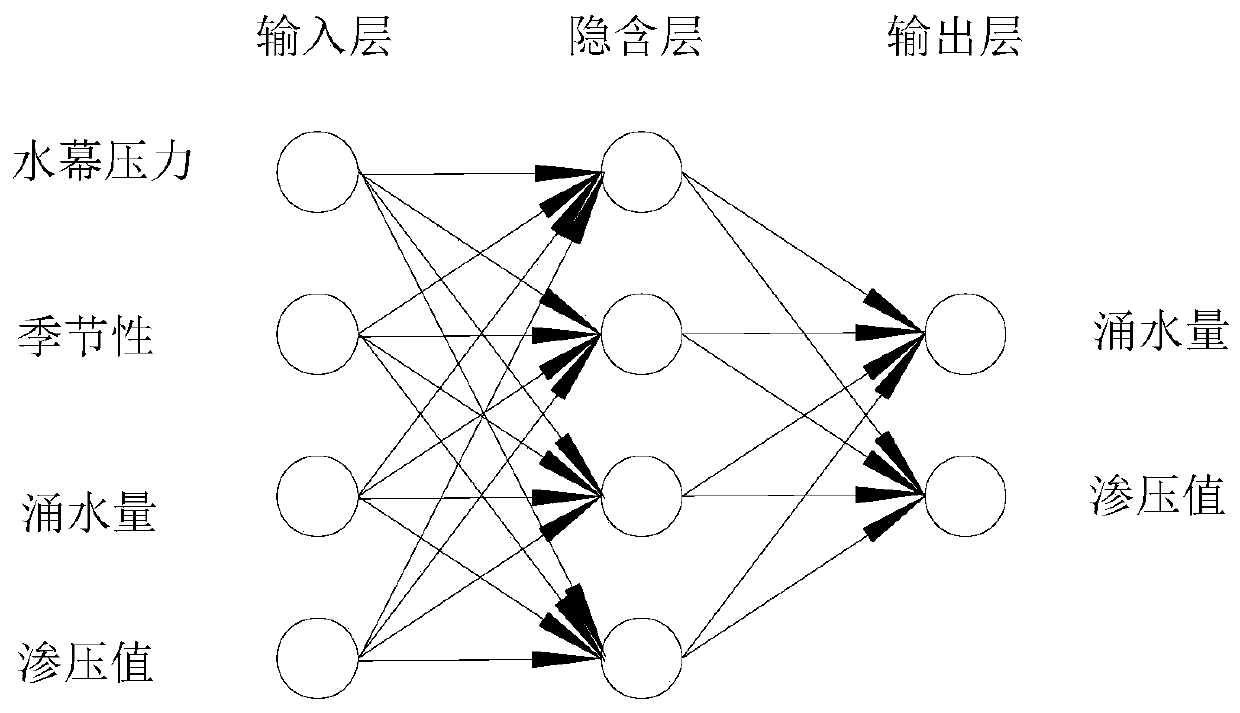

Comprehensive evaluation and prevention method for seepage field of operation-period underground water-sealed oil storage

ActiveCN111260216AAddressing Spill RisksSolve the excessive water gushing in the oil storage cavernGeometric CADDesign optimisation/simulationHydrometrySequence analysis

The invention discloses a comprehensive evaluation and prevention method for a seepage field of an underground water seal oil storage in an operation period, and the method combines engineering geology and hydrogeological reports, and obtains hydrological survey data in a survey period. The daily water inflow of the reservoir site area is counted by combining the construction period with the actual situation, and the drilling water level change value is periodically observed and recorded. And underground water distribution of an unexcavated surrounding rock area is detected through a geological advanced prediction method, and whether a water curtain system is additionally arranged or not is judged. The pumping capacity of the water pump station and the osmotic pressure value of the oil storage cavern surrounding rock during operation are counted. A time sequence analysis method, a finite element analysis method and a nonlinear method BP neural network are combined, comprehensive analysis and evaluation are conducted on the seepage field of the underground oil depot in the operation period, the benefit of a water curtain system is evaluated, and an adjustment scheme is given.

Owner:SHANDONG UNIV

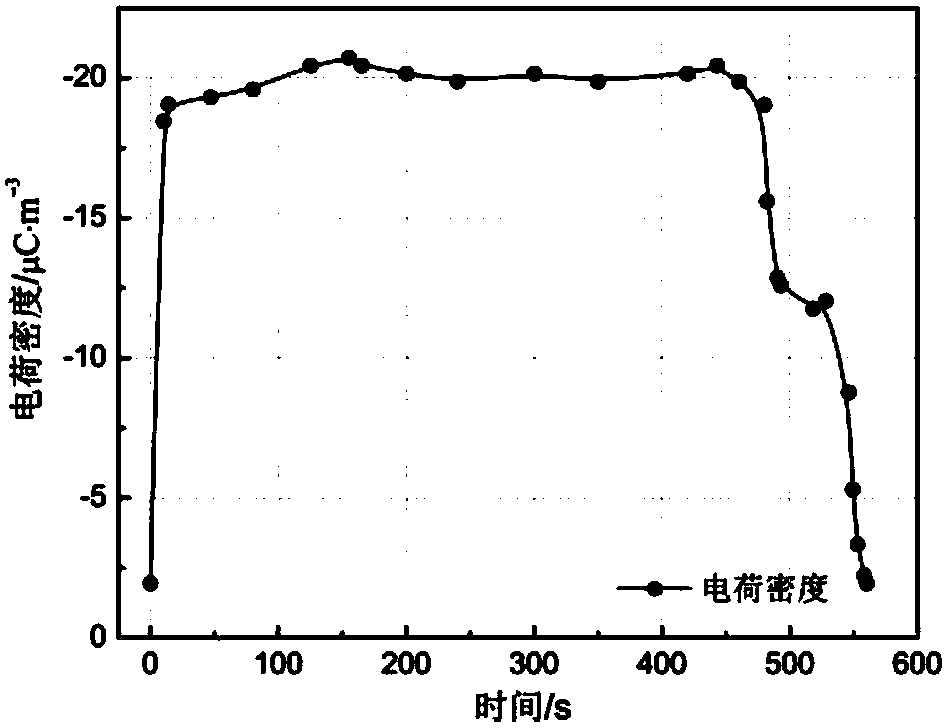

Oil depot oil-loading electrostatic monitoring system

InactiveCN108020730AAvoid accumulationReal-time monitoring of electrostatic groundingElectrostatic field measurementsMonitoring systemData acquisition

The invention provides an oil depot oil-loading electrostatic monitoring system, which comprises an oil-loading unit, an oil-loading pipeline, a crane pipe, an oil tank, an oil flow charge density meter and a control unit, wherein the oil-loading unit is connected with the crane pipe through the oil-loading pipeline, the crane pipe is inserted into the oil tank, the oil-loading pipeline is provided with the oil flow charge density meter, and the control unit is in signal connection with the oil flow charge density meter and the oil-loading unit. The beneficial effects are that the oil flow charge density meter monitors the charge density of the oil flow in the oil-loading pipeline in real time and realizes real-time monitoring for the oil flow electrostatic charge quantity and variations thereof, an electrostatic grounding monitoring unit monitors electrostatic grounding conditions of the oil tank of a tank truck in real time, an oil surface potential monitoring unit monitors oil surface potential conditions inside the oil tank in real time, and a liquid level monitoring unit monitors liquid level conditions of an oil product in the oil tank in real time so as to enable the liquidlevel of the oil product to be kept within a safe height; and the oil depot oil-loading electrostatic monitoring system is safe, convenient, quick and accurate in data acquisition, and facilitates thestaff to know the electrostatic state of the oil product in real time so as to take measures timely to prevent electrostatic potential safety hazards.

