Patents

Literature

98results about How to "Small excavation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water supply and drainage pipeline repair technique adopting size film lining method

A water supply and drainage pipeline repair technique adopting a size film lining method comprises the steps of: (1) dredging and cleaning a pipeline; (2) inspecting a pipeline internal observing video; (3) producing a working pit; (4) welding a lining pipe; (5) plugging, deflecting and transferring water to the pipeline; (6) internally pretreating and repairing the pipeline to be repaired; (7) drawing the lining pipe into the pipeline to be repaired; (8) sealing the two ends of the lining pipe and embedding a pipe fitting; (9) filling water into the lining pipe and pressurizing; (10) preparing size and auxiliary vacuum casting; (11) keeping the internal water pressure of the lining pipe, and supplying water again after the size is solidified; (12) videoing the inner side of the pipeline and recording the videos after the repair; and (13) the step 1 to step 12 belong to repair construction, taking every two continuous inspection wells as a construction working segment, constructing towards the upstream and downstream sequentially from the inspection well which is next to the working pit, after completing all the working pipeline segments, laying a new pipeline in the working pit, refilling the soil and compacting to restore the pavement; and the pipeline has long service life, high water flow, fast construction speed, less pollution and small influence to roads.

Owner:杨兵

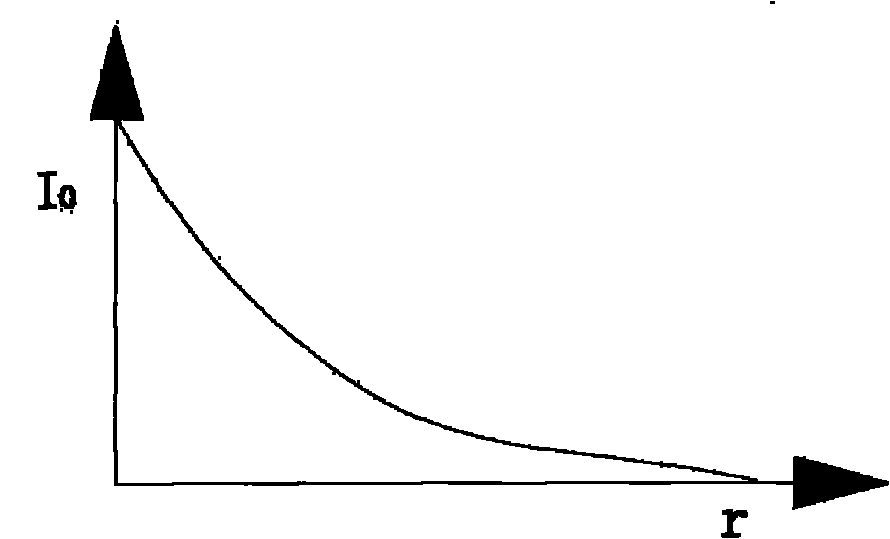

Method for detecting leaking point position of buried pipeline by gas

The invention provides a method for detecting a leaking point position of a buried pipeline by gas. In the method, gas with light relative molecular mass is artificially introduced into a pipeline which is suspected to be leaked, and gas can escape from a leaking port and flows above the surface; a corresponding gas detector is used on the surface to detect the concentration of gas, so that damage, leakage and the like on the position of the buried pipeline can be judged to solve the problem that the position of a water leaking point cannot be detected by the conventional sound wave method in leak detection after the current non-metal material pipeline has sand hole leakage, seepage and other small leaking conditions in the using process. Furthermore, the specific position of any leaking point of any buried pipeline can be detected by the method, and the leaking position is positioned accurately in + / -1m. The method can greatly reduce the time for finding the leaking point and reduce the dig area which the leaking point is repaired.

Owner:广东精测勘测科技股份有限公司

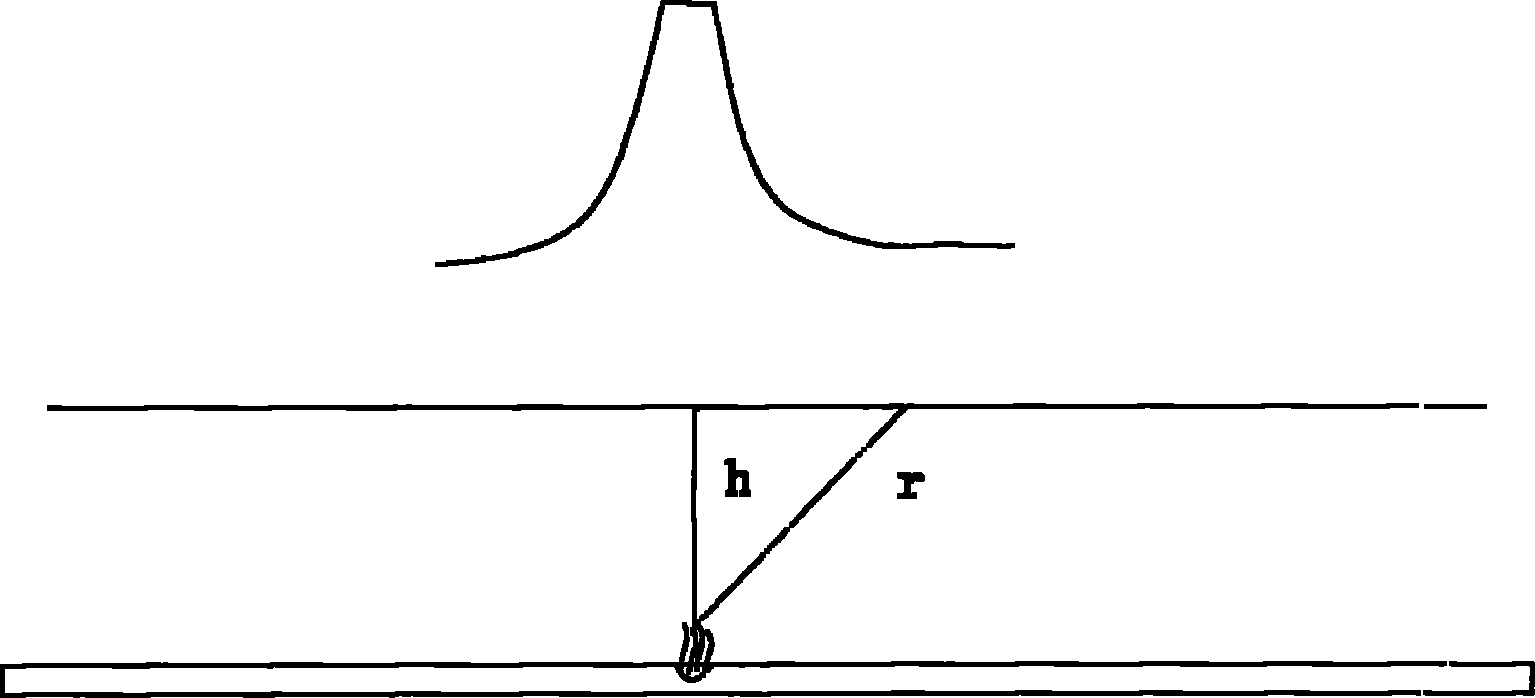

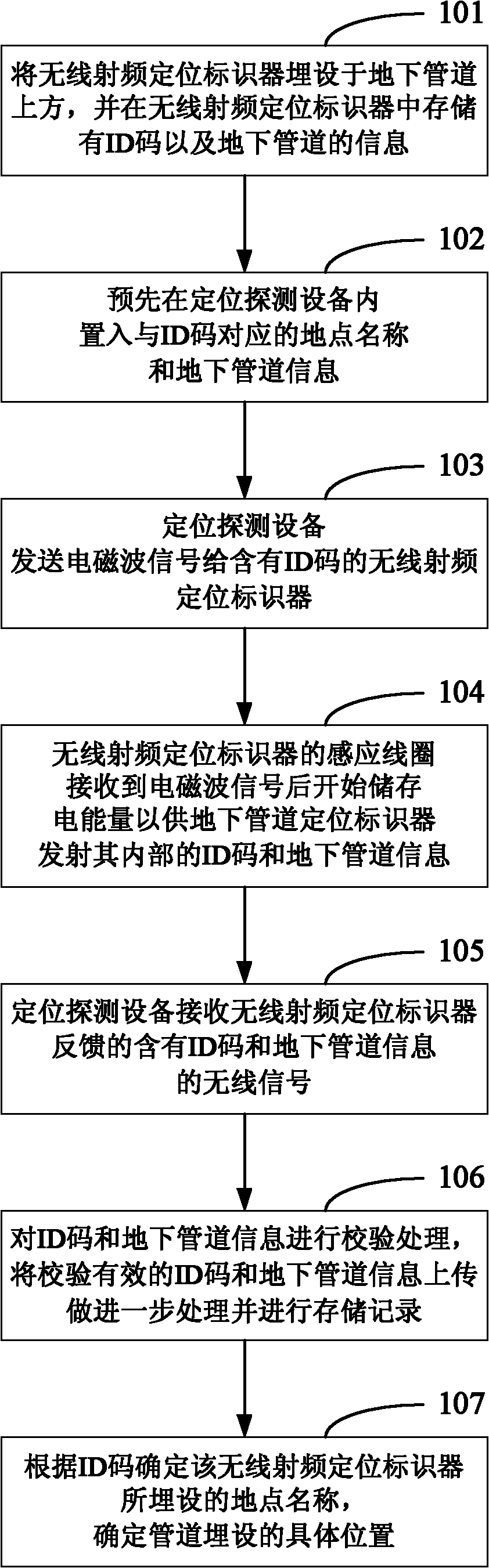

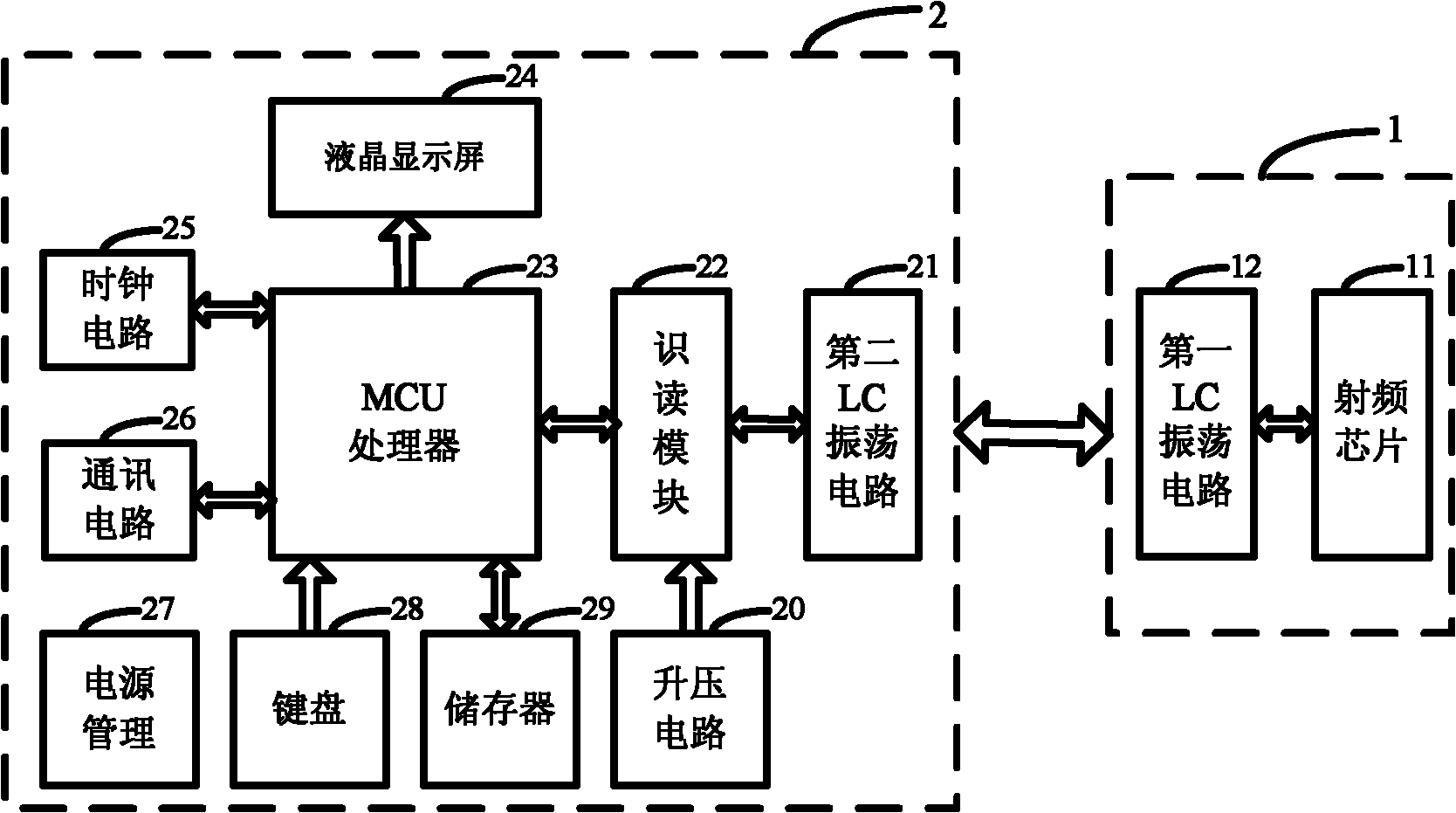

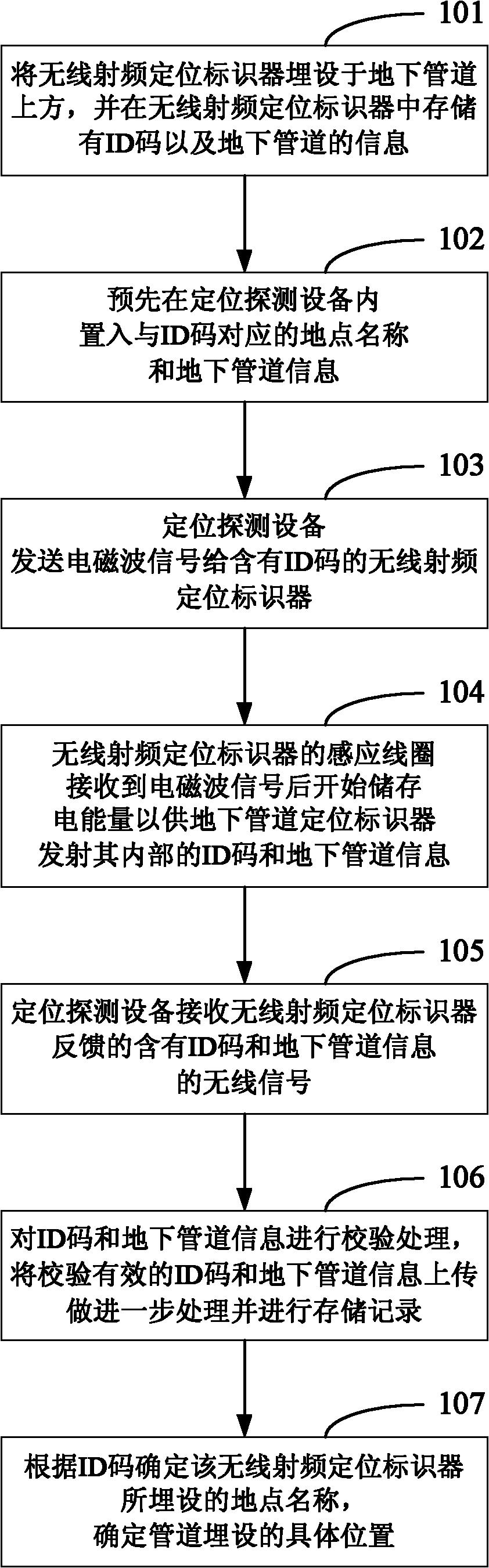

Method for positioning underground pipeline and system thereof

ActiveCN101915941ARapid positioningImprove rescue efficiencyElectric/magnetic detectionAcoustic wave reradiationLine tubingEngineering

The embodiment of the invention relates to a method for positioning an underground pipeline and a system thereof. The method comprises the following steps of: transmitting an electromagnetic wave signal to a wireless radio-frequency positioning marker containing an ID code; receiving a wireless signal which is fed back by the wireless radio-frequency positioning marker and contains the ID code and the underground pipeline information; carrying out checking treatment on the ID code and the underground pipeline information; determining an embedded place name of the wireless radio-frequency positioning marker according to the ID code; determining the embedded concrete position of the pipeline; and determining the trend of the pipeline according to the orientation information of the adjacent wireless radio-frequency positioning marker. The embodiment of the invention also provides a positioning system of the underground pipeline. The positioning method and the positioning system in the embodiment of the invention can realize the accurate positioning of the underground pipeline, find fault points as soon as possible when faults happen, reduce the digging area and the compensation cost,furthermore help maintainers establish the records of maintaining in normal times and overhauling the underground pipeline.

Owner:BEIJING RXG TECH

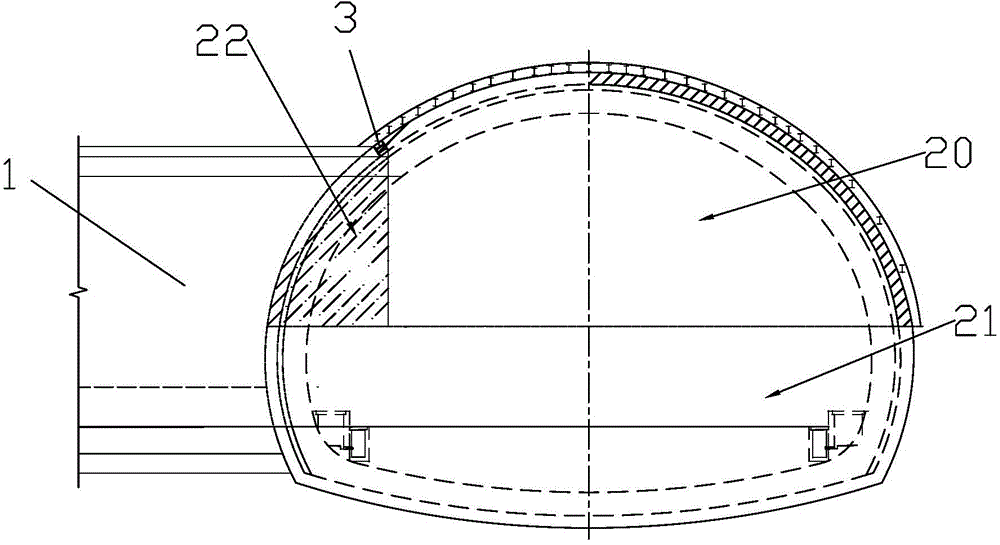

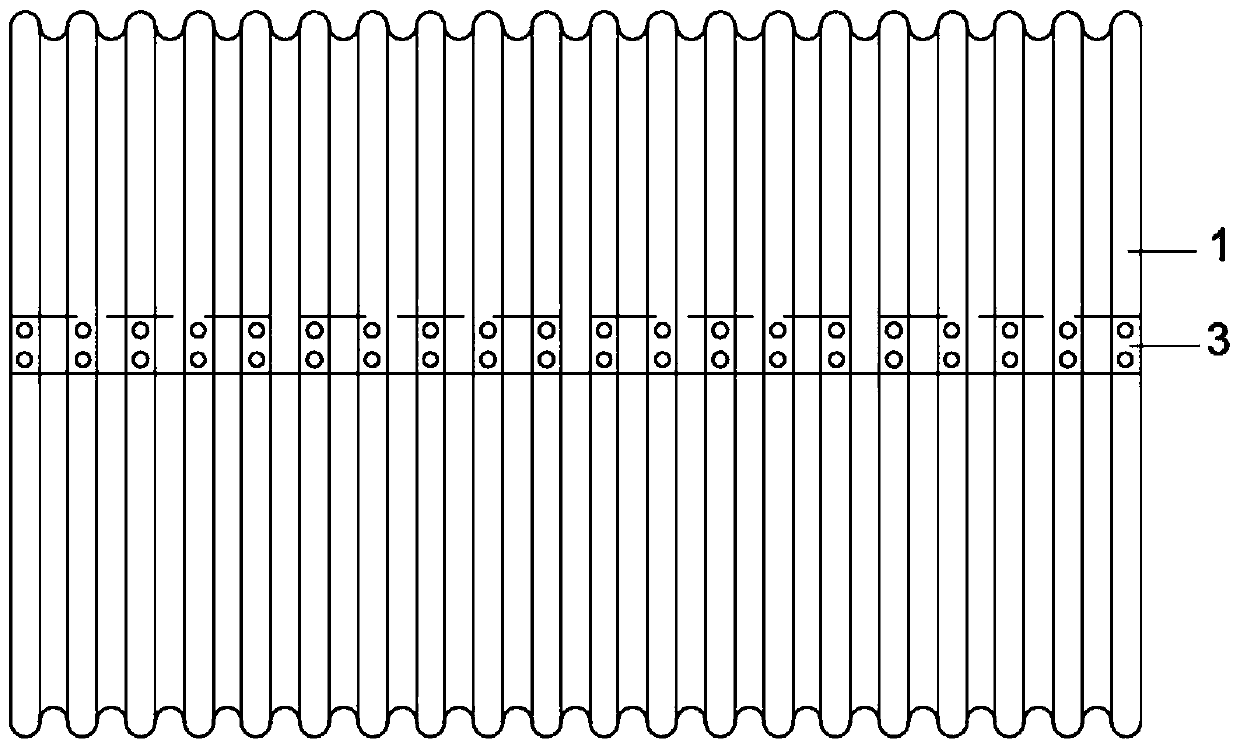

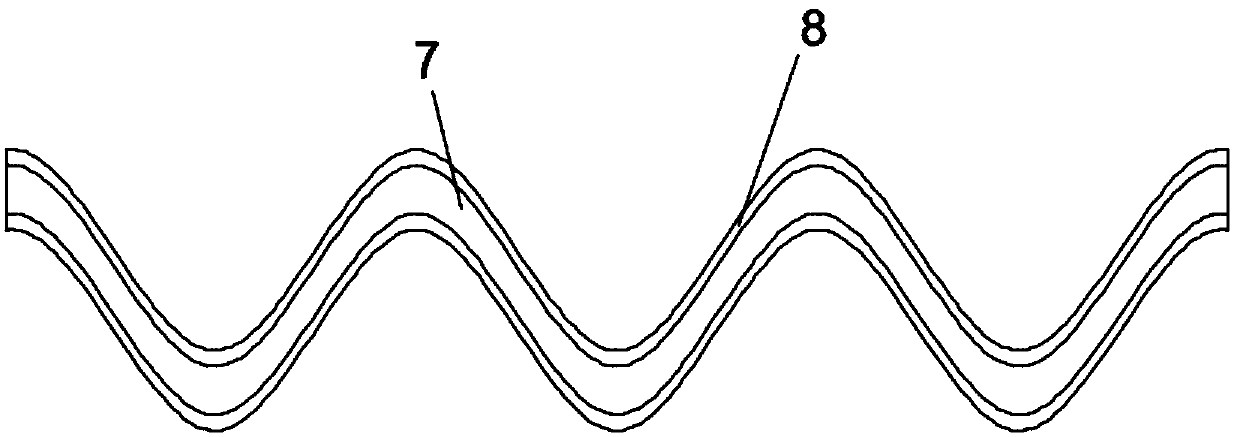

Steel-FRP (fiber reinforced plastic) composite corrugated plate tunnel supporting method

The invention discloses a steel-FRP (fiber reinforced plastic) composite corrugated plate tunnel supporting method and belongs to the technical field of research and development of composites and novel structures in the tunnel engineering field. The method comprises procedures as follows: prefabrication of a corrugated plate, reinforcement of surrounding rock by driving advanced small pipes, excavation of upper steps, mounting of a top corrugated plate, excavation of lower steps, mounting of side wall corrugated plates, excavation of an inverted arch, fixation of a corrugated plate at the inverted arch, setting of a waterproofing and drainage system and secondary lining construction. After the steps are implemented, construction of preliminary tunnel supporting, the waterproofing and drainage system and a secondary lining structure is completed, and the whole tunnel supporting structure can be completed through repeated implementation of the steps with advancing of the tunnel during specific construction. According to the method, performance of an FRP material and a steel material are sufficiently played, advantages of the corrugated plate are combined, and the method has the advantages that the corrosion resistance is good, the bearing capability is high, the hoop rigidity is high, the construction speed is high, the operation environment is excellent, the excavation range issmall and the like.

