Patents

Literature

359results about How to "Save construction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

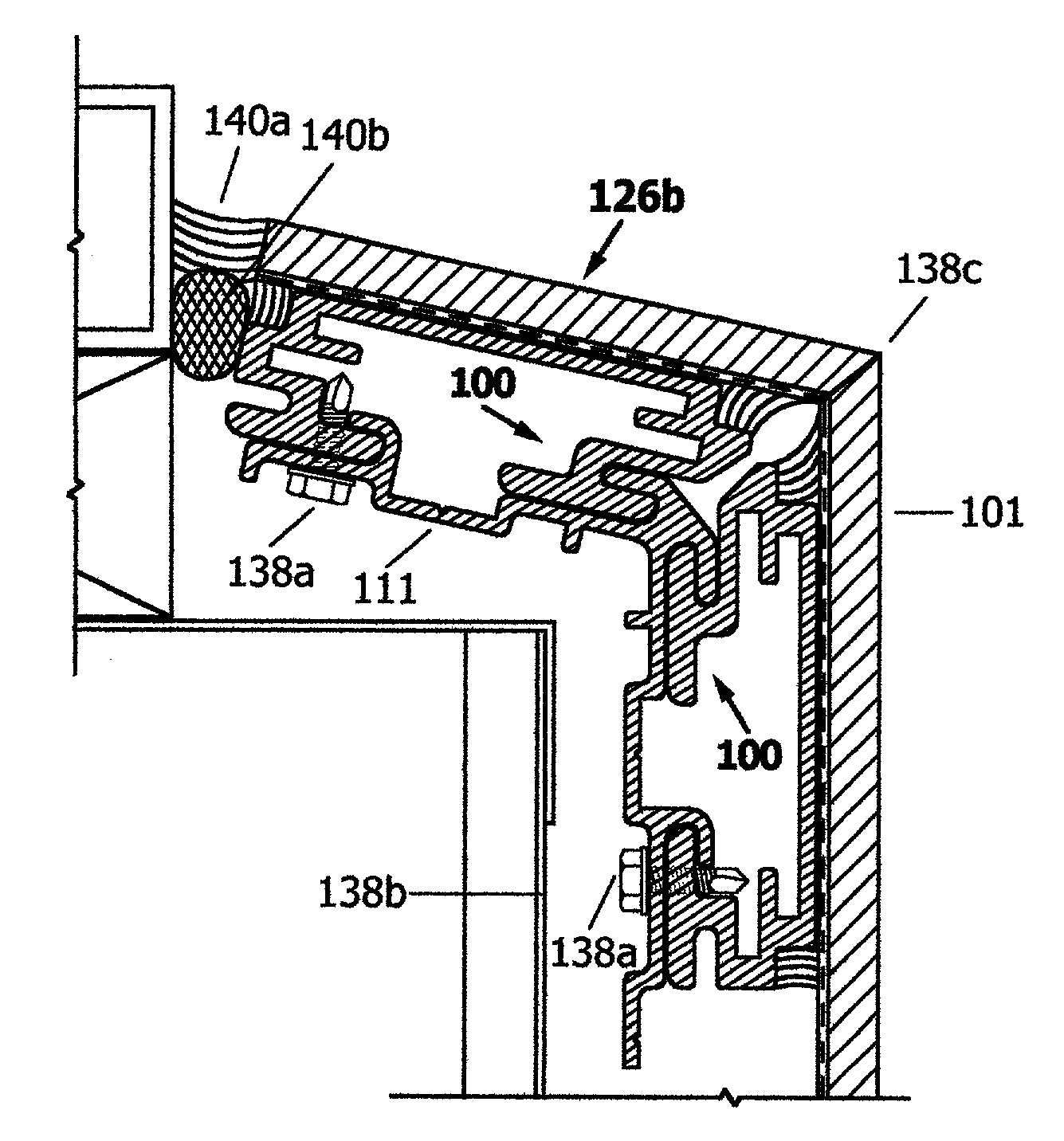

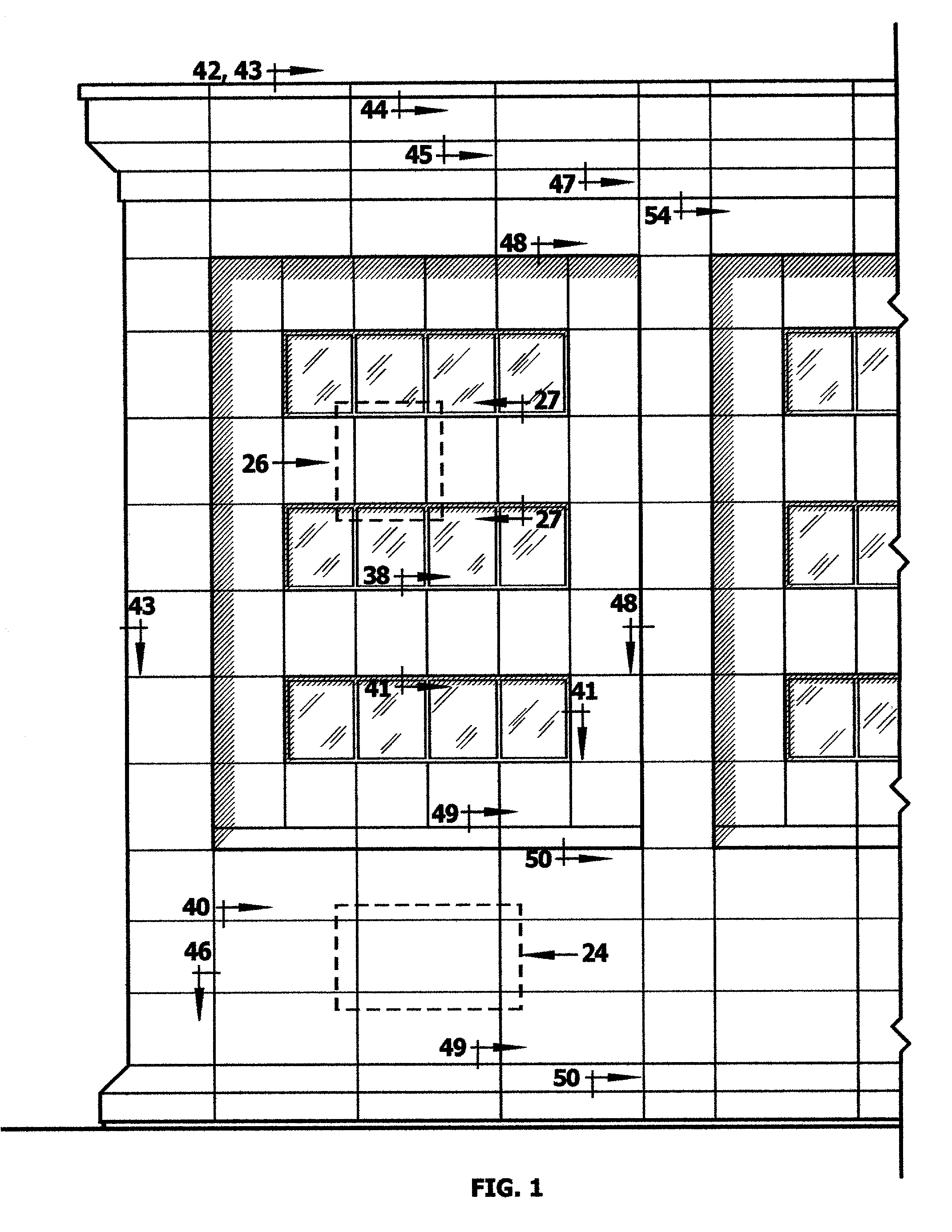

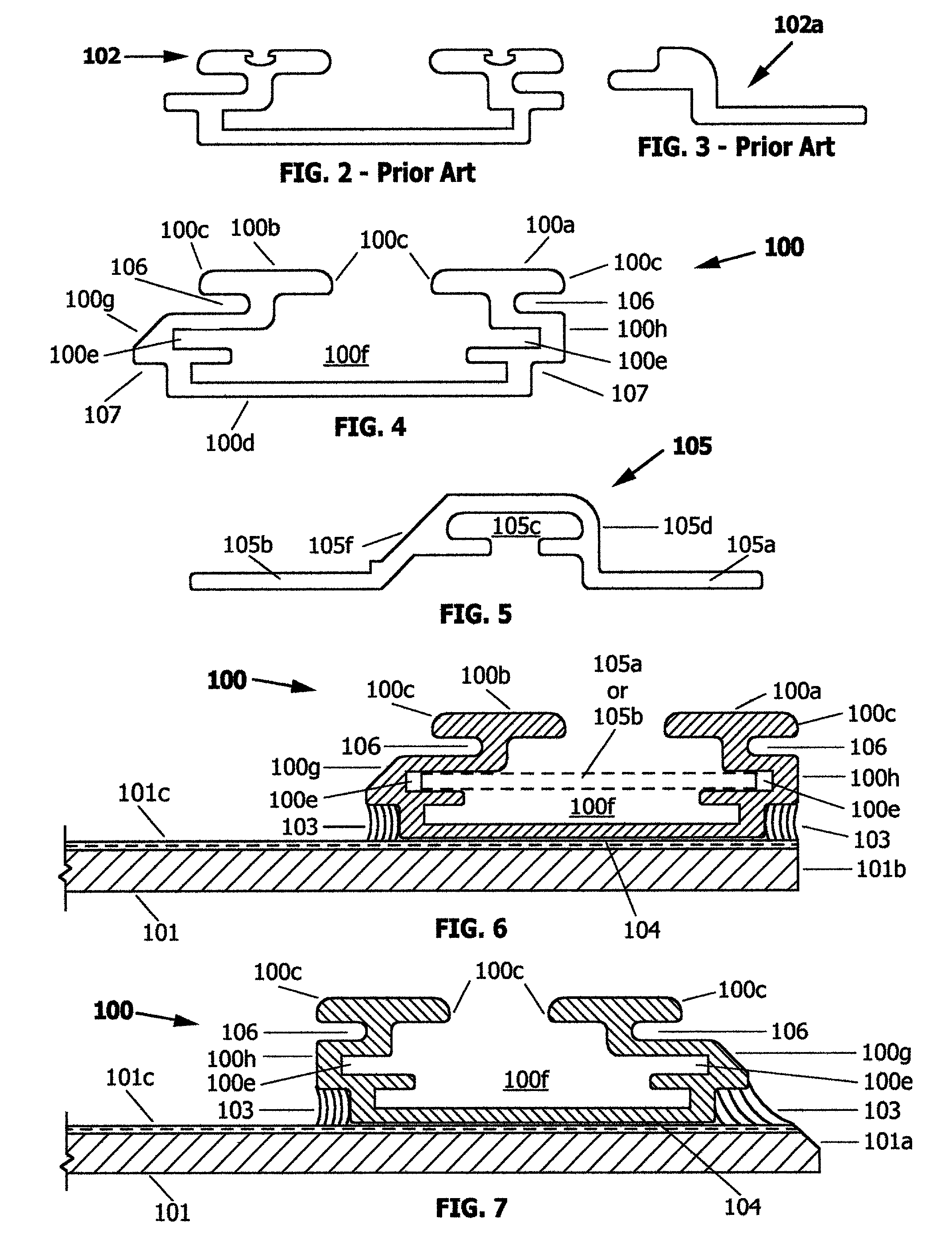

Exterior wall cladding system for panels of thin reinforced natural stone

An installation system designed specifically for thin reinforced natural stone panels used as exterior cladding, re-cladding, or over-cladding of buildings is comprised of a series of extruded aluminum shapes which, when properly applied to the back side of the thin reinforced stone panels, provide structural support for the thin panels and facilitate their installation and will also provide the means for the panels to be pre-assembled in order to obtain desired shapes or profiles and to be easily installed on the building. The series, or family, of extruded aluminum shapes are designed to mate or interlock to perform a variety of tasks such as perimeter frames, structural stiffeners, corner angle supports, interlocking sleeves, runner clips which facilitate attachment to various substrates of a building such as steel stud framing, aluminum curtain wall frames, brick or concrete walls or plywood sheathing.

Owner:THIN STONE SYST

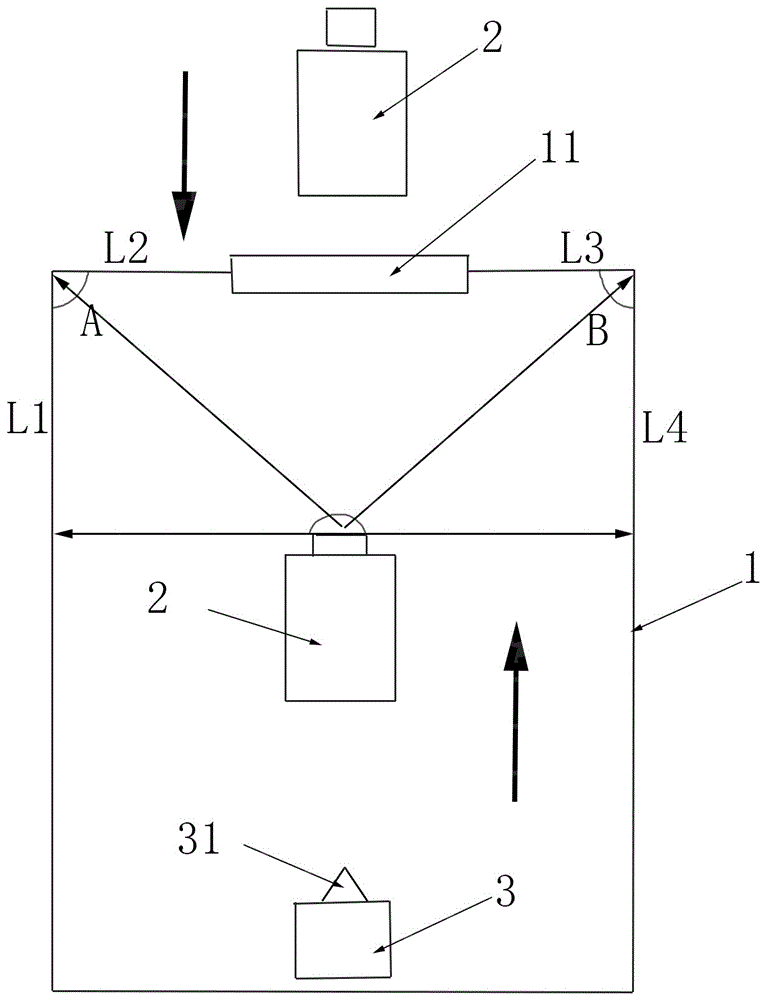

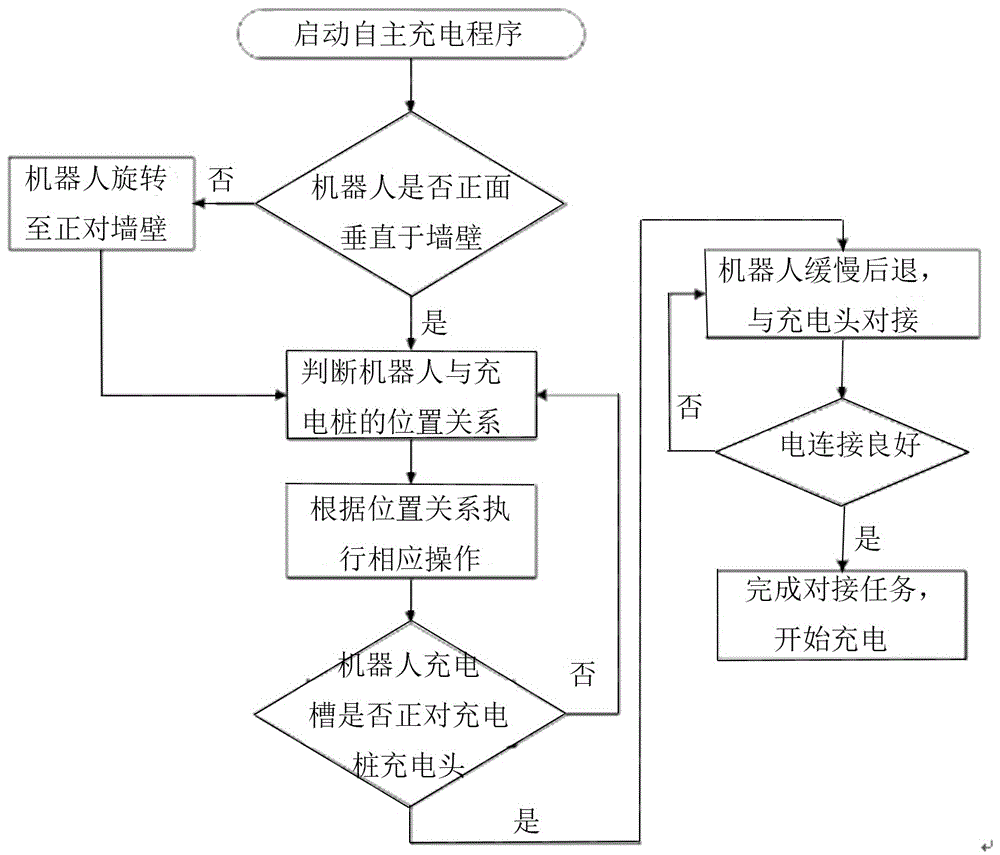

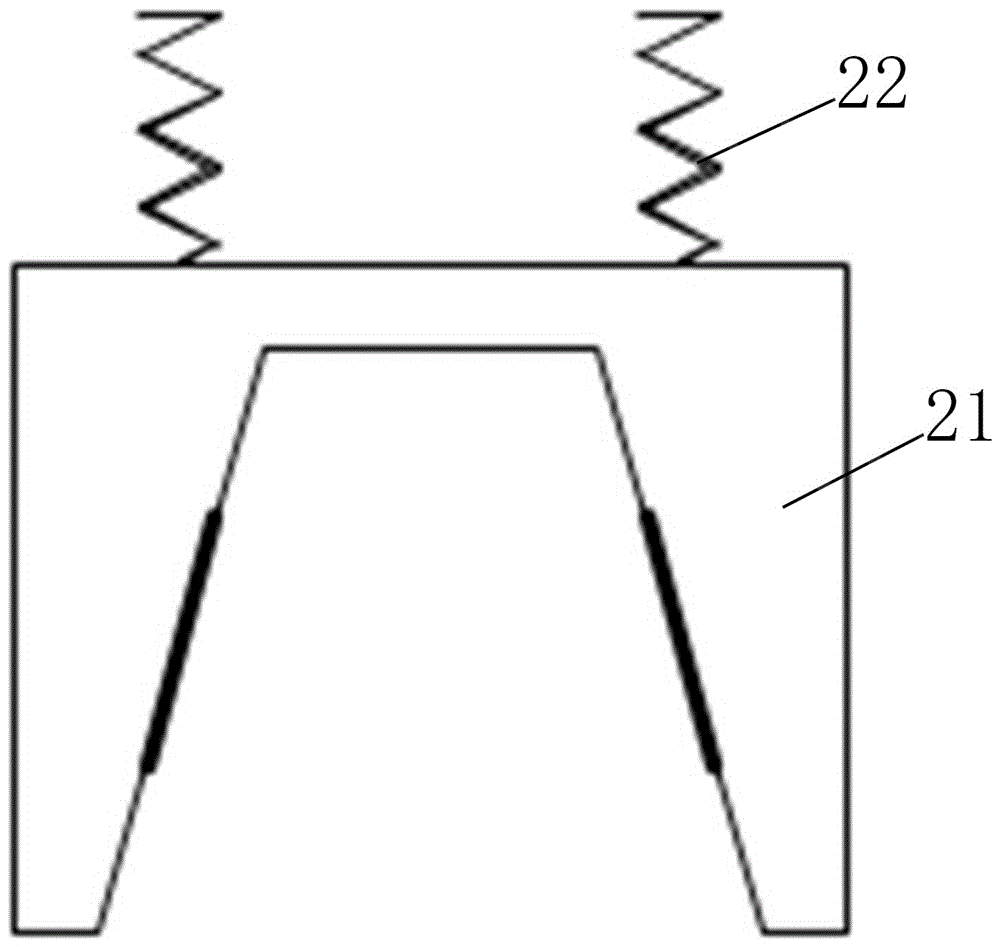

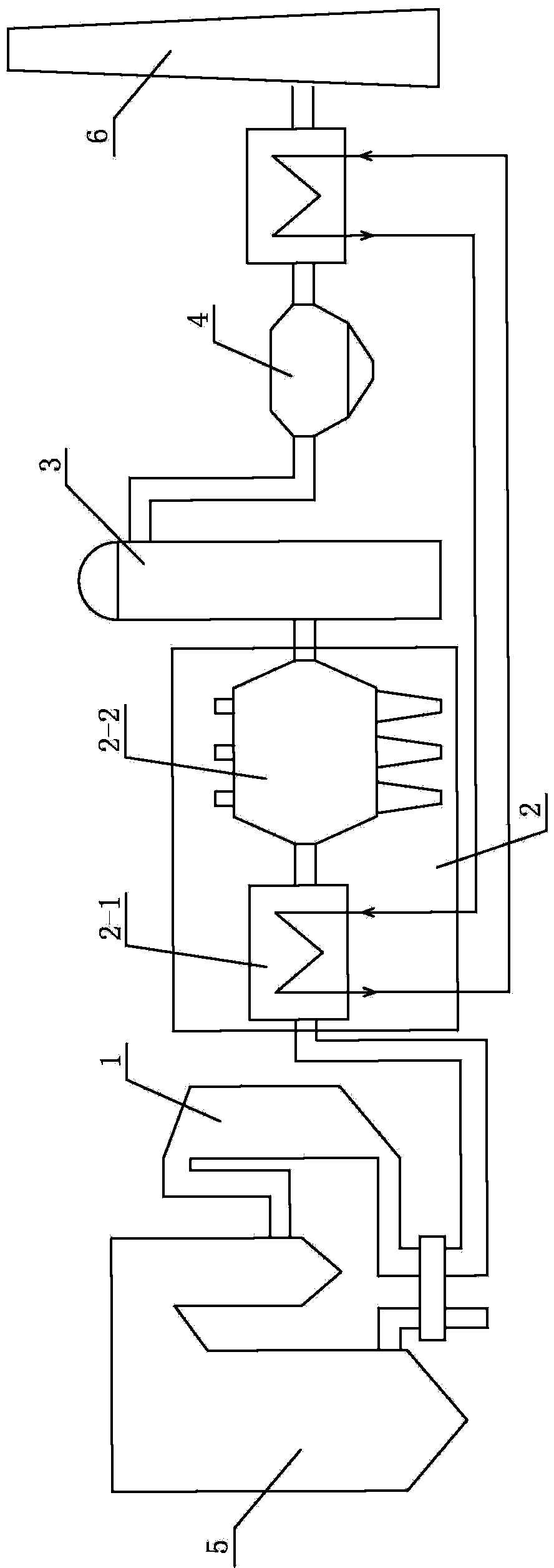

Substation patrol robot autonomous charging method based on laser navigation

ActiveCN106020188ASave construction cost and timeFlexible location designPosition/course control in two dimensionsAir navigationMarine navigation

The invention discloses a substation patrol robot autonomous charging method based on laser navigation. The method comprises the following steps: 1) building a patrol robot charging room; 2) during charging, a patrol robot backing up to the charging room, and scanning wall information at the two sides and right ahead of the robot 3) issuing motion control information through positioning of the robot; 4) fitting straight lines; 5) selecting four lines meeting requirements; 6) calculating coordinates of angle points A and B to obtain pose information of the robot; 7) according to the pose information, adjusting the angle of the robot; 8) judging distance between the robot and a charging pile; 9) when reaching the preset distance, the robot backing up to the charging pile directly, and the robot starting charging; and 10) after finishing charging, the robot moving forwards to separate from the charging pile to finish charging. The method can realize trackless autonomous charging; track laying is not needed; and construction cost and time can be saved, and the charging room can be arranged flexibly.

