Patents

Literature

34results about How to "Reduced sidewall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

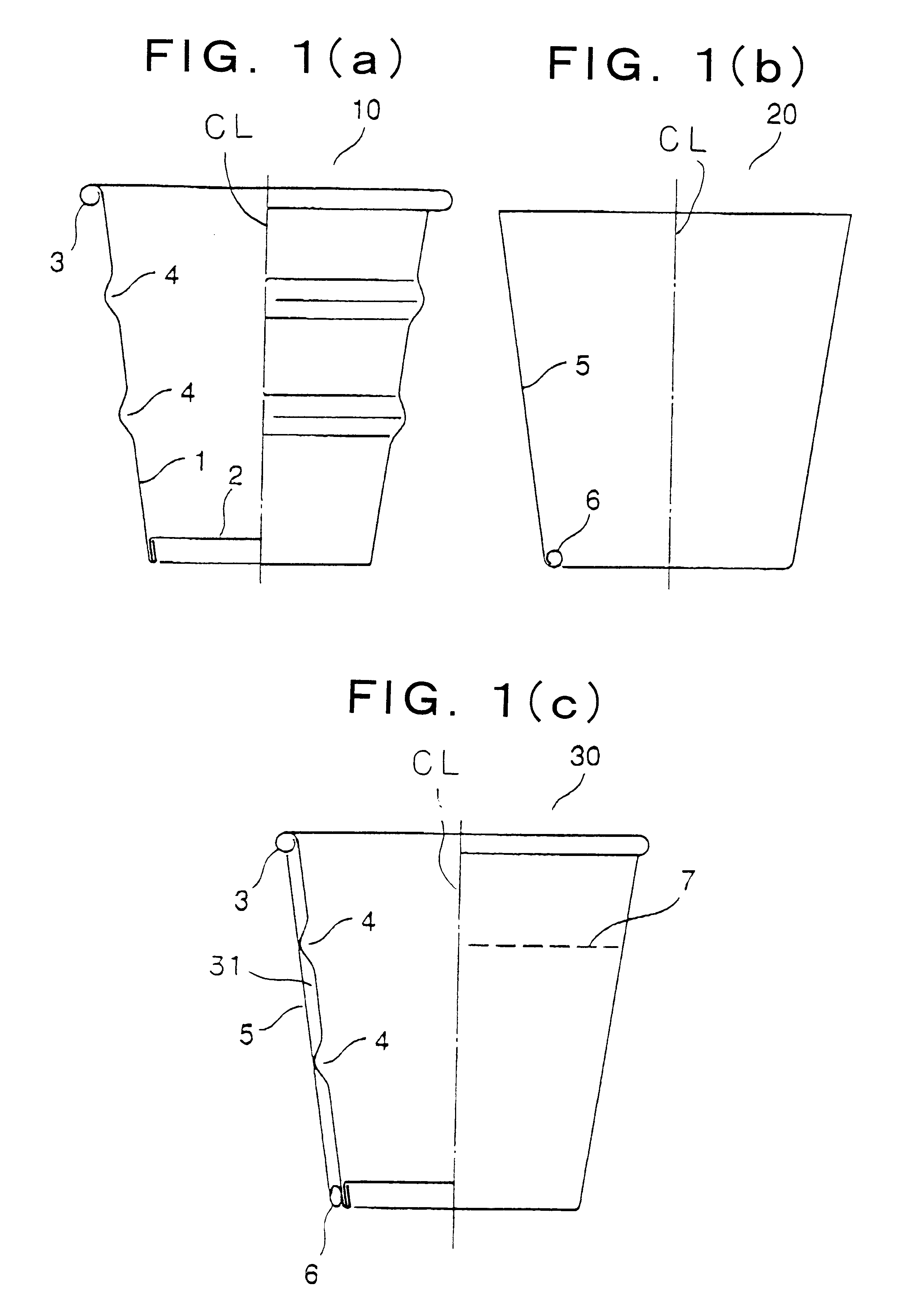

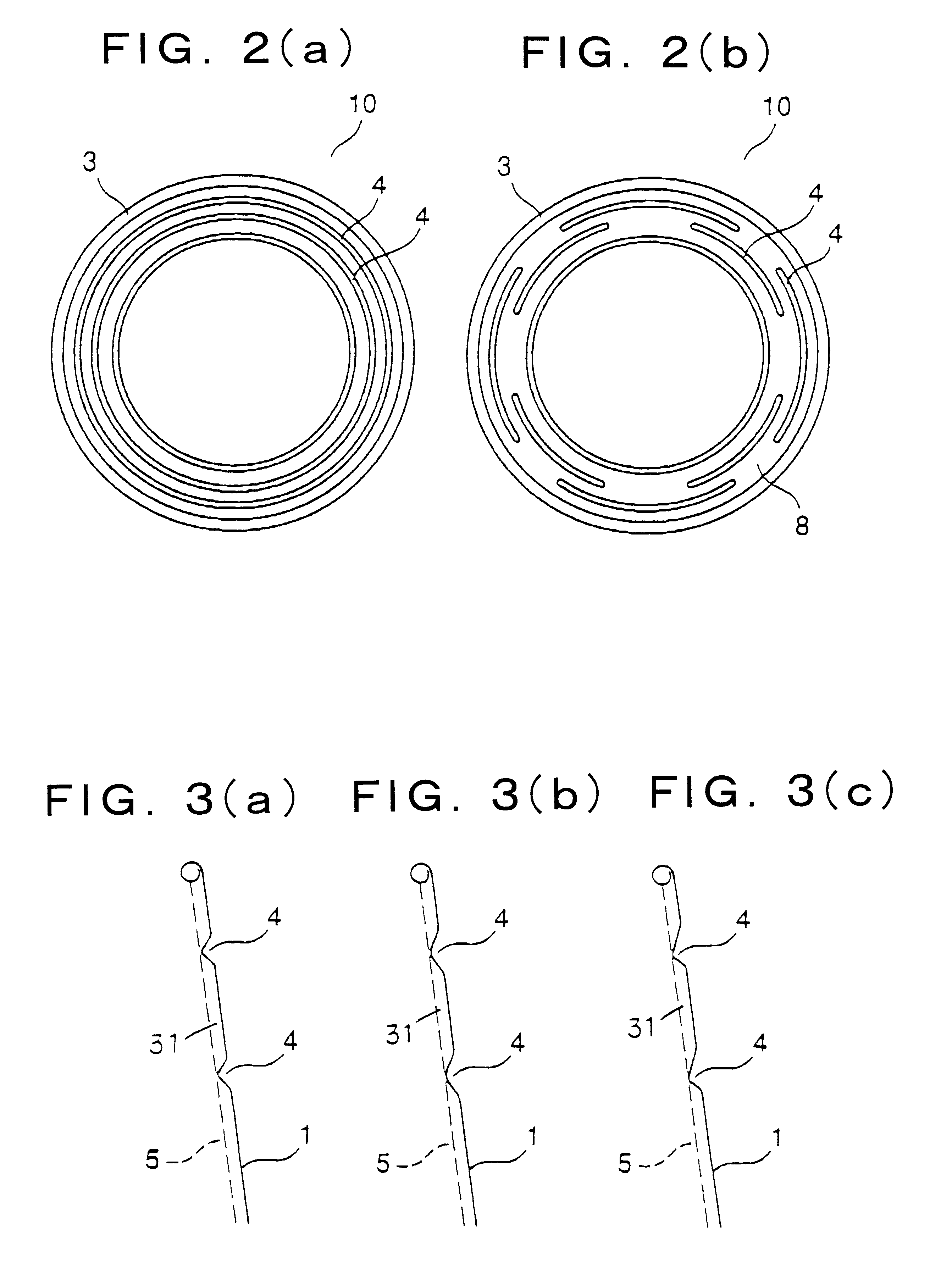

Insulating container

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

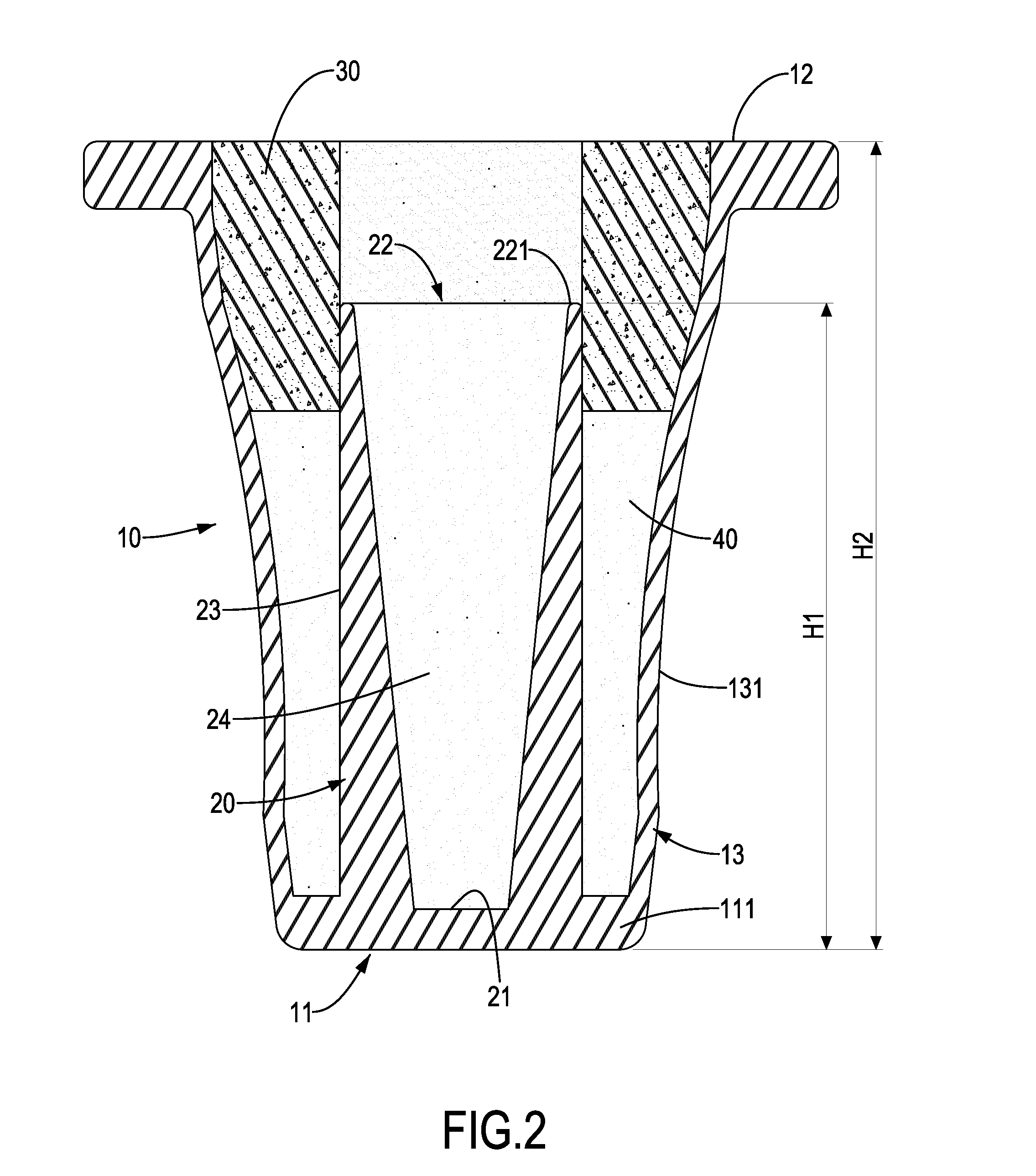

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

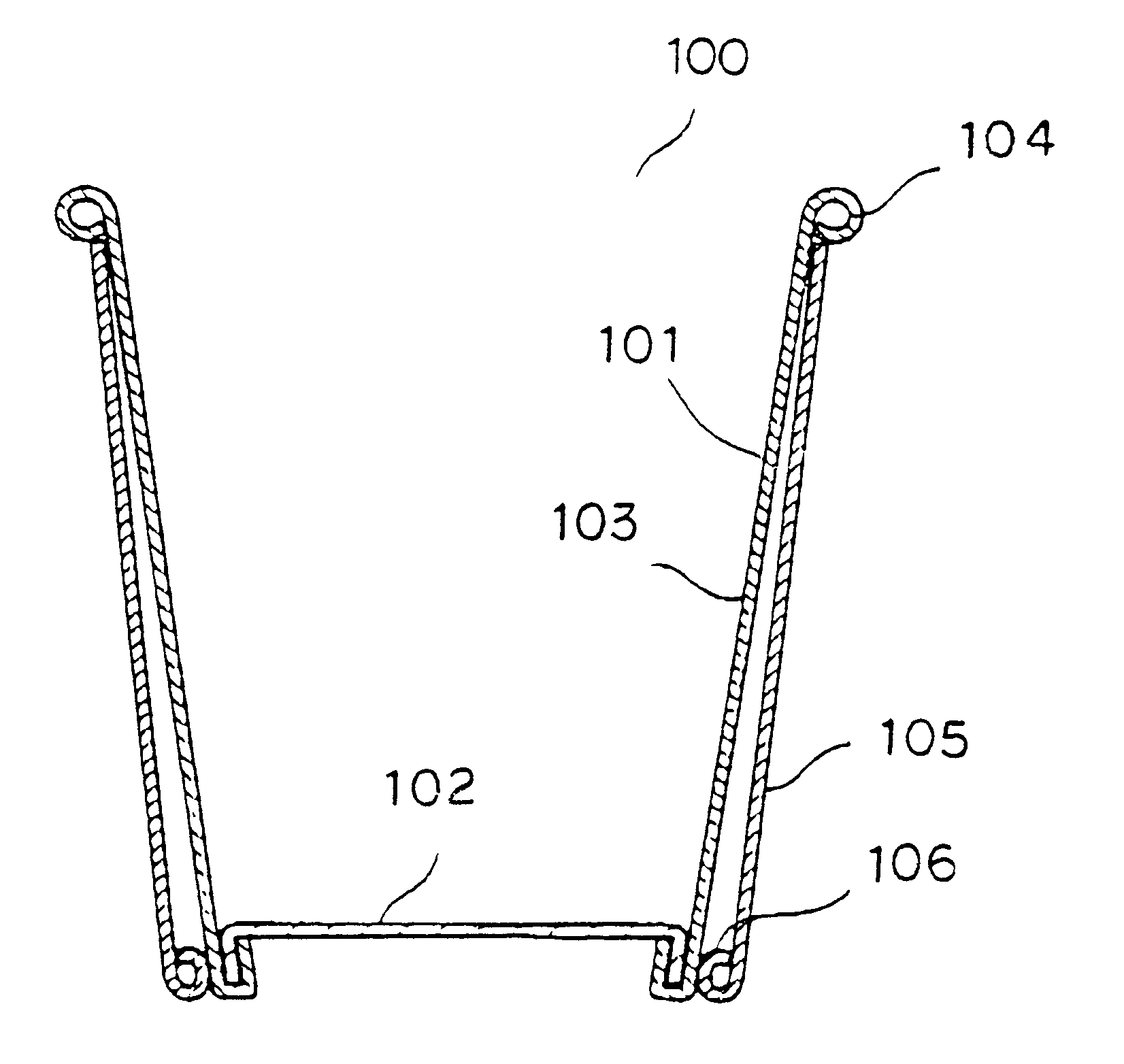

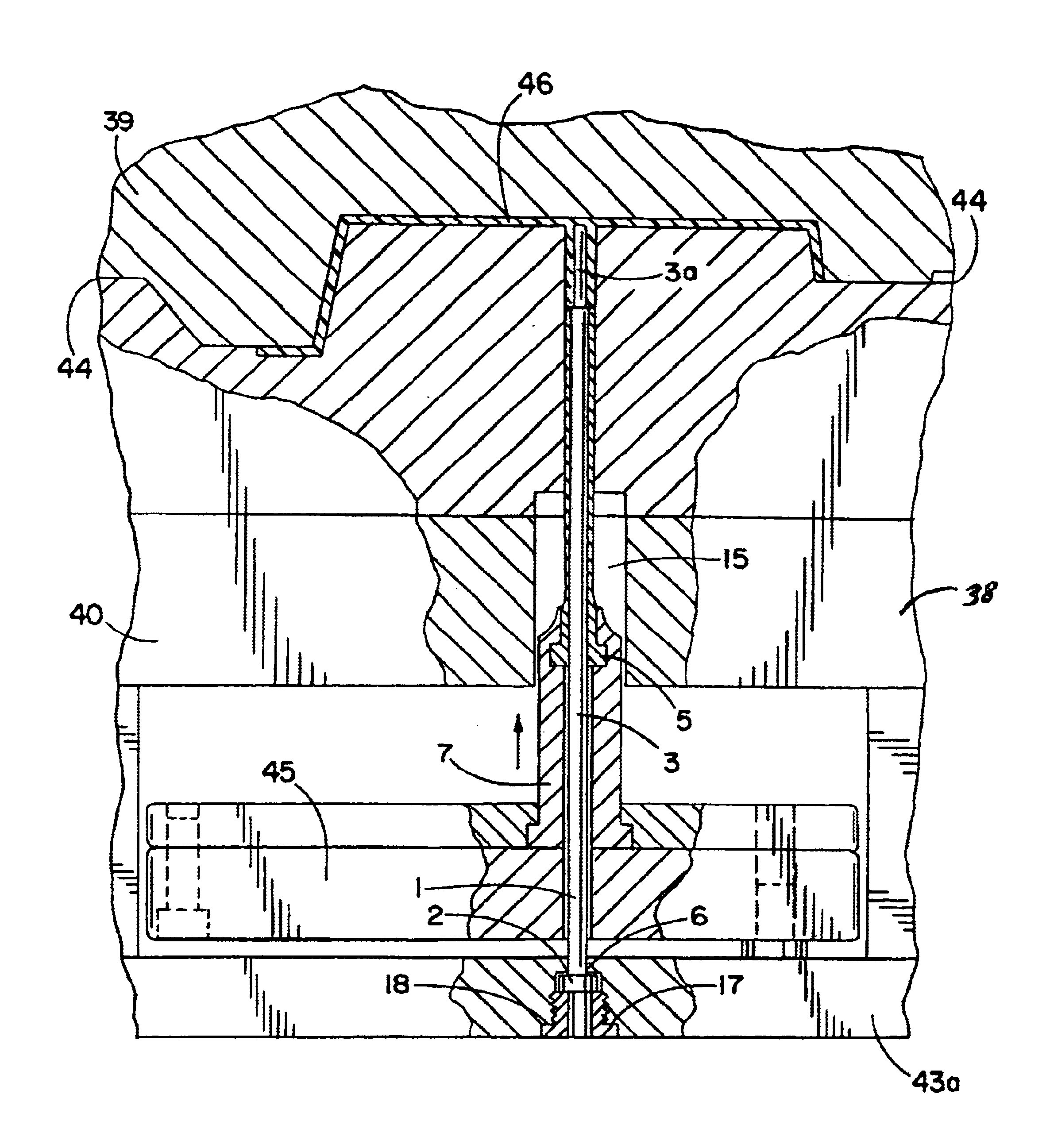

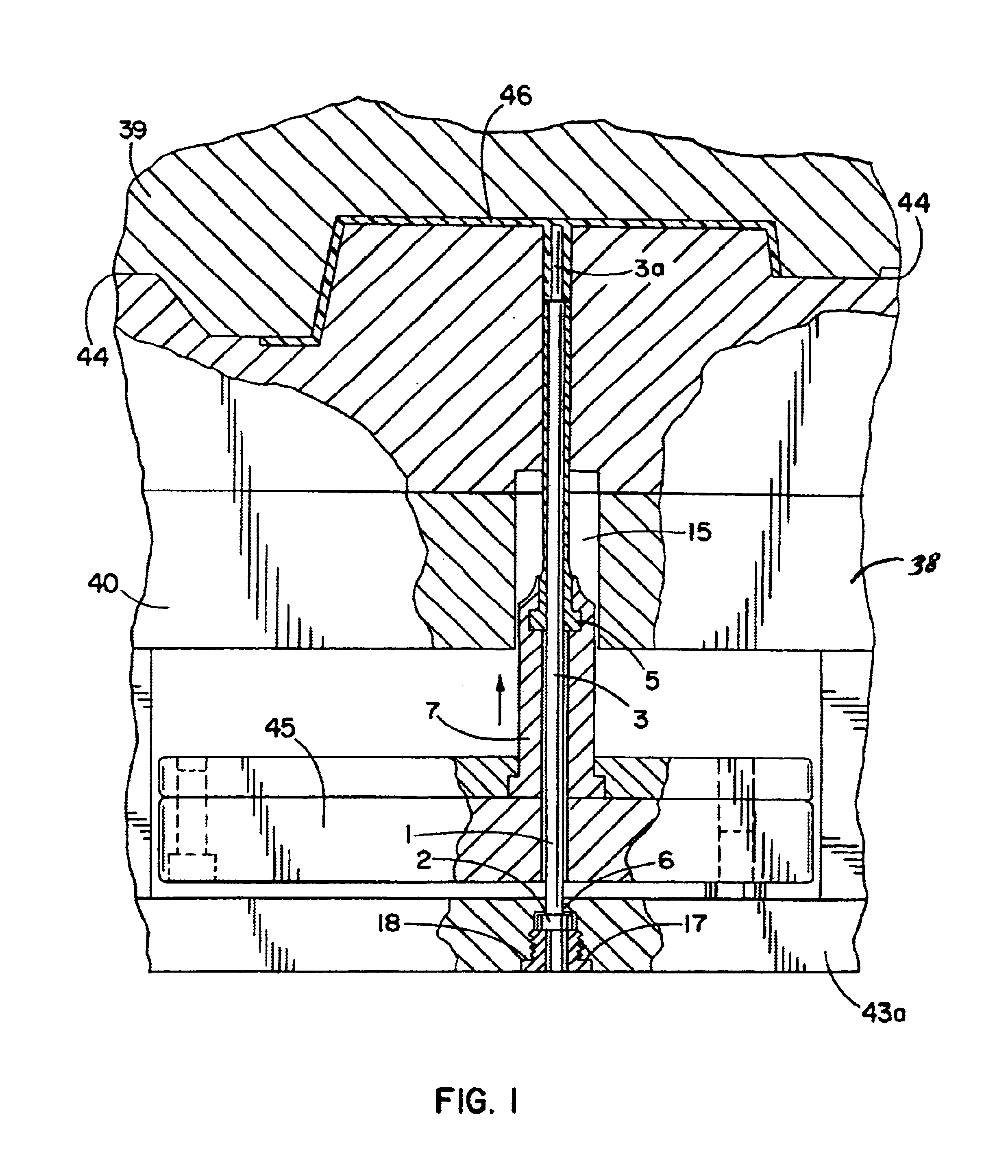

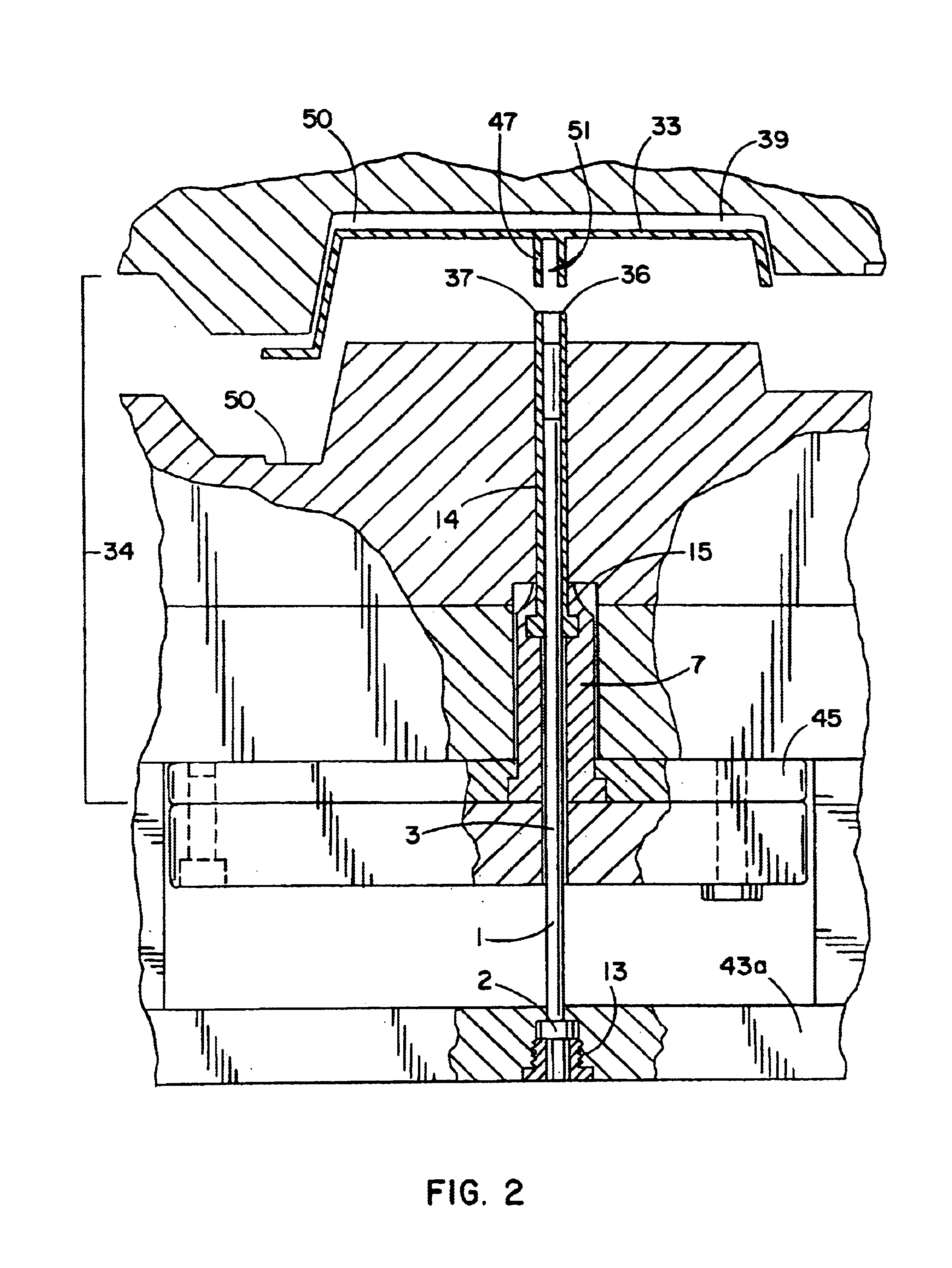

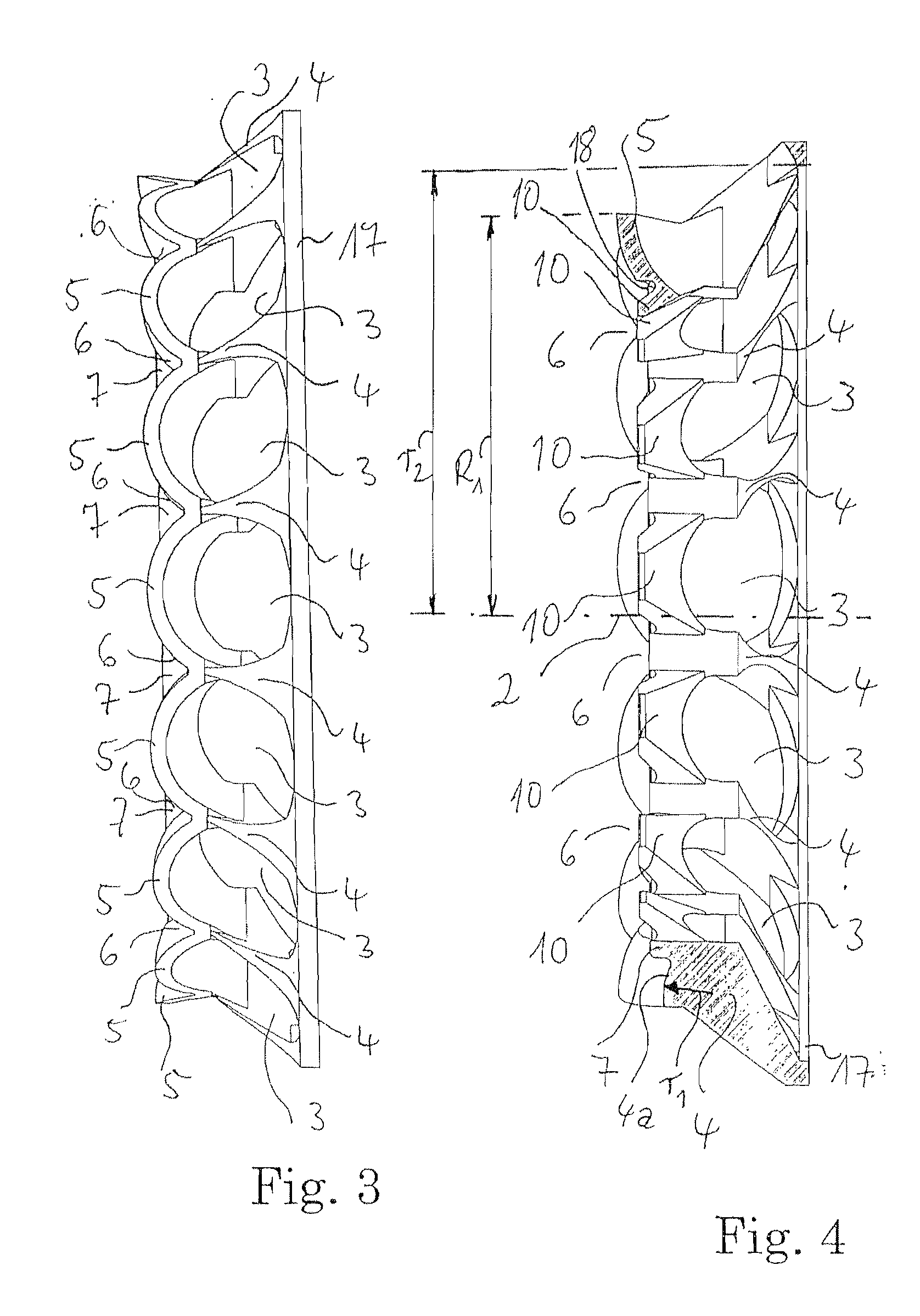

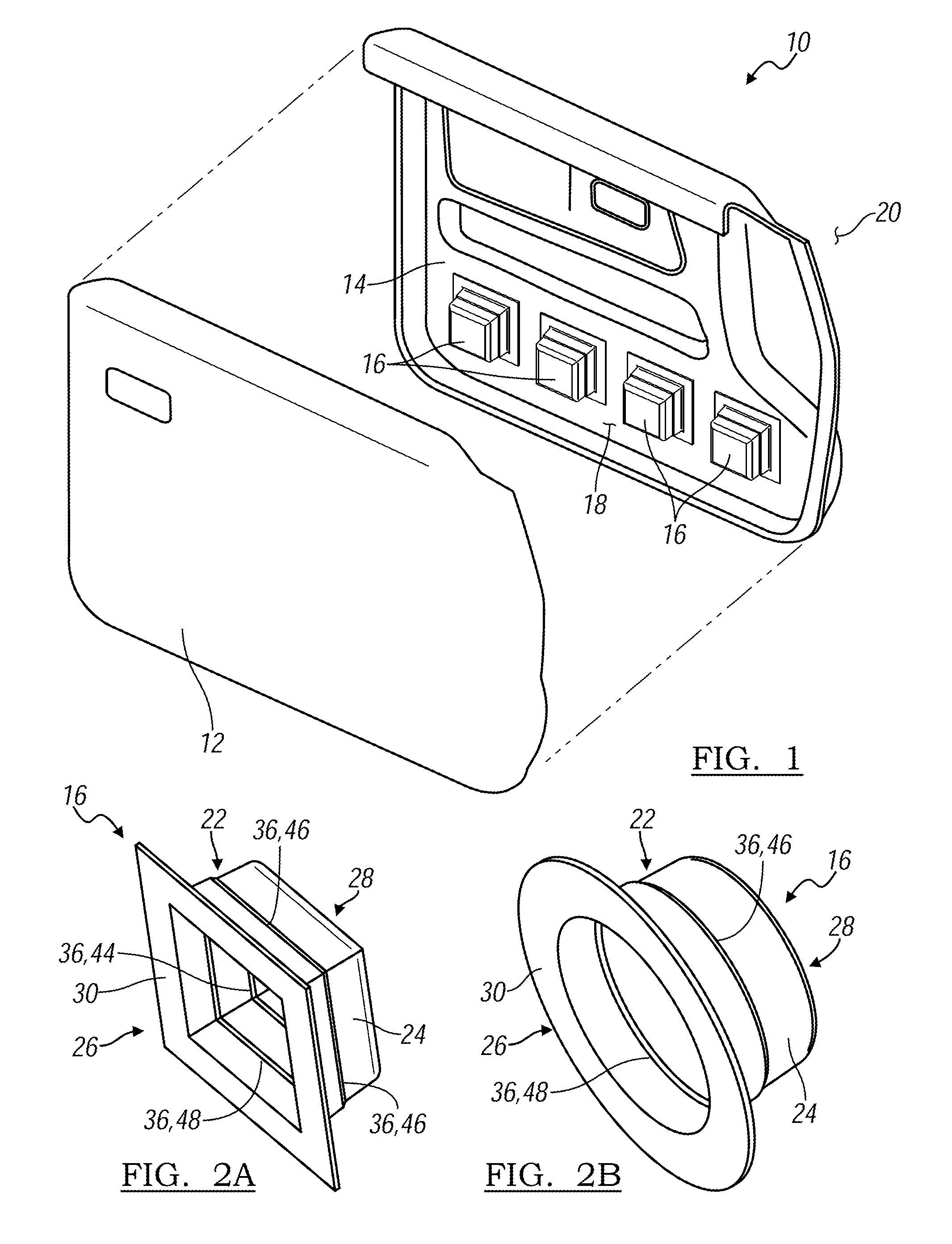

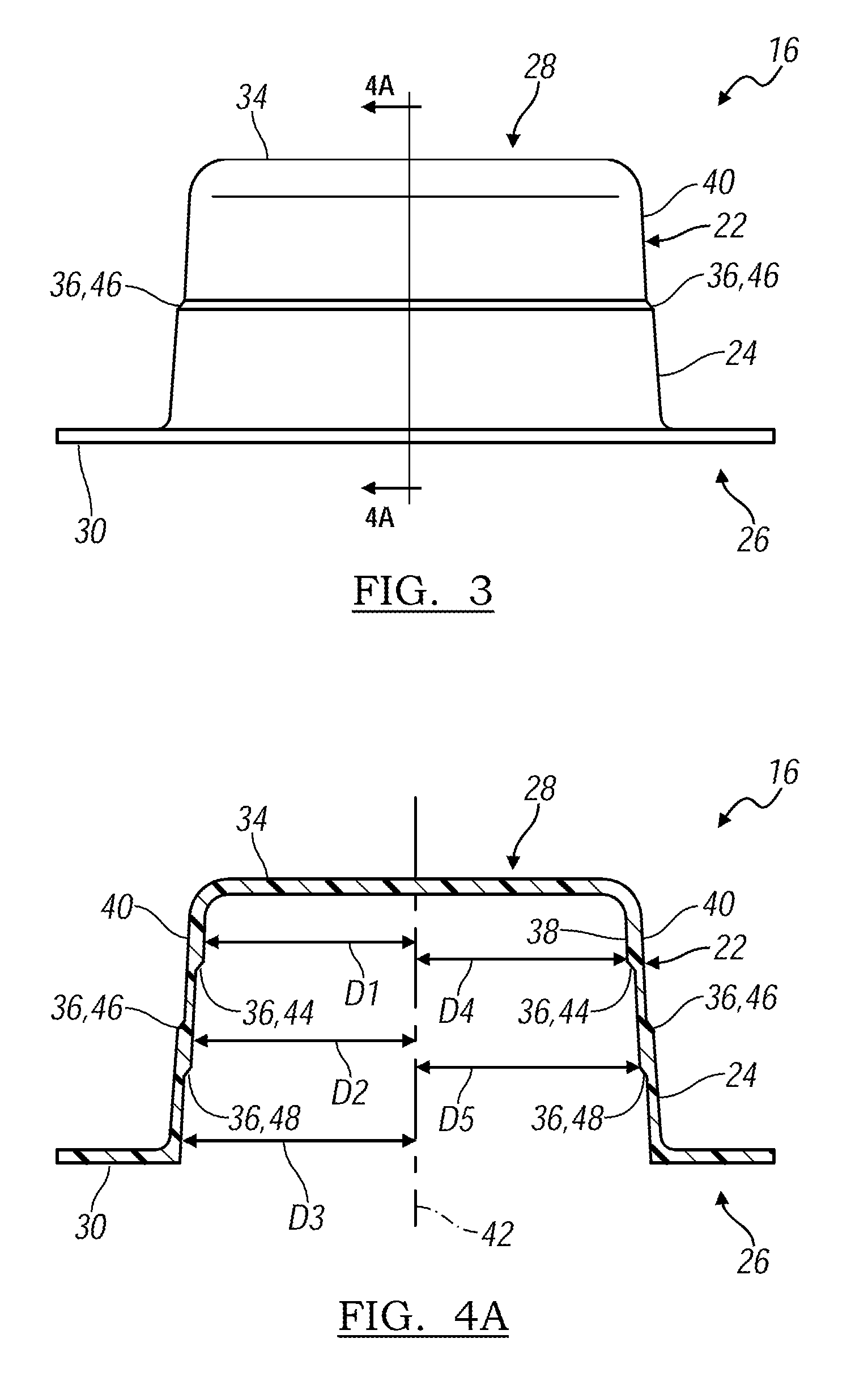

Ejector sleeve for molding a raised aperture in a molded article

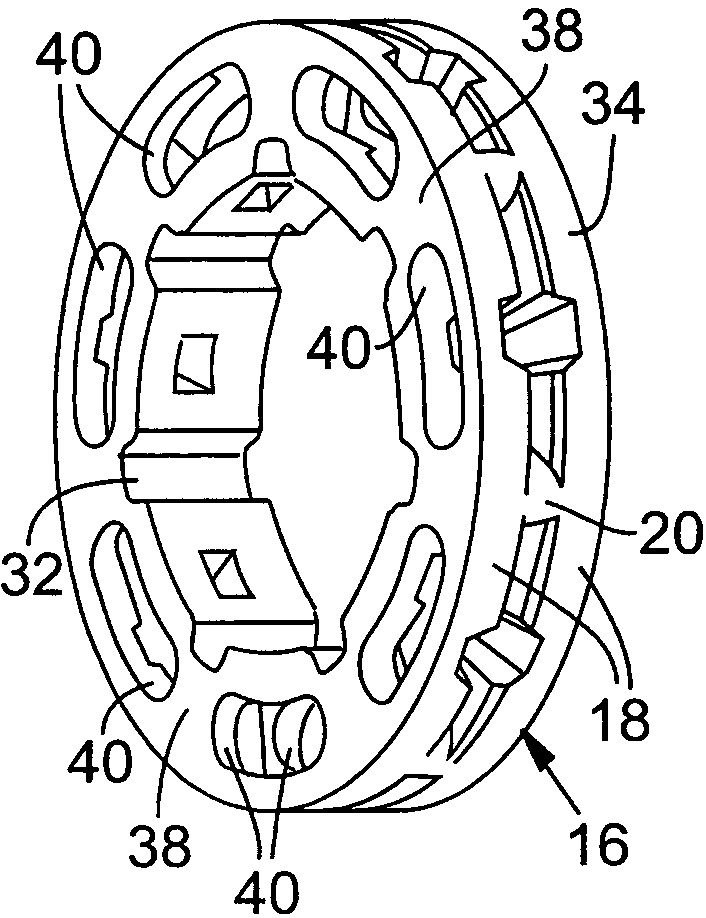

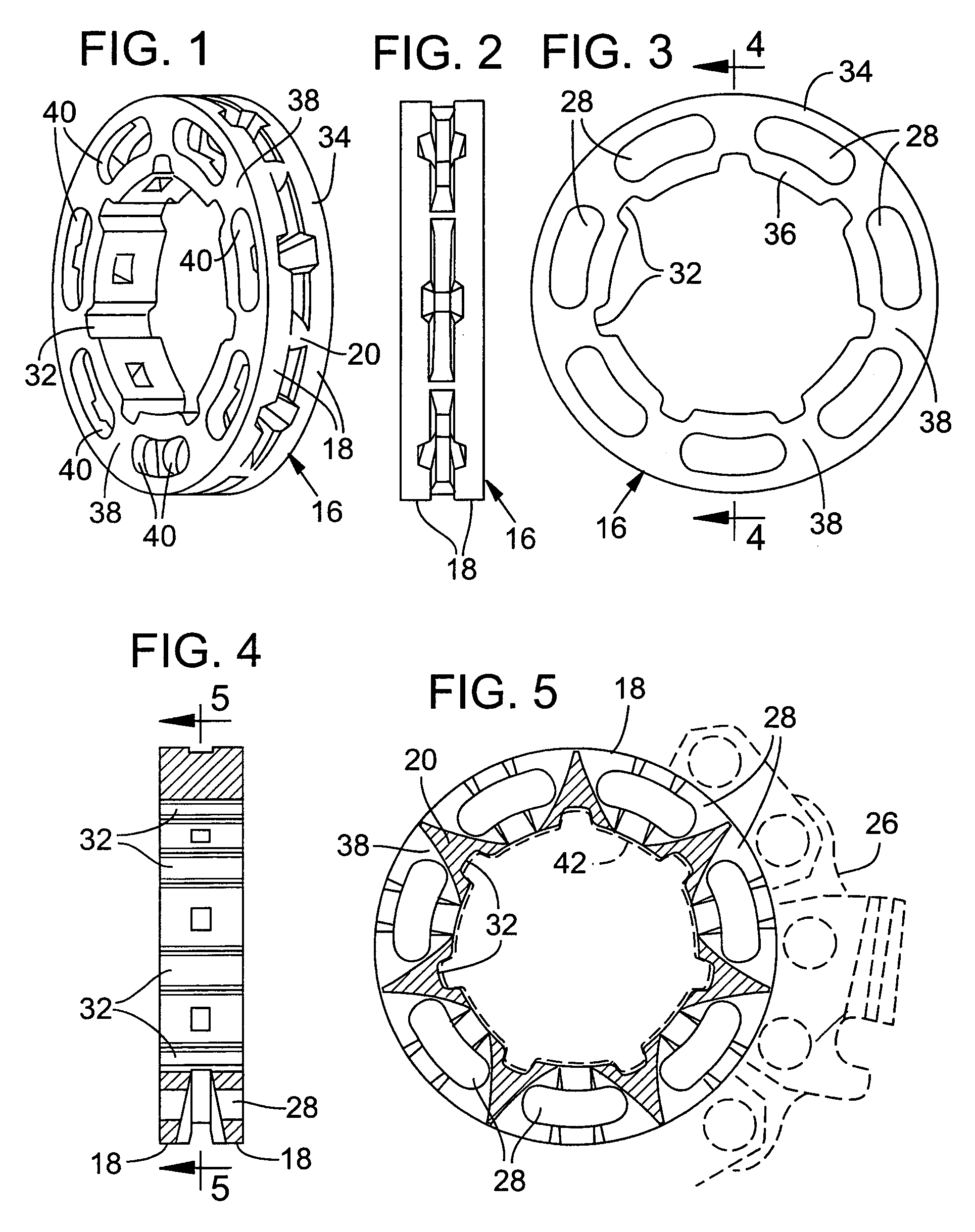

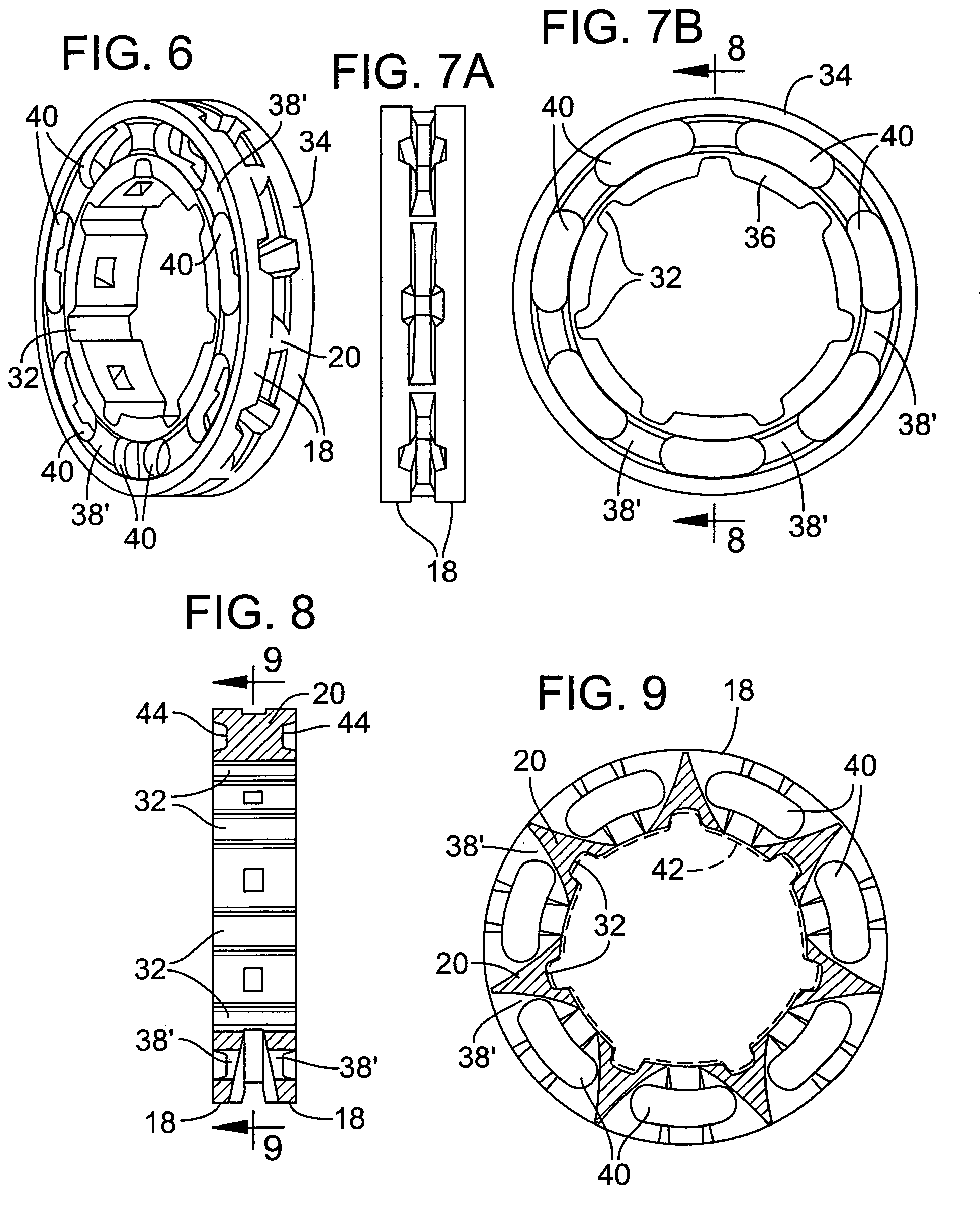

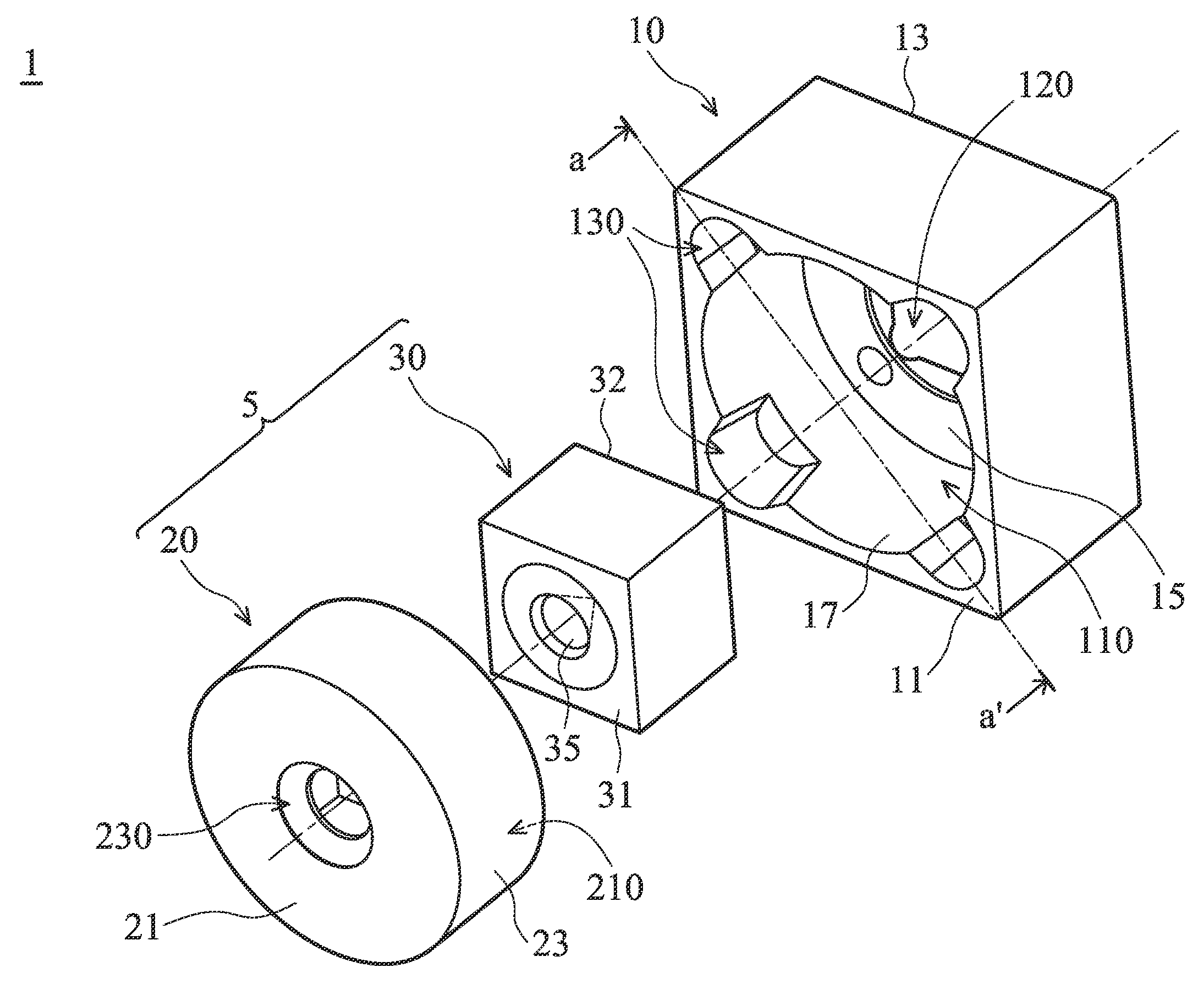

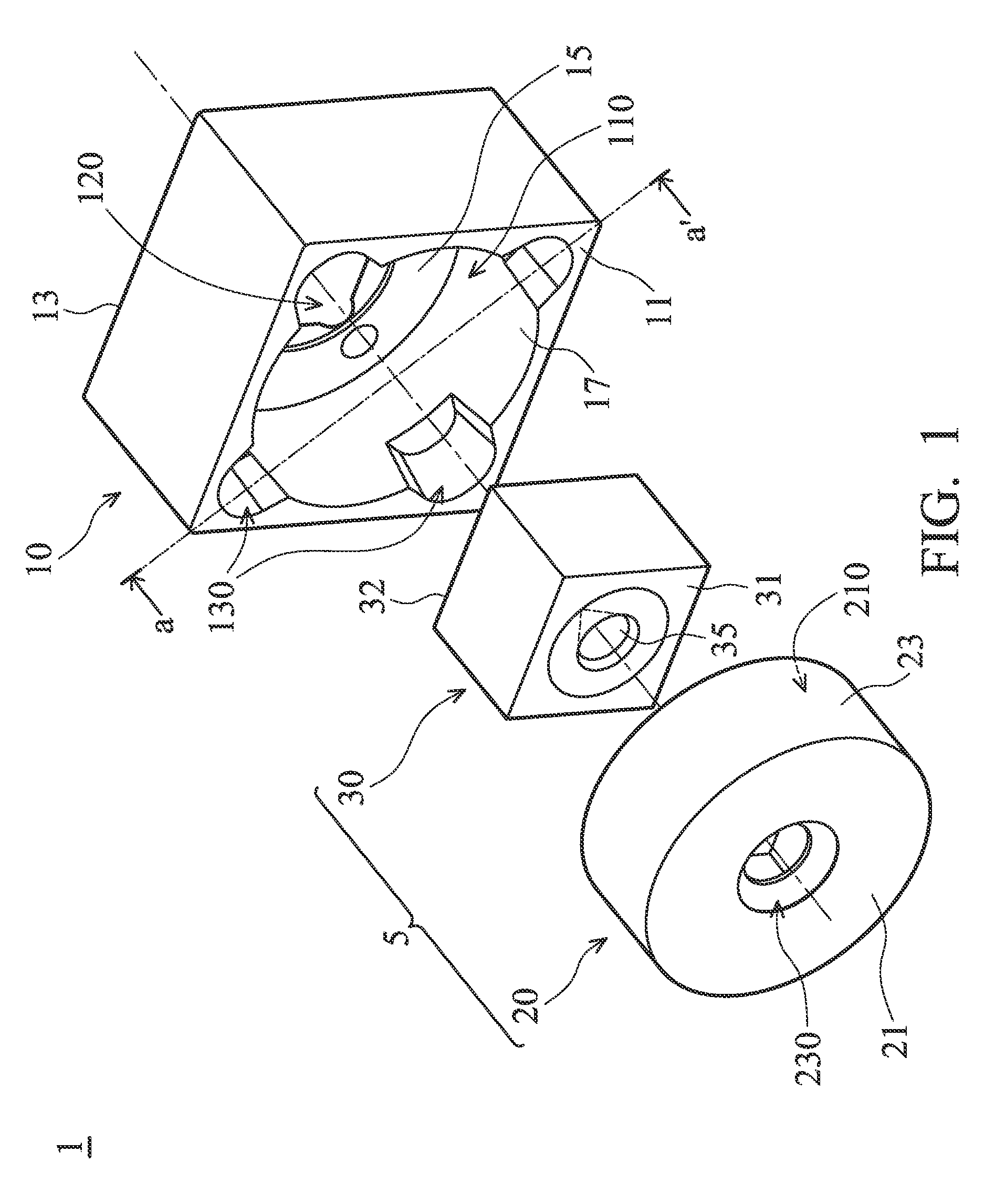

