Patents

Literature

46results about How to "Improve Disposability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

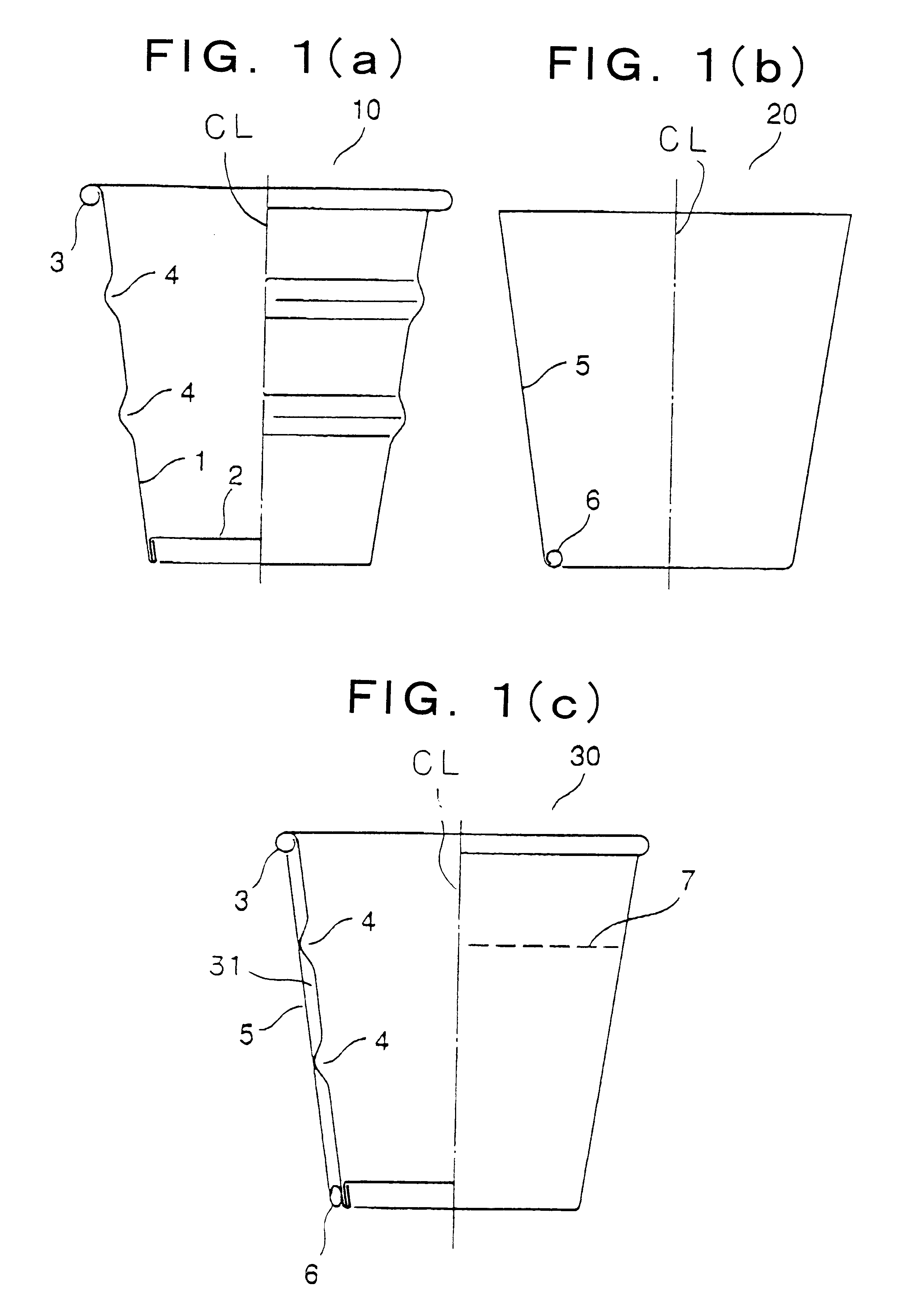

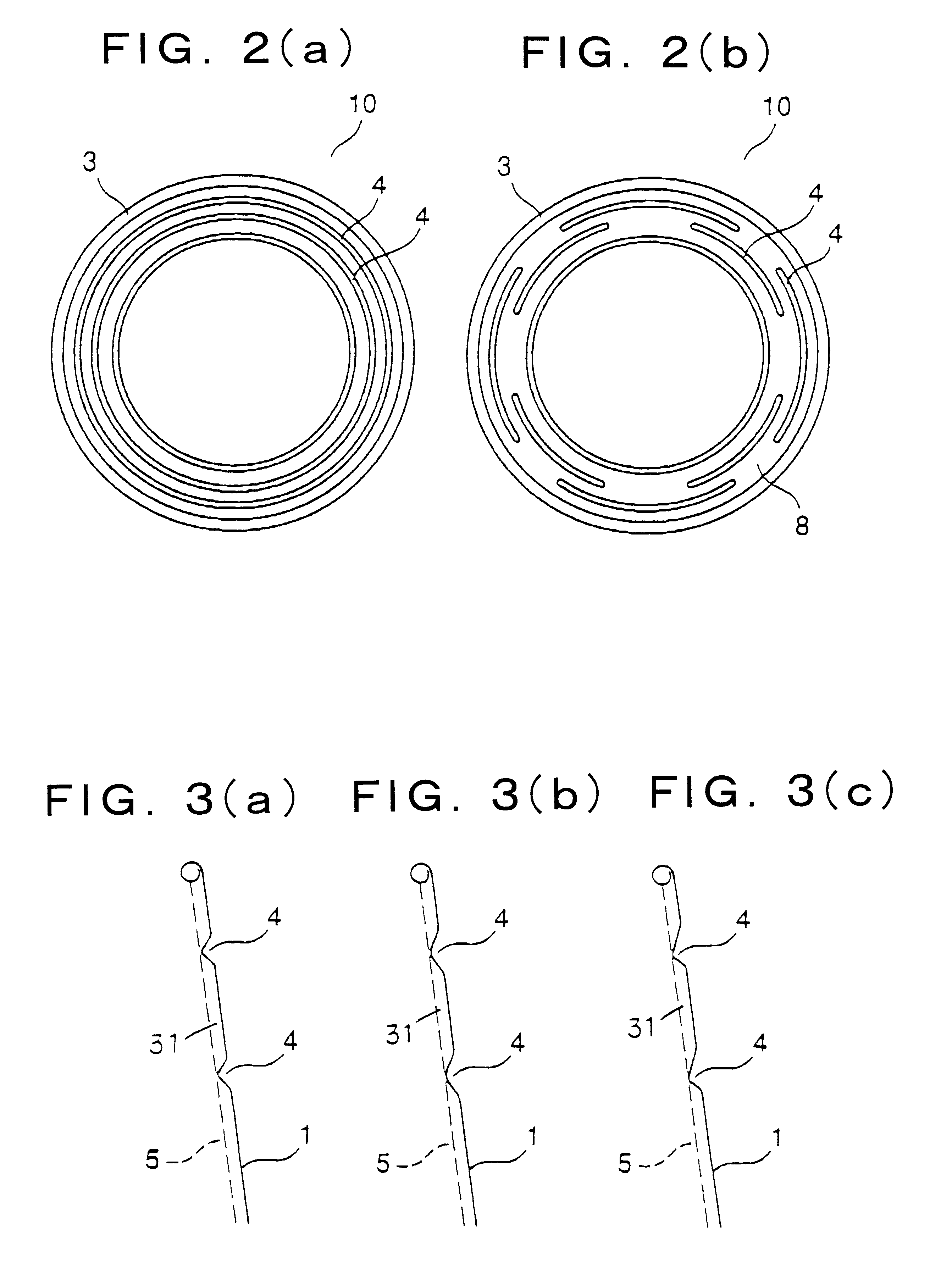

Insulating container

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

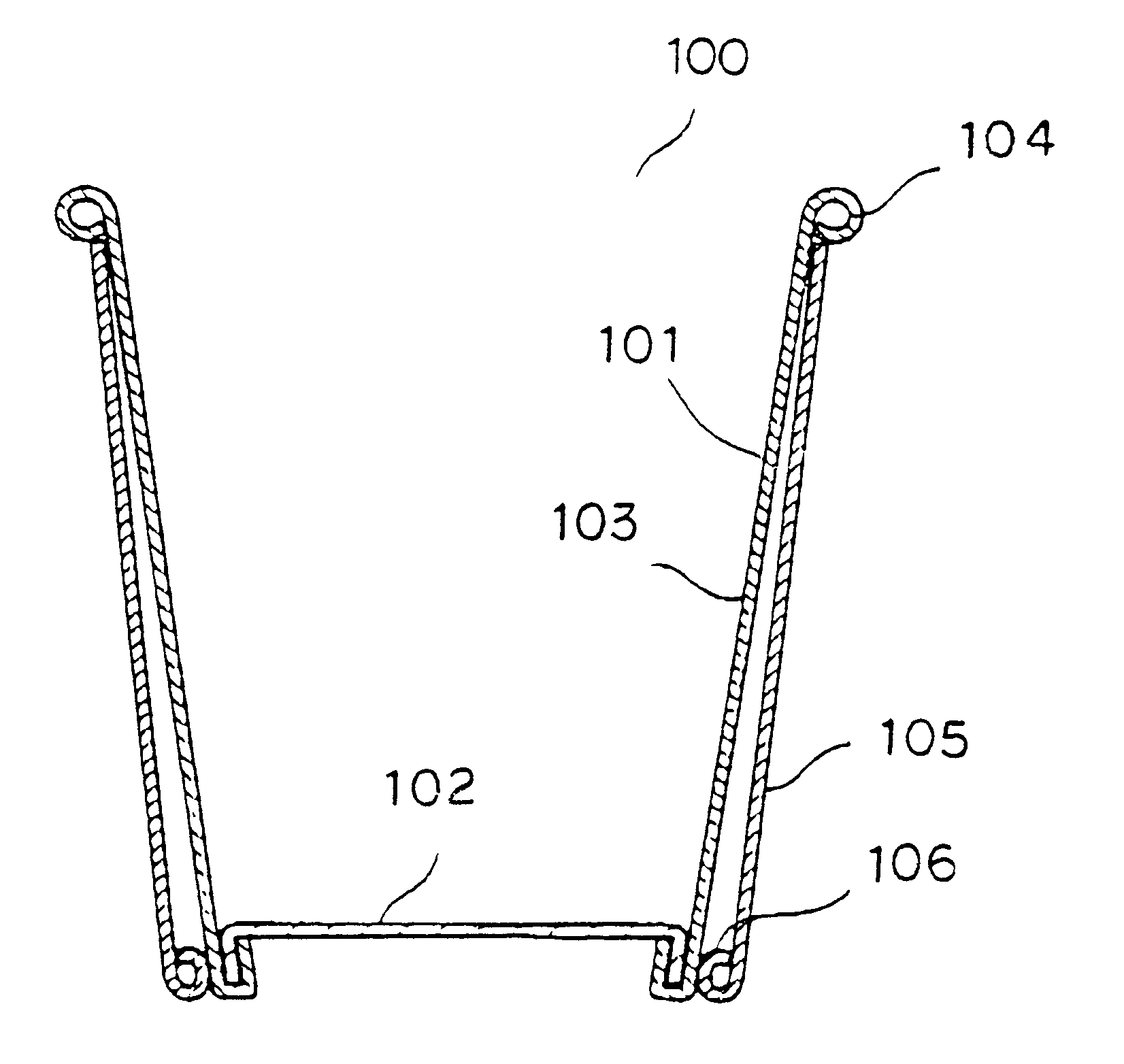

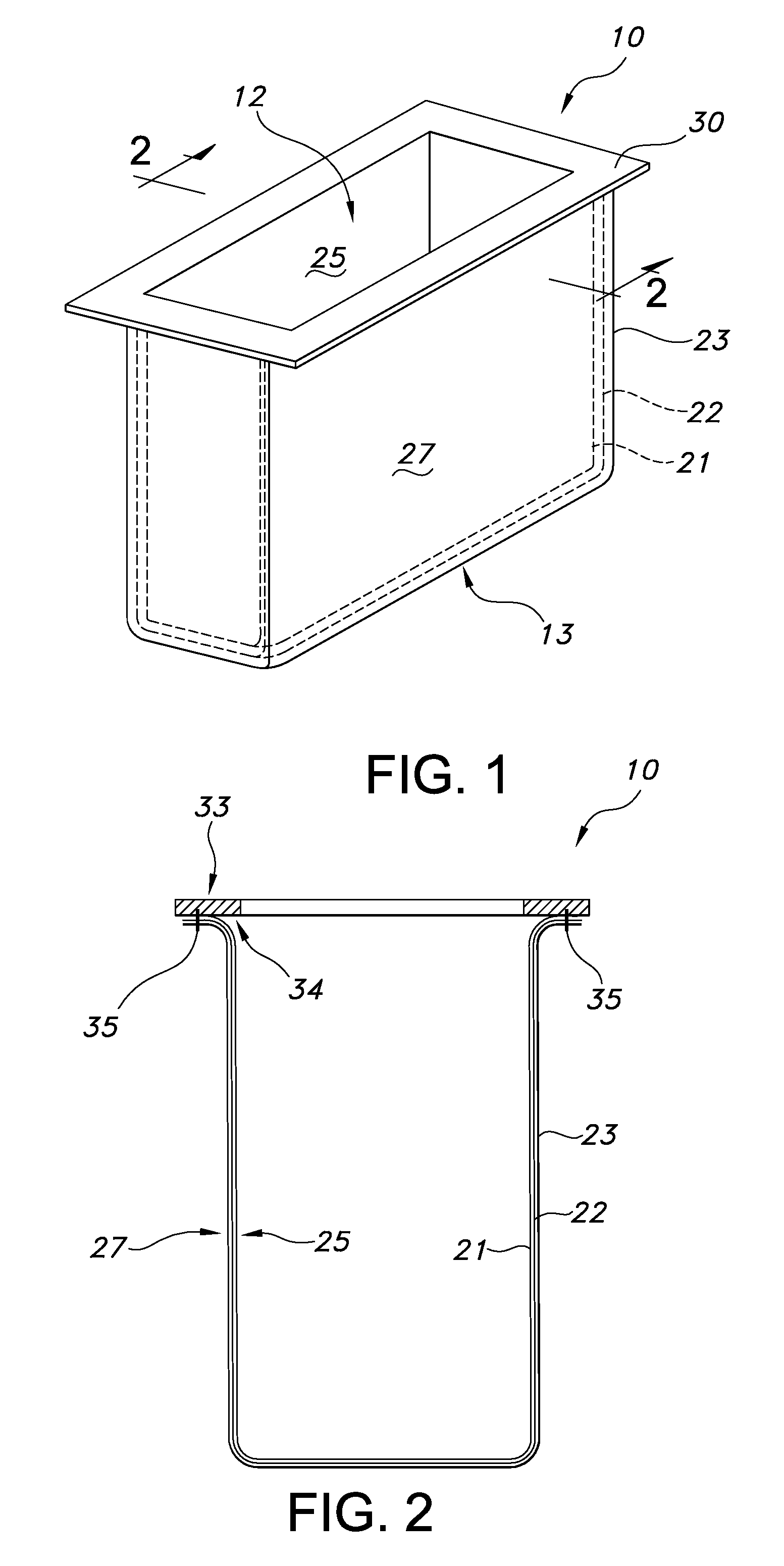

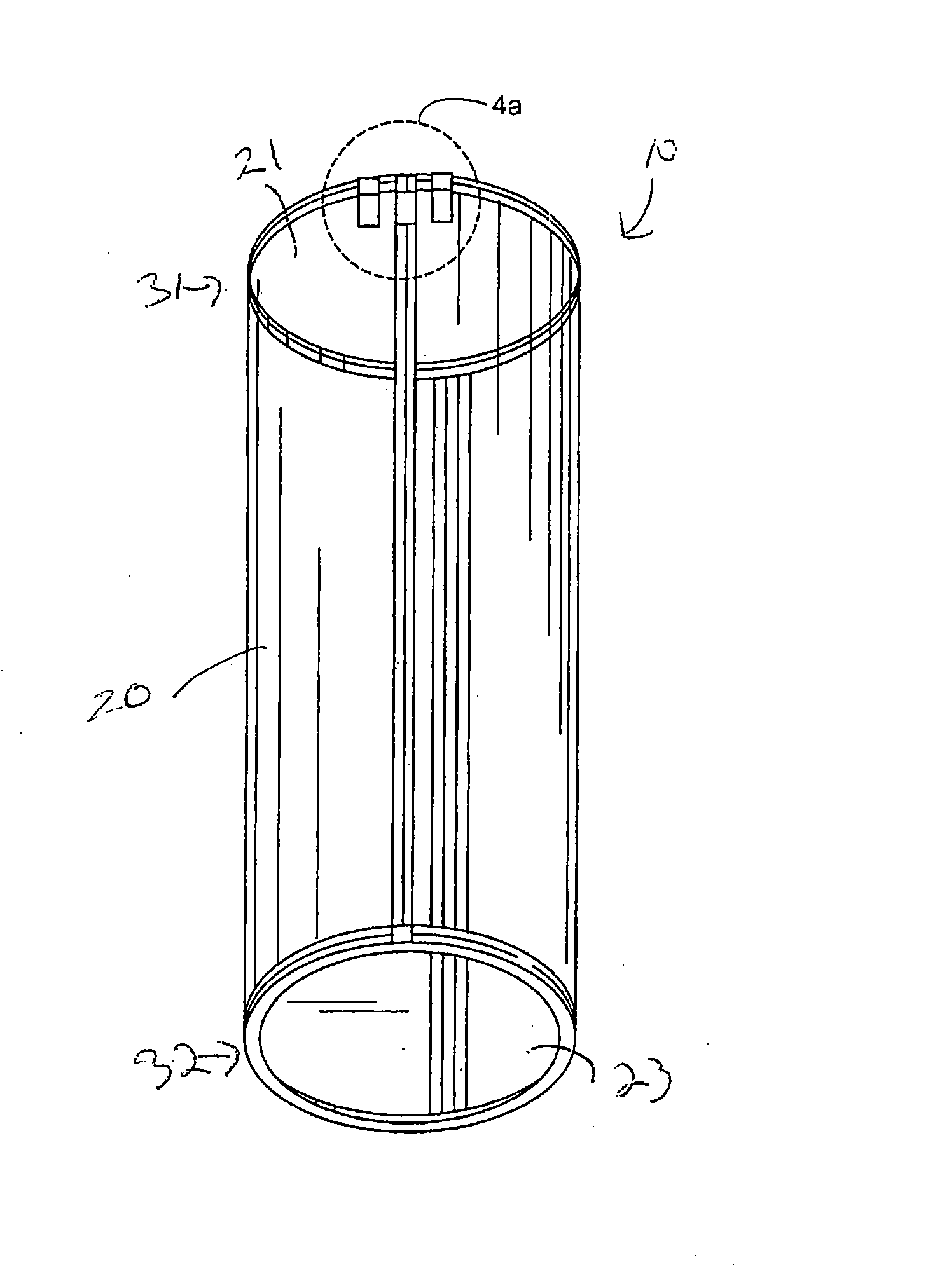

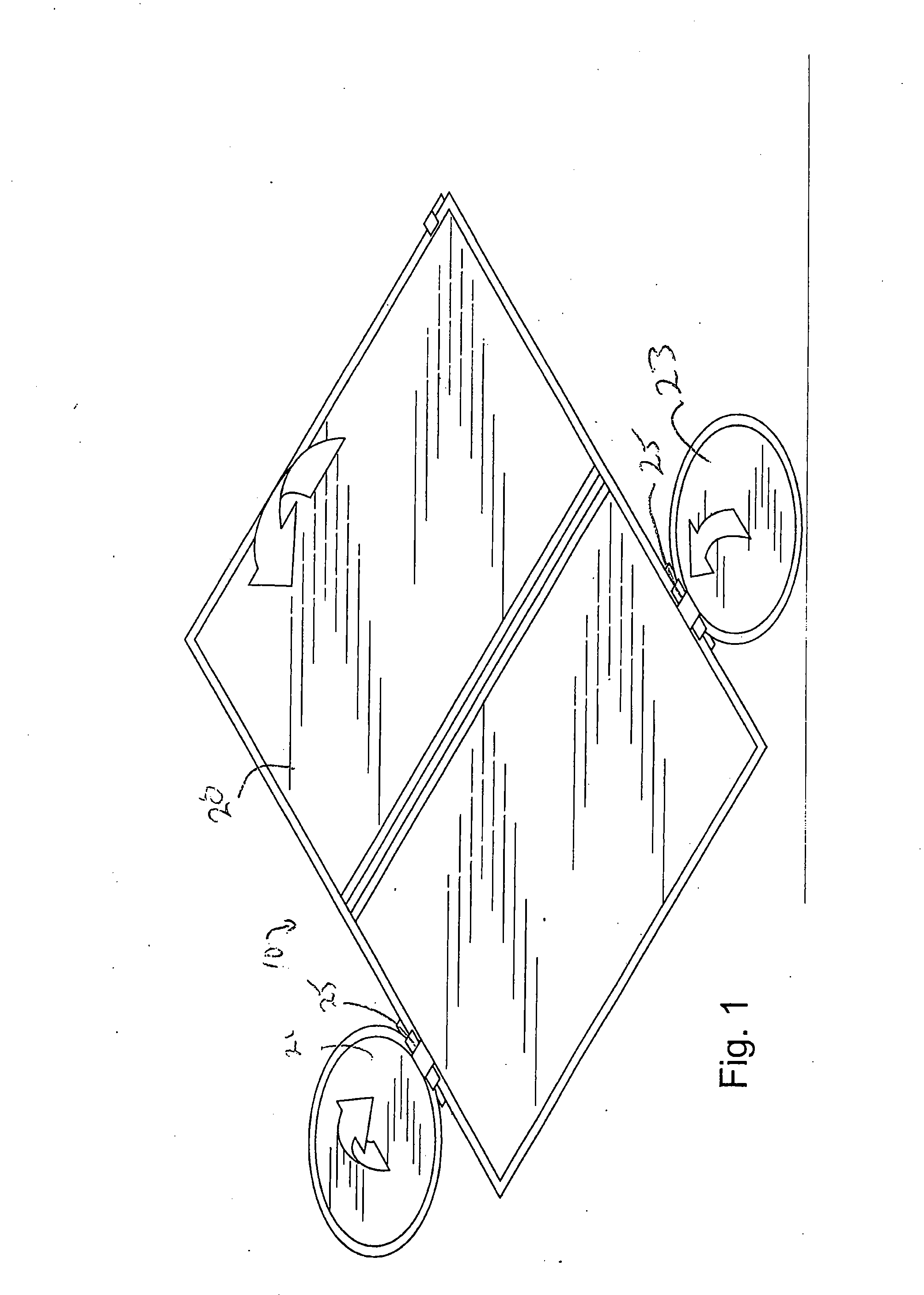

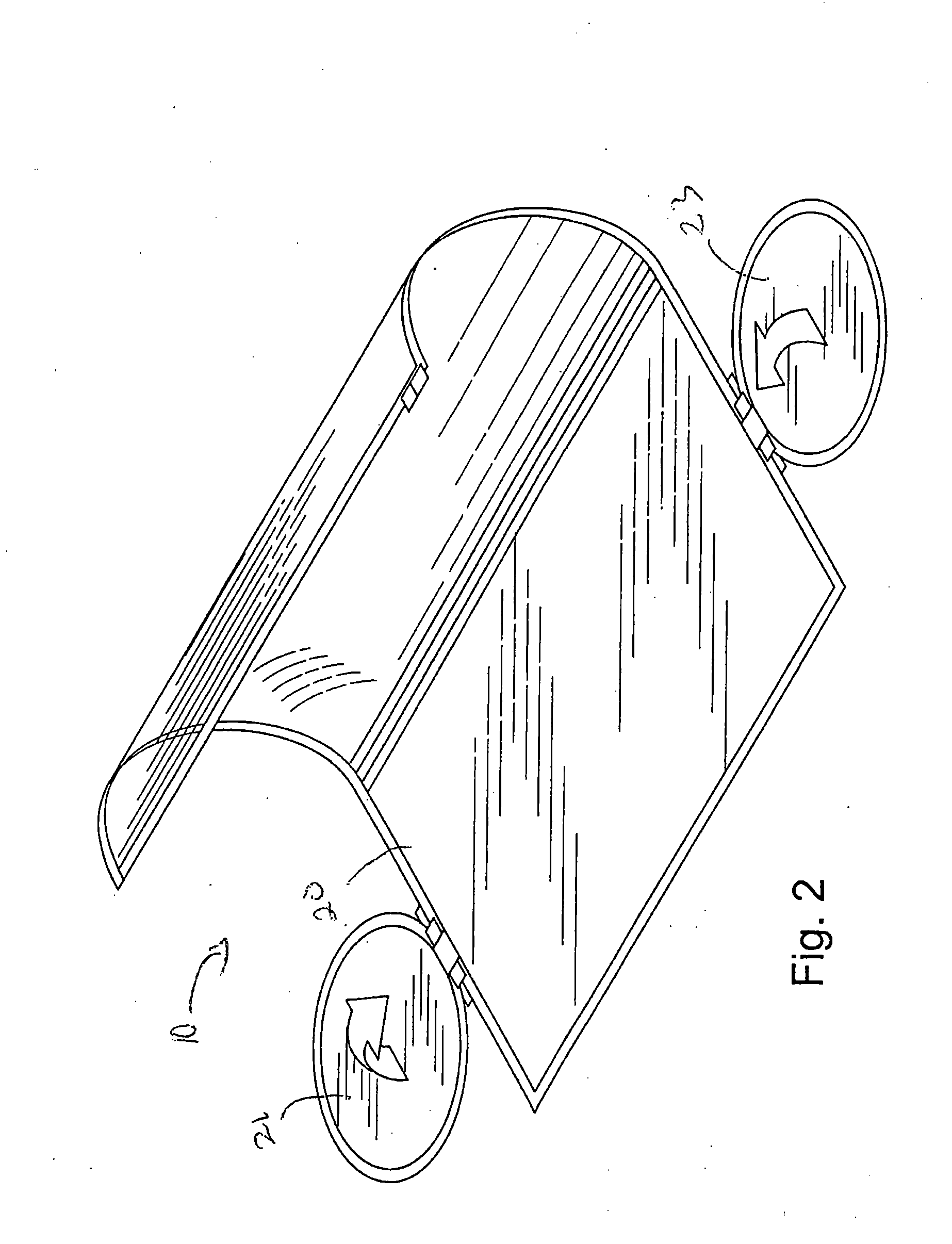

Disposal Bag Assembly And Disposal System

InactiveUS20070045326A1Easy to optimizeImproves operation of systemLarge containersRefuse receptaclesWaste treatment

A system for disposal of refuse adapted for use within a waste disposal unit is disclosed. The system includes a frame and a plurality of bags, nested within each other and within an outermost bag, where the bags are attached to the frame and are held open for the disposal of refuse thereinto. A disposal bag assembly for disposal of refuse is also disclosed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Film and process for producing the same

ActiveUS20050131162A1Easy to produceLow costSynthetic resin layered productsCoatingsPolymer scienceCarboxylic acid

The invention is directed to a film which comprises a poly(carboxylic acid) polymer and a polyvalent metal compound, which is endowed with excellent gas barrier property against, for example oxygen, which has such resistance that the appearance, shape, and gas-barrier properties are not impaired by neutral water, high-temperature water vapor, or hot water; a laminate produced by use of the film; and a process for producing the film or laminate industrially conveniently at low cost. The film or laminate of the present invention is suitable for use as a package, packaging container, or vacuum insulation material for articles which are apt to be deteriorated by oxygen, etc., such as foods, beverages, chemicals, medicines, and metallic precision parts; e.g., electronic parts. Furthermore, there can be provided a packaging material suitable for use with articles which are required to be reliably insulated from gases for prolonged periods and should be treated under high-temperature, hot-water conditions as in boiling or pressurized high-temperature sterilization.