Owner:CHINA PETROLEUM & CHEM CORP +1

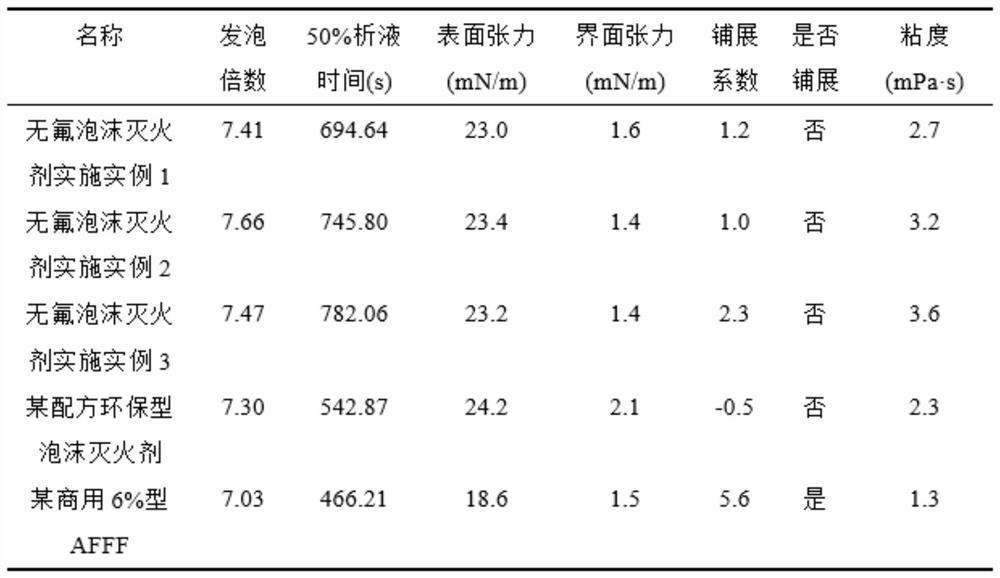

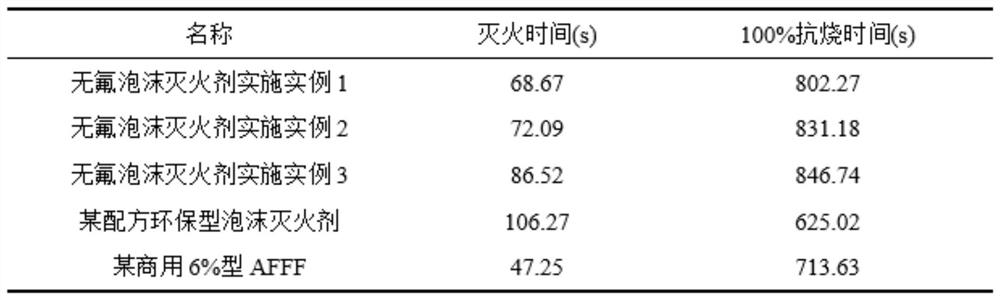

Environment-friendly fluoride-free foam extinguishing agent and preparation method thereof

InactiveCN111991744AImprove stabilityImprove fire extinguishing efficiencyFire extinguisherEthyleneglycol monobutyl etherActive agent

The invention belongs to the technical field of fire extinguishing materials, particularly relates to an environment-friendly fluoride-free foam extinguishing agent and a preparation method thereof, and solves the problems that a traditional extinguishing agent in the prior art is toxic, not environment-friendly and limited in application range, and a fluorocarbon surfactant, a chelating agent andthe like used in an existing foam extinguishing agent are harmful to the environment. The technical scheme of the invention is as follows: the environment-friendly fluoride-free foam extinguishing agent is formed by mixing a foam concentrate liquid and water according to the volume ratio of 6:94; and the foam concentrate liquid includes the following ingredients: a modified organic silicon surfactant, lauryl sodium sulfate, alkyl glycoside, water-soluble imidazoline, dodecyl dimethyl betaine, dodecanol, polyethylene glycol, xanthan gum, sodium carboxymethylcellulose, ethylene glycol, urea, diethylene glycol monobutyl ether and water. According to the product, a traditional fluorocarbon surfactant is replaced with the modified organic silicon surfactant, so that the product is green and pollution-free, and can be widely applied to fire prevention key units such as oil fields, oil depots, ships, submarines, petrochemical plants, hangars, airports and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Tapered optical fiber temperature sensor and sensing probe manufacture method thereof

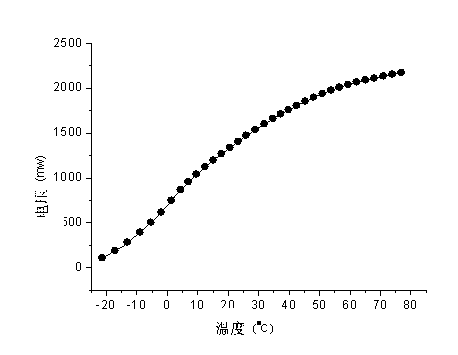

InactiveCN102735368AChange the refractive indexHigh test sensitivityThermometer detailsThermometers using physical/chemical changesEngineeringMechanical engineering

The present invention relates to a tapered optical fiber temperature sensor and a sensing probe production method thereof. The temperature sensor comprises a tapered optical fiber temperature sensing probe. An input terminal of the tapered optical fiber temperature sensing probe is connected with a light source. An output terminal of the tapered optical fiber temperature sensing probe is connected to a signal processing unit through an optical detector. When a cone zone ambient temperature of the tapered optical fiber temperature sensing probe changes, a cone zone evanescent field changes correspondingly, so that an optical power outputted by the tapered optical fiber temperature sensing probe is changed. The optical detector converts an optical signal outputted by the tapered optical fiber temperature sensing probe into an electric signal and sends the electric signal to the signal processing unit, and temperature information is obtained through voltage conversion. The sensor and the method have the advantages of simple structure and high sensitivity, the sensing probe is easy to manufacture and low in cost, and is suitable for diverse industrial, agricultural, scientific research occasions of oil depot tank group temperature monitoring, power system temperature monitoring, mine tunnel fire monitoring, greenhouse granary temperature monitoring, building structure health monitoring and the like.

Owner:SHANGHAI UNIV

Terminal for partial discharge tests on crosslinked polyethylene power cable of 10 kV or lower

ActiveCN103869227AEasy to installQuick installationTesting dielectric strengthElectrical conductorHigh tension line

The invention relates to a terminal for partial discharge tests on a crosslinked polyethylene power cable of 10 kV or lower. The terminal comprises a stress ring, a voltage-sharing sleeve and a high-voltage connecting voltage-sharing ring. Screws for fixing the stress ring to a cable shielding layer are arranged on the stress ring. The joint of the cable shielding layer and an insulator is sleeved with the lower end of the stress ring. An insulating cable core is sleeved with the voltage-sharing sleeve. A semiconductor connector of the voltage-sharing sleeve is connected with the lower end of the stress ring. Two to four umbrella skirts are arranged on the voltage-sharing sleeve. The upper end of the high-voltage connecting voltage-sharing ring is connected with a cable core conductor of the insulating cable core. Screws for fixing the high-voltage connecting voltage-sharing ring to the cable conductor are arranged on the high-voltage connecting voltage-sharing ring. The lower end of the high-voltage connecting voltage-sharing ring is provided with a high-voltage connector connected with a high-voltage cable. Due to the terminal, the test terminal can be conveniently and rapidly installed, material consumption is low, and the terminal can be repeatedly used. The peeling and cutting length of the ends of the crosslinked polyethylene power cable is decreased, time for peeling and cutting the cable and installing the terminal is effectively shortened, the test efficiency is improved, damage caused by a freon terminal to the environment is avoided, and test stability is improved compared with an oil terminal.