The present invention includes an improved ejector sleeve (5) having thinner side-walls than prior sleeves. The sleeves generally include a ring (31) for mounting the sleeve, a central bore (42) for receiving a core pin (1), a tube portion extending from the ring to a tube end portion. The side-walls defining the tube end portion have a thickness of less than forty thousandths, and preferably thirty thousandths of an inch. Preferably, the coated ejector sleeve is provided in which a thin, lubricous coating of nickel, chromium or alloys of chromium or nickel is applied to at least a portion of the sleeve. The coating is applied in thickness of less than 0.0001 inch which improves the wear characteristics of the pins and sleeves as well as allowing the coated pins and sleeves to be stocked and used as nominal thickness parts.

Owner:PROGRESSIVE COMPONENTS INT CORP

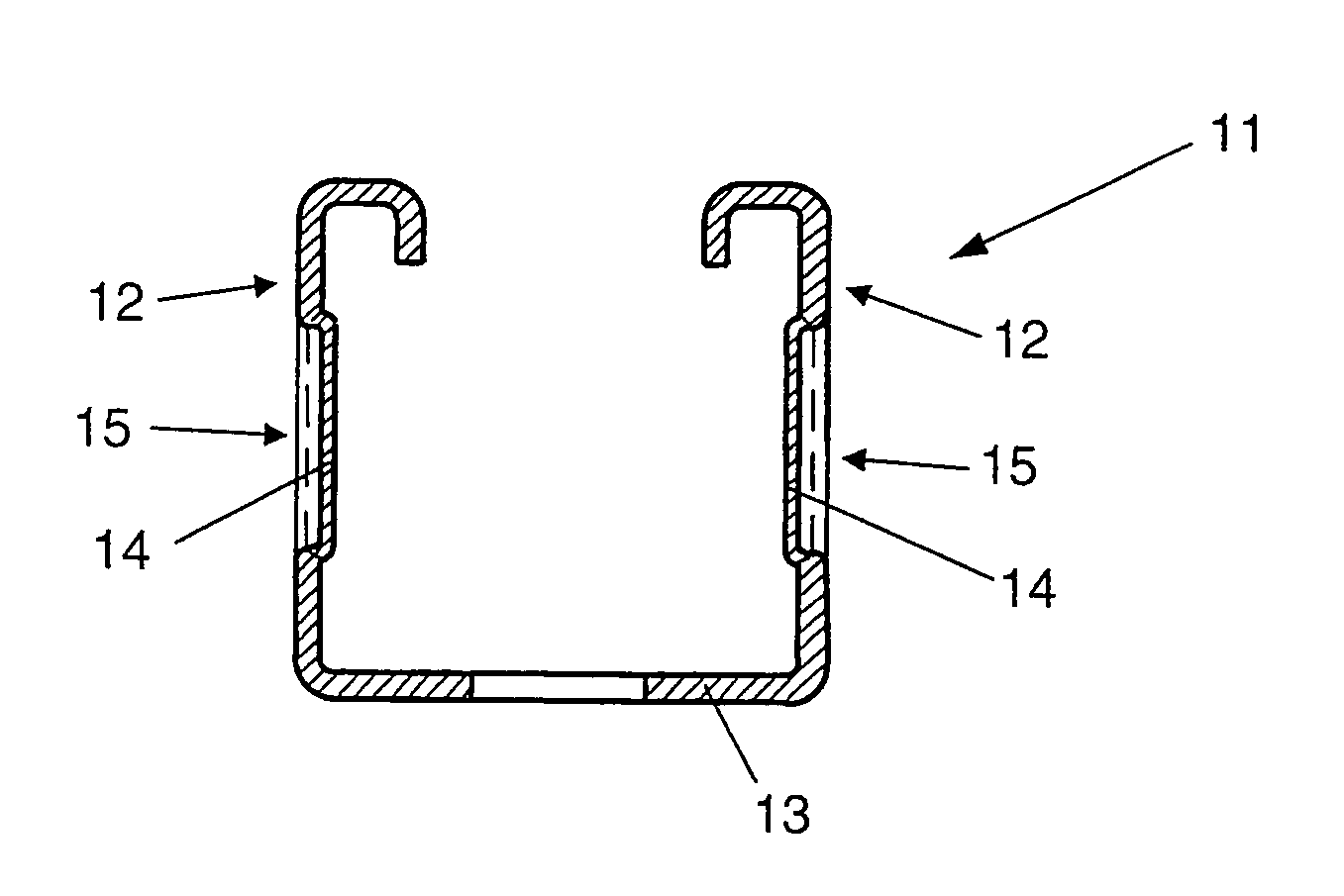

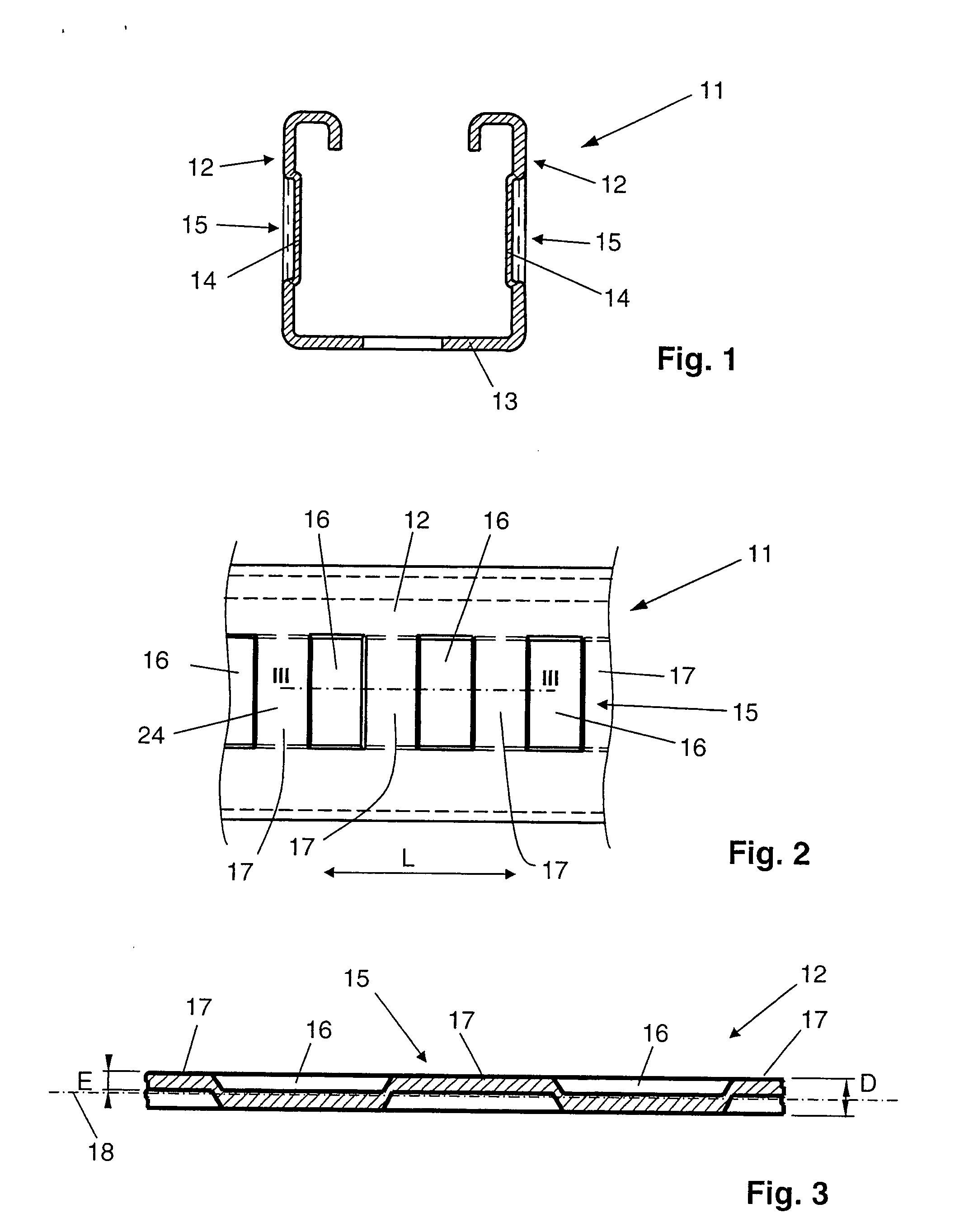

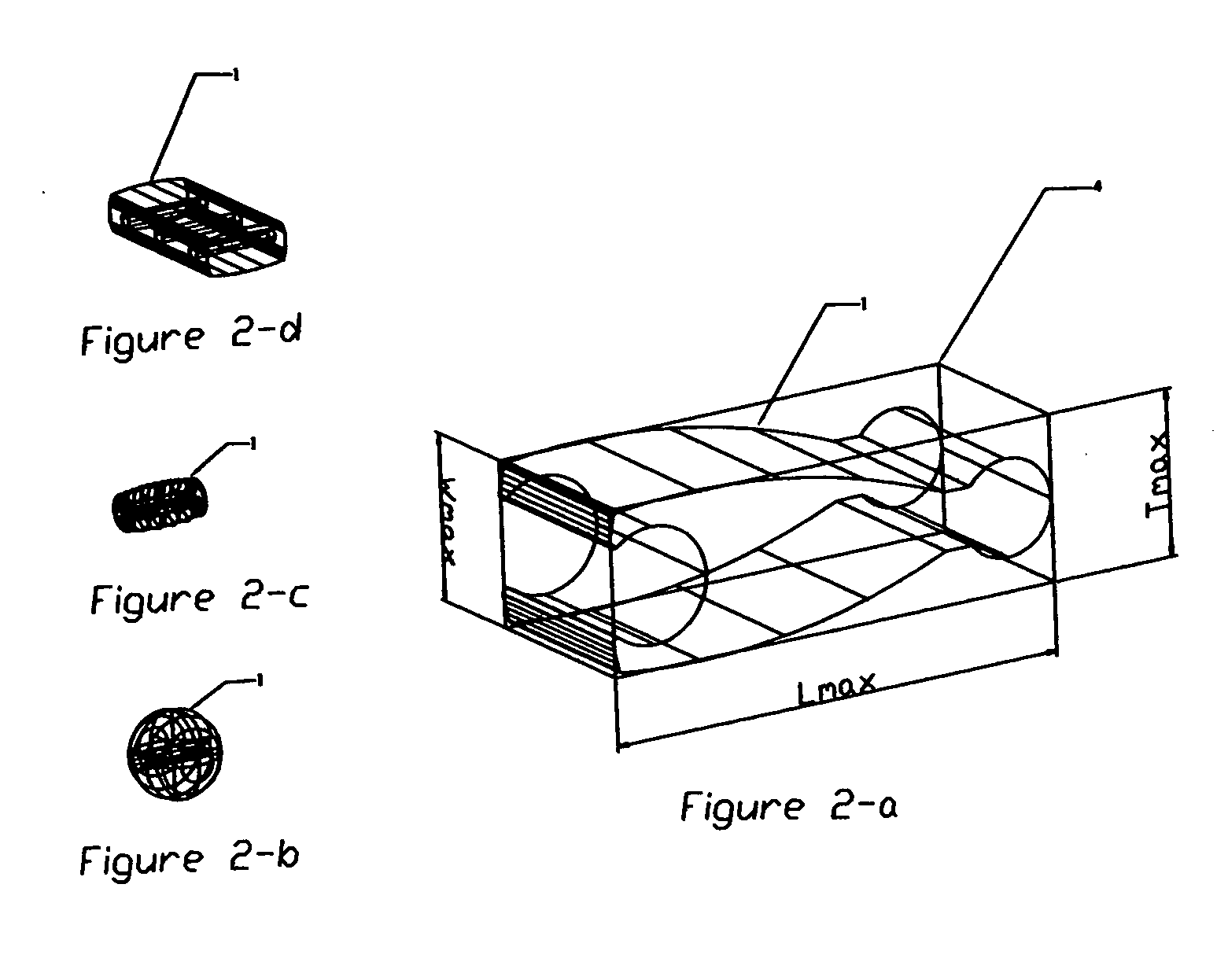

Open elongate profile

InactiveUS20070248793A1Avoid warpingIncreasing the thicknessLayered productsRollsEngineeringMechanical engineering