Owner:BEIJING UNIV OF TECH

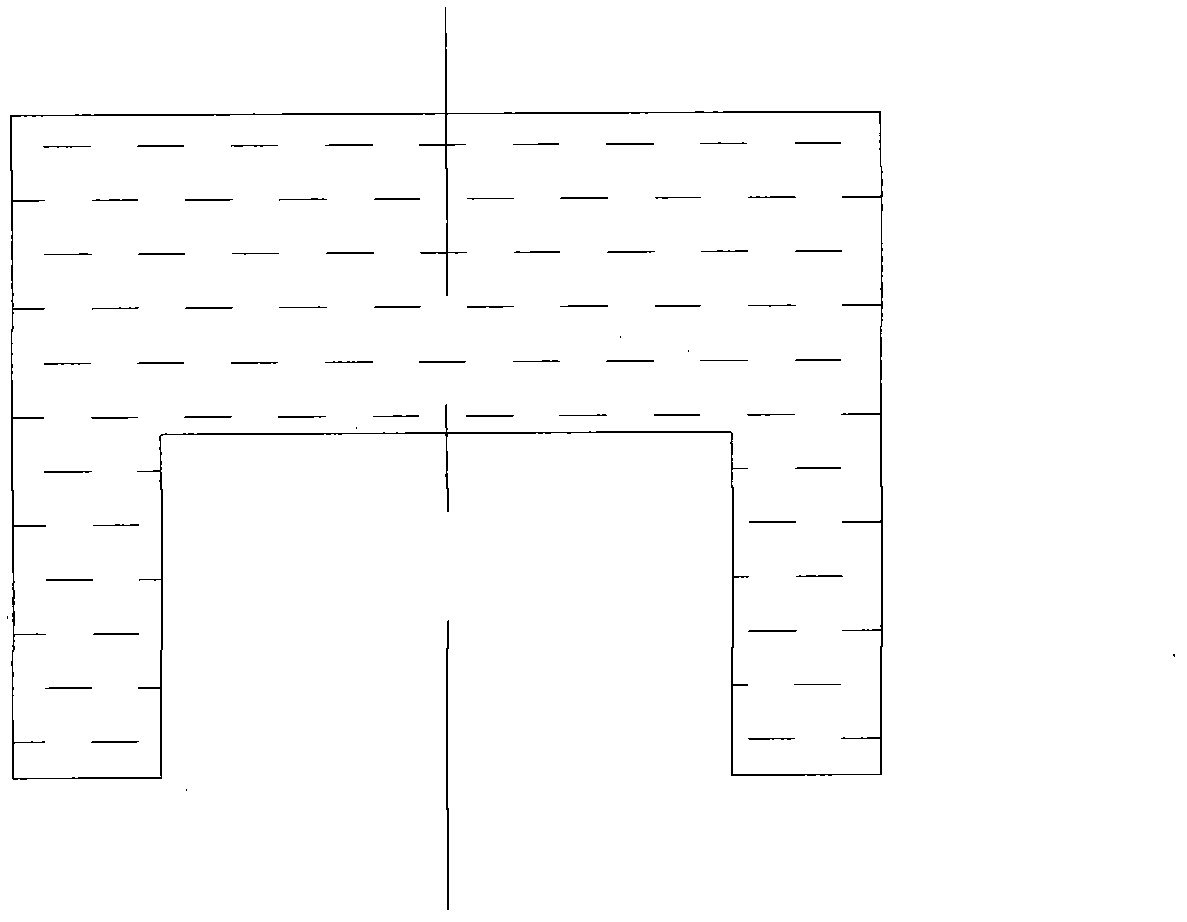

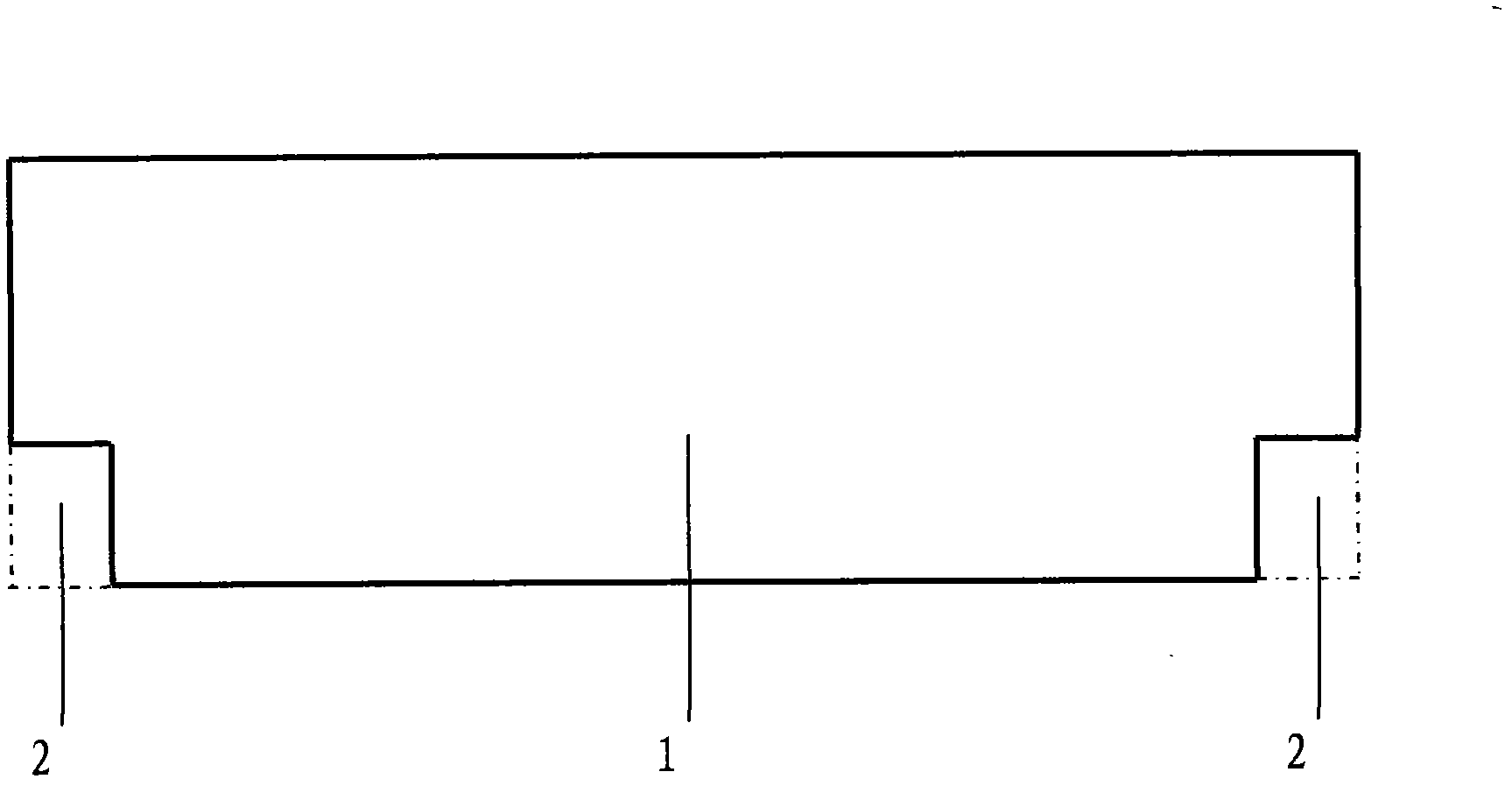

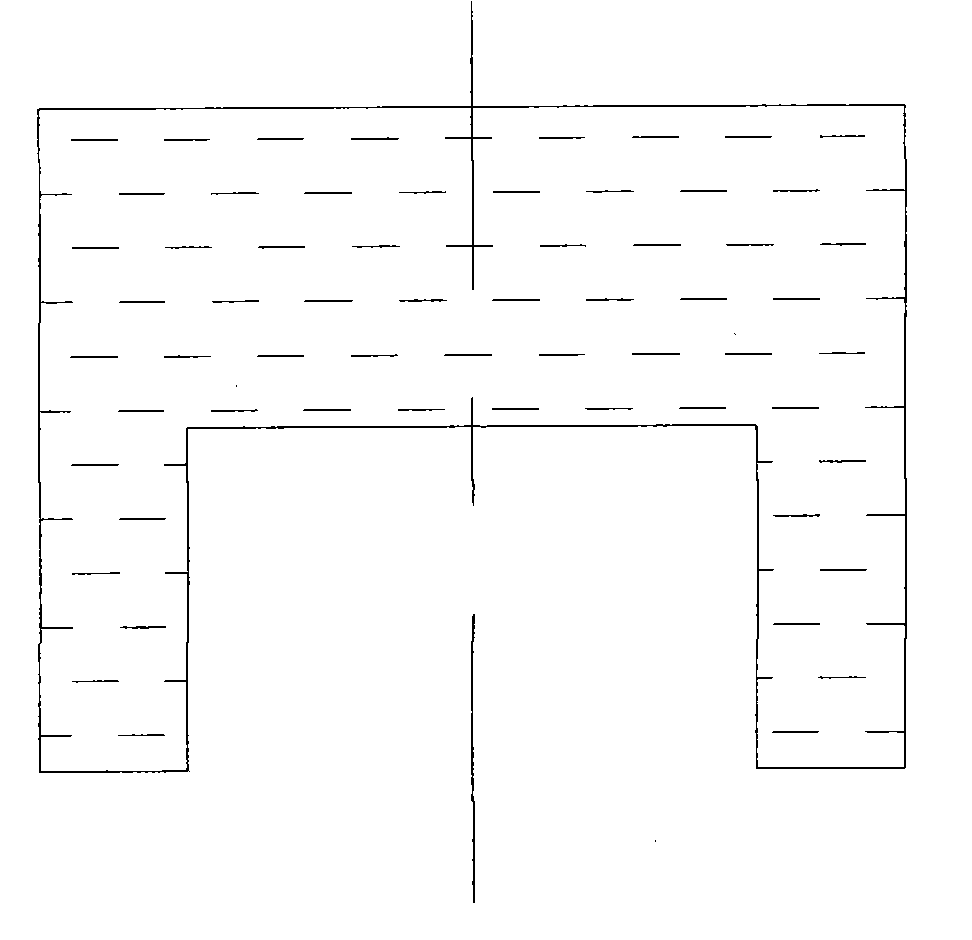

Method and structure for excavating soil in core tube region based on raft pile supporting

InactiveCN102116028AFast constructionReduce earthwork excavation areaExcavationsEarth anchorRapid construction

The invention discloses a method and structure for excavating soil in the core tube region based on raft pile supporting. The method comprises the following steps: vertically driving first layer of raft piles one by one on the edge of a foundation pit according to the length and width requirements of the foundation pit and fixing a circle of horizontal timber piles with gate type forcers at one side of the foundation pit of the first layer of raft piles; vertically driving steel ground anchors on the ground outside the first layer of raft piles; tensioning the steel ground anchors and the horizontal timber piles with tie bars; excavating a foundation pit at the inner sides of the first layer of raft piles; vertically driving second layer of raft piles on the edge of the bottom of the foundation pit; fixing a circle of horizontal timber piles with gate type forcers at one side of the foundation pit of the second layer of raft piles; connecting the first layer of raft piles with the second layer of raft piles with tie piles via the gate type forcers; continuously excavating a foundation pit at the inner sides of the second layer of raft piles; driving third layer of raft piles at the bottom of the foundation pit; connecting the second layer of raft piles with the third layer of raft piles with timber piles via the forcers; and doing the rest in the same manner until the foundation pit is excavated to the design depth. The method and the structure have the characteristics of simple and rapid construction and economy.

Owner:THE THIRD CONSTR & ENG OF CCFED

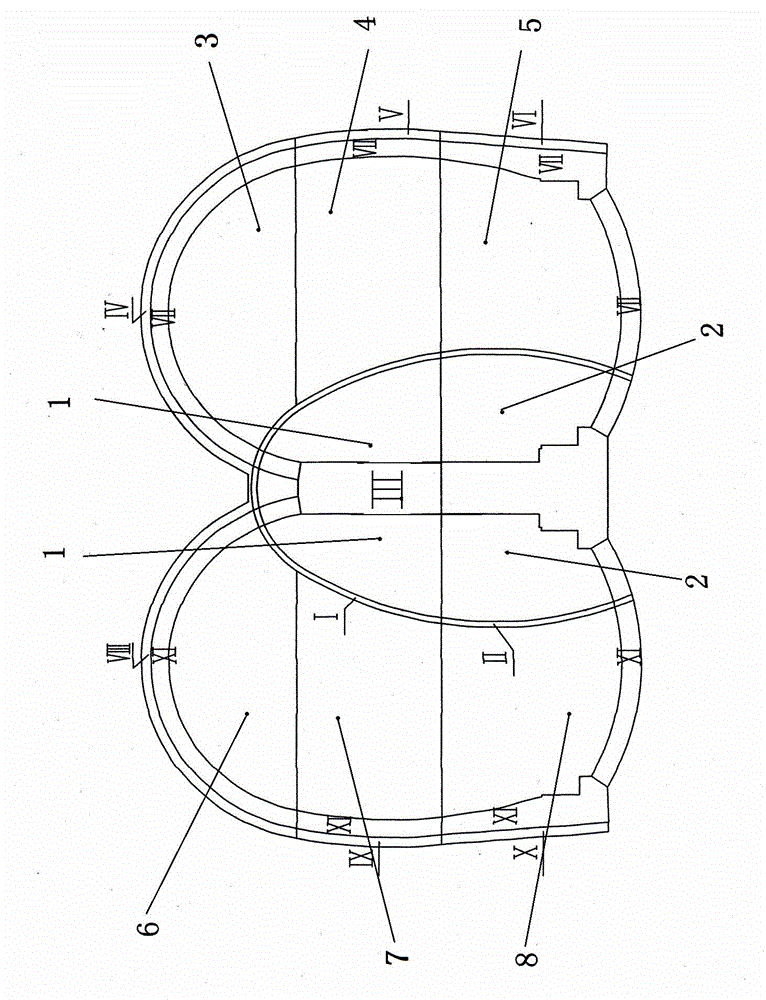

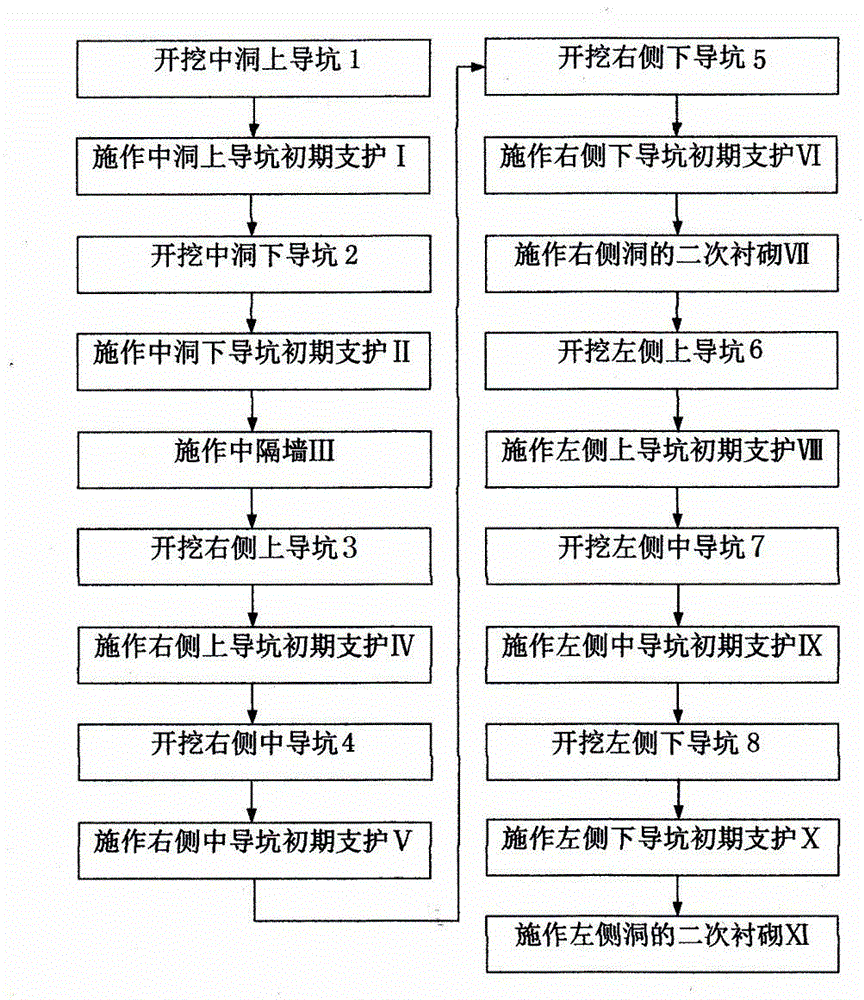

Dovetail section tunnel construction process

ActiveCN104832181AAvoid damageImprove construction progressUnderground chambersTunnel liningRailway tunnelRapid construction

The invention discloses a dovetail section tunnel construction process, relating to a railway tunnel construction process; the dovetail section tunnel construction process mainly aims to solve the problem of slow construction speed of the current dovetail section tunnel, and comprises the following steps: excavating a middle pilot tunnel top heading and constructing a middle pilot tunnel top heading primary support; excavating a middle pilot tunnel bottom heading and constructing a middle pilot tunnel bottom heading primary support II; constructing a middle partition wall III; meanwhile, installing a temporary transverse support on the left of the middle partition wall; excavating a right top heading and constructing a right top heading primary support IV; excavating a right middle heading and constructing a right middle heading primary support V; excavating a right bottom heading and constructing a right bottom heading primary support VI; constructing a secondary lining VII of the right pilot tunnel; evacuating a left top heading and constructing a left top heading primary support VIII; evacuating a left middle heading and constructing a left middle heading primary support IX; evacuating a left bottom heading 8 and constructing a left bottom heading primary support X; constructing a secondary lining XI of the left pilot tunnel. The dovetail section tunnel construction process has the advantage of rapid construction progress.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG

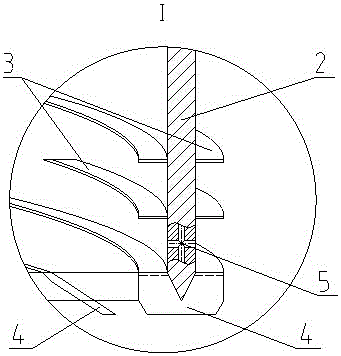

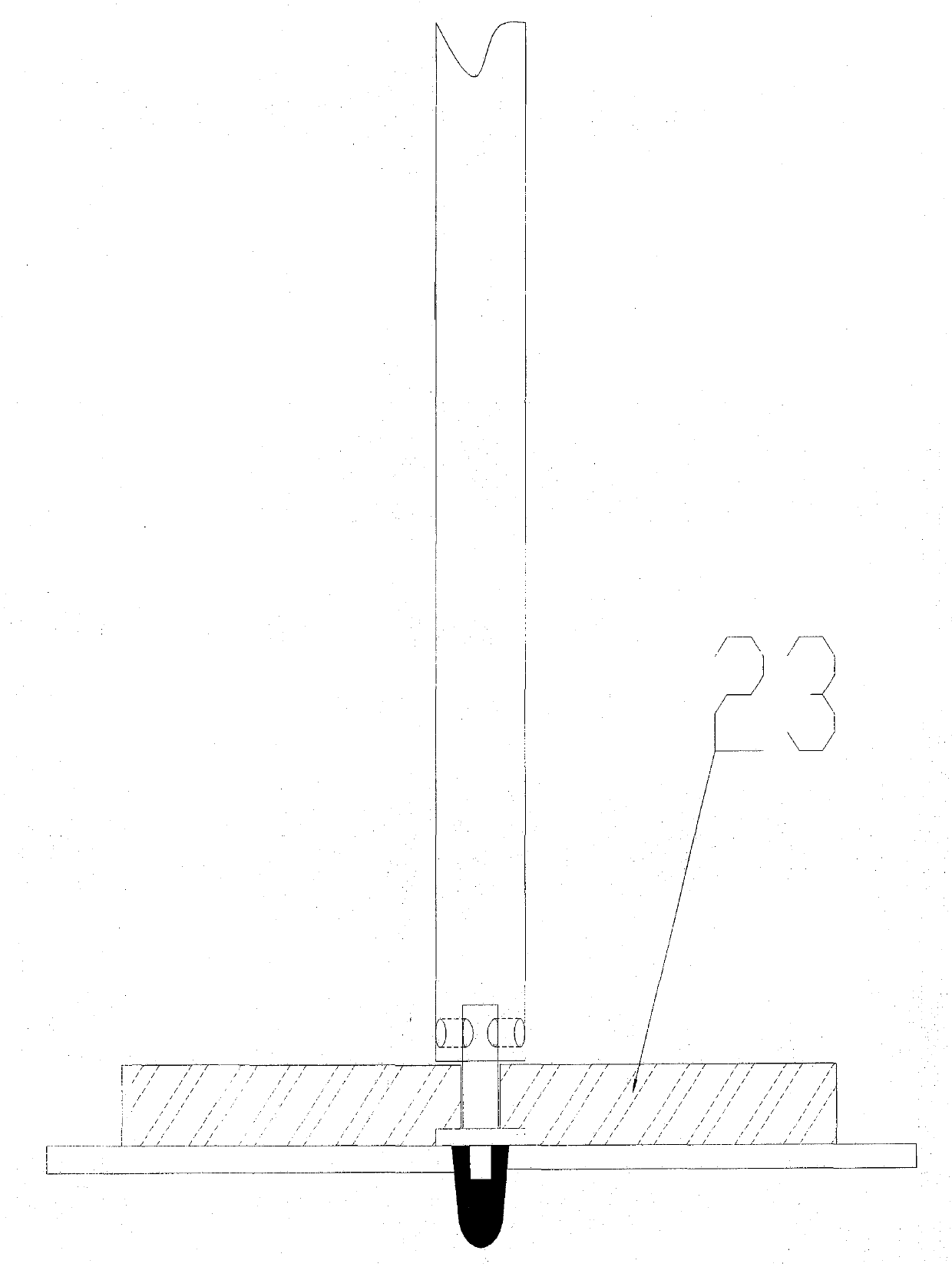

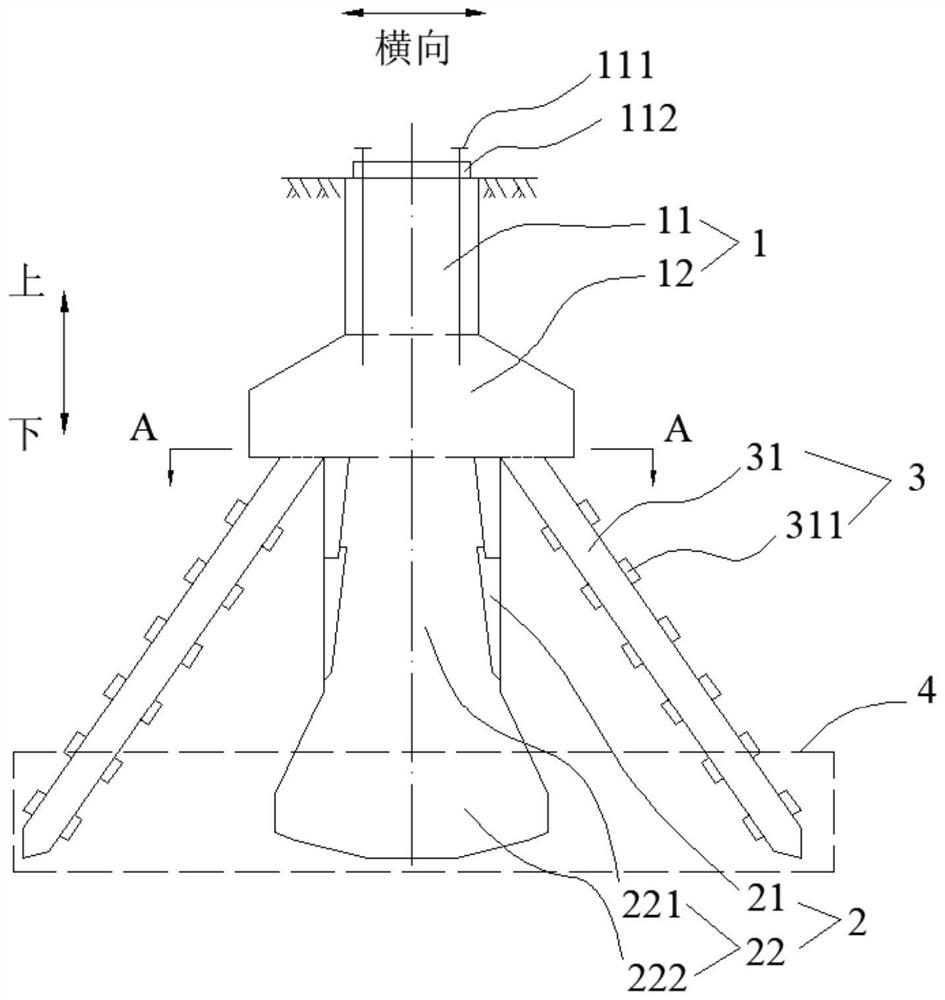

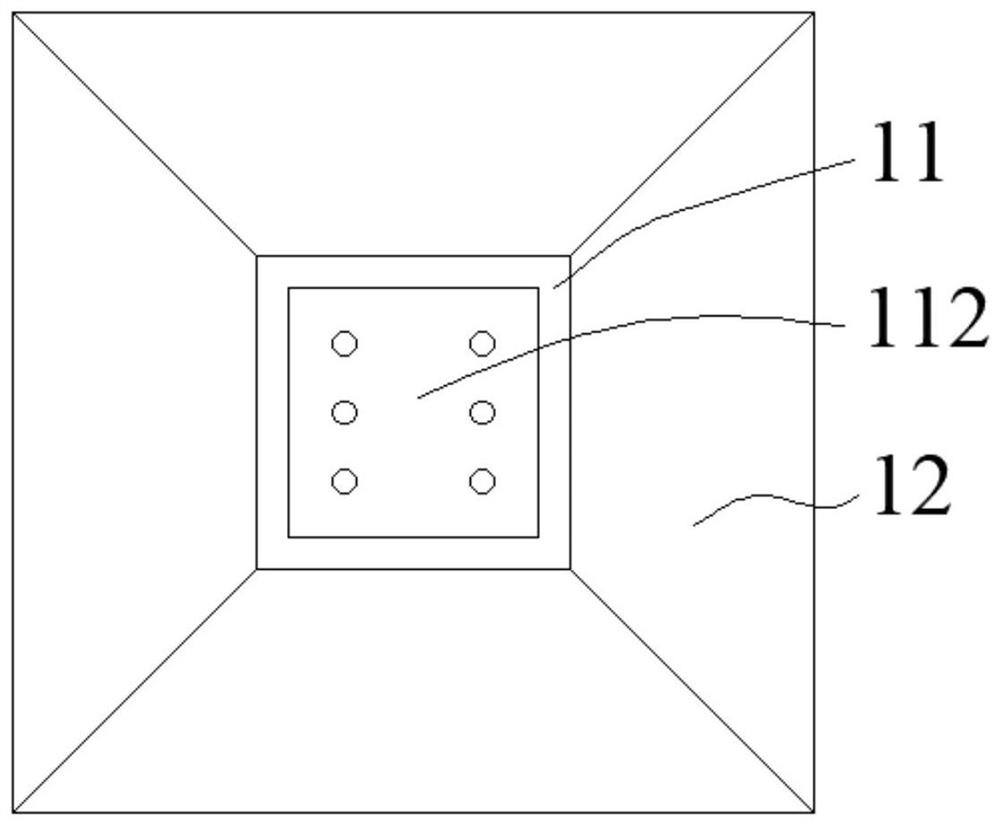

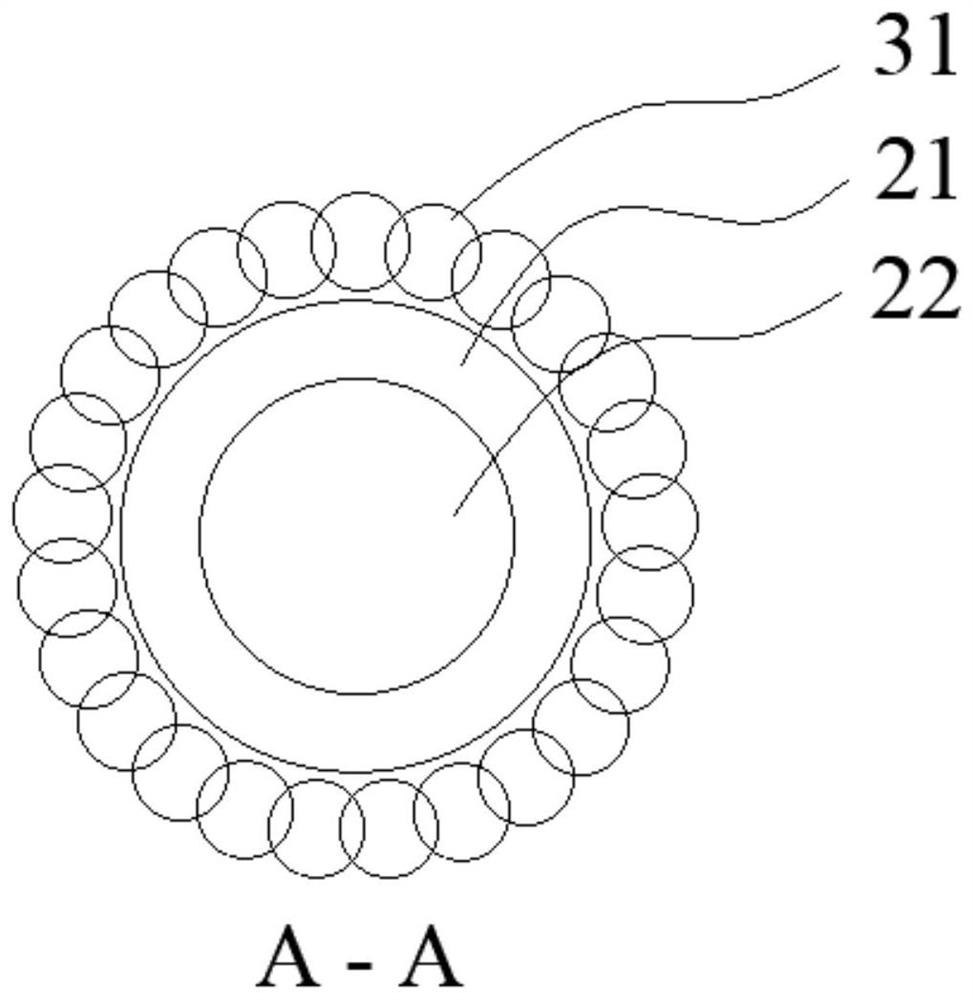

Construction method for spiral barrel-shaped foundation

InactiveCN105821874ASmall excavation areaShorten the construction periodBulkheads/pilesSpiral bladeBarrel Shaped

The invention discloses a construction method for a spiral barrel-shaped foundation. The construction method comprises the following steps that (1), the spiral barrel-shaped foundation 1 is prefabricated, spiral blades 3 are arranged on the inner wall and the outer wall of a barrel body 2 of the spiral barrel-shaped foundation 1, and an opening is formed in the bottom; (2), the spiral barrel-shaped foundation 1 is erected at a set position; and (3), the spiral barrel-shaped foundation 1 is rotated under the action of power and gradually descends to the set position. The construction method has the beneficial effects that the prefabricated spiral barrel-shaped foundation is erected at the set position and rotated under the action of the power to gradually descend to the set position. In the descending process, only rock soil in an annular area is cut, the excavation area is small, the construction period can be shortened, and the labor intensity can be relieved.

Owner:王燏斌

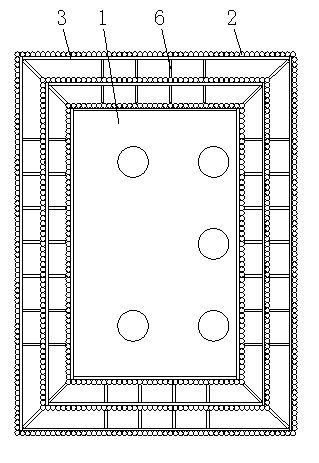

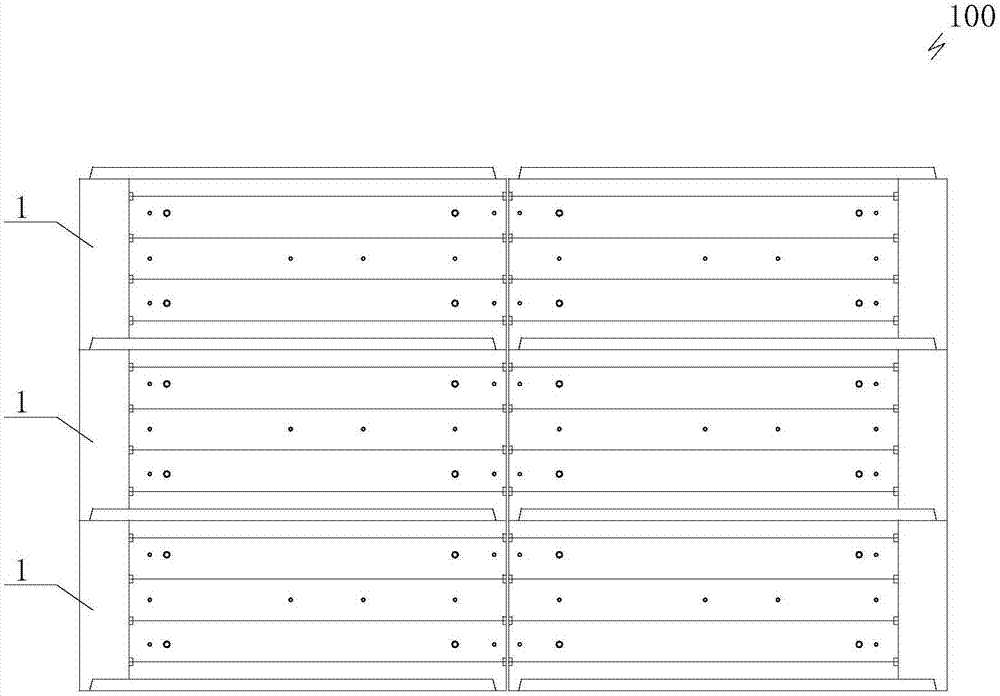

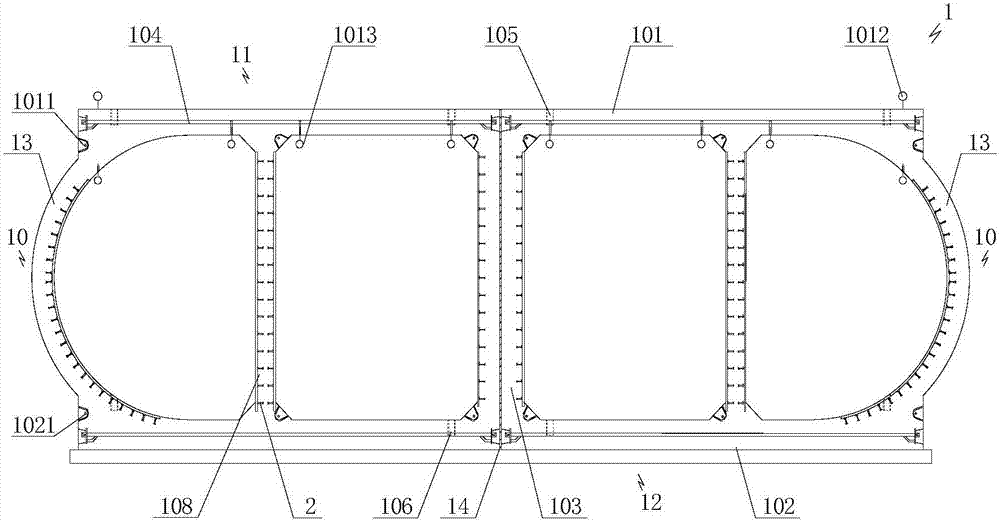

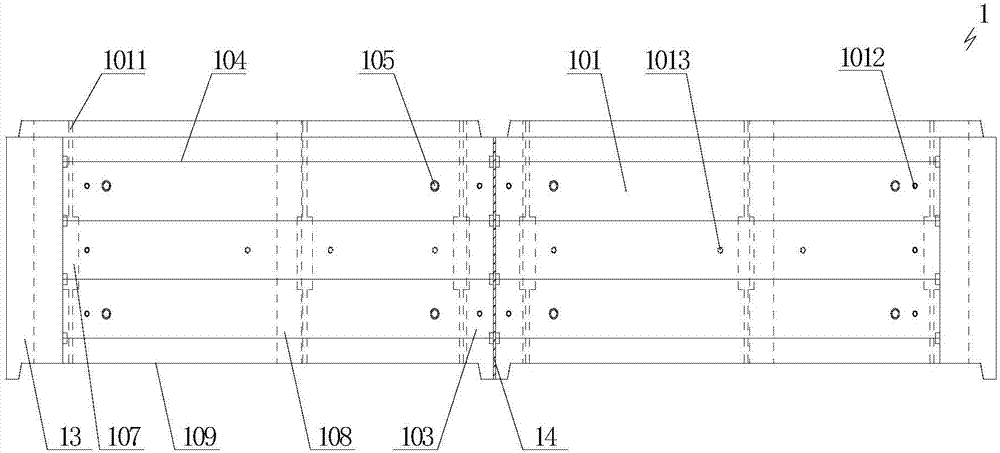

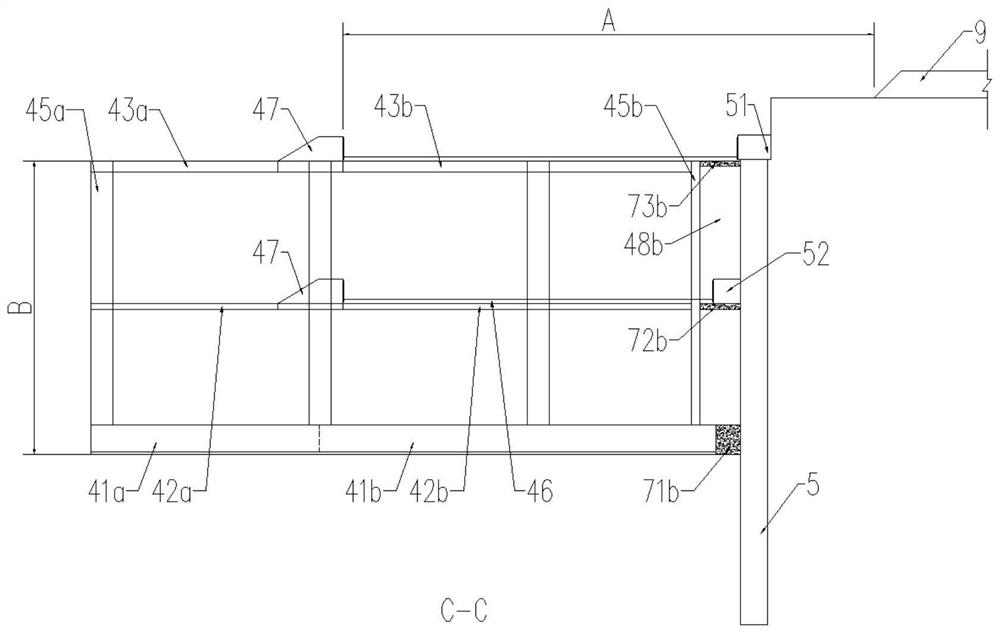

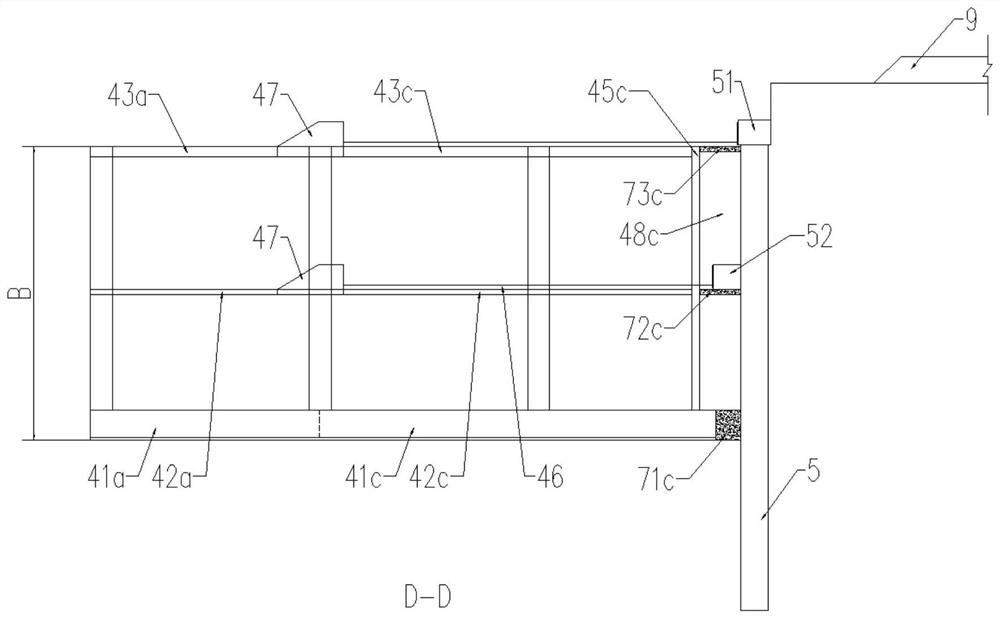

Prefabricated comprehensive pipe gallery

ActiveCN107313452AReasonable forceReduced sidewall thicknessArtificial islandsHydro energy generationUtility tunnelSelf weight

The invention provides a prefabricated comprehensive pipe gallery which is formed in the manner that multiple pipe gallery prefabricated units are longitudinally spliced. Each pipe gallery prefabricated unit comprises a top plate and a bottom plate, wherein the top plate and the base plate are parallel and arranged in a spaced manner. The two sides of each pipe gallery prefabricated unit are provided with arc side walls which are connected with the top plate and the bottom plate in a seal manner. The prefabricated comprehensive pipe gallery solves the problems that in the prior art, construction of the cast-in-place technology is slow, the construction quality is difficult to guarantee, a rectangular cross section is large in dead load in the prefabricating technology, transportation and installation are inconvenient, and cost is high. According to the prefabricated comprehensive pipe gallery, the arc side walls are adopted to optimize the stress of the comprehensive pipe gallery, the dead load and cost of the comprehensive pipe gallery are reduced, the durability of the comprehensive pipe gallery is improved, and the construction quality is easy to guarantee.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