Owner:TOPPAN PRINTING CO LTD

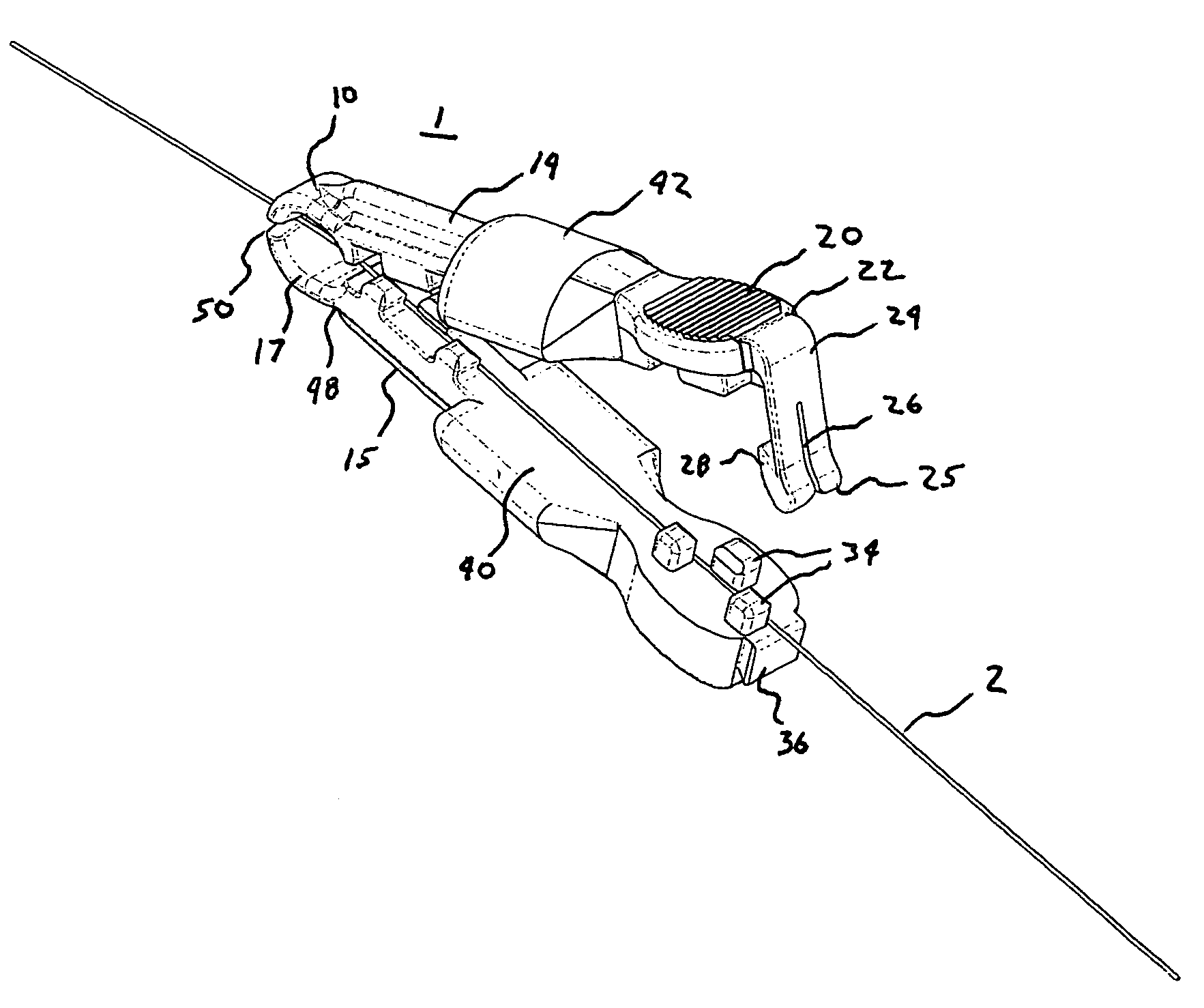

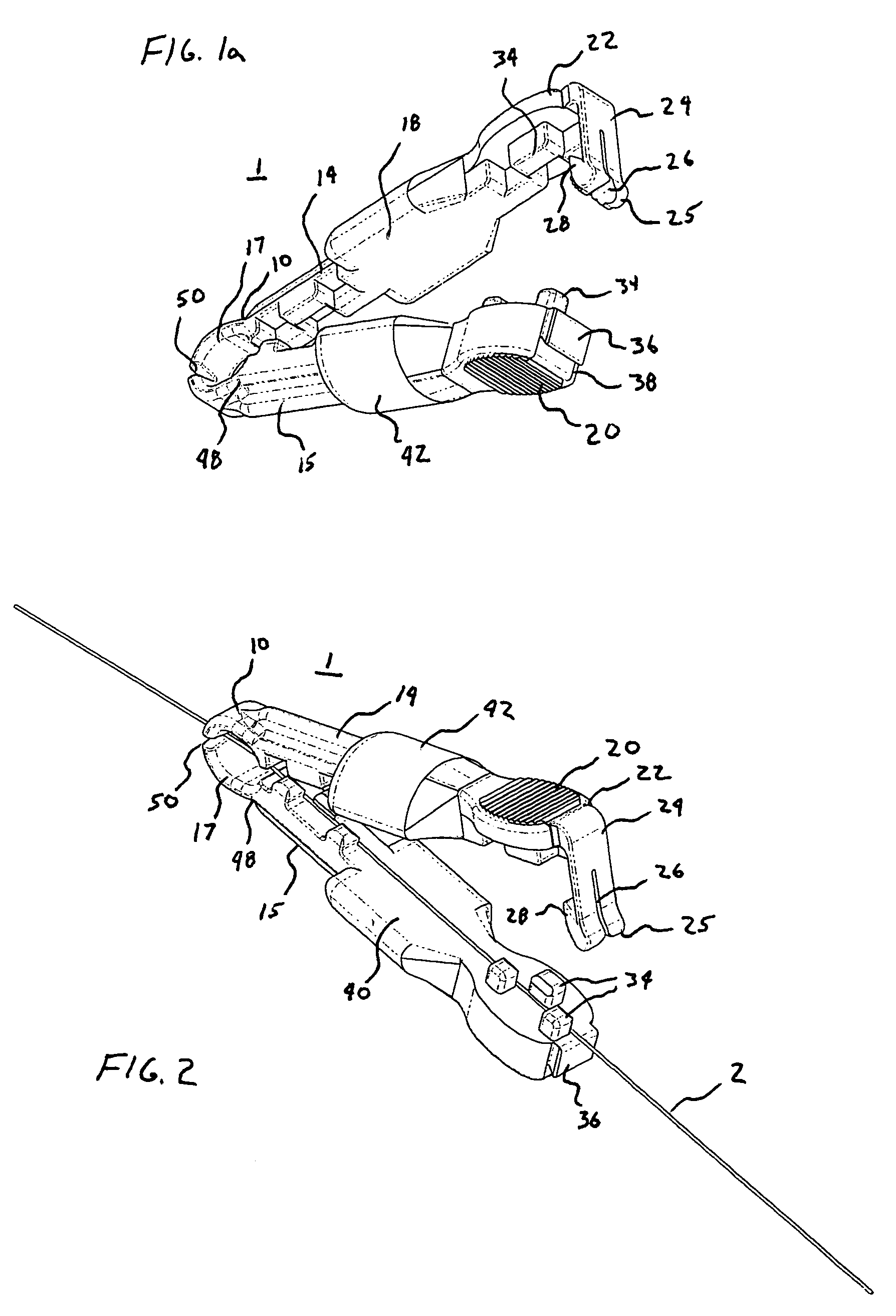

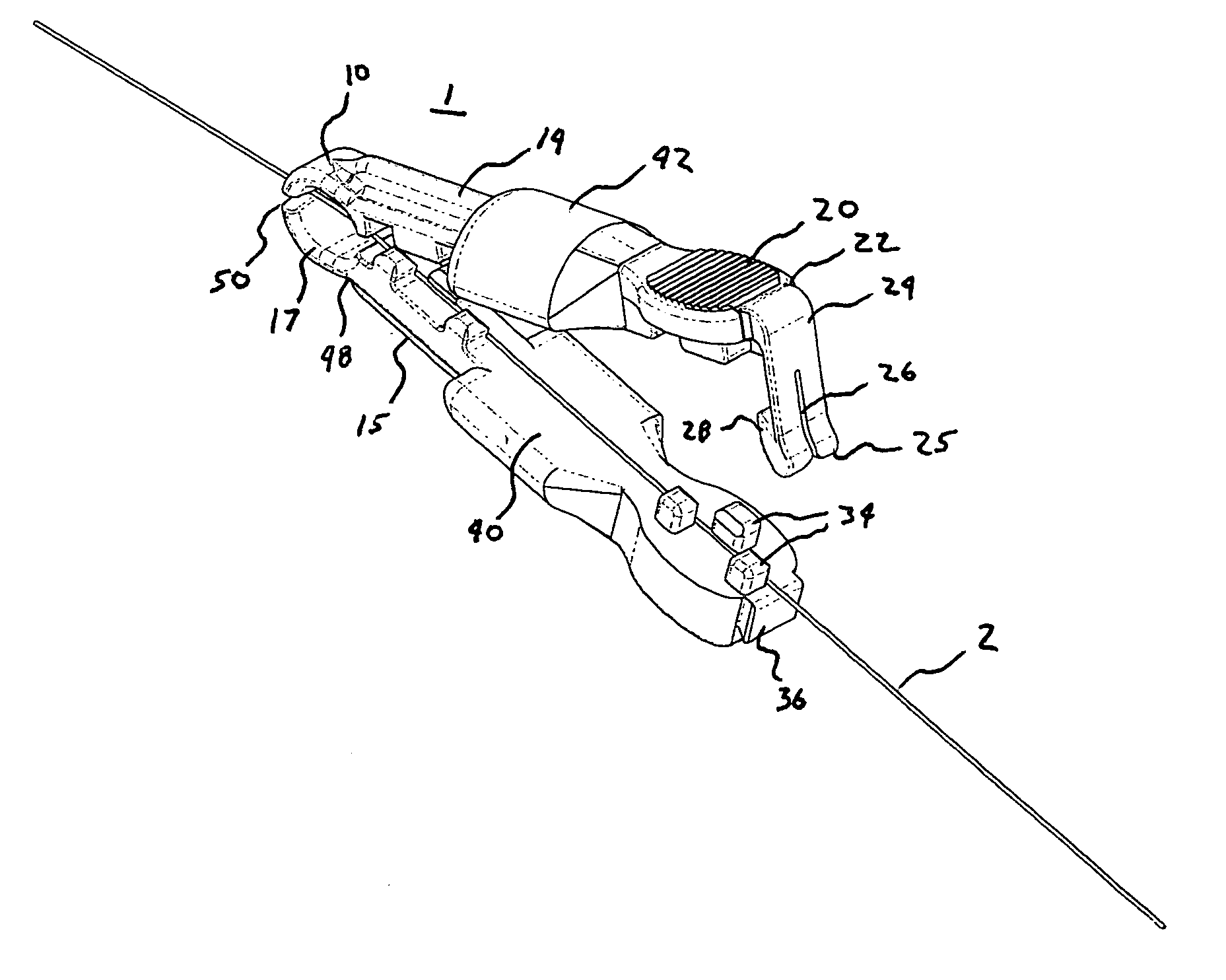

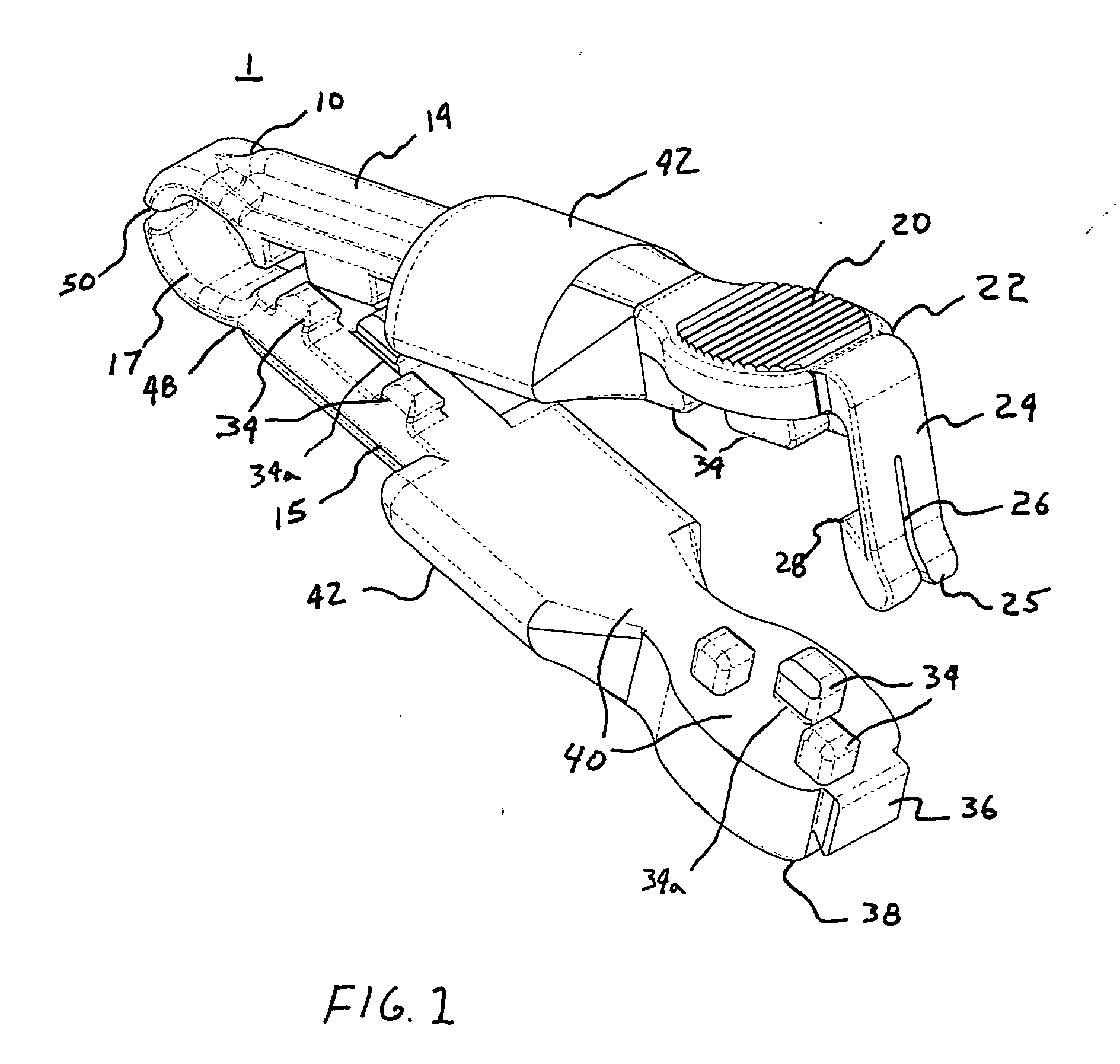

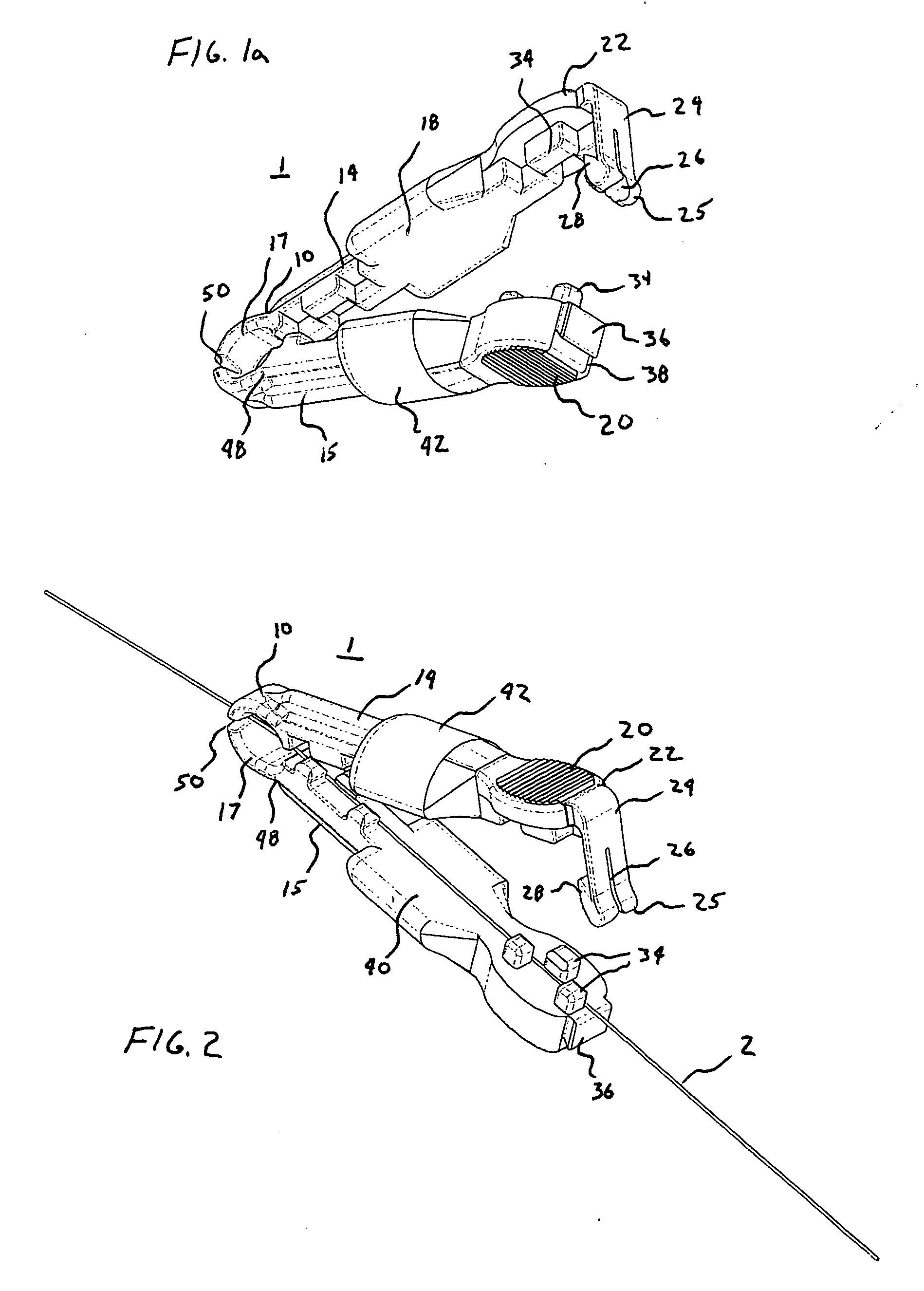

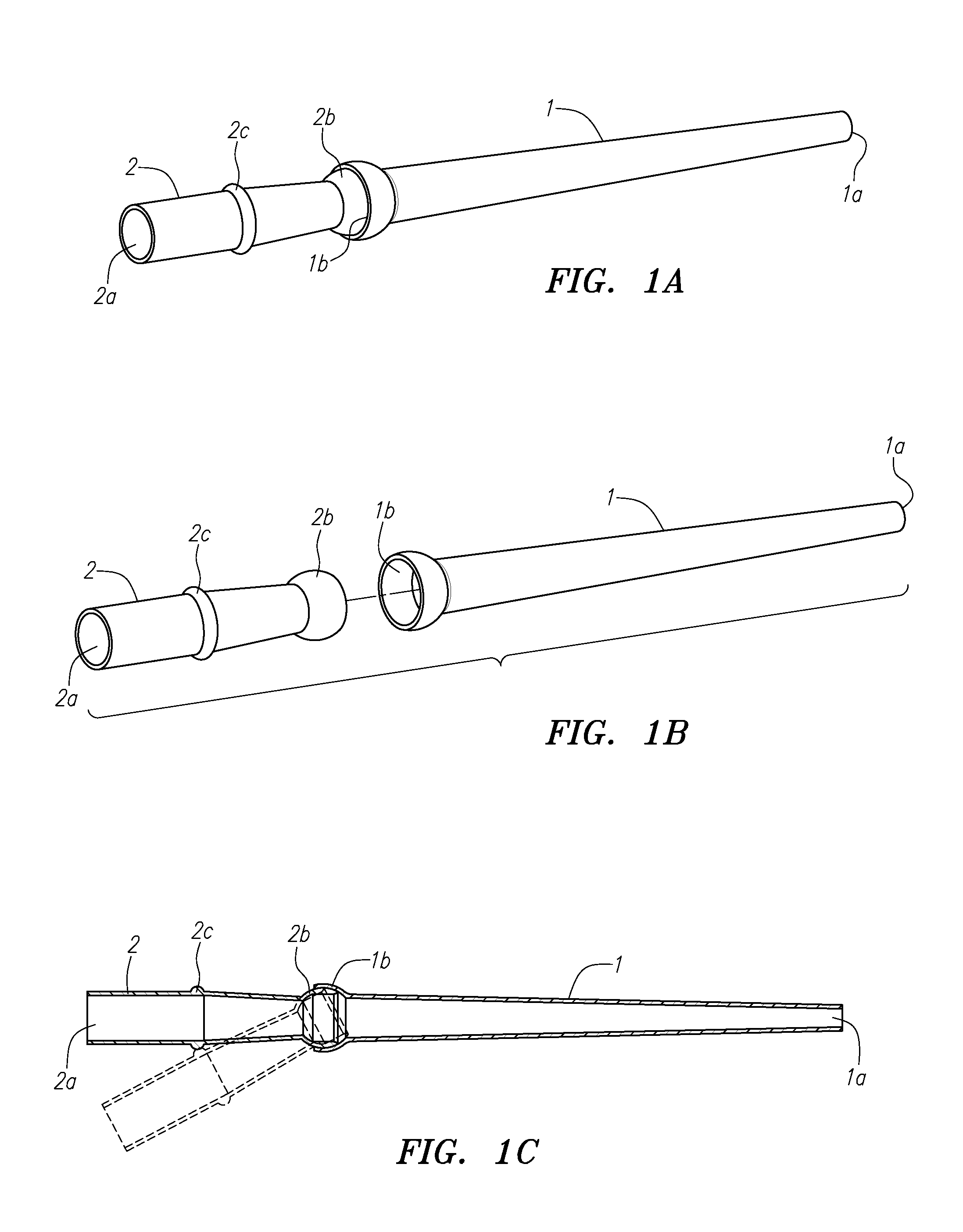

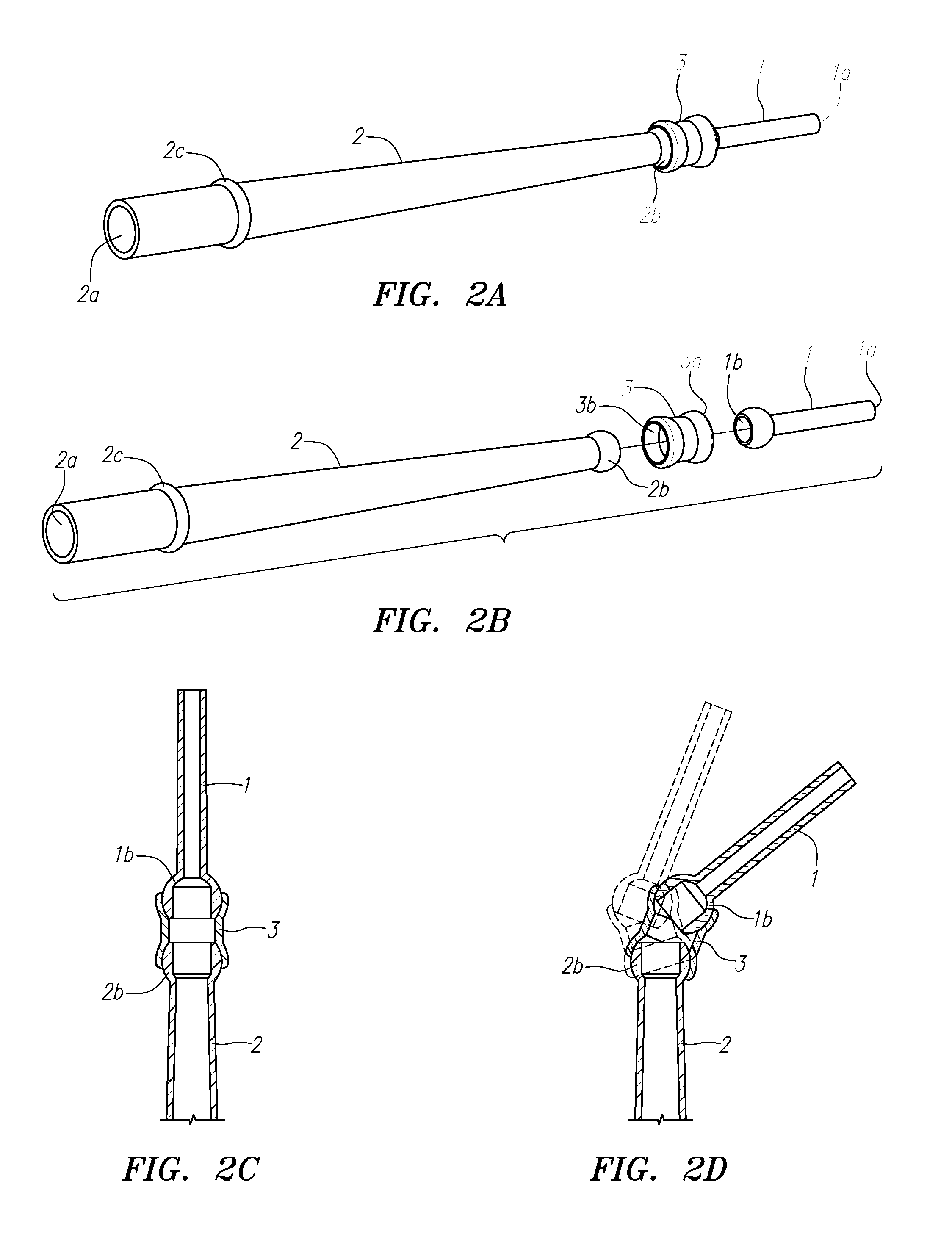

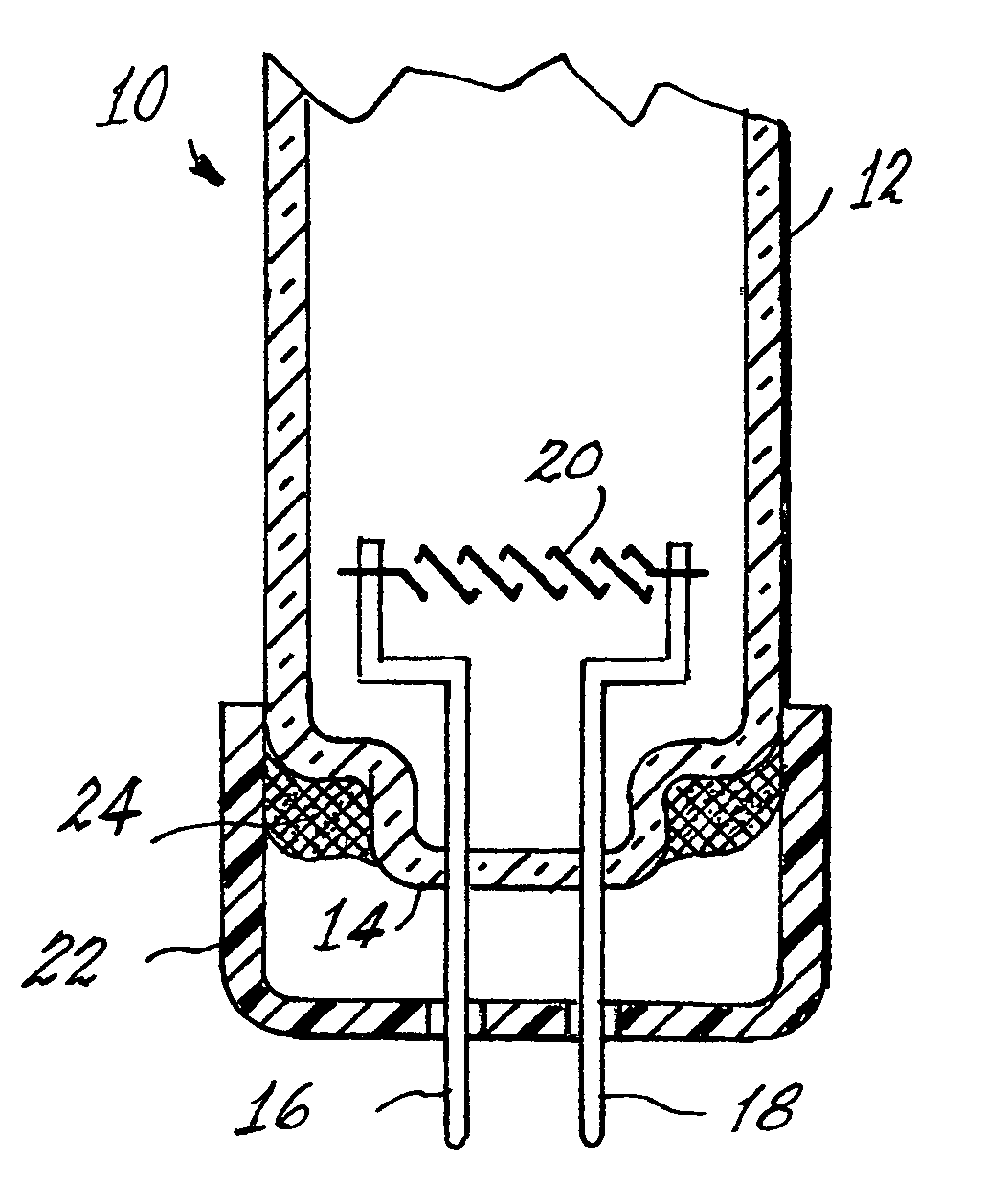

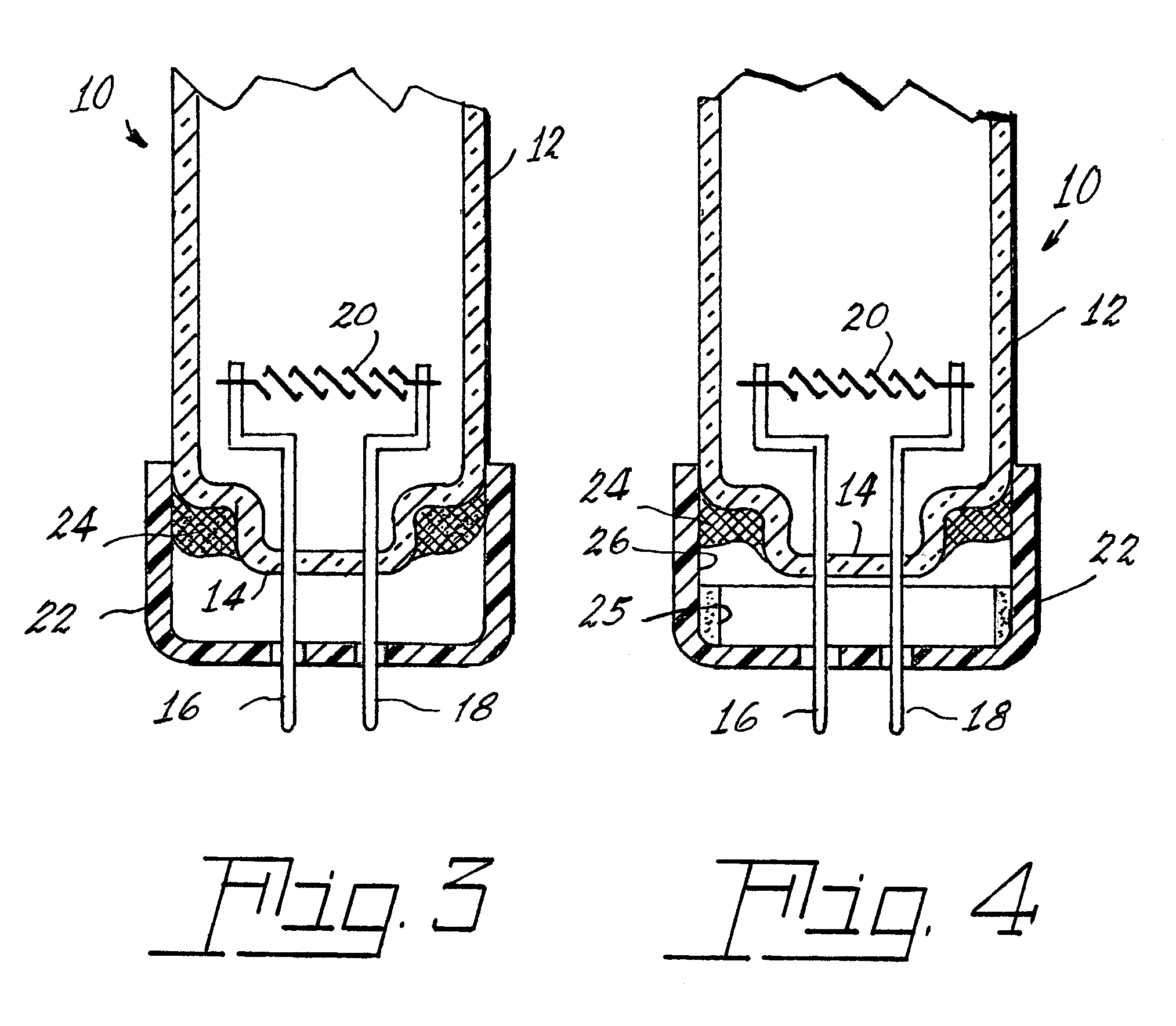

Quick-release torquer apparatus for delivering and maintaining a medical guideware

InactiveUS7144378B2Facilitate manipulation and maneuverabilityAssist in manipulation and maneuverabilityEar treatmentInfusion syringesFast releaseBlood vessel

The present invention provides a torquer for maneuvering a medical guidewire during endovascular surgical procedures or the like, which can be easily positioned and re-positioned along the length of the wire. A clamp-like device is formed with a top arm and a bottom arm connected to one another by means of a flap hinge. A horizontal slit is defined within the flap hinge, and a vertical slit is defined on a clamping tongue positioned at the top distal end of the top arm, such that the torquer is placed onto the guidewire and snapped into place with the guidewire penetrating the vertical slit. A wire channel means is further defined between the two arms to hold the guidewire within the torquer.

