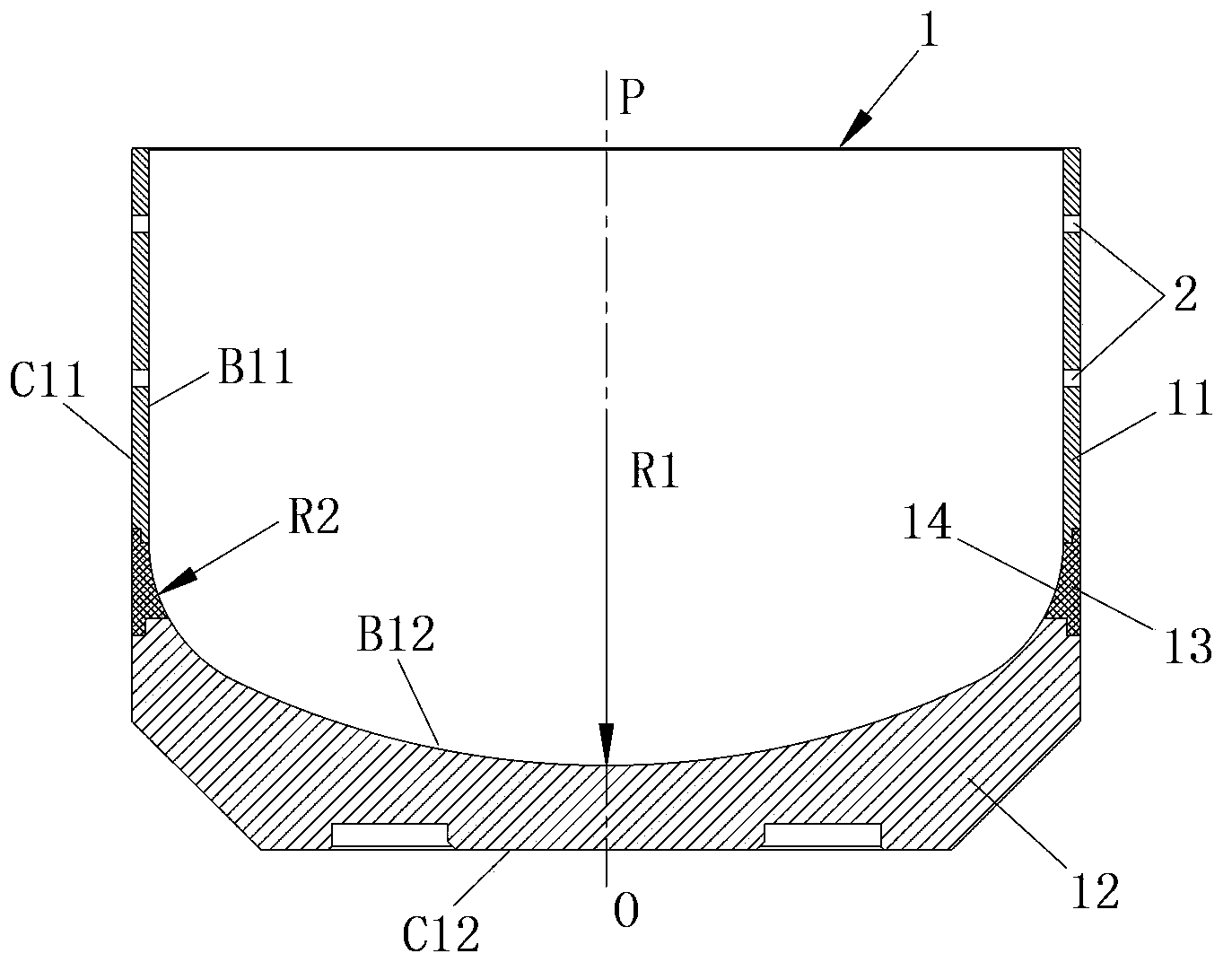

Crucible used for preparing monocrystalline silicon by czochralski method

A single crystal silicon, Czochralski technology, applied in the field of crucibles, can solve the problems of long heating time, shorten the service life of the crucible, slow heating, etc., and achieve the effects of good temperature control performance, reduced sidewall thickness, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