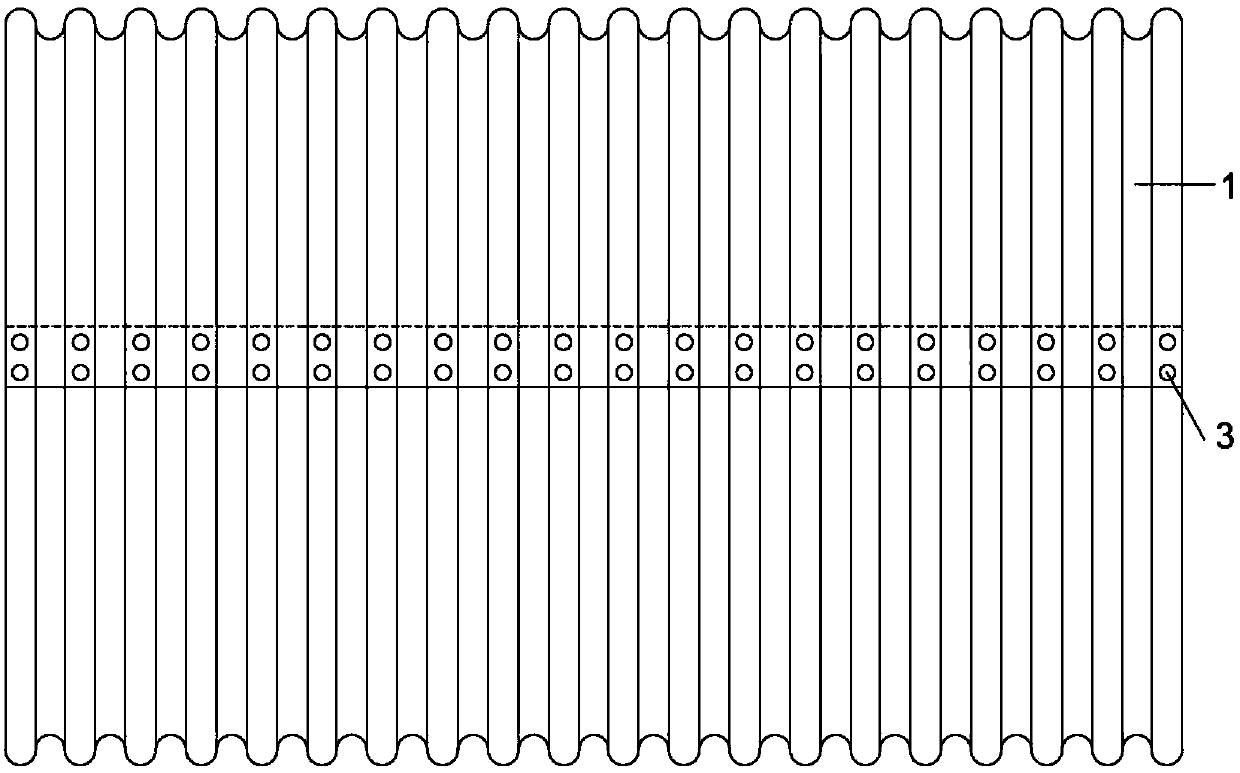

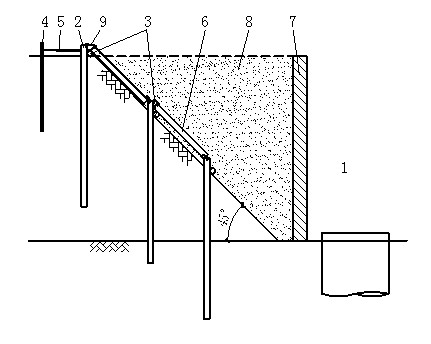

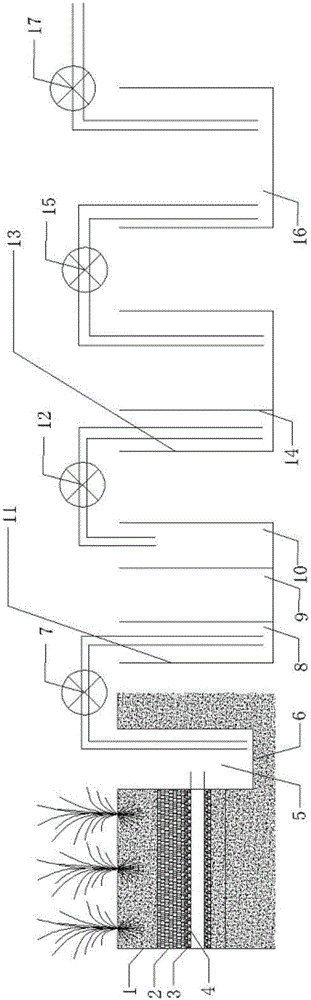

Circular leaching system for farmland polluted soil repair treatment

InactiveCN106734150AAchieve the purpose of repairDoes not affect growthContaminated soil reclamationDouble wallPlant soil

The invention discloses a circular leaching system for farmland polluted soil repair treatment. The system comprises an irrigation leaching system, a decontamination purifying system and a pure water storage and recharge system connected in sequence; drained water of the pure water storage and recharge system is supplied to the irrigation leaching system; the irrigation leaching system mainly consists of planting soil, an organic matter filter layer, a coarse sand filter layer, a double-wall corrugated seepage pipe and a water collecting pool; the planting soil, the organic matter filter layer, the coarse sand filter layer and the double-wall corrugated seepage pipe are arranged in sequence from top to bottom; an outlet of the double-wall corrugated seepage pipe is connected with the water collecting pool; and an outlet of the water collecting pool is connected with the decontamination purifying system. The system adopts the leaching method to reduce the content of pollutants in soil, and meanwhile, lowers the underground water level to prevent repeated pollution; and after polluted water permeated after soil leaching is decontaminated and purified, and the polluted water is recharged for irrigation leaching of the soil again, so that the pollutants in the soil are removed, farmlands are irrigated, and meanwhile, secondary pollution is not generated.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

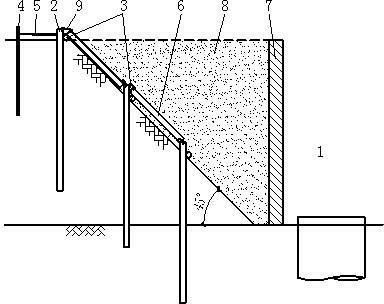

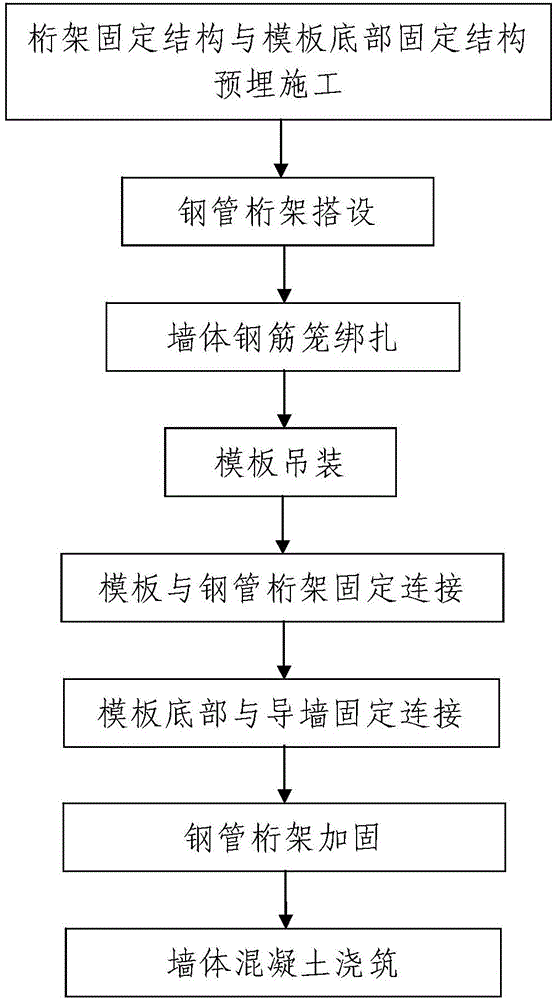

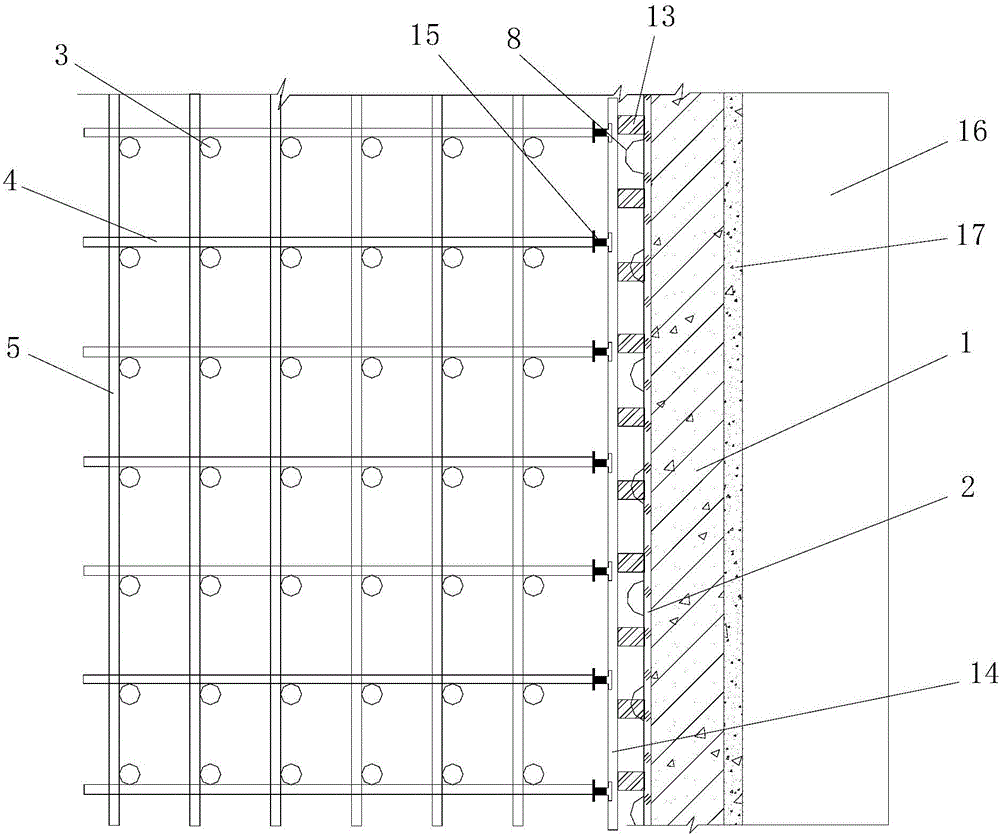

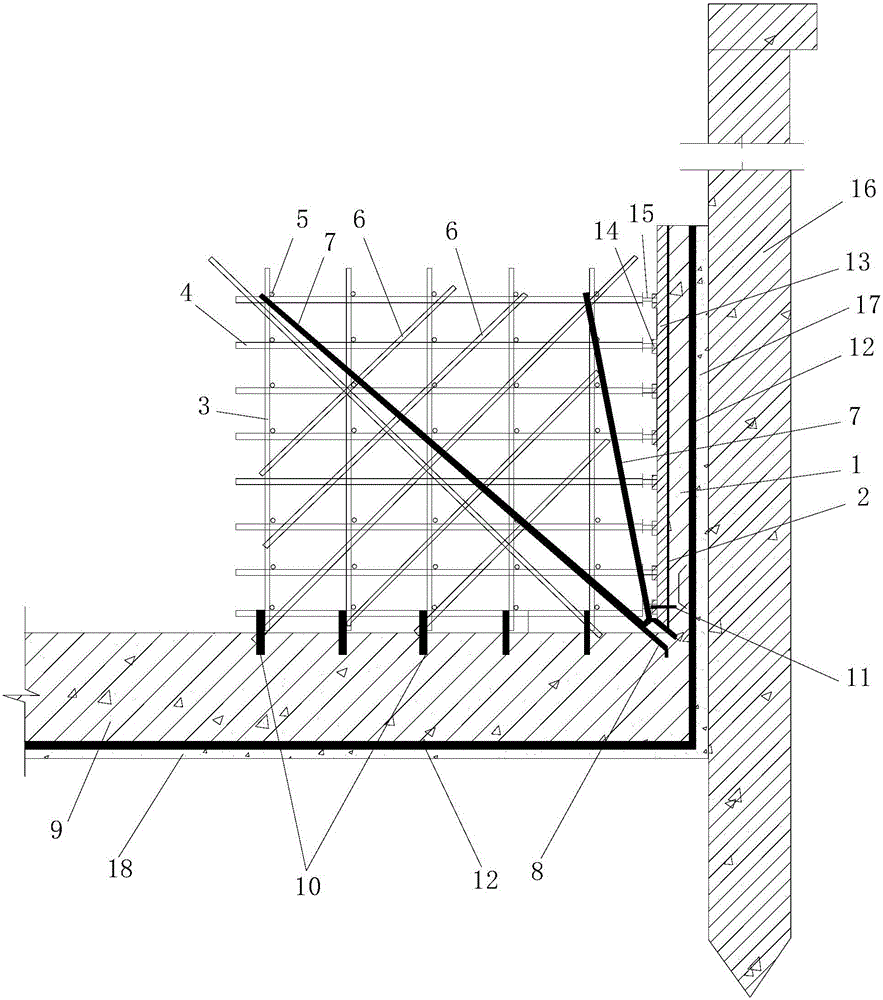

Unilateral formwork supporting construction method for basement exterior wall on basis of steel pipe truss

ActiveCN106245678AThe method steps are simpleEasy to implementArtificial islandsWallsSteel tubeBasement

The invention discloses a unilateral formwork supporting construction method for a basement exterior wall on the basis of a steel pipe truss. The method includes the steps of 1, carrying out embedment construction of a truss fixing structure and a formwork bottom fixing structure, specifically embedding the truss fixing structure for fixing the steel pipe truss into a supporting foundation and embedding the formwork bottom fixing structure for fixing a formwork into a guide wall; 2, erecting the steel pipe truss on the supporting foundation; 3, binding reinforcement cages of a wall body; 4, hoisting the formwork; 5, fixedly connecting the formwork to the steel pipe truss; 6, fixedly connecting the bottom of the formwork to the guide wall and specifically fixing the bottom of the formwork to the guide wall in a fastened mode through the formwork bottom fixing structure; 7 reinforcing the steel pipe truss; and 8, carrying out concrete pouring. The method has the advantages that the steps are simple, the design is reasonable, the construction is simple and convenient, and the use effect is good; and the steel pipe truss serves as a supporting structure, the truss fixing structure and the formwork bottom fixing structure realize the dual reinforcement effect, and therefore the unilateral formwork supporting effect of the basement exterior wall can be effectively improved.

Owner:陕西建总安装工程有限公司

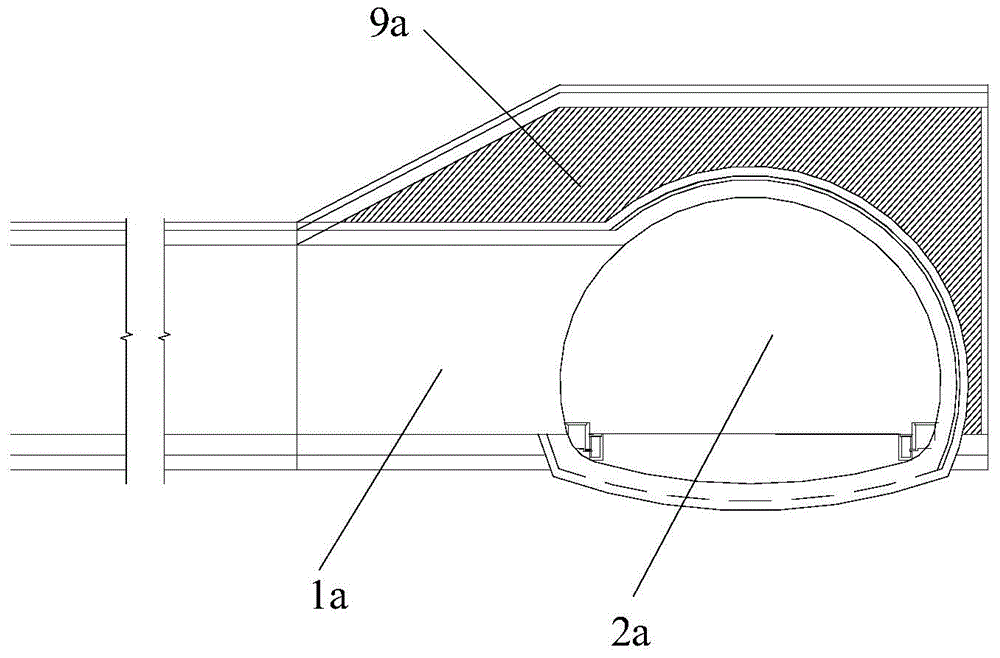

Tunnel transverse cave-to-master cave top brushing construction method and top brushing structure

InactiveCN104929649ASmall excavation areaImprove securityUnderground chambersTunnel liningStep methodBuilding construction

The invention discloses a tunnel transverse cave-to-master cave top brushing construction method. The tunnel transverse cave-to-master cave top brushing construction method comprises the steps that firstly, a transverse cave is constructed to an upper step of a regulated master cave, climbing and direct top brushing are carried out from the top arc outline of the master cave to the width direction of the master cave through a small guiding cave, and a beam is erected at the joint of the transverse cave top and the master cave; secondly, a primary support is carried out on the master cave of the small guiding cave part; thirdly, a vertical support temporarily supported by the small guiding cave in the master cave large mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave large mileage direction; fourthly, a vertical support temporarily supported by the small guiding cave in the master cave small mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave small mileage direction through a step method. The invention further discloses a tunnel transverse cave-to-master cave top brushing structure. The small guiding cave top and the master cave top of the top brushing structure are consistent in structure, the beam is erected at the joint of the transverse cave top and the master cave, and a small guiding cave temporary support is located above a master cave primary support. The top brushing excavation area is small, and the construction risk is low.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

Large-span and large-load prestressed trough-shaped composite slab used as the roof of civil air defense basement

PendingCN102287022AFirmly connectedSolve the problem of layer height reductionArtificial islandsFloorsRebarShock wave

The invention discloses a large-span prestressed groove-shaped laminated plate used as the top plate of a civil air defense basement. In the short range of a few seconds or tens of seconds, there are both wave compression and wave absorption, and the deformation ability and deformation recovery ability of this kind of component are much better under external nuclear explosion, that is, under static loading; ③ remove the large The flange of the load-bearing double T plate becomes a groove shape, which can withstand greater loads, reduce the height of the bottom section, reduce the cost, and it is easy to form a complete section height and shape with its own ventilation channel, and the prestressed large span saves steel bars and saves Pillars, thereby saving the parking area, the same area increases 10%∽20% of the parking space or saves 10%∽20% of the excavation area compared with the traditional method.

