Safe and covert high-capacity oil depot arranged underground

A large-capacity oil depot technology, which is applied in the field of large-capacity storage of crude oil, liquefied petroleum gas, and refined oil, can solve the problems of construction and operation cost constraints of oil storage methods, occupying large land resources, and air pollution, so as to facilitate maintenance and monitoring and centralized management, saving costs and construction time, and reducing the effects of brittle hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

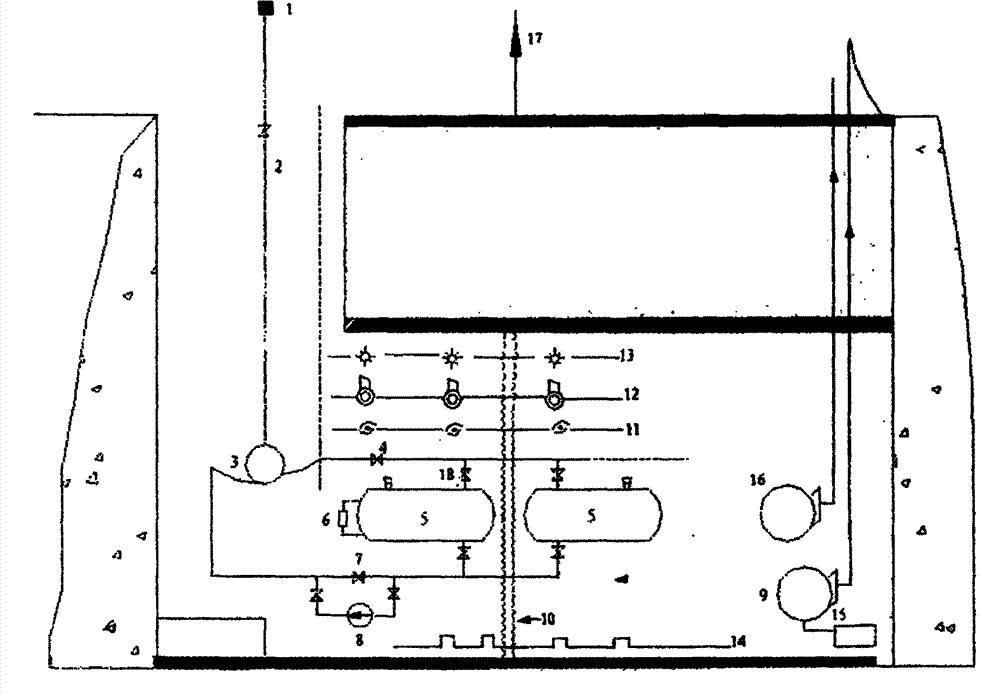

[0017] Referring to the schematic diagram of the embodiment of the accompanying drawings, referring to the schematic diagram of the embodiment of the accompanying drawings, the large-capacity oil depot is placed underground safely and concealed, including: 1. Oil unloading device, 2 oil inlet and outlet main pipes, 3 buffer tanks, 4 oil injection pipes, 5 oil storage Tank, 6 oil level gauge, 7 pumping (row) oil pipe, 8 oil pump, 9 water pump, 10 flame retardant screen, 11 camera monitoring, 12 gas detection alarm, fire alarm, 13 explosion-proof lighting, 14 fire fighting facilities, 15 Cistern, 16 ventilator, 17 lightning rod, 18 breather valve, 19 foundation of oil storage tank. The oil enters the oil storage tank 5 through the oil unloading device 1, the oil inlet and outlet pipe 2, and the buffer tank 3. The oil storage tank 5 is welded on-site by steel plates according to the original space section, and is connected to each other through the pipe network, and an anti-corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com