Owner:SHANGHAI HUAPU CABLE

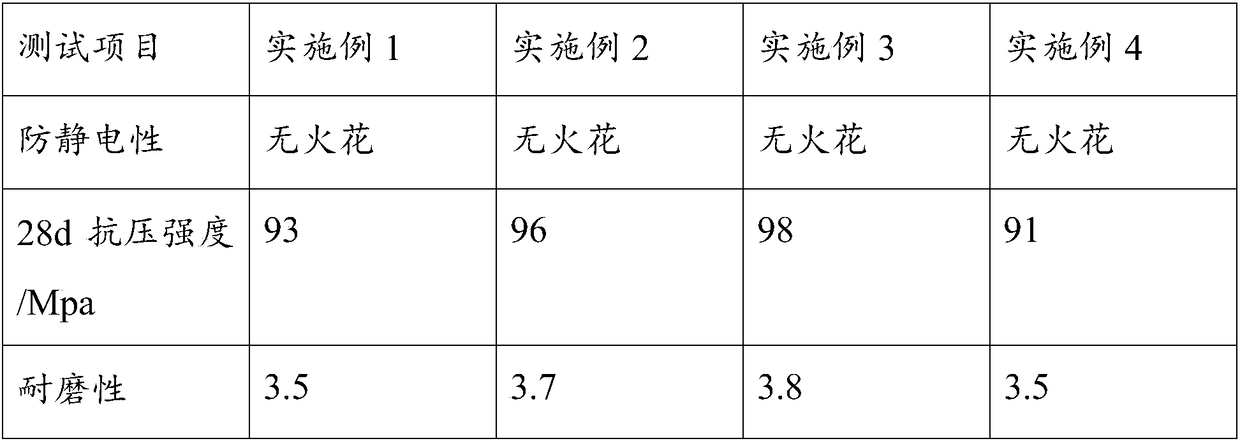

Antistatic spark-free metal wear-resistant floor material and preparation method thereof

The invention provides an antistatic spark-free metal wear-resistant floor material and a preparation method thereof, wherein the antistatic spark-free metal wear-resistant floor material comprises, by mass, 3.1-4.5 parts of cement, 5.1-6.8 parts of, 0.1-0.6 part of a concrete admixture, and 0.01-0.1 part of an electric conduction material. According to the present invention, the antistatic spark-free metal wear-resistant floor material has effects of static electricity resistance, no spark and explosion prevention, and contains the spark-free metal aggregate and the electric-conduction material so as to effectively prevent static sparks; and the prepared floor cannot produce sparks under a certain height or a certain speed impact or wear with iron tools or grinding wheels, has the anti-static performance meeting the national standard requirement, has advantages of high ground strength and good wear resistance, and can be widely used in the ground of areas with high ground and wall requirements in military industry, petrochemical industry, coal chemical industry, oil depots, gas station terminals, aerospace, aerospace, microelectronics and other high-tech industries.