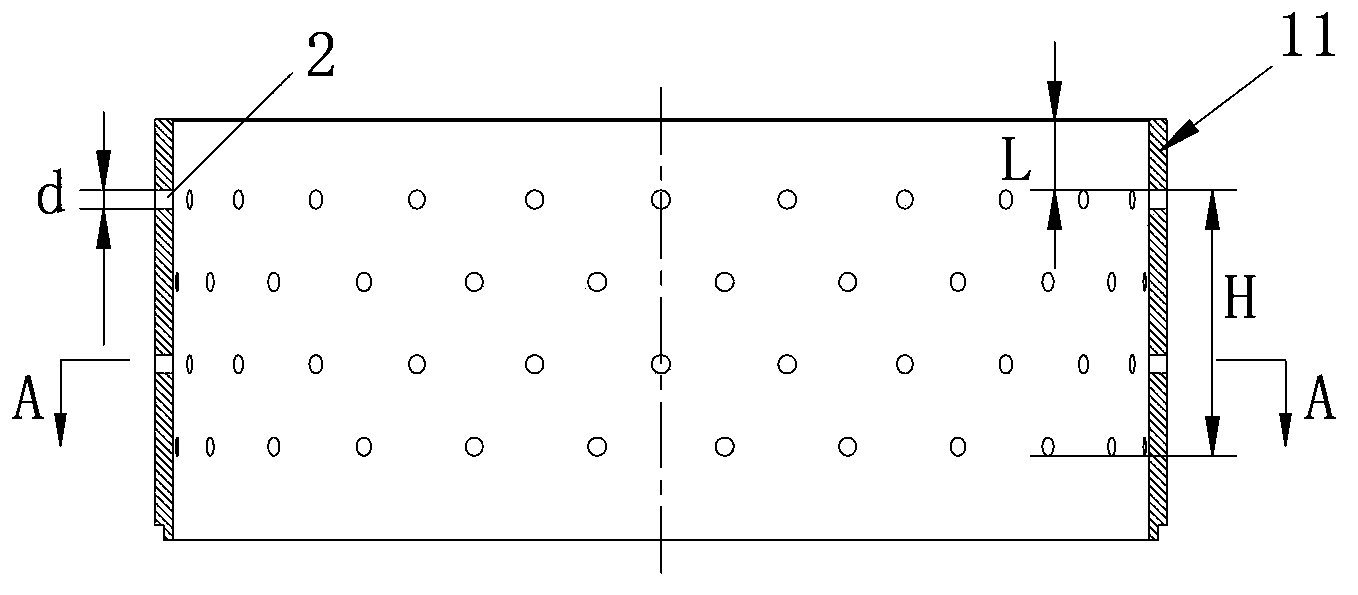

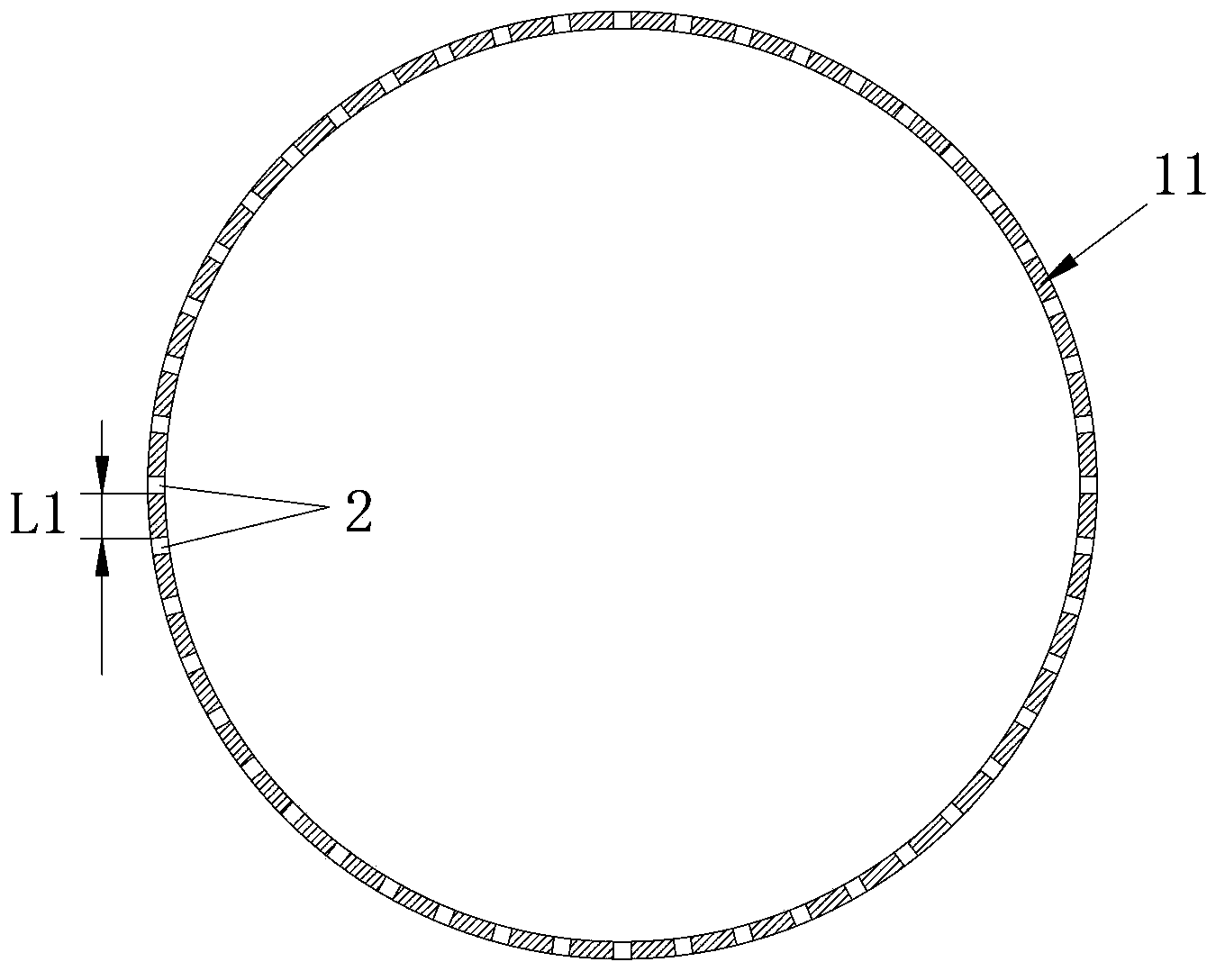

[0033] The diameter d of the heat conduction hole of the crucible side wall 11 of the carbon-carbon composite material described in this embodiment is 8-15 mm; the distance L1 between the boundaries of two adjacent heat conduction holes 2 is 30-50 mm.

Embodiment 2

[0035] The diameter d of the heat conduction hole of the crucible side wall 11 of the carbon-carbon composite material described in this embodiment is 10 mm, and the distance L1 between the boundaries of two adjacent heat conduction holes 2 is 50 mm.

Embodiment 3

[0037] The crucible described in this embodiment is a two-stage crucible structure (not shown in the figure), including the side wall of the upper layer of carbon-carbon composite material and the bottom of the lower layer of graphite material, and the heat conduction holes are arranged on the side wall .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com