Owner:HILTI AG

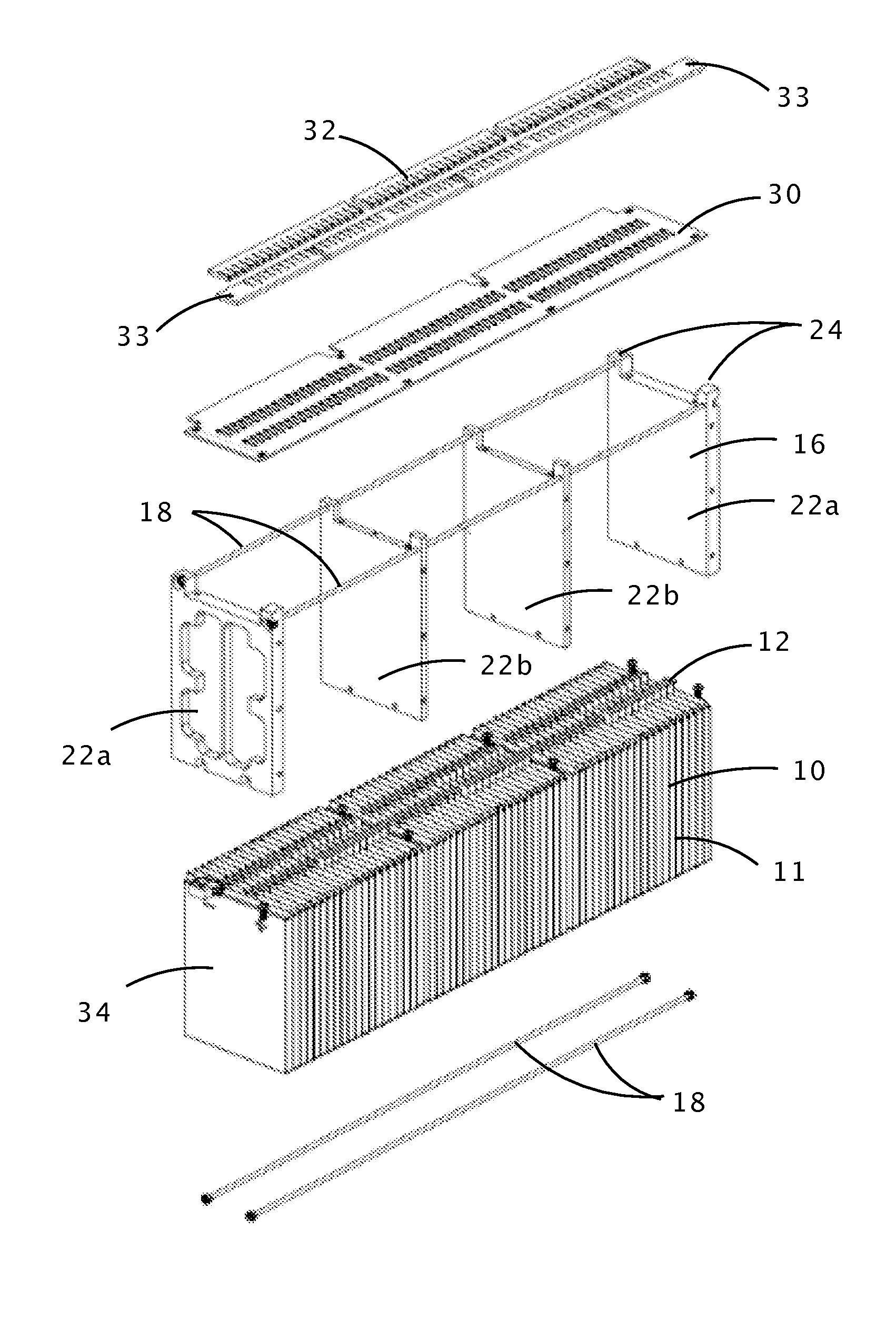

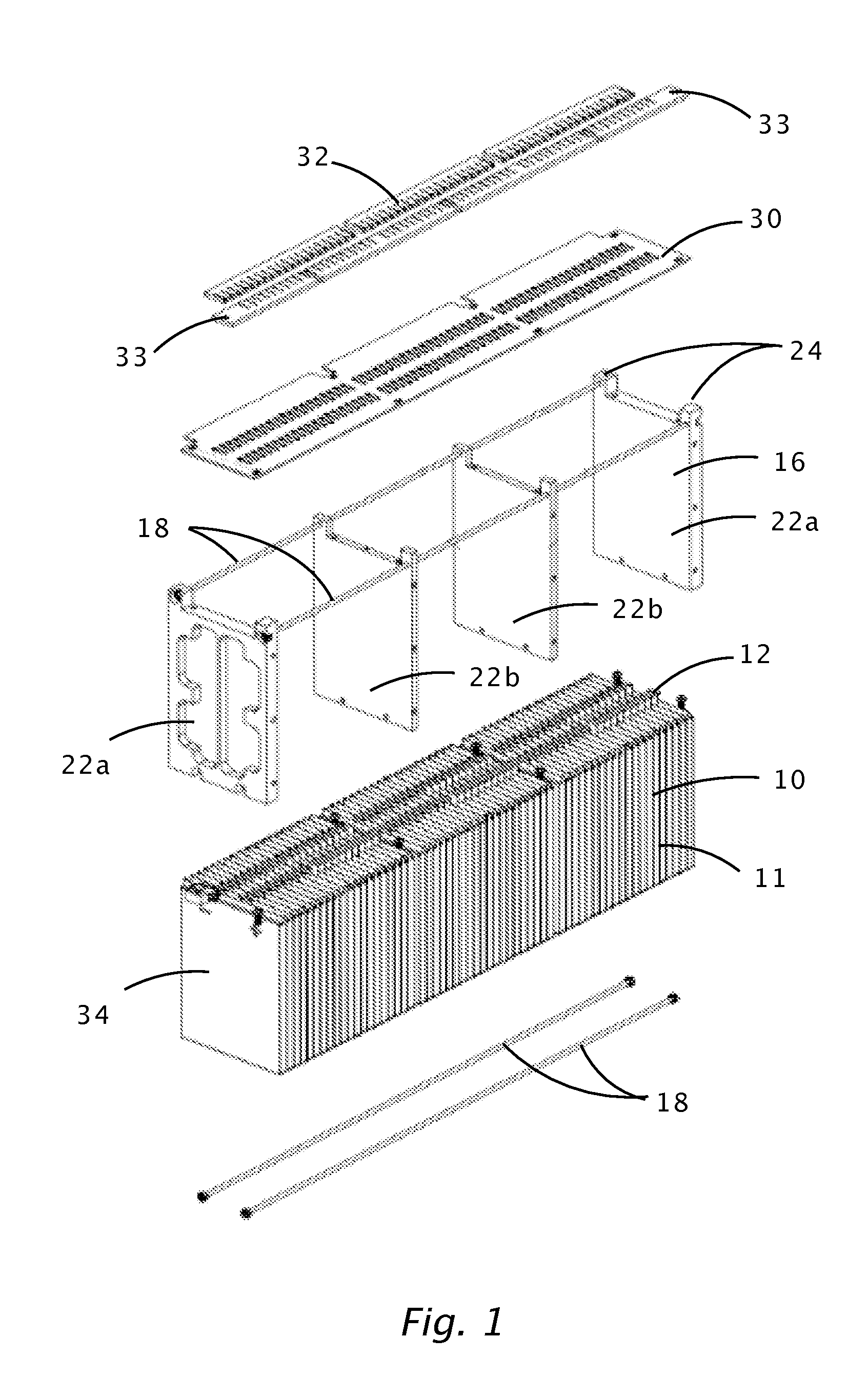

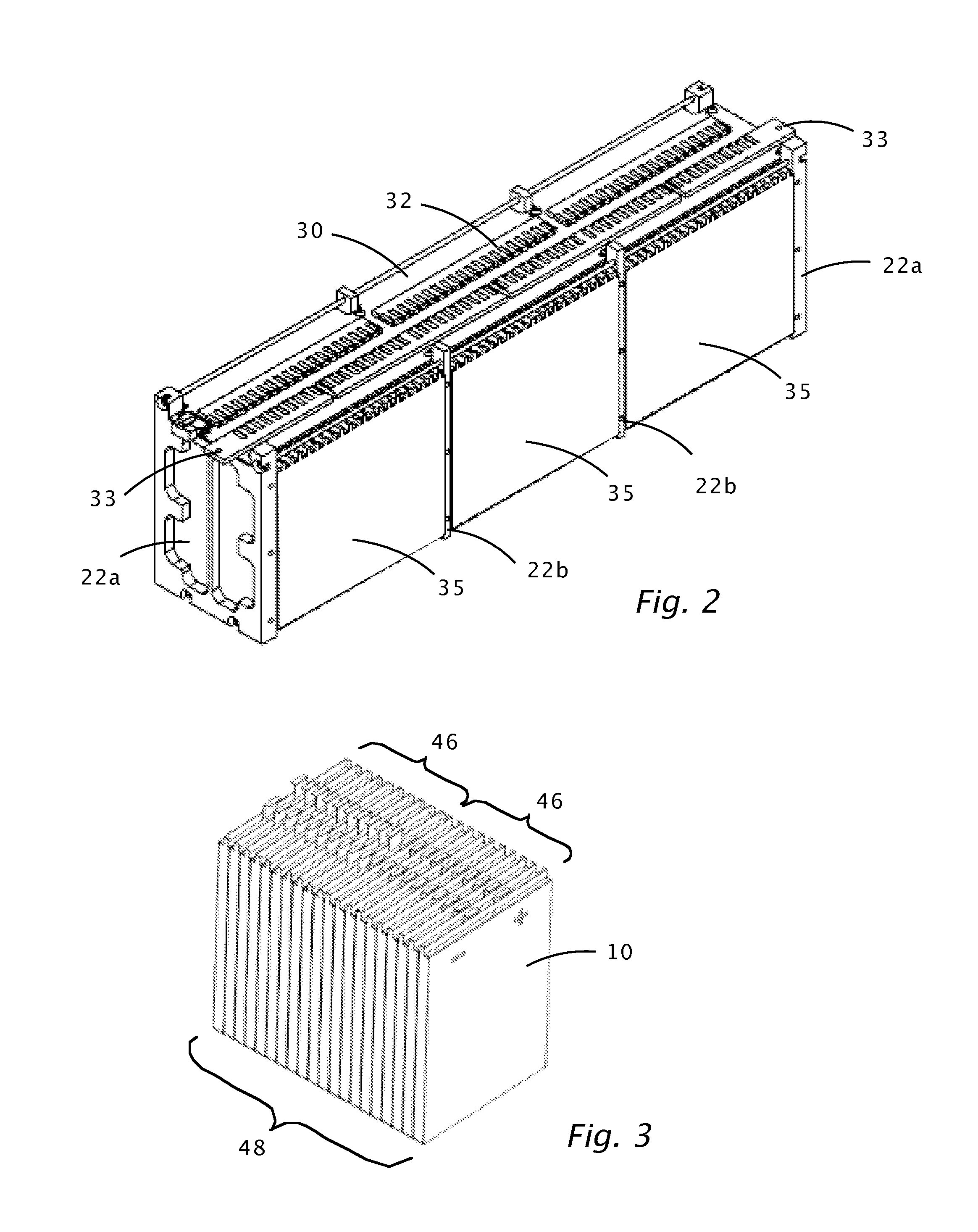

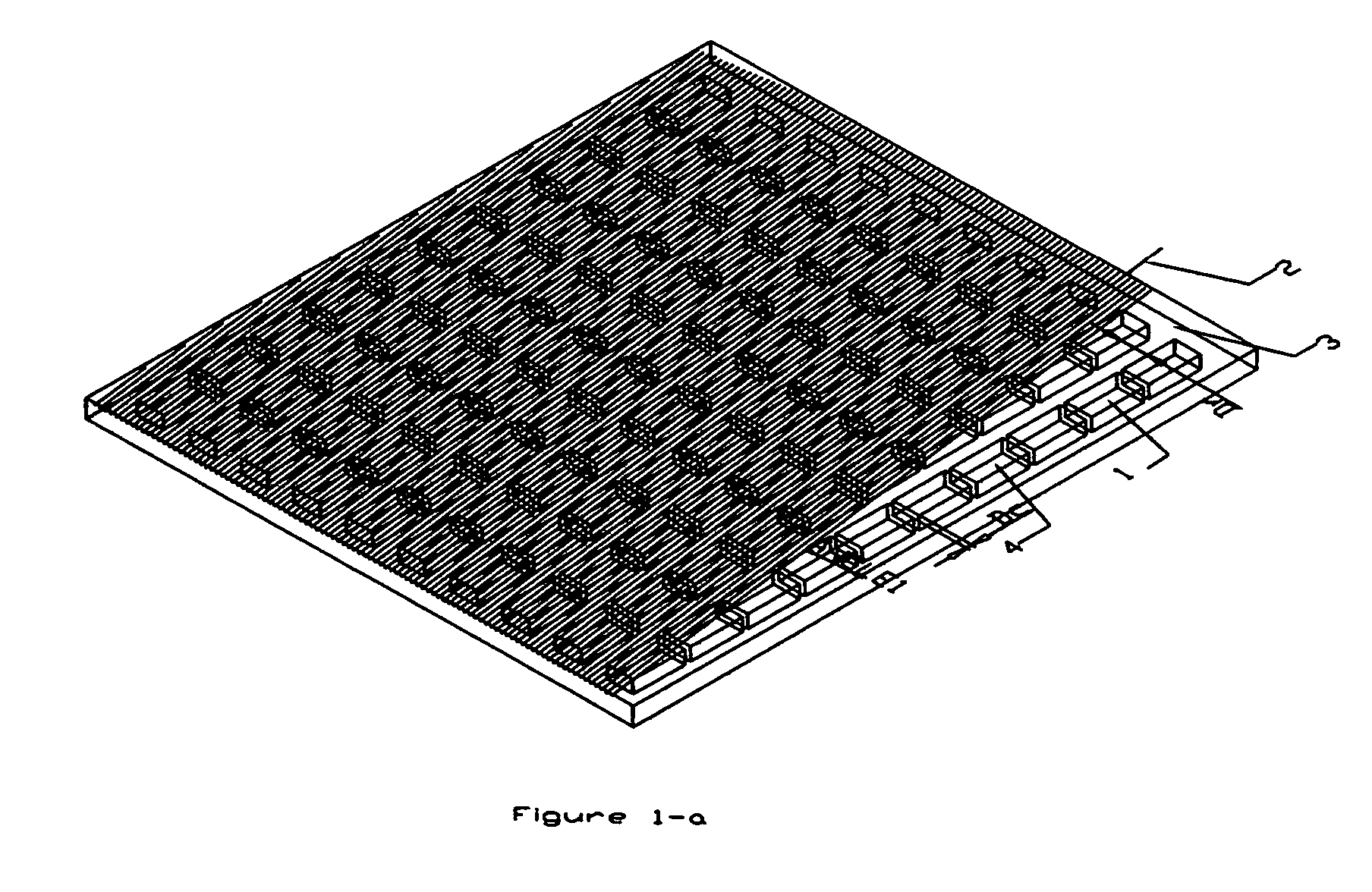

Low profile battery module and improved thermal interface

ActiveUS9225035B1Low overall parts countImprove thermal characteristicsLarge-sized flat cells/batteriesFinal product manufactureEpoxyLithium

An arrangement of a battery module and a method for making this module are presented. An embodiment is comprised of a plurality of Lithium-ion pouch type unit cells stacked in a linear array. A lightweight frame structure compresses the unit cells and the cells are encapsulated with thermally conductive epoxy. A method of assembly constrains the unit cells during encapsulation such that a thin wall of epoxy is achieved, reducing the thermal resistance of the side walls. A slotted flat panel is placed over the unit cells and the cell tabs protrude through the panel. An arrangement of slotted bus bars reside on the flat panel and the cell tabs are bent at right angles in a manner that allows the tabs to be attached to the bus bars by a soldering or similar means. In an embodiment of the battery module, the flat panel contains battery management circuitry.

Owner:KLEENSPEED TECH

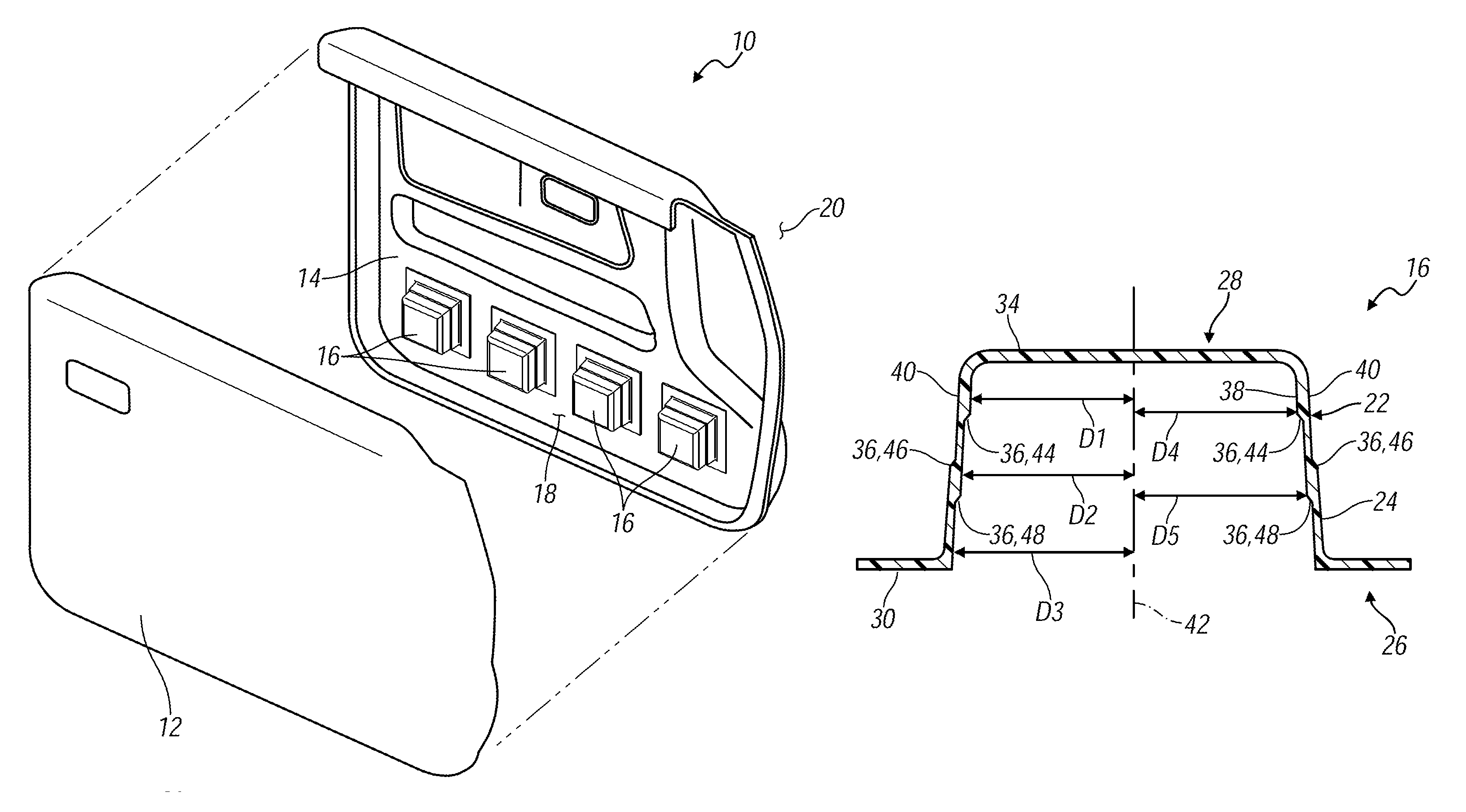

Energy absorbing component

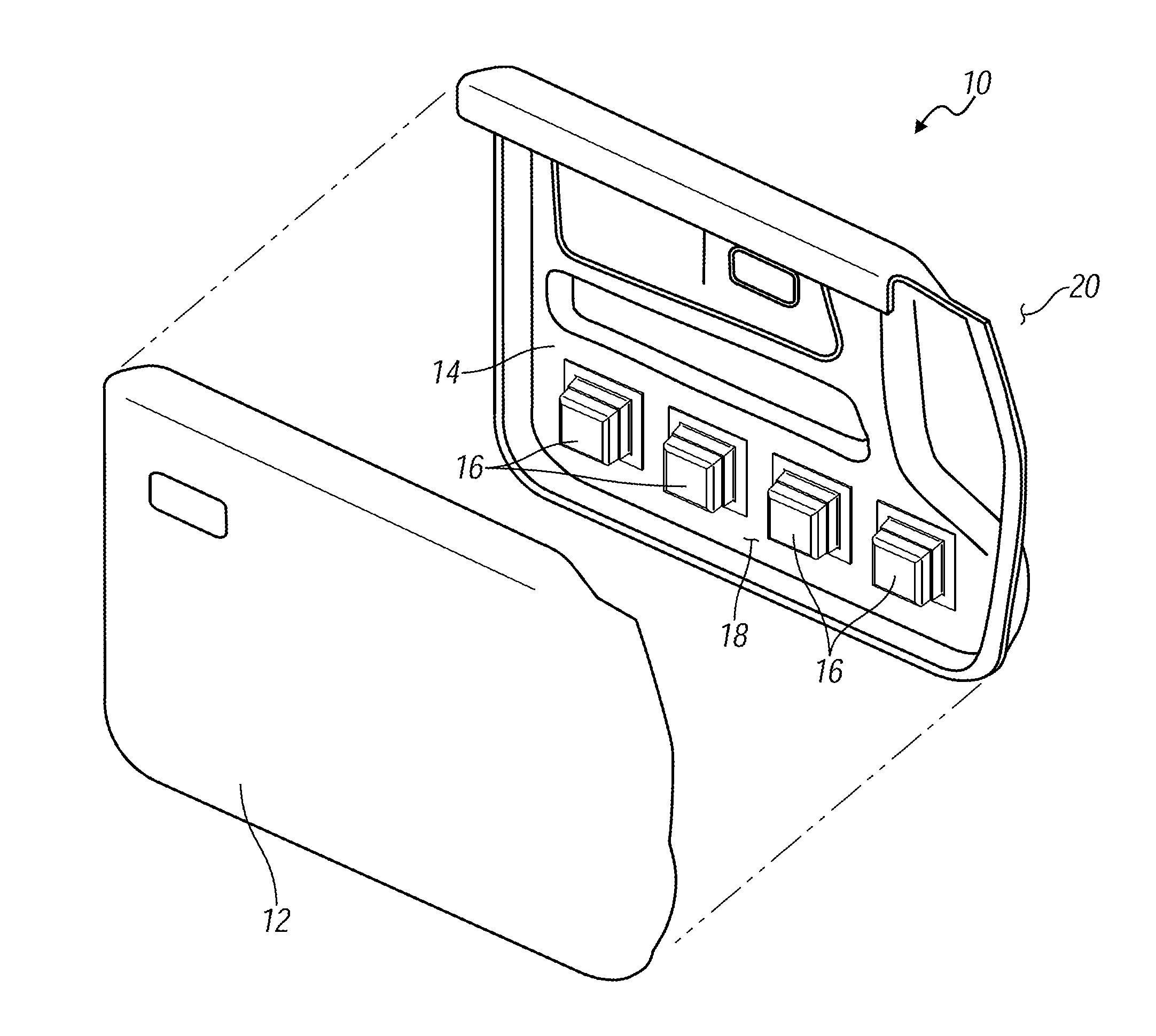

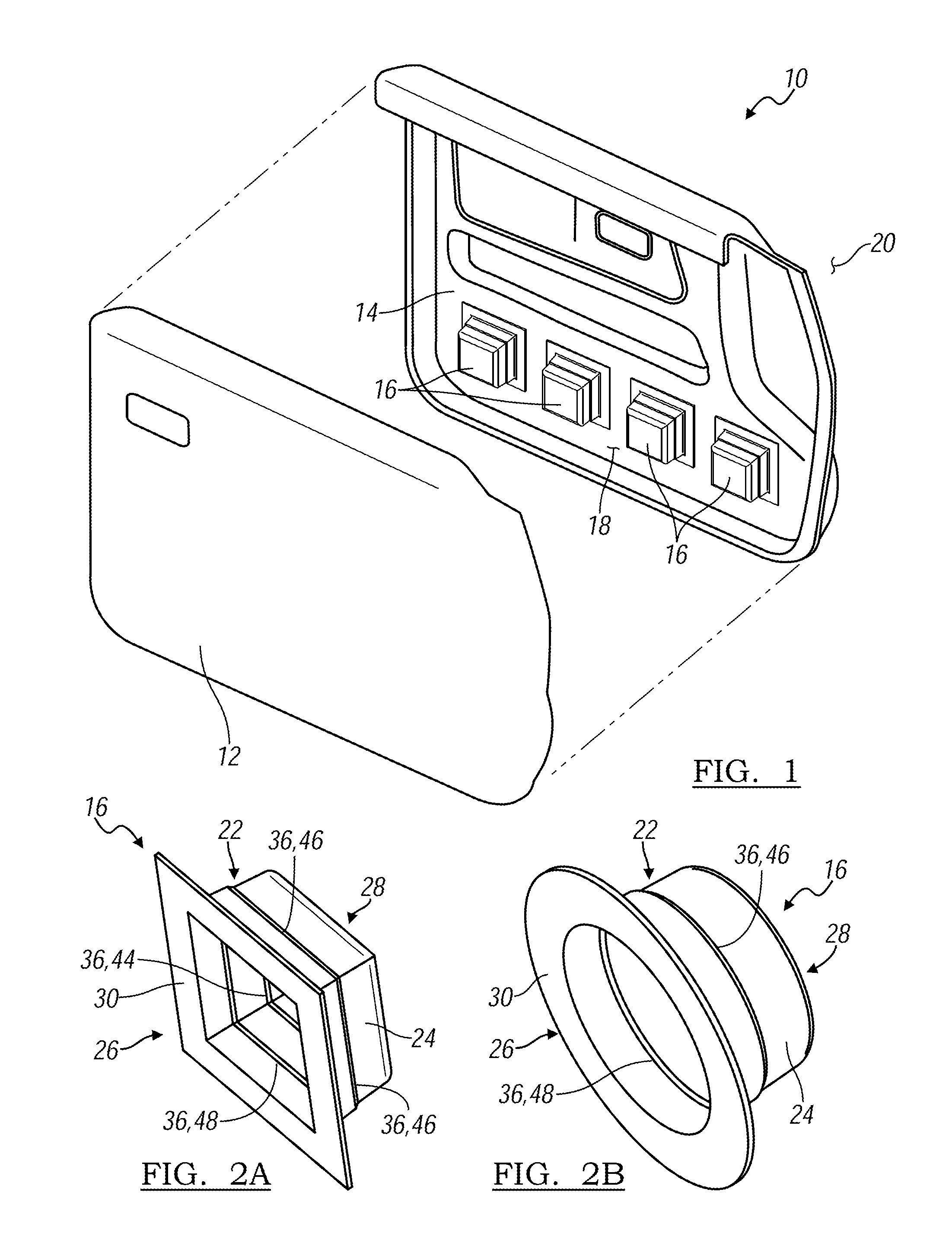

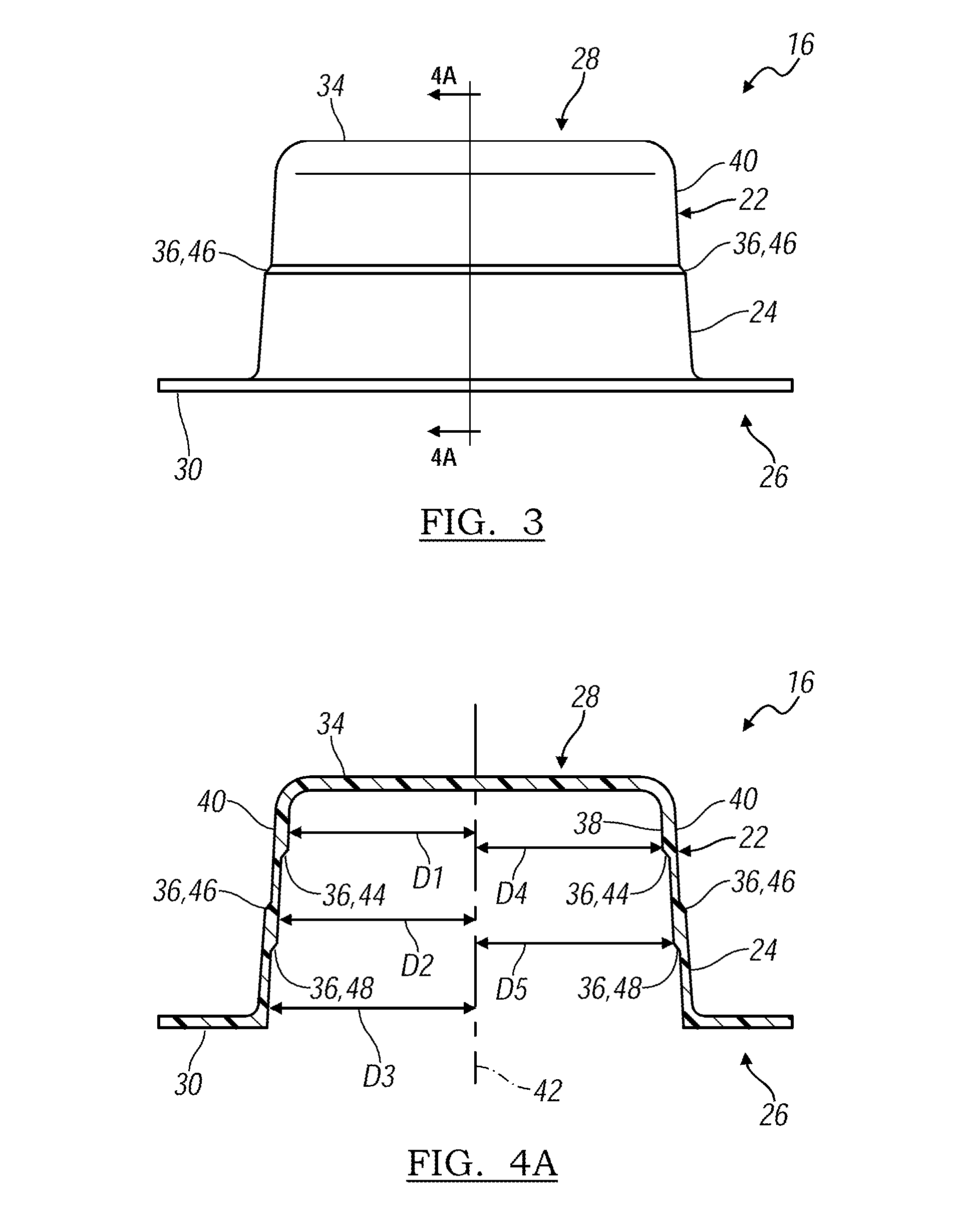

ActiveUS20150123426A1Improve securityImproving passenger safetyVehicle seatsPedestrian/occupant safety arrangementEnergy absorbingEngineering

An energy absorber for improving passenger safety in a vehicle during an impact to the vehicle, the energy absorber comprising a hollow body having a base defining a proximal end of the body, the base being configured to affix the body to a portion of the vehicle, the body further including a sidewall extending from the base and terminating in a distal end of the body, the sidewall having an interior surface and an exterior surface, the interior surface including a portion defining an interior step transition, the exterior surface including a portion defining an exterior step transition, the interior and exterior step transitions being provided at locations axially offset from each other along the sidewall.

Owner:TOYOTA JIDOSHA KK

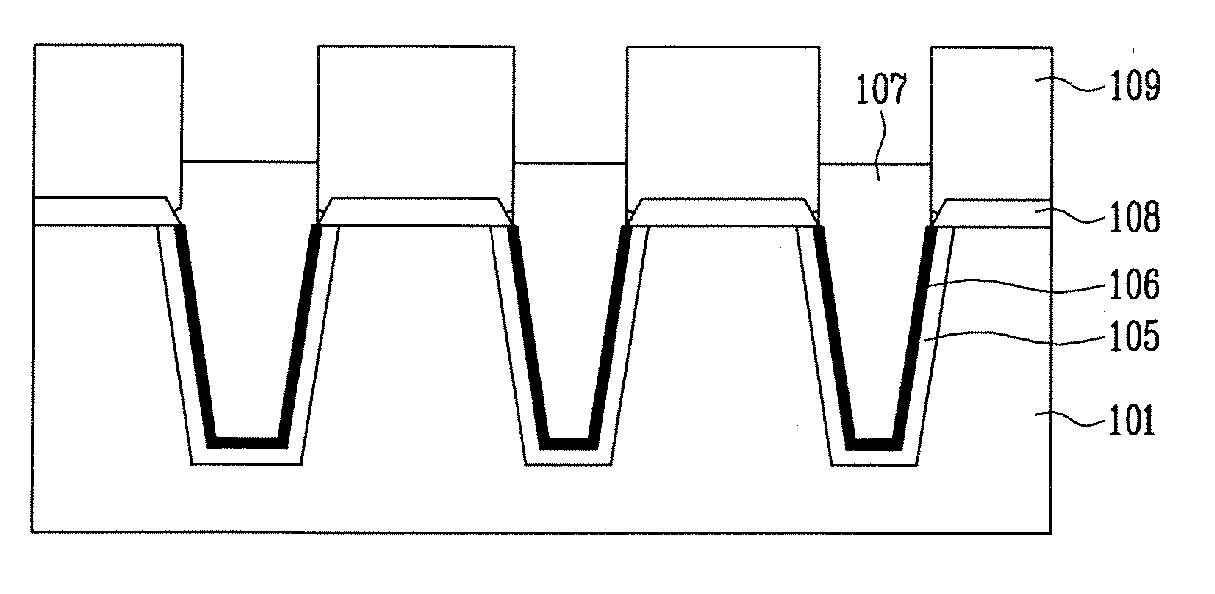

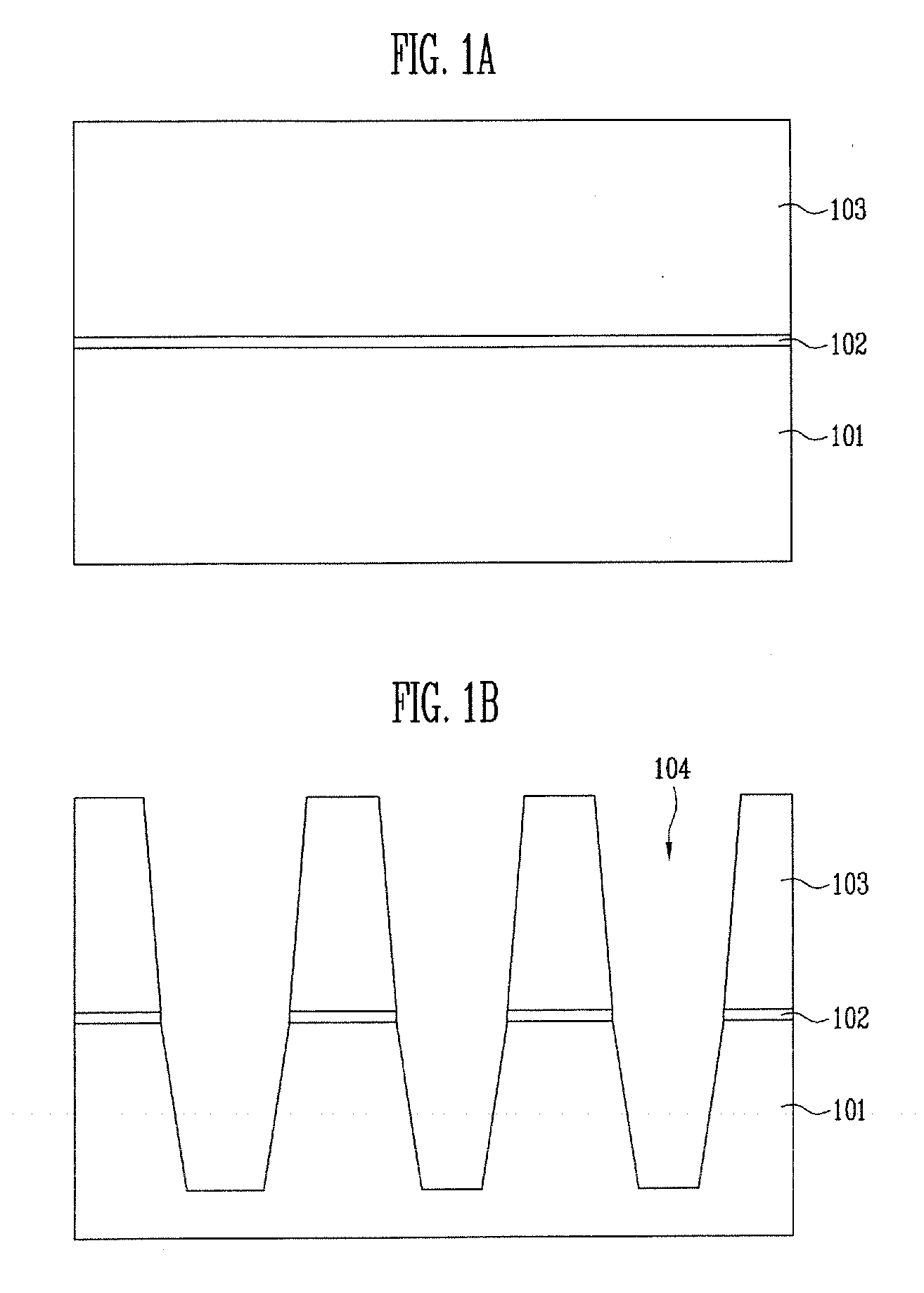

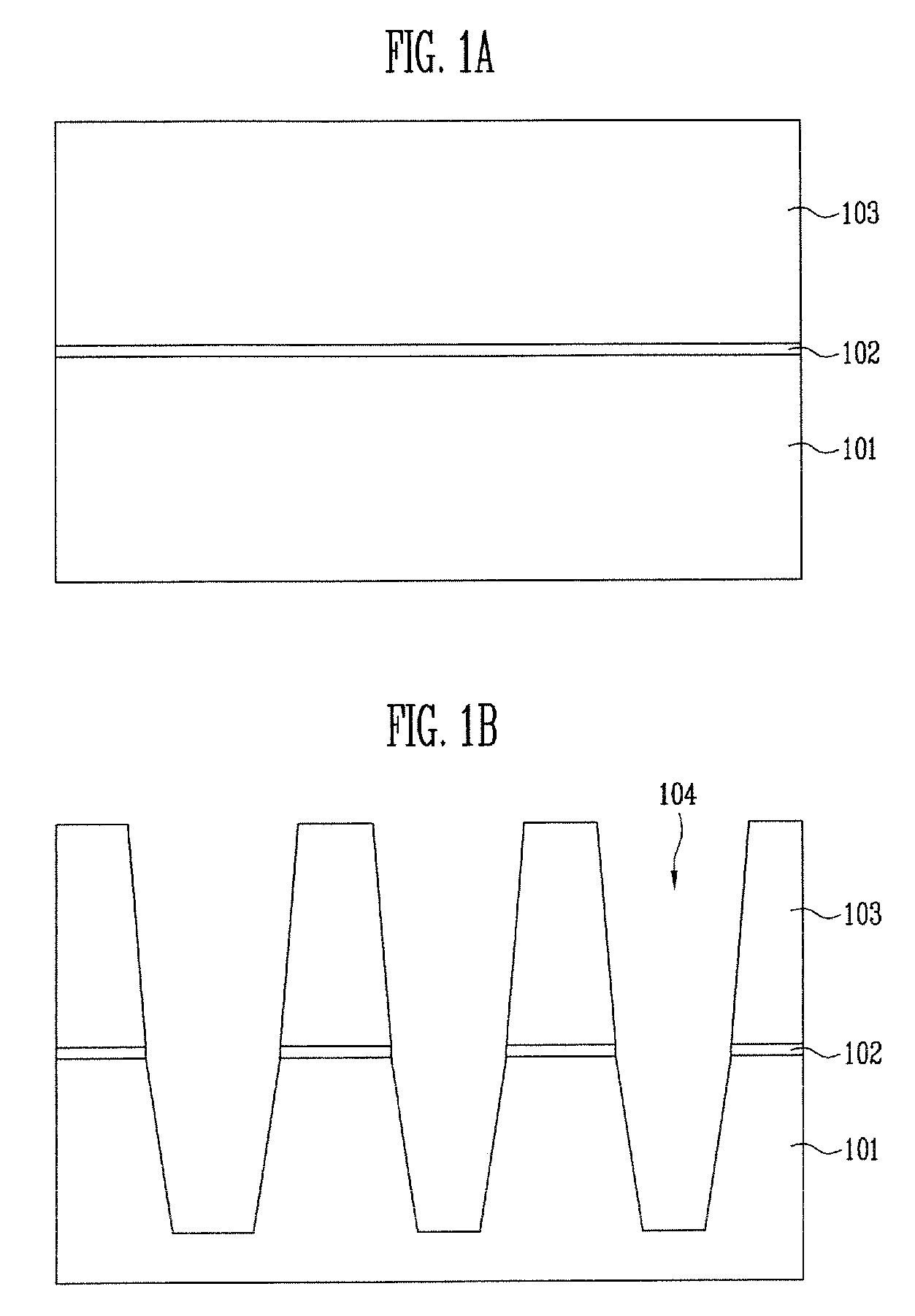

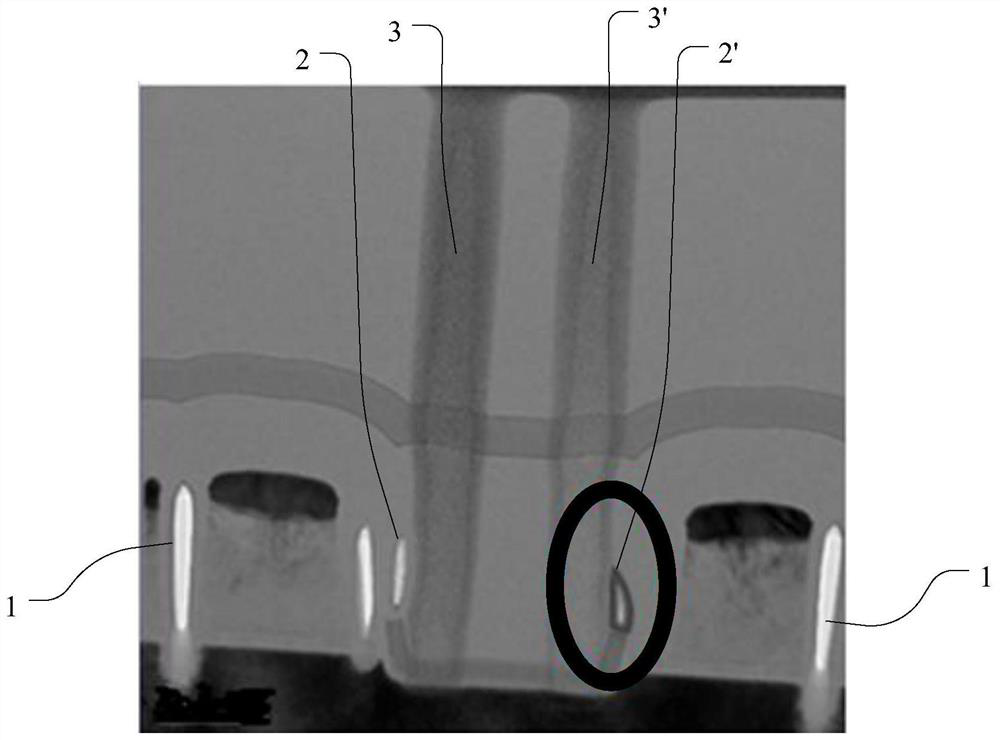

Method of fabricating flash memory device

InactiveUS20060205150A1Improve characteristicReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPre treatmentEngineering

A method of fabricating a flash memory devices disclosed wherein, upon formation of sidewall oxide films, a regrown thickness of a screen oxide film is controlled. The width of an element isolation film is reduced by means of an etch process for removing the re-growth oxide film. This allows a floating gate space to be easily secured, and a thickness of the sidewall oxide films is reduced by means of a liner nitride film pre-treatment cleaning process. It is thus possible to secure the trench space, which facilitates gap-filling.