Owner:北京安信三通防静电工程技术有限公司

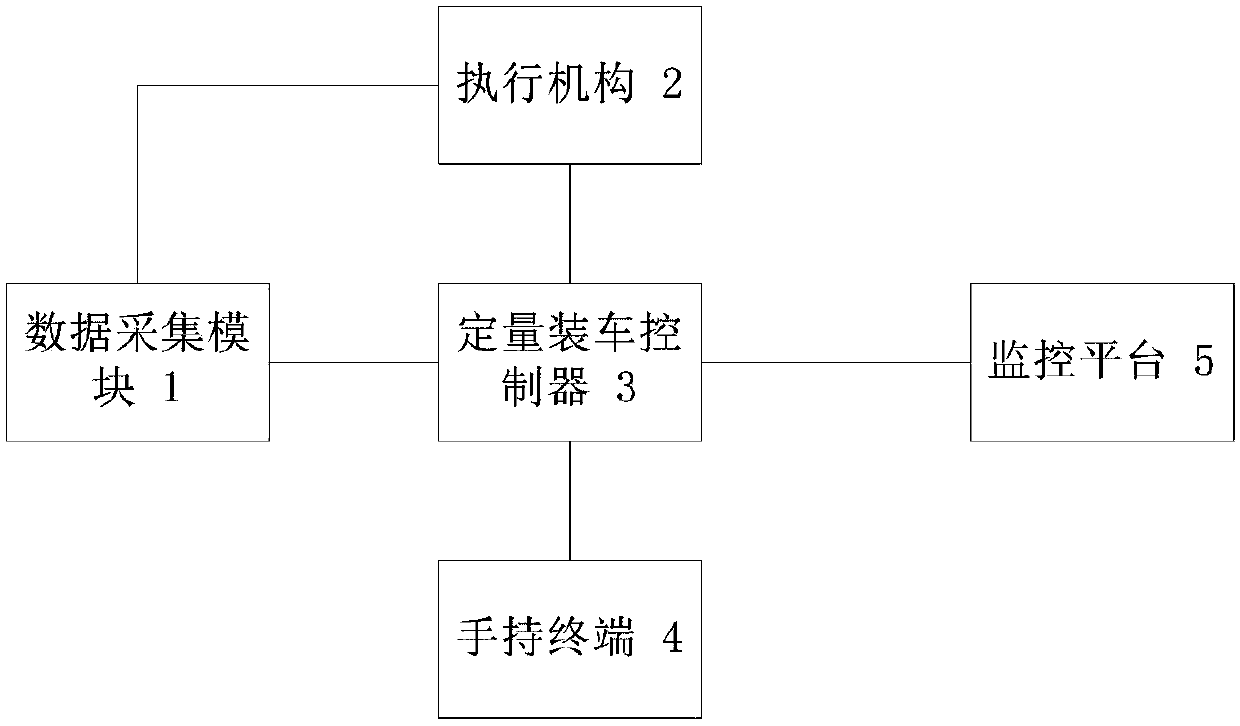

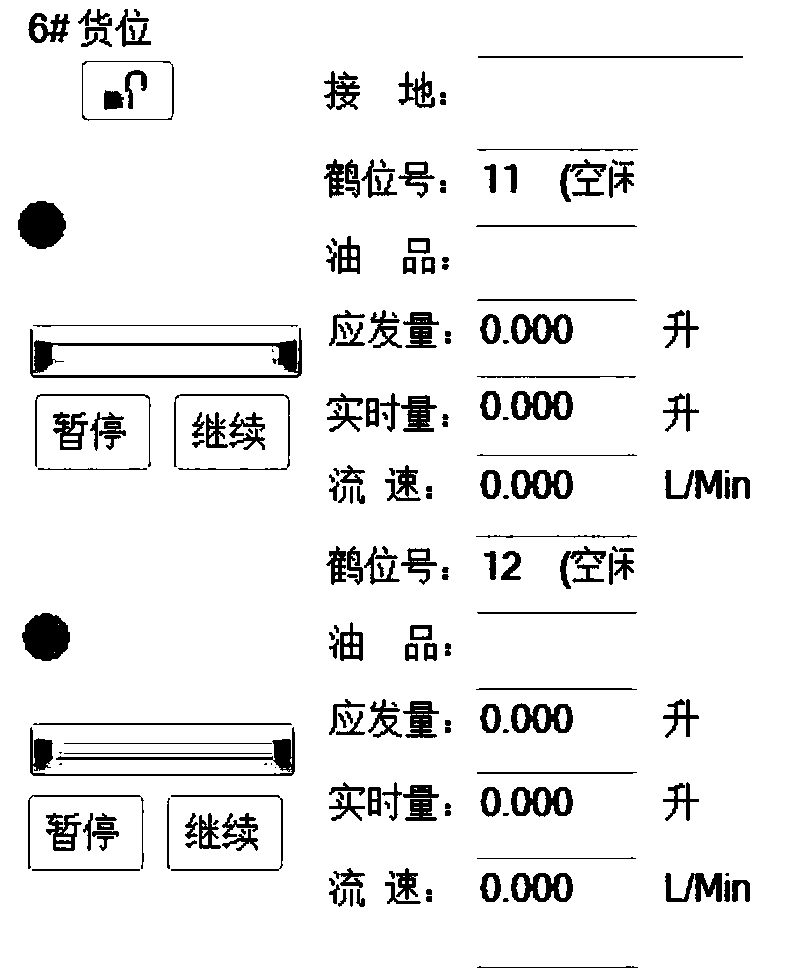

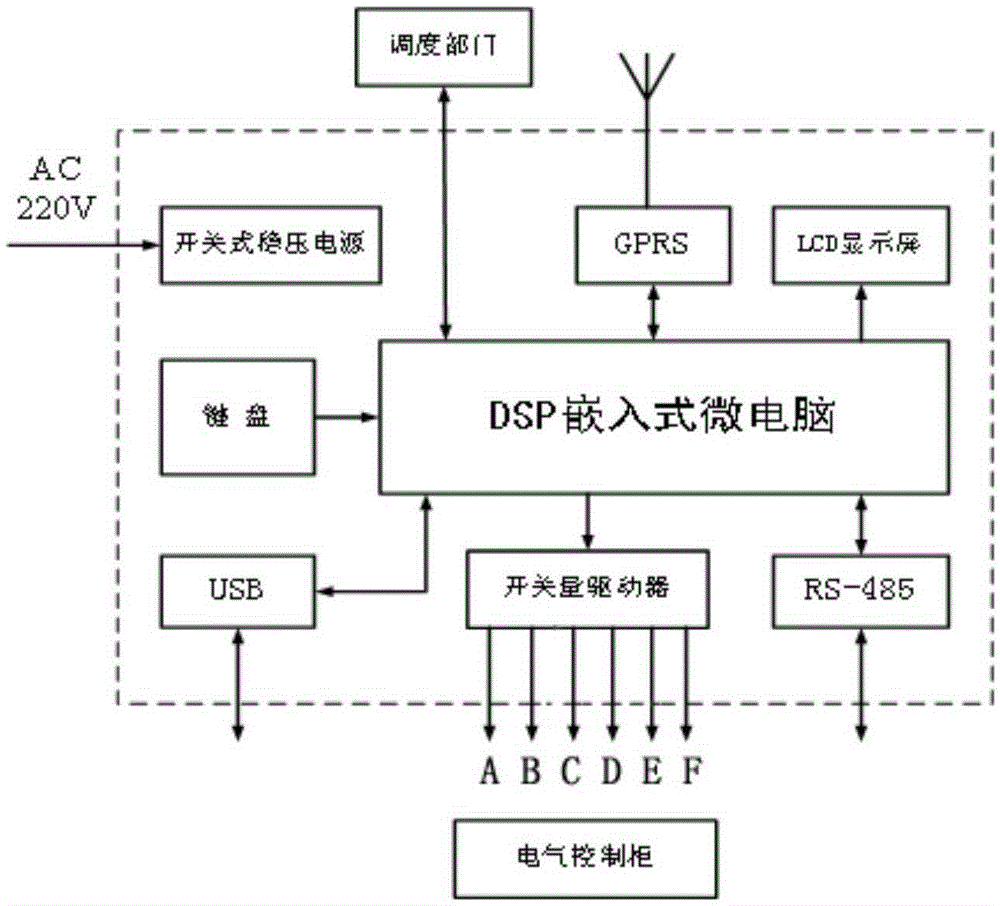

Intelligent oil delivery monitoring system and monitoring method thereof

InactiveCN107450440AImprove securityRealize the whole network sharingProgramme controlComputer controlMonitoring systemData acquisition

The invention provides an intelligent oil delivery monitoring system and a monitoring method thereof. The system includes a data acquisition module, a quantitative loading controller, an executing mechanism, and a monitoring platform. The data acquisition module is installed in the executing mechanism and is used for acquiring working parameters and uploading the working parameters of the executing mechanism to the quantitative loading controller. The quantitative loading controller is used for receiving an oil extraction application form sent by a user, converting the oil extraction application form into an oil extraction instruction, and sending the oil extraction instruction to the executing mechanism for oil delivery operation. The monitoring platform is used for regularly inspecting a set monitoring model of the data acquisition module and timely checking potential safety problems through the regular inspections to assist oil depot managers in safety supervision and safety responsibility confirmation. Through the sharing of monitoring results, the whole network sharing of oil depot information is achieved, through the arrangement of alarm devices and anti-overflow electrostatic devices, oil depot safety facilities and the entire monitoring system are connected in a co-ordination manner, and the comprehensive safety supervision is achieved.