Owner:HANGZHOU SHENHAO TECH

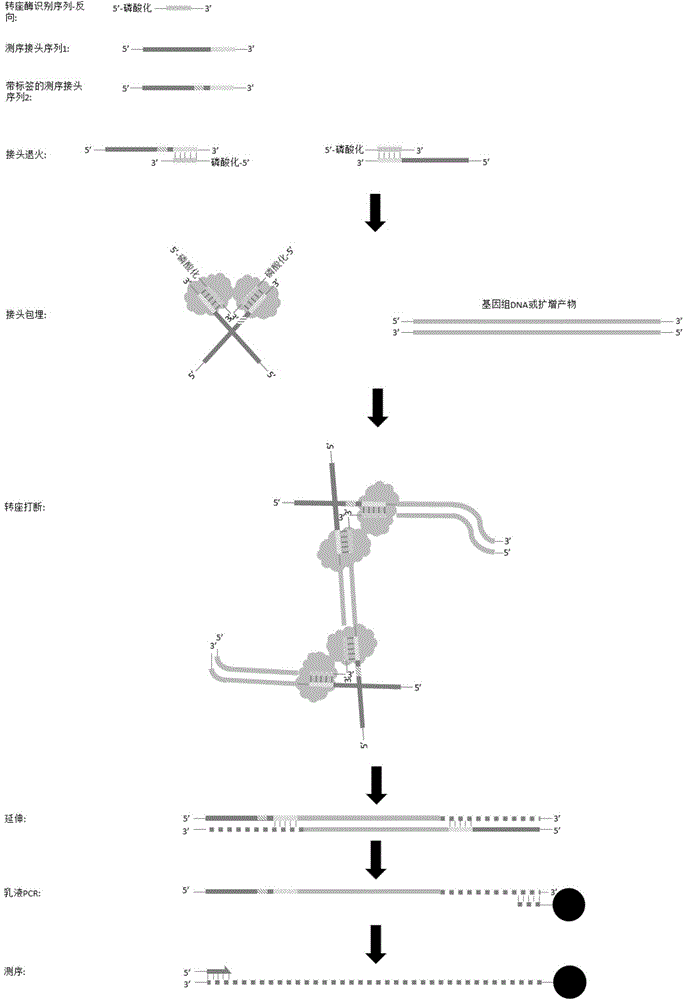

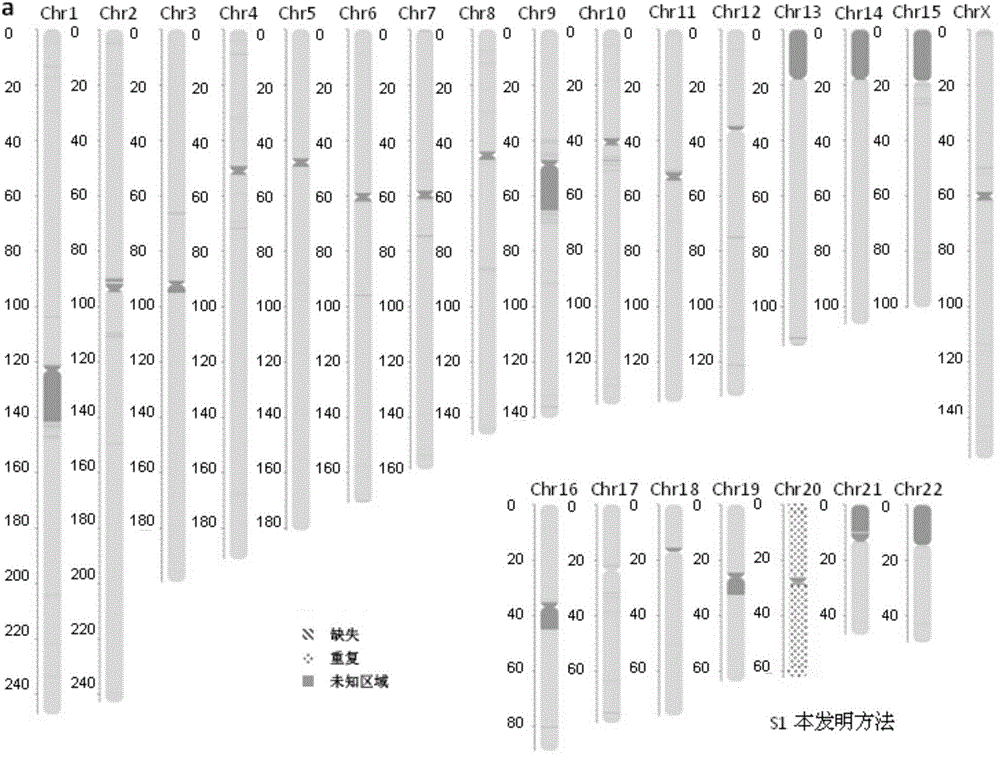

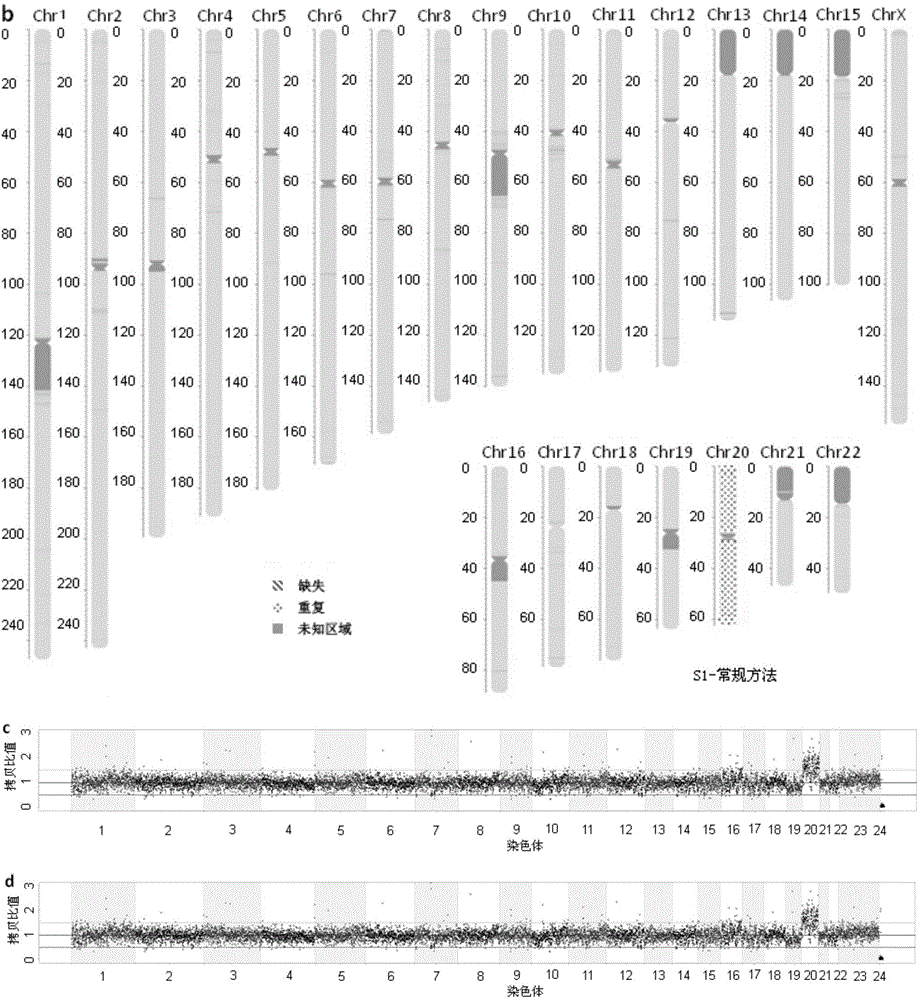

Sequencing library construction method, and kit and application thereof

ActiveCN105525357ASave construction timeImplement number anomaly detectionMicrobiological testing/measurementLibrary creationA-DNARecognition sequence

The invention discloses a sequencing library construction method, and a kit and an application thereof. The method comprises the following steps: target DNA and a transposase-embedding complex are incubated under transposition reaction conditions, such that a DNA library with double linkers on the two ends is produced, wherein the transposase-embedding complex comprises transposase, a transposase recognition sequence complementary sequence, a first sequencing linker sequence and a second sequencing linker sequence. The first sequencing linker sequence comprises a first sequencing tag sequence at the 5' end and a transposase recognition sequence at the 3' end. The second sequencing linker sequence comprises a second sequencing tag sequence at the 5' end, a sample tag sequence and a transposase recognition sequence at the 3' end. With the method provided by the invention, with transposase, DNA can be broken with a one-step method, and sequencing linkers can be respectively added to the 5' end and the 3' end. Compared with a conventional library construction method, the method is time-saving, and the operation is simple.

Owner:BGI GENOMICS CO LTD +1

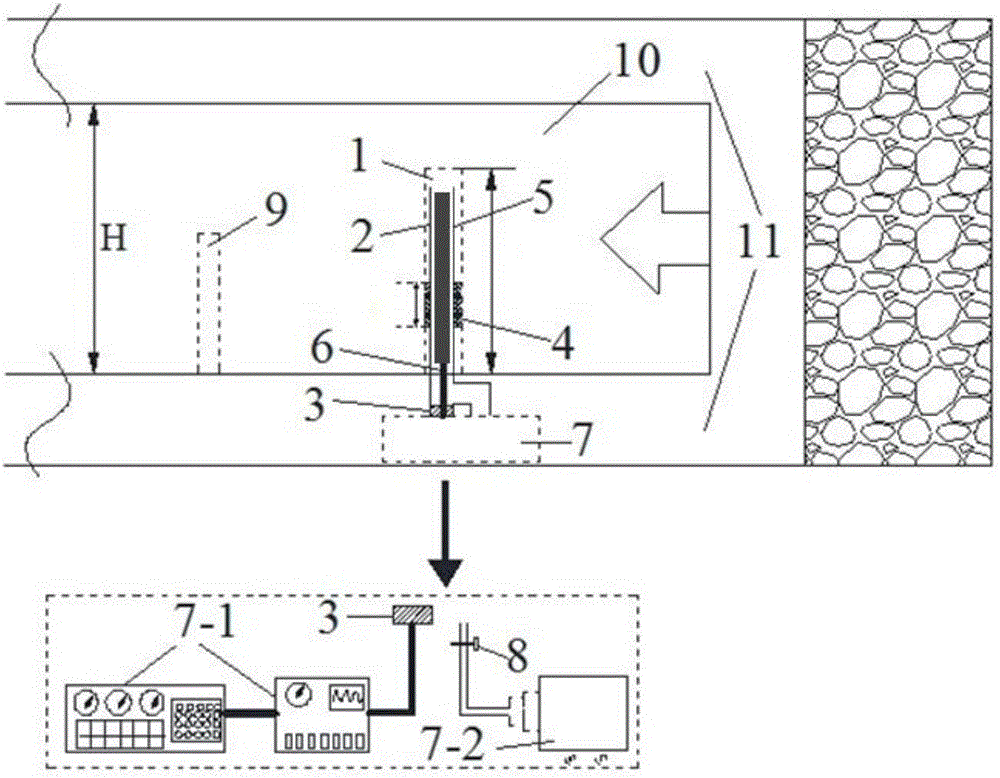

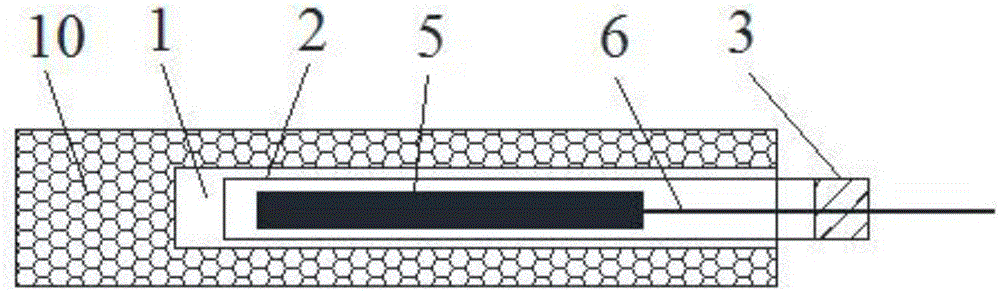

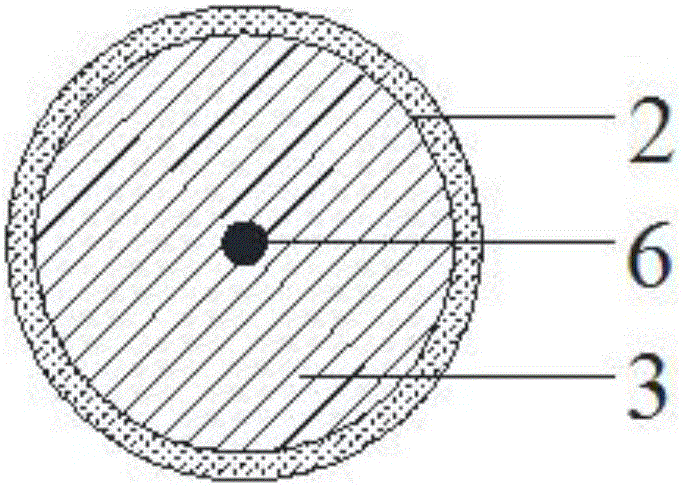

Ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method

ActiveCN105971660ASave construction timeGreat practicabilityFluid removalGas removalUltrasonic cavitationHydraulic fracturing

The invention discloses an ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method. A main drill hole and a monitoring drill hole are constructed in an air inlet way or an air return way of the working face at first, a steel pipe of a built-in ultrasonic transducer is sent into the main drill hole after a drill bit in the main drill hole reaches a coalbed preset target position, the main drill hole is subjected to high-pressure-resistant hole sealing through a conventional grouting method, and an ultrasonic generator is turned on to continuously emit low-frequency ultrasonic waves with the frequency being 20-25 kHz to the coalbed after hole sealing is completed; hydrofracture equipment is started in 1-2 h to conduct hydrofracture operation on the main drill hole; the power of the ultrasonic waves is kept unchanged while coalbed hydrofracture is conducted, and the frequency of the ultrasonic waves is adjusted to 30-35 kHz; and hydrofracture is stopped when water flows out of the monitoring drill hole or pressure of a water injection pump decreases suddenly, the frequency and power of the ultrasonic waves are kept unchanged at the time, ultrasonic waves are emitted to the coalbed continuously, and the ultrasonic generator is turned off in 30 min. The coalbed permeability-increase method is free of pollution, low in cost and good in effect.