Owner:SK HYNIX INC

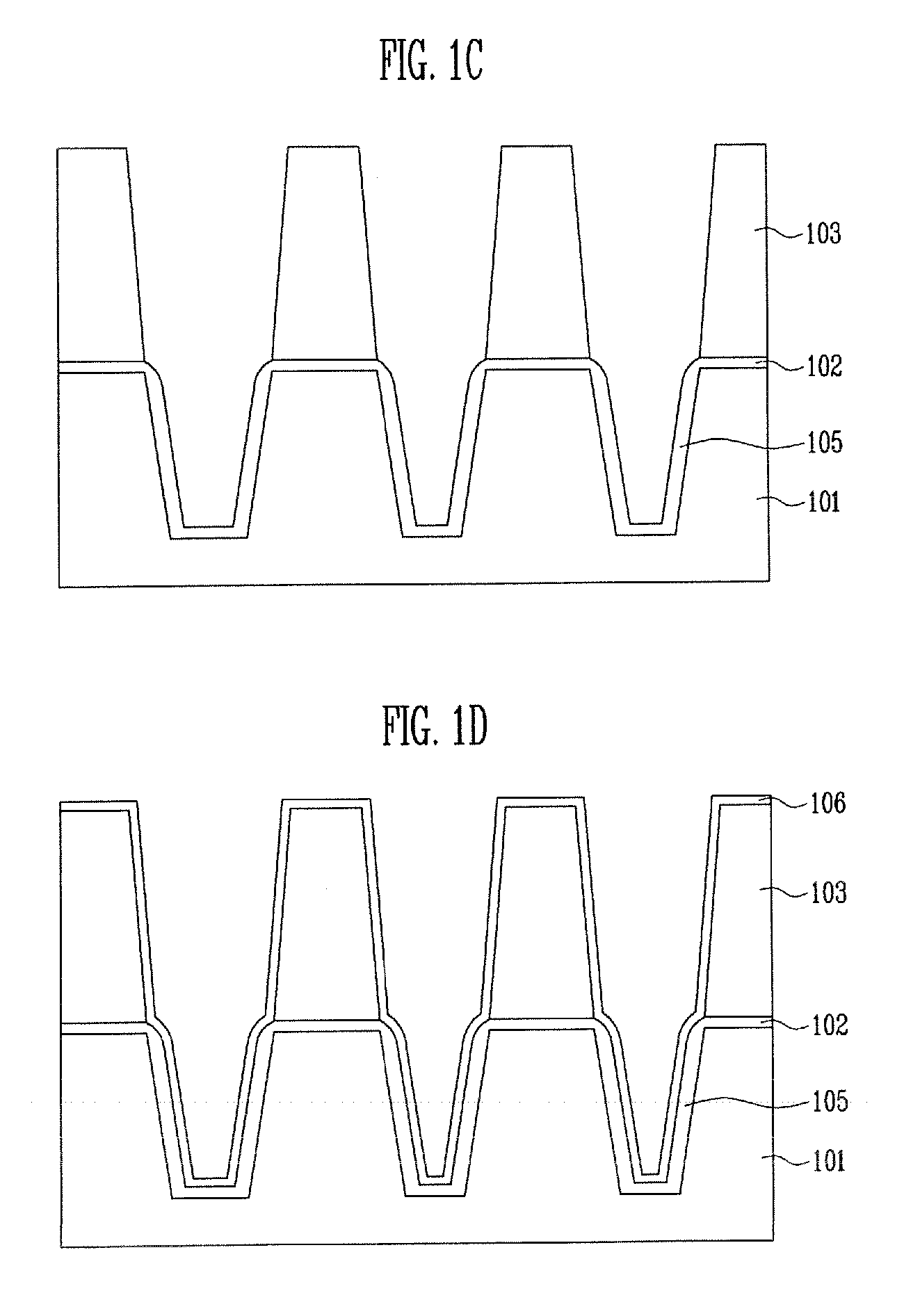

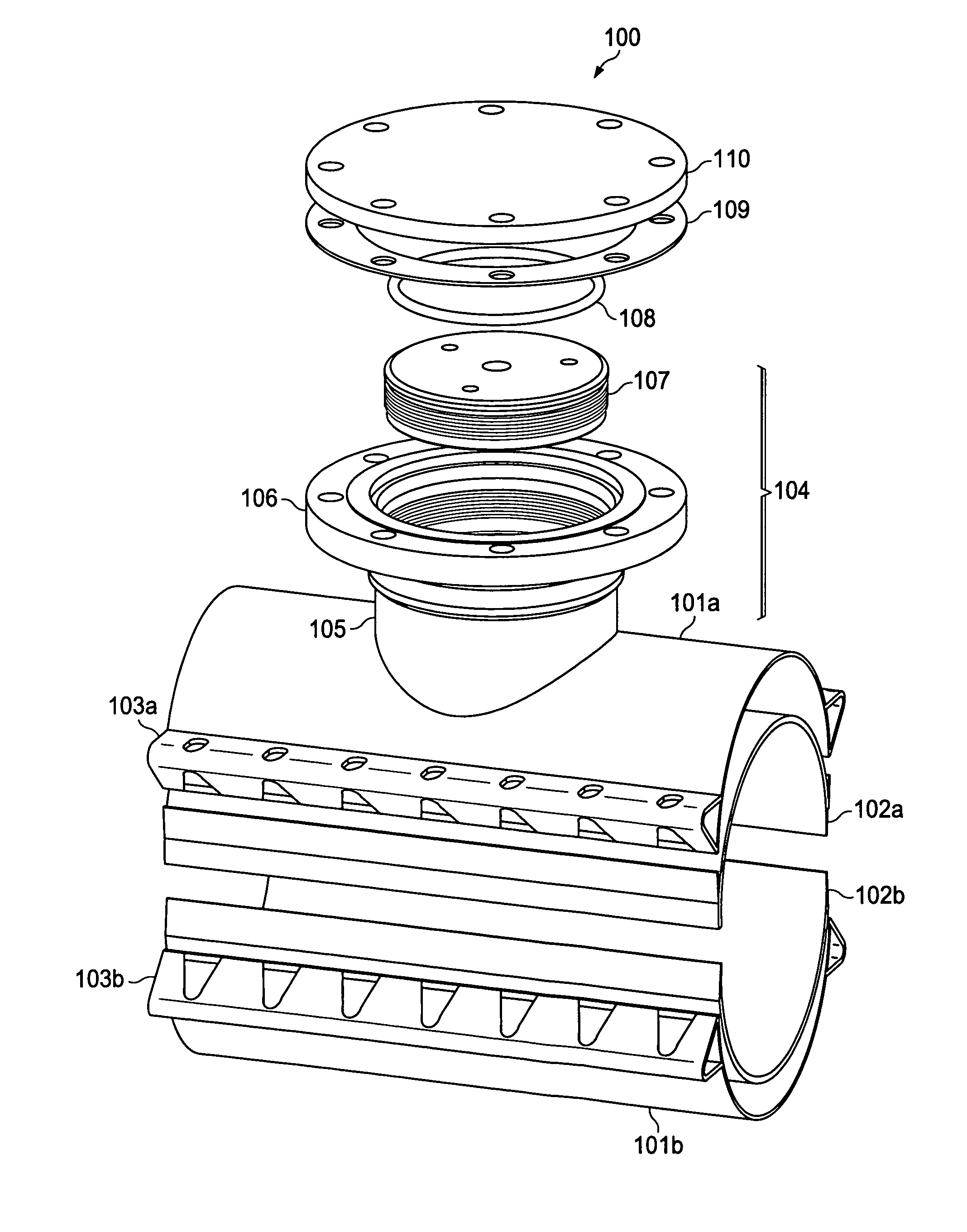

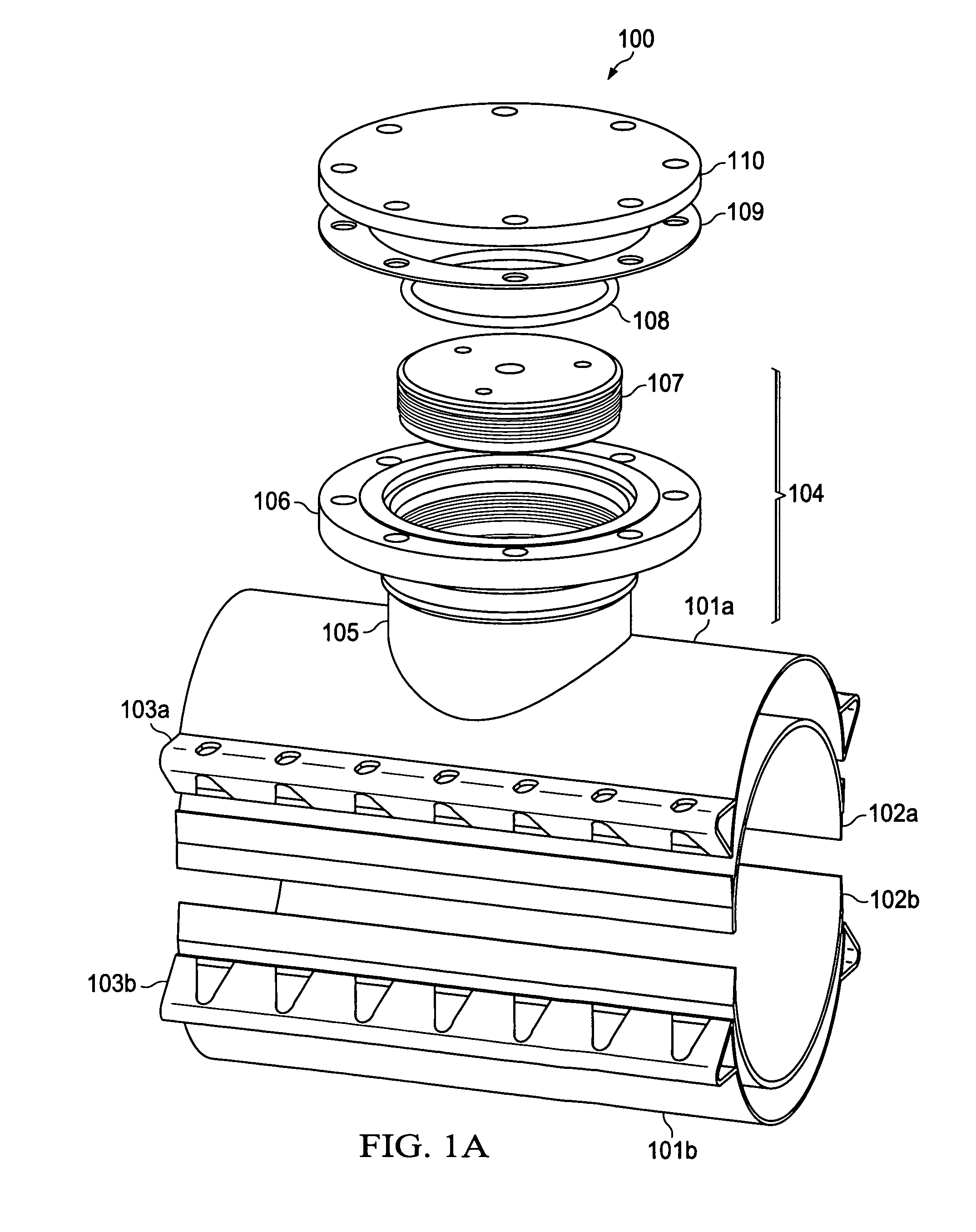

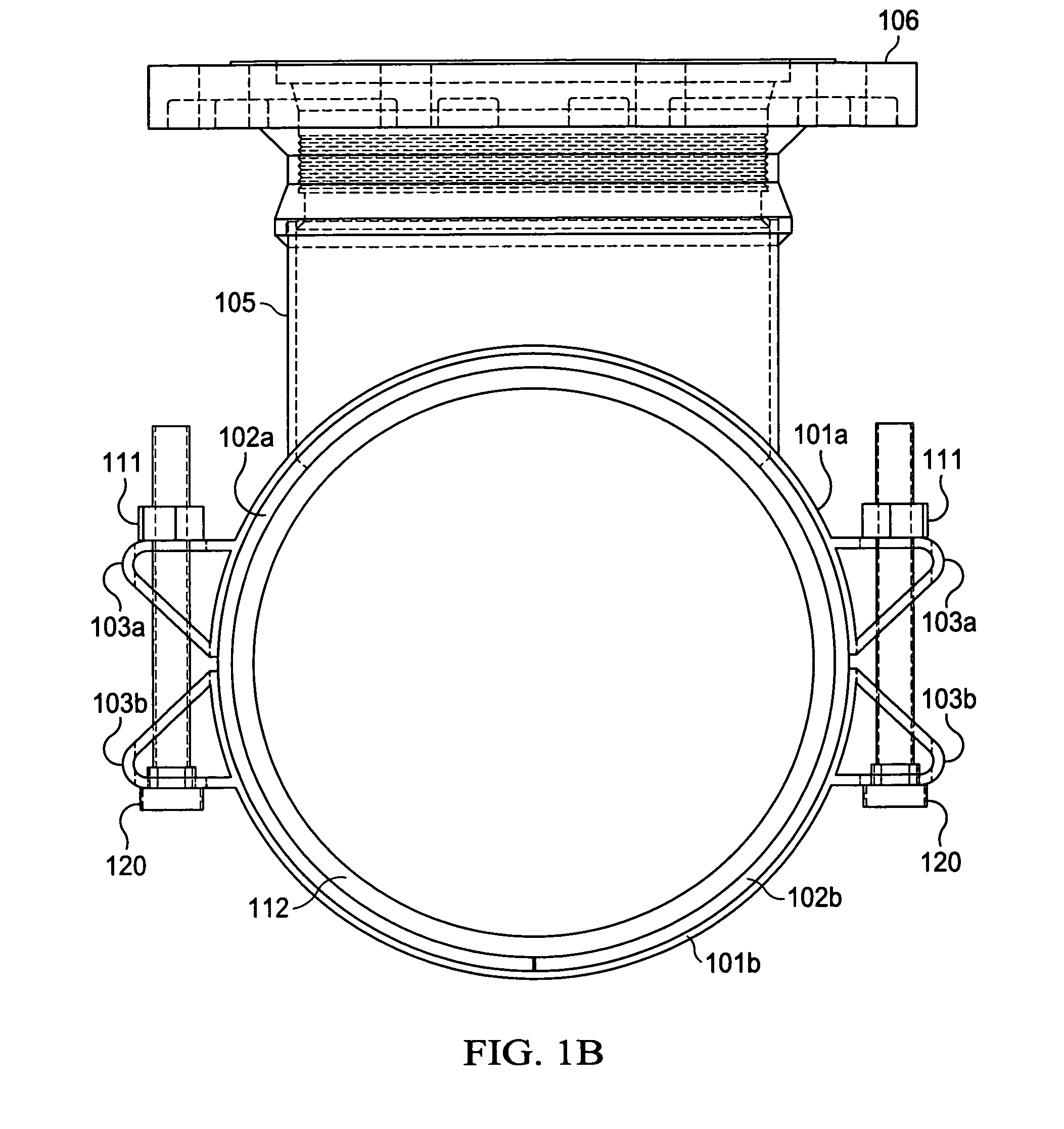

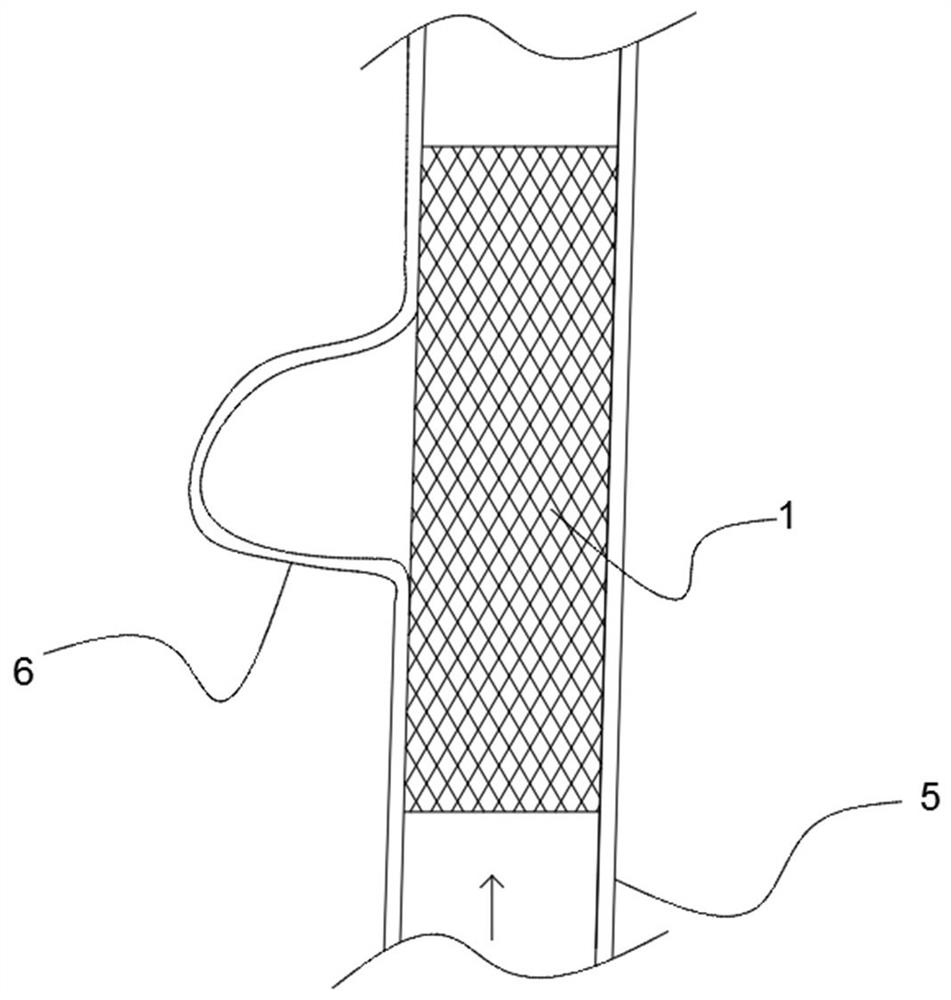

Line-stopping sheath spigot assemblies and line-stopping sheath assemblies using the same

InactiveUS8176929B1Reduce manufacturing costReduced sidewall thicknessValve arrangementsFlanged jointsEngineeringFlange

A spigot for a line-stopping sheath assembly includes a flange including a flange plate and a flange barrel. The flange barrel includes a wall extending from the flange plate, with an end of the wall of the flange barrel opposing the flange plate having a projection defining a periphery of a socket area for receiving an end of a pipe. The spigot also includes a pipe having an end disposed within the periphery of the socket area defined by the projection of the flange barrel.

Owner:JCM IND

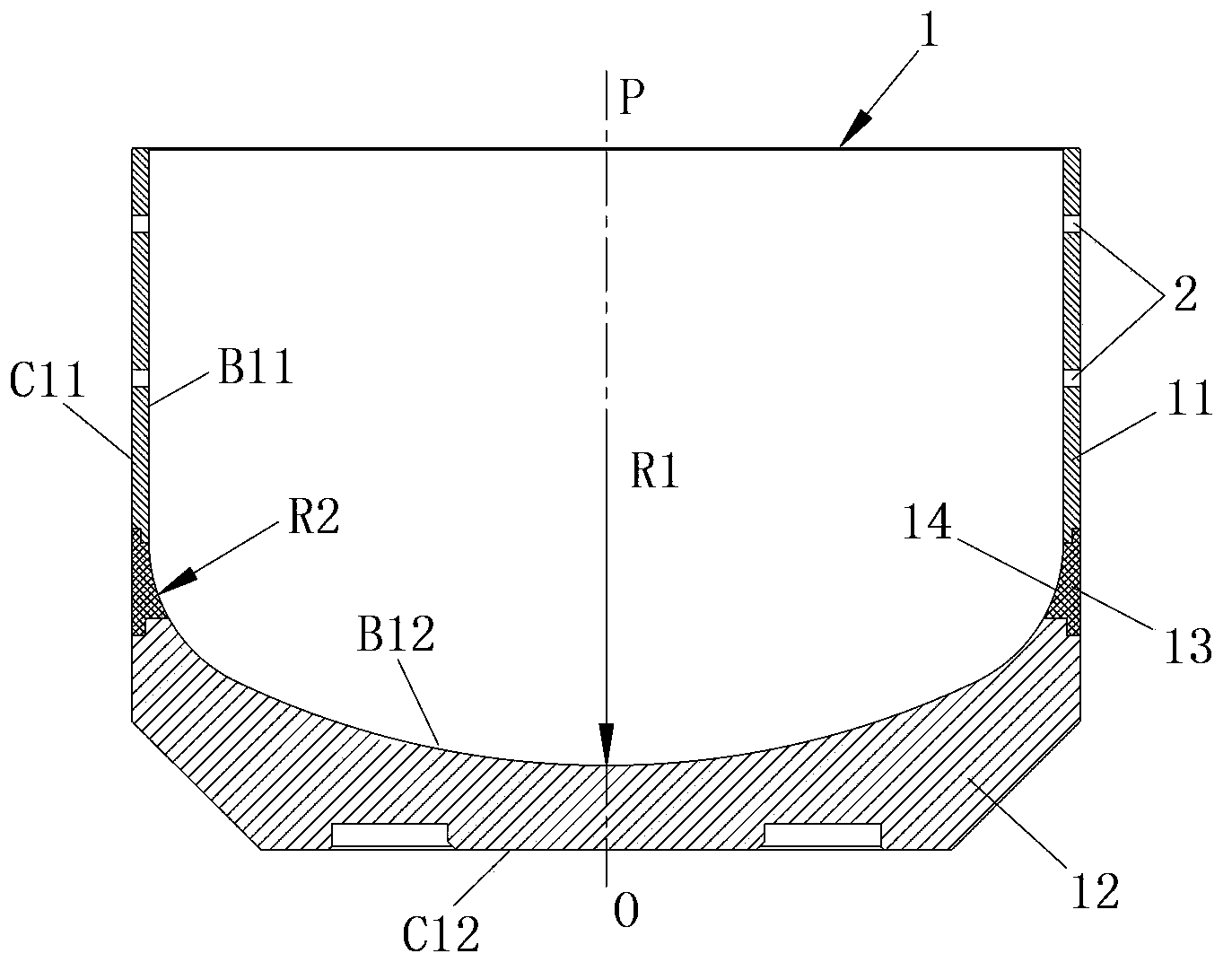

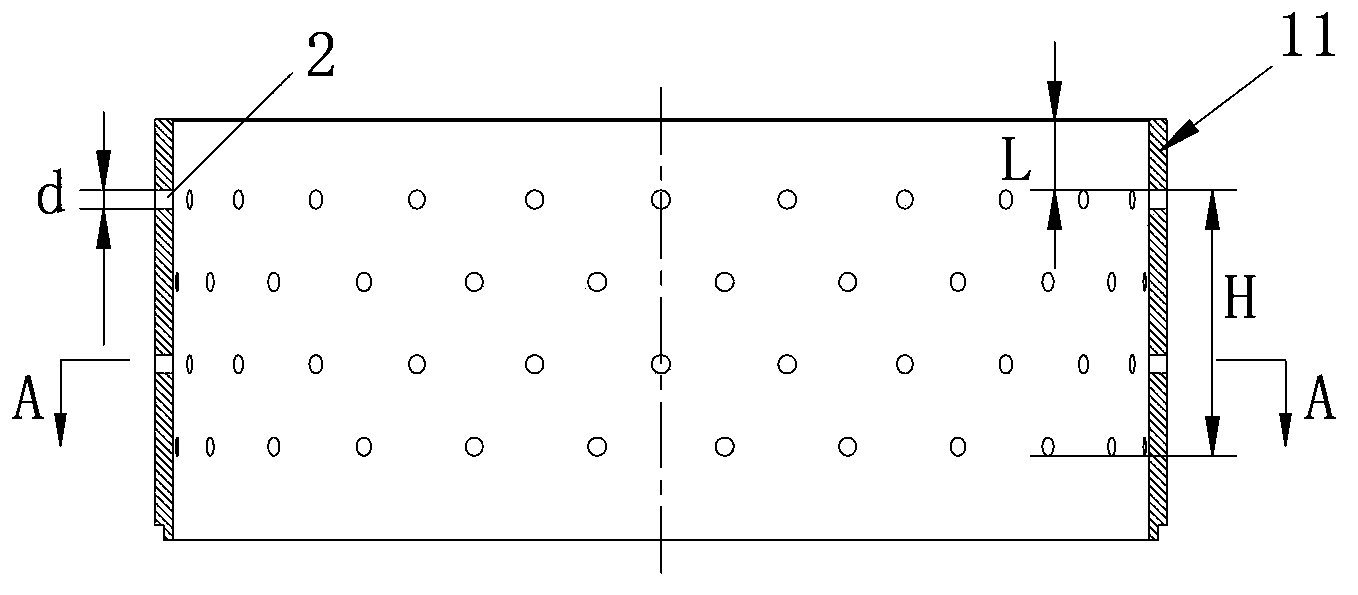

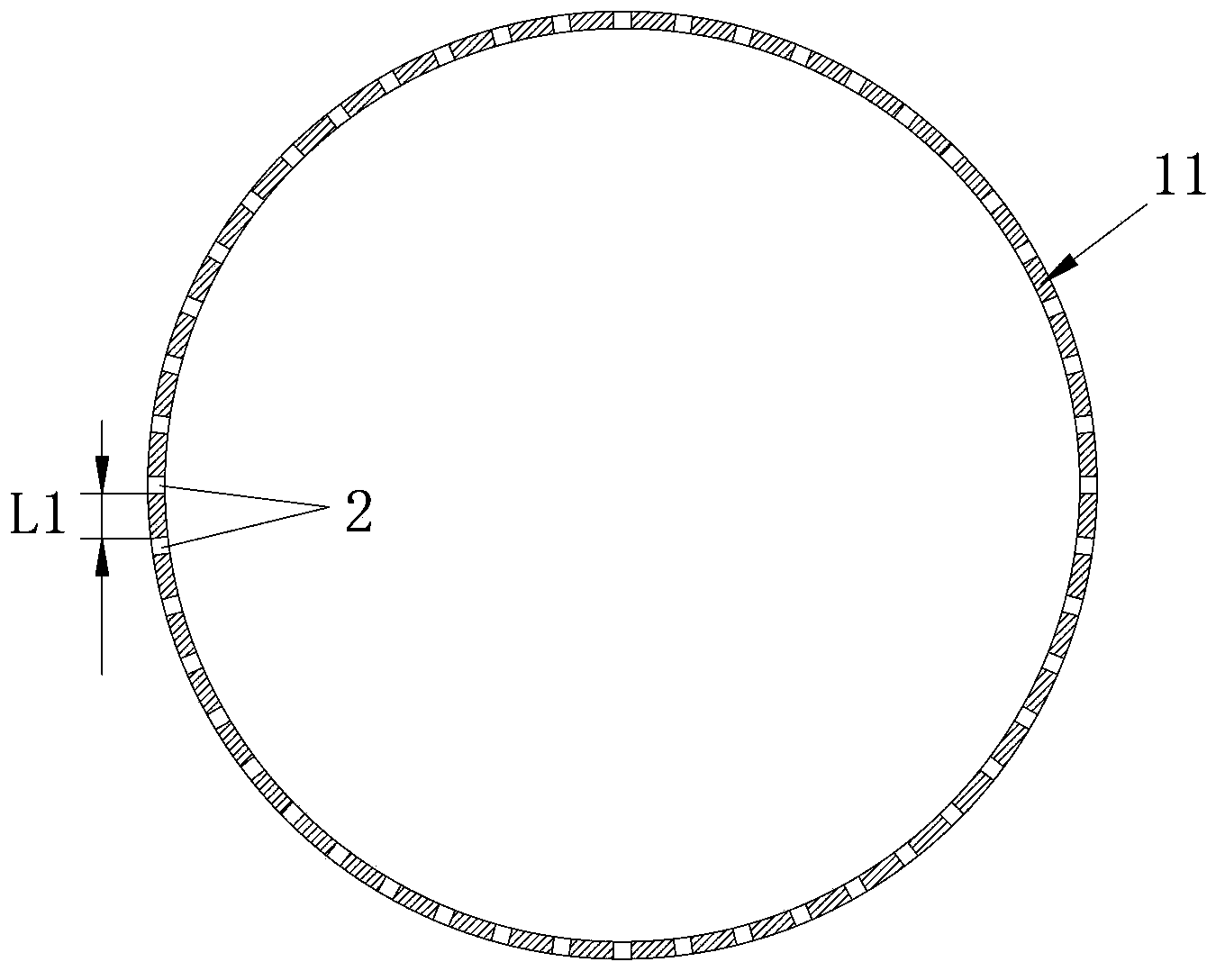

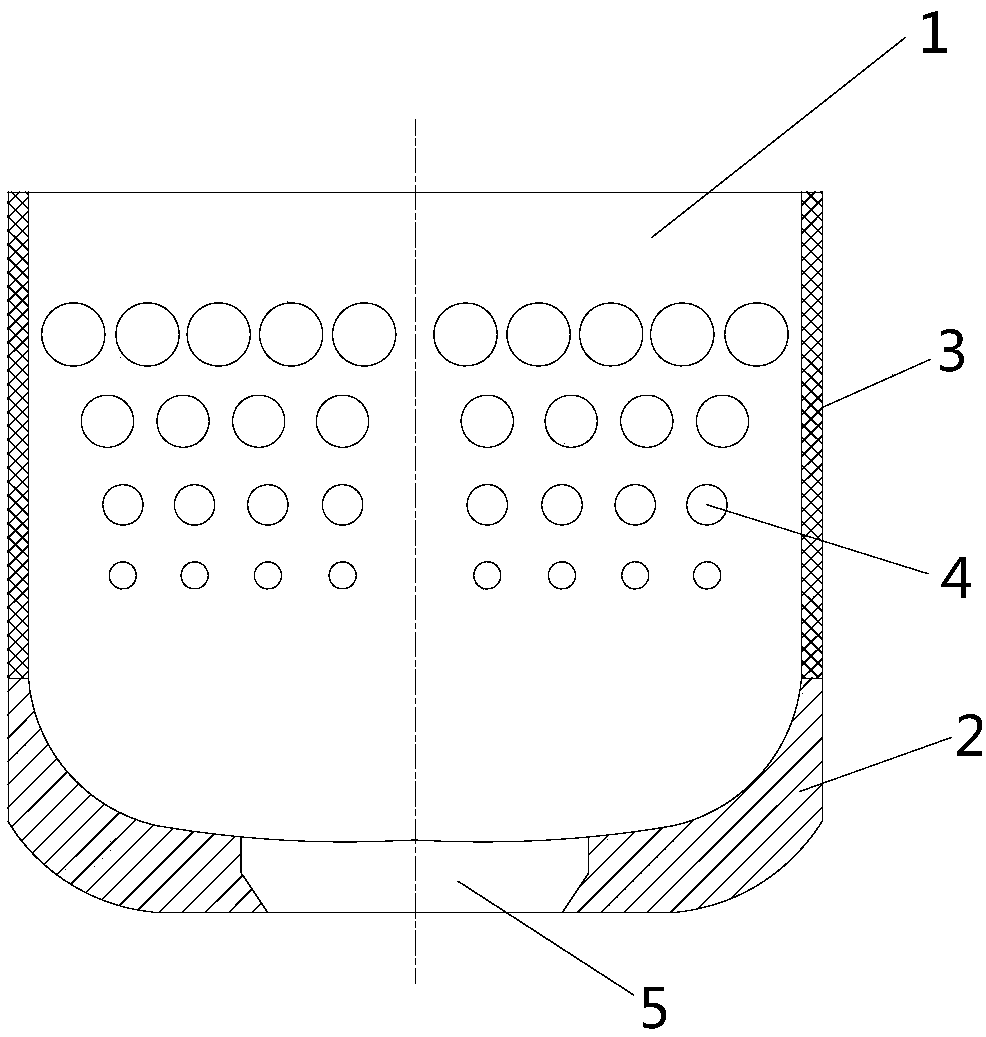

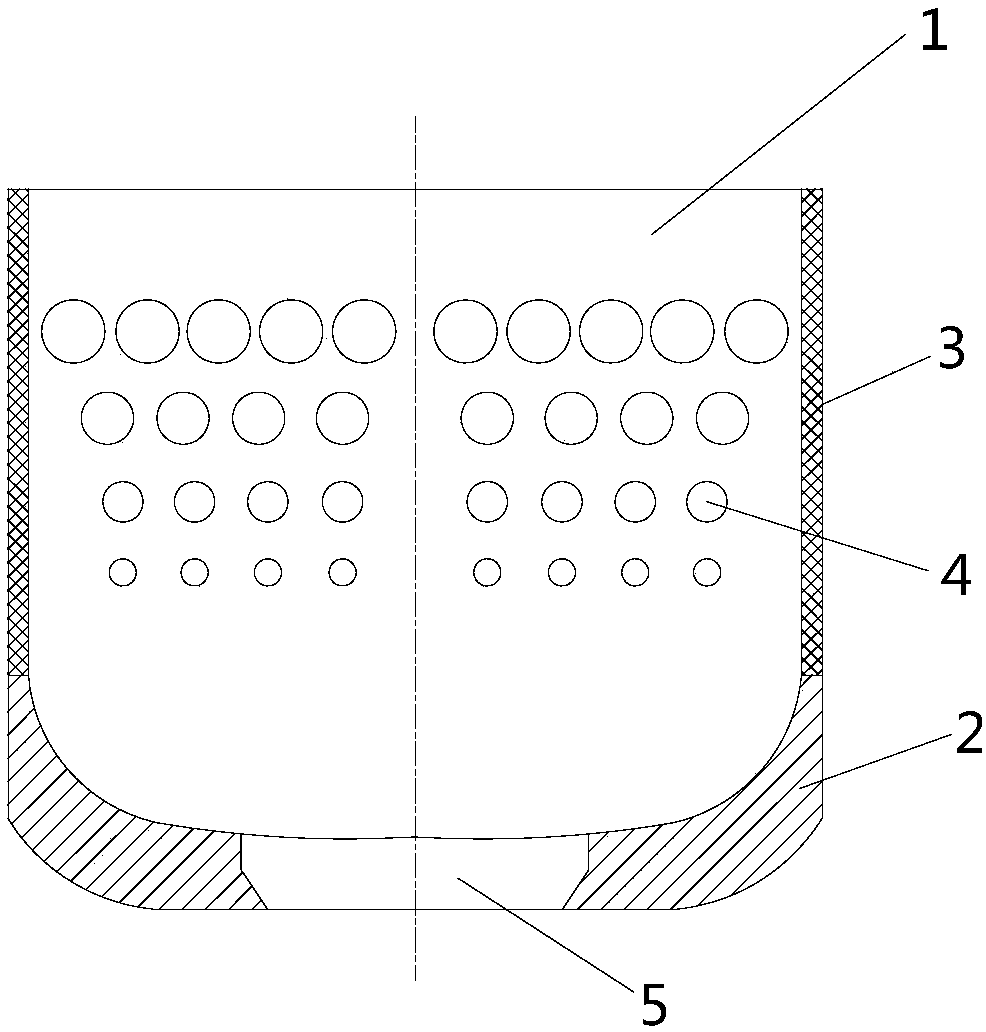

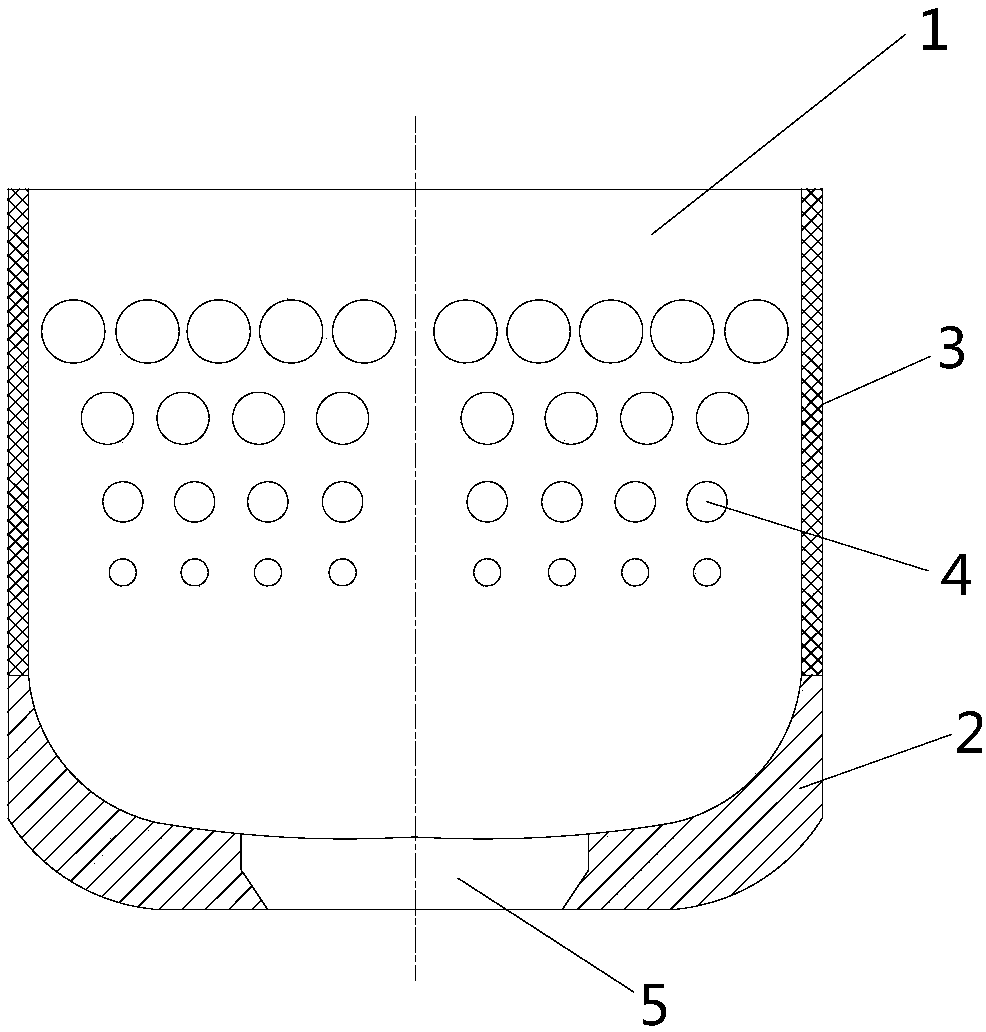

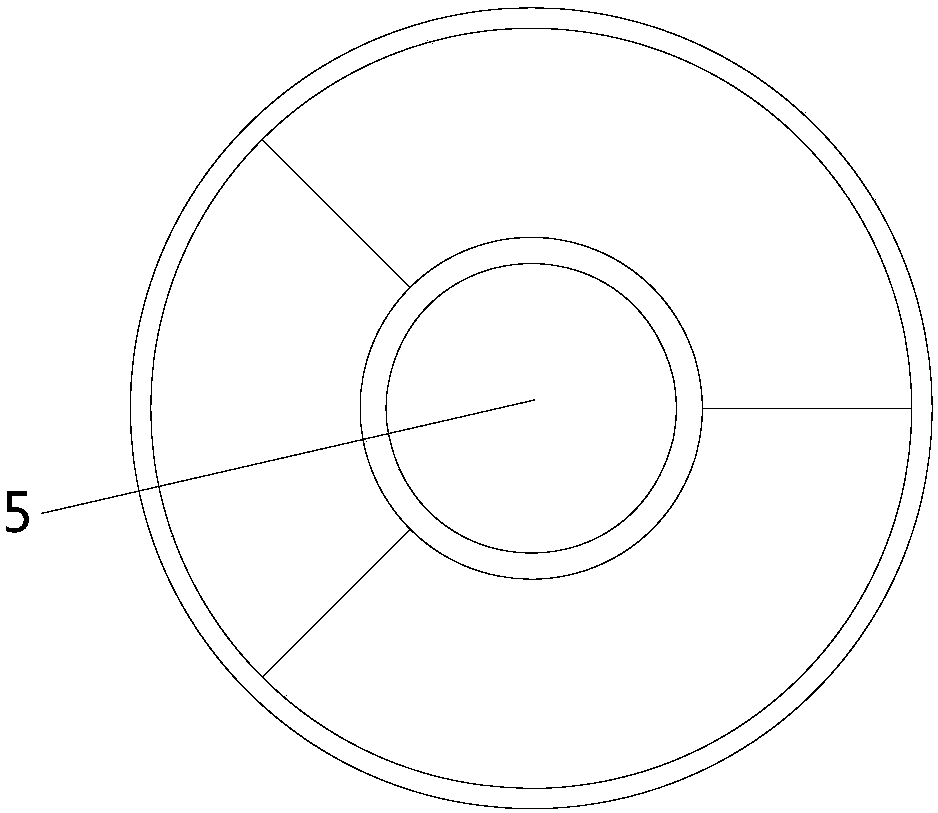

Crucible used for preparing monocrystalline silicon by czochralski method

InactiveCN103668437AImprove thermal conductivityGood temperature controlPolycrystalline material growthBy pulling from meltTemperature controlCarbon composites