Owner:ARNOTT RICHARD J

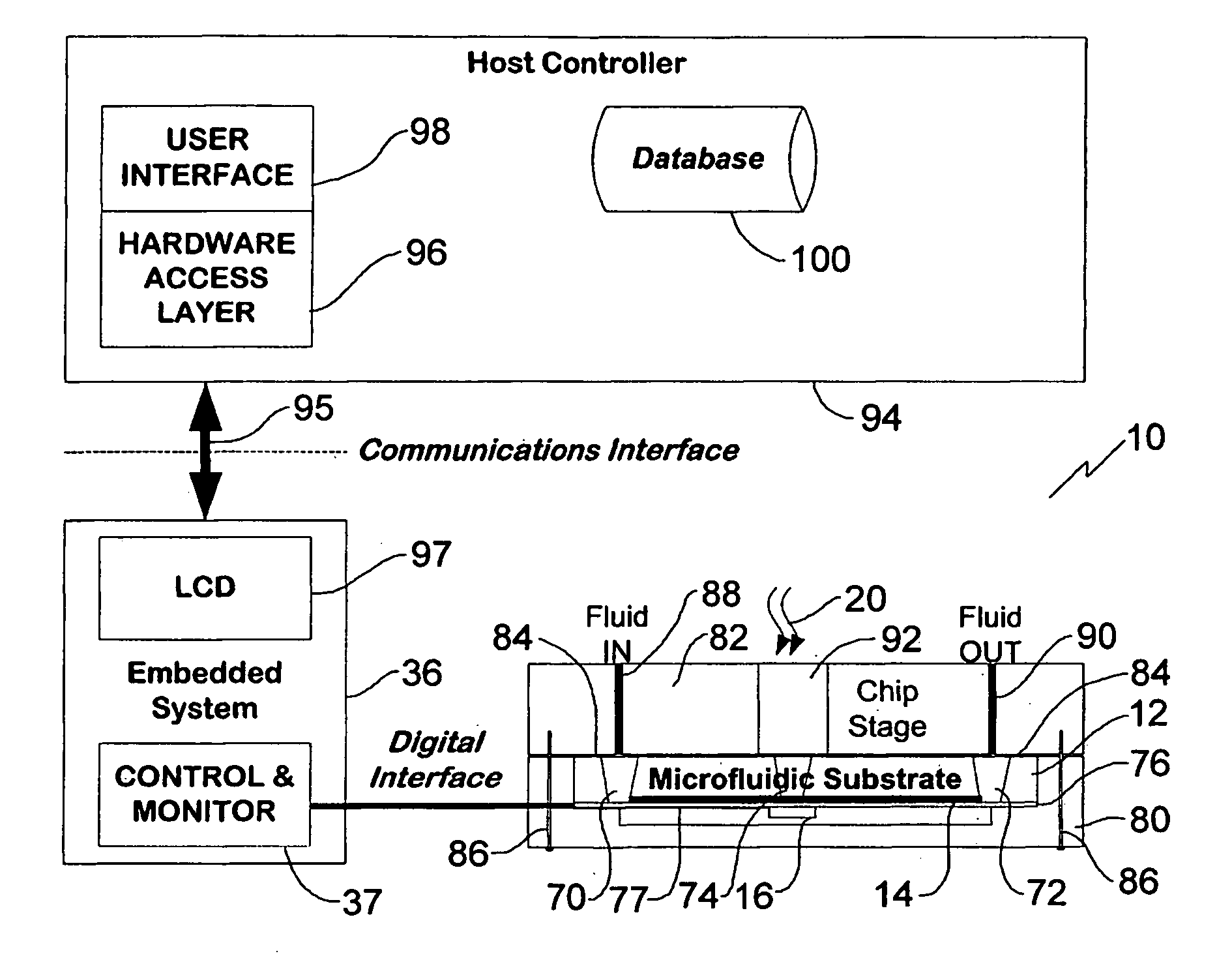

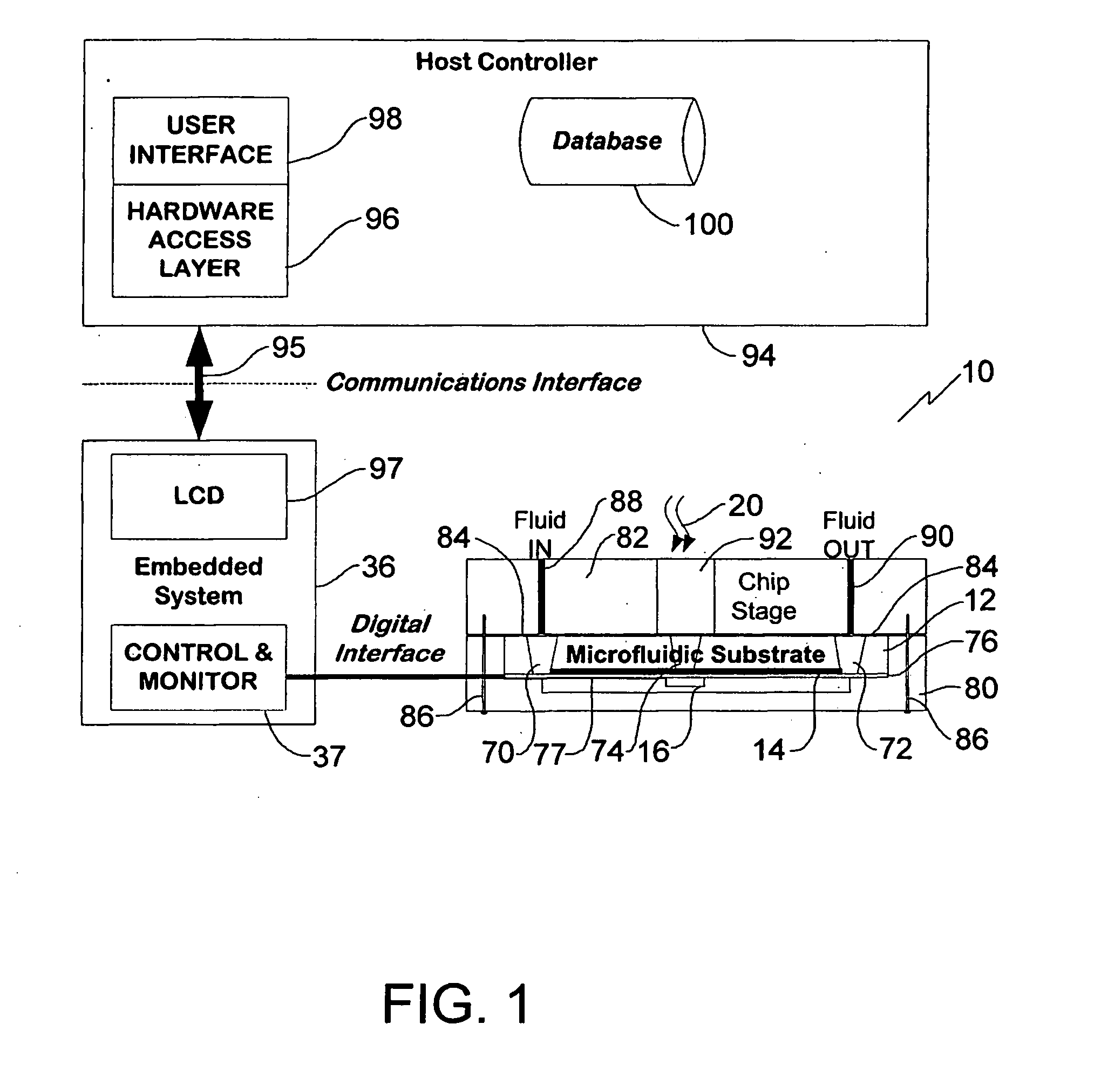

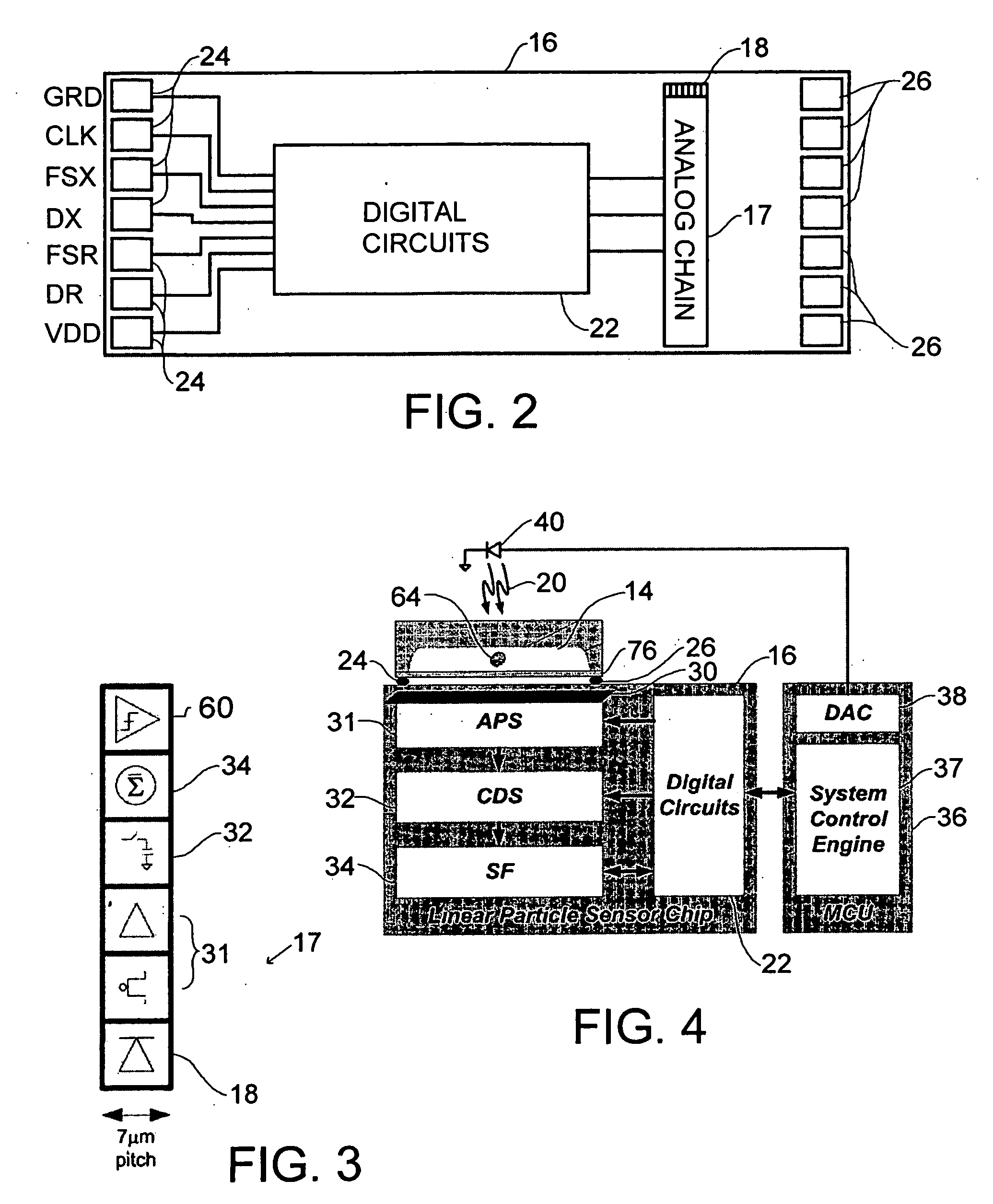

Cytometer

A real-time digital cytometer on a chip system utilizing a custom near field CMOS active pixel intelligent sensor that is flip-chip attached to a fluidic microchannel etched in a thin glass substrate. The CMOS active pixel sensor, fabricated using a 0.18 micron process, is a mixed signal chip comprising a sixteen pixel linear adaptive spatial filter coupled to a digital serial interface. This near field hybrid digital sensor topology obviates the need for both high resolution analog to digital conversion as well as conventional microscopy for the realization of real time optical cytometry. The custom sensor based design approach affords efficient scaling into a tiled multi-channel sensing configuration. The complete system, supported by a handheld graphical user interface and control module, demonstrates a viable micro total analysis sub-system for sample preparation and analysis which can support a wide range of applications ranging from cytometry to cell growth kinetics and analysis and various forms of fluid and droplet metering on an integrated and compact microfluidic platform.