Owner:CHINA UNIV OF MINING & TECH

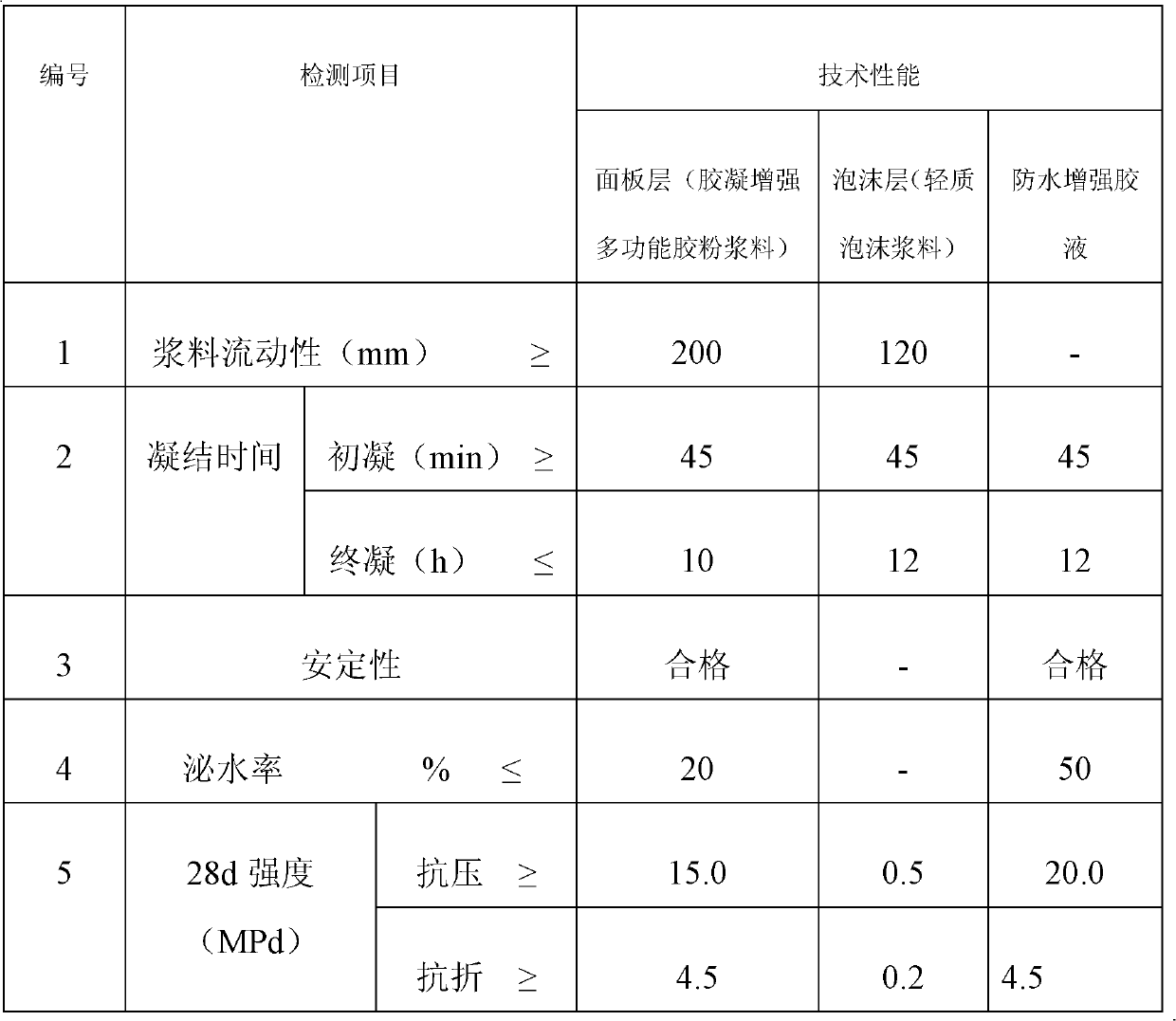

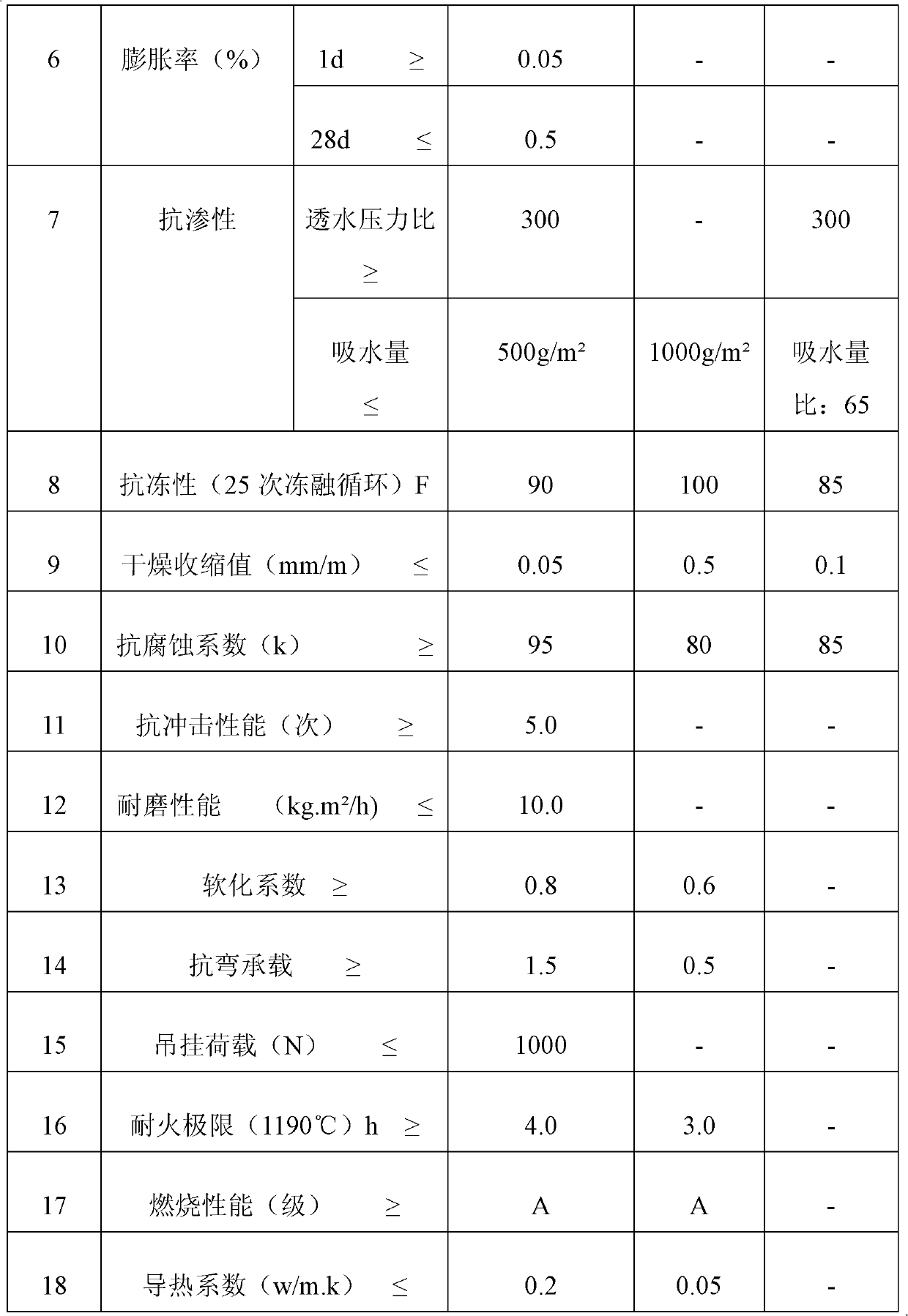

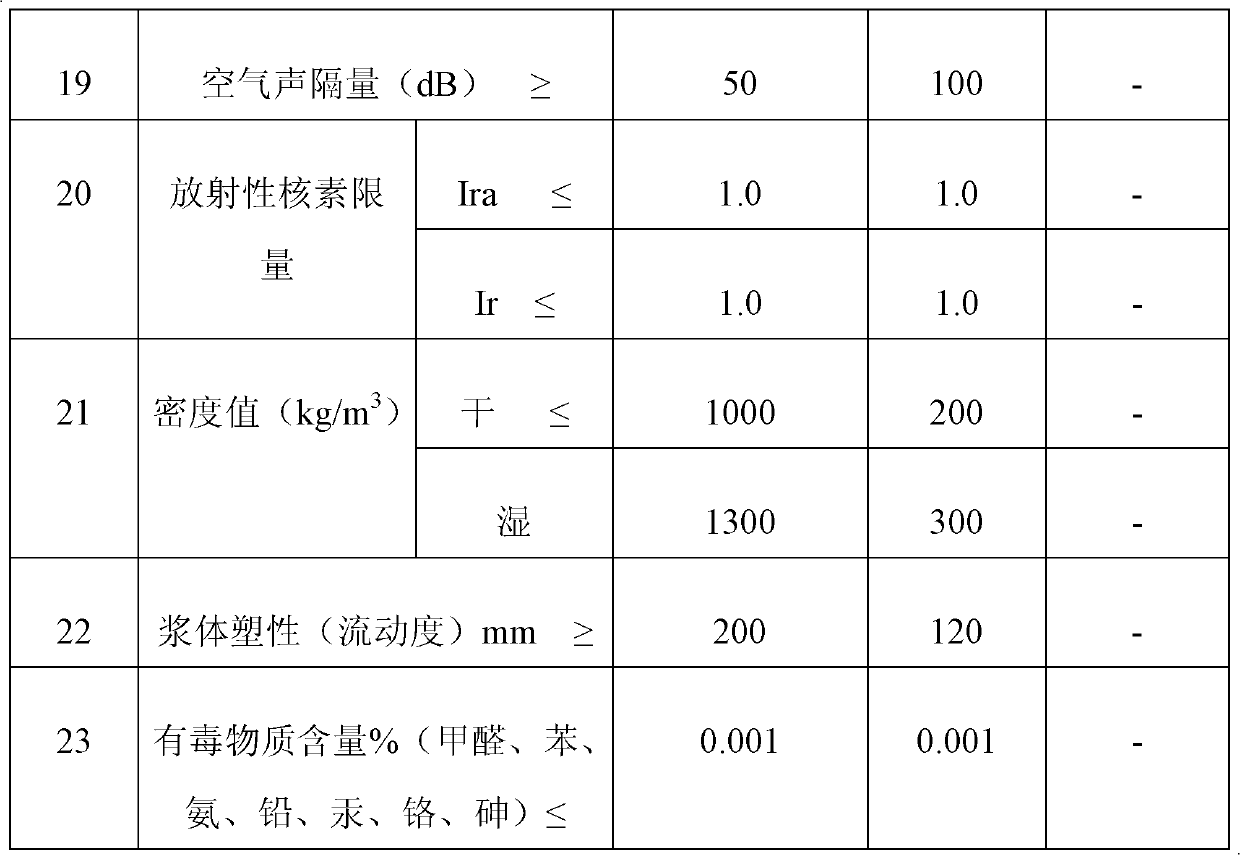

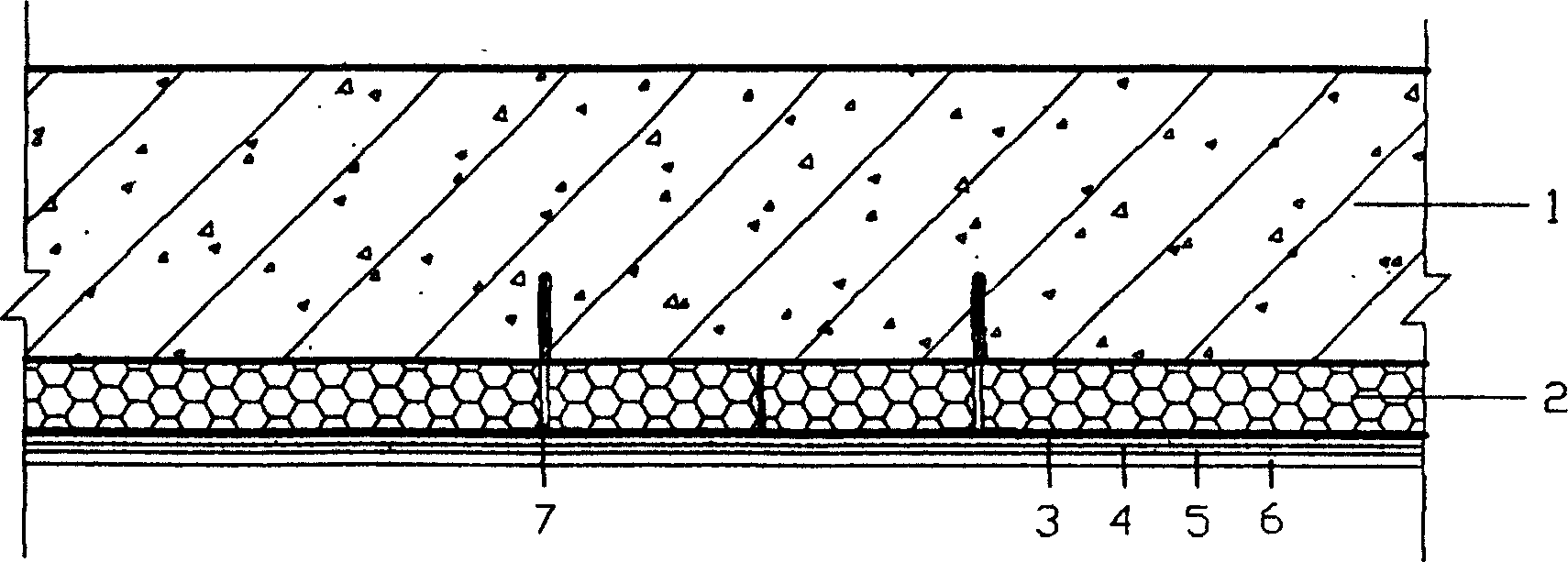

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

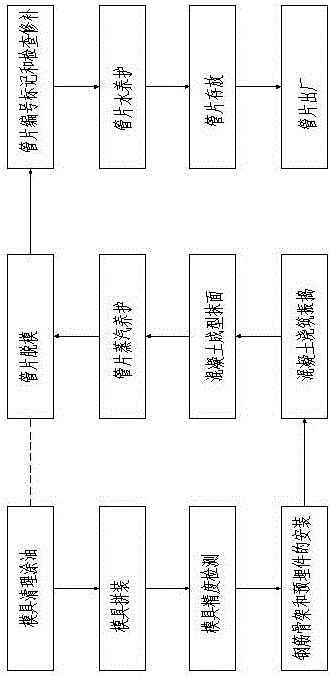

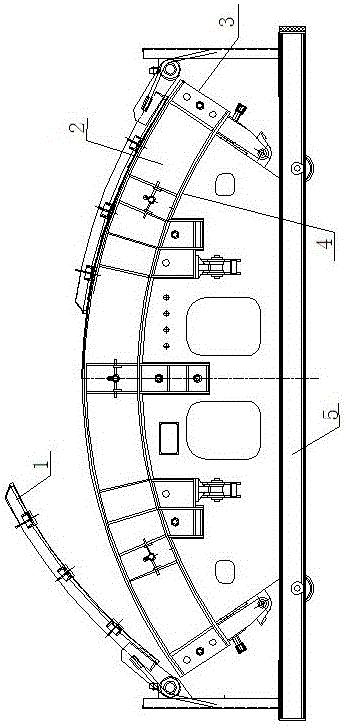

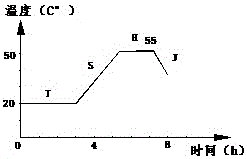

Production process for prefabricated reinforced concrete duct pieces

InactiveCN106584654AEasy to manage preciselySave construction timeShaping reinforcementsReinforced concreteRebar

The invention discloses a production process for prefabricated reinforced concrete duct pieces. The production process comprises the following steps of: a, clearing a mould and removing oil of the mould; b, assembling the mould; c, detecting precision of the mould; d, mounting a steel reinforcement framework and embedded parts; e, pouring and vibrating concrete, wherein vibrating time is controlled to be 4-10 minutes; f, molding and plastering concrete; g, carrying out steam curing on the duct pieces, resting for 3-4 hours and starting heating and steam-curing after vibrating is ended, wherein the duct piece steam-curing comprises four stages of a still resting stage T, a heating stage S, a constant-temperature stage H and a cooling stage J; h, de-molding the duct pieces; i, numbering and marking the duct pieces, and checking appearance to repair; j, carrying out water curing on the duct pieces; and k, storing the duct pieces. According to the production process disclosed by the invention, factory construction time can be saved, the whole construction period is effectively shortened, and factory construction cost is reduced; a fixed mould is on a designated position, and therefore, designated duct pieces with errors are favorably managed, and problem causes can be quickly determined; tunnel shield reinforced concrete duct pieces with high quality can be produced; and construction operation is normalized, programmed and standardized.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

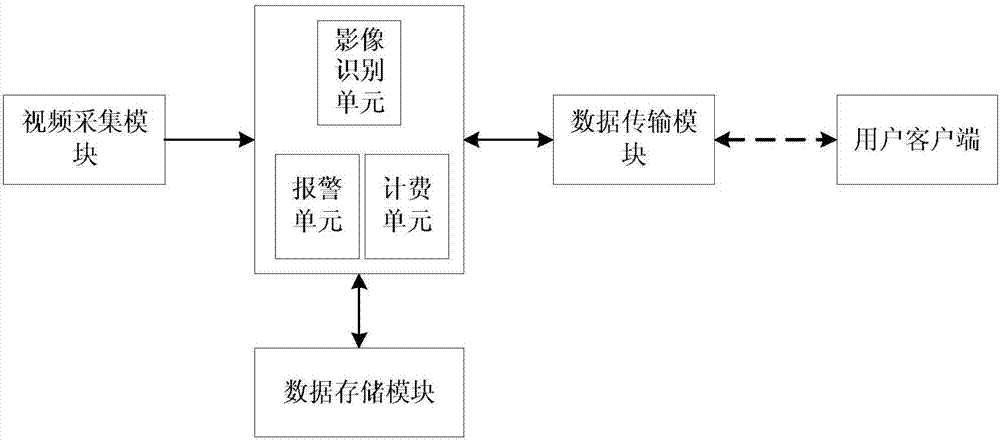

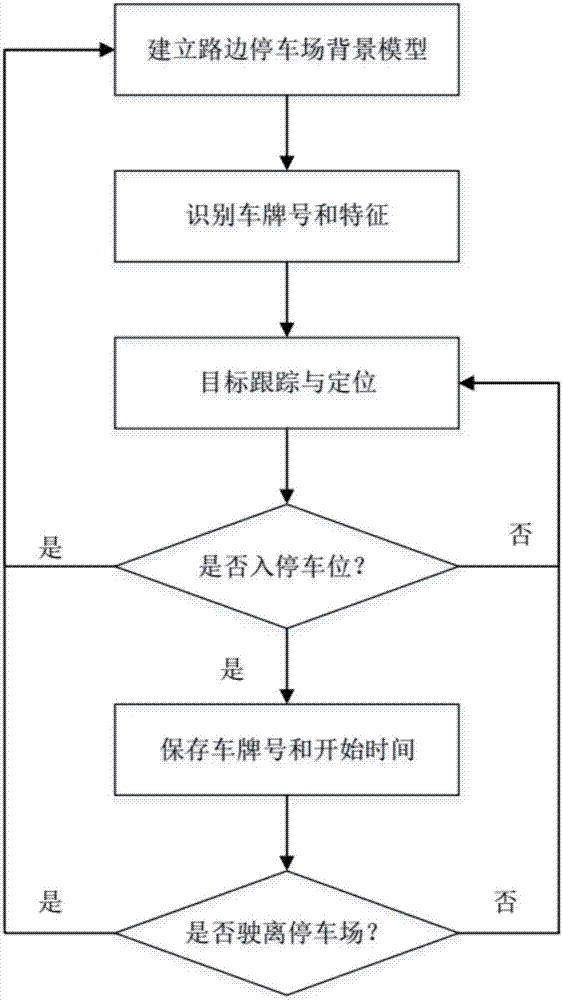

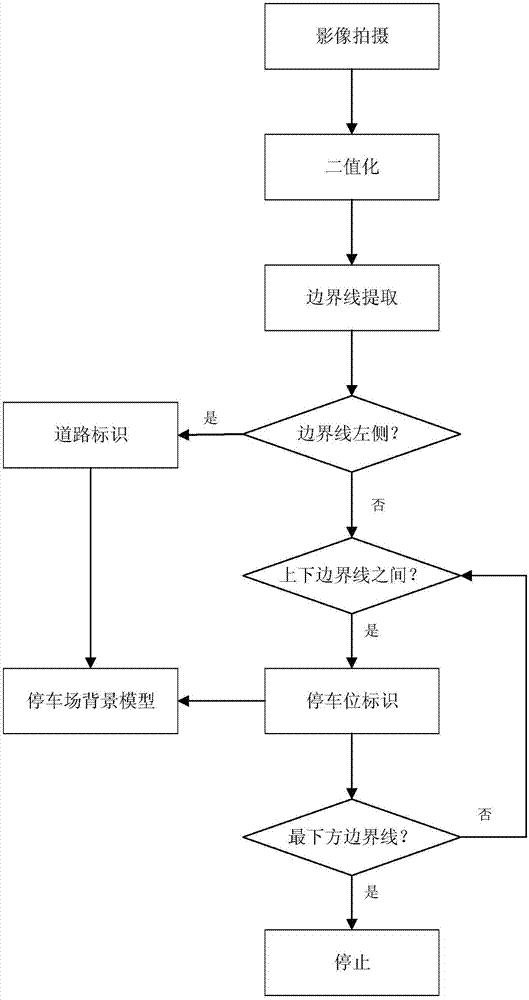

Unmanned roadside parking toll collection system

InactiveCN107274495ARealize no chargeSave human resourcesTicket-issuing apparatusCharacter and pattern recognitionPaymentParking area

The invention discloses an unmanned roadside parking toll collection system which comprises a data processing module, a video acquiring module, a data storage module and a data transmission module, wherein the video acquiring module, the data storage module and the data transmission module are connected with the data processing module. The video acquiring module acquires video frame data in a parking area. The data storage module stores user information, user parking information, a parking toll collection standard and a user backlist. The data transmission module realizes data exchange between the data processing module and a user client. The data processing module comprises an image recognition unit, a toll collection unit and an alarm unit. The image recognition unit detects and traces a vehicle target which drives the parking area. The charging unit calculates a parking expense of the user and transmits an electronic invoice to the user client. The alarming unit transmits alarm information to the user client which does not confirm parking, drive out of a parking space or pay the parking expense in a preset threshold time period. The unmanned roadside parking toll collection system realizes full-process electronic management for identification, charging and expense payment of a roadside vehicle parking behavior.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

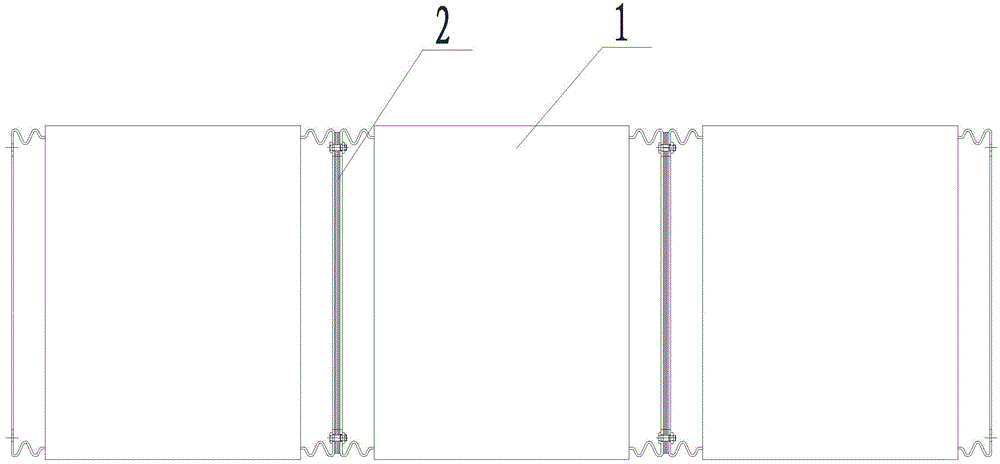

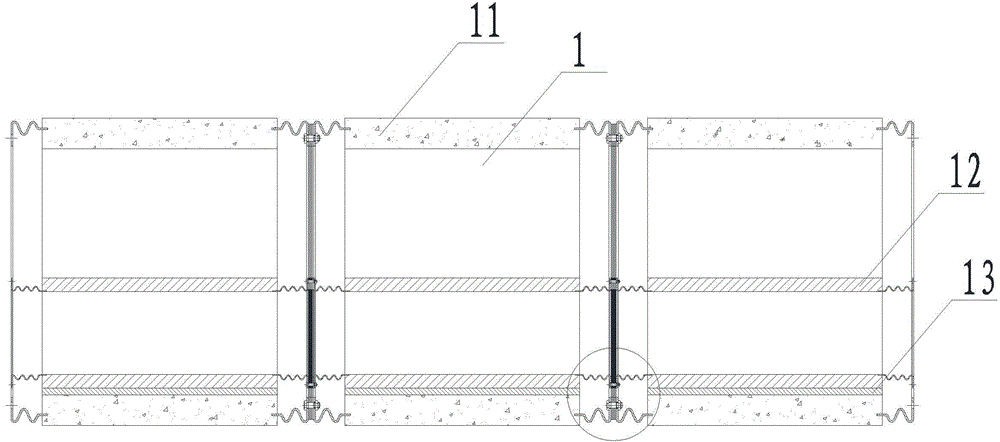

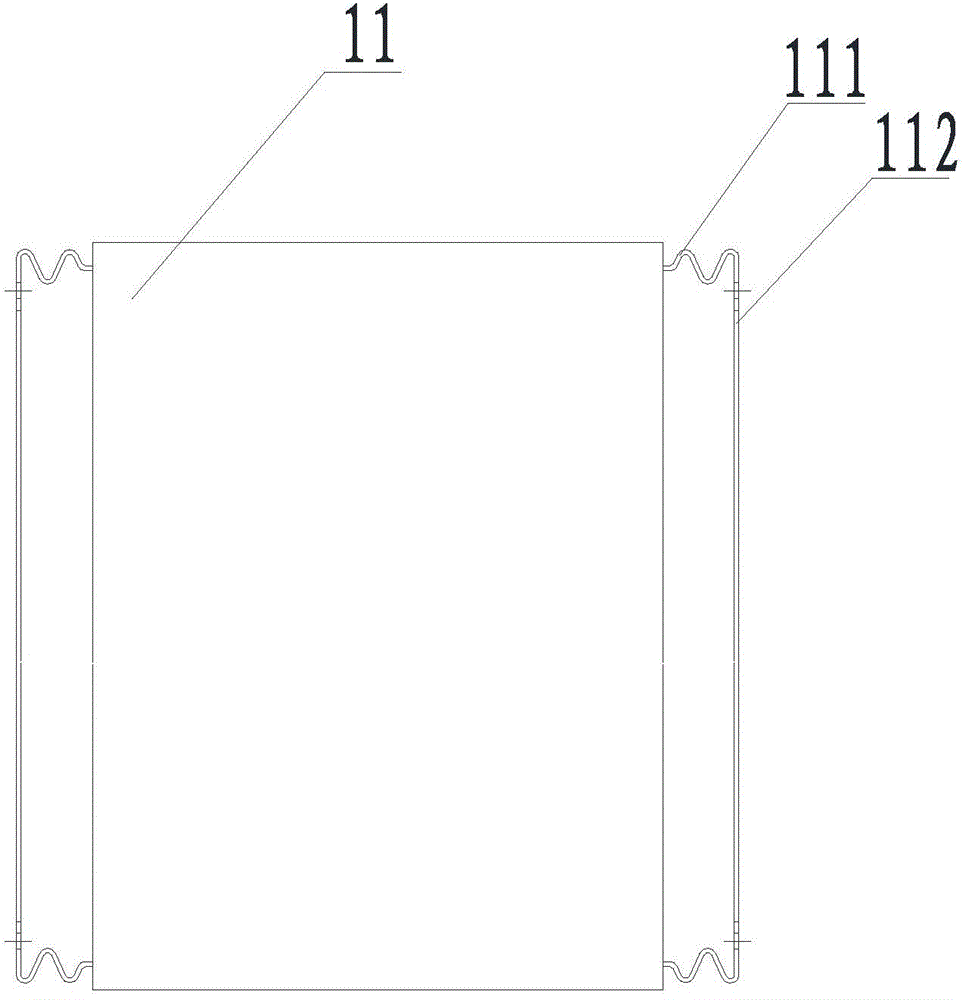

Integrated underground pipe gallery with compensation device

InactiveCN104455889AImprove carrying capacityImprove stress resistancePipeline expansion-compensationAdjustable jointsParallel pipelineFlange

The invention provides an integrated underground pipe gallery with a compensation device, and the integrated underground pipe gallery with the compensation device is high in mounting efficiency, low in cost, high in bearing capacity, long in service life and convenient to repair. The integrated underground pipe gallery with the compensation device comprises a plurality of pipe joint sealing bars and a plurality of pipe joint units connected end to end, the pipe joint sealing bars are arranged between the adjacent pipe joint units, the pipe joint units comprise pipe joints and a plurality of parallel pipelines, the pipelines are arranged on the inner bottom faces of the pipe joints through fixing seats, the two ends of each pipe joint are provided with pipe joint telescopic connecting pipes matched with the pipe joint in shape respectively, the two ends of each pipeline are provided with pipeline telescopic connecting pipes respectively, first flanges are arranged at the ends, away from the pipe joints, of the pipe joint telescopic connecting pipes, and second flanges are arranged at the ends, away from the pipelines, of the pipeline telescopic connecting pipes. According to the integrated underground pipe gallery with the compensation device, mounting efficiency is improved, construction time and cost are saved, and the capacity of resisting differential settlement of a foundation is enhanced.

Owner:杨帆

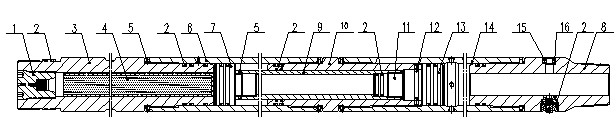

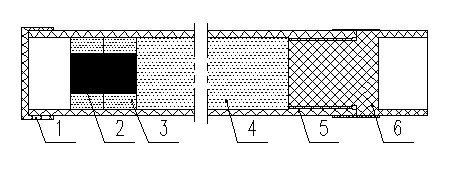

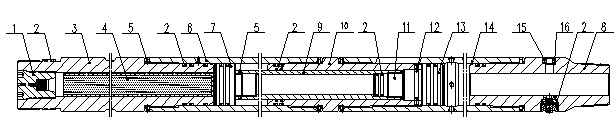

Multi-stage perforation supercharging method

The invention discloses a multi-stage perforation supercharging method. In the technological processes, a supercharging device is connected with the tail of a perforation gun of the upper level, after the perforation gun of the upper level is detonated, the perforation gun transmits detonation waves to the supercharging device, a baffle igniter of the supercharging device is detonated to ignite a supercharging gun powder mechanism, the supercharging gun powder mechanism generates high-pressure gas to push a supercharging piston to move to shear a shear pin of the supercharging device, and to push the piston to extrude a liquid inside an interlayer oil pipe so as to increase the pressure inside the interlayer oil pipe, and the shear pin of the lower-level detonation device is shorn off to detonate a pressure detonation device and a perforation gun of the lower level so as to complete the perforation operation of the lower level. The method can ensure the stability and the controllability of pressure generated due to the combustion of supercharging gun powder in a supercharging cavity, the pressure is then acted on the supercharging piston to ensure that the supercharging piston moves stably, the method can also realize high-precision shearing, can be used in a pressure type multi-stage perforation process, and is suitable for various well conditions.

Owner:CHUANNAN ENERGY TECH CO LTD

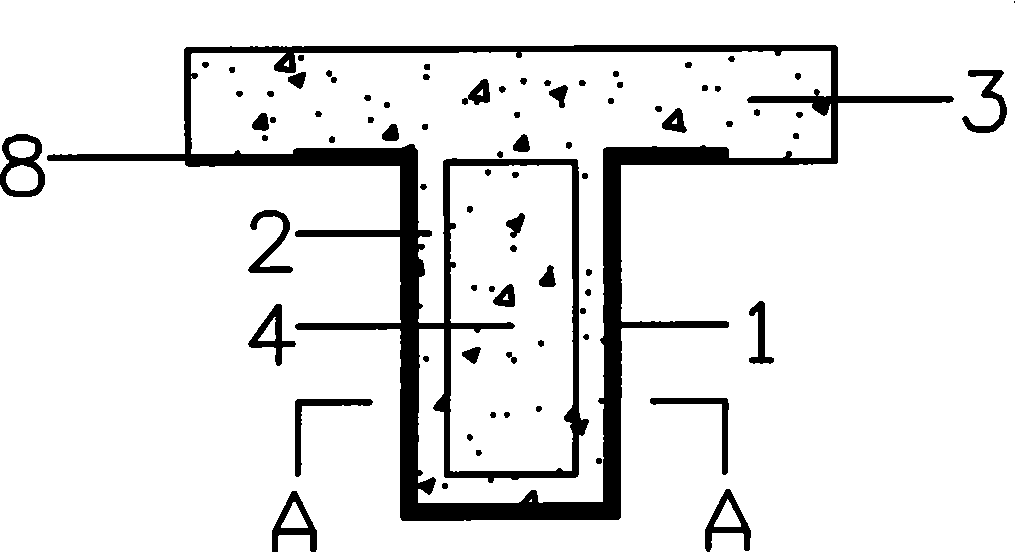

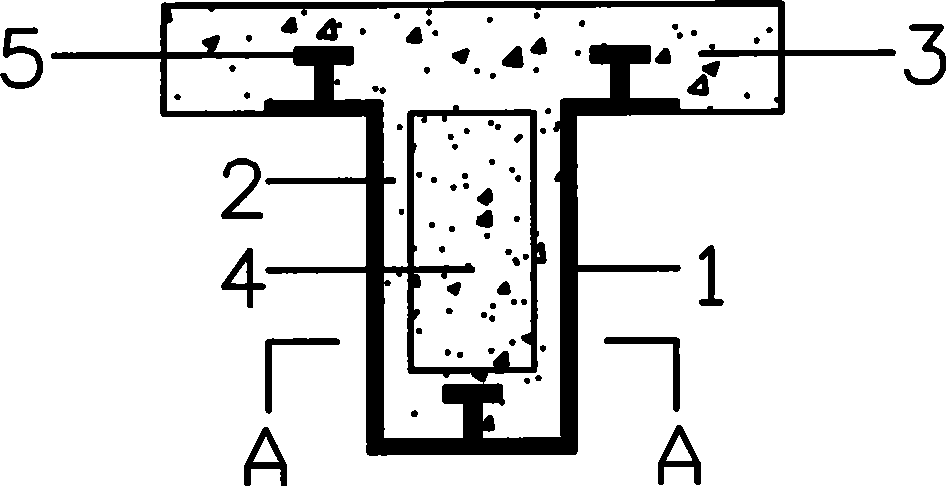

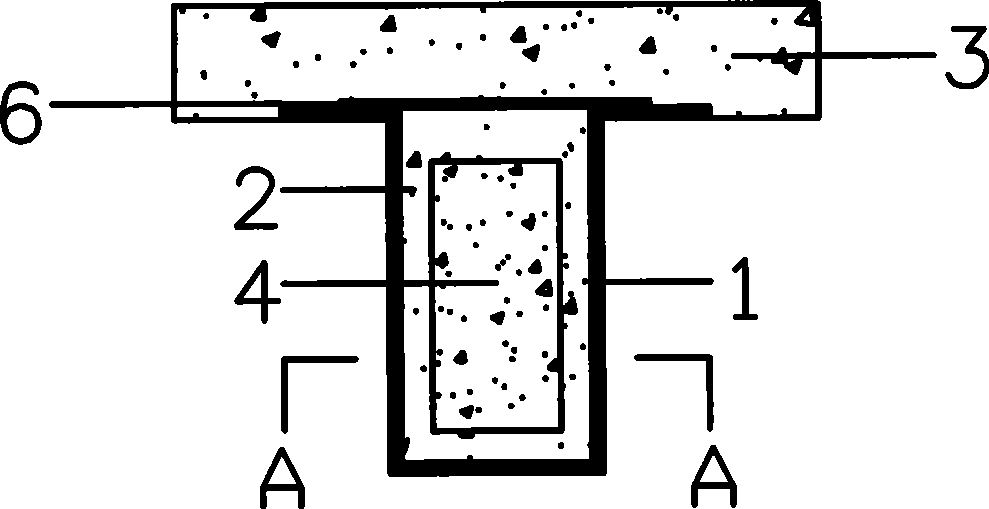

U-shaped steel-coated Regenerated composite beam of and construction method thereof

InactiveCN101418631AIncrease stiffnessImprove ductilityFloorsLoad-supporting elementsFloor slabRebar

The invention discloses a U-shaped steel-encased regenerated composite beam and a construction method thereof. The U-shaped steel-encased regenerated composite beam comprises one or more disused concrete blocks, new concrete, and U-shaped encased steel, the disused concrete blocks are arranged inside the U-shaped encased steel, and the gap between the disused concrete block and the U-shaped encased steel is filled with the new concrete. The method includes the following steps: the U-shaped encased steel is made as the formwork of a beam and is integrated with the formwork of the floor slab or roof slab; a layer of new concrete is first poured into the U-shaped encased steel, then the disused concrete blocks and new concrete are alternately put into the U-shaped encased steel, tamping is utilized then to distributed the disused concrete blocks into the new concrete; steel bars of the floor slab or the roof slab are put into the formwork of the floor slab or the roof slab, and the new concrete is poured into the formwork of the floor slab or the roof slab. The invention can save a great amount of energy consumed in the processes of breaking, screening, purifying and the like for the concrete waste.