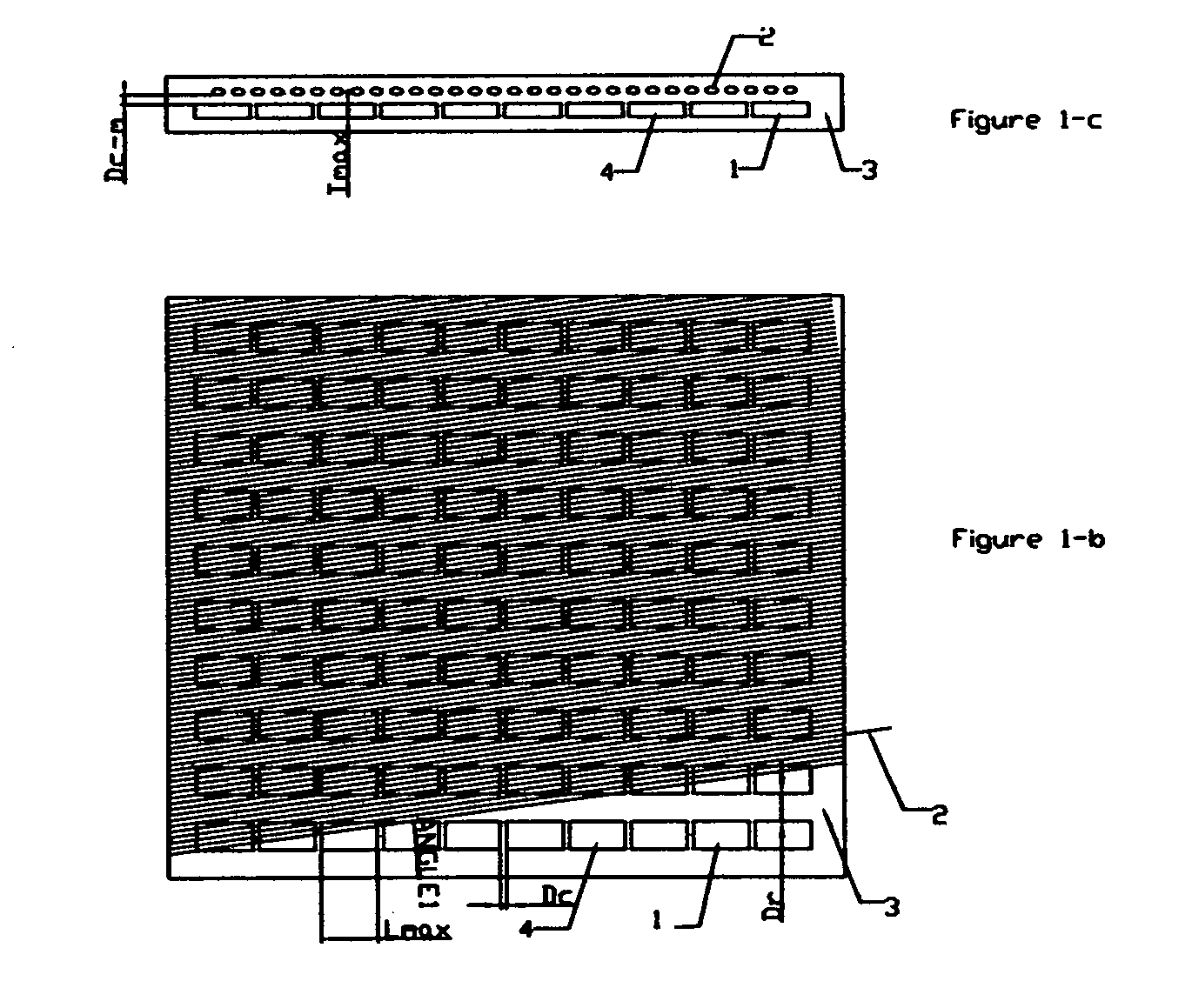

The invention discloses a crucible used for preparing monocrystalline silicon by a czochralski method. The crucible comprises a crucible main body which is composed of a bottom and a side wall, wherein the crucible is of a sectional type crucible structure; the crucible main body is at least divided into two sections from top to bottom according to difference of materials; the crucible main body comprises an upper-layer side wall made of a carbon-carbon composite material and a lower-layer bottom made of a graphite material, wherein a plurality of heat-conducting holes are uniformly distributed on the side wall; the diameter of the heat-conducting holes is 5mm-20mm; distance between borders of the heat-conducting holes is 10mm-50mm according to different pore densities; an area, which is uniformly distributed with the heat-conducting holes, on the side wall is 2cm-6cm from the side wall; the width of the side wall in the downwards vertical direction is 16cm-25cm; the inner side surface of the side wall of the area is parallel to a center shaft of the crucible. The crucible disclosed by the invention has characteristics of good heat conductivity, good temperature control, long service life and great loading amount.

Owner:SHANGHAI JMS ELECTRONICS MATERIALS

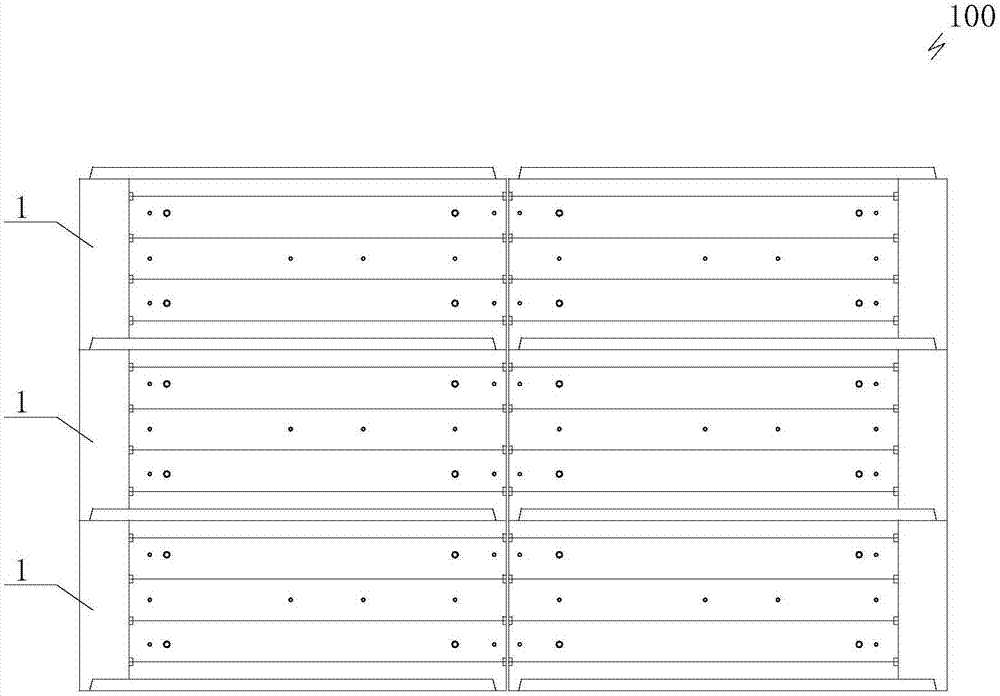

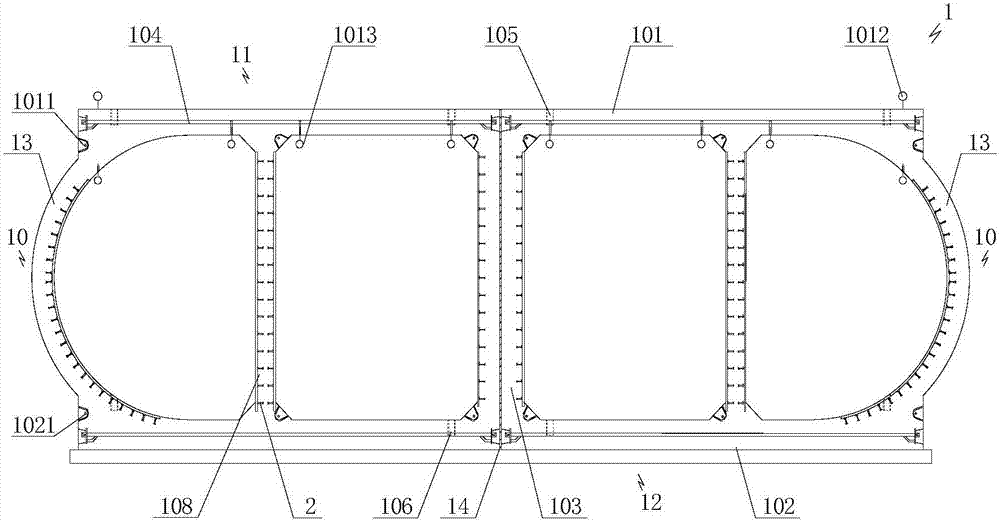

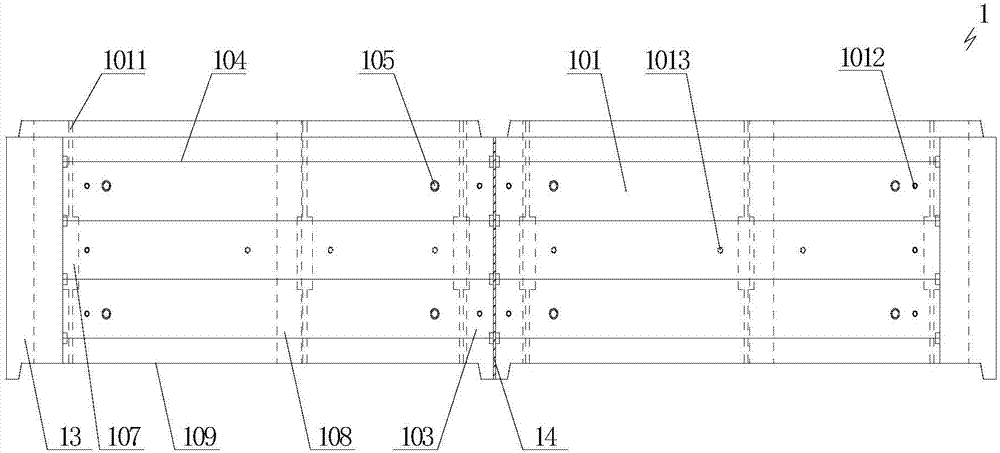

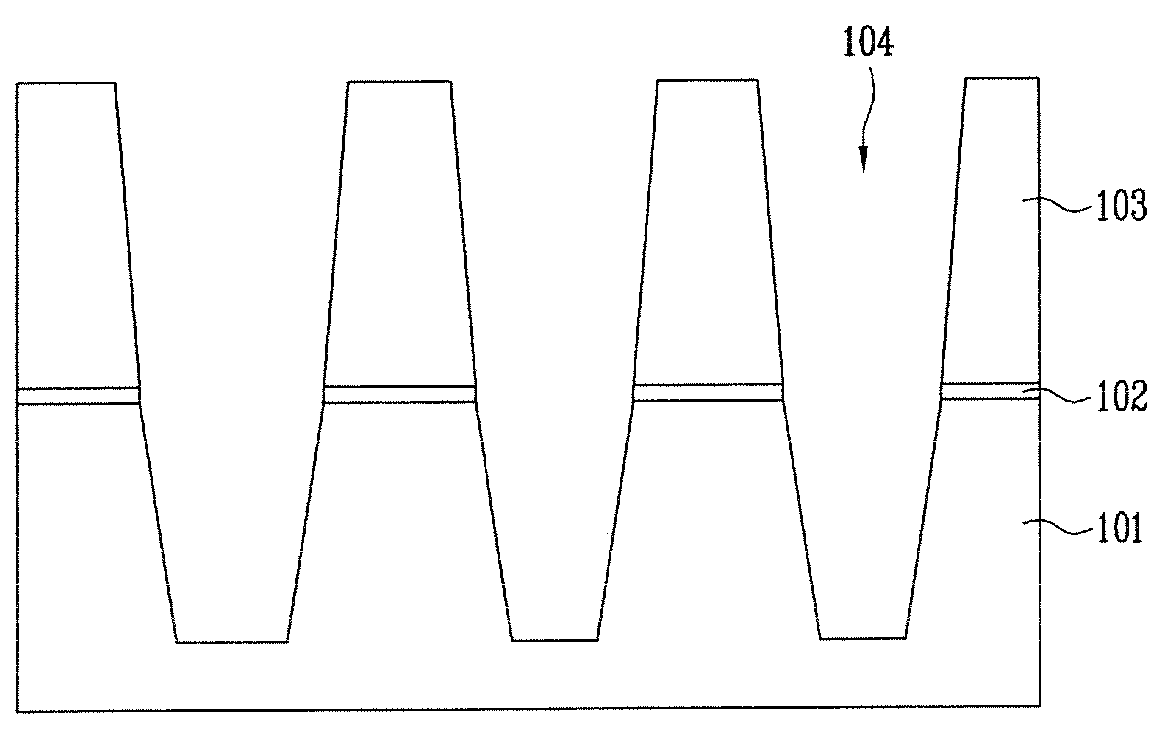

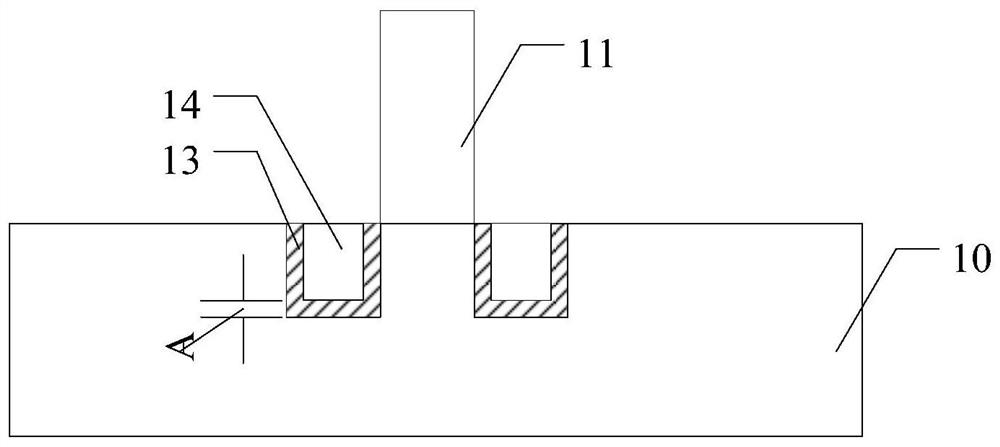

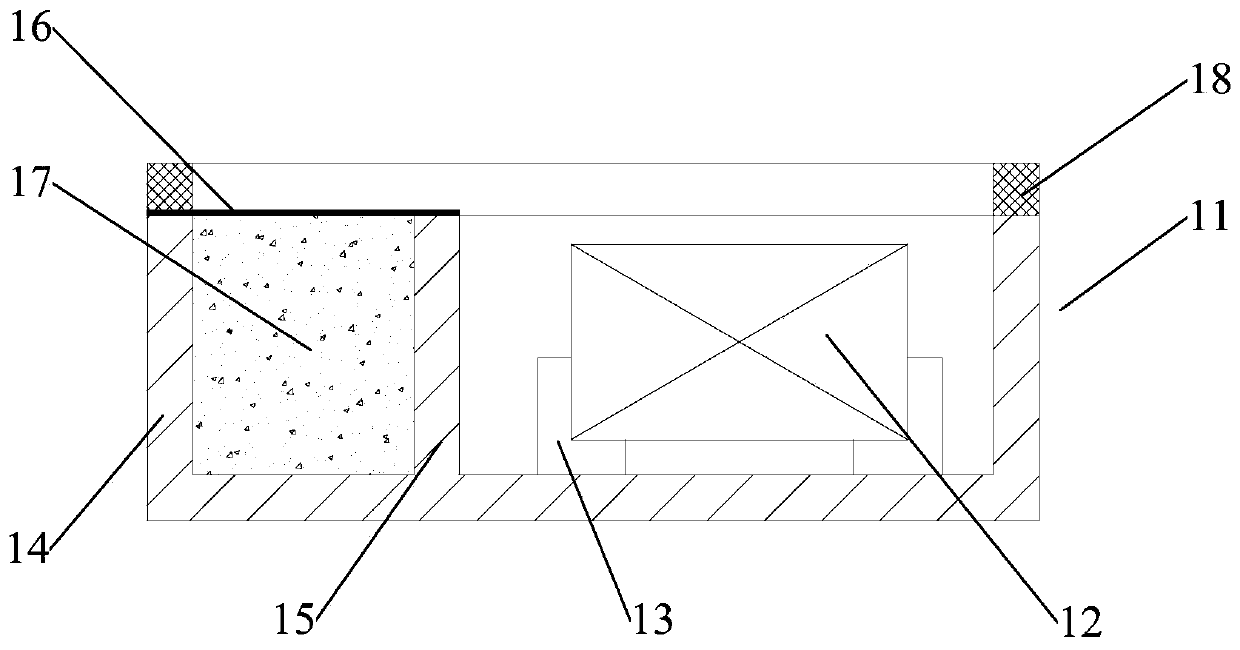

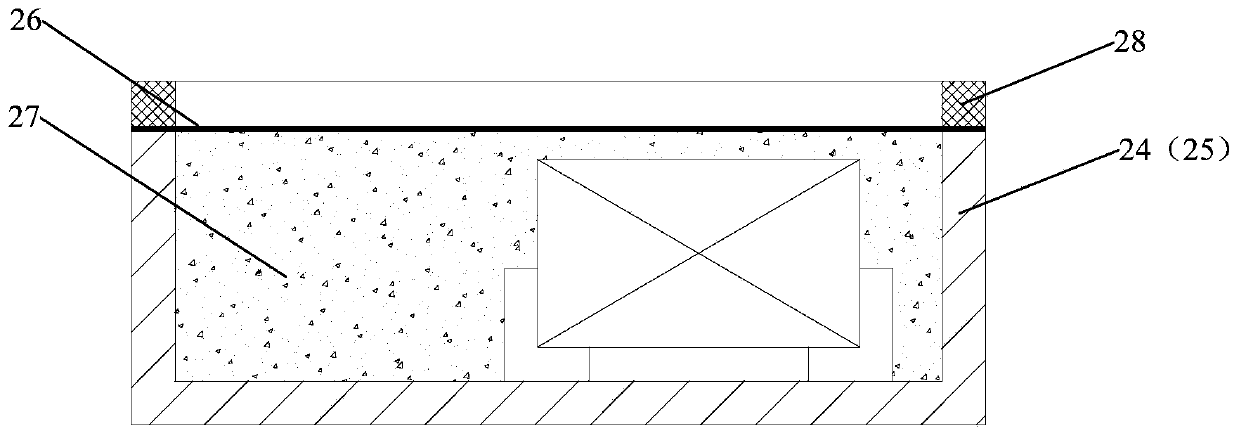

Prefabricated comprehensive pipe gallery

ActiveCN107313452AReasonable forceReduced sidewall thicknessArtificial islandsHydro energy generationUtility tunnelSelf weight

The invention provides a prefabricated comprehensive pipe gallery which is formed in the manner that multiple pipe gallery prefabricated units are longitudinally spliced. Each pipe gallery prefabricated unit comprises a top plate and a bottom plate, wherein the top plate and the base plate are parallel and arranged in a spaced manner. The two sides of each pipe gallery prefabricated unit are provided with arc side walls which are connected with the top plate and the bottom plate in a seal manner. The prefabricated comprehensive pipe gallery solves the problems that in the prior art, construction of the cast-in-place technology is slow, the construction quality is difficult to guarantee, a rectangular cross section is large in dead load in the prefabricating technology, transportation and installation are inconvenient, and cost is high. According to the prefabricated comprehensive pipe gallery, the arc side walls are adopted to optimize the stress of the comprehensive pipe gallery, the dead load and cost of the comprehensive pipe gallery are reduced, the durability of the comprehensive pipe gallery is improved, and the construction quality is easy to guarantee.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Method of fabricating flash memory device

InactiveUS7125769B2Improve featuresReduced sidewall thicknessTransistorSolid-state devicesEngineeringPre treatment