Owner:柳忠林

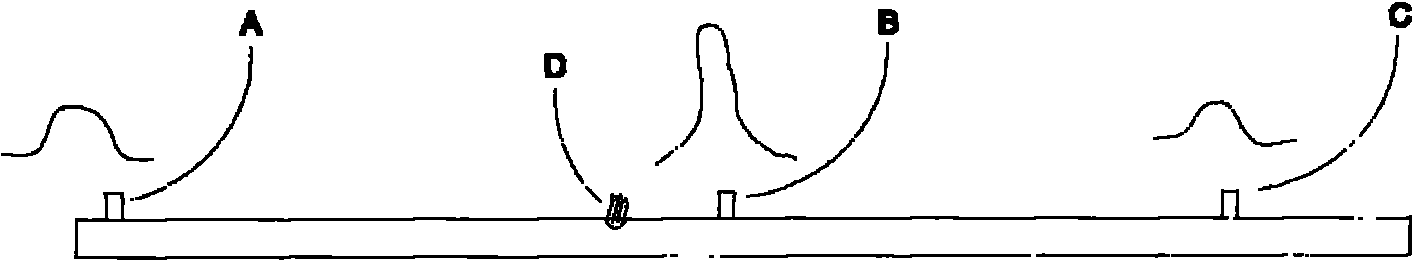

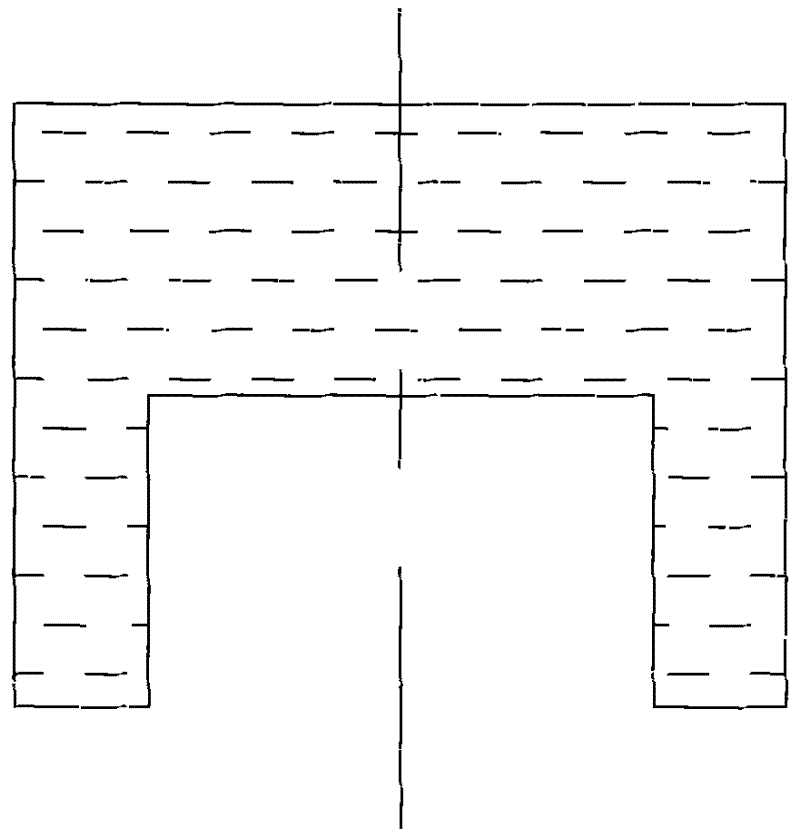

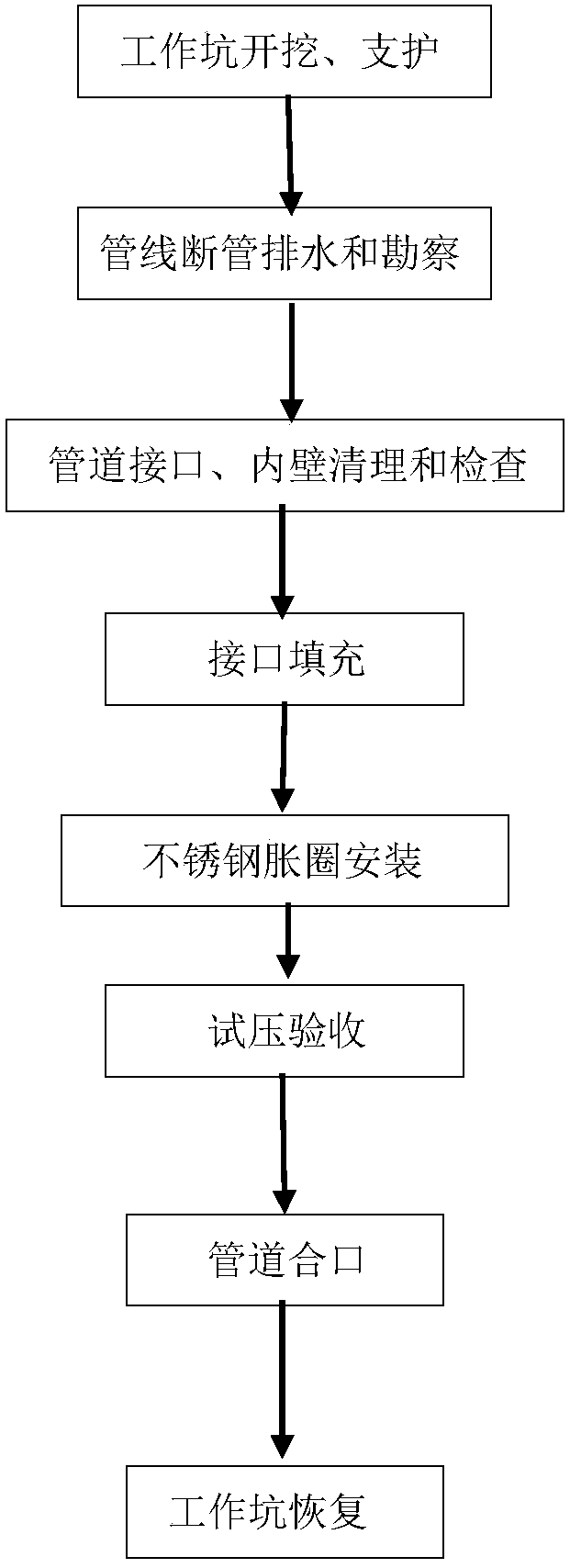

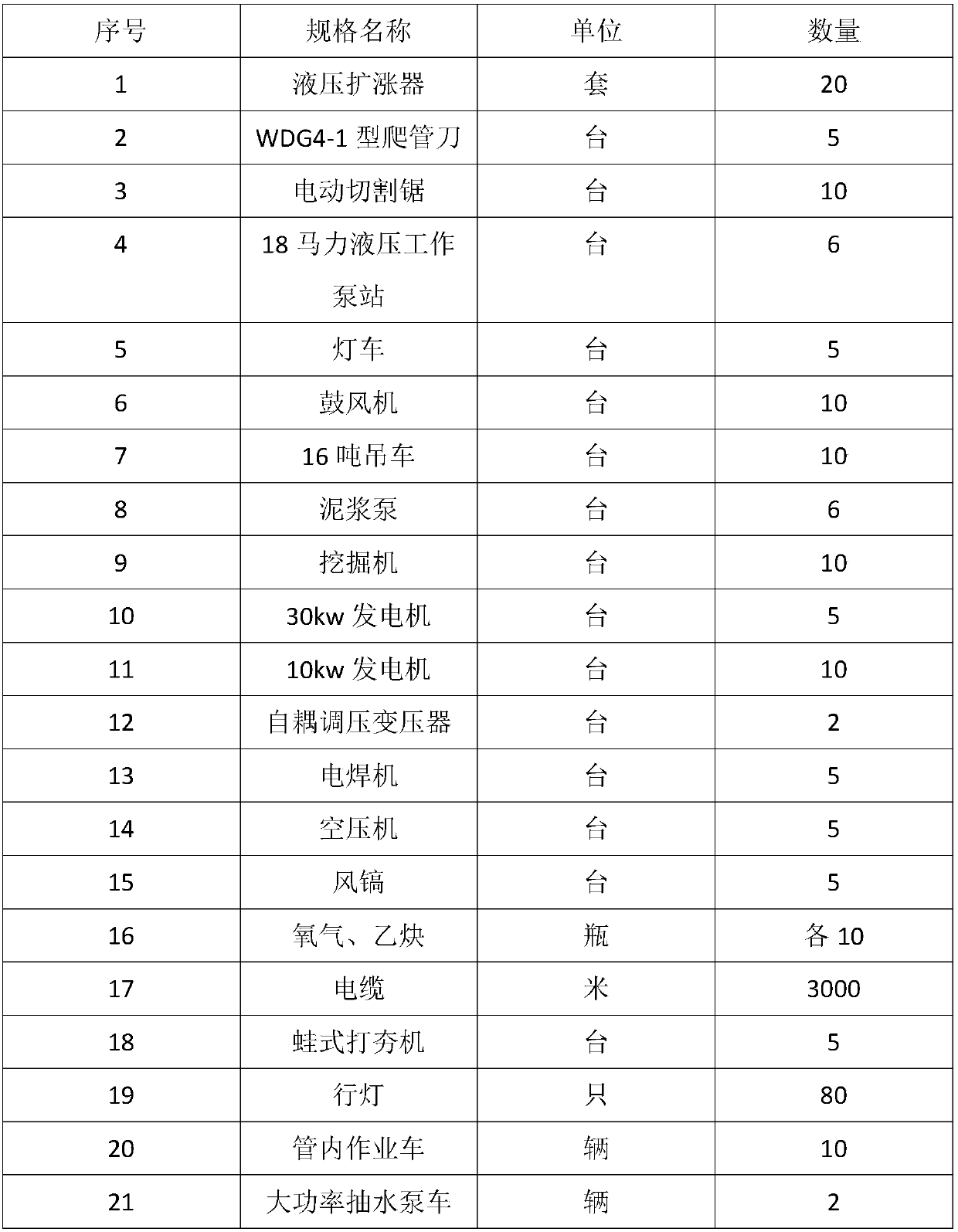

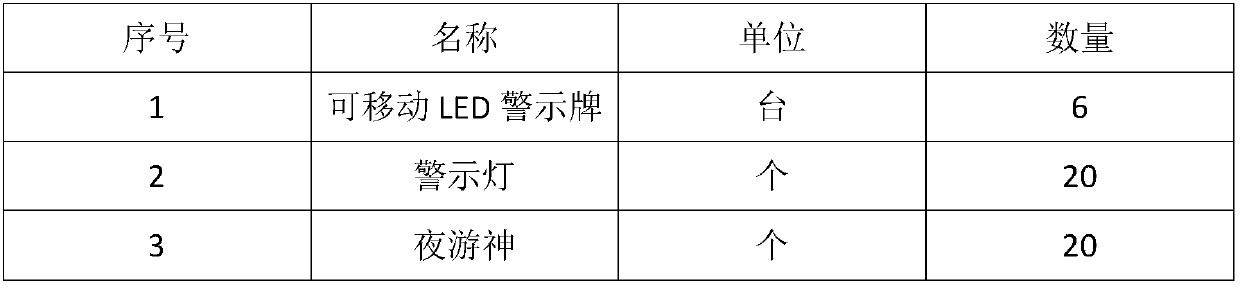

Internal expansion ring method pipe joint repair construction method

InactiveCN107763362AReduce construction intensityReduce construction areaPipe laying and repairPipe elementsState of artFlushing time

The invention discloses an internal expansion ring method pipe joint repair construction method, solves the problem of incapability of quickly and effectively repairing pipes in the prior art, and achieves such effects as high construction speed, no construction limitation from the ground and the environment, low cost and no limitation to the joint repair from the pipes. The internal expansion ring method pipe joint repair construction method comprises the following steps: working pits are excavated along pipelines in a construction site by every other set distance; the pipes are cut for breakage in the working pits to drain water remained in the pipes; pipe joints are cleaned and filled; sealing strips are bonded on the inner walls of the pipes in the pipe joints; internal expansion ringsare clamped in annular grooves of the sealing strips, and set pressure is applied to the internal expansion rings; two ends of the pipelines are blocked, and the pipe flushing time is set; steel pipes are arranged in the breakage places of the pipes to join the broken pipes; and the working pits are backfilled to recover pavements.

Owner:济南普利市政管网工程有限责任公司

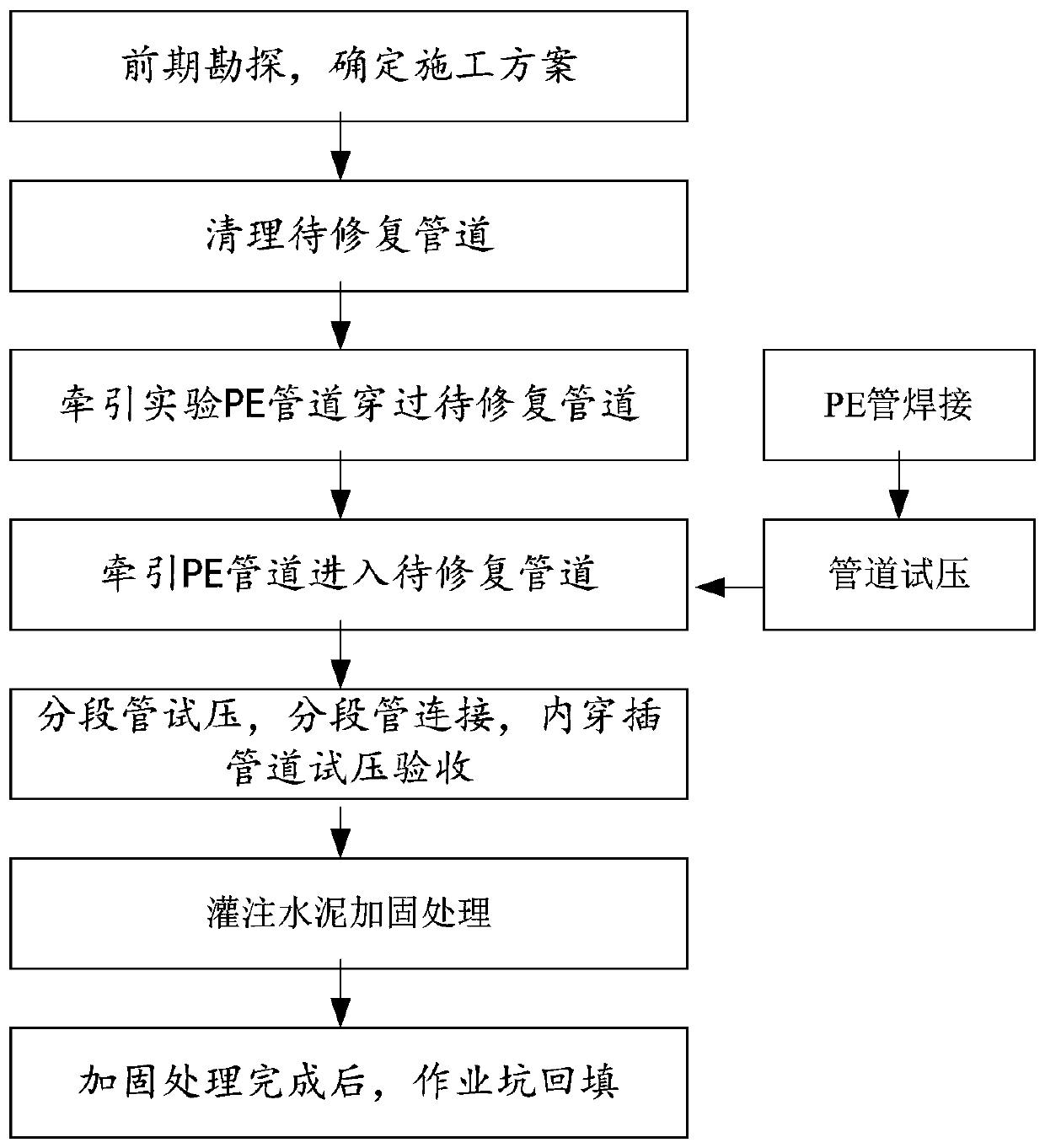

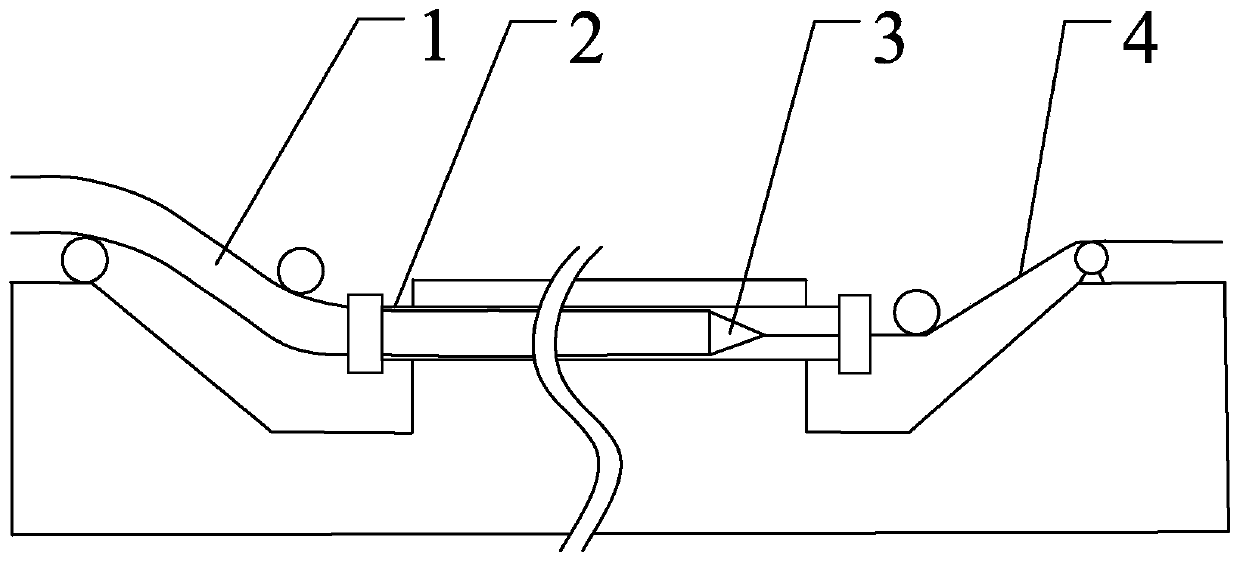

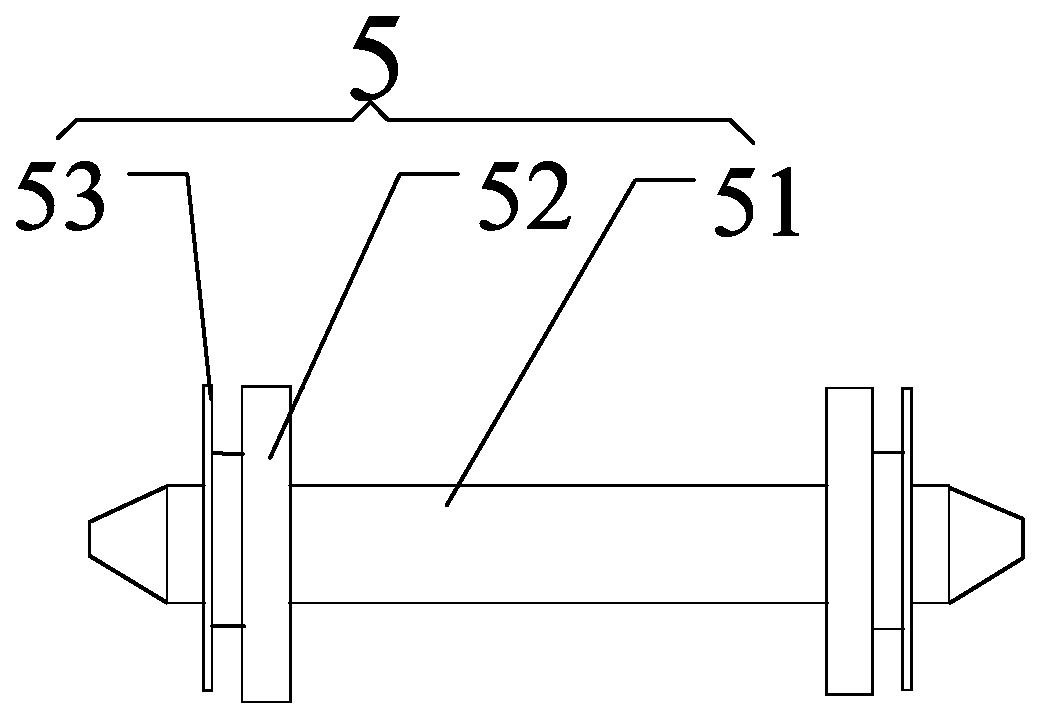

Non-excavation internal PE pipeline penetration restoration method

InactiveCN110159867AIncrease the lengthNo safety hazardPipe laying and repairPipeline systemsRestoration methodEngineering

The invention discloses a non-excavation internal PE pipeline penetration restoration method. The method comprises the following specific steps that early-stage exploration is performed; a working pitis excavated, and a to-be-restored pipeline is cleaned; an experiment PE pipeline is pulled to penetrate through the to-be-restored pipeline, and whether the damage degree of the experiment PE pipeline meets a standard or not is observed; the PE pipeline is pulled to enter the to-be-restored pipeline, wherein the PE pipeline is composed of a plurality of PE pipeline segments, the tail end of eachfront PE pipeline segment is welded to the front end of a corresponding rear PE pipeline segment, and pulling is performed again after cooling and pipeline pressure testing are completed; pressure testing is performed on the pipeline segments one by one, every two pipeline segments are connected, and a pipeline penetrates through the pipeline segments for pressure testing; and after reinforcing treatment is completed, working pit backfilling is performed. According to the non-excavation internal PE pipeline penetration restoration method adopting the above structure, the to-be-restored pipe does not need to bear pressure, no potential safety hazard exists, the single-time pipeline penetration length is increased and can reach 1500 meters, the excavation area is greatly decreased, and influences on transportation and production are less.

Owner:保定市金马漏水检测有限公司

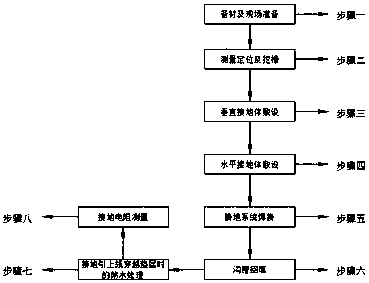

Construction process of argilloid geological ground network

InactiveCN108511930AImprove securityLower resistanceContact member manufacturingConnection contact member materialMaterials preparationElectrical resistance and conductance

The invention discloses a construction process of an argilloid geological ground network. The construction process comprises the following steps of 1, material preparation and site preparation; 2, measurement, positioning and groove digging; 3, vertical grounding body laying; 4, horizontal grounding body laying; 5, grounding system welding; 6, groove filling; 7, waterproof processing during a grounding leading-up line penetrating through a cushion layer; and 8, grounding resistance measurement, in which the 50-by-6 galvanized flat steel horizontal grounding body with length larger than or equal to 6 meters, the 50-by-50-by-5 vertical grounding body in 2,500 millimeters, a 50-by-6 horizontal pressure-sharing belt, a 50-by-6 galvanized flat steel grounding leading-out line and resistance reduction agent are prepared, a corresponding construction operating surface is ensured, the leveling of a base is completed, and check and acceptance are performed according to bearing capability of foundation pit. By the process, the resistance is favorable reduced, the corrosion-resistant capability is improved, the step voltage can be reduced, the personal safety is improved, water prevention isfacilitated, the excavation area of a plant is favorably reduced, and the construction cost is reduced.

Owner:SHANXI INSTALLATION GRP CO LTD

Large-span large-load prestressed grooved laminated slab used as basement roof

The invention discloses a large-span large-load prestressed grooved laminated slab used as a basement roof, which is characterized in that the large-span large-load prestressed grooved laminated slab has appearance of a grooved slab; a functional component is formed by the grooved slab and an upper laminating layer; due to the groove shape and the large load of the large-span large-load prestressed grooved laminated slab, the application requirement of an underground parking garage is met; due to the large span, parking spaces are saved; due to the grooved narrow slab surface, the cost and the story height are saved; and due to the suitable rib height, not only can the load requirement be met, but also the requirement for opening an air duct on a rib can be met, the story height is not increased and the grooved transverse air duct is easy to connect. When the large-span large-load prestressed grooved laminated slab is used at the top of an underground parking garage slab, the construction period can be quickened, the story height is reduced, the cost is reduced, column grids are saved, the parking spaces are increased, and the grade of the underground parking garage is improved.