Owner:SOUTH CHINA UNIV OF TECH

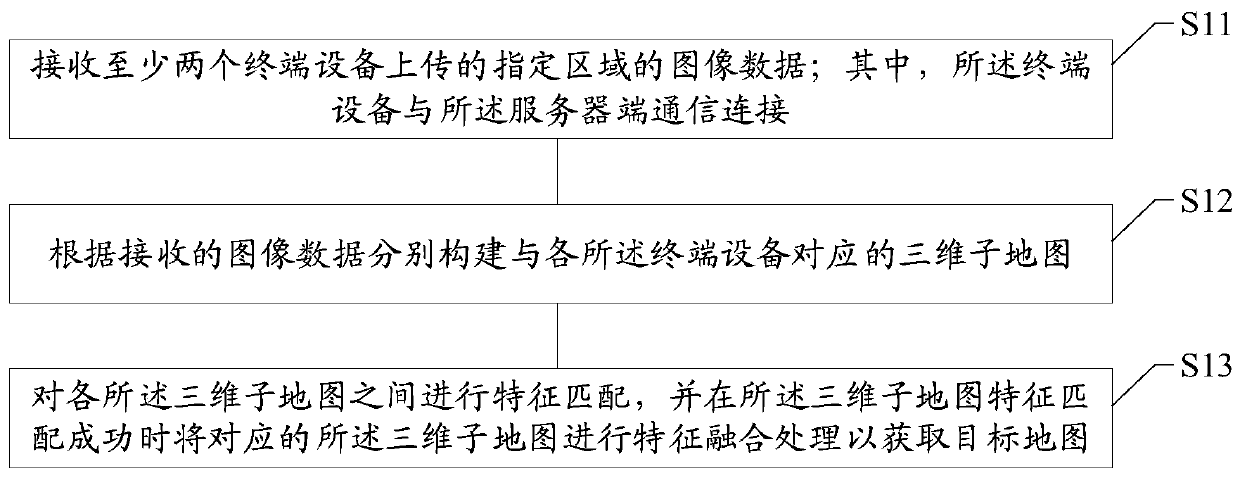

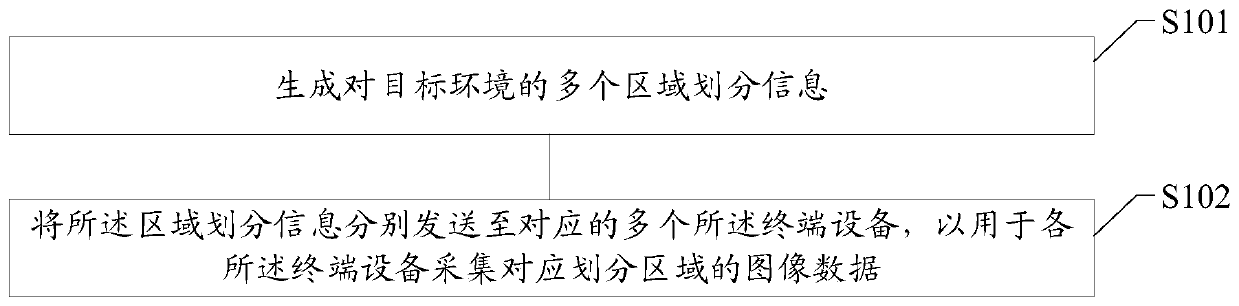

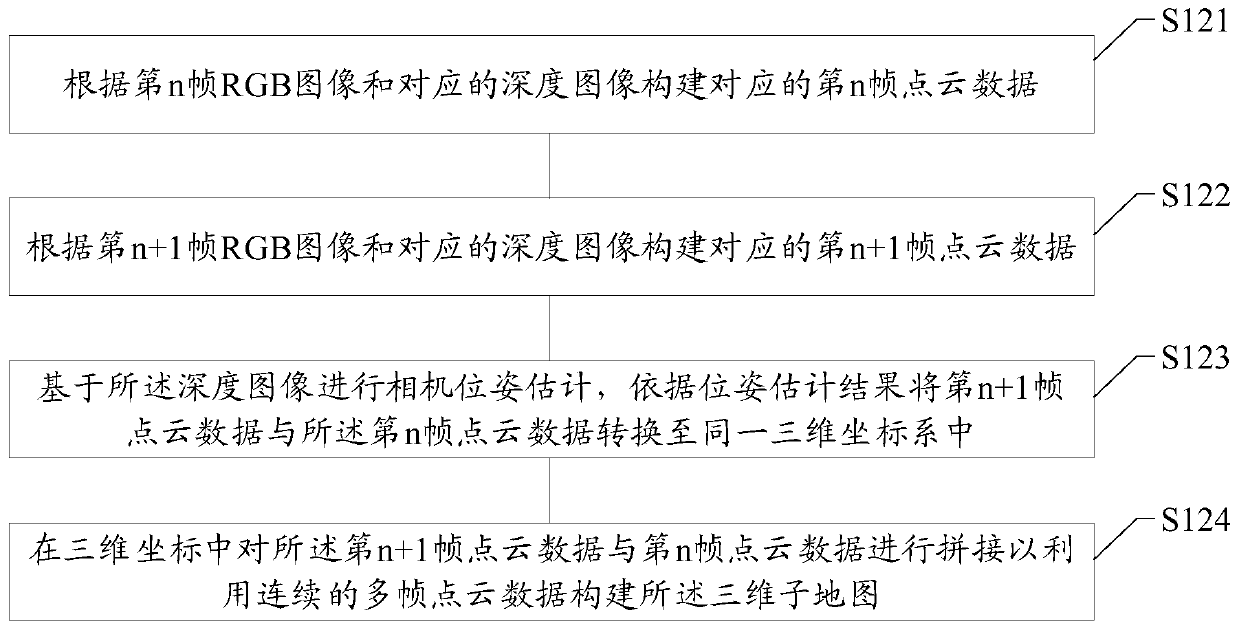

Map construction method and device, computer readable medium and terminal equipment

ActiveCN111174799ASave construction timeInstruments for road network navigationNavigational calculation instrumentsComputer graphics (images)Terminal equipment

The invention relates to the technical field of mobile communication, in particular to a map construction method, a map construction device, a computer readable medium and terminal equipment. The method is applied to a server side and comprises the following steps: receiving image data of a specified area uploaded by at least two sets of terminal equipment, wherein the terminal equipment is in communication connection with the server side; constructing a three-dimensional sub-map corresponding to each set of terminal equipment according to the received image data; and carrying out feature matching on the three-dimensional sub-maps, and carrying out feature fusion processing on the corresponding three-dimensional sub-maps when the feature matching of the three-dimensional sub-maps succeedsso as to obtain a target map. According to the method, the image data can be acquired by using a plurality of sets of terminal equipment, and the accurate target map can be established so that the mapping time can be effectively saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

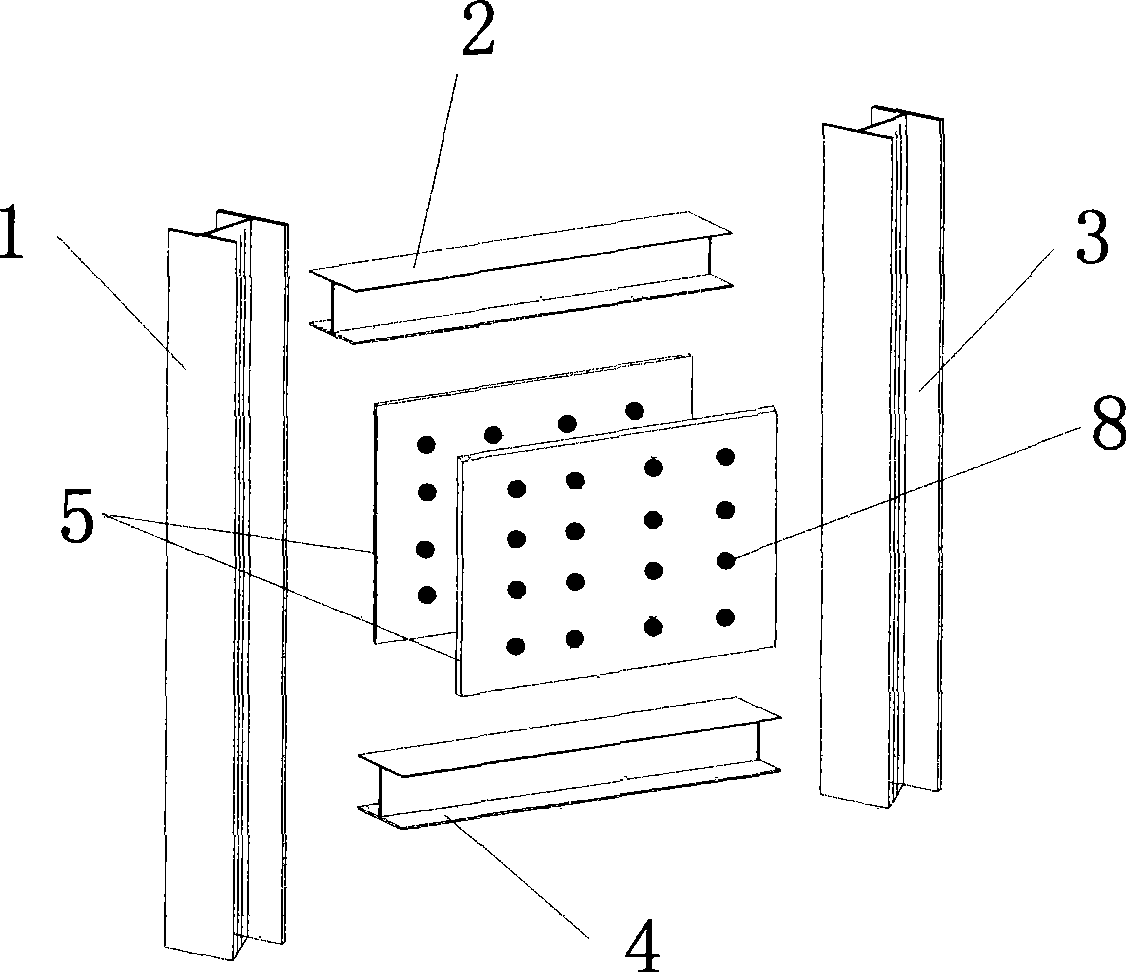

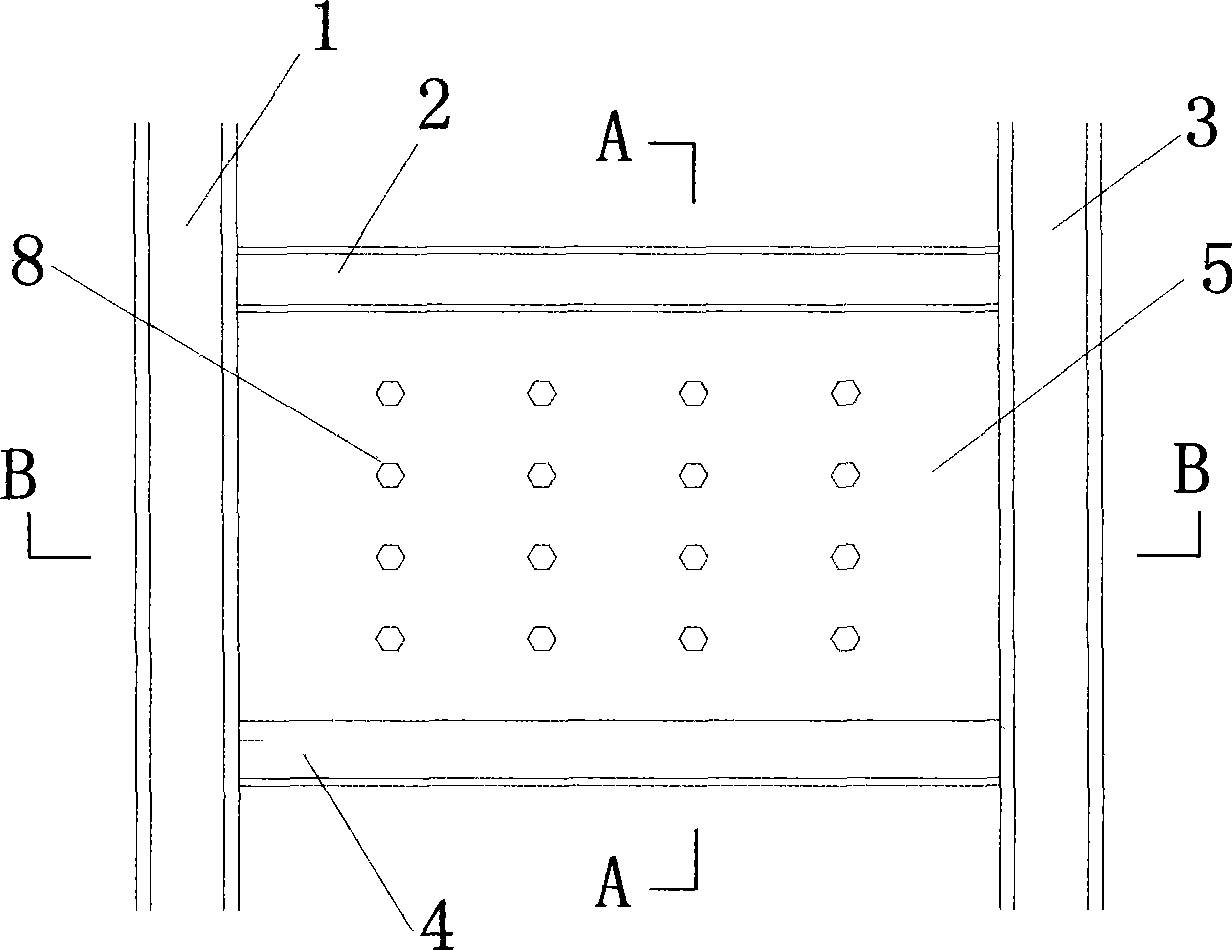

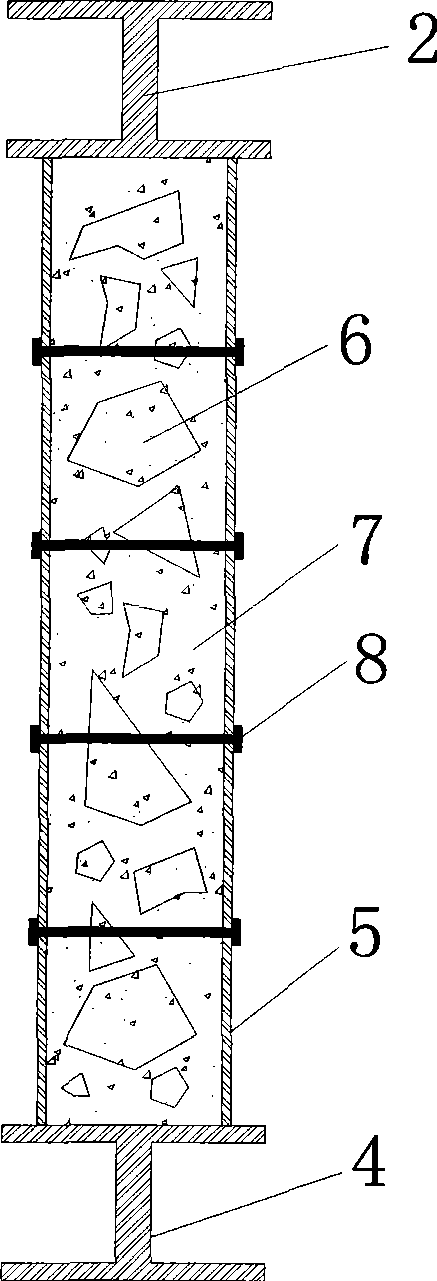

Steel sheet regeneration mixed wall and construction method thereof

The invention discloses a steel plate regenerative composite wall and a construction method thereof. Holes are reserved on front and back corresponding positions of a front steel plate and a back steel plate of the steel plate regenerative composite wall, bolts pass through the reserved holes to connect the two steel plates, concrete is filled between the two steel plates, the concrete comprises new concrete and one or more waste concrete blocks, and the new concrete is filled among the waste concrete blocks and between the waste concrete blocks and the steel plates; the mass ratio of the waste concrete blocks to the new concrete is 1.4 to 1.1; and the diameter of the waste concrete block is more than 50 millimeters. The steel plate regenerative composite wall is suitable for a building structure, has the characteristics of large side rigidity resistance, good ductility, high bearing capacity and the like, has stable hysteresis performance and large absorbed energy in destructive process, can reduce large usage amount of templates, and can use the waste concrete to reach the aim of environmental protection, energy saving and discharge reduction.

Owner:SOUTH CHINA UNIV OF TECH

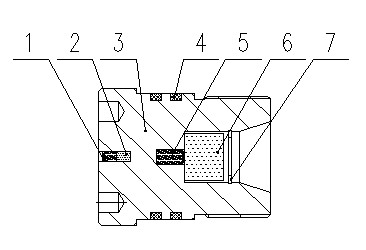

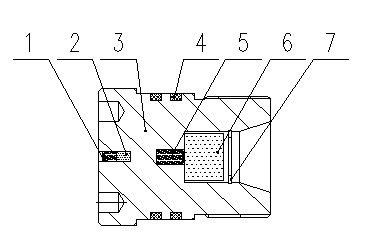

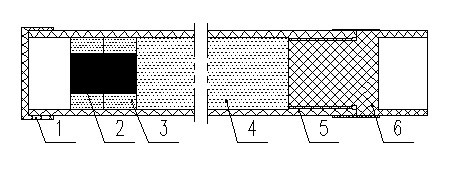

Multi-stage perforating pressurizing device

The invention discloses a multi-stage perforating pressurizing device. The device comprises a power shell and a pressurizing shell positioned on the lower part of the power shell, wherein a power cavity is formed in the power shell; a pressurizing cavity is formed in the pressurizing shell; the power cavity is communicated with the pressurizing cavity; a diaphragm igniter and a pressurizing gunpowder mechanism positioned on the lower part of the diaphragm igniter are arranged in the power cavity; a pressurizing piston driven by power generated by the power cavity is arranged in the pressurizing cavity and is connected with a piston through a push rod; and the piston is fixed on an intermediate joint through a shear pin. The stability and controllability of pressure generated by the combustion of gunpowder in the pressurizing cavity can be ensured; the pressure is applied to the pressurizing piston, so that the pressurizing piston moves stably; pressure increment is generated in an interlayer oil pipe, so that a next stage pressure initiation device and a next stage perforating gun are reliably detonated; and the multi-stage perforating pressurizing device is used for the pressure multi-stage perforating process, is suitable for various well conditions, and particularly can meet the requirements of a high-inclination well and a horizontal well on multi-section, large-distance and negative pressure perforating.