Owner:SK HYNIX INC

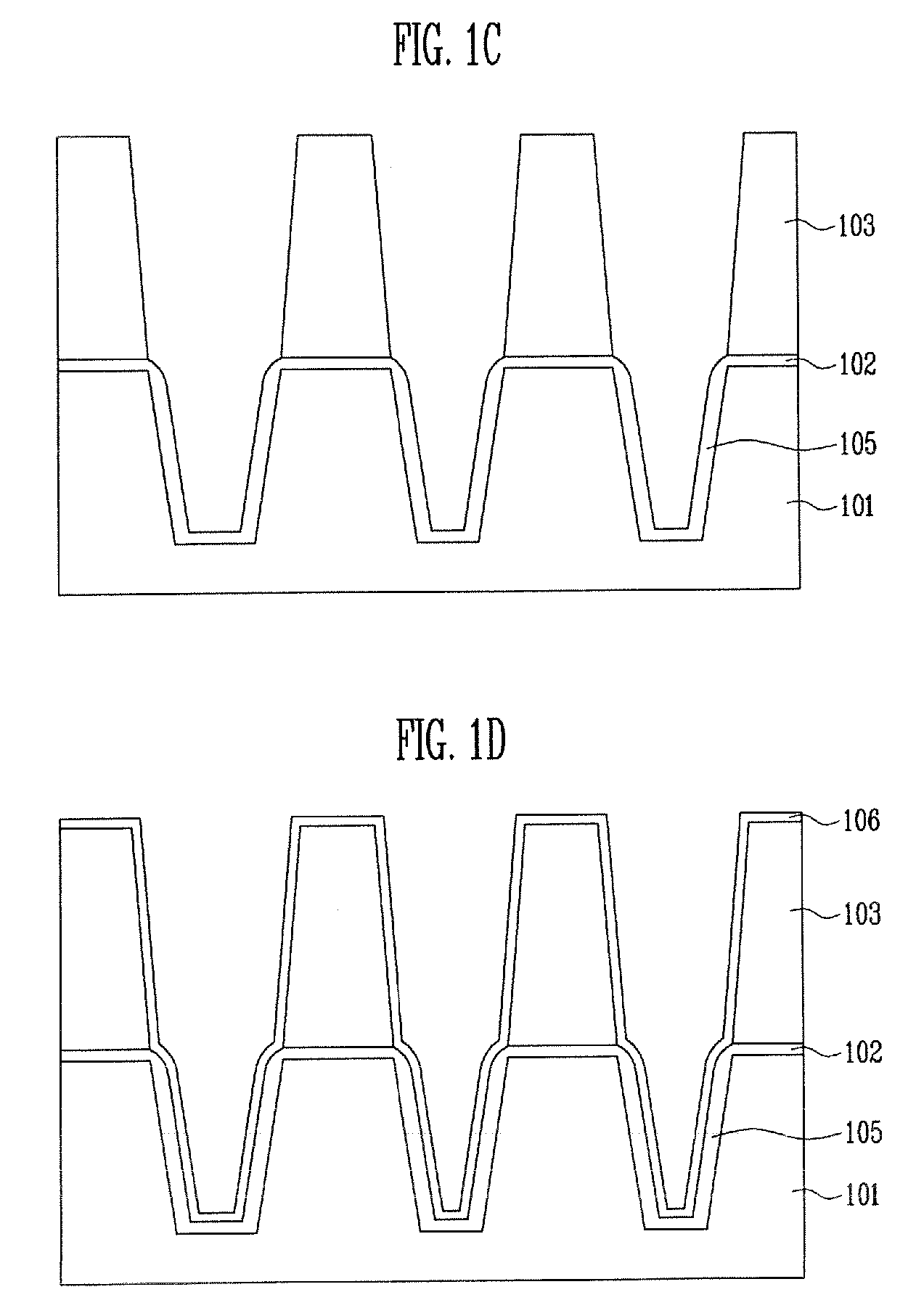

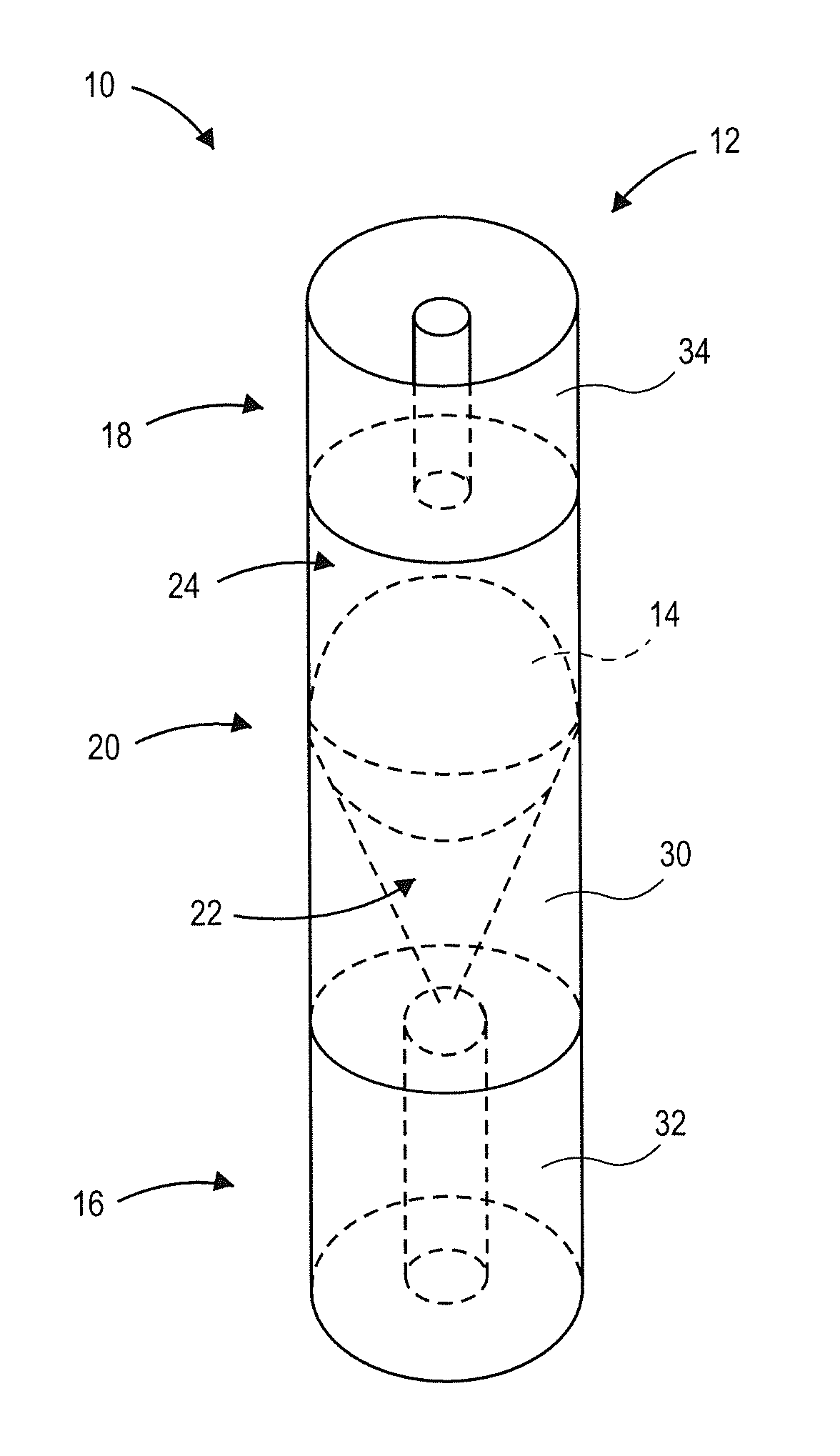

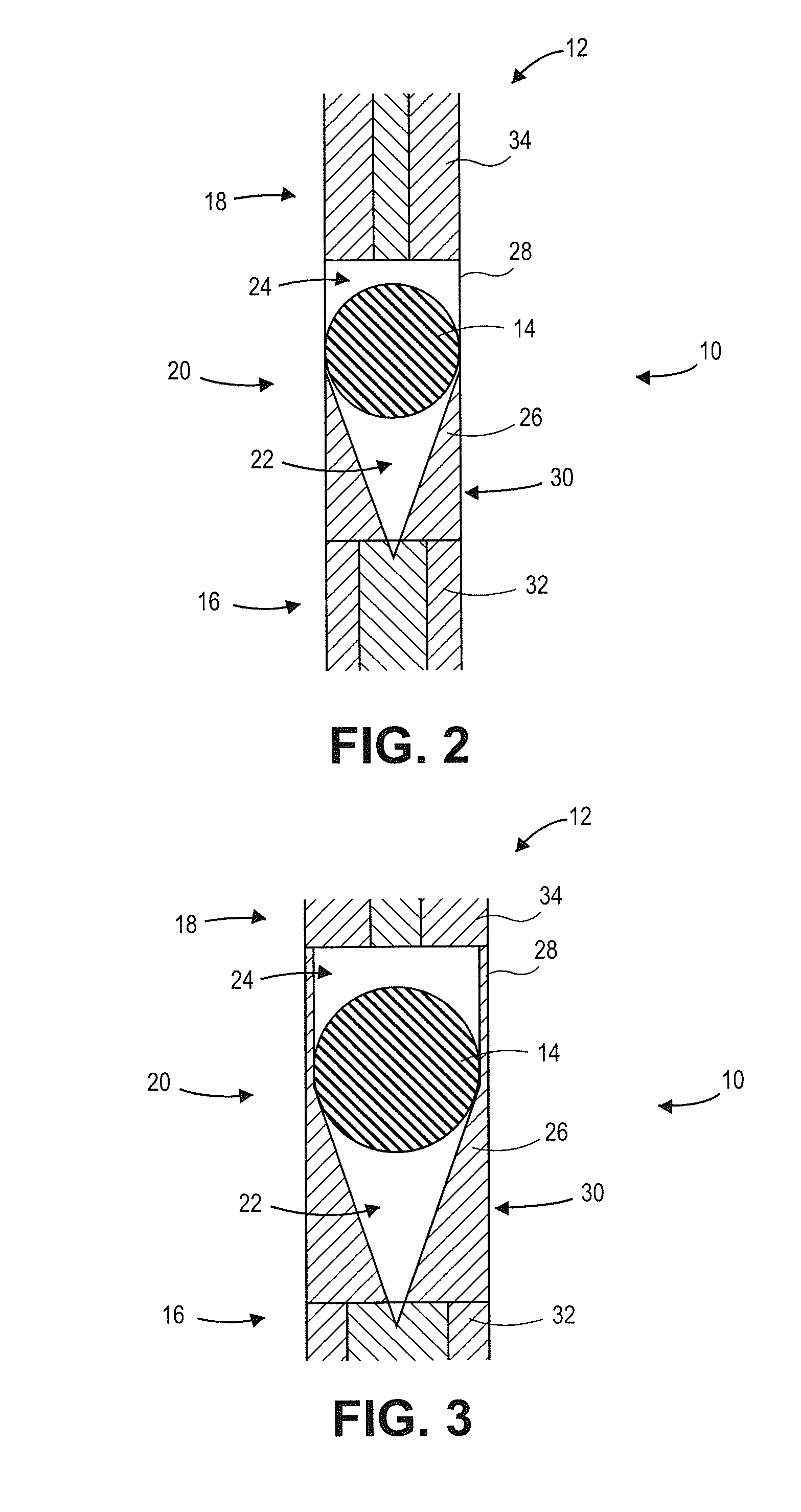

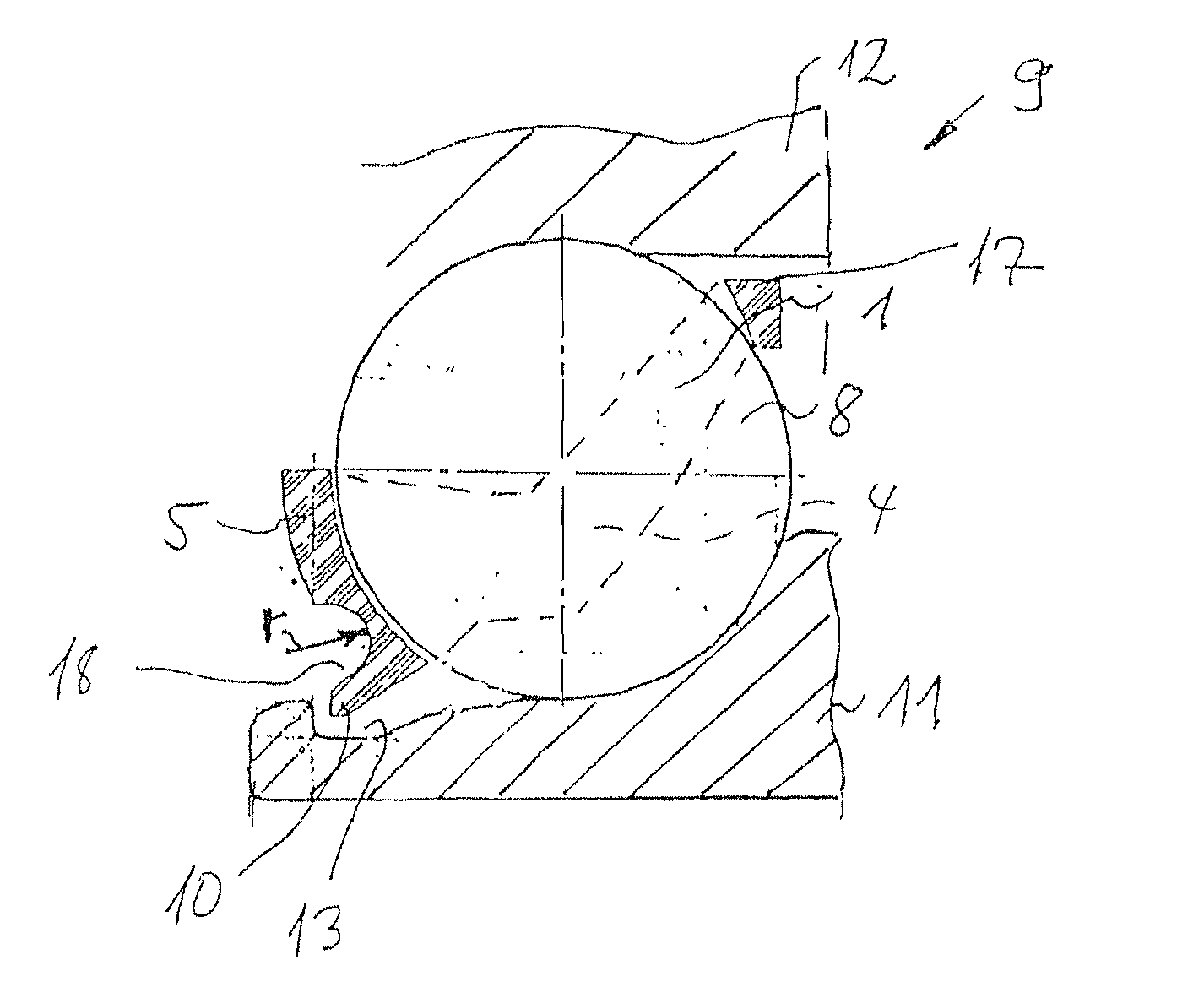

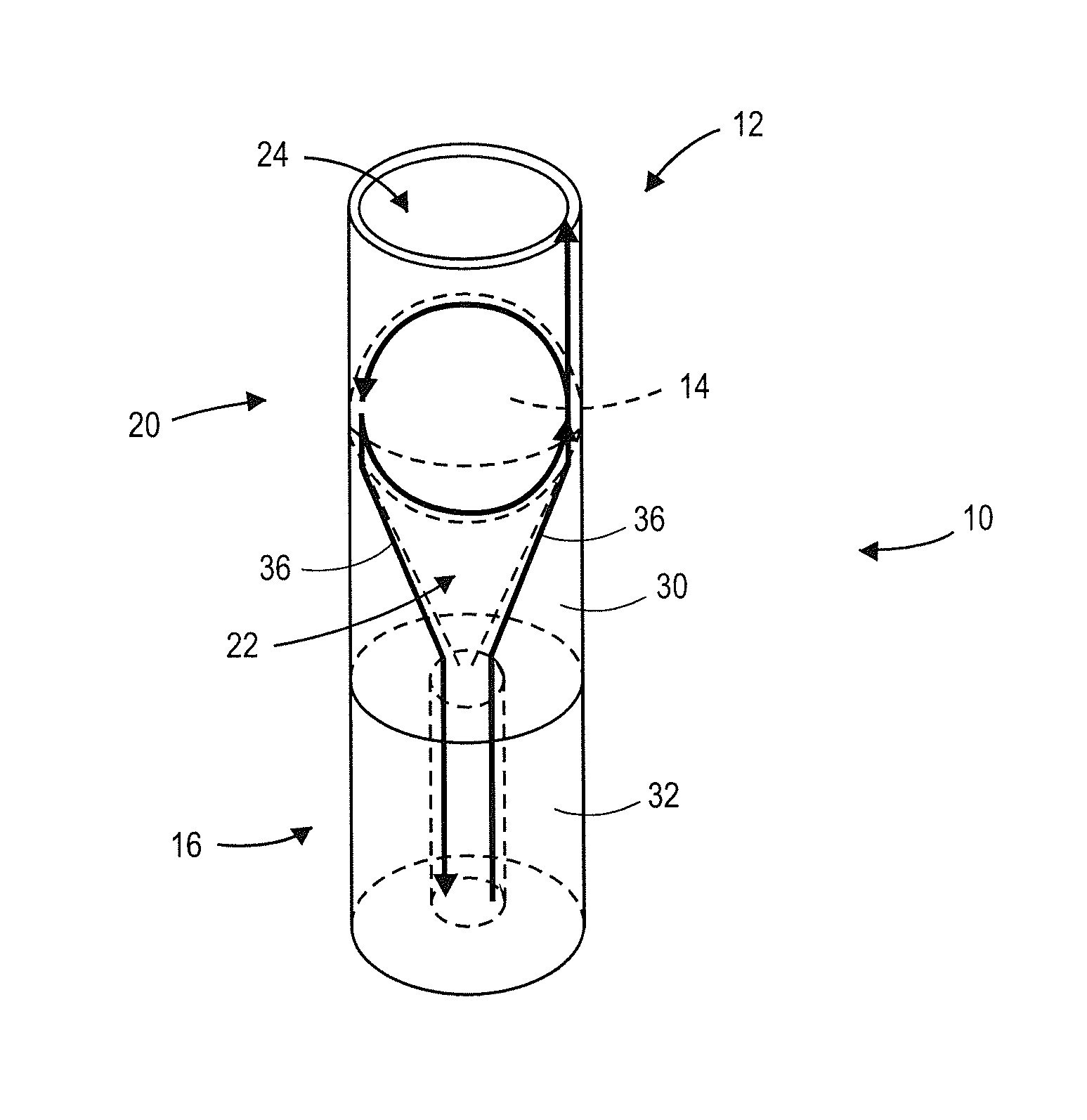

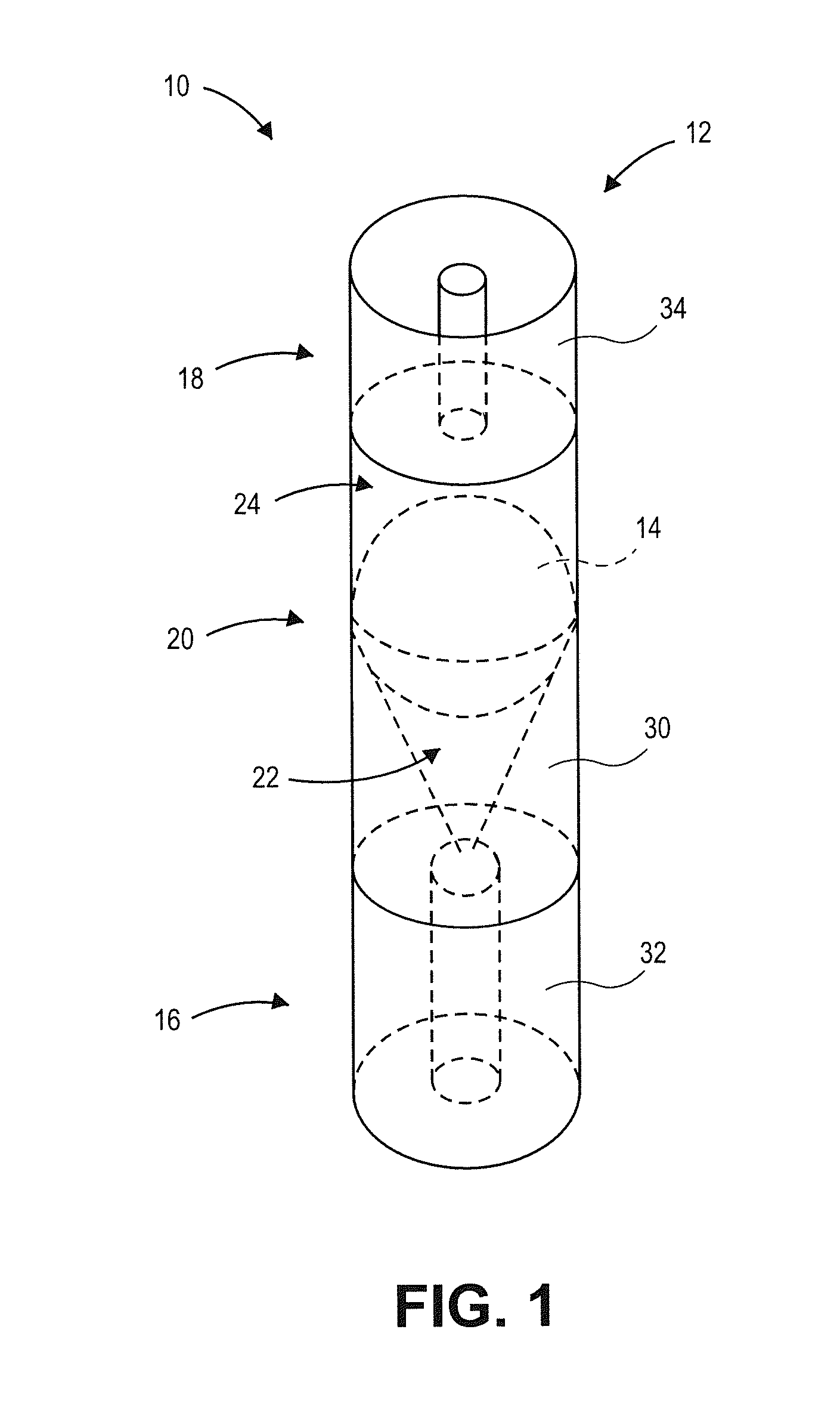

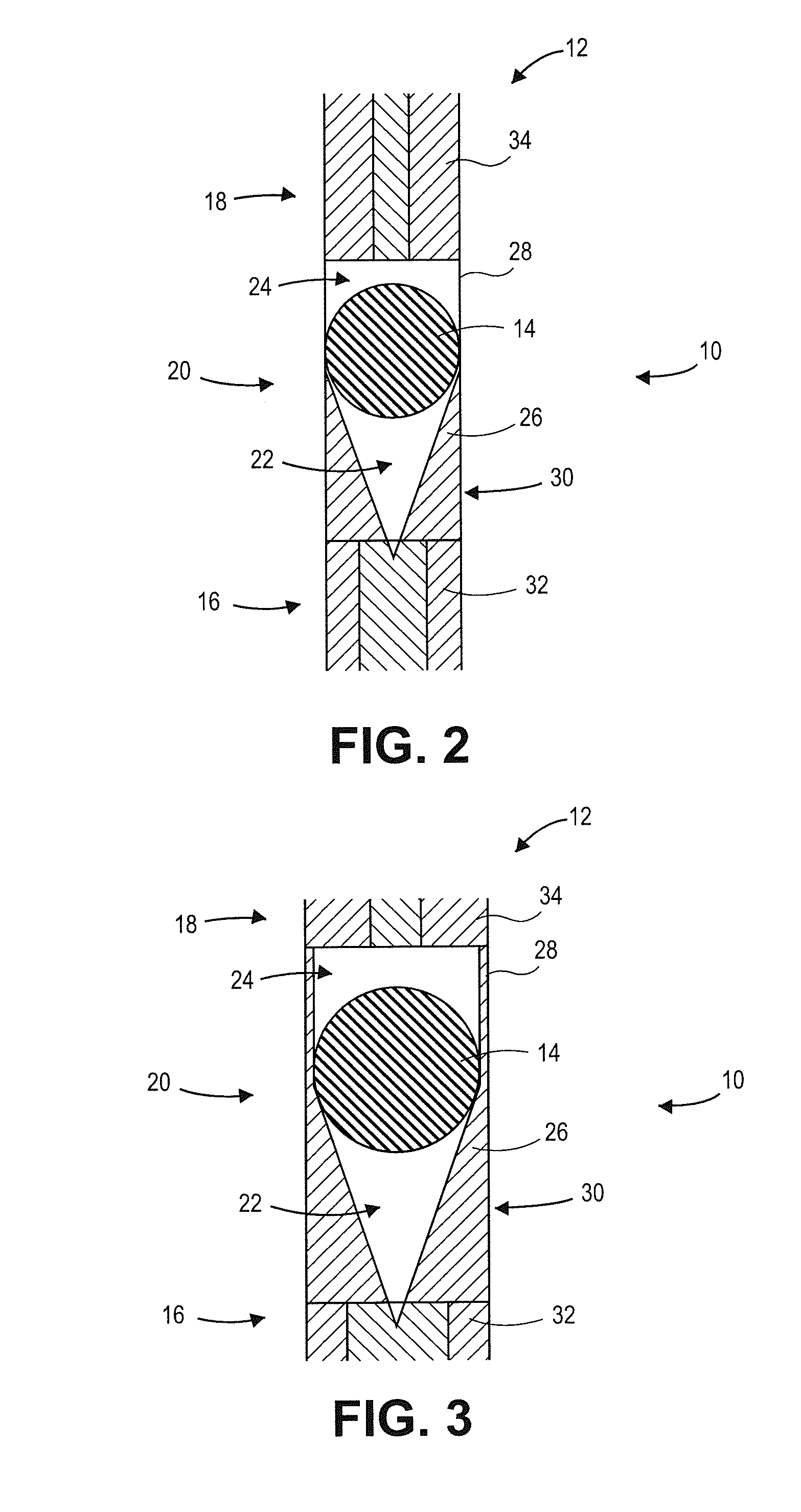

Capillary wall coupled whispering gallery mode microresonator

ActiveUS20140314375A1Reduced sidewall thicknessCoupling light guidesMetal working apparatusWhispering galleryMicrosphere

A microresonator structure comprises a waveguide and a microsphere. The waveguide is of elongated cylindrical shape and includes a first section of optical transmission material and a cavity section axially aligned with the first section. The cavity section includes a first cavity and a second cavity. The first cavity is adjacent to the first section and includes a first sidewall of optical transmission material with an inner surface that tapers inward to an apex positioned adjacent to the first section. The second cavity is positioned adjacent to the first cavity of hollow cylindrical shape and includes a circumferential second sidewall of optical transmission material that abuts the first sidewall. The microsphere has a spherical outer surface and is positioned within the cavity section such that the outer surface contacts a portion of the first sidewall and a portion of the second sidewall.

Owner:UNIVERSITY OF MISSOURI

Monocrystalline silicon crucible

InactiveCN108330532AImprove stress toleranceExtended service lifePolycrystalline material growthBy pulling from meltMonocrystalline siliconCarbon composites

The invention discloses a monocrystalline silicon crucible, which comprises a crucible part, wherein the crucible part is configured into a quartz containing crucible; the crucible part comprises a first crucible unit, a second crucible unit and hole units; the first crucible unit is arranged at the bottom of the crucible part; the second crucible unit is connected with the first crucible unit andforms the side wall of the crucible part; the hole units are arranged at the second crucible unit and are communicated with the inside and outside space of the crucible part; the proportion of the hole units in the circumference direction of the second crucible unit is gradually increased from one side of the bottom of the crucible part to the other side. Carbon-carbon composite materials are used as the crucible side wall, so that the side wall thickness is reduced; the crucible volume is increased; the yield of monocrystalline silicon is improved; through the arrangement of the side wall hole units, the heat transfer of a heater heating body on the quartz crucible and a silicon melt can be improved; through the arrangement of the hole units with different sizes, different shapes or different distribution densities, the temperature gradient distribution inside the silicon melt can be effectively controlled; the convection of the silicon melt is controlled, so that the oxygen contentof the monocrystalline silicon is reduced.

Owner:周俭

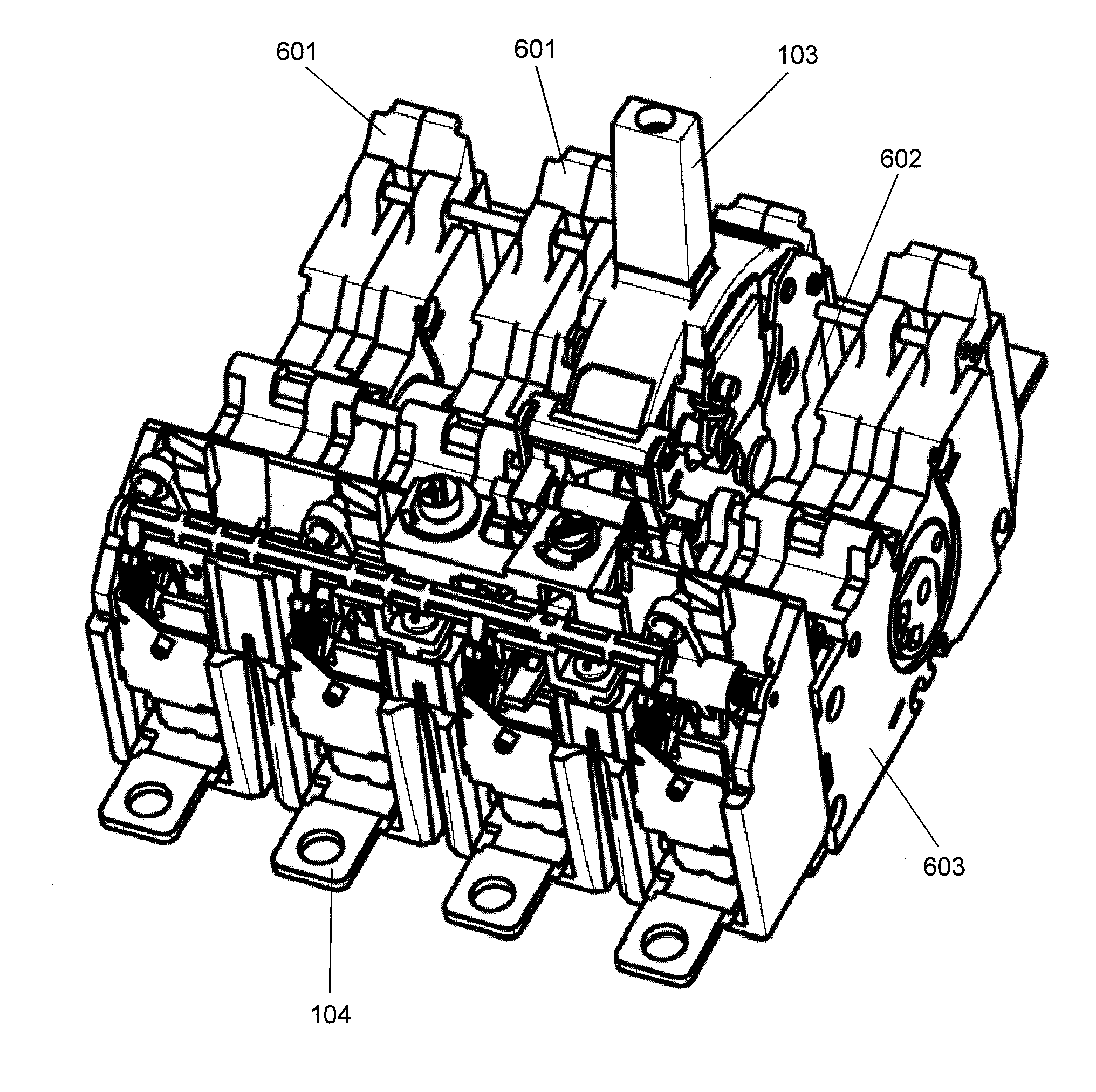

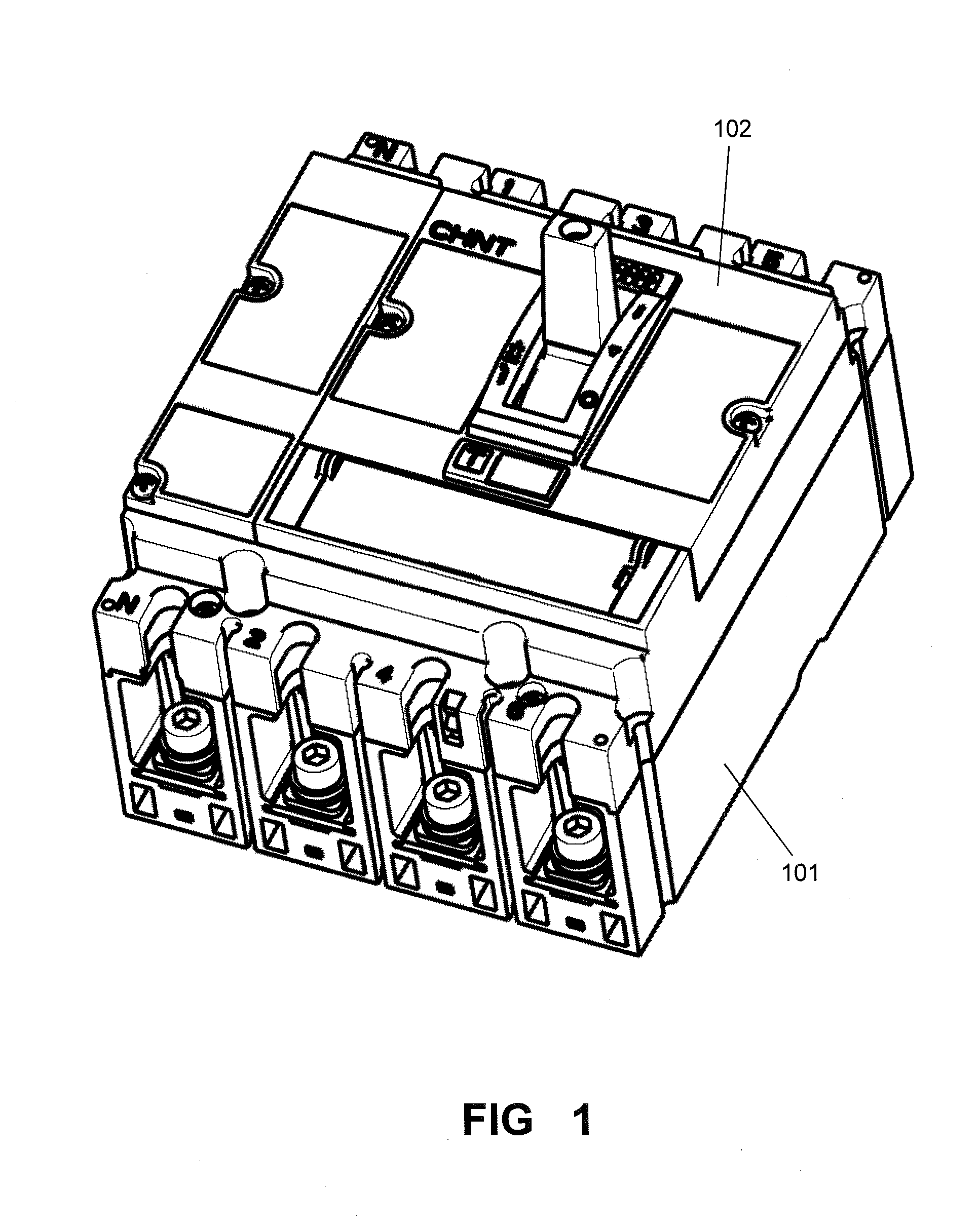

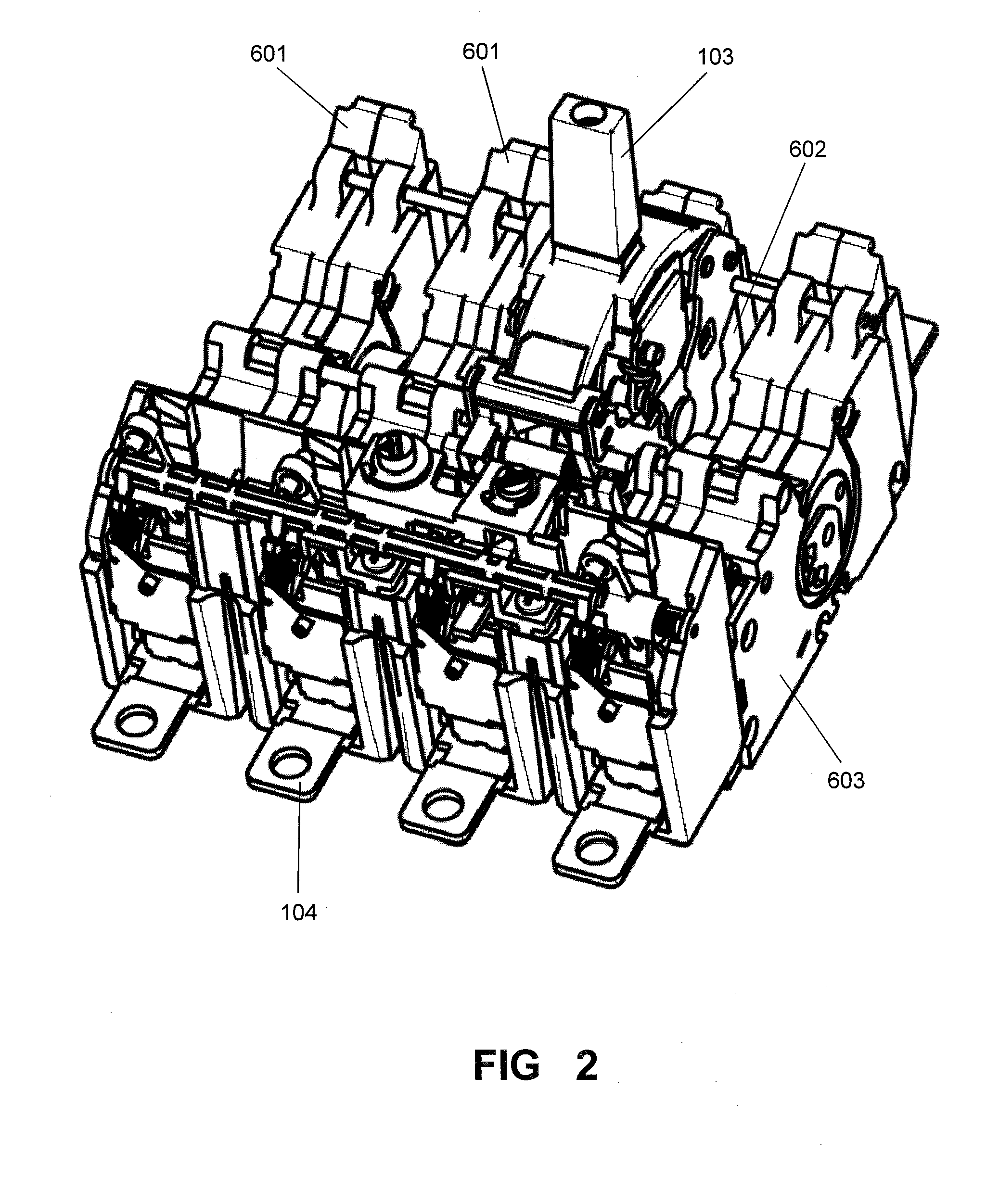

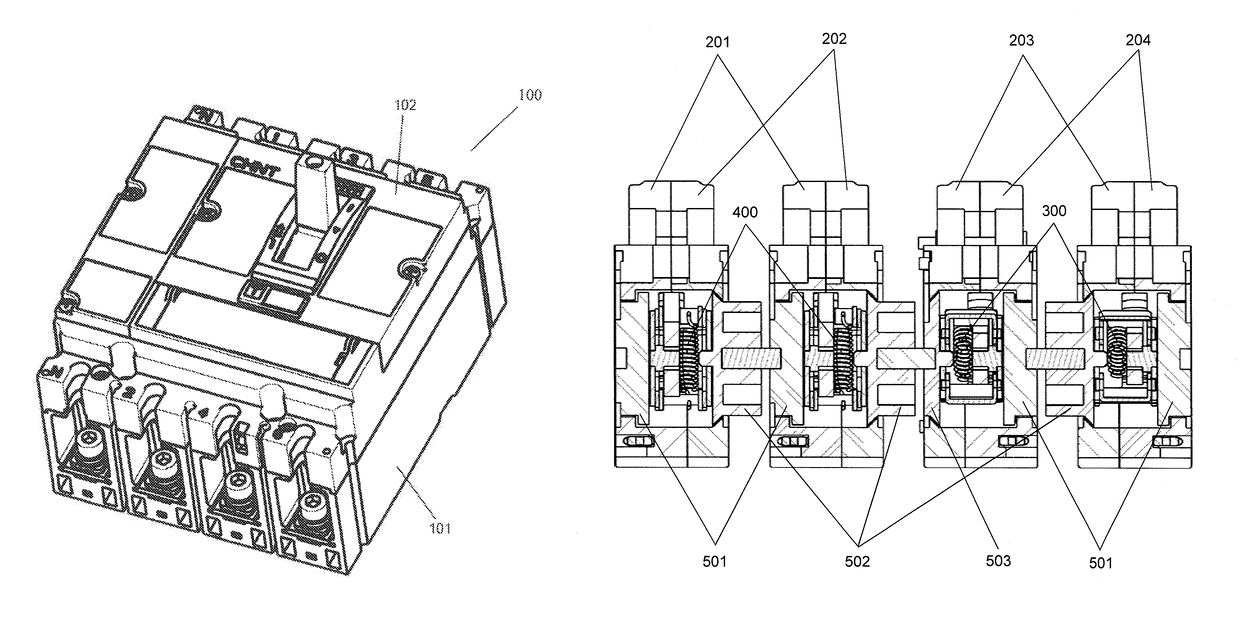

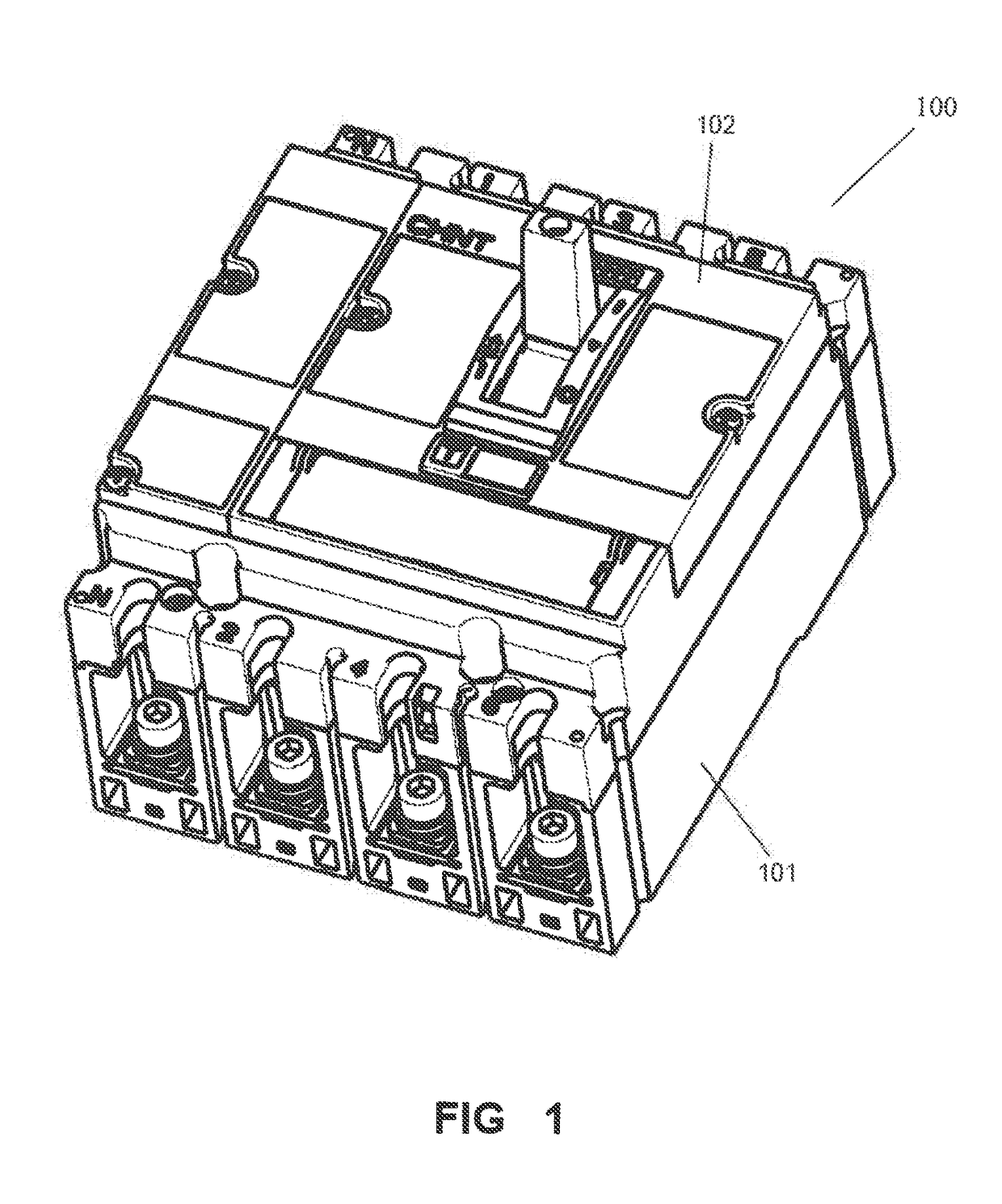

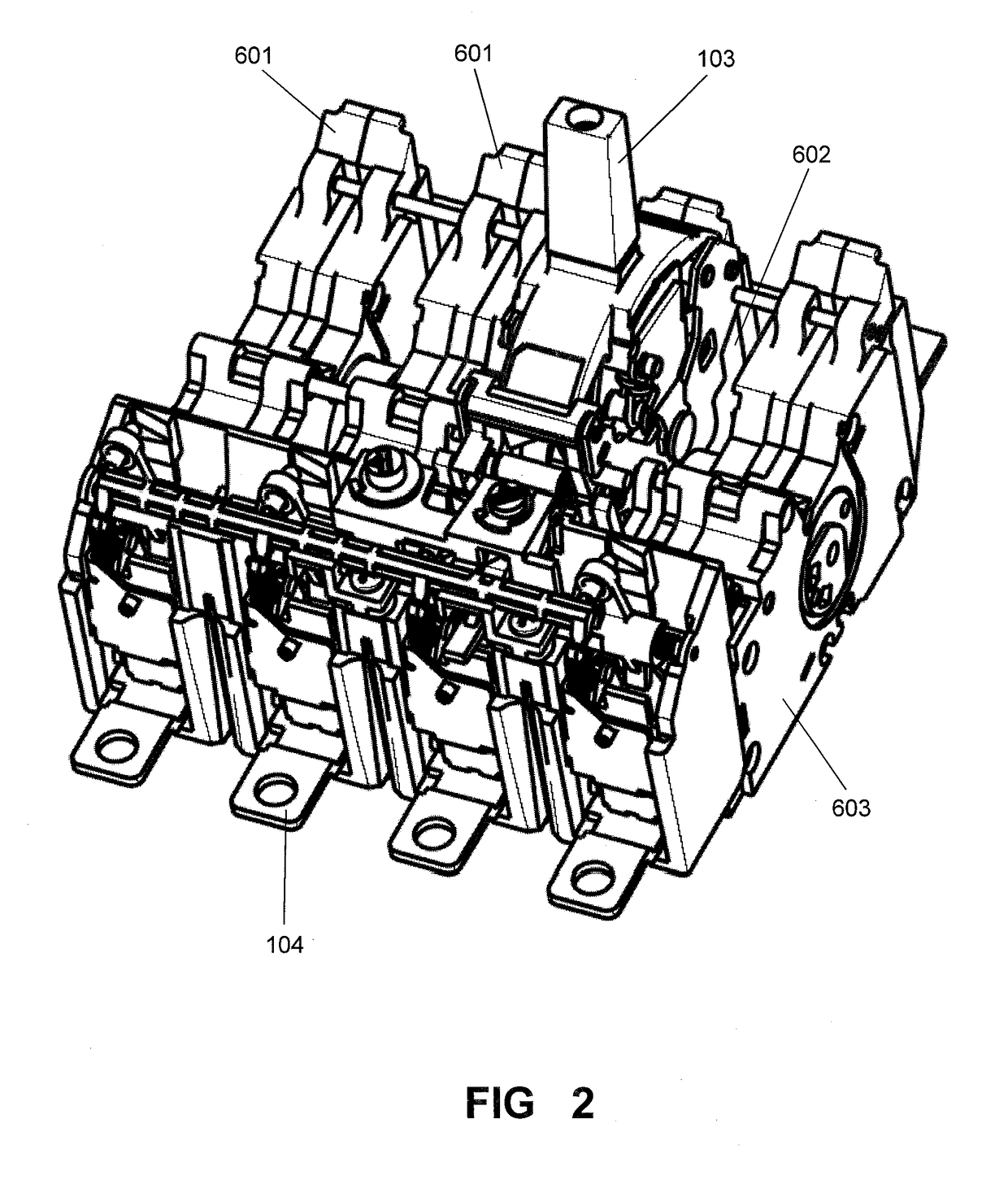

Contact module for circuit breaker

ActiveUS20160233038A1Reduced sidewall thicknessReduced dimensionProtective switch detailsCircuit-breaking switches for excess currentsEngineeringCircuit breaker

The present invention discloses a contact module for circuit breaker. The contact module comprises: a base, a cover, an operation mechanism, three kinds of single-pole switches and a release mechanism. The cover is mounted on the base to form an accommodation space, the operation mechanism, the three kinds of single-pole switches and the release mechanism are disposed in the accommodation space. The operation mechanism is connected to one kind of the single-pole switch, the release mechanism is connected to the three kinds of the single-pole switches. All of the three kinds of single-pole switches are asymmetrical. Each kind of single-pole switch comprises a strong side and a weak side, for each kind of single-pole switch, a contact housing on the strong side is thick and is connected to a thick shaft, a contact housing on the weak side is thin and is connected to a thin shaft. A rotor component in each kind of single-pole switch only has a single contact spring and the single contact spring is mounted on the weak side. Rotation shafts of adjacent single-pole switches are connected by a linkage shaft so that the single-pole switches are connected, a strong side of one single-pole switch is connected to a weak side of another single-pole switch.