Owner:UTI LLP

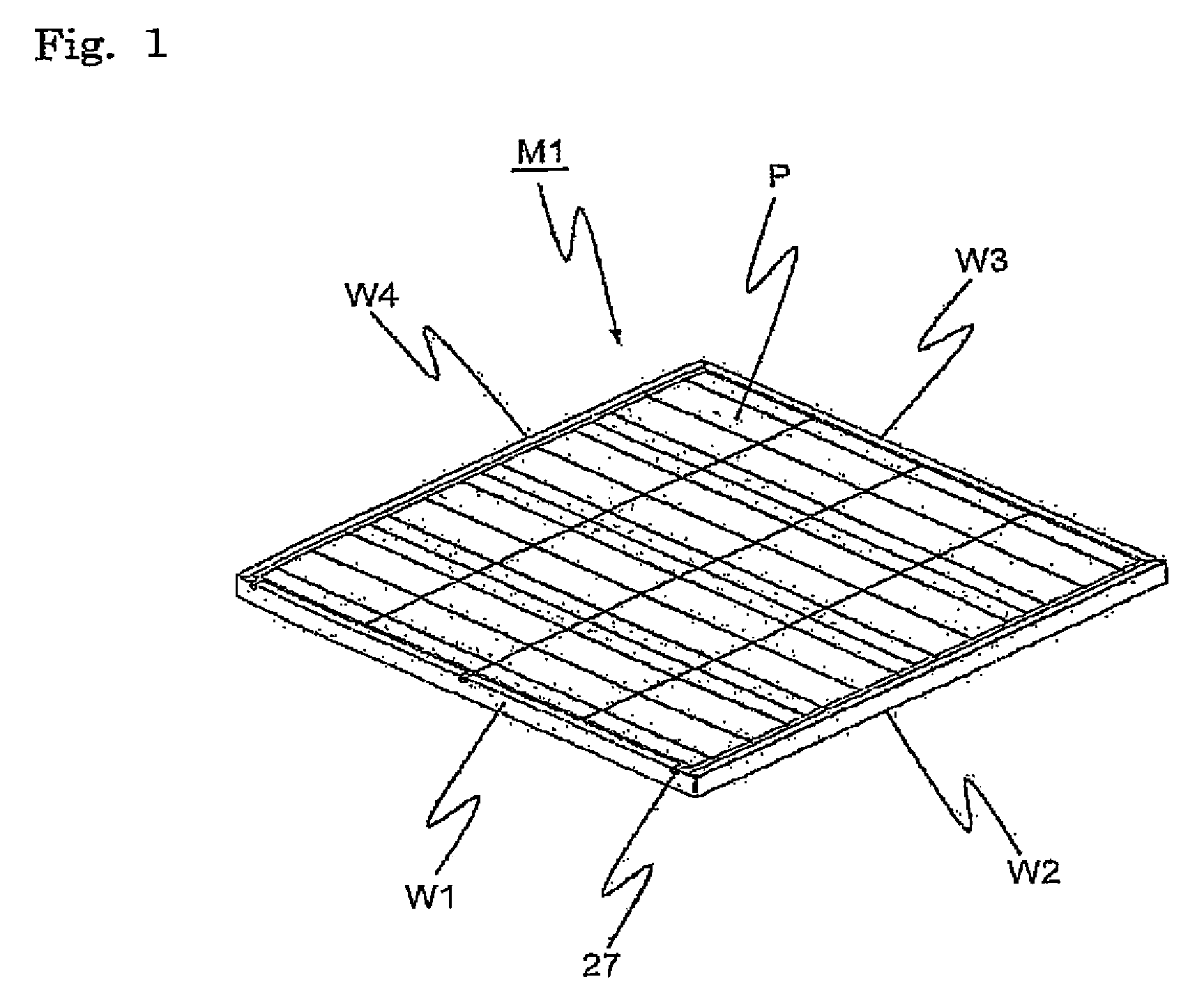

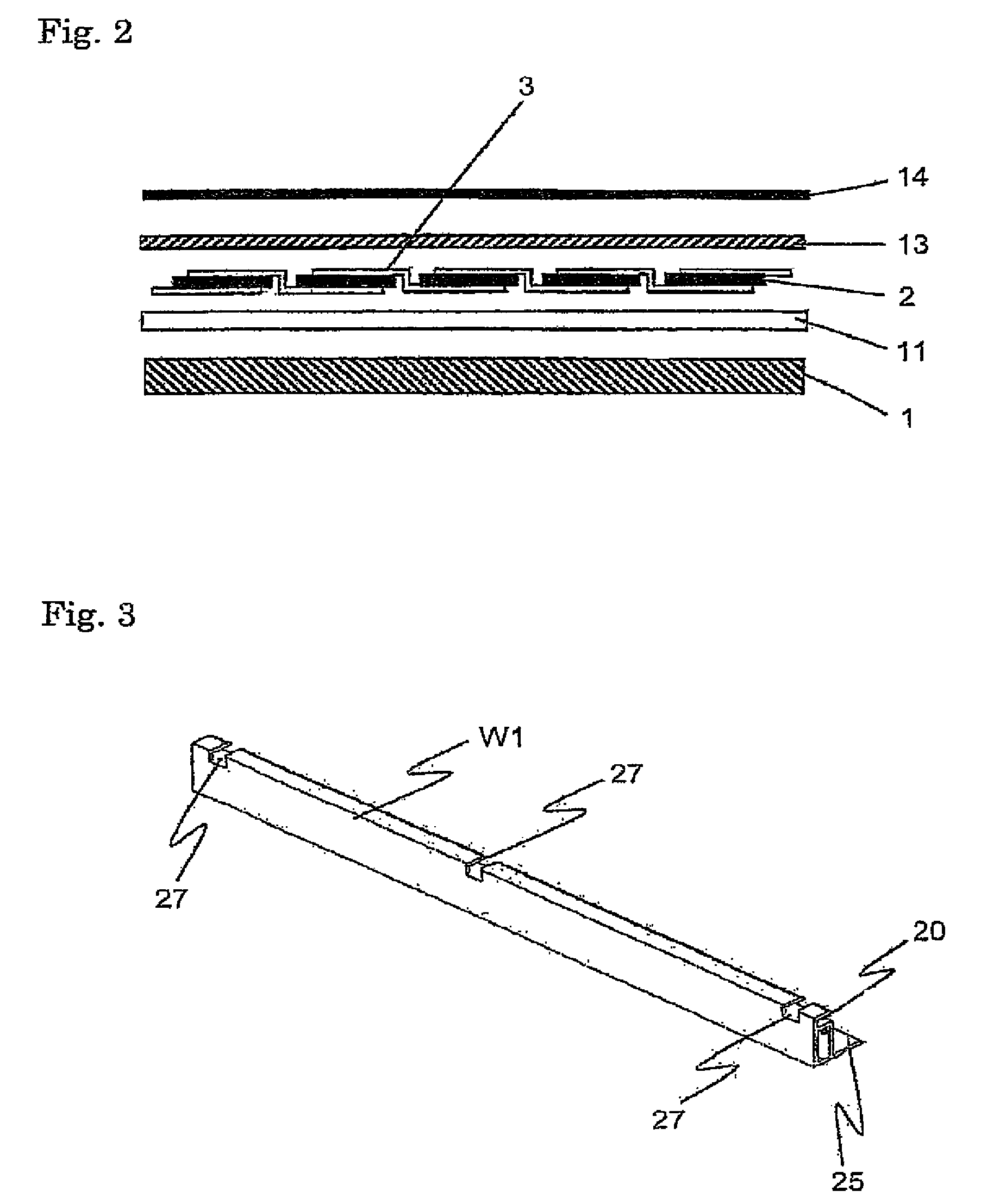

Solar cell module and solar cell array

ActiveUS7956279B2Reduce power outputSufficient hydrophilicityPhotovoltaic supportsSolar heating energyEngineeringSolar cell

A reliable solar cell module is provided whereby the liquid is less likely to stay thereon, thus dirt is less likely to occur on the light receiving surface of the solar cell module even in a prolonged use. A solar cell module comprising a solar cell panel P configured by arranging a solar cell element between a light receiving surface side member and a rear surface side member, and a module frame W1 fixed to the solar cell panel P surrounds the solar cell panel P with its interior surface being abutted with an external peripheral part of the light receiving surface side member is provided. In this solar cell module, the module frame W1 has a notch 27 that extends from its inner part towards its external part in plan view from a side of the light receiving surface side member and is provided with an end portion 5 on an exterior side surface of the frame member, and this notch 27 has a draw part 4 with smallest width at an inner part rather than at the end portion 5.