Owner:天津市毅进通用石油工业设备有限公司

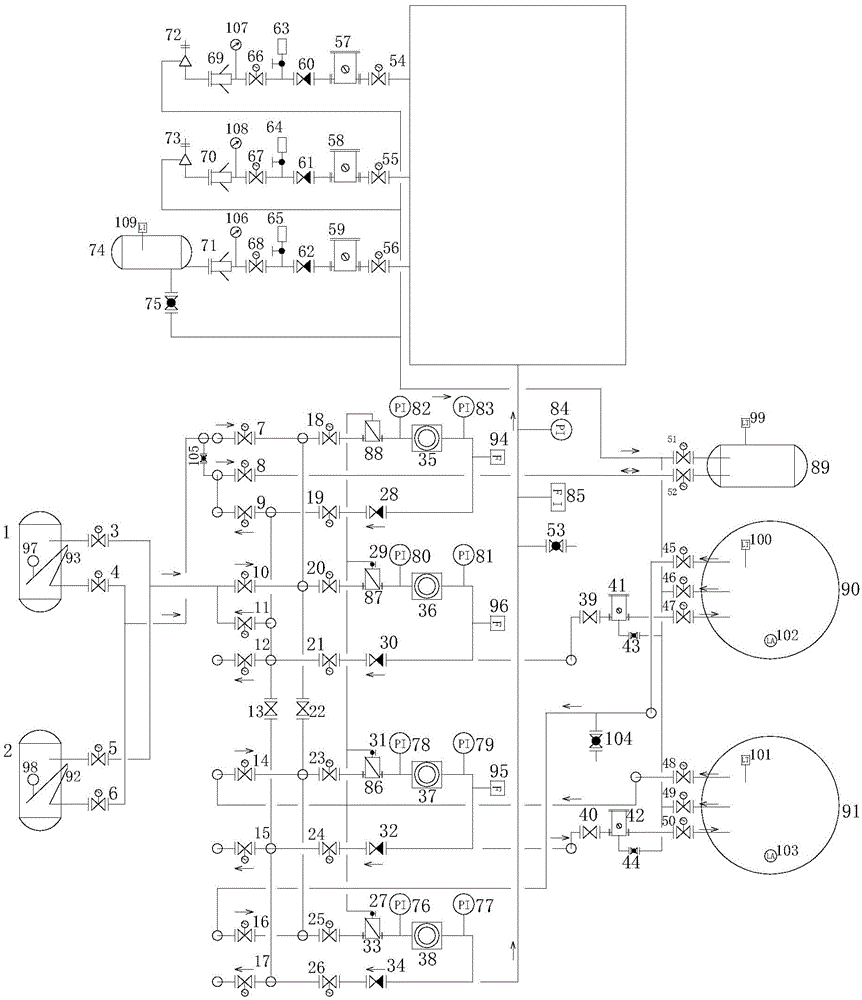

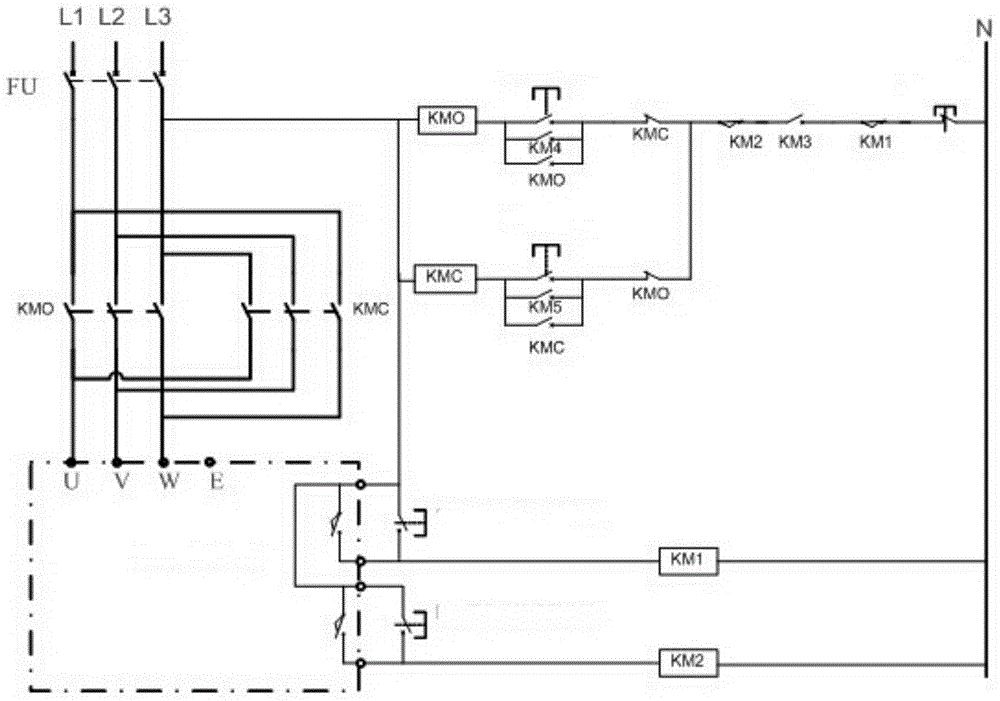

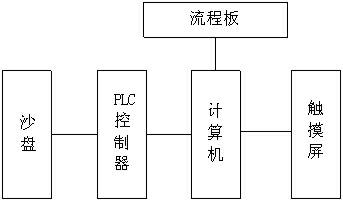

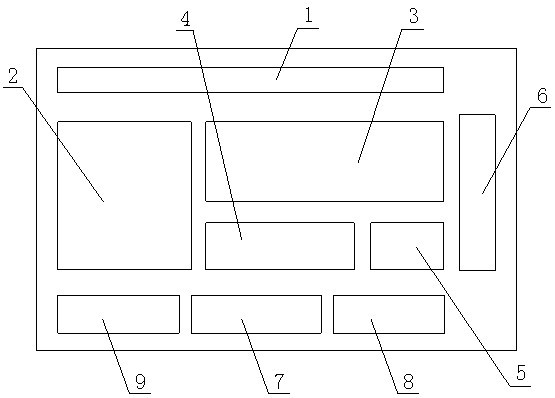

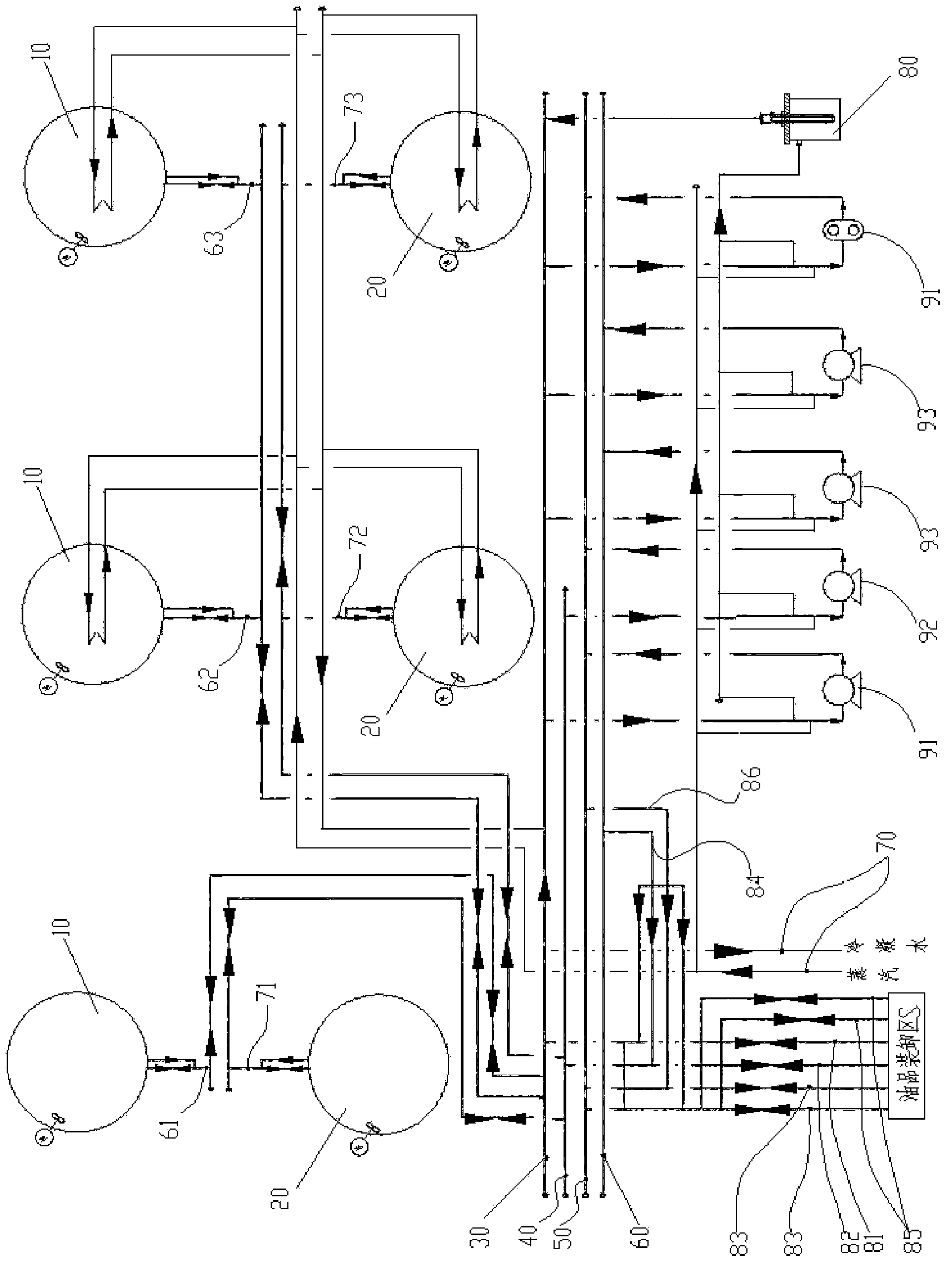

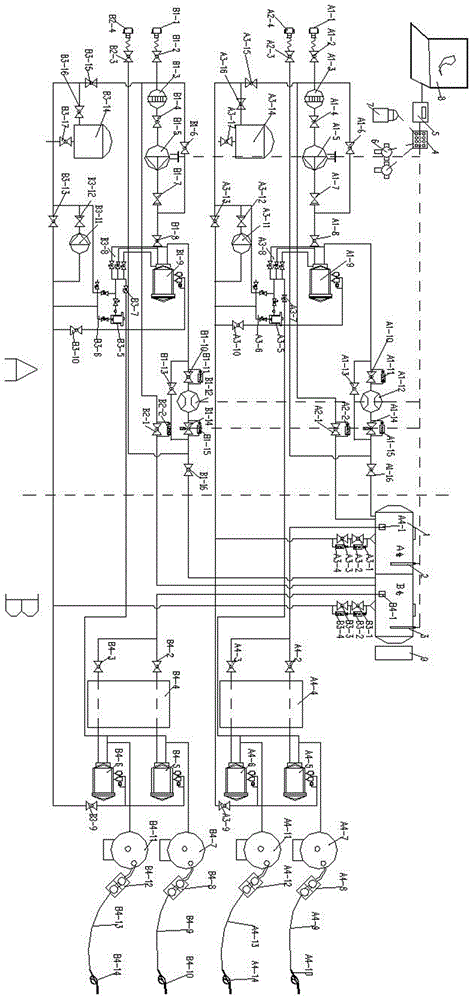

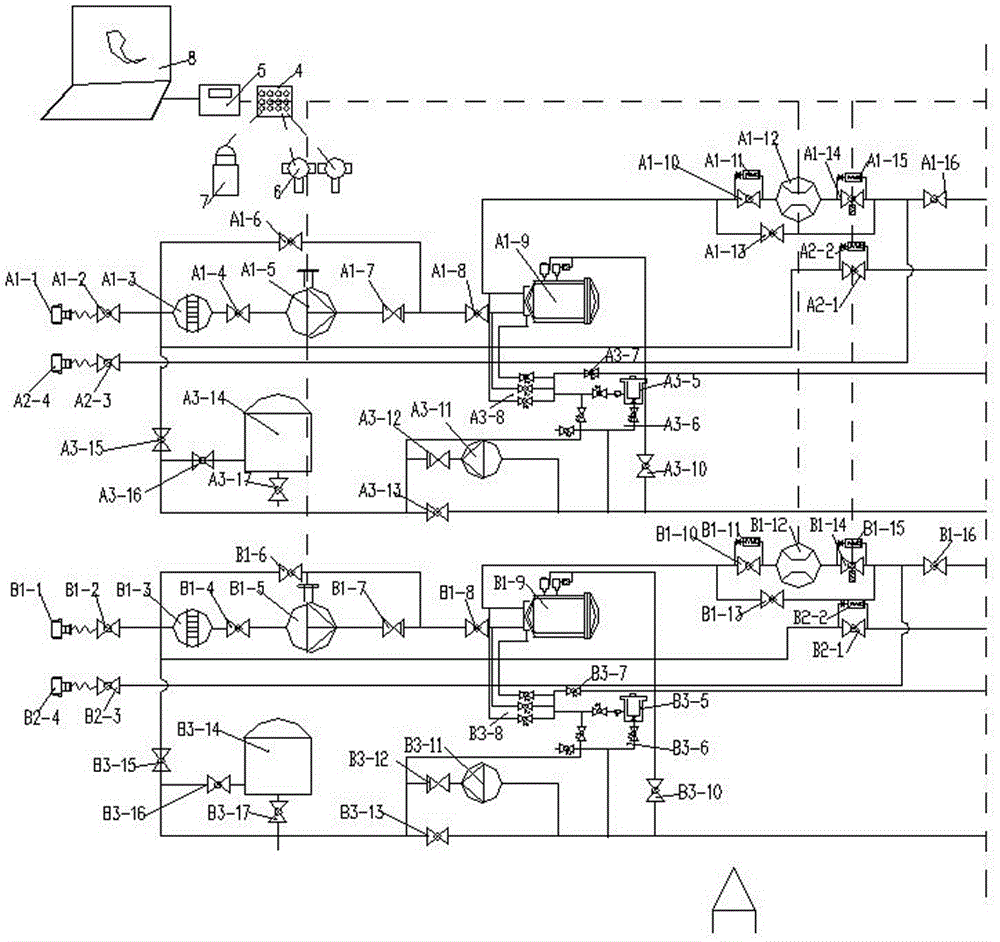

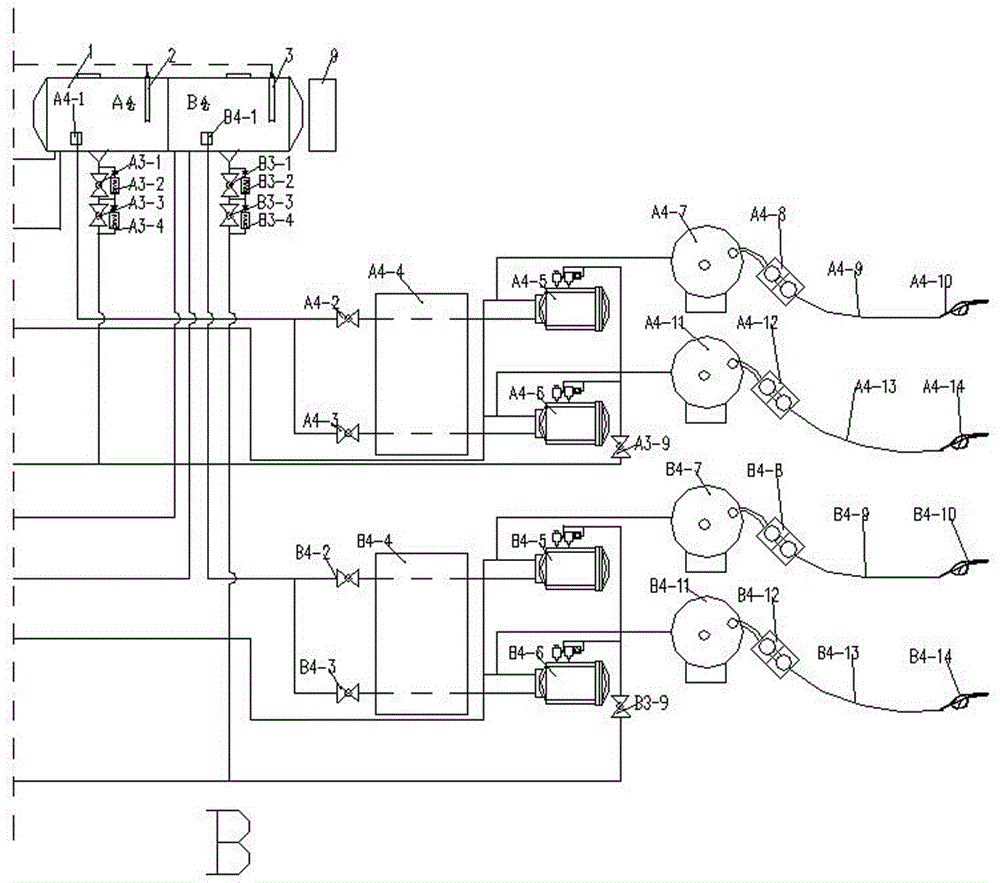

System and method for simulating oil depot for oil and gas storage and transportation

ActiveCN102314783AImprove training effectReduce the cost of trainingCosmonautic condition simulationsSimulatorsProgrammable logic controllerGasoline

The invention discloses a system and method for simulating an oil depot for oil and gas storage and transportation. The system comprises a sand table, a touch screen and a flow plate, wherein oil and gas storage and transportation equipment and pipelines for connecting the oil and gas storage and transportation equipment are arranged on the sand table, control valves and LED lamp belts are arranged in the inlet / outlet pipelines of the oil and gas storage and transportation equipment, the oil and gas storage and transportation equipment is distributed on a train trestle bridge (1), a tank field (2), a pump room region (3), a fire pump region (4), a marine valve chamber (5), a wharf (6), a gasoline delivery region (7), a filling region (8) and an office region (9) according to functions, and a PLC (Programmable Logic Controller) is arranged below the sand table and is connected with the control valves and the LED lamp belts on the sand table as well as a computer in the touch screen. Inthe invention, the process flow of the oil depot is simulated by adopting the forms of the sand table, cartoons and the