Owner:CHINA PETROLEUM LOGGING CO LTD +1

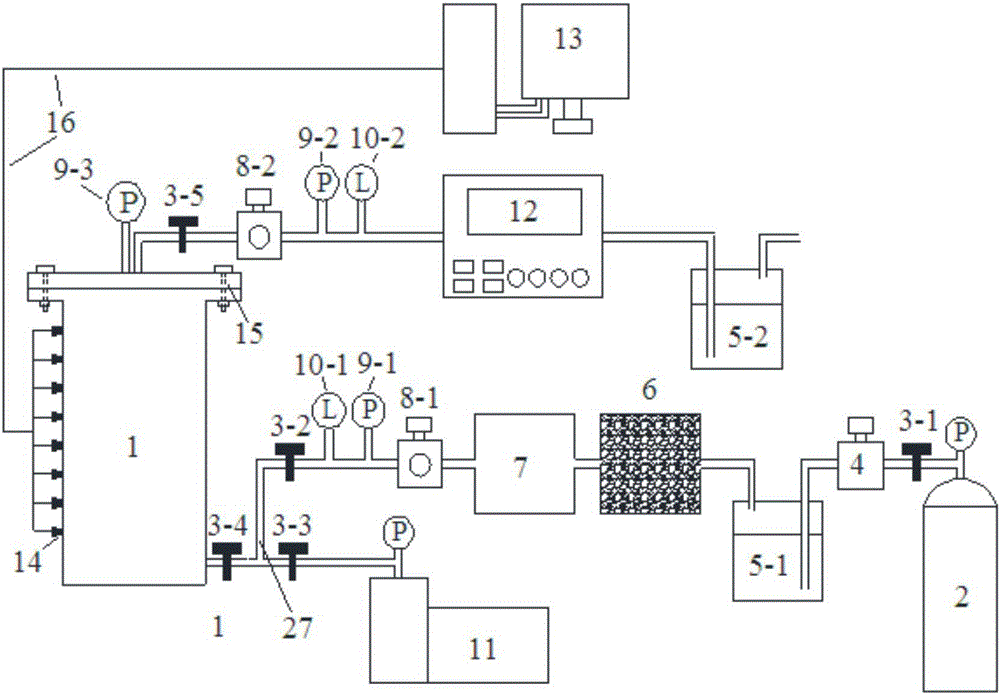

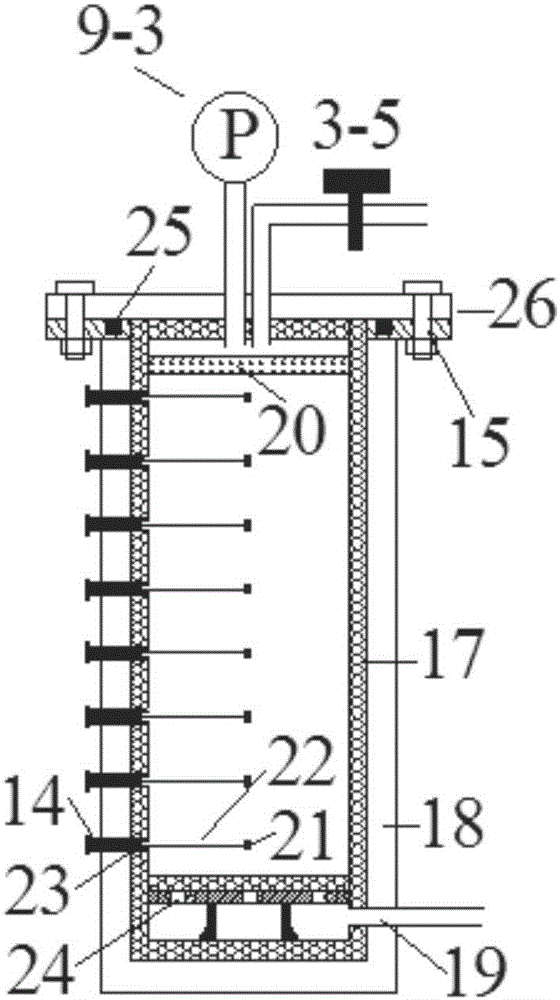

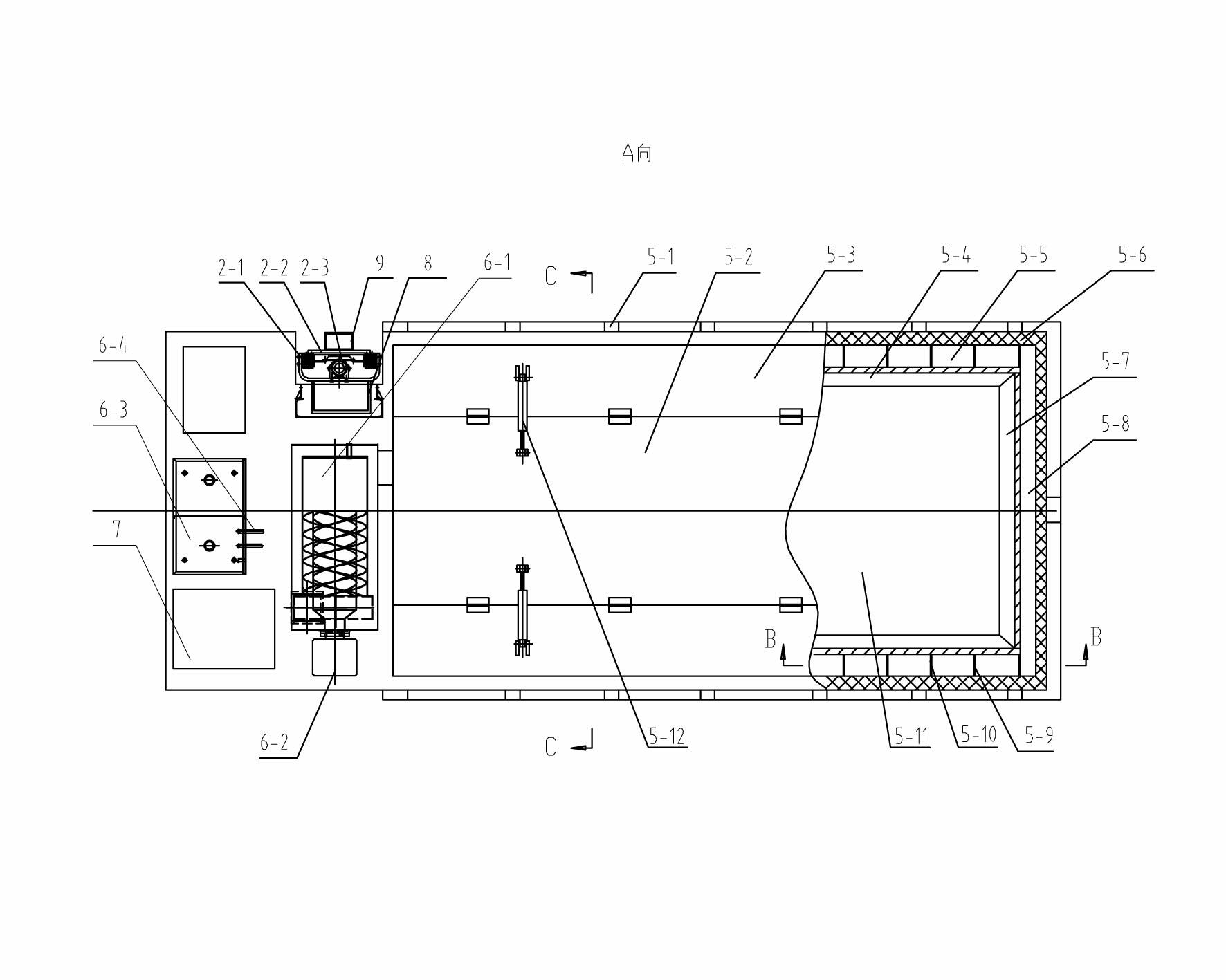

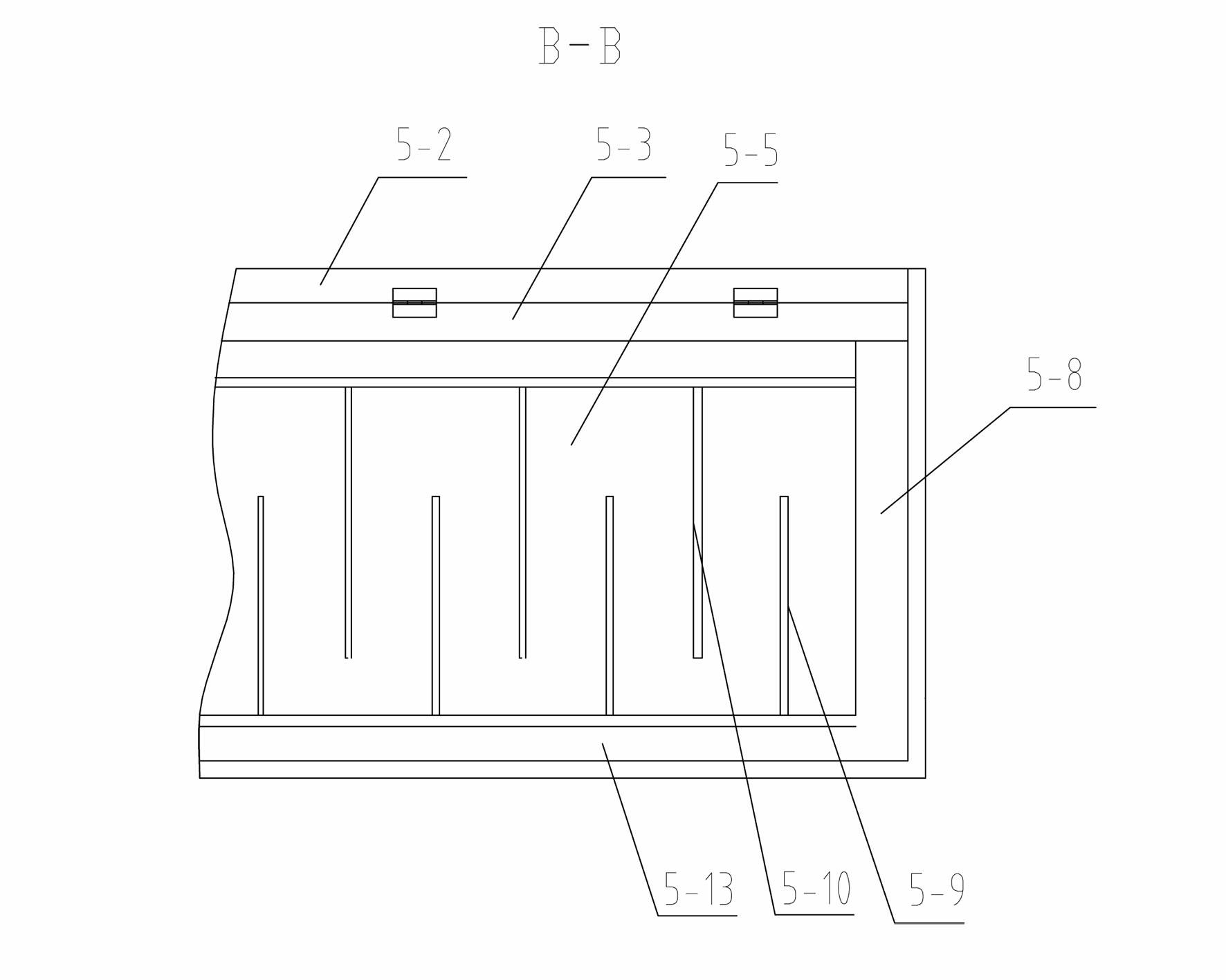

Gas extraction and coal spontaneous combustion coupling disaster-causing experimental simulation apparatus and method

InactiveCN106770897AScientific and preciseLow costChemical analysis using combustionSteel tubeProcess engineering

The invention discloses a gas extraction and coal spontaneous combustion coupling disaster-causing experimental simulation apparatus and method in a coal mine. The gas extraction and coal spontaneous combustion coupling disaster-causing experimental simulation apparatus comprises a pressure-resistant insulation seal tank, a gas extraction and filling apparatus and a monitoring apparatus; the gas extraction and filling apparatus comprises a vacuum gas extraction pump and a constant-pressure gas filling apparatus, the constant-pressure gas filling apparatus comprises a gas filling bottle with a pressure gauge, a decompression valve, an explosion-proof gas washing box, a gas drying box, a constant-temperature heating box, a pressure stabilizing valve, a pressure gauge, a flow gauge and two gas switch valves; the monitoring apparatus comprises a plurality of temperature sensors, a temperature analysis instrument and a gas chromatograph; the pressure-resistant insulation seal tank is internally provided with a coal sample, and the gas extraction and filling apparatus enables the vacuum gas extraction pump and the constant-pressure gas filling apparatus to be respectively connected with the coal sample in the heat-resistant insulation seal tank through an h-shaped steel pipe; and the monitoring apparatus is connected with the pressure-resistant insulation seal tank. By adopting the gas extraction and coal spontaneous combustion coupling disaster-causing experimental simulation apparatus and method, a gas extraction and coal spontaneous combustion coupling disaster causing process in the underground gas extraction process of a coal mine can be really and accurately simulated.

Owner:CHINA UNIV OF MINING & TECH

Defect reinforcing and processing construction method of drill filling pile

The invention discloses a construction method for consolidation treatment of a defective bored pile, which comprises the following steps: 1. measure lofting: according to the result obtained by the sound wave detection of a defective pile foundation, the measure lofting of the defective pile foundation is performed, and the central position of the defective pile foundation and the thickness of the defective position are determined; 2. excavating a central hole: according to the position of the pile foundation undergoing the measure lofting, the hole is excavated from the center of the pile foundation; 3. processing the defective part: when the defective part is reached by manual excavation, the defective part is checked and cleaned, and no less than 0.5m is excavated in thickness; and, 4. casting concrete: reinforcing steel material which is the same as that used in the pile foundation is processed into a reinforcing steel cage for consolidation, the reinforcing steel cage for consolidation is placed on the bottom part of the hole and fixed; the concrete is cast in the mode of layered casting and layered vibration, after casting the concrete, the pile foundation is naturally cured. The method ensures the engineering quality and saves construction cost and time. The method is particularly suitable for the treatment of the casting pile which has high ground water level and big infiltration capacity and of which the defective part is arranged on the medium upper part of the bored pile and less than 10m away from the ground and the diameter is more than 1.5m.

Owner:TIANJIN 20 CONSTR

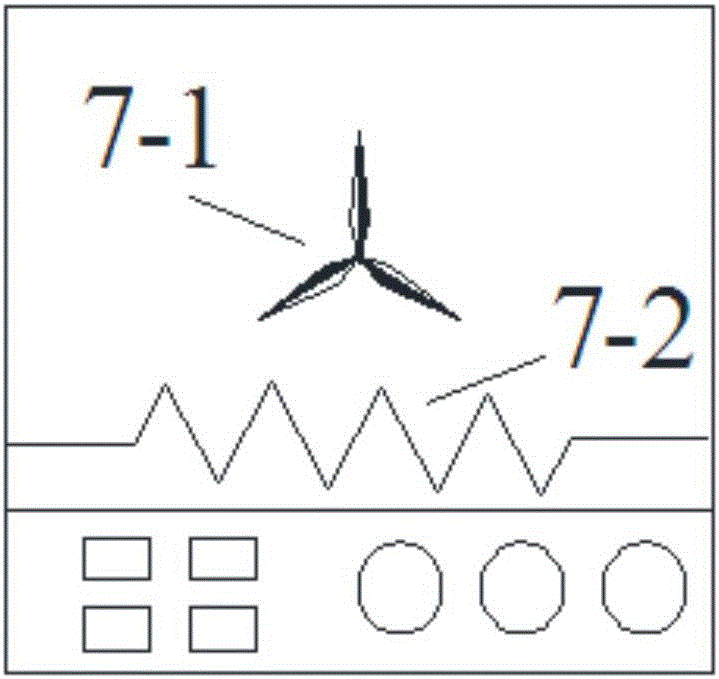

Integrated system for efficiently and synergistically removing multiple pollutants

ActiveCN103994456AImprove removal efficiencyImprove compatibilityLighting and heating apparatusAtmospheric pollutionDust collector

The invention relates to an integrated system for efficiently and synergistically removing multiple pollutants. The integrated system reduces discharge values of smoke, SO2, NOx, mercury, SO3 and other main smoke pollutants to achieve the discharge standard of a fuel gas unit. According to the technical scheme, the system comprises an SCR reactor, low-temperature dust removing equipment, a desulfurizing absorption tower and a wet-type electrostatic dust collector, wherein the inlet of the SCR reactor is connected with a smoke outlet through a tail smoke channel of a boiler improved through low-nitrogen combustion, and SCR denitration catalysts are modified catalysts capable of improving oxidation susceptibility of zero-valent mercury; the inlet of the low-temperature dust removing equipment is connected with the outlet of the SCR reactor to be used for removing dust and SO3; the inlet of the desulfurizing absorption tower is connected with the outlet of the low-temperature dust removing equipment to be used for desulfuration and dust removal; the inlet of the wet-type electrostatic dust collector is connected with the outlet of the desulfurizing absorption tower, and the outlet of the wet-type electrostatic dust collector is connected to a chimney through warming equipment to be used for removing the dust, gypsum fogdrops, the mercury and SO3. The integrated system is used for the technical field of atmospheric pollution prevention.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

Non-excavation and top drilling combined crossing and spanning pipeline laying method

ActiveCN106594386ASave construction costSave construction timePipe laying and repairEngineeringDirectional drilling

The invention provides a non-excavation and top drilling combined crossing and spanning pipeline laying method. The method comprises the steps of carrying out pipe-jacking construction and horizontal directional drilling construction at the same time; getting through the position, where pipelines are to be laid, at the bottom of a receiving shaft; then, enabling the pipelines to communicate with each other; and finally, carrying out backfilling, so as to achieve pipeline laying. According to the method, the part, difficult to construct through a horizontal directional drilling machine, of a pipeline construction zone of a complex stratum is selected as a pipe-jacking construction section, other complex stratums are adopted as horizontal directional drilling machine construction parts according to reconnaissance information, the one-time crossing distance is long, the constructable pipe diameter is large, large-diameter long-distance pipelines can be laid in the complex stratums through one step, construction cost is greatly reduced, and construction time is greatly saved.

Owner:CHINA PETROCHEMICAL CORP +3

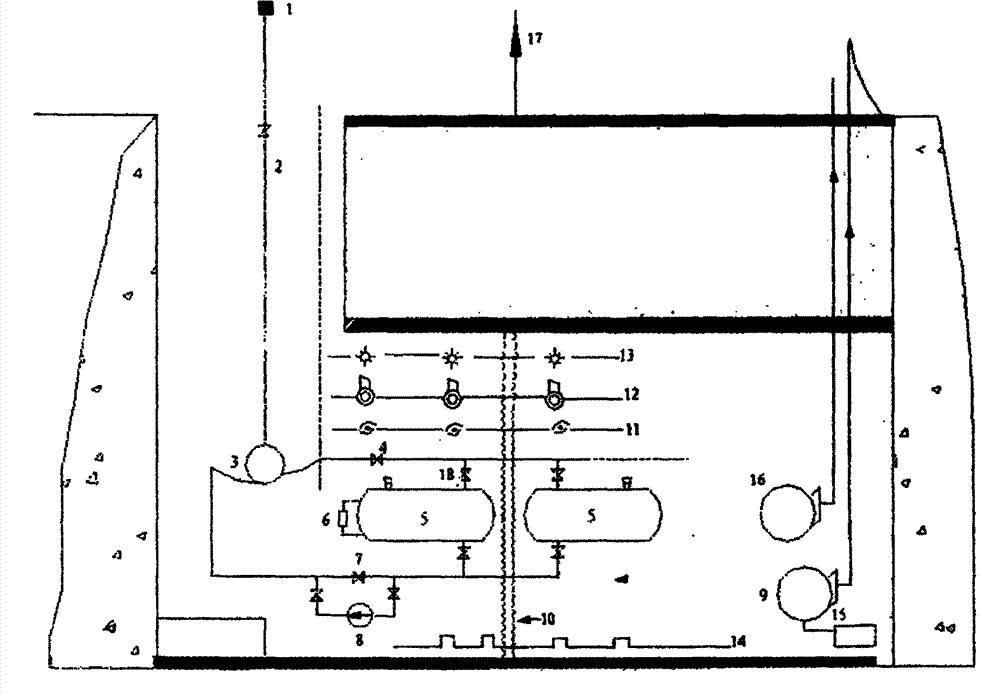

Safe and covert high-capacity oil depot arranged underground

InactiveCN102852367ALarge storage capacityLow costBulk storage containerOperational costsLight equipment

The invention discloses a technical method of a safe and covert high-capacity oil depot arranged underground. The safe and covert high-capacity oil depot arranged underground is characterized in that the oil depot is built in mines to be wasted or abandoned mines or idle tunnels, caves, cave dwellings and culverts. The oil depot is composed of a plurality of nonstandard single storage tanks, wherein the storage tanks are connected through pipelines, and tube valves are mutually communicated and isolated. An oil inlet tube and an oil outlet tube are respectively installed on the upper portion and the lower portion of a tank body and connected with an oil inlet and outlet main tube, the oil inlet tube and the oil outlet tube extend to the ground to be connected with an oil discharge device, and a buffer pump and an oil well pump are installed on the main tube. Inflaming retarding isolation protective screens are arranged among the storage tanks, and a pedestrian path is arranged on the side. Ventilation equipment, fire control equipment, lighting equipment and dewatering equipment are installed in the depot, and a camera shooting monitoring instrument and a gas automatic detecting instrument are installed. The safe and covert high-capacity oil depot arranged underground has functions of fire protection, thunder prevention, war prevention and man-made sabotage prevention, solves the problem that the prior art is large in land occupation, high in construction and operational cost, small in storage content, multiple in environmental factor influence, poor in elusive performance and poor in safety and reliability, and has safety risks on the periphery.

Owner:孔令先 +1

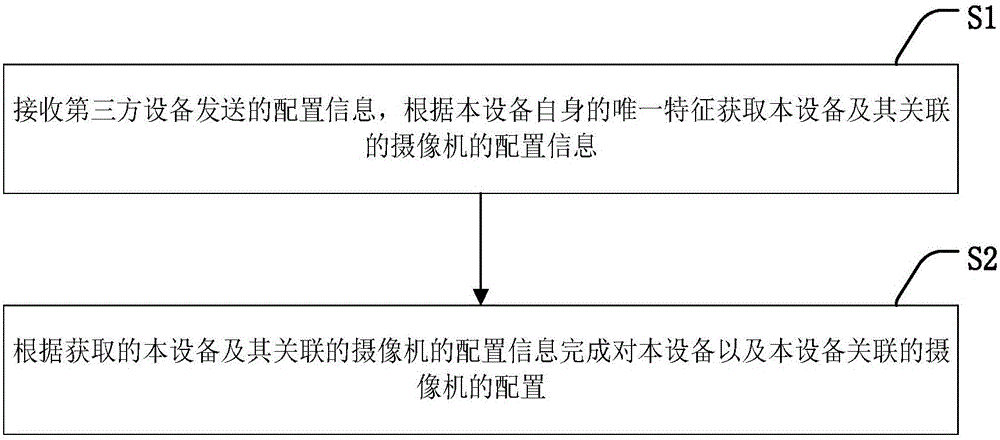

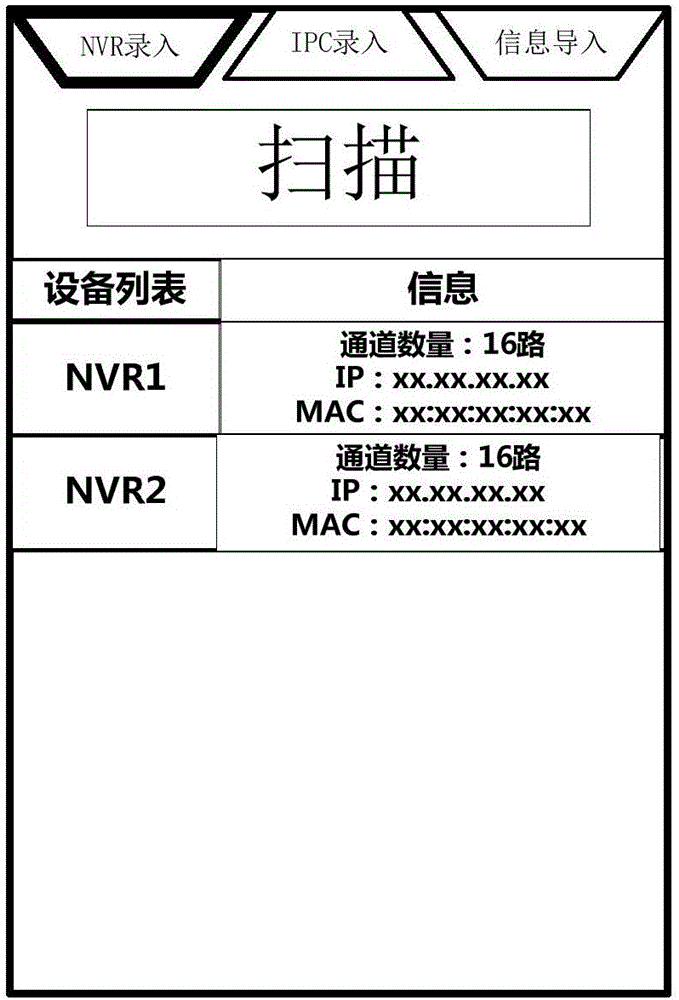

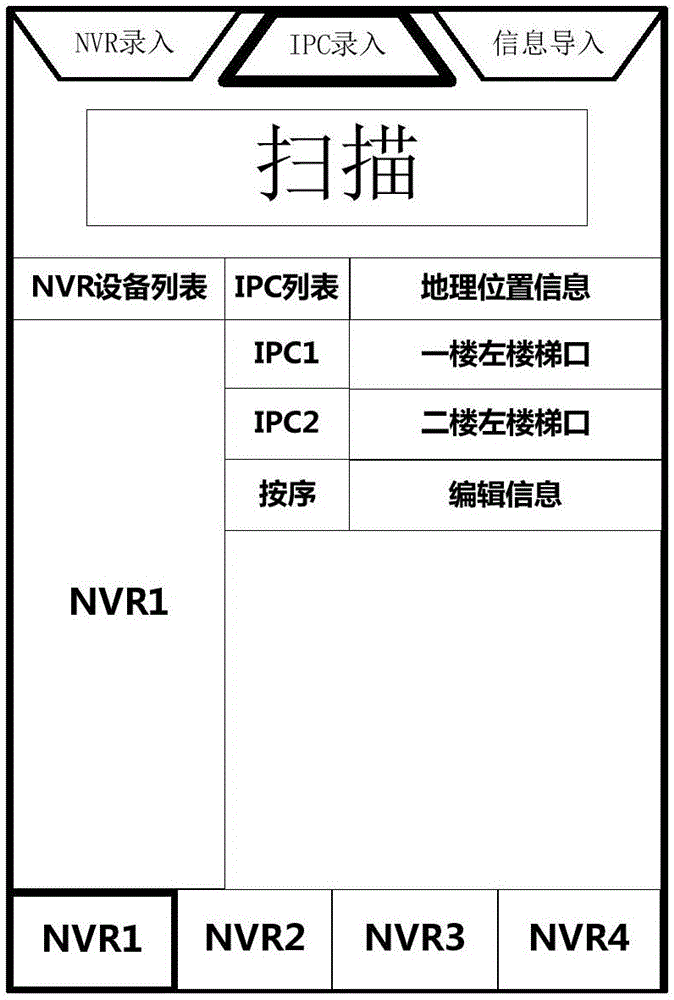

Method and device for configuration of video monitoring equipment

ActiveCN105959644AAddress geolocation additionSave construction time and costTelevision system detailsColor television detailsFeature codeThird party

The invention discloses a method and a device for configuration of video monitoring equipment. The method comprises the following steps that third-party equipment scans feature codes of a network video recorder and a camera in a planning network to generate configuration information, and the network video recorder receives configuration information of the network video recorder and the associated camera thereof from the third-party equipment and obtains configuration information of the equipment and the associated camera thereof according to the unique feature of the equipment; and the equipment and the associated camera thereof are configured according to the configuration information of the network video recorder and the associated camera thereof. The corresponding device comprises a receiving module and a configuration module. According to the method and the device, the construction time and the cost are greatly saved, and the construction access threshold is effectively reduced.