Owner:QINGDAO JINCHAO SPECIAL CONCRETE PROD

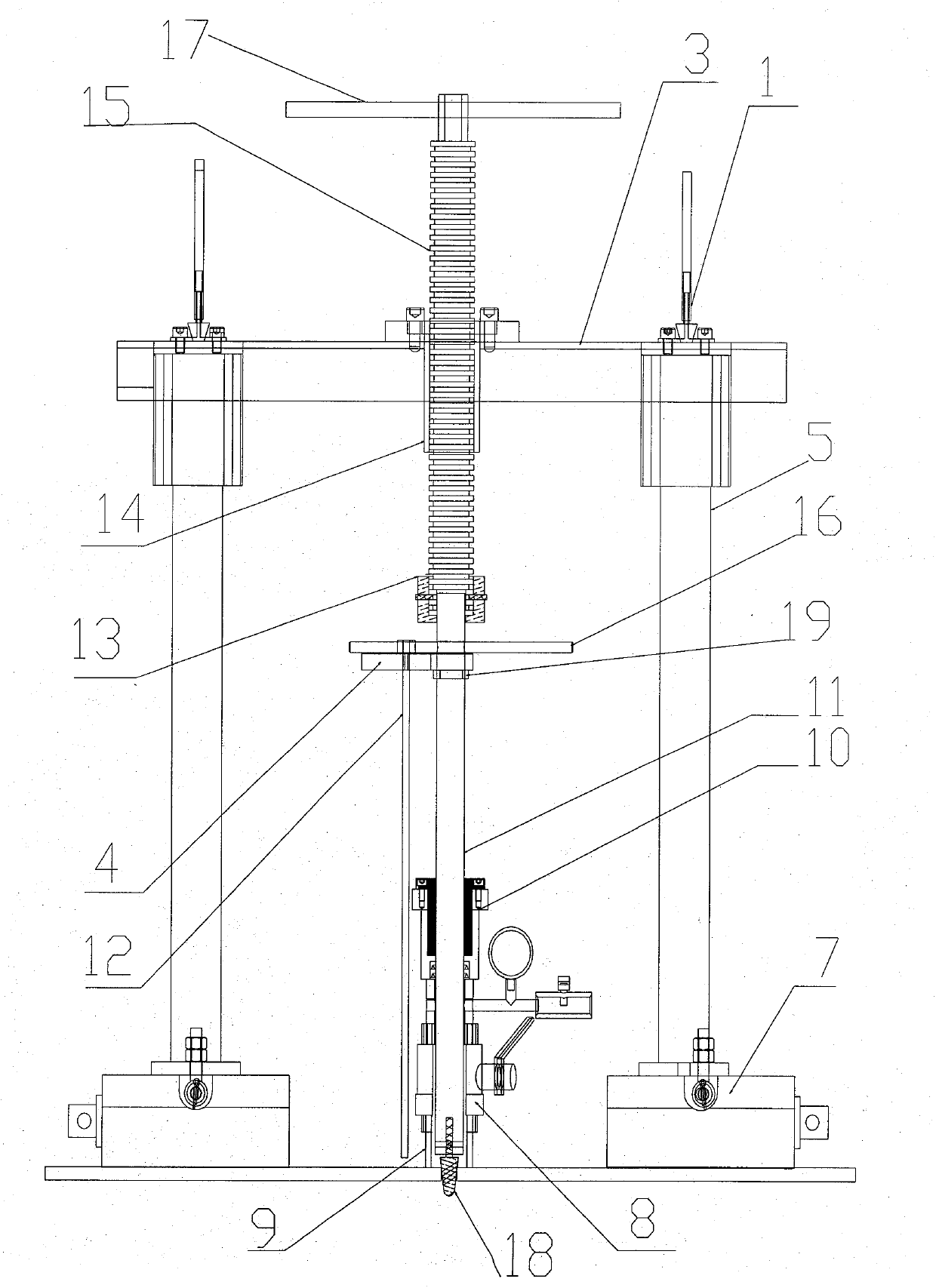

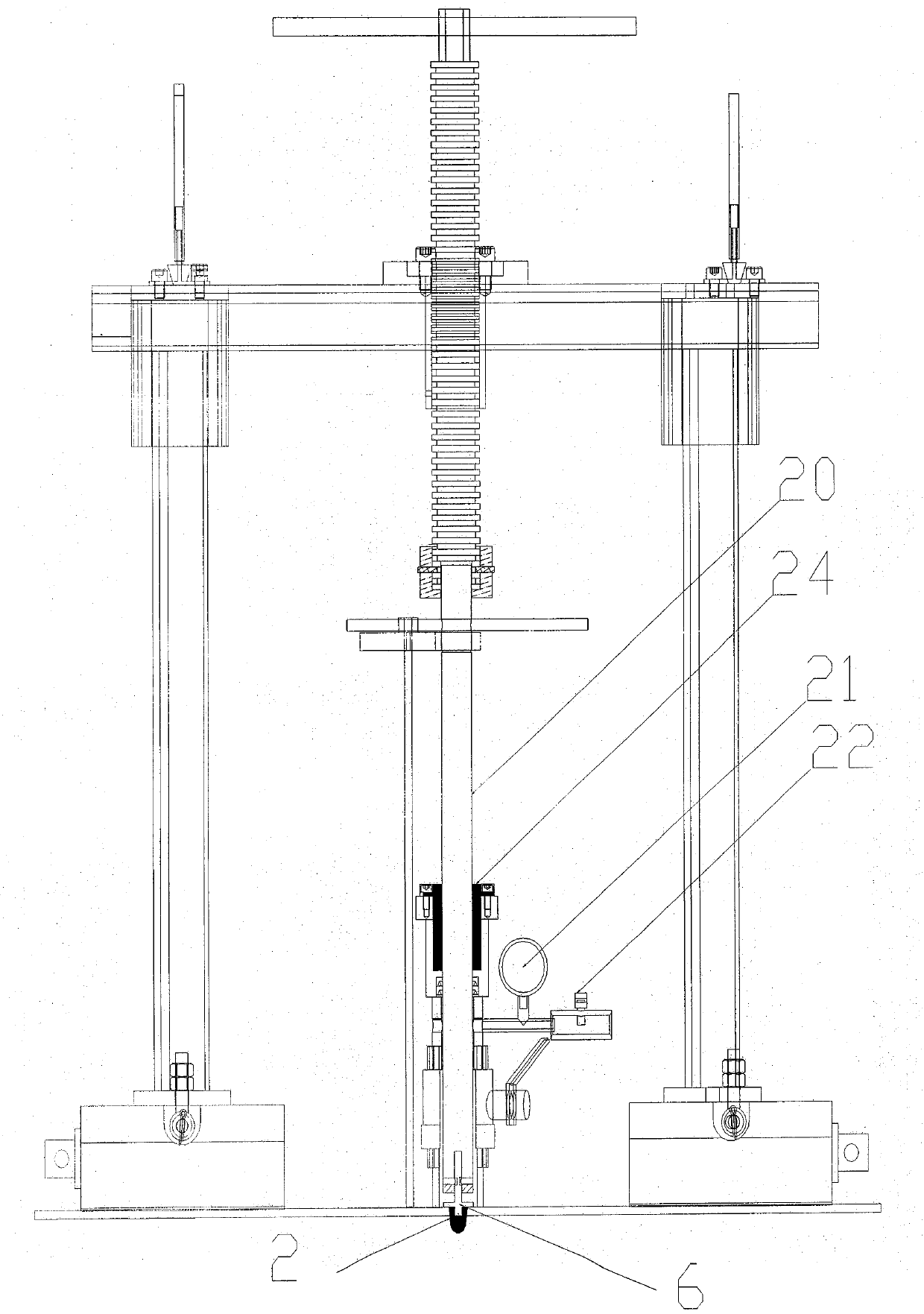

Stealing hole pressure plugging device of oil pipeline

The invention discloses a stealing hole pressure plugging device of an oil pipeline. The stealing hole pressure plugging device of the oil pipeline is mainly composed of a rapid clamp, a rubber plug, a beam, a needle frame, a side upright, a plug, a magnetic base, a main cylinder, a diameter measuring shaft, a pointer, a check ring, a locknut, a screw rod, an axial rotary lever, a screw rod feeding lever, a grinding head, a metal gasket, a plugging shaft, a hydraulic meter, a pressure release valve and a cover board. The magnetic base is attracted to the oil pipeline. The side upright is fixed to the magnetic base. The beam is pressed tightly by the rapid clamp and fixed to the upper end of the side upright. The screw rod penetrates through the locknut on the beam and presses the diameter measuring shaft or the plugging shaft tightly. The diameter of a stealing hole is measured through the grinding head at the lower end of the diameter measuring shaft. The stealing hole is plugged through the plug and the rubber plug at the lower end of the plugging shaft. After a short tube is cut off, the plugs are tightly pressed through the cover board and are welded. According to the stealing hole pressure plugging device of the oil pipeline, on the premise that the oil pipeline is under pressure and delivery is not stopped, the diameter of the stealing hole is measured, the stealing hole is plugged, the whole process is conducted in a sealed mode, crude oil is not leaked, the structure is simple, use is safe and convenient, and economic loss caused by a delivery stop of the oil in the oil pipeline is avoided.

Owner:QINGDAO UNIV OF SCI & TECH

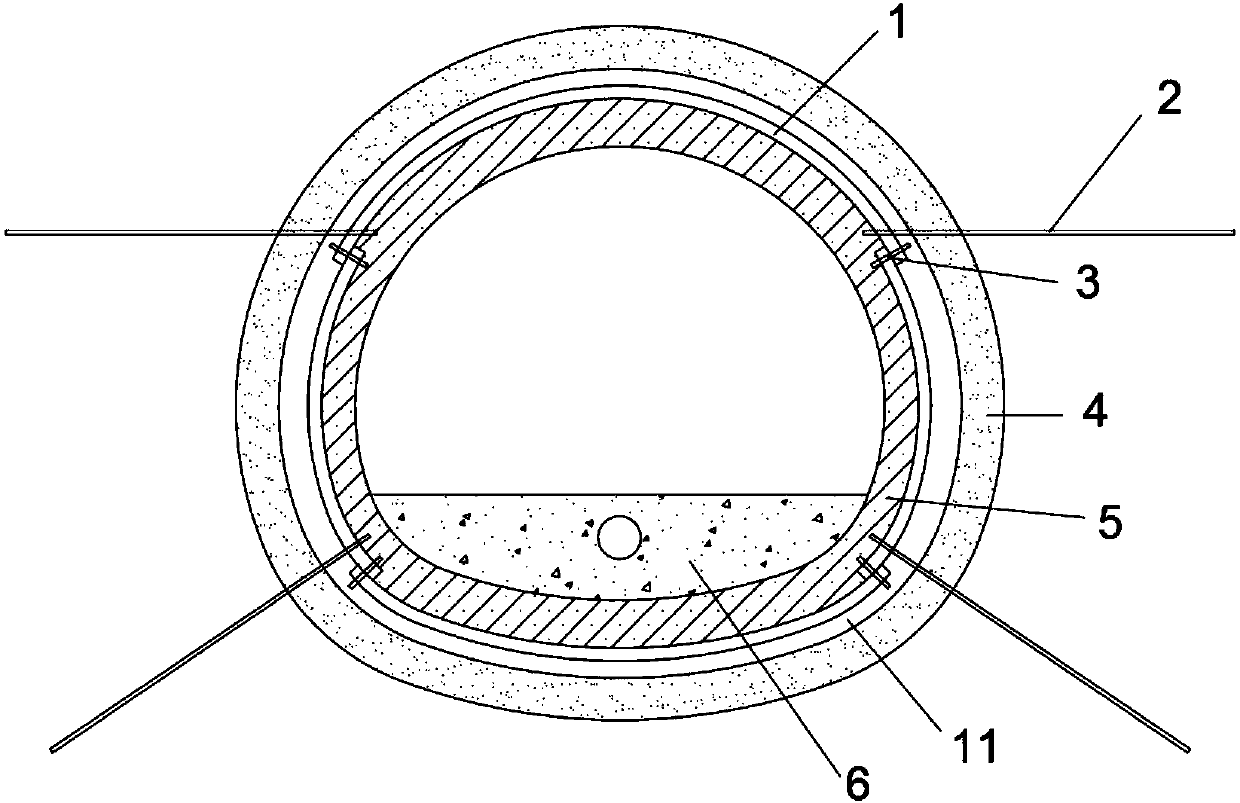

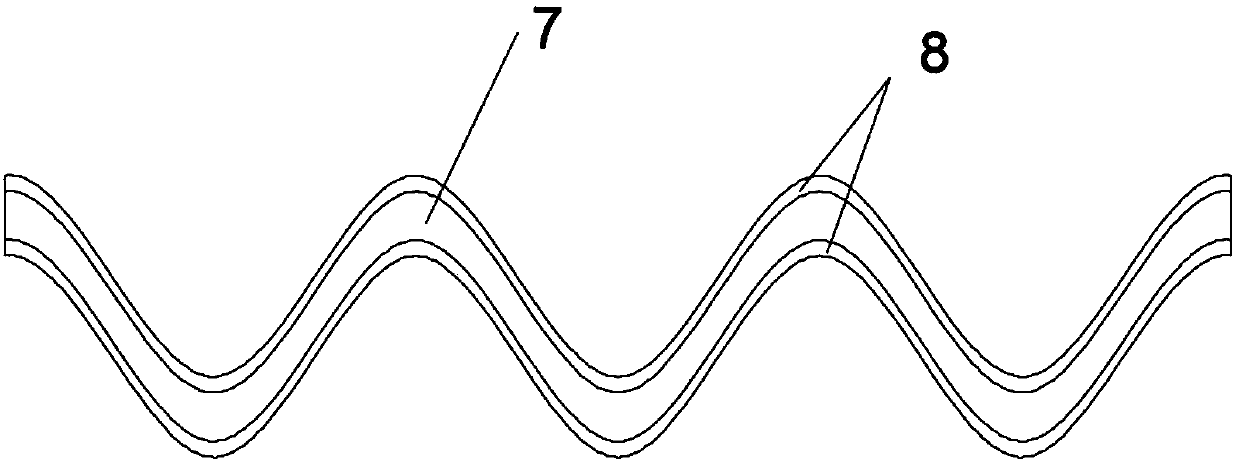

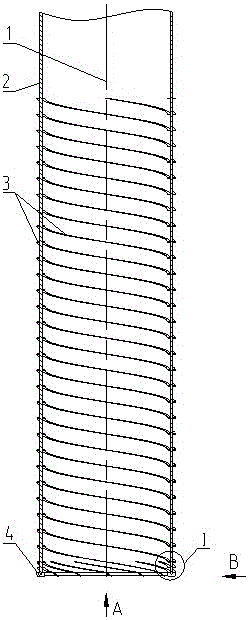

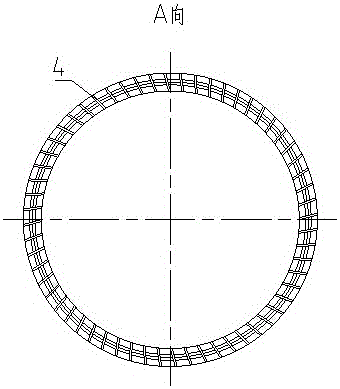

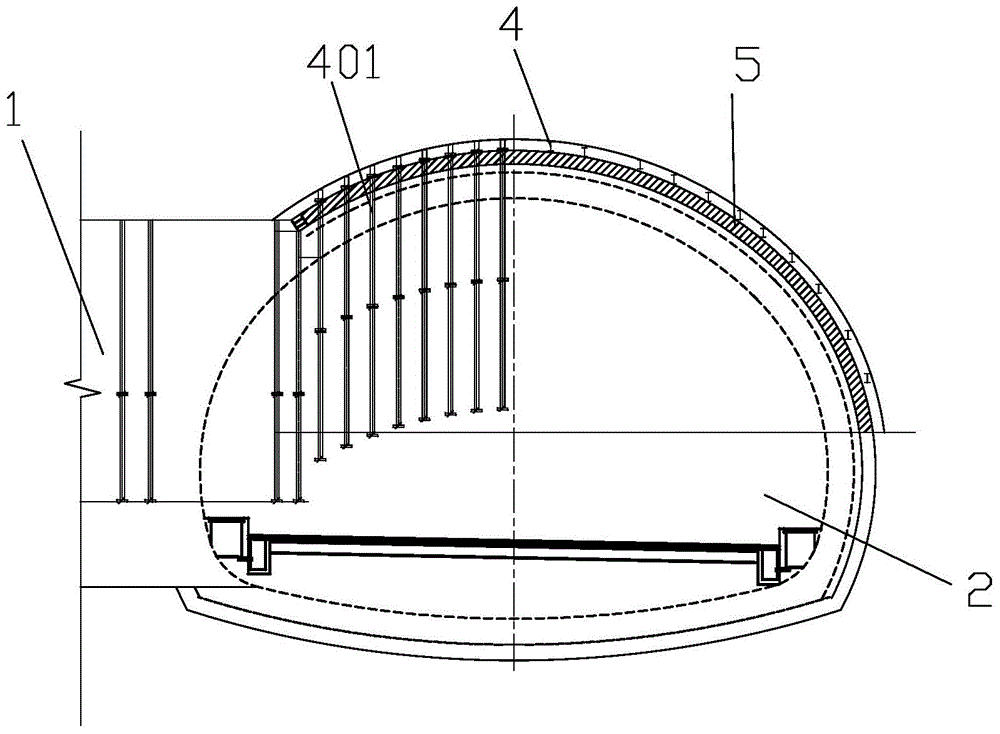

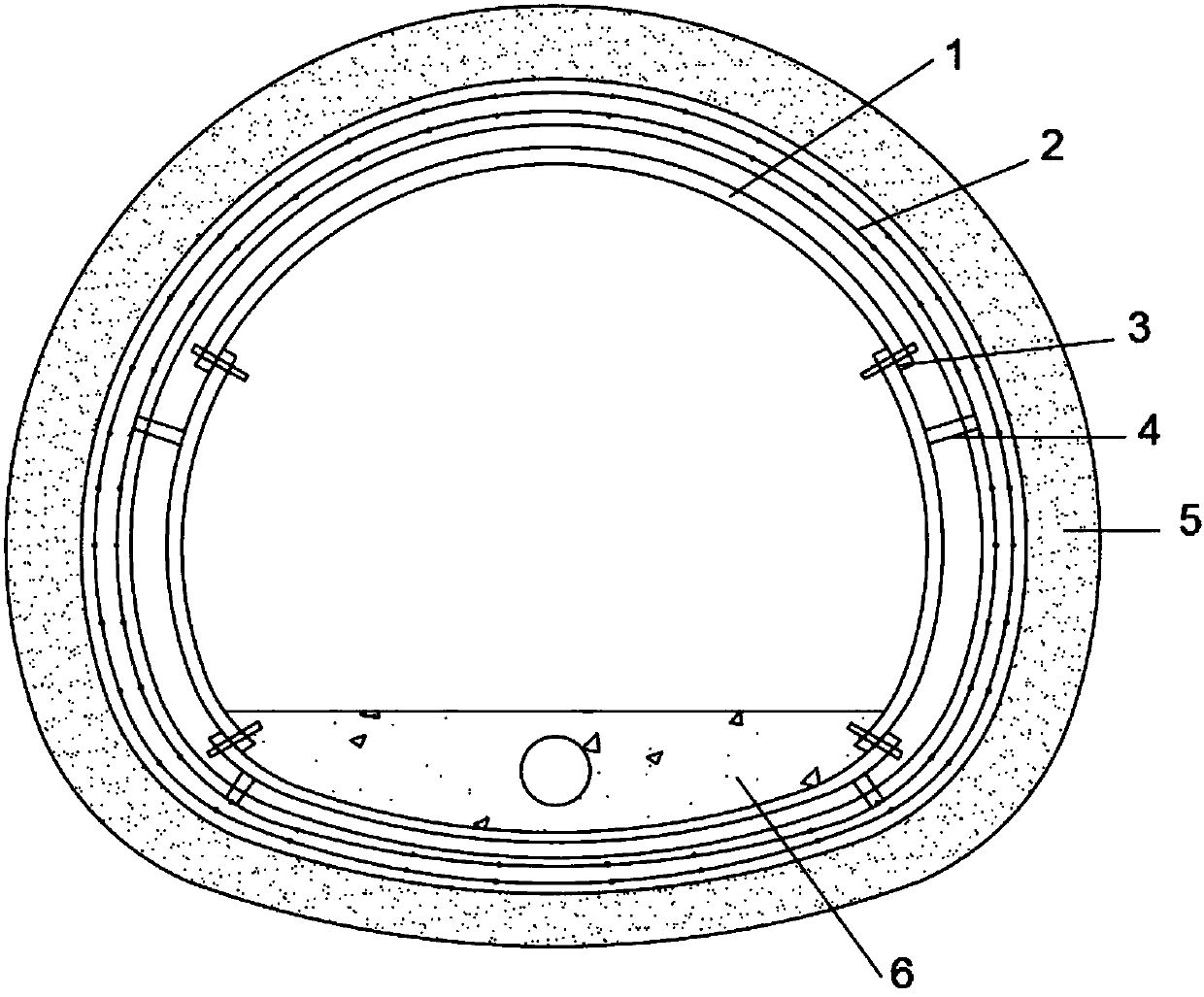

Steel-FRP composite corrugated plate tunnel secondary lining structure and construction method thereof

ActiveCN107806349ALow costShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringWater seepage

The invention discloses a steel-FRP composite corrugated plate tunnel secondary lining structure and a construction method thereof and belongs to the technical field of tunnel engineering. The secondary lining structure is formed by prefabricating and splicing steel-FRP composite corrugated plates, the middles of the corrugated plates are inlaid steel cores, and the inlaid steel cores are wrappedwith FRP. The FRP and the inlaid steel cores are composited and formed though a heat curing forming technique, the thickness of the inlaid steel cores is 60-70% of that of the corrugated plates, and the thickness of the FRP is 30-40% of that of the corrugated plates. The thickness of the corrugated plates is calculated and determined according to stress. The direction of corrugated lines is perpendicular to the longitudinal direction of a tunnel. The curve radian of the corrugated plates accords with the designed outline of the tunnel. Bolt holes and grouting holes are reserved in corrugated plate bodies. Flanges for connection are arranged on the two sides of the corrugated plates in the longitudinal direction. Water-stop belts are arranged at the connecting positions of the corrugated plates, so that underground water seepage is prevented. Supports adopt prefabricated component splicing type construction, and the construction period is shortened. The construction environment is improved, the tunnel outline is optimized, the excavation area is reduced under the premise that the building boundary is ensured, and the engineering manufacturing cost is reduced.