Owner:SEARI ELECTRIC TECH +1

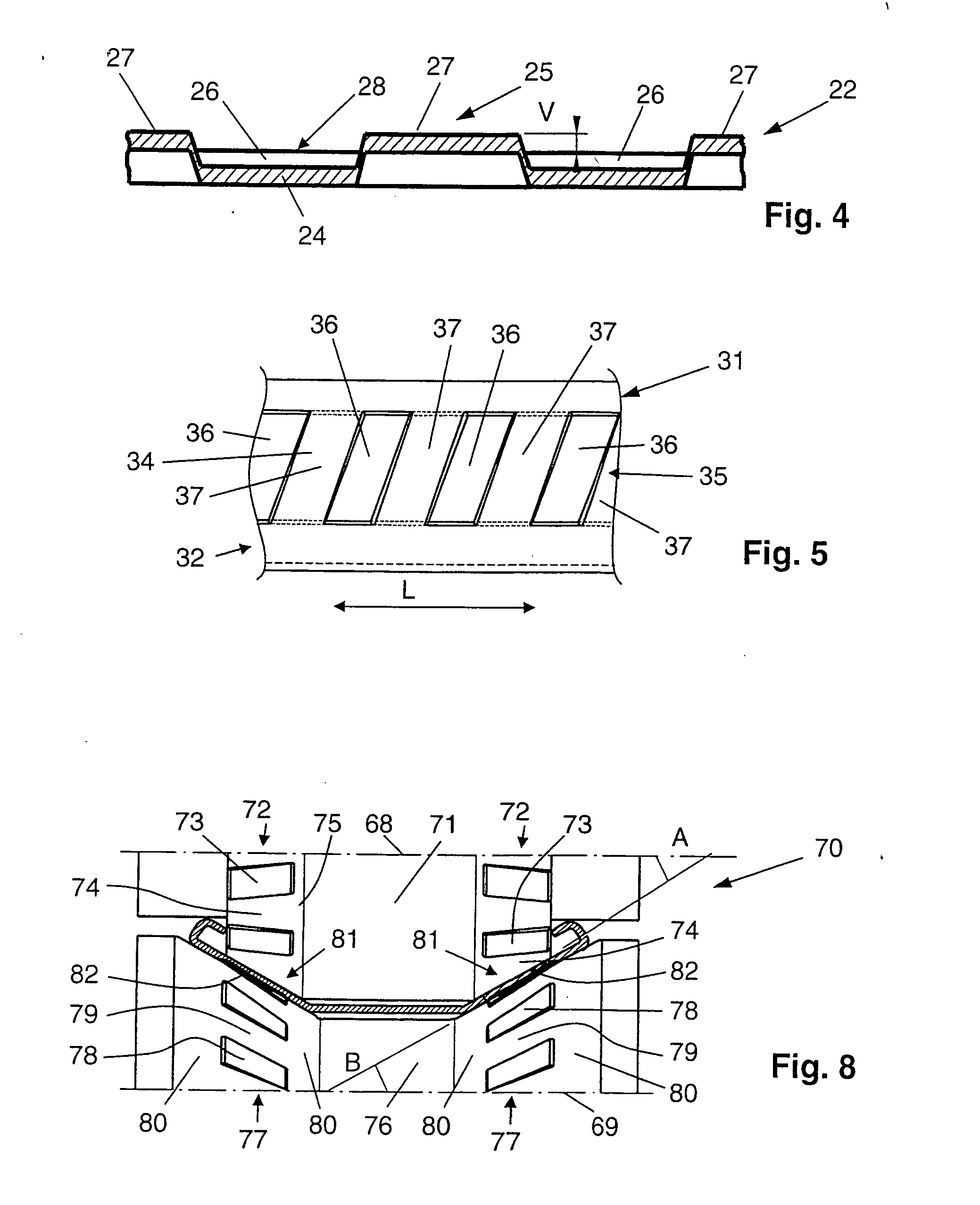

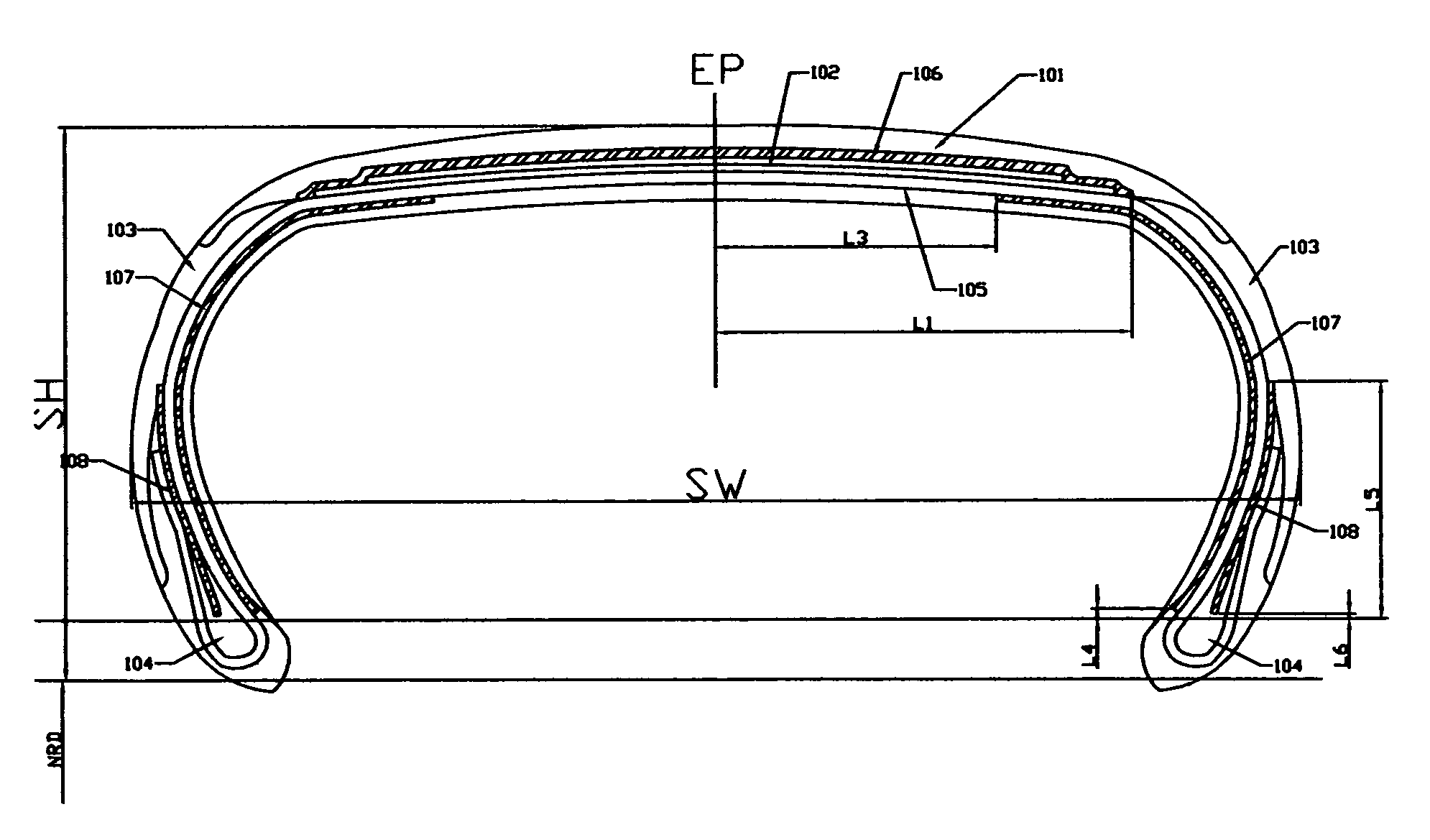

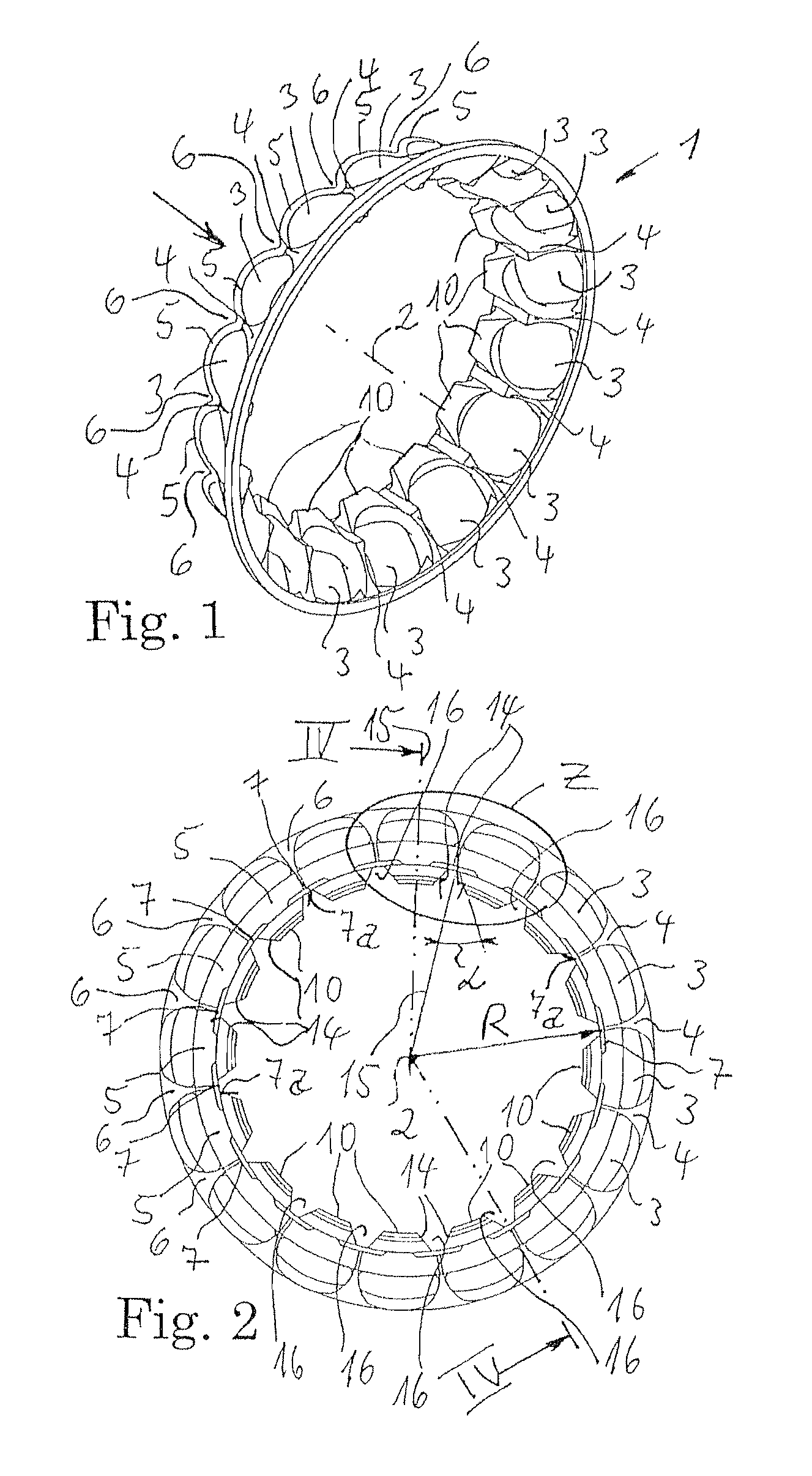

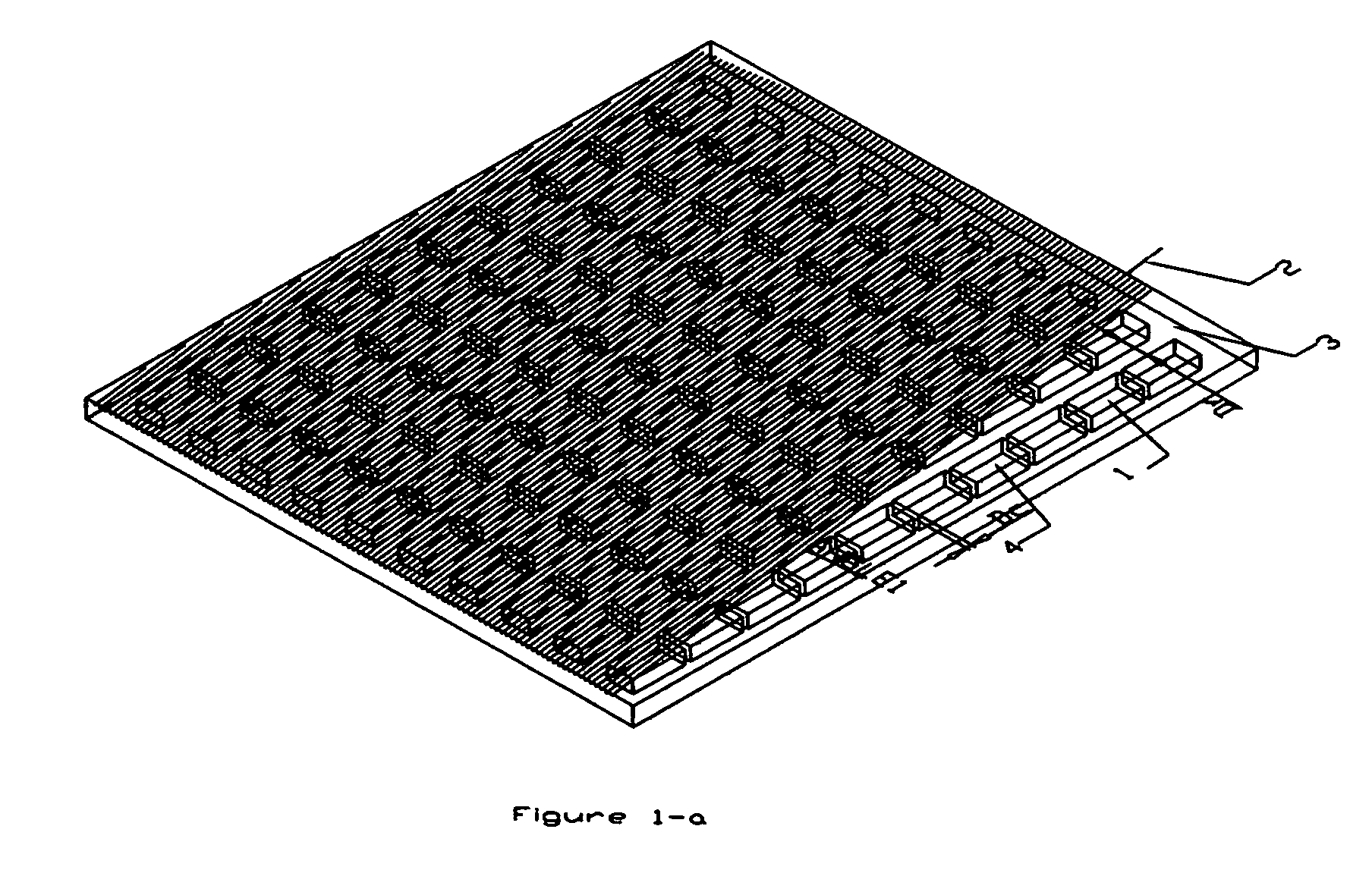

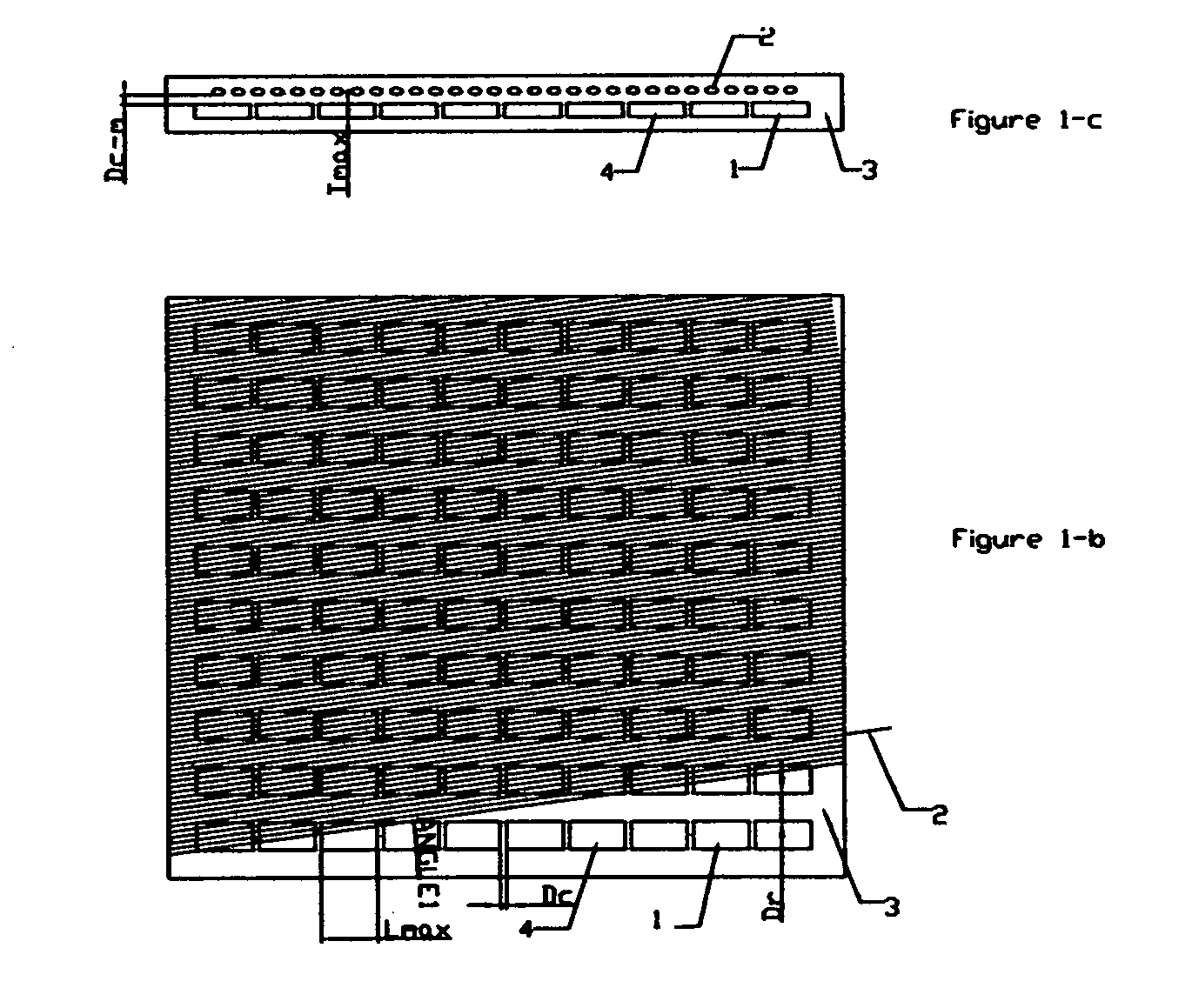

Safety tire including composite sheet with confined flexibility

InactiveUS7506675B2Low modulusLarge deformationWithout separate inflatable insertsLayered productsPliabilityComposite plate

A composite sheet has confined flexibility and is used in a safety pneumatic tire which is self-supporting under zero inflation pressure. The composite sheet comprises a matrix of high modulus solid objects, low modulus material, and optionally a matrix of cords, the high modulus solid objects being assembled to form a mechanism which allows the composite sheet to bend easily within predetermined ranges and confines the composite sheet from further bending when the limits of the predetermined ranges are reached. The safety pneumatic tire comprises a pair of the composite sheets disposed at sidewall regions under a carcass and / or a layer of the composite sheet disposed above a belt package. A method of making the composite sheet includes forming a chain of the high modulus solid objects having a desired locking position.

Owner:SU LIFENG +1

Rim sprocket for chain saw

ActiveUS7044025B2Reduce the amount of metalSmall portalMetal sawing devicesMetal sawing accessoriesPorosityGram

Batch casting of rim sprockets for chain saws as particularly applied to larger rim sprockets experience undesired high scrap rate resulting from porosity and chip-out. The solution is to ensure flow of molten steel throughout solidification of the molten steel in the sprocket mold while retaining molten steel portals or gates of a size that permits breakaway of portal stems. Such enhances the cooling rate of the molten steel in the sprocket mold which was found beneficial. The objective of reduced scrap rate is thus accomplished by maintaining a ratio of mass to surface area of the sprockets being cast to no greater than about 4 grams of material to each square inch of surface area and alternatively provide through bores through the rim sprockets which additionally assist in wood chip removal. This design also reduces the material content which reduces the cost and weight of the product.

Owner:OREGON TOOL INC

Cage for inclined ball bearings

ActiveUS20070189651A1Inexpensive to manufactureMeet the requirementsBall bearingsBearing componentsRotational axisEngineering

Owner:SCHAEFFLER TECH AG & CO KG

Energy absorbing component

ActiveUS9259995B2Improving passenger safetyReduced sidewall thicknessPedestrian/occupant safety arrangementSuperstructure subunitsEngineeringMechanical engineering

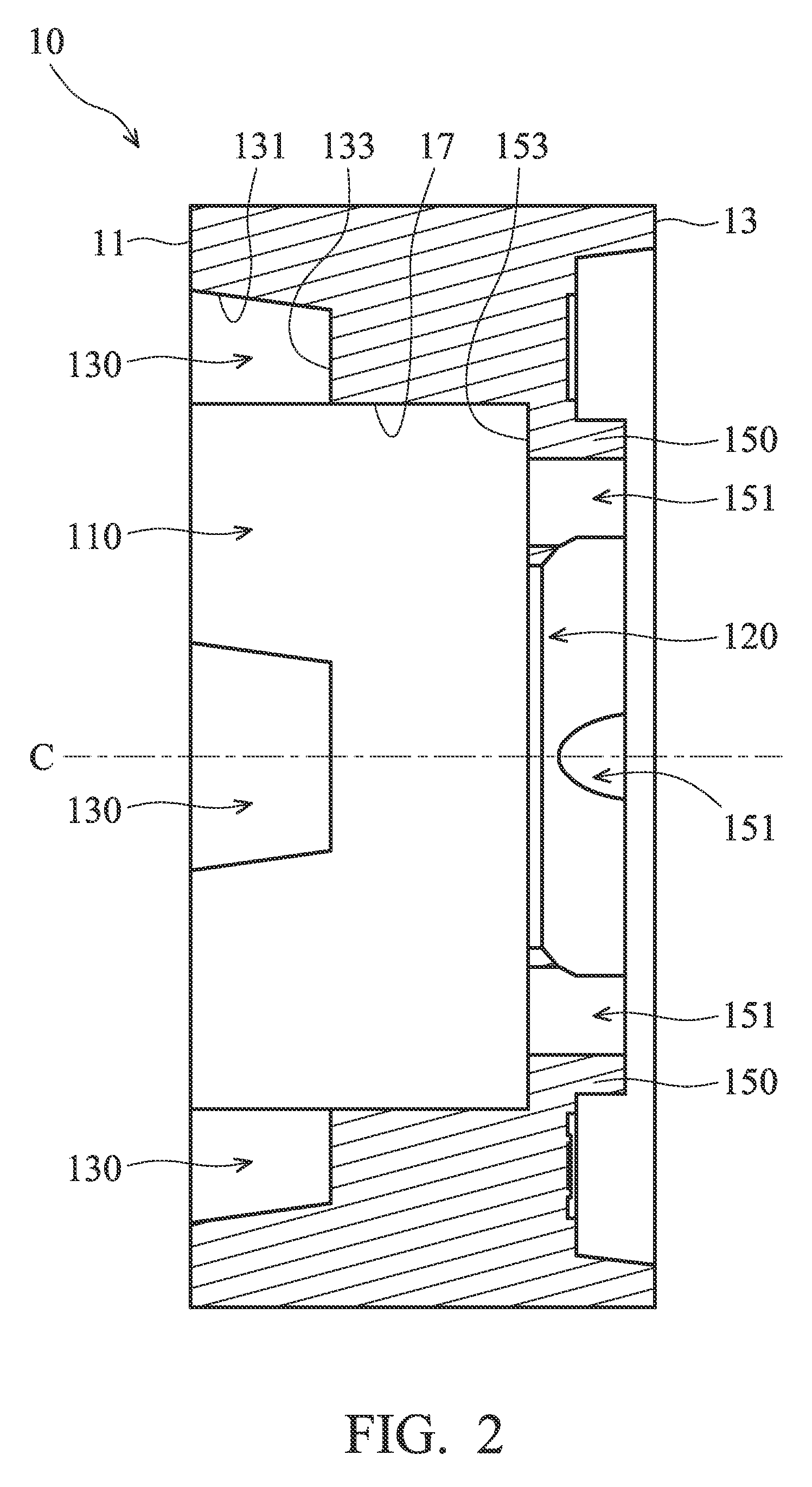

An energy absorber for improving passenger safety in a vehicle during an impact to the vehicle, the energy absorber comprising a hollow body having a base defining a proximal end of the body, the base being configured to affix the body to a portion of the vehicle, the body further including a sidewall extending from the base and terminating in a distal end of the body, the sidewall having an interior surface and an exterior surface, the interior surface including a portion defining an interior step transition, the exterior surface including a portion defining an exterior step transition, the interior and exterior step transitions being provided at locations axially offset from each other along the sidewall.

Owner:TOYOTA JIDOSHA KK

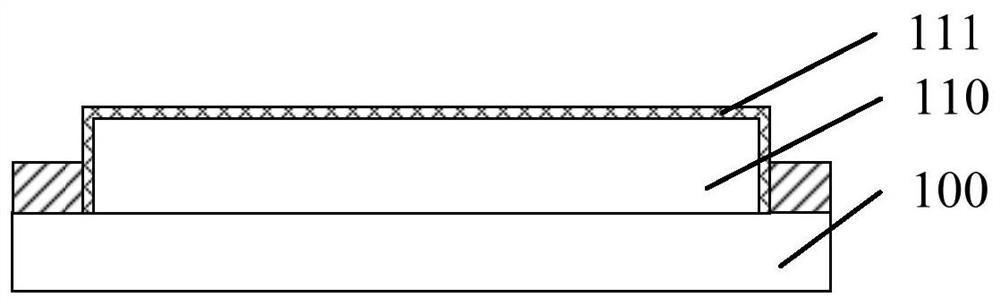

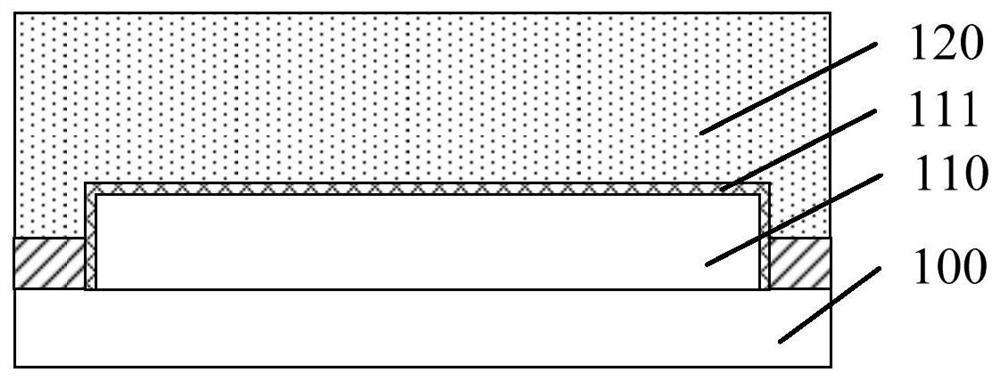

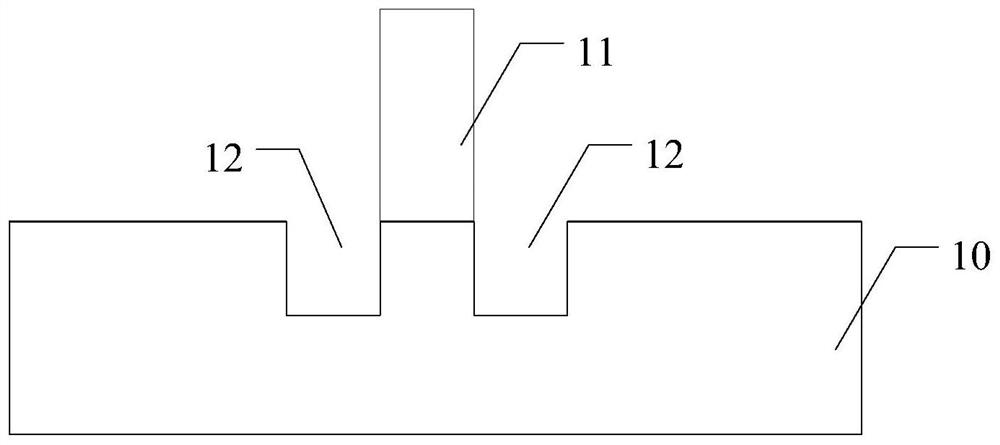

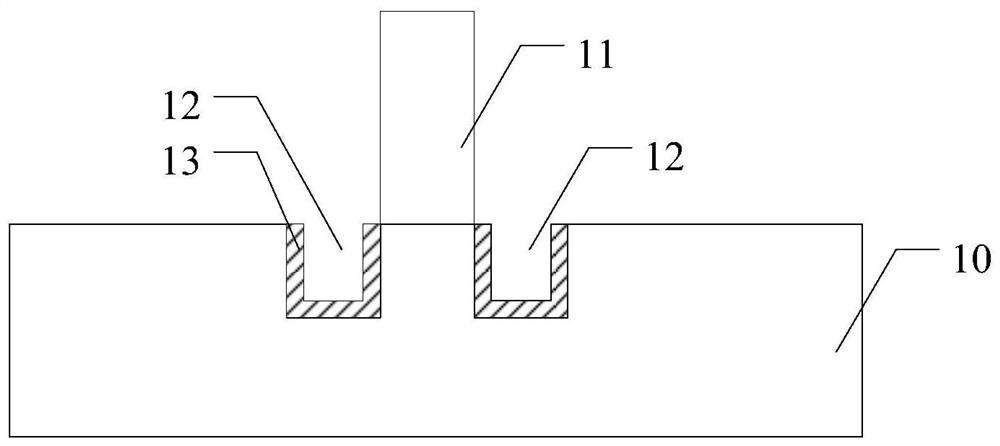

Semiconductor structure and forming method thereof

PendingCN113745108AImprove electrical performanceReduce etch rateSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureStructural engineering

The invention discloses a semiconductor structure and a forming method thereof, and the method comprises the steps: providing a substrate which is provided with a fin part; forming a dummy gate structure across the fin part on the substrate, wherein the surface of the side wall of the dummy gate structure is provided with a second protection layer; carrying out modification treatment on the second protective layer to enable the second protective layer to form a second modified layer; and carrying out a cleaning process. By selecting proper modification treatment, the etching rate of the second modification layer is within a preset range in the cleaning process, that is, the etching rate of the cleaning process on the second modification layer is relatively low, so that the size degree of thickness reduction of the side wall of the dummy gate structure is relatively low, the change of the included angle of a corner area at the junction of the fin part and the dummy gate structure is small, and the electrical performance of the formed semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

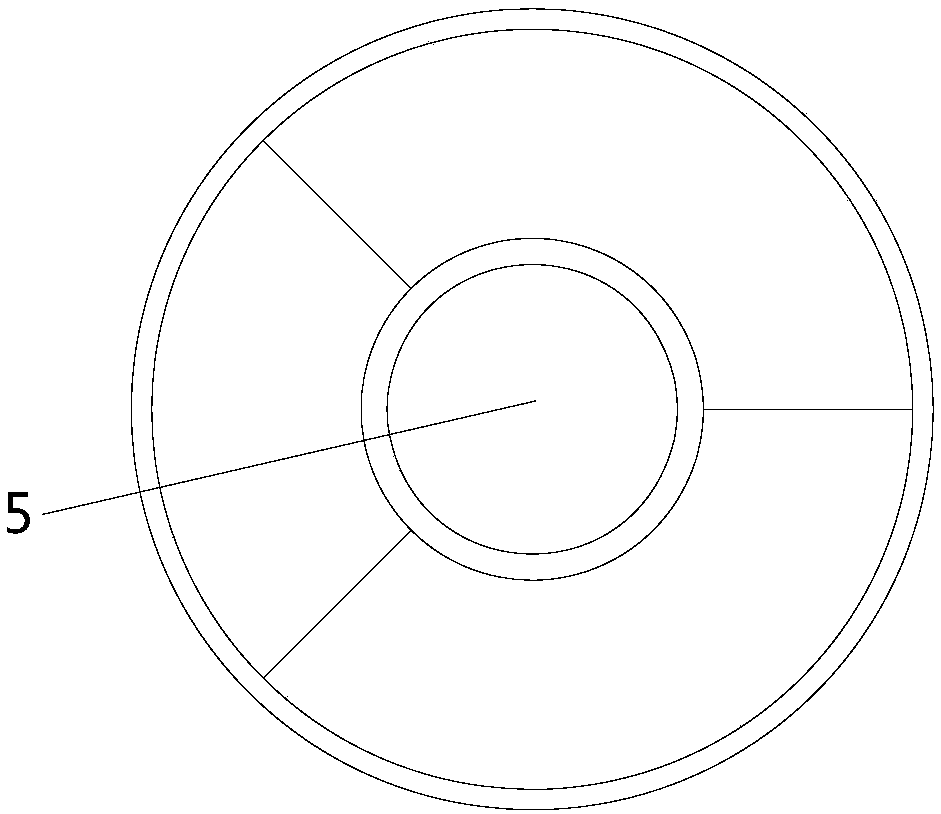

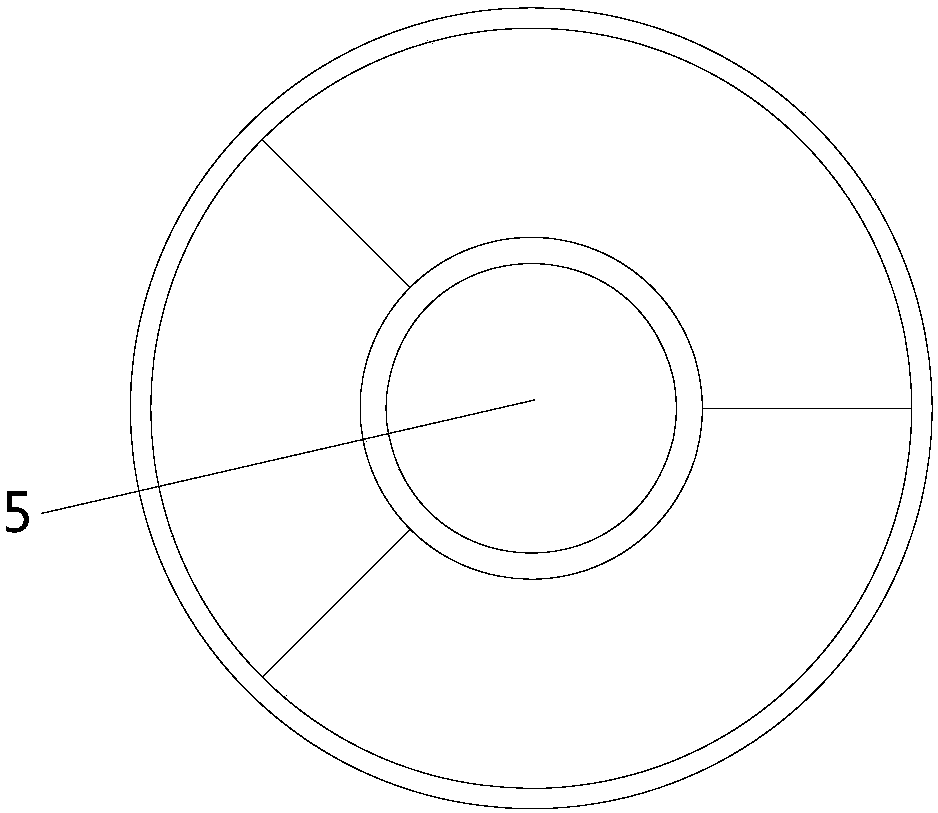

Monocrystal silicon crucible

InactiveCN108396373AImprove stress toleranceExtended service lifePolycrystalline material growthBy pulling from meltMonocrystalline siliconSegment structure

The invention discloses a monocrystal silicon crucible. The monocrystal silicon crucible comprises a crucible part body which is configured to store a quartz crucible, wherein a crucible part comprises a first crucible unit, a second crucible unit and hole units; the first crucible unit is configured to be the bottom of the crucible part and is enclosed by segments of at least two parts; a throughhole is formed in the center of the first crucible unit; the second crucible unit is connected with the first crucible unit to form a side wall of the crucible part; the hole units are arranged on the second crucible unit and are used for communicating inner and outer spaces of the crucible part; the ratio of the hole units on the second crucible unit in the peripheral direction is gradually increased from one side of the bottom of the crucible part to the other side. According to the monocrystal silicon crucible, the crucible part body is set to be a two-section type structure and the through hole is formed in the center of the bottom; when the crucible is heated, stress caused by an inner quartz crucible is concentrated; meanwhile, the bottom is enclosed by a segment structure and the crucible is convenient to detach; the thickness of a side wall of the crucible is reduced so that the capacity of the crucible is enlarged; the crucible has the advantages of effectively controlling the oxygen content of monocrystal silicon, the yield of the monocrystal silicon and the like.