Owner:ZHEJIANG UNIVIEW TECH

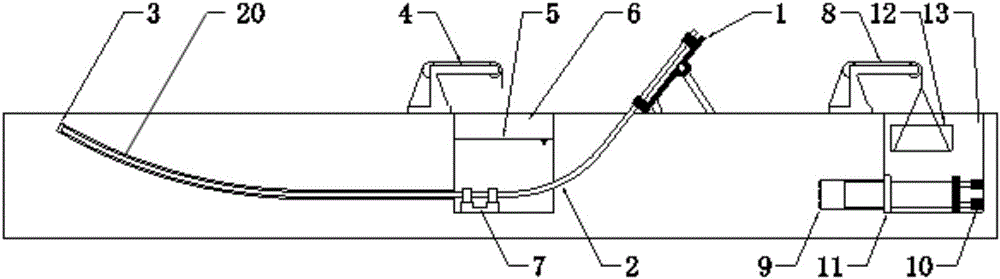

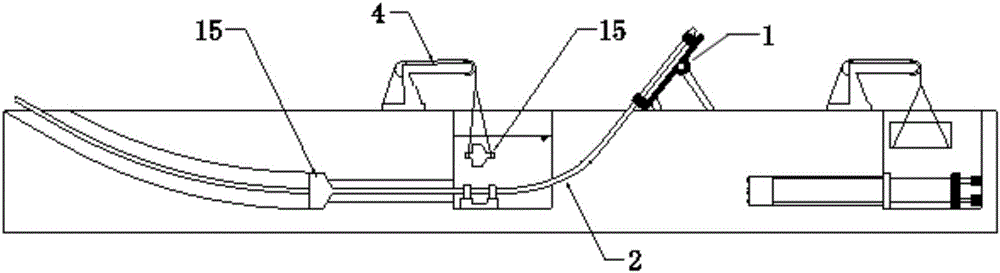

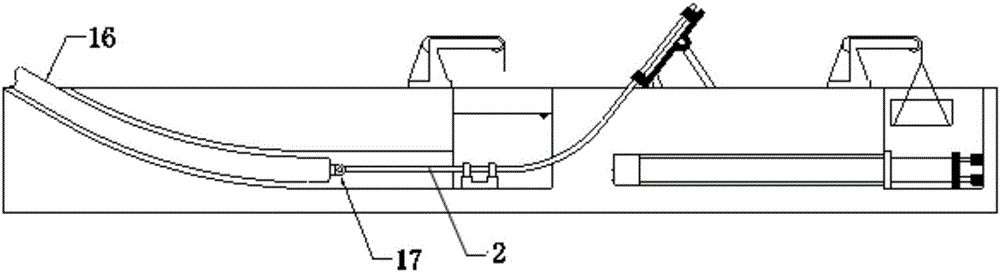

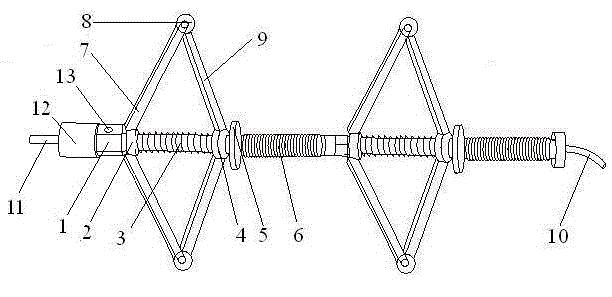

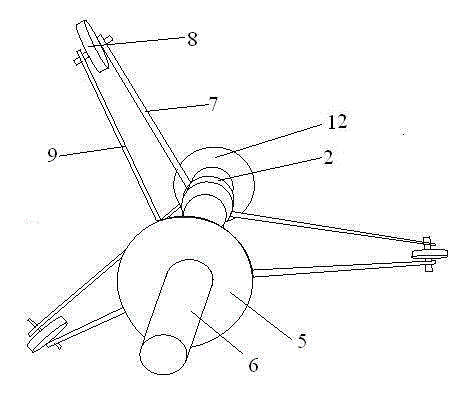

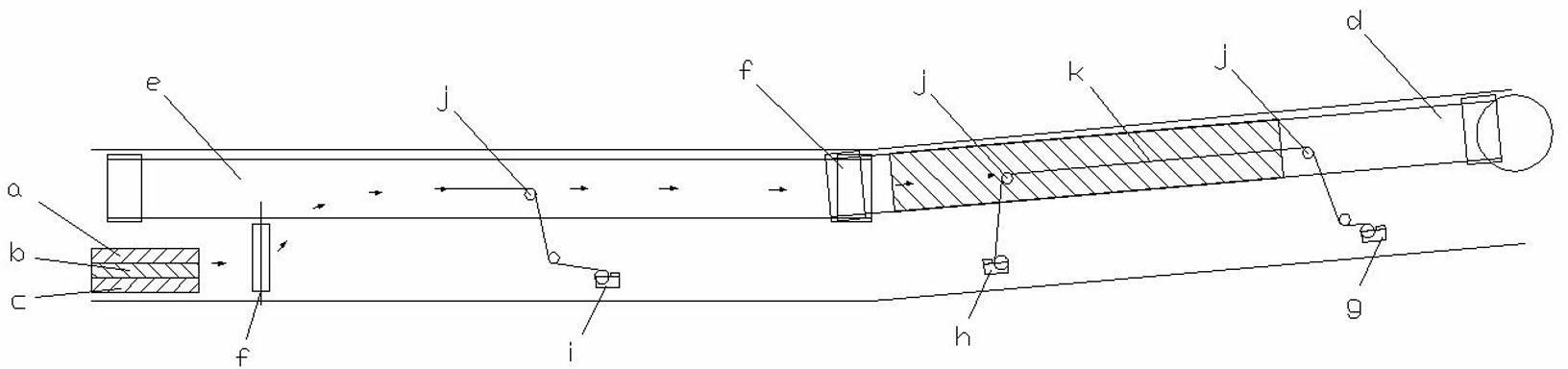

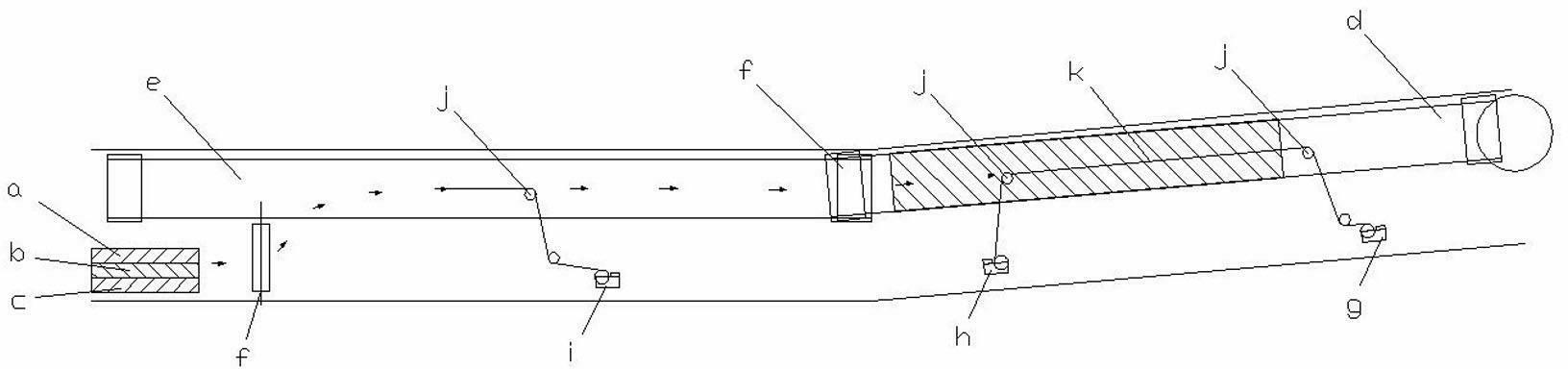

Adjustable pipe center transillumination device

ActiveCN102749340AImprove work efficiencyImprove efficacyMaterial analysis by transmitting radiationDouble wallSingle image

The invention introduces an adjustable pipe center transillumination device, which comprises a radiation source, an exposure head, a source protection cavity, positioning bolts, a first bracket, a second bracket, and a radiation source conveying pipe. Each bracket comprises a hollow tube with thread, a reset spring, a front support ring, a rear support ring, three supporting arms, a fastening adjusting ring with thread; each supporting arm comprises a front supporting leg, a rear supporting leg and a guide wheel; two ends of each supporting leg are respectively fixed on shaft ends of a fixing ring and of the guide wheel; and the second bracket is located behind the first bracket, and connected with the first bracket through threads. The invention has good effect and efficiency improved by 10 times compared with an original double wall single image method, and can save a large amount of construction and detection time, greatly reduce the difficulty of a nondestructive detection, and ensure realization of the whole project goals due to the short radiation time; therefore, the device provided by the invention solves a bottleneck problem of technical pipeline detection construction for a high pressure hydrogenation device or a similar device.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

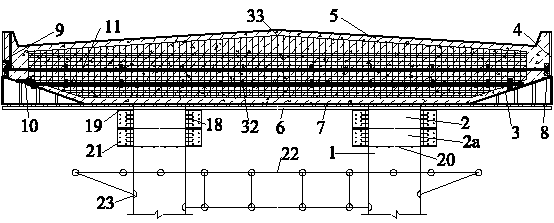

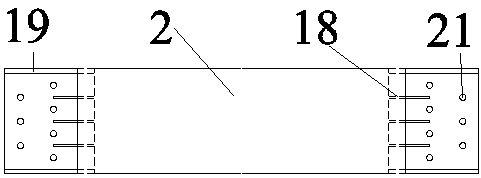

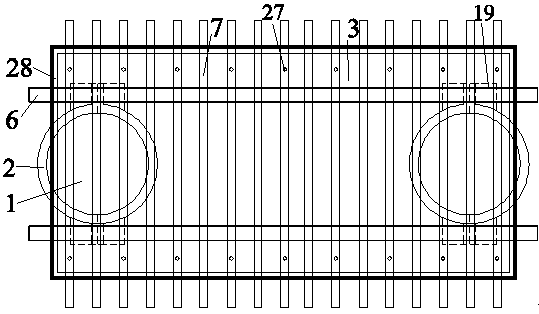

Bridge pier capping beam hoop steel beam template system and construction method thereof

PendingCN108505448ASave on foundation hardening treatment costsSave on hardening costsBridge erection/assemblyPre stressEngineering

The invention discloses a bridge pier capping beam hoop steel beam template system and a construction method thereof. A template system support comprises pier columns, upper hoops, lower hoops, a capping beam pouring template, a cross beam and so on; the upper hoops and the lower hoops are connected with the pier columns through high-strength bolts; hoop cover plates are arranged at the end partsof the upper hoops and the lower hoops; hoop cover plate cross beam placing grooves are formed in the hoop cover plates at the upper end parts of the upper hoops; the cross beam is mounted on the hoopcover plates; longitudinal distribution beam limiting devices are arranged on the cross beam; longitudinal distribution beams are mounted on the cross beam; bottom dies are arranged on the longitudinal distribution beams; an integral steel reinforcement cage, a corrugated pipe, prestressed steel strands and P-shaped anchorage devices are arranged in the capping beam pouring template; and an unitplug-in type safety protective frame is mounted on the pier columns through pier column reserved placing holes. According to the bridge pier capping beam hoop steel beam template system, the bracket foundation treatment cost can be saved, the construction efficiency can be enhanced, the concrete filling difficulty after pre-stressed construction is finished can be reduced by using a tensioning notch sealing anchor concrete filling duct, and the flatness and smoothness of the surface of the tensioned beam body is guaranteed.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

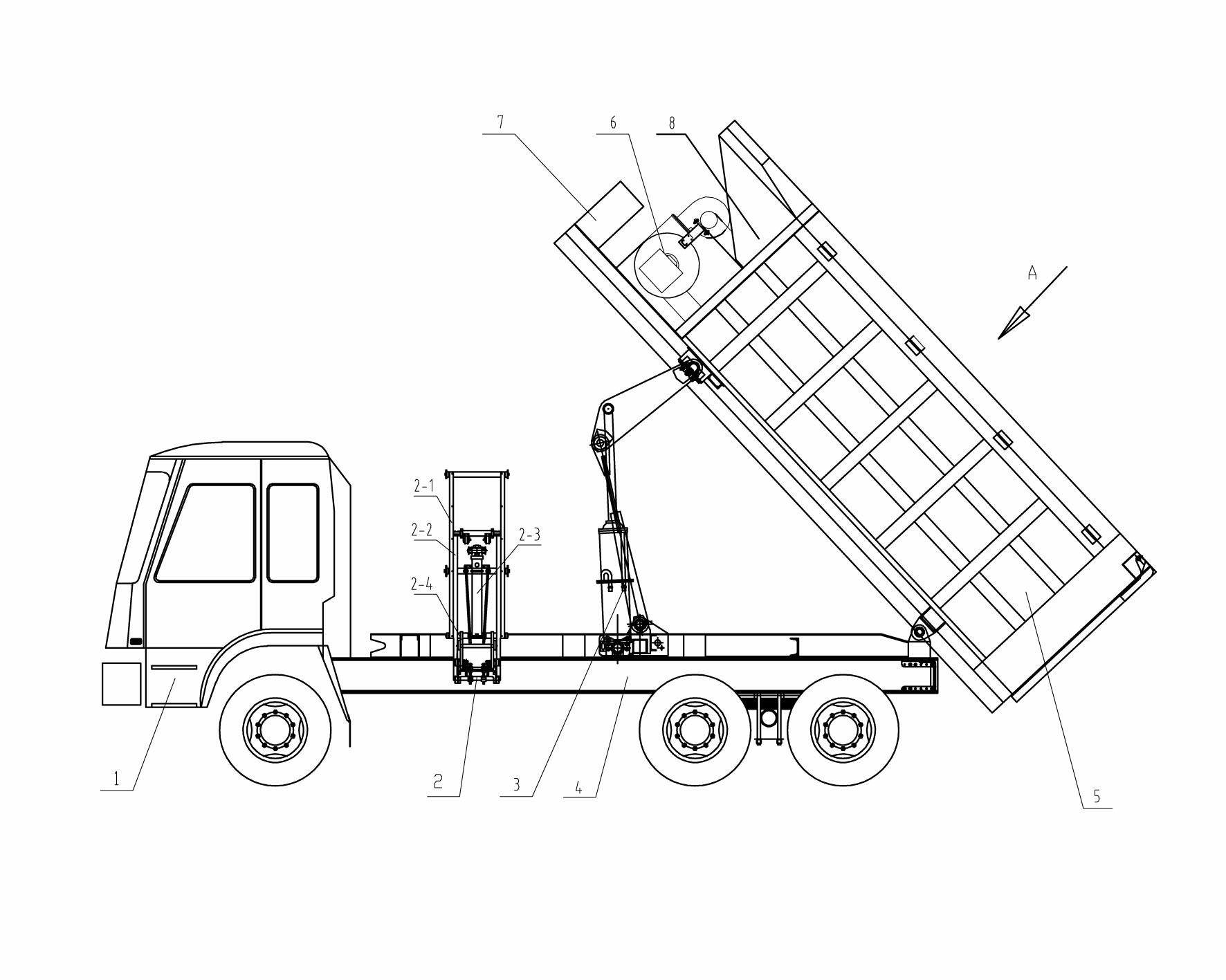

Heat insulation recycling transport vehicle for hot air circulation asphalt mixture

InactiveCN102660917AIncrease the heating areaReduce lossesConcrete transportationRoads maintainenceHeat conservationElectric control

A heat insulation recycling transport vehicle for hot air circulation asphalt mixture comprises a vehicle chassis, an asphalt mixture bin, a bin lifting mechanism, an excess material recycling transport mechanism, a follow charging hopper and an electric control device. The asphalt mixture bin is a tipper-hopper discharge type hot air circulation heating heat insulation bin mechanism, the heat insulation bin mechanism comprises a flipping frame, a heat insulation bin, a hot air circulation furnace device and a generator set, a feeding hopper is arranged on the heat insulation bin and is in butt joint with the follow charging hopper, the heat insulation bin comprises a heat insulation box, a bottom hot air channel, a tail hot air channel, two side wall hot air channels, two groups of spoilers and an inner bin, and the hot air circulation furnace device comprises a diesel tank, a diesel supply device, a hot air furnace and a high-temperature circulation fan. The heat insulation recycling transport vehicle has the advantages that heating is quick and uniform, the heat efficiency is high, hot air with waste heat can be recycled, loading transport heat insulation effects are fine, and the best laying temperature and quality of the asphalt mixture are constantly ensured.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

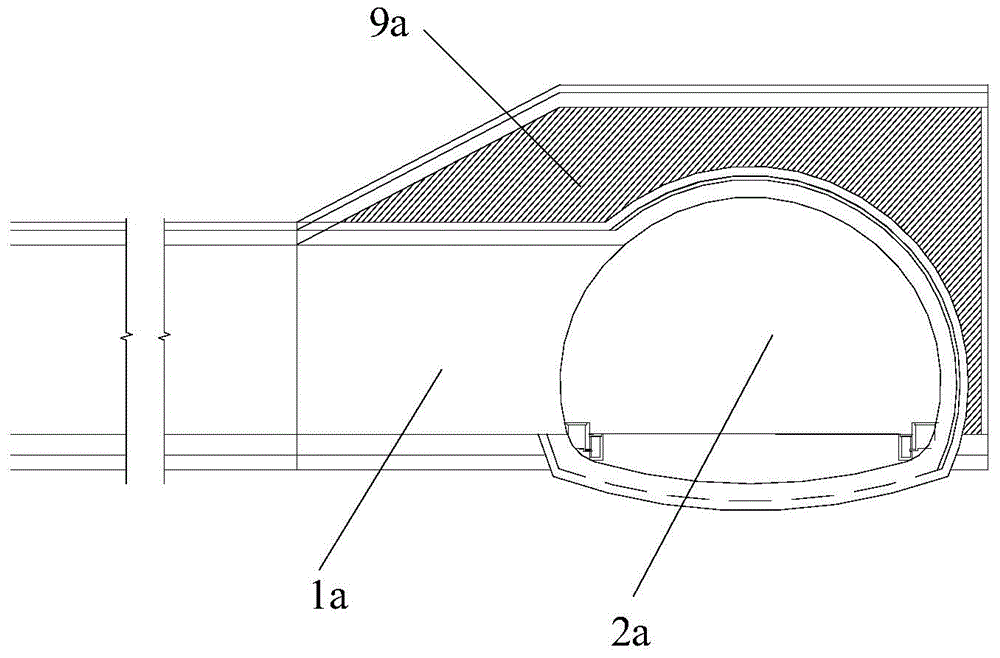

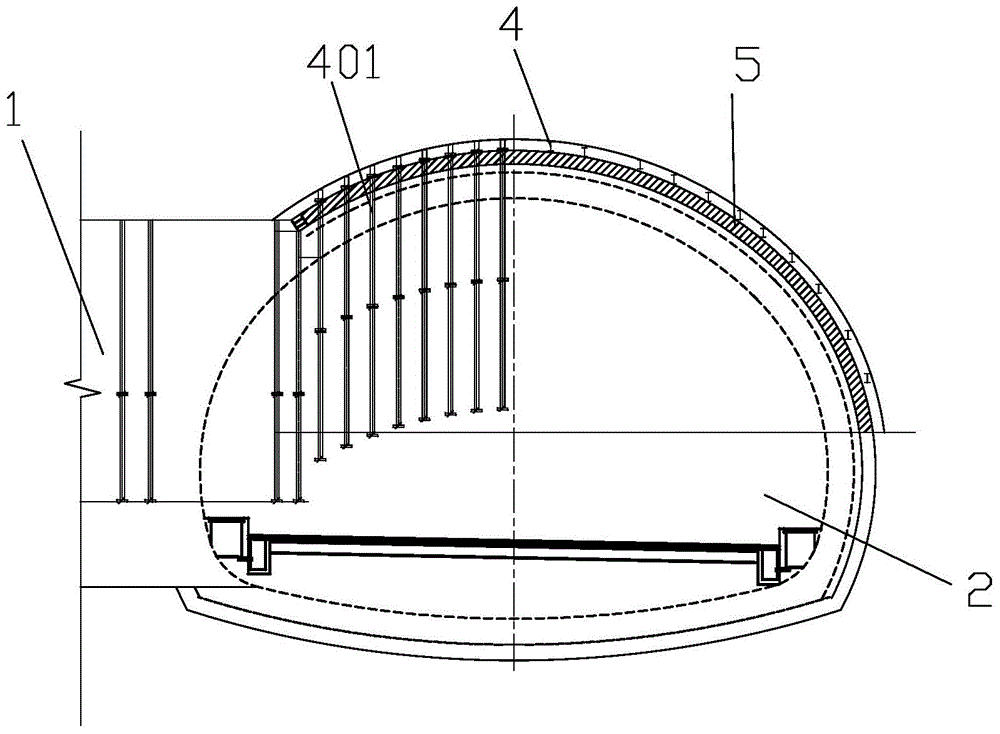

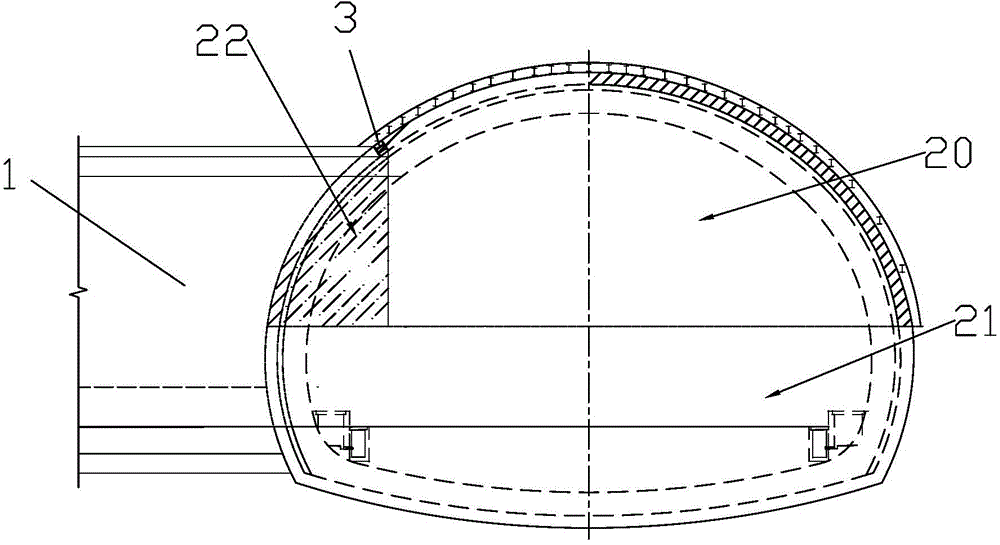

Tunnel transverse cave-to-master cave top brushing construction method and top brushing structure

InactiveCN104929649ASmall excavation areaImprove securityUnderground chambersTunnel liningStep methodBuilding construction

The invention discloses a tunnel transverse cave-to-master cave top brushing construction method. The tunnel transverse cave-to-master cave top brushing construction method comprises the steps that firstly, a transverse cave is constructed to an upper step of a regulated master cave, climbing and direct top brushing are carried out from the top arc outline of the master cave to the width direction of the master cave through a small guiding cave, and a beam is erected at the joint of the transverse cave top and the master cave; secondly, a primary support is carried out on the master cave of the small guiding cave part; thirdly, a vertical support temporarily supported by the small guiding cave in the master cave large mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave large mileage direction; fourthly, a vertical support temporarily supported by the small guiding cave in the master cave small mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave small mileage direction through a step method. The invention further discloses a tunnel transverse cave-to-master cave top brushing structure. The small guiding cave top and the master cave top of the top brushing structure are consistent in structure, the beam is erected at the joint of the transverse cave top and the master cave, and a small guiding cave temporary support is located above a master cave primary support. The top brushing excavation area is small, and the construction risk is low.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