Owner:BEIJING UNIV OF TECH

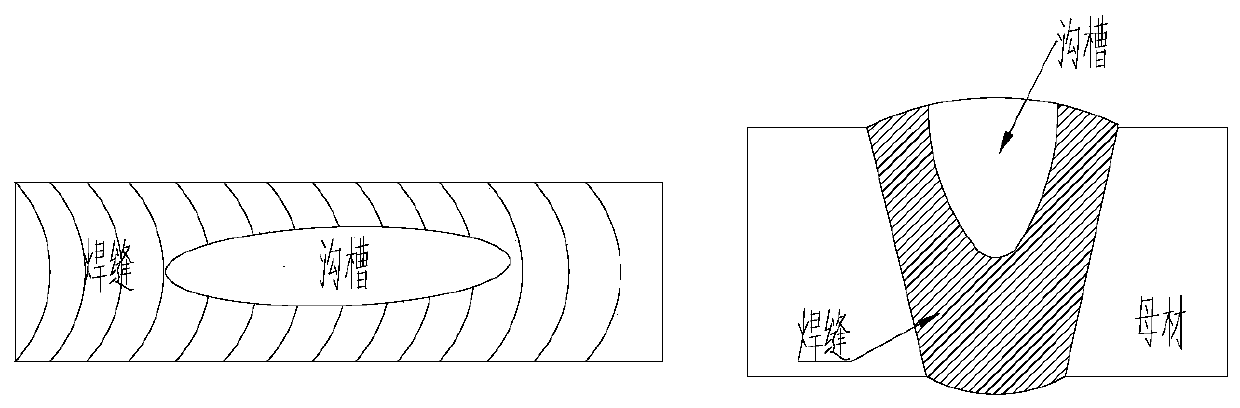

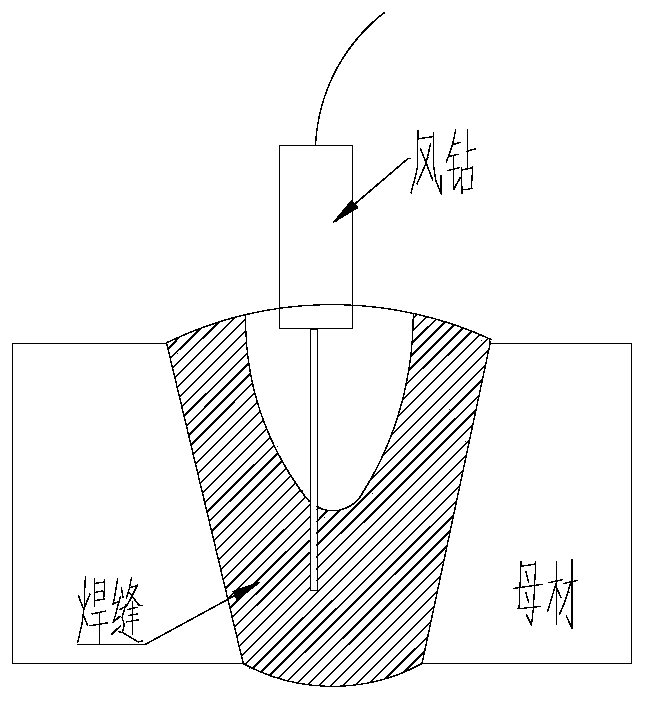

Aluminum alloy special-shaped structural part drilling and repair welding method

The invention discloses an aluminum alloy special-shaped structural part drilling and repair welding method. The method comprises the following steps of 1, defect elimination, 2, defect positioning and drilling, 3, groove and hole finishing and cleaning, 4, repair welding area preheating, 5, repair welding and post-heating, and 6, weld seam finishing and X-ray fluoroscopy. Compared with the priorart, the method has the advantages that welding defects are eliminated through drilling, the digging area is small, the heat input time acting on a weld seam during repair welding is short, a weld seam melting pool is cooled and quickly crystallized, accordingly tiny air holes in the weld seam are crystallized without nucleation due to large supercooling degree, and therefore the welding qualifiedrate is ensured. Meanwhile, the repair welding area is small, welding stress is small, and therefore product welding deformation is small. By means of the drilling and repair welding method, the one-time repair welding qualified rate is greatly improved to 80%, and the period for treating the repair welding problem caused by repeated welding defect elimination of products is greatly shortened.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Rapid construction method of pipe jacking working well in upper soft and lower hard stratum

The invention discloses a quick construction method of a pipe jacking working well in an upper soft and lower hard stratum. A site is smoothed, staking out in survey is carried out, the position of apile hole is positioned; a rotary drilling machine is used for drilling in an upper soil layer, every time a certain distance is drilled, a drill head of the rotary drilling machine exits out of the pile hole, and a pile casing is put into the pile hole; the method is repeated until drilling is carried out into a lower base rock layer, and all the pile casings are anchored in the upper soil layer;the rotary drilling machine is continuously used for drilling in the lower base rock layer until drilling is carried out to a specified elevation; transverse excavation is carried out in the hole wall at the bottom of the pile hole to form a pipe jacking operation space, wherein the pipe jacking operation space is provided with an opening into which the pipe jacking to be constructed can enter; ajacking device is installed in the pipe jacking operation space; and at the bottom of the pile hole and at the position of the pipe jacking construction, the lower base rock layer is excavated transversely, and jacking construction is carried out on the pipe jacking through the jacking device. The quick construction method reduces the construction workload, reduces the construction difficulty, shortens the construction period and reduces the impact on the environment.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Large-span high-load prestressing force groove-shaped composite plate used as top plate of anti-aircraft basement

The invention discloses a large-span prestressing force groove-shaped composite plate used as a top plate of an anti-aircraft basement of 6 grades and lower than 6 grades. The composite plate is characterized in that a groove-shaped composite plate with a large span, a high load, a narrow board width and a low rib height forms a functional member together with an upper composite layer. Due to the adoption of an elastic-plastic deformation resilience characterization coefficient of a prestressing force plate, the resistance of the member under the action of a short-term effect of a nuclear explosion shock wave is improved. Therefore, materials are substantially saved, and the floor height is reduced. A groove-shaped large load meets the using requirements of an underground garage; parking spaces are saved in a large span; due to the adoption of a groove-shaped narrow board, the manufacturing cost and the floor height can be reduced; and the composite plate has an appropriate rib height and can meet load bearing requirements and the requirement of forming an air channel on a rib, the floor height is not increased, and a groove-shaped horizontal air channel is easy to connect. When the composite plate is used for the top plate of the underground garage, a construction period can be accelerated, the floor height can be reduced, the manufacturing cost can be reduced, a column grid can be saved, the parking spaces can be increased, and the grade of the underground garage can be improved.

Owner:柳忠林

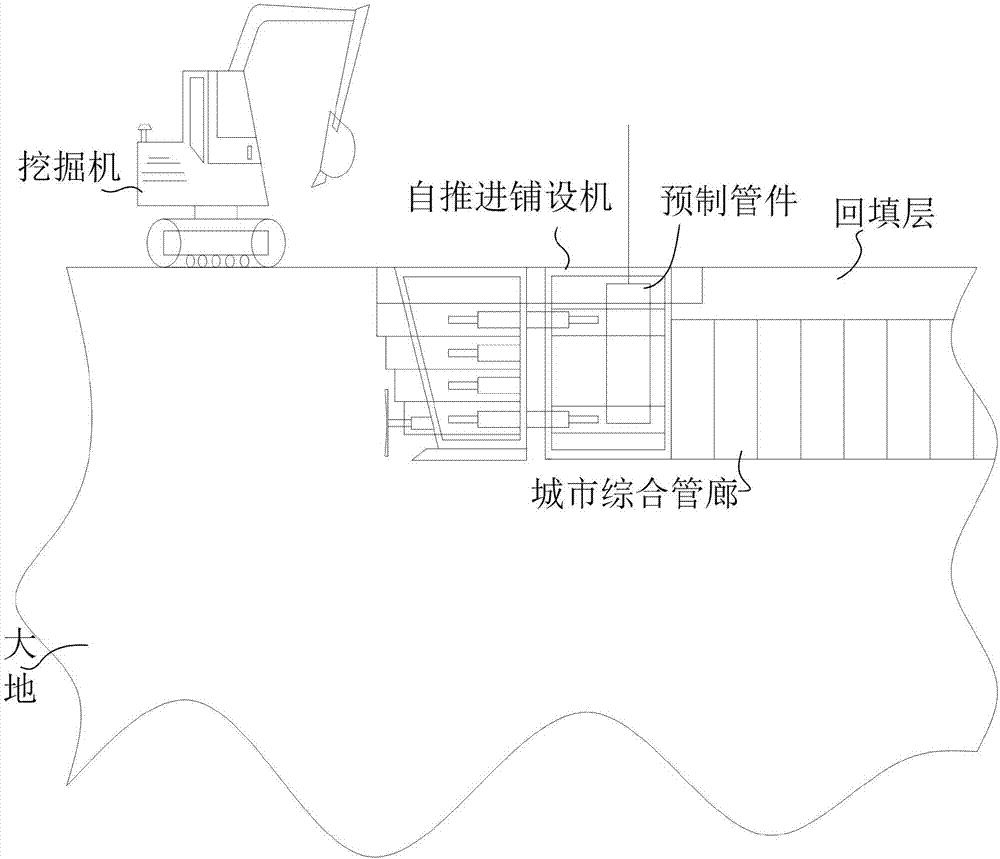

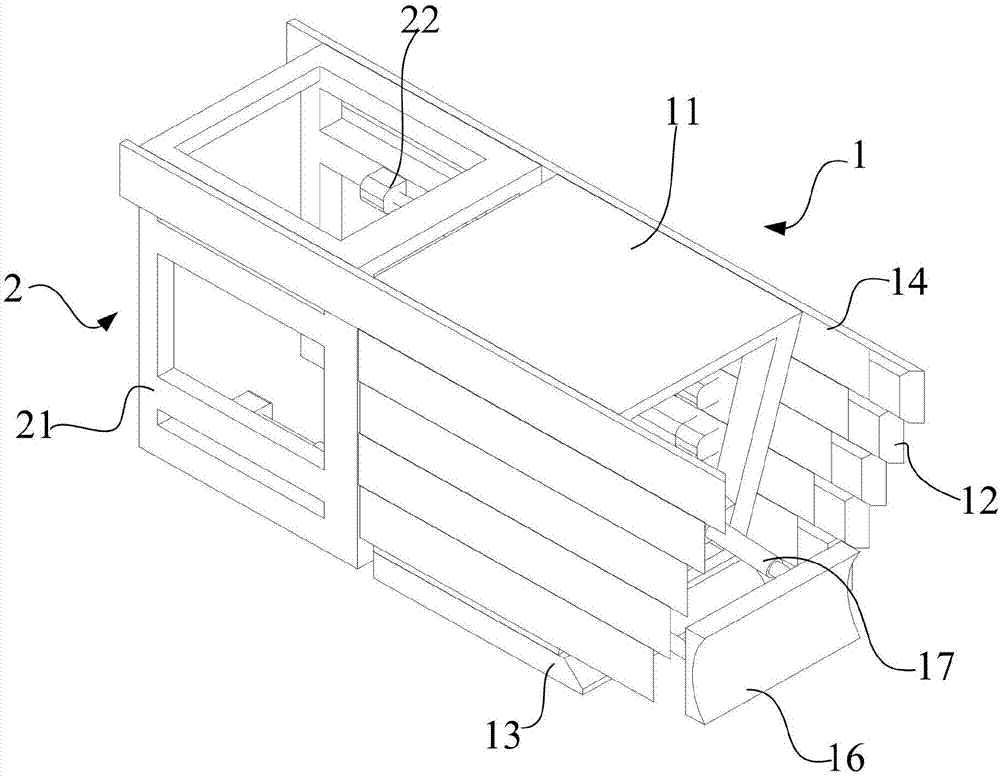

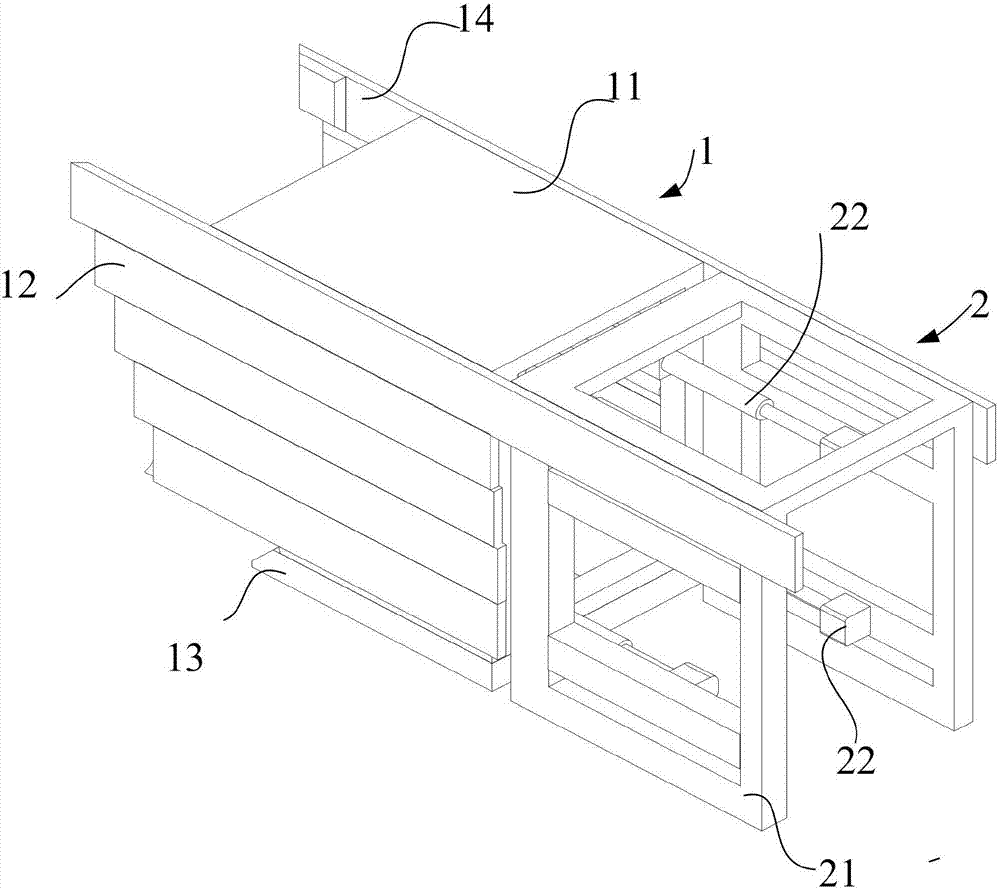

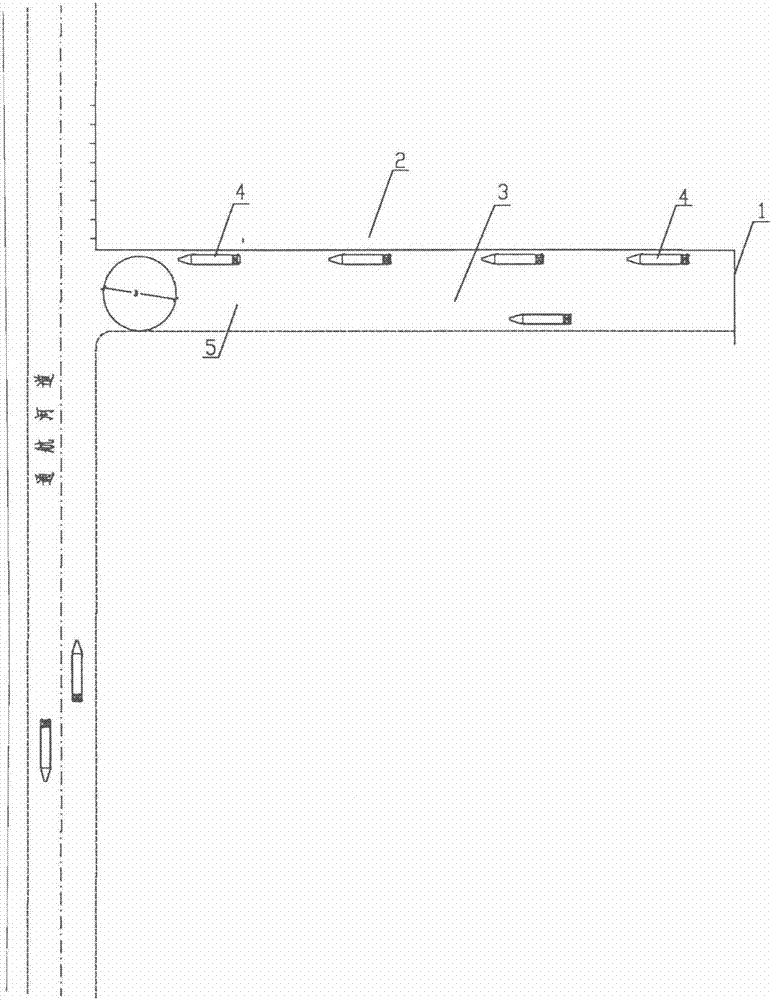

Open-cut type self-protective construction method of city comprehensive prefabricated pipe rack and self-propelling laying machine

PendingCN106869165AWork lessSmall excavation areaArtificial islandsUnderwater structuresSlagPipe fitting

The invention relates to an open-cut type self-protective construction method of a city comprehensive prefabricated pipe rack and a self-propelling laying machine. The open-cut type self-protective construction method comprises the following effective methods that (a), a device assembling working face is built at the front end of a construction route firstly; (b), the self-propelling laying machine is installed on a device assembling working face site; (c), after the self-propelling laying machine is installed, an open trench with the width and the depth being slightly smaller than the width of the pipe rack needed to be laid is excavated through an excavator; (d), the width and the depth which are needed for pipe rack laying are excavated through the self-propelling laying machine; (e), after the self-propelling laying machine completes excavating, soil slag excavated through the self-propelling laying machine is excavated through the excavator, and meanwhile prefabricated pipe fittings are lifted through a lifting machine, stored into the self-propelling laying machine and well fixed; (f), after the self-propelling laying machine is driven to move according to the construction route, the prefabricated pipe fittings which are laid just now are backfilled through the excavator; and (g), motion from the step (c) to the step (g) is repeated till a device assembling working face at the other end of the construction route is built, and namely, building of the whole city comprehensive prefabricated pipe rack is completed.

Owner:曾庆如 +1

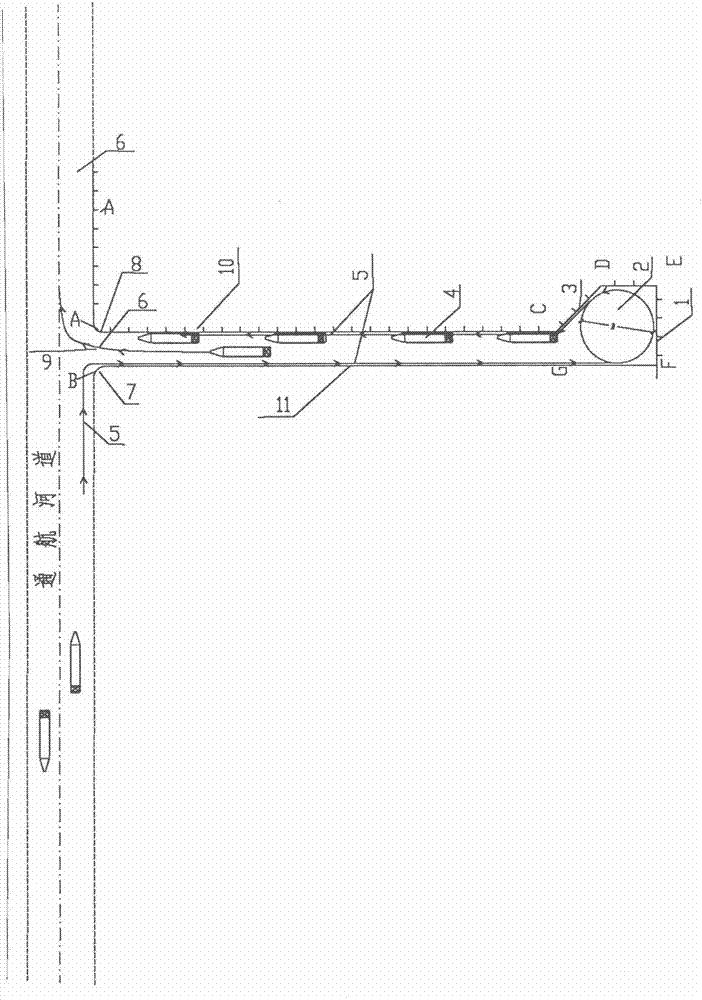

Excavated-in harbor basin arrangement method for reducing excavation area

InactiveCN107288100AReduce widthSimple designShipping equipmentWater resource managementBuilding construction

The invention provides an excavated-in harbor basin and relates to the field of harbor approaches. The excavated-in harbor basin comprises a wharf and a harbor basin water area, wherein the wharf is provided with an entrance and a closed end, and the harbor basin water area is surrounded by the wharf. A turning water area connected with the harbor basin water area is arranged on the outer side of the entrance of the wharf, wherein the width of the turning water area is larger than that of the harbor basin water area. The turning water area of the wharf is intensively arranged on the inner side of the harbor basin, so that the space utilization ratio of the harbor basin is improved, the excavation area of the harbor basin is reduced, and the construction cost is reduced.

Owner:JSTI GRP CO LTD

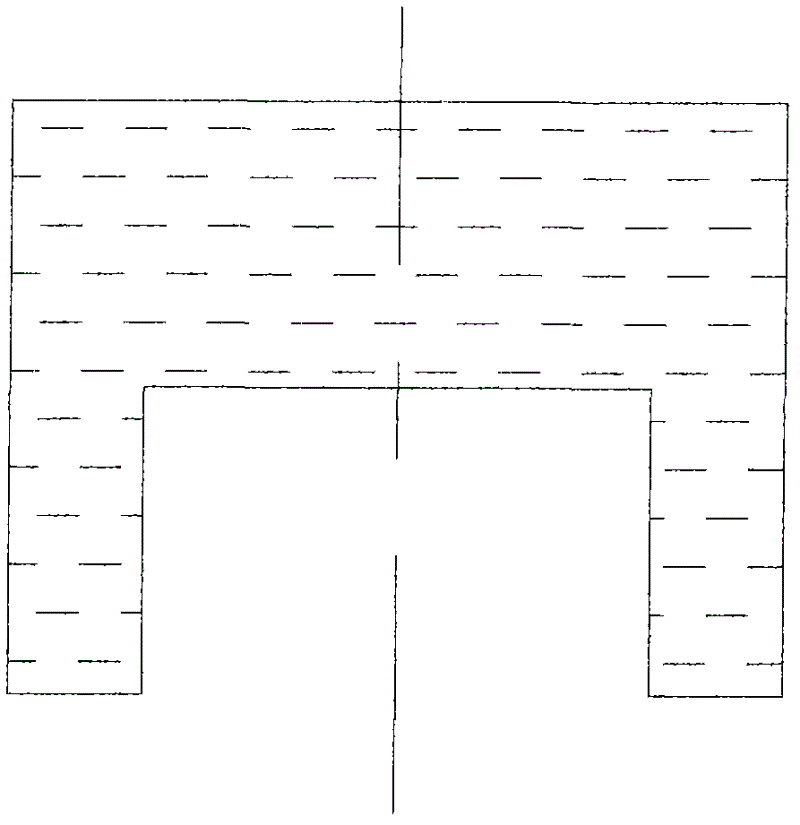

Underground excavation construction method for additionally arranging underground connecting passage between new and old buildings

ActiveCN110486019ASmall excavation areaPrevent water seepageUnderground chambersBuilding repairsBasementSlurry wall

The invention discloses an underground excavation construction method for additionally arranging an underground connecting passage between new and old buildings, and relates to the technical field ofunderground structure reconstruction of old buildings. The problem that it is difficult to develop and reconstruct underground spaces connecting old buildings with newly constructed buildings is aimedat. The underground construction method comprises the steps that wall bodies and original foundations of the old buildings are strengthened, deformation and uneven settlement of superstructures of the old buildings during later excavation construction are limited, vertical shafts capable of communicating with jacking construction areas are constructed in the old buildings, pipe jacking opening envelope structures are constructed at both ends of the jacking construction areas respectively to prevent water seepage in the pipe jacking work areas during construction, the vertical shafts of the old buildings and external walls, underground continuous walls, and corresponding pipe jacking opening envelope structures of the newly constructed buildings are subjected to hole opening, a no receiving well pipe jacking construction technology is adopted to perform the jacking construction, and the basement structures of the old buildings and the basement structures of the newly constructed buildings are connected through underground connecting passages.