like, whether the operation of a student on the sand table is proper or not canbe dynamically and interactively shown on the flow plate in real time, so that the student can achieve a feeling of being personally on the scene, thus, the training effect is increased and the training cost is reduced.

Owner:CHENGDU ESIMTECH GASOLINEEUM EQUIP SIMULATION TECH EXPL

Distributing method for automatic filling system of island oil depot

The invention provides a distributing method for an automatic filling system of an island oil depot. The method comprises the following steps: a tank car enters the depot; when the grounding does notmeet the requirements, unloading is not allowed and an alarm is given; a field operator presses a start button to start loading; loading is started; the opening degree of a valve is adjusted, and a small-flow loading stage is started; the valve is controlled to stop rapidly; the system automatically closes a two-section control valve and stops a pump, and loading is finished; the operator removesan electrostatic grounding clamp, dismounts an anti-overflow protector, and recovers a loading crane pipe; after the tank car is loaded, the tank car returns to a loading control room; and a monitoring station in the loading control room monitors the liquid level, the on-off state of the valve and the whole loading process. The time and labor are saved; with adoption of a flow feedback closed-loopcontrol strategy for the opening degree of the valve, the control valve is stably opened and closed; water hammer is effectively reduced on the premise of ensuring the filling precision; damage to aflowmeter and valve equipment is avoided; and the service life of the equipment is prolonged.