Owner:周俭

Contact module for circuit breaker

ActiveUS9704675B2Reduced sidewall thicknessReduced dimensionEmergency springsHigh-tension/heavy-dress switchesCircuit breakerEngineering

A contact module for a circuit breaker is disclosed, comprising: a base, a cover, an operation mechanism, at least three kinds of asymmetrical single-pole switches and a release mechanism. The cover is mounted on the base to form a space, where the mechanisms and the switches are disposed. The operation mechanism is connected to one switch; the release mechanism to the at least three switches. Each switch comprises a strong side and a weak side. For each switch, there is a thick contact housing on the strong side connected to a thick shaft, and a thin one on the weak side connected to a thin shaft. A rotor component has a single contact spring mounted on the weak side. Rotation shafts are connected by a linkage shaft to connect the single-pole switches; a strong side of one switch is connected to a weak side of another switch.

Owner:SEARI ELECTRIC TECH +1

Composite sheet with confined flexibility and safety tire

InactiveUS20050008843A1Improve securityComparable comfortnessWithout separate inflatable insertsLayered productsPliabilityPuncture resistance

This invention discloses a composite sheet with confined flexibility, a method of making it and a safety tire in which said composite sheet of present invention is used. Said composite sheet comprises a mechanism embedding in rubber. Said mechanism allows the composite sheet bend easily within predetermined ranges and confines the composite sheet from further bending when the limits of said predetermined ranges are reached. Said safety tire comprises a pair of said composite sheets disposing at sidewall regions and a layer of said composite sheet disposing above belt package. Said safety tire has high puncture-resistance and comparable riding comfortness over conventional tire. Said safety tire is self-supporting and still provides good maneuverability to vehicle under zero inflation pressure.

Owner:SU LIFENG +1

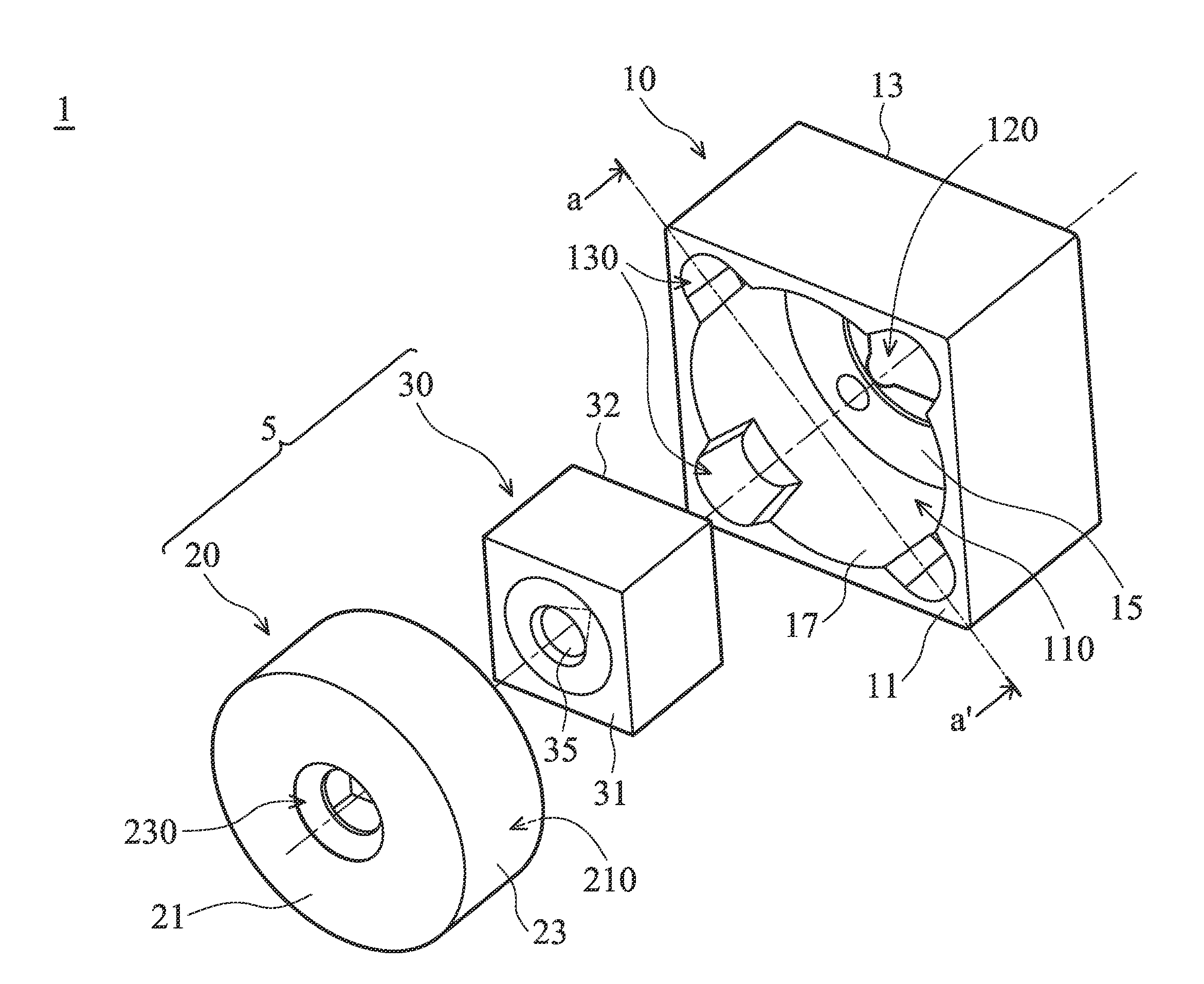

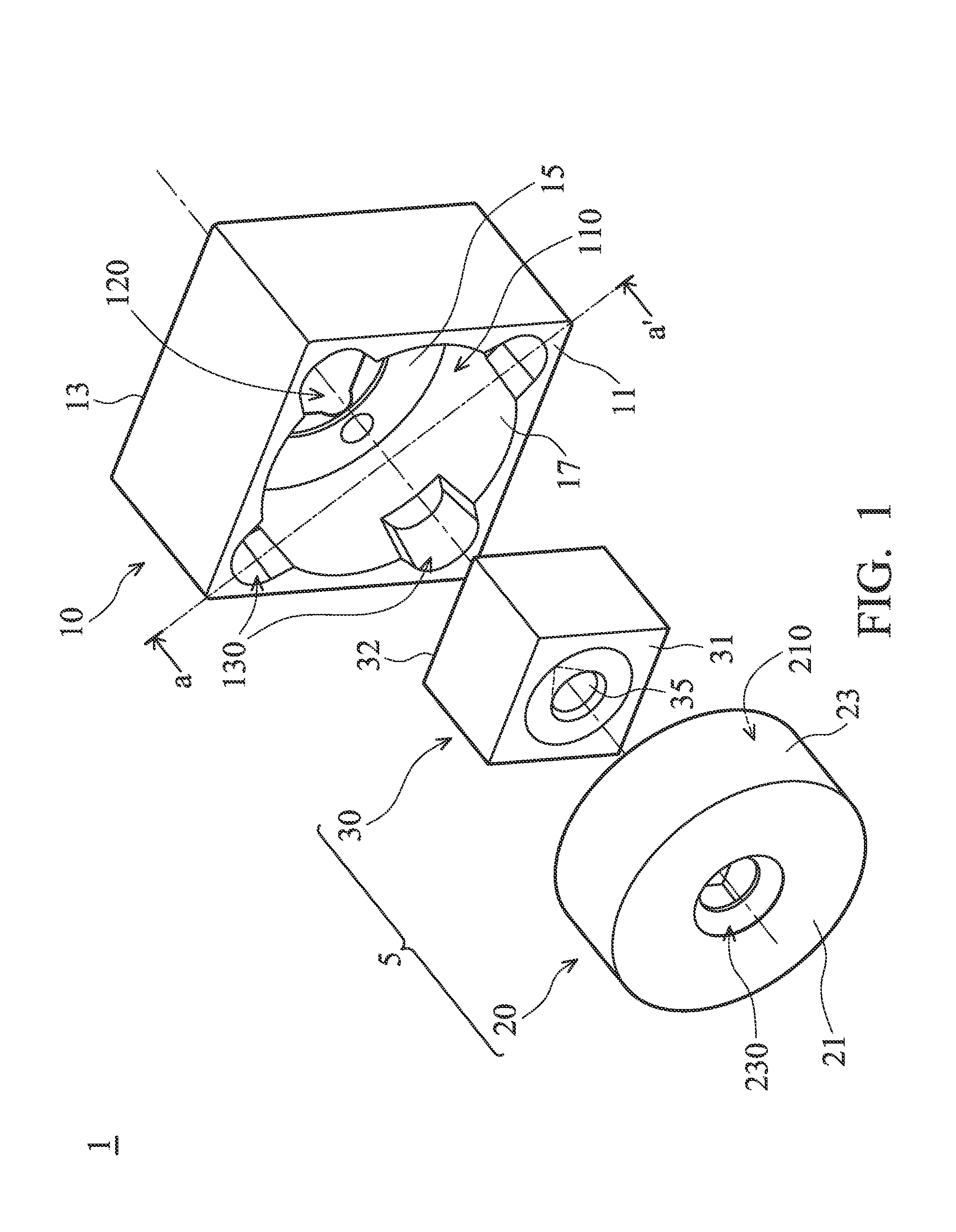

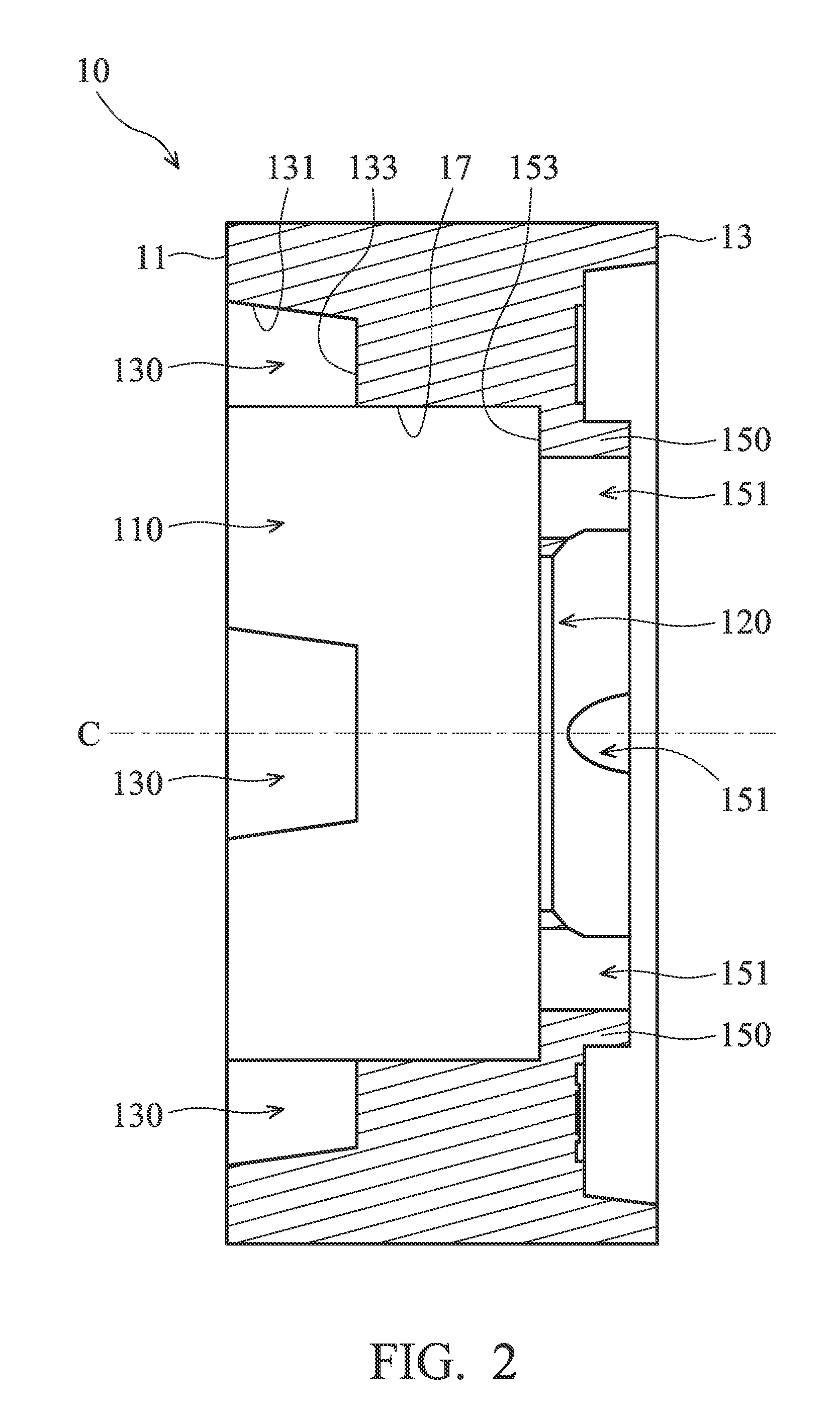

Lens assembly and method for assembling the same

A lens assembly is disclosed, which includes a base and a lens barrel. The base has a front edge, a back edge opposite to the front edge and a passage penetrating the front edge and the back edge. The lens barrel is disposed in the passage and includes a lens and a lens holding member holding the lens, wherein an outer surface of the lens holding member is in contact with an inner wall of the passage, and at least one of the inner wall of the passage and the outer surface of the lens holding member includes a smooth surface, arranged such that a thrust force applied on the lens barrel while assembling the lens assembly causes a sliding movement between the base and the lens barrel on the smooth surface.

Owner:HIMAX TECH LTD

Monocrystalsilicon crucible

InactiveCN108396374AExtended service lifeImprove stress tolerancePolycrystalline material growthBy pulling from meltEngineeringQuartz crucible

The invention discloses a monocrystal silicon crucible. The single monocrystal crucible comprises a crucible part body which is configured to store a quartz crucible, wherein a crucible part comprisesa first crucible unit, a second crucible unit and hole units; the first crucible unit is configured to be the bottom of the crucible part and is enclosed by segments of at least two parts; the secondcrucible unit is connected with the first crucible unit to form a side wall of the crucible part; the hole units are arranged on the second crucible unit and are used for communicating inner and outer spaces of the crucible part; the ratio of the hole units on the second crucible unit in the peripheral direction is gradually increased from one side of the bottom of the crucible part to the otherside. According to the monocrystal silicon crucible, the bottom is enclosed by a segment structure and the crucible is convenient to detach; the crucible part body is set to be a two-section type structure so that the stress bearing capability of a connection part of the side wall and the bottom is improved, the service life of the crucible is prolonged and the like.

Owner:周俭

Semiconductor structure and forming method thereof

PendingCN112992680AIncrease drive currentQuick responseSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureDevice material

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the following steps: providing a substrate; forming a first gate structure on the surface of the substrate; forming source and drain openings in the substrate at two sides of the first gate structure; forming a first stress layer on the bottom surface and the side wall surface of the source and drain openings; and thinning the side wall of the first stress layer. The semiconductor structure formed by the forming method can improve the performance of a semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

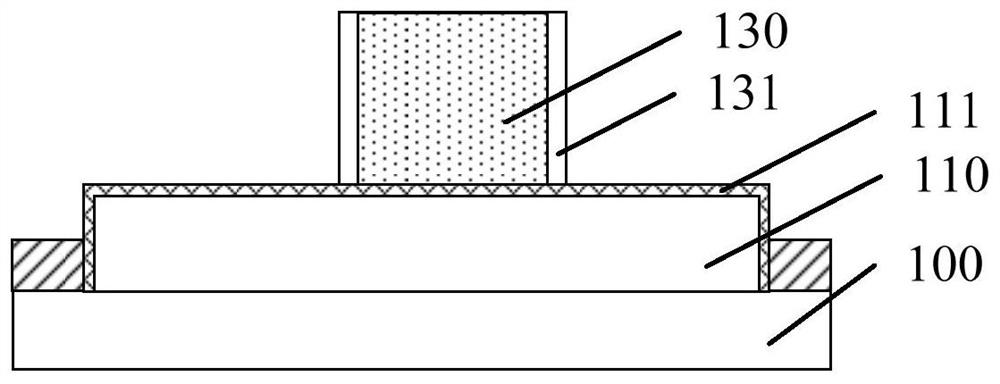

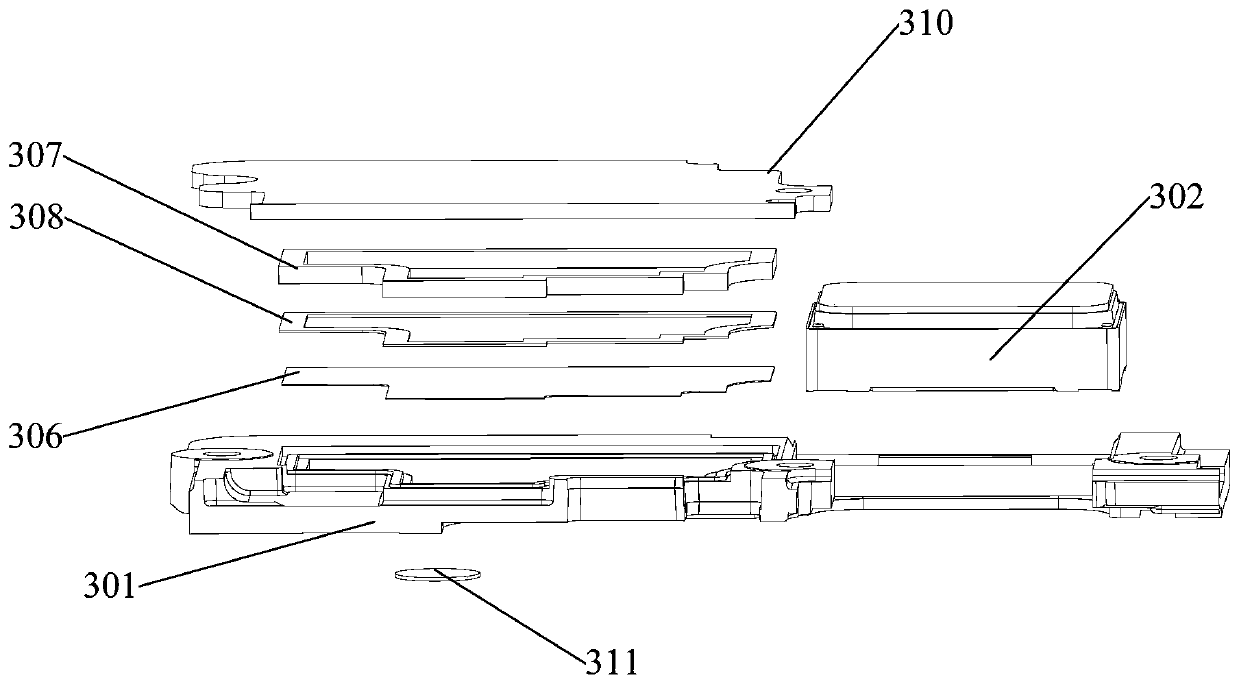

A sounding device and electronic equipment

ActiveCN108377451BImprove acoustic performanceImproved effect of improving acoustic performanceSingle transducer incorporationLoudspeakersEngineeringSound production

Disclosed is a sound production apparatus, comprising a housing and a sound generator. A rear cavity is formed between the housing and the sound generator; the housing is provided with an opening communicated with an outer part of the rear cavity and the sound generator; the periphery of the opening is surrounded by an opening wall, and the top surface of the opening wall is configured to be sealingly connected to an external device to realize sealing of the rear cavity; a filling area is provided in the rear cavity, the filling area is filled with a sound-absorbing material, and the filling area is surrounded by an enclosing wall; at least a portion of the opening corresponds to the filling area, and at least a portion of the opening wall overlaps with the enclosing wall; a packaging part used for sealing the filling area is provided on the top surface of the enclosing wall; an annular elastic gasket having a sealing effect is provided on the top surface of the opening wall; at the position where the opening wall overlaps with the enclosing wall, the annular elastic gasket is pressed on the upper surface of the edge of the packaging part. Further disclosed is an electronic device comprising the sound production apparatus. The present invention can improve the filling volume of the sound-absorbing material, and improve the acoustic performance of the sound production apparatus.

Owner:GOERTEK INC

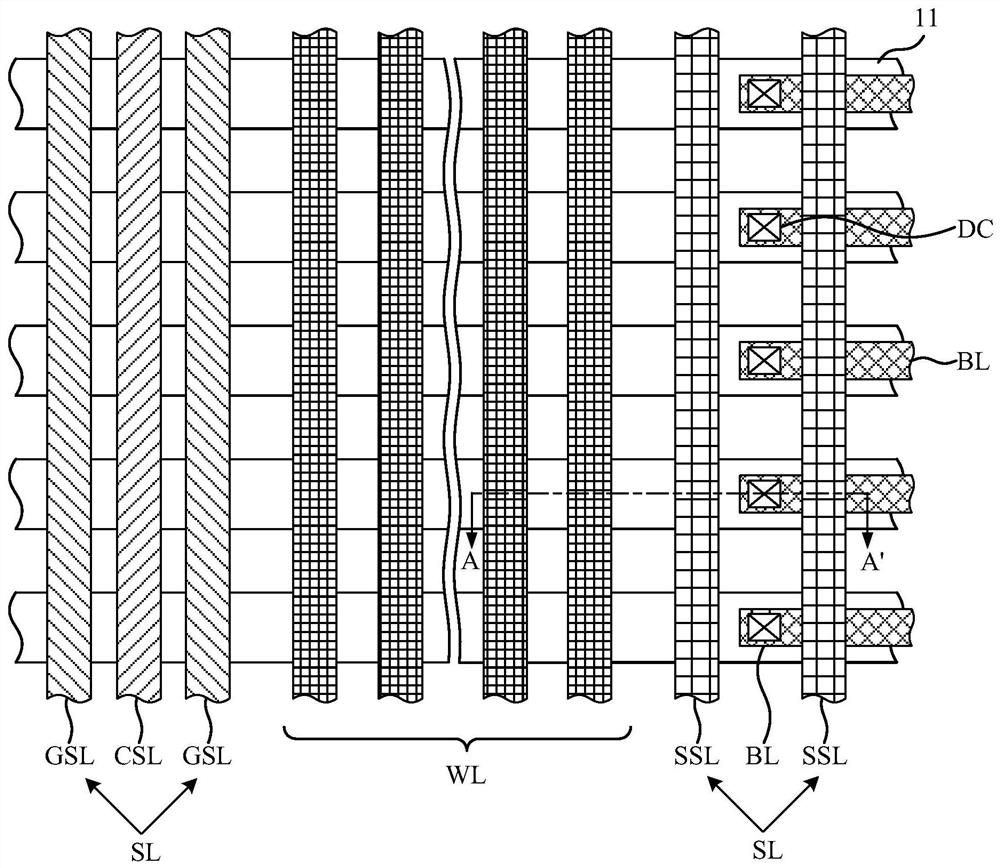

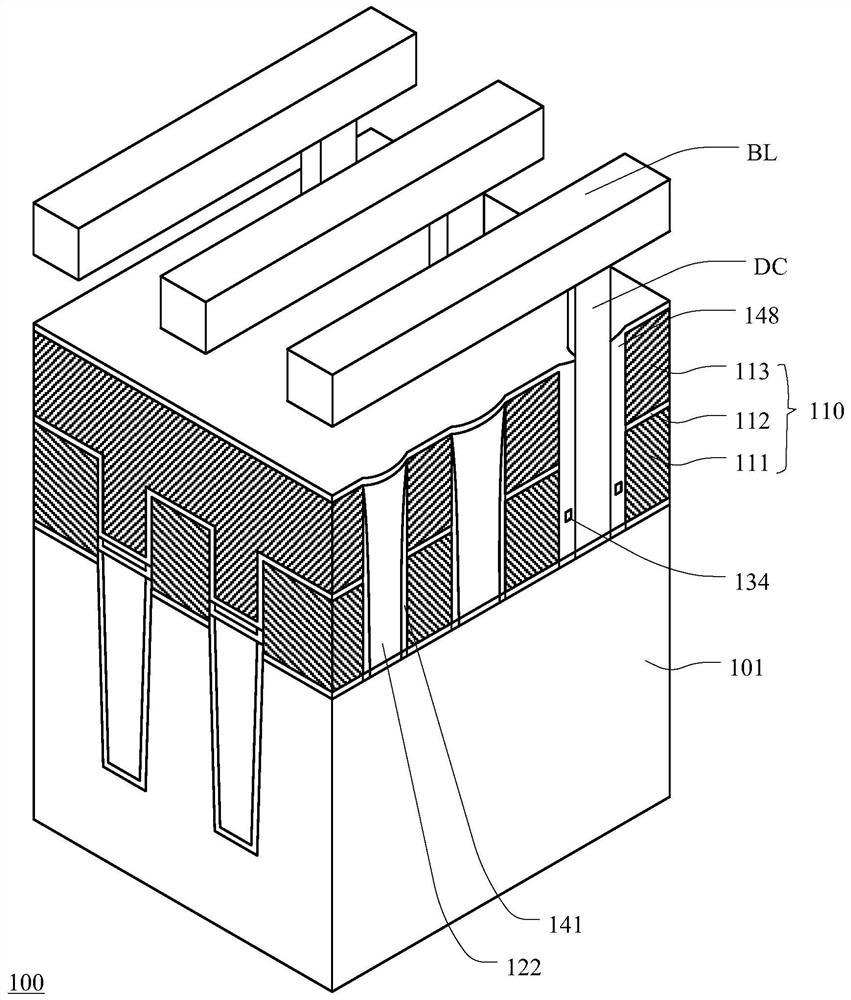

Semiconductor device and manufacturing method thereof

PendingCN114256248AImprove yieldImprove reliabilitySolid-state devicesSemiconductor devicesDevice materialEngineering

The invention discloses a semiconductor device and a manufacturing method thereof. The semiconductor device includes: a substrate; the gate stack structure is positioned on the substrate; a plurality of openings penetrating through the gate stack structure; a slot penetrating through the gate stack structure; the sacrificial layer, the barrier layer and the contact structure are located in the open groove; the insulating layer is used for forming a first air gap in the plurality of holes and realizing electrical isolation among the barrier layer, the contact structure and the gate stack structure, the contact structure penetrates through the insulating layer and the barrier layer, the sacrificial layer and the barrier layer are separated by the insulating layer, and a part of the barrier layer extends to the upper part of the sacrificial layer. According to the semiconductor device, the distance between the first end part and the second end part of the barrier layer and the contact structure is increased, so that the possibility that the second air gap is in contact with the contact structure is greatly reduced, and the yield and the reliability of the semiconductor device are improved.

Owner:GIGADEVICE SEMICON SHANGHAI INC +1

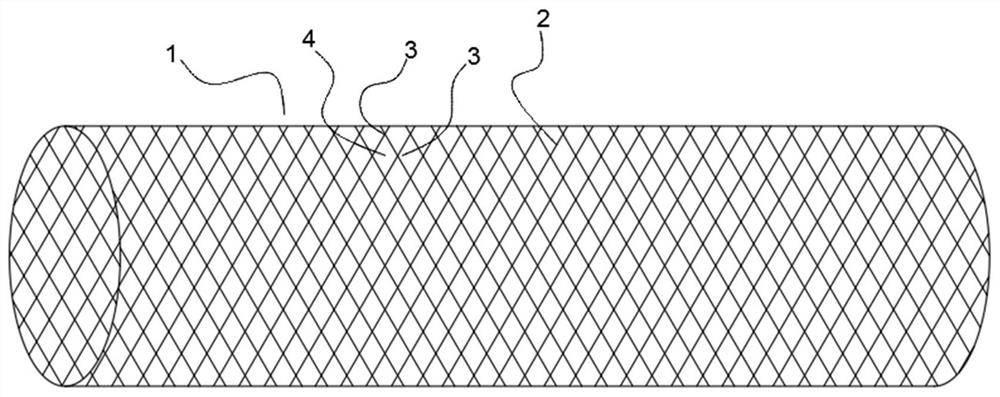

Blood flow guiding device

InactiveCN114028048AGood orientationDoes not change metal coverageStentsProsthesisBiomedical engineeringBlood vessel

The invention relates to a blood flow guiding device which comprises a support body which is of a tubular structure and formed by weaving weaving wires, meshes are formed in the support body, every two crossed weaving wires form a crossed part, one of the two weaving wires defining the crossed part is an inner side weaving wire close to the center of the support body, and the other weaving wire is an outer side weaving wire. The cross section of each weaving wire is in a strip shape with the length extending in the axial direction of the support body, the inner side weaving wires gradually incline towards the center of the support body in the blood flow direction in the tumor carrying blood vessel, and an inner side weaving wire guiding face gradually extending towards the center of the support body in the blood flow direction in the tumor carrying blood vessel is arranged on the inner side face of the inner side weaving wire. The invention provides the blood flow guiding device capable of improving the blood guiding effect.

Owner:李立

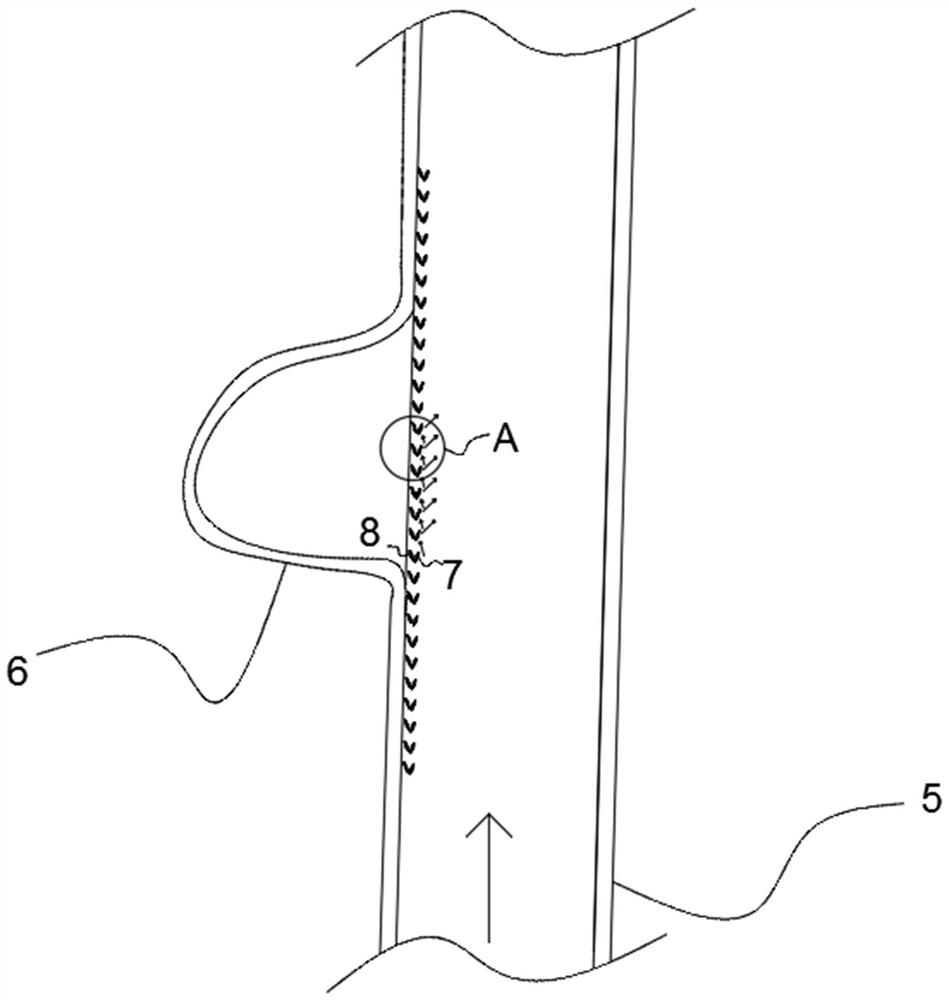

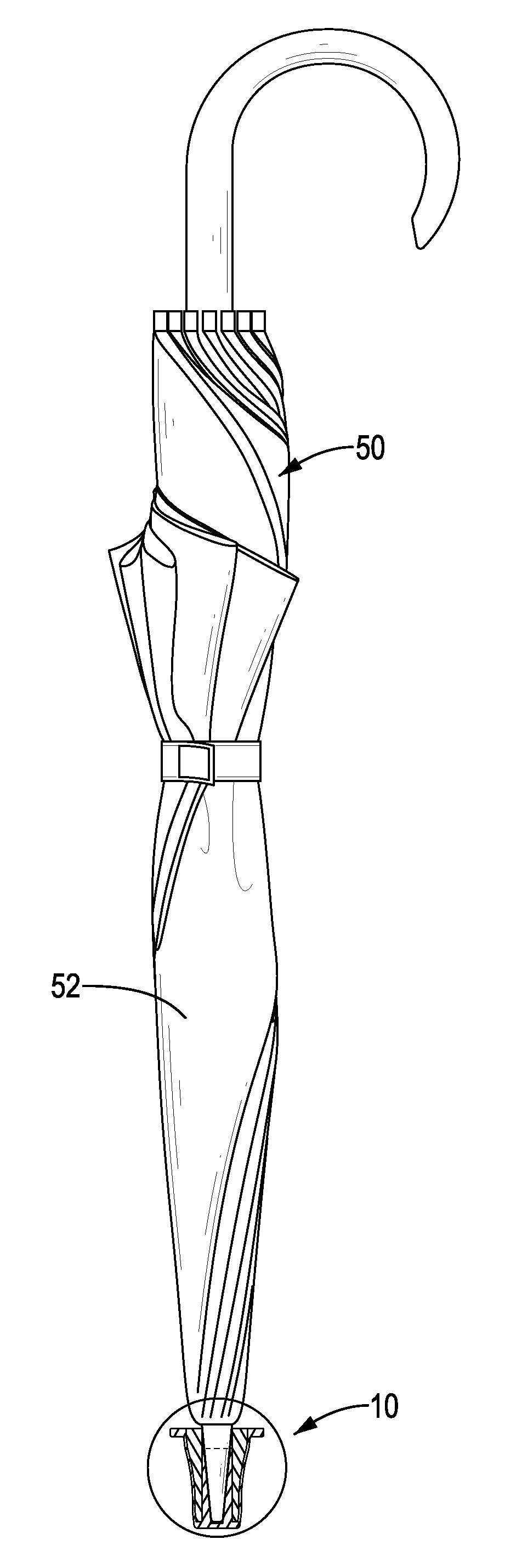

Water catchment device for umbrella

Provided is a water catchment device for an umbrella, the water catchment device including: a cover, a protrusion, and an absorbent element. The protrusion further has an insertion channel for an umbrella to be inserted into and combined with the water catchment device. Furthermore, a catchment is formed between the cover and the protrusion and an absorbent element is mounted in the catchment. The absorbent element can absorb rainwater and retain the rainwater in the catchment. The water catchment device prevents the rainwater from overflowing from the catchment and dripping around. In addition, the cover and the protrusion are made of flexible materials. The absorbent element in the catchment can be dried by pressing the cover. The absorbent element also can be removed from the catchment for drying or replacement whenever needed.

Owner:CHENG YU FENG

Lens assembly and method for assembling the same

Owner:HIMAX TECH LTD

Capillary wall coupled whispering gallery mode microresonator

A microresonator structure comprises a waveguide and a microsphere. The waveguide is of elongated cylindrical shape and includes a first section of optical transmission material and a cavity section axially aligned with the first section. The cavity section includes a first cavity and a second cavity. The first cavity is adjacent to the first section and includes a first sidewall of optical transmission material with an inner surface that tapers inward to an apex positioned adjacent to the first section. The second cavity is positioned adjacent to the first cavity of hollow cylindrical shape and includes a circumferential second sidewall of optical transmission material that abuts the first sidewall. The microsphere has a spherical outer surface and is positioned within the cavity section such that the outer surface contacts a portion of the first sidewall and a portion of the second sidewall.

Owner:UNIVERSITY OF MISSOURI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com