Steel-FRP composite corrugated plate tunnel secondary lining structure and construction method thereof

A secondary lining and corrugated plate technology, applied in the direction of tunnel lining, shaft lining, tunnel, etc., can solve the problems of brittle failure, poor corrosion resistance of steel, and high price, so as to reduce project cost, improve construction environment, and reduce excavation. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below with reference to the accompanying drawings and embodiments.

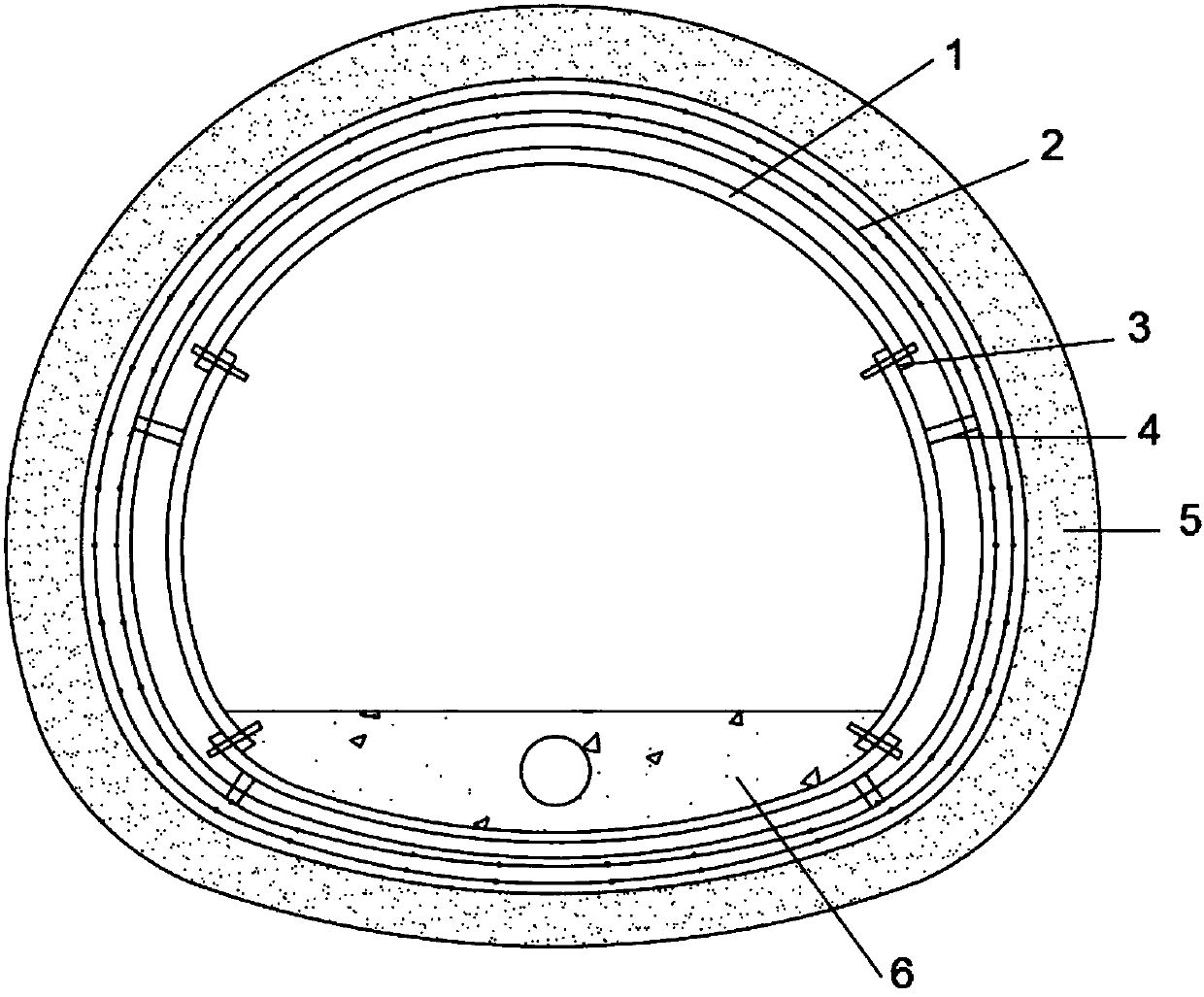

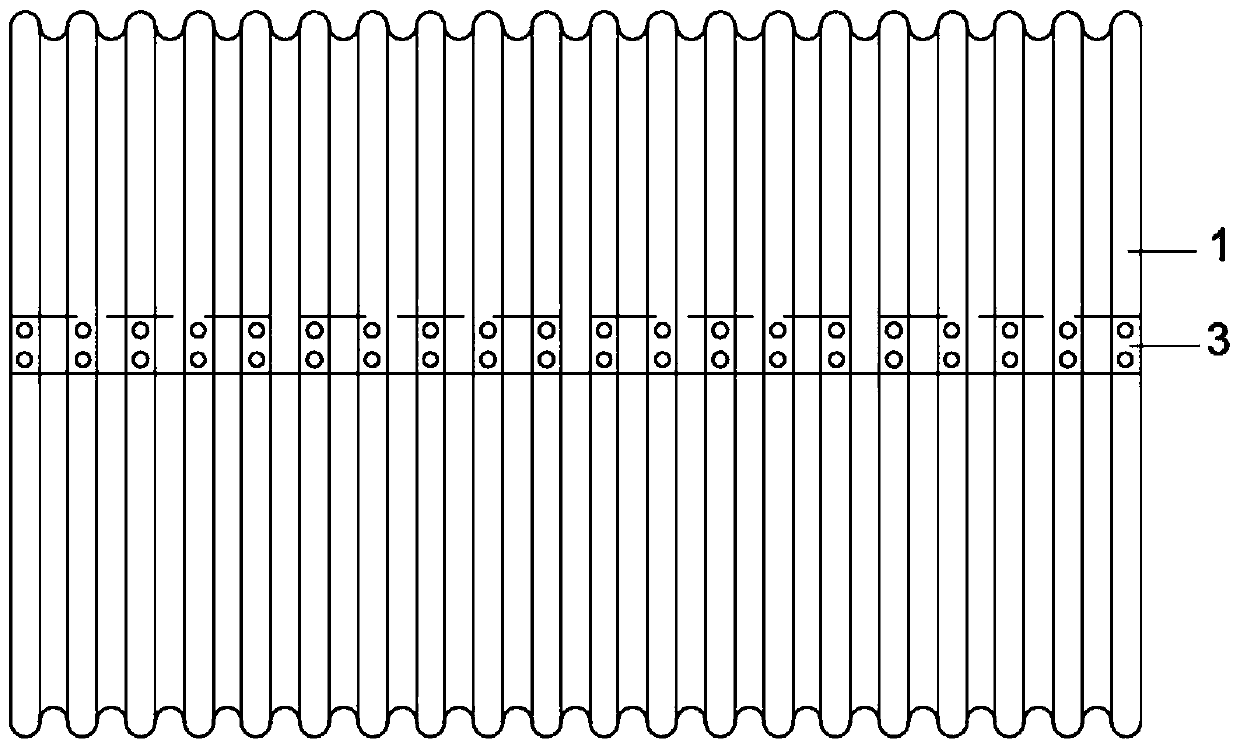

[0021] like figure 1 A steel-FRP composite corrugated plate tunnel secondary lining structure and a construction method thereof shown in the present invention, the