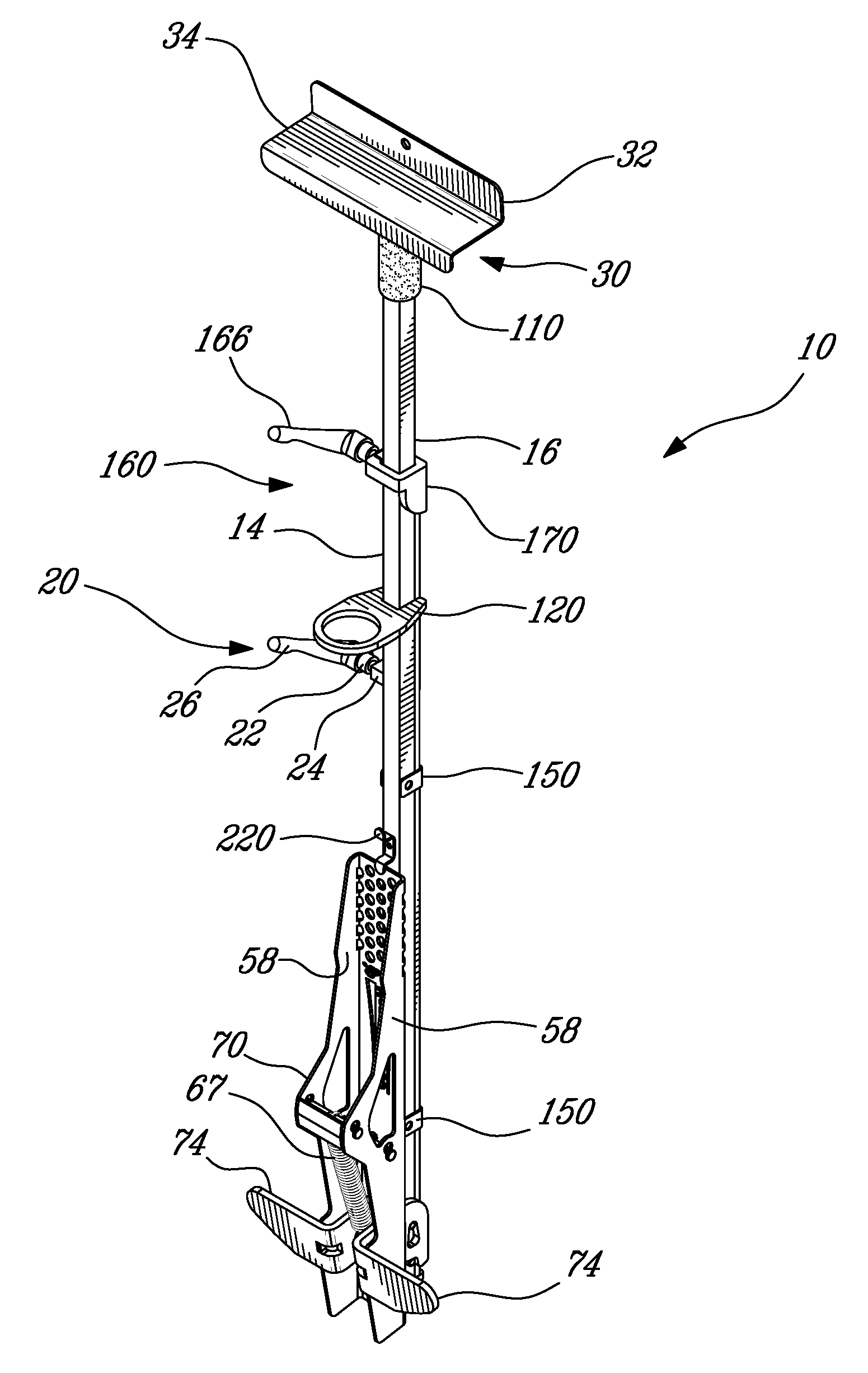

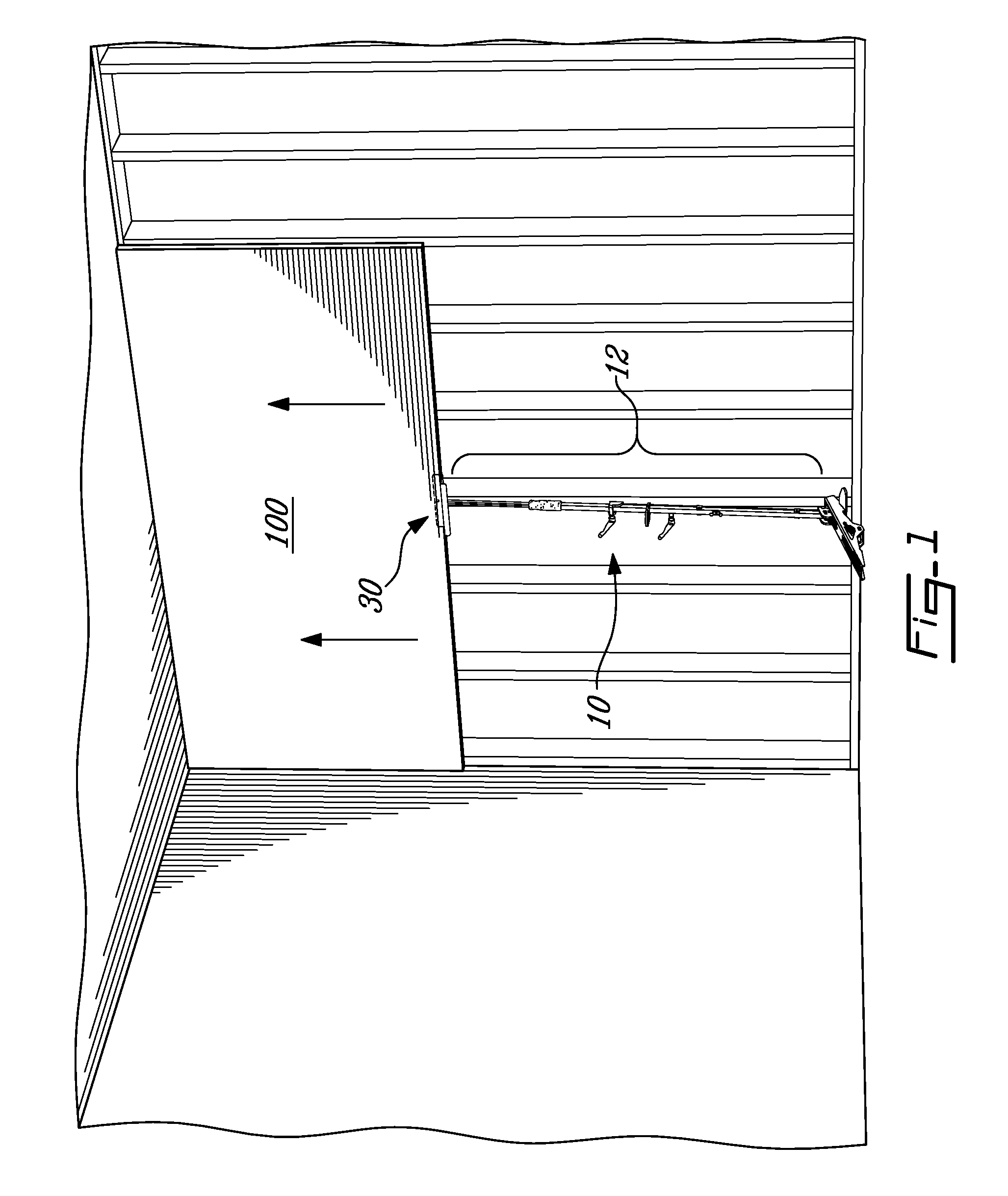

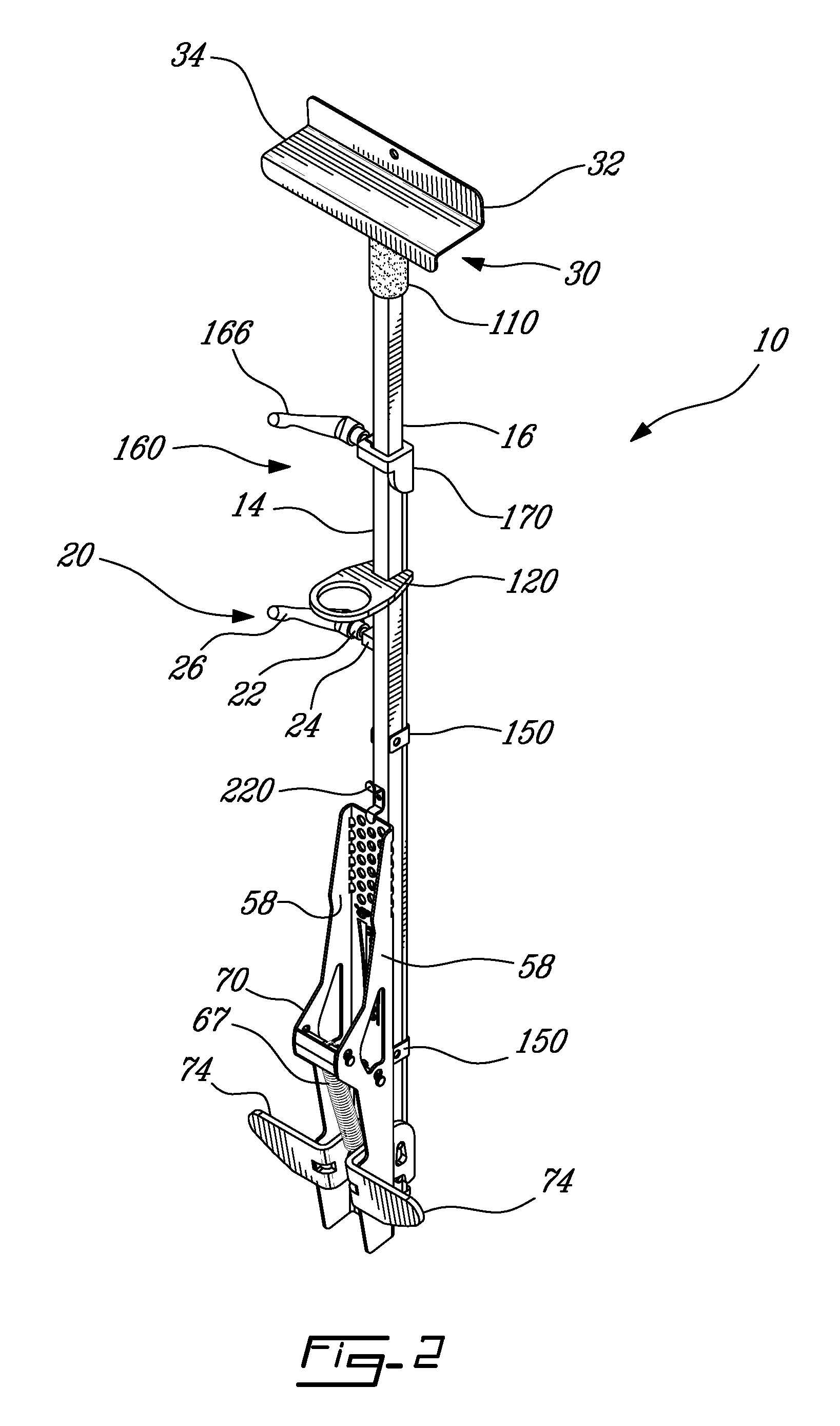

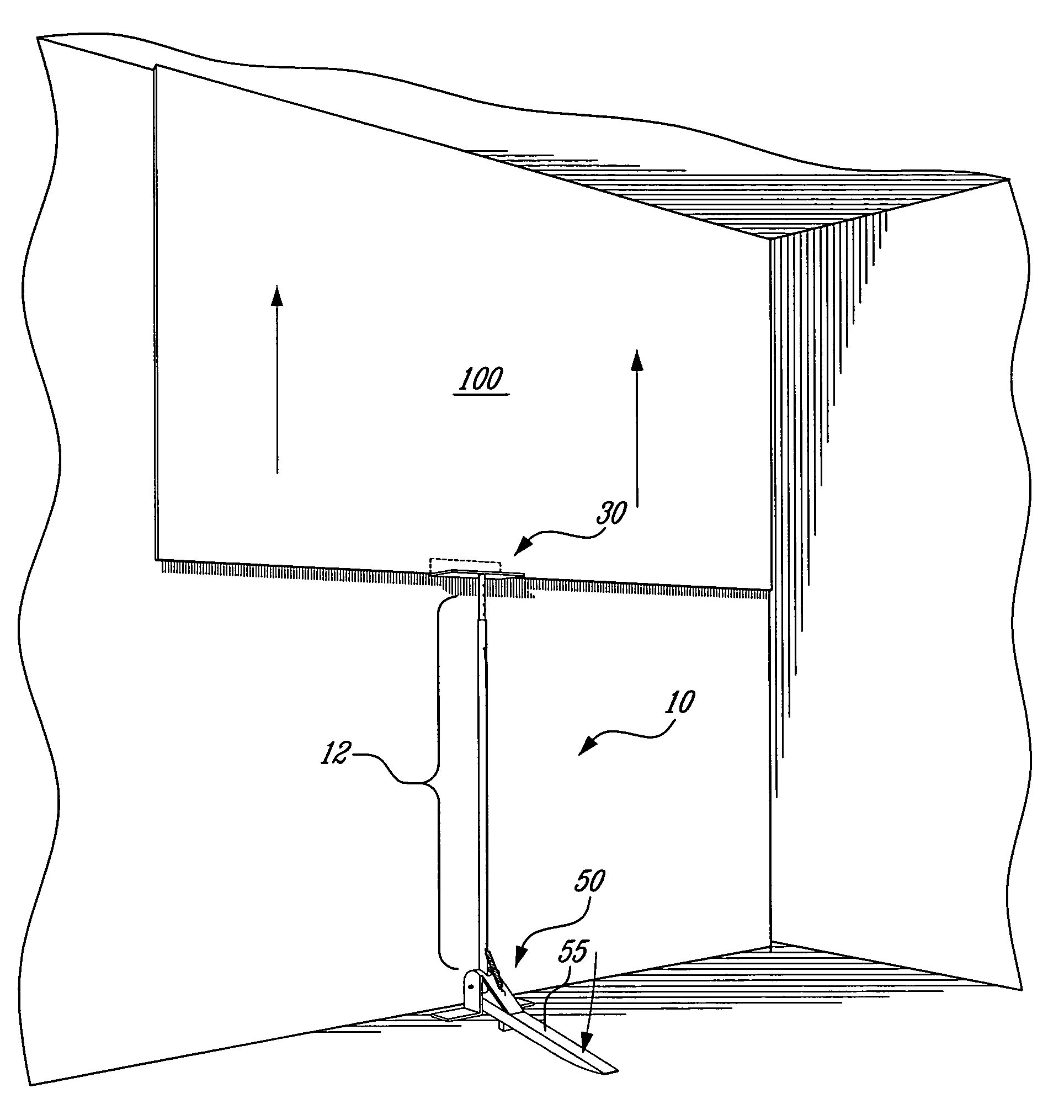

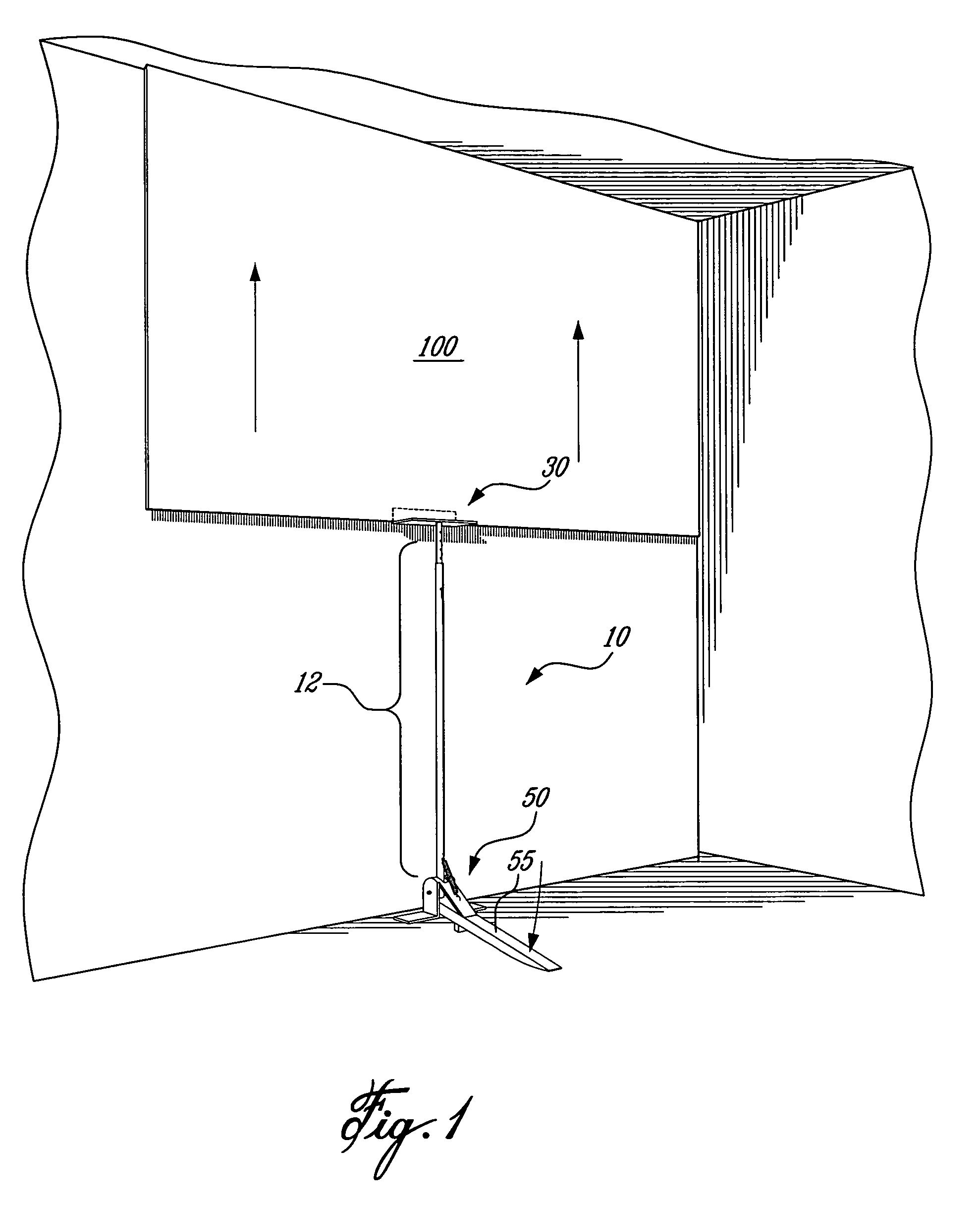

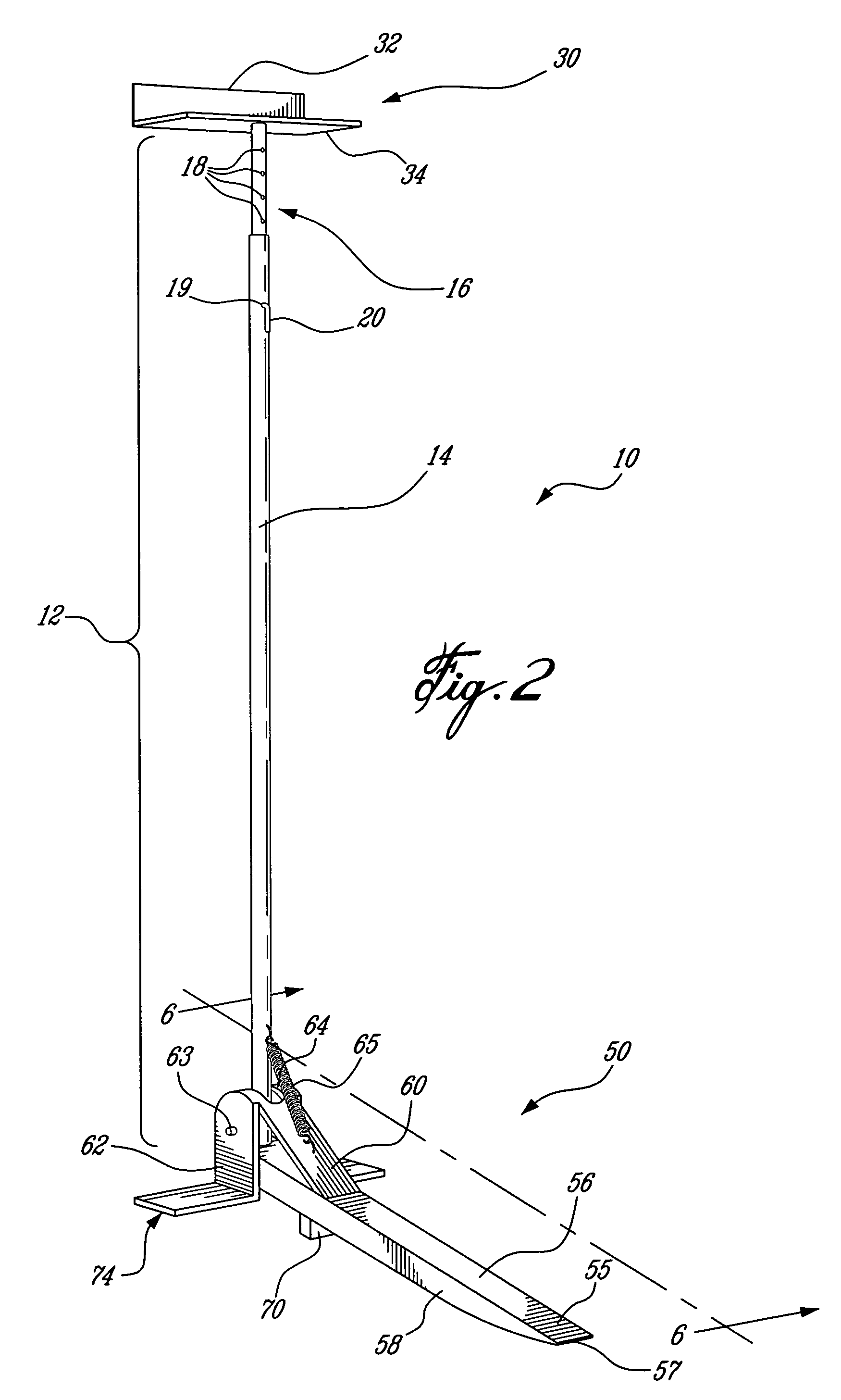

Device for holding and positioning construction materials

InactiveUS20080209850A1Easy to transportSave construction timeBuilding repairsRoof toolsDrywallBuilding material

A device and method that allows the installation of construction materials, such as drywall, by a single person, is described. The device includes an extension (or hoist) section coupled at one end to a support that can receive and support a piece of drywall during installation. The extension section is further coupled to a base portion at the end opposite to the support. The base portion includes a pivot feature that serves to lift the construction materials into an elevated position once it has been positioned on the support. The extension is adjustable to install construction drywall on a stud wall at various heights. A stand member allows the drywall to be supported in the elevated position. The base portion is foldable between a transport position and an operating position to facilitate transport and shipping.