Owner:CCCC FIRST HARBOR ENG +1

Petroleum conveying system applicable to large petroleum reserve depot

The invention relates to design of petroleum depot technological systems, in particular to a petroleum conveying system applicable to a large petroleum reserve depot. The petroleum conveying system is a single-pipe process technological system or a double-pipe procedure technological system, thus, a single-pipe technological process can be adopted in terms of large petroleum reserve depots with low turnover frequency and a double-pipe technological process device can be adopted in terms of large petroleum reserve depots with high turnover frequency. Under the condition that oil discharging of the large petroleum reserve depots is not affected, the problems of diseconomy and complicated operation of a multiple-pipe technological process are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

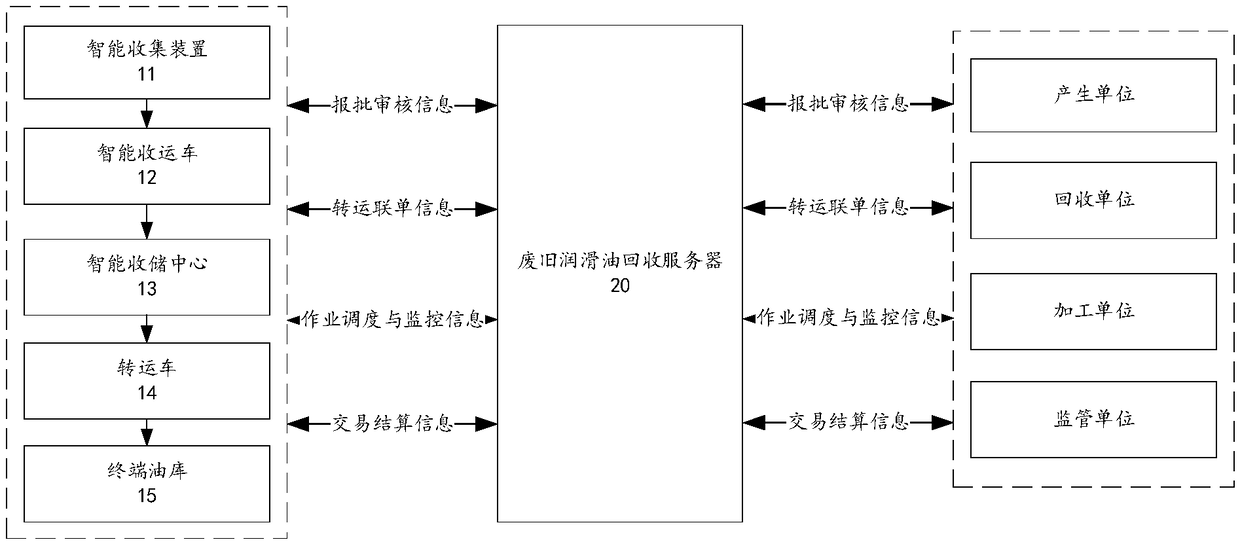

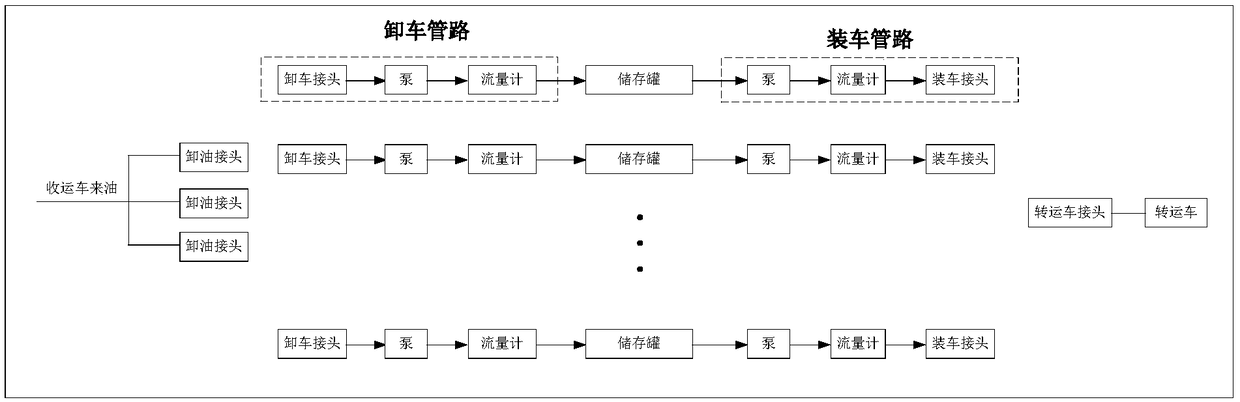

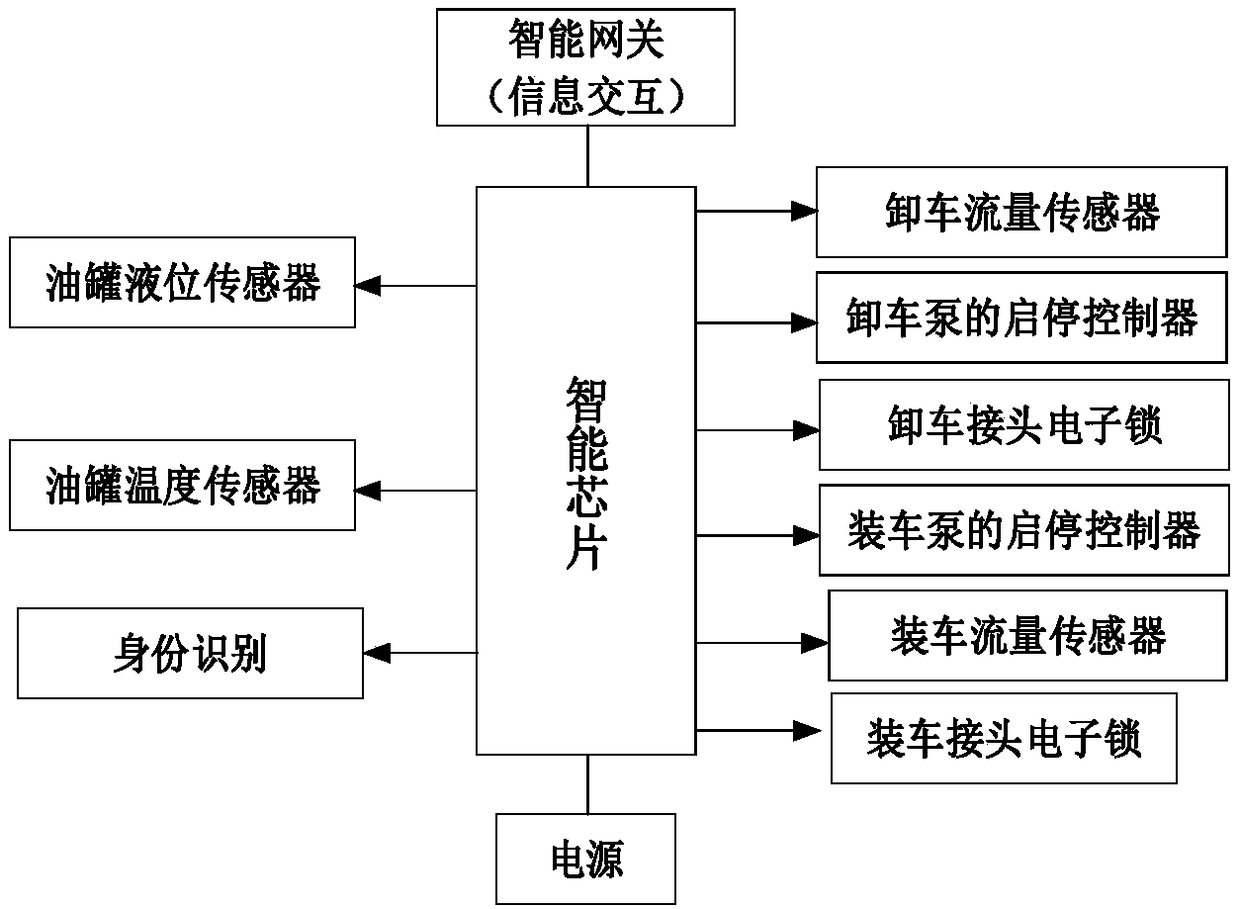

IOT-based Waste lubricating oil recycling system server and method

ActiveCN108833496AImprove recycling efficiencyReduce recycling costsIndividual entry/exit registersTransmissionInformation processingRecovery method

The invention provides an IOT(Internet of Things)-based waste lubricating oil recycling system server and method and relates to the technical field of resource recycling. The system comprises an intelligent collection device, an intelligent receiving vehicle, an intelligent storage center, a transfer vehicle and a terminal oil depot. The waste lubricating recycling server includes an M2M IOT access system, a support system and an application system. The waste lubricating oil recycling method includes a classification and collection stage, a classification and reception stage, a classificationand storage stage, a classification and transportation stage, and a circulation information processing stage. According to the IOT-based Waste lubricating oil recycling system server and method provided by the invention, the problems of difficult classification and recycling, a low operation efficiency, high operation cost, a low recycling efficiency and difficult supervision of a waste oil recycling process are fundamentally solved.