Owner:KYOCERA CORP

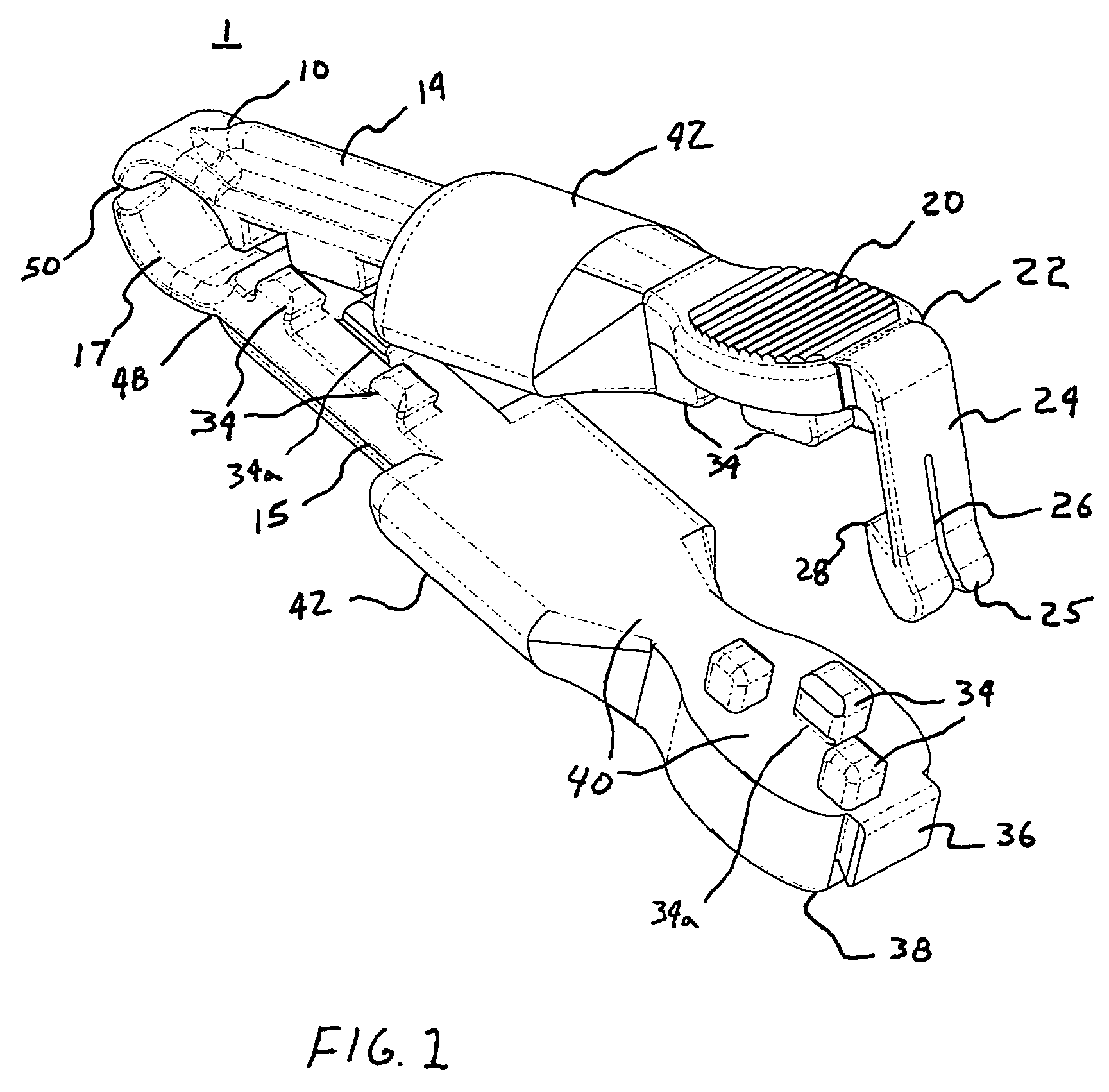

Quick-release torquer apparatus for delivering and maintaining a medical guidewire

InactiveUS20050096566A1Quick exchangeFacilitate manipulation and maneuverabilityEar treatmentInfusion syringesMedicineSurgical department

The present invention provides a torquer for maneuvering a medical guidewire during endovascular surgical procedures or the like, which can be easily positioned and re-positioned along the length of the wire. A clamp-like device is formed with a top arm and a bottom arm connected to one another by means of a flap hinge. A horizontal slit is defined within the flap hinge, and a vertical slit is defined on a clamping tongue positioned at the top distal end of the top arm, such that the torquer is placed onto the guidewire and snapped into place with the guidewire penetrating the vertical slit. A wire channel means is further defined between the two arms to hold the guidewire within the torquer.

Owner:ARNOTT RICHARD J

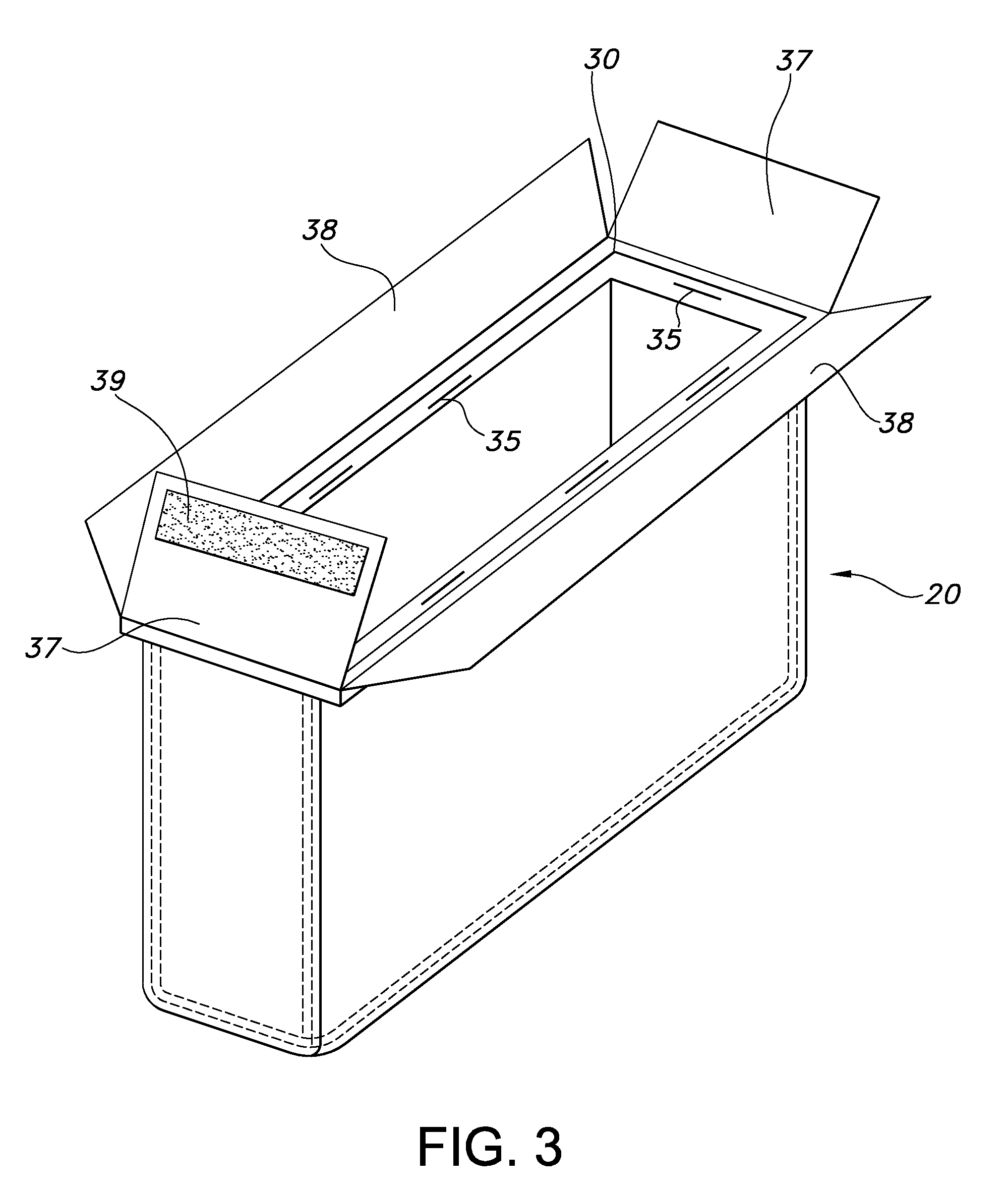

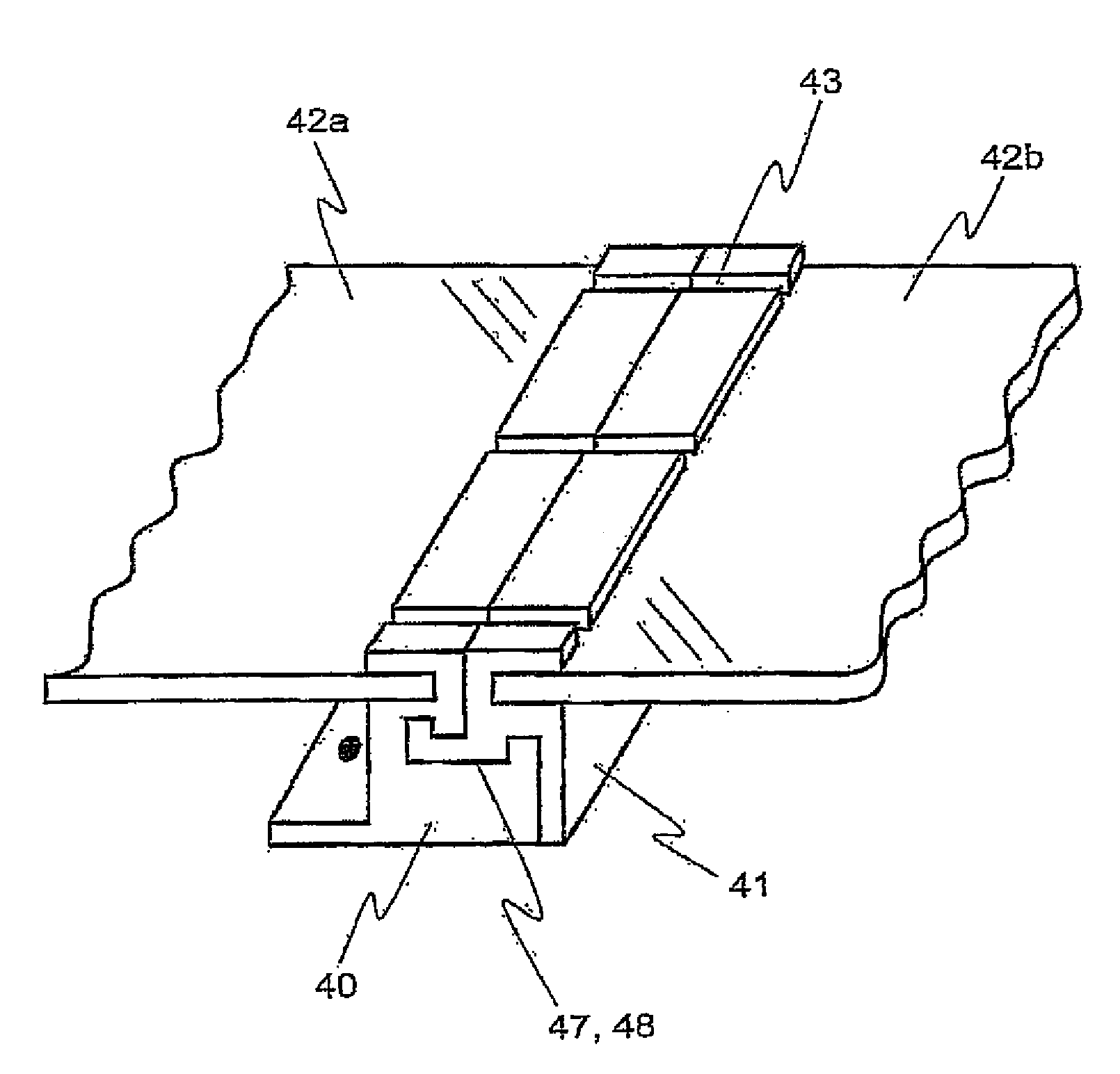