Owner:BOUCHER LAWRENCE +1

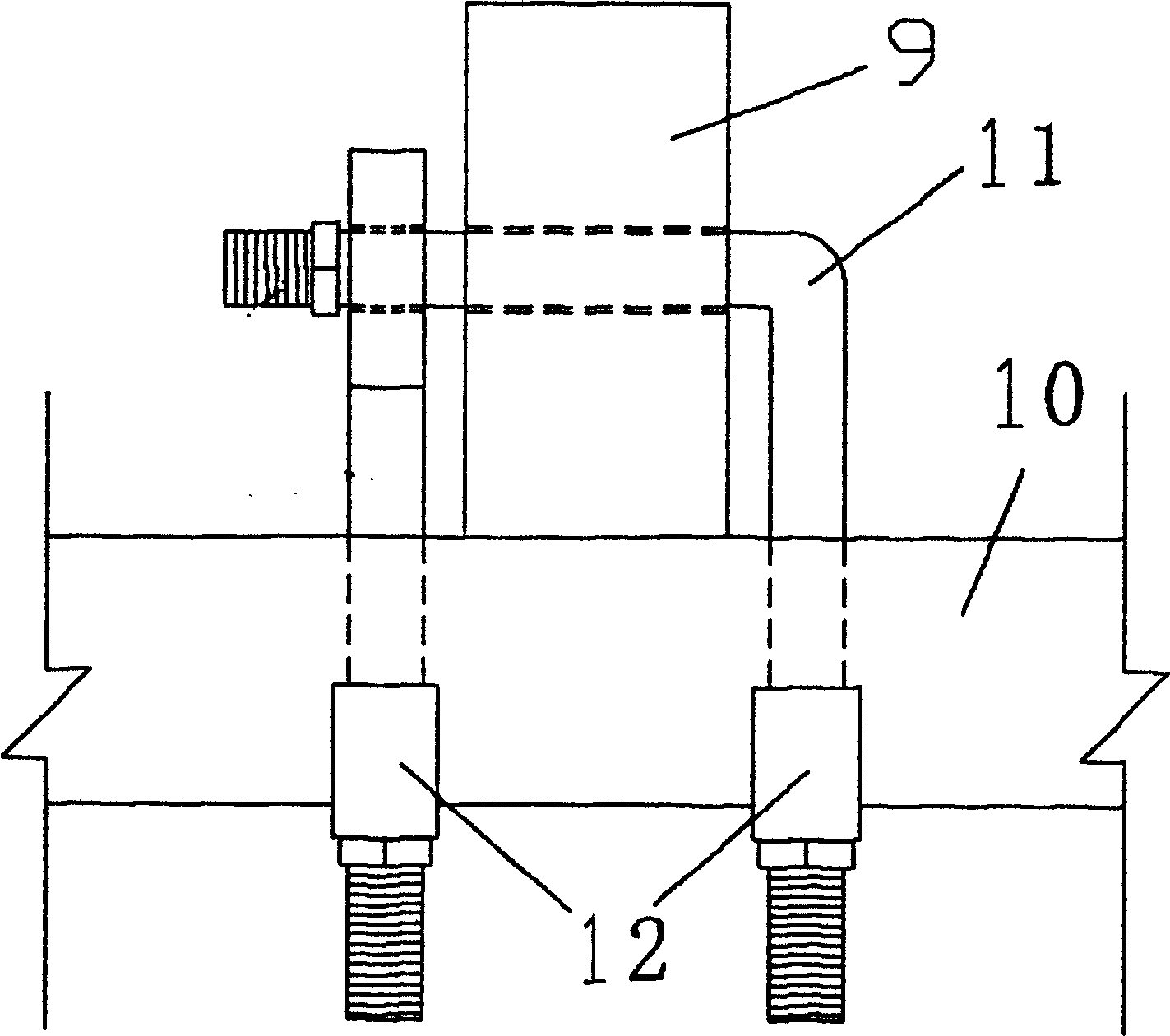

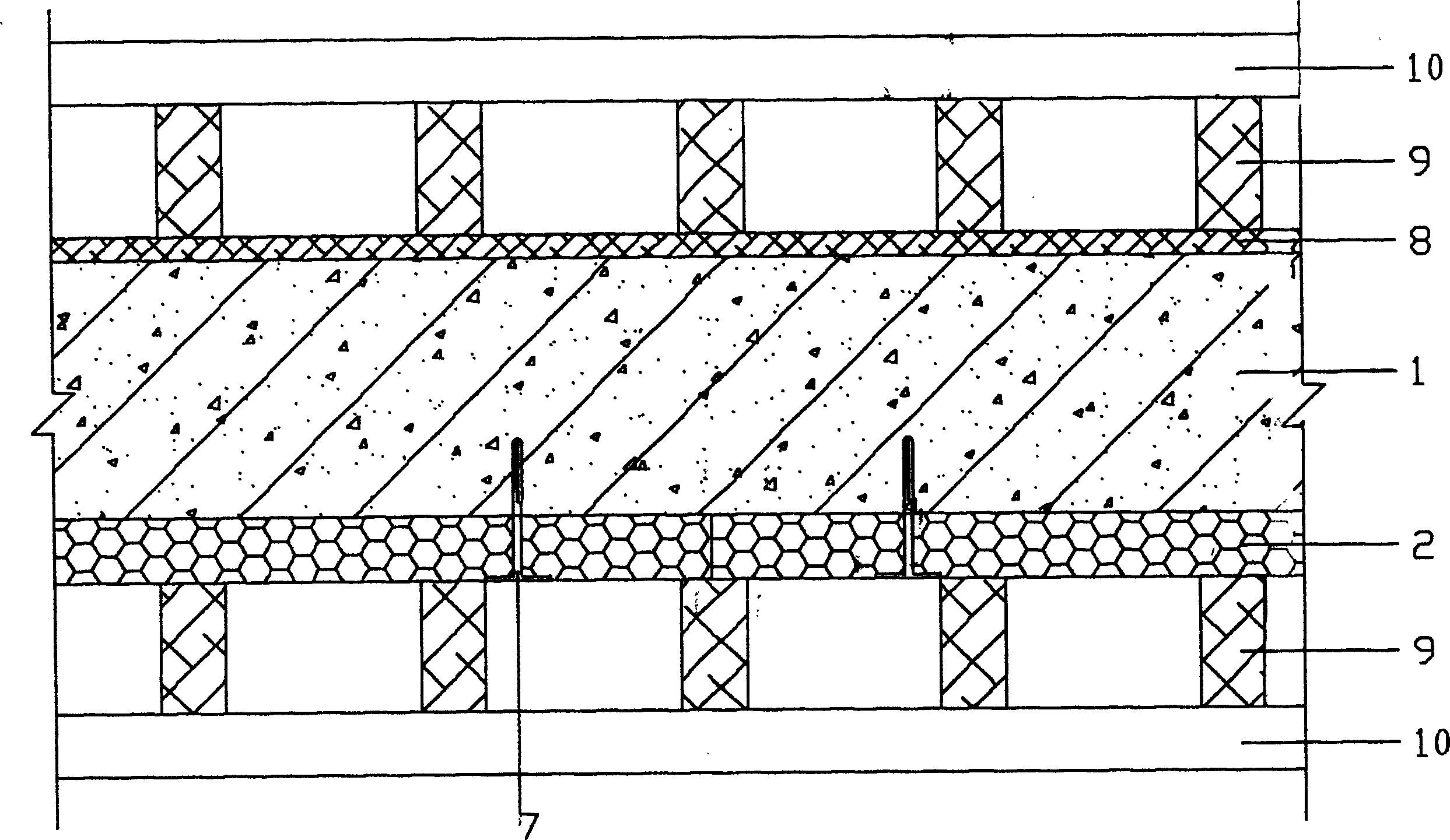

Wall body heat insulating construction method

ActiveCN1651674AReduce labor costsSave on machinery costsHeat proofingSurface constructionEngineering

The present invention discloses a wall body heat-insulating construction method. Said method includes the following main construction steps: firstly, making heat-insulating form and its support, binding steel bar of base wall body, supporting general form at inside of basewall body position, and placing support, then placing heat-insulating form embedded stay bolt at outside of base wall body position, placing wood square at outside of heat-insulating form, placing steel pipe at outside of wood square, concreting, after the concrete is formed, repairing heat-insulating form and making surface treatment, using grooving machine to cut recessed groove on heat-insulating form to make dividing seam, brushing interfacial agent, applying first layer of polymer mortar, laying grid fabric, applying second layer of polymer mortar, finally making surface construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Device for holding and positioning construction materials

ActiveUS7387293B2Easy to transportSave construction timeVehicle with pivoted armsCeilingsArchitectural engineeringEngineering

The present invention discloses a device and method that allows the installation of construction materials, such as drywall, by a single person. The device comprises an extension (or hoist) section coupled at one end to a support which can receive and support a piece of drywall during installation. The extension section is further coupled to a base portion at the end opposite to the support. The base portion includes a pivot feature that serves to lift the drywall once it has been positioned on the support. The extension is adjustable to install drywall on a stud wall at various heights. Advantageously, the device is lightweight, easily transportable and easy to use. The device's convenient design enables its utilization immediately upon reaching a construction site.

Owner:LAWRENCE BOUCHER CONSTR

Method for rapidly replacing adhesive tape

The invention specifically relates to a method for rapidly replacing an adhesive tape, which solves the problems that the efficiency is low, the process is complicated and the time and the labor are consumed in the existing overall replacement of belts. The method for rapidly replacing the adhesive tape comprises the following steps that: all of a plurality of coils of new adhesive tapes are respectively vulcanized into three segments, and three prop drawing cars, two groups of pulley block devices, and a roller arranged on an adhesive tape conveyor are utilized to realize the segmented conveying and cycle work until complete replacement. According to the method, the initial preparation is full and careful, the utilization rate of construction man-hour is extremely high, and simultaneously, the method has inserting and parallel operation characteristics, is fast and safe, and is suitable for replacing various adhesive tapes in different working environments.

Owner:DATONG COAL MINE GRP

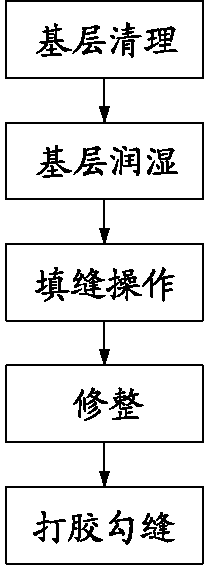

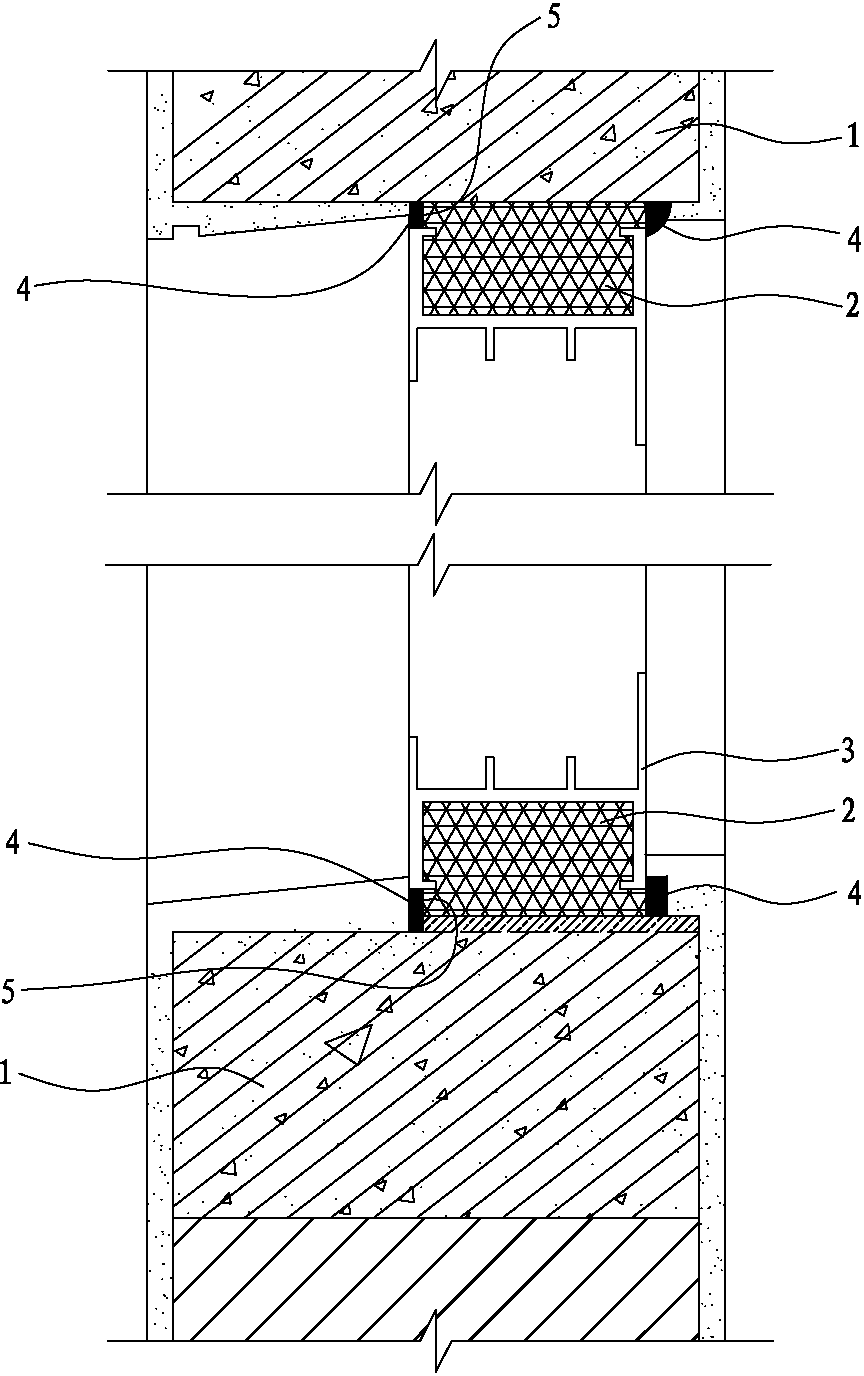

Building door and window mounting rigid foamed polyurethane filling construction process

The invention discloses a building door and window mounting rigid foamed polyurethane filling construction process, which comprises the following steps of: (1) cleaning a base layer, i.e., cleaning the surface of the base layer by using rigid hair; (2) wetting the base layer, i.e., spraying a layer of clear water on the base layer; (3) performing joint filling operation, i.e., adopting a gun type polyurethane foam filler, inverting a material tank and connecting the material tank with a spray gun through thread in use, rotating to open a flow valve, adjusting flow and then spraying; and immediately spraying water fog on a filling part after the filling is finished, thereby facilitating full expansion of a foaming agent. Practice proves that the building door and window gap filling operated and constructed by the construction method realizes an extremely obvious door and window frame seepage prevention effect, easiness in operation and convenience in construction.

Owner:福建省泷澄建设集团有限公司

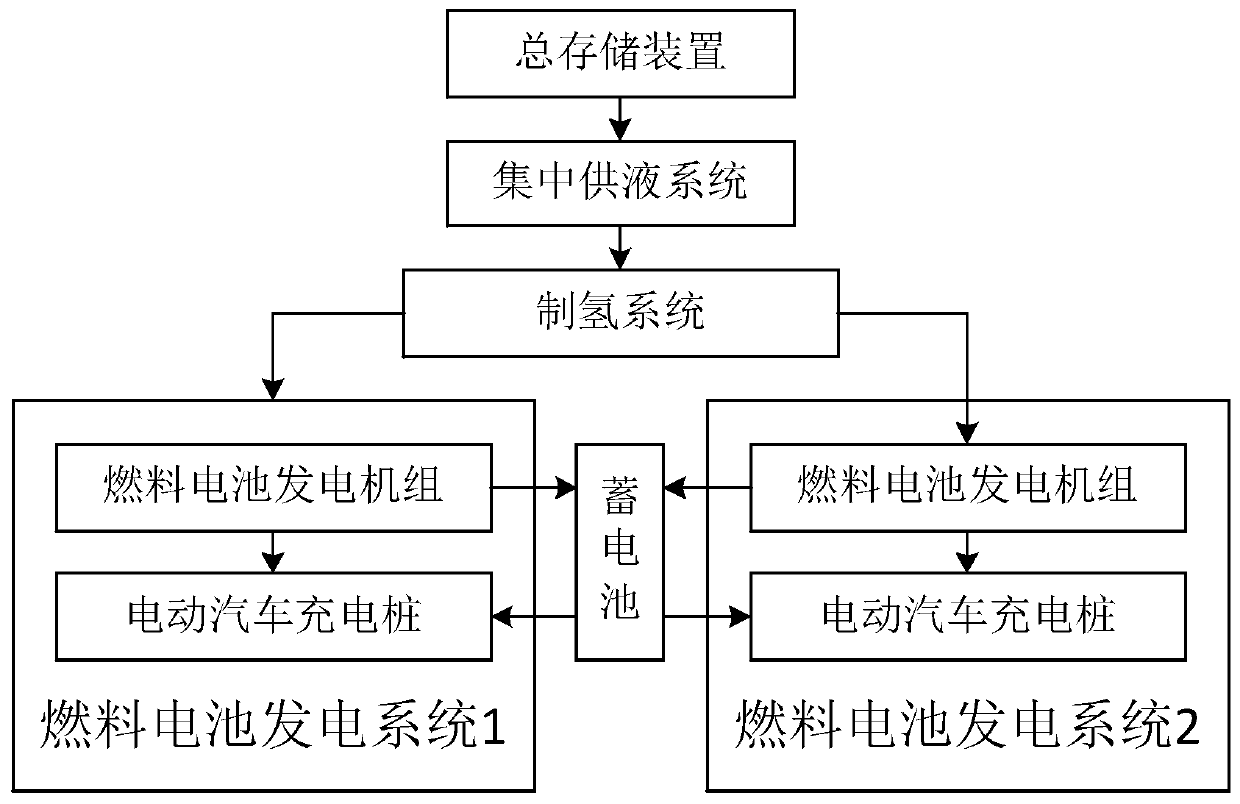

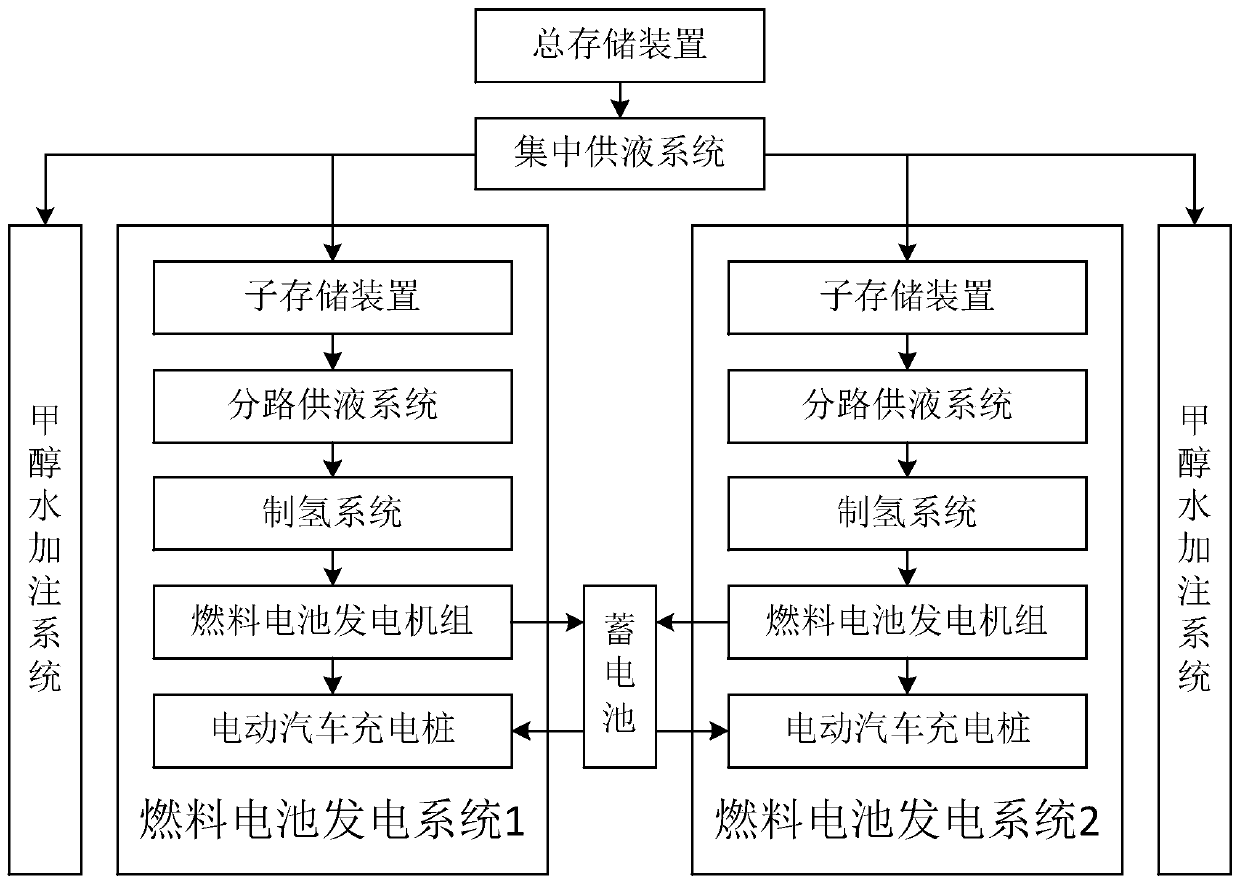

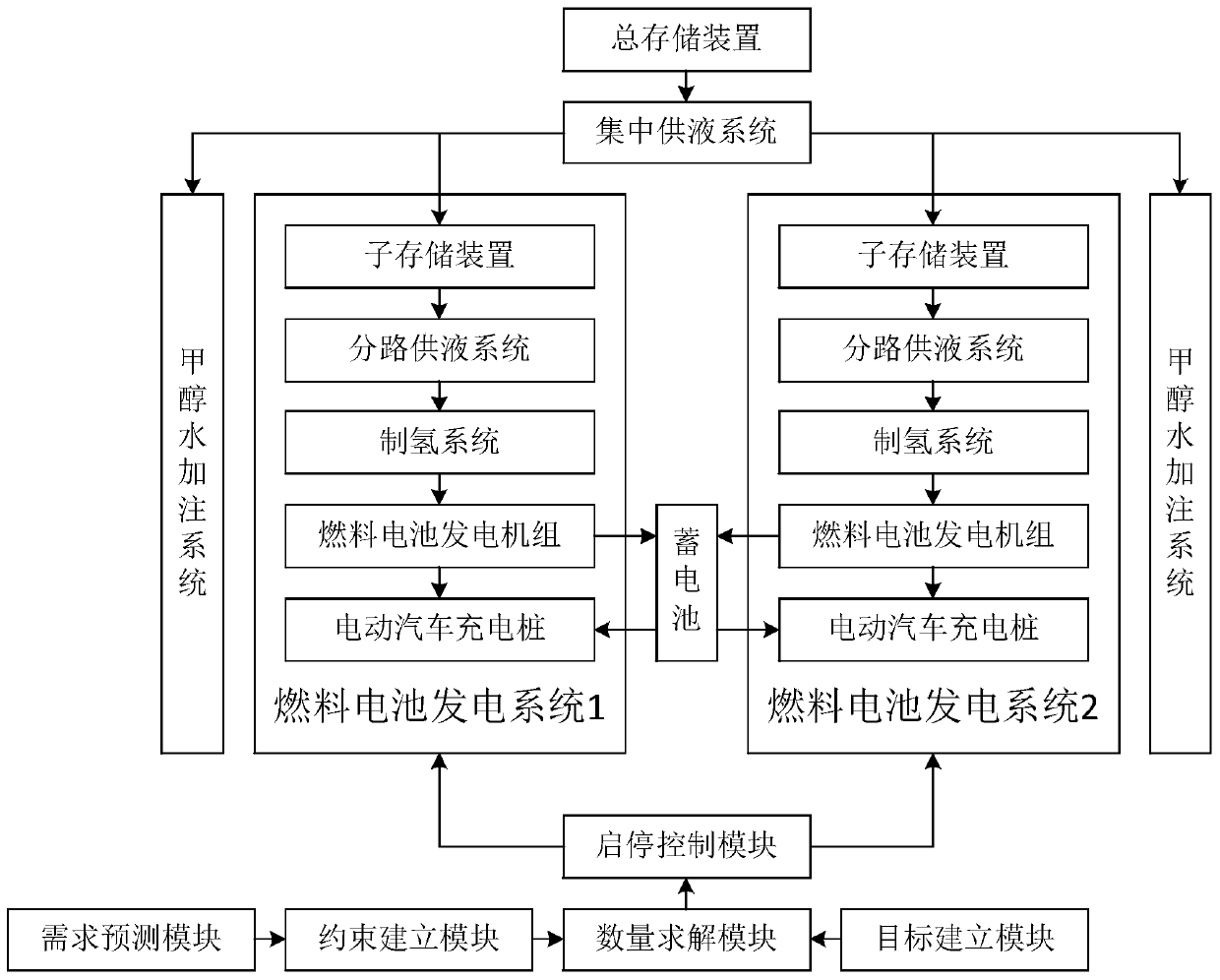

Electric vehicle charging station based on electricity generation by reforming hydrogen production fuel cells

ActiveCN110843566ASolve the inconvenience of chargingSave costsCharging stationsElectric vehicle charging technologyElectrochemical responseHydrogen fuel

The invention discloses an electric vehicle charging station based on electricity generation by reforming hydrogen production fuel cells. The electric vehicle charging station includes a total storagedevice, a centralized liquid supply system and a plurality of fuel cell electricity generation systems. The total storage device is used for storing hydrogen-containing fuel in the charging station,and the centralized liquid supply system is used for conveying the hydrogen-containing fuel stored by the total storage device to a hydrogen production system to produce hydrogen. Each fuel cell electricity generation system includes a fuel cell generator set and an electric vehicle charging pile. The fuel cell generator sets use the hydrogen produced by the hydrogen production system to perform electrochemical reactions to generate electricity, and the electric vehicle charging piles store generated electric energy which is used for charging electric vehicles. Through layout of the charging station which use hydrogen compounds as raw materials and use the fuel cell generator sets to generate the electricity, charging for the battery-based home electric vehicles without the need to re-laya dedicated transmission network in a large area is realized, and initial investment costs and construction time are saved; and the problem of inconvenient charging during long-distance travel of theelectric vehicles is solved.

Owner:德州新动能铁塔发电有限公司

Waterborne anticorrosive coating for improving interface bonding force of rusty metal and anticorrosive coating and preparation method thereof

InactiveCN104559668AEffective dissolutionEffectively dissolves and transformsAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention discloses a waterborne anticorrosive coating for improving the interface bonding force of a rusty metal and an anticorrosive coating. The waterborne anticorrosive coating comprises a component A and a component B in a mass ratio of (2-4): 1, wherein the component A consists of the following components in parts by mass: 40-60 parts of waterborne epoxy emulsion, 5-15 parts of rust protection padding, 5-20 parts of transformation liquid, 1-5 parts of a pH stabilizer, 1-3 parts of an aid and 10-35 parts of deionized water; and the component B consists of a curing agent and deionized water in a mass ratio of (4-6): 1. The waterborne anticorrosive coating contains the active group transformation liquid capable of converting a rust layer, the activity of the transformation liquid in the waterborne anticorrosive coating can be ensured in the presence of the pH stabilizer, and the rust layer can be effectively dissolved and transformed, so that the interface bonding force of the rusty metal and the anticorrosive coating can be greatly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com