Owner:SHANGHAI CONSTR NO 1 GRP

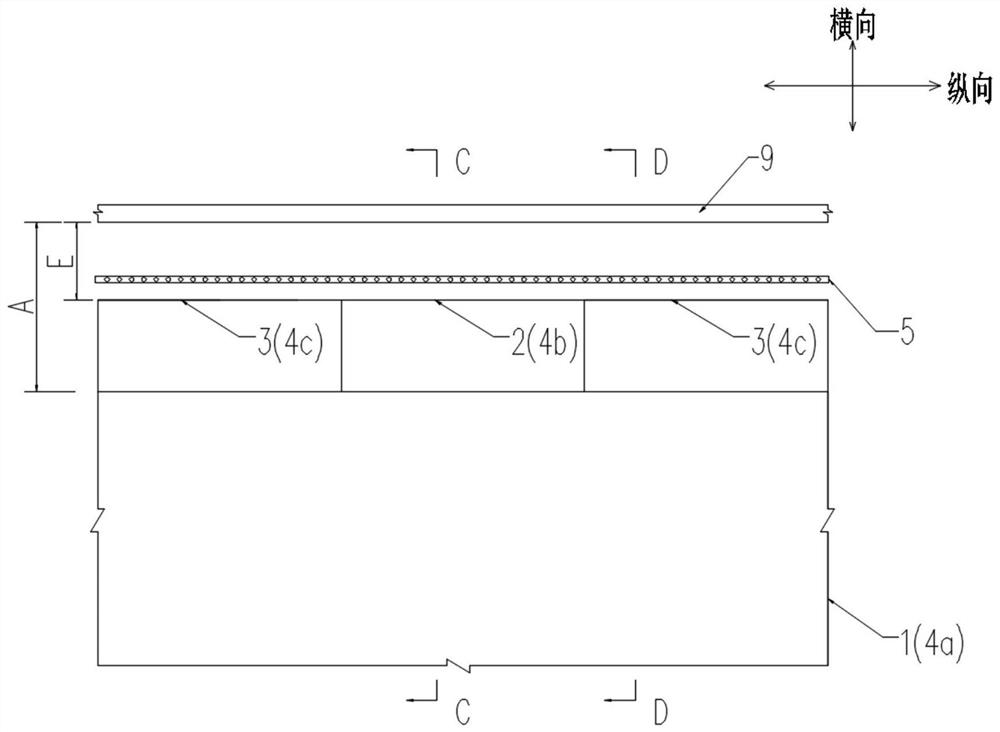

Overall flow creating method for deep-water test basin

ActiveCN106087851AGuaranteed uniformityGuaranteed Effective DepthHydraulic modelsWater flowEngineering

The invention discloses an overall flow creating method for a deep-water test basin. The overall flow creating method for the deep-water test basin is characterized in that by the adoption of a horizontal partitioning flow creating mode in a false bottom, a plurality of independent flow channels are arranged in the false bottom in the direction parallel to the width direction of the deep-water test basin so as for form a complete flow field, a flow creating water outlet and a flow creating water return port are arranged in the two ends of each independent flow channel and located on the surface of the false bottom, inlet water is located on one side, and outlet water is located on the other side; each flow creating water outlet is provided with an outlet water flow rectifying section composed of a flow guide groove, a contracting trench, a flow rectifying plate and a flow rectifying baffle; and each flow creating water return port is provided with a return water flow rectifying section. Compared with the prior art, the overall flow creating method for the deep-water test basin is advantageous in that a circulating flow creating system does not protrude out of the surface of the false bottom of the basin, the complete flow field is formed on the false bottom, the overall uniformity of water flow in the width direction of the basin within a certain depth of the surface of the basin is ensured, disturbance factors such as turbulence flow and vortexes are avoided, the structure is simple, the flow rectifying effect is good, and a test model of an ocean environment can be correctly simulated.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

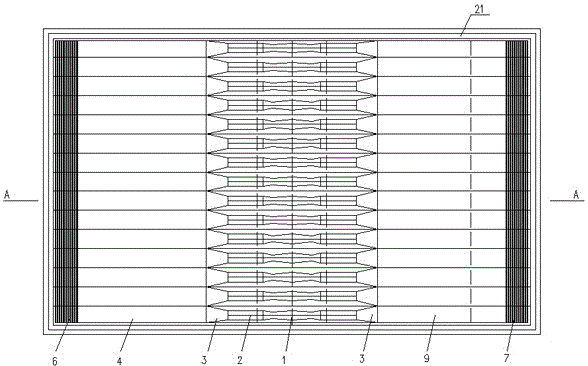

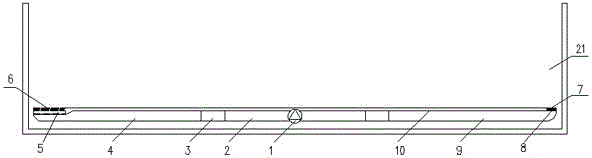

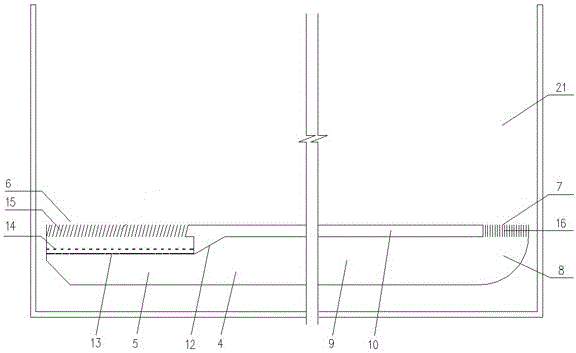

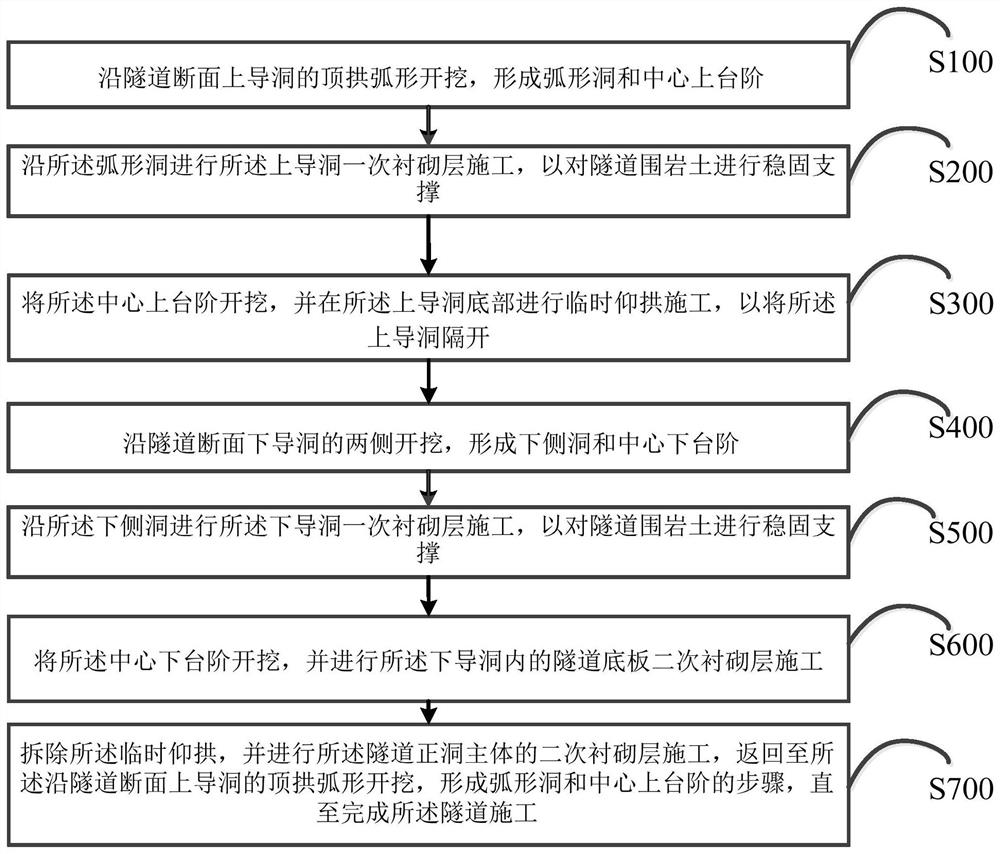

Tunnel construction method

PendingCN112855179AEnsure safetyIncreased tunnel excavation faceUnderground chambersTunnel liningTunnel constructionCivil engineering

The invention discloses a tunnel construction method. The method comprises the steps that arc excavation is conducted along a top arch of an upper pilot tunnel of a tunnel section, and an arc hole and a center upper step are formed; primary lining layer construction of the upper pilot tunnel is conducted along the arc hole, so that tunnel surrounding rock soil is stably supported; the center upper step is excavated, and temporary inverted arch construction is conducted at the bottom of the upper pilot tunnel, so that the upper pilot tunnel is separated; excavation is conducted along the two sides of a lower pilot tunnel of the tunnel section, and a lower side hole and a center lower step are formed; primary lining layer construction of the lower pilot tunnel is conducted along the lower side hole, so that the tunnel surrounding rock soil is stably supported; the center lower step is excavated, and secondary lining layer construction of a tunnel bottom plate in the lower pilot tunnel is conducted; and a temporary inverted arch is dismantled, and secondary lining layer construction of a main tunnel body is conducted. According to the tunnel construction method, the tunnels are excavated step by step, the tunnel excavation working face is increased, the construction progress is high, and the construction period is shortened; and meanwhile, the excavation area of each time is small, supporting construction can be conducted in time, and the safety of tunnel excavation construction is guaranteed.

Owner:中铁二十局集团第三工程有限公司

Large-span prestressed trough composite slab used as roof of basement

InactiveCN102758450ASatisfy ductile playFirmly connectedBuilding roofsArtificial islandsPre stressArchitectural engineering

The invention discloses a large-span prestressed trough composite slab used as a roof of a basement. The large-span prestressed trough composite slab is characterized in that: the large-span prestressed trough composite slab is a trough slab in the appearance, and the large-span prestressed trough composite slab and an upper composite layer form a functional component. The trough large load meets the use requirements of underground garages; the large span saves parking spaces; the trough narrow slab surface saves the cost and the floor height; the moderate rib height can meet the requirement on load bearing, and the requirement that air channels are formed on the ribs, and does not increase the floor height; and the trough transverse air channels are easy to connect. The large-span prestressed trough composite slab is used on the roofs of the underground garages, can quicken the construction period, reduces the floor height and the cost, saves column grids, increases the parking spaces and improves the level of the underground garages.

Owner:柳忠林

Large-span and large-load pre-stress groove-shaped composite slab serving as top plate of basement

The invention discloses a large-span and large-load pre-stress groove-shaped composite slab serving as a top plate of a basement. The composite slab is characterized in that: the composite slab is a groove-shaped plate in appearance; and the groove-shaped plate and an upper part overlapping layer form a functional component. Due to the groove shape and the large load, the requirements on the utilization of an underground garage are met; due to the large span, the parking space can be saved; due to a groove-shaped narrow panel, the construction cost and the layer height are saved; the rib height is moderate, so the requirement on loading capacity and the requirement of forming a ventilating passage on a rib can be met, and the floor height is not increased; and a groove-shaped horizontal ventilating passage is easy to connect. When the composite slab is used on the top plate of the underground garage, the construction period can be reduced, the floor height is reduced, the cost is reduced, column nets are saved, the parking space is increased, and the grade of the underground garage is improved.

Owner:柳忠林

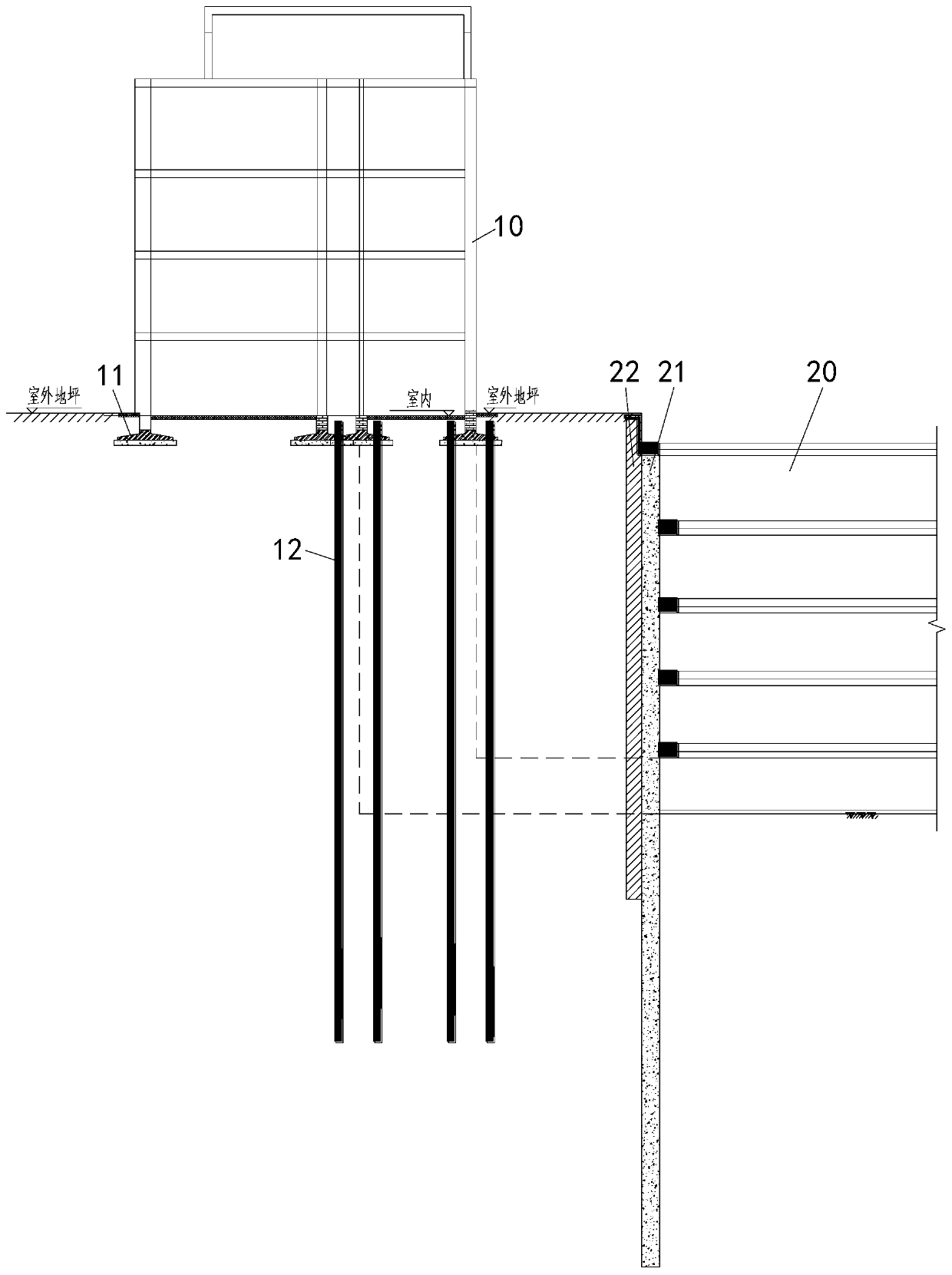

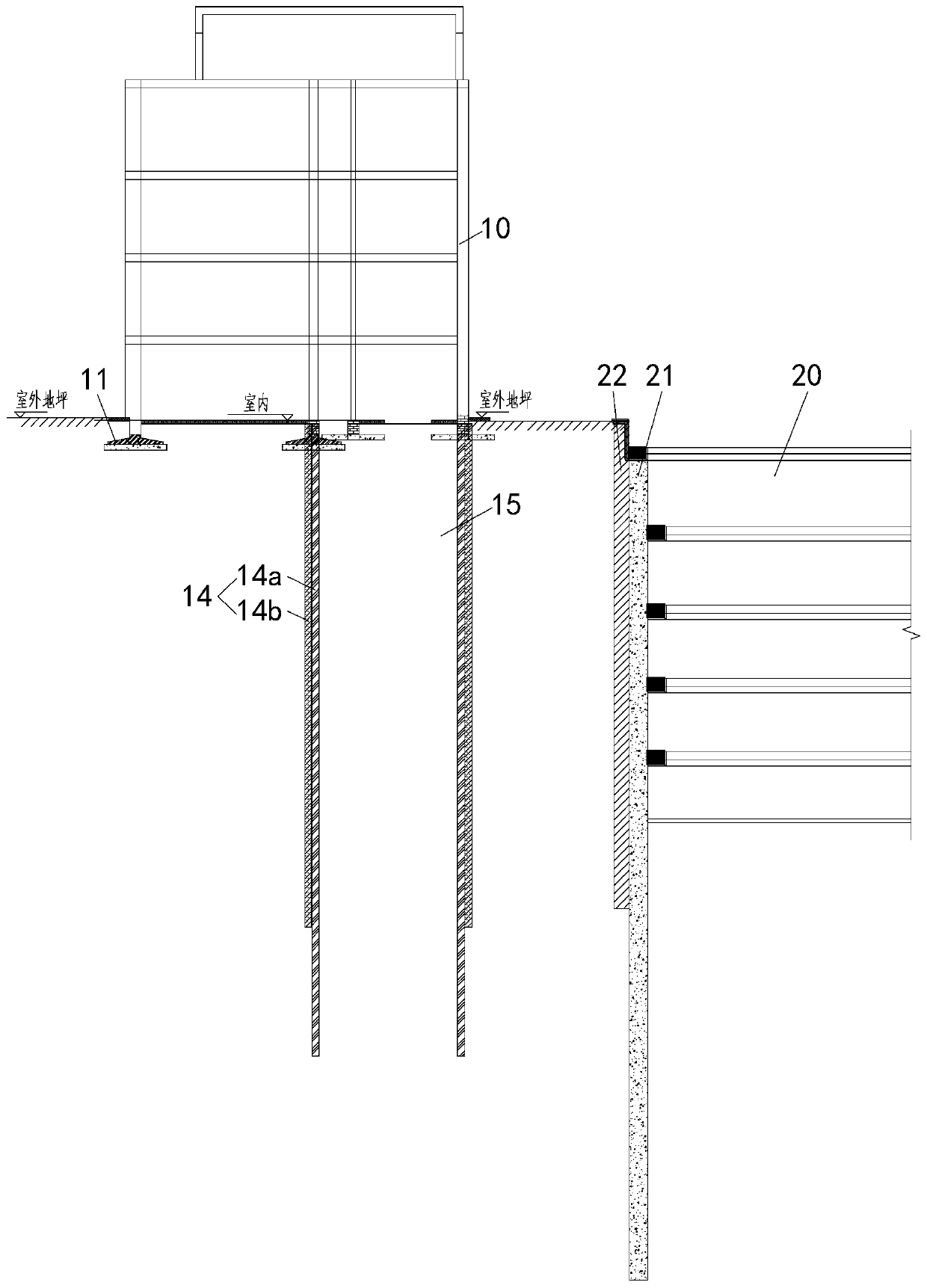

Pillar foundation structure of overhead line system and construction method thereof

PendingCN113107000AImprove carrying capacityImprove anti-overturn performanceBulkheads/pilesArchitectural engineeringOverhead line

The invention discloses a pillar foundation structure of an overhead line system. The pillar foundation structure comprises a supporting part, a pile foundation part, and a waterproof curtain; the upper end of the supporting part is used for mounting a pillar of the overhead line system; the upper end of the pile foundation part is connected with the lower end of the supporting part; and the waterproof curtain is located below the supporting part and surrounds the pile foundation part. The invention further provides a construction method of the pillar foundation structure of the overhead line system. According to the pillar foundation structure of the overhead line system and the construction method thereof, the excavation depth is small, the excavation area is small, the vertical bearing capacity and the anti-overturning capacity of the pillar foundation structure of the railway overhead line system are improved, the influence of construction of the pillar foundation structure of the overhead line system on the surrounding environment is reduced, and particularly, the operation risk and the safety risk of an existing railway line are reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Foundation pit structure and construction method thereof

PendingCN112411556AReduce the impactSpeed up the construction cycleExcavationsArchitectural engineeringRail transit

The embodiment of the invention discloses a foundation pit structure and a construction method thereof. The foundation pit structure comprises a first-stage foundation pit, a second-stage foundation pit, a third-stage foundation pit, a supporting unit, a first-stage basement, a second-stage basement and a third-stage basement, wherein the first-stage foundation pit and a rail transit are arrangedin a spaced manner; the supporting unit is arranged in a soil layer on the side, close to the first-stage foundation pit, of the rail transit; the second-stage foundation pit and the third-stage foundation pit are arranged between the first-stage foundation pit and the supporting unit side by side; the first-stage basement comprises a plurality of supporting piers, a first-stage bottom plate, a first-stage middle plate and a first-stage top plate; the plurality of supporting piers are fixedly arranged on the first-stage middle plate and the first-stage top plate correspondingly; the second-stage basement comprises a second-stage bottom plate, a second-stage middle plate and a second-stage top plate; the third-stage basement comprises a third-stage bottom plate, a third-stage middle plate and a third-stage top plate; and the supporting piers and the supporting unit can serve as the two ends of a temporary support correspondingly. The foundation pit structure and the construction methodthereof have the beneficial effect that the construction cost is low.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com