Owner:安洁行方流体管理技术有限公司

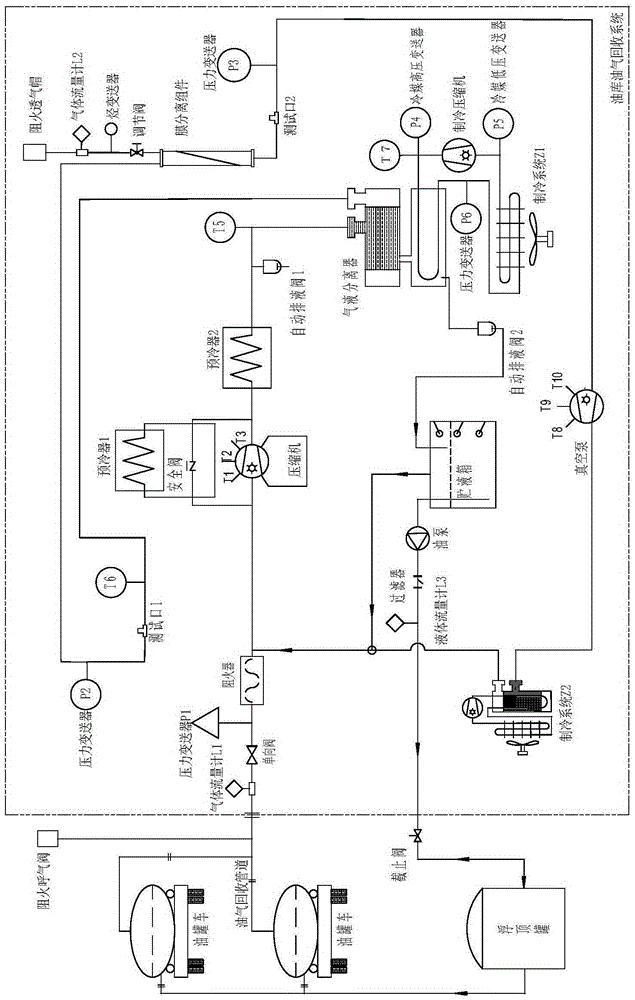

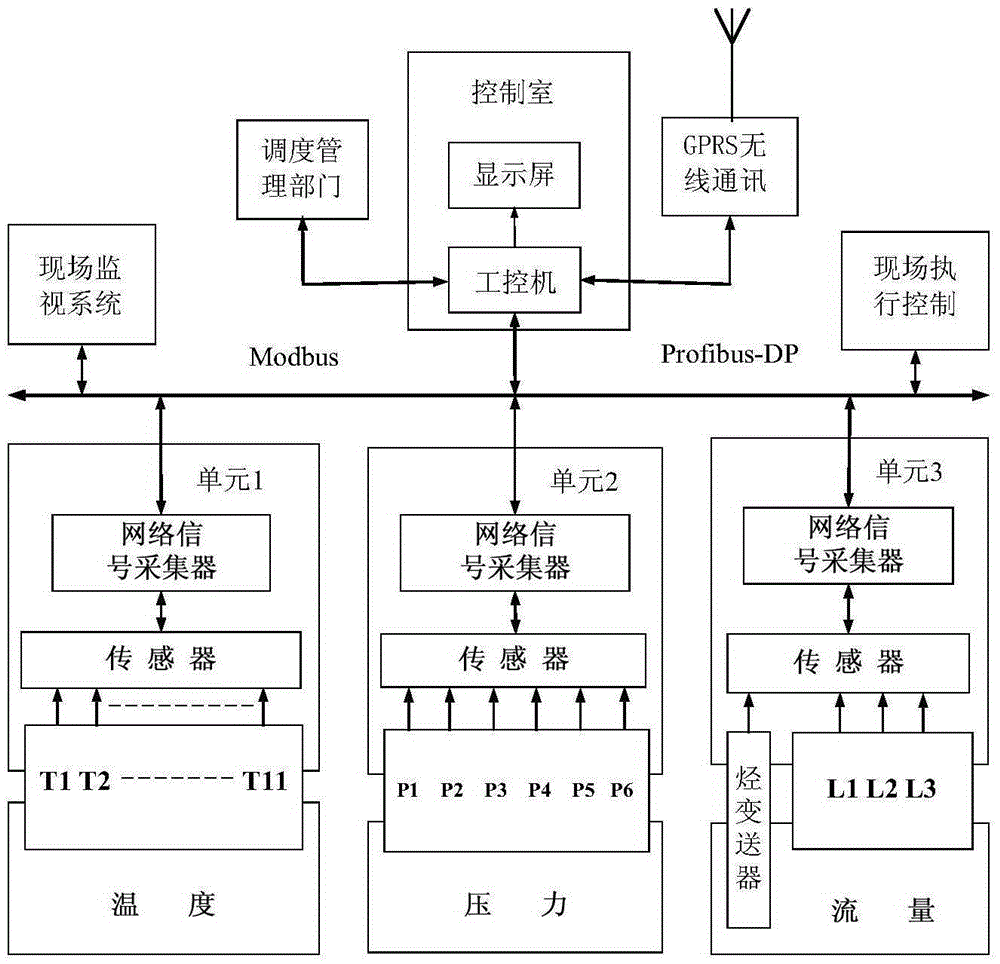

Intelligent oil gas recovery system and oil gas recovery method for oil depots

ActiveCN105300032AImprove recycling efficiencySimple lineSolidificationLiquefactionRecovery methodVapor–liquid separator

The invention relates to an intelligent oil gas recovery system and an oil gas recovery method for oil depots. The intelligent oil gas recovery system comprises a compressor, a first precooler, a second precooler, a gas-liquid separator, a membrane separation assembly, a first refrigerating system, a second refrigerating system, a liquid storage box and a control system. Oil gas sequentially flows through a one-way valve, a pressure transmitter P1 and a fire barrier through an oil gas recovery pipeline, then gets compressed by the compressor, enters the second precooler so as to be condensed and finally is separated by the gas-liquid separator, the air and the oil gas in the gas part are separated through the membrane separation assembly, the oil gas enters the compressor to be recycled, and the liquid part returns to a floating roof tank through the liquid storage box. The intelligent oil gas recovery system has the advantages that the condensation technology and the membrane separation technology are combined so as to improve the recovery efficiency of the oil gas; the network intelligence detection technology and the network intelligence control technology are adopted for achieving network data detection, the wired technology and the GPRS wireless technology, and therefore lines of a measurement and control system are simplified, message passing is reliable, response is rapid, monitoring is timely, and the safety is high.

Owner:连云港华鑫石化机械设备有限公司

Gravity refueling type multifunctional integrated aviation oil filling device

InactiveCN105775155AReduce construction costsReduce maintenance costsLiquid handling installationsAviationTank truck

The invention belongs to the technical field of refueling in airports and discloses a gravity refueling type multifunctional integrated aviation oil filling device which solves the problem that existing oil depots and refueling vehicles are not suitable for small-and medium-flow airports.The device comprises a skid-mounted seat, an oil tank with oil chambers is arranged on the skid-mounted seat, each oil chamber is provided with a refueling pump, an oil collection mechanism and an oil filling mechanism.Each oil collection mechanism comprises a first connector for communication with a tank truck, each first connector is communicated with a pump which is communicated with an oil collection filter separator, and each oil collection filter separator is communicated with a flow meter which is communicated with the corresponding oil chamber of the oil tank.Each oil filling mechanism comprises an oil filling pump which is communicated with a first oil outlet pipe used for communication with the corresponding oil chamber, each first oil outlet pipeline is communicated with an oil filler which is connected with at least one oil filling filter separator, and each oil filling filter separator is provided with at least one oil gun.

Owner:SICHUAN FEIDA SOURCE ENERGY EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com