method includes: prefabricating corrugated plates, excavating tunnels, applying initial support, applying waterproofing and drainage systems, and inverted arch corrugations. Slab installation, side wall corrugated board installation, top corrugated board installation, concrete grouting and inverted arch fill.

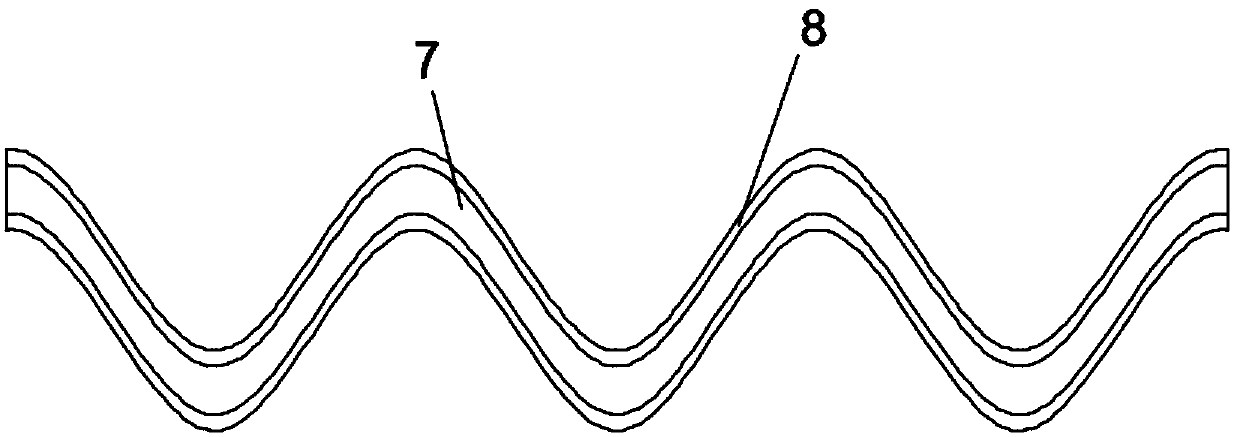

[0022] Specifically, the corrugated board 1 is prefabricated according to the design requirements, and the thickness of the corrugated board 1 is determined. The corrugated board is a composite material corrugated board compounded by a thermosetting molding process. . The steel core thickness is about 60-70% of the plate thickness, and the FRP thickness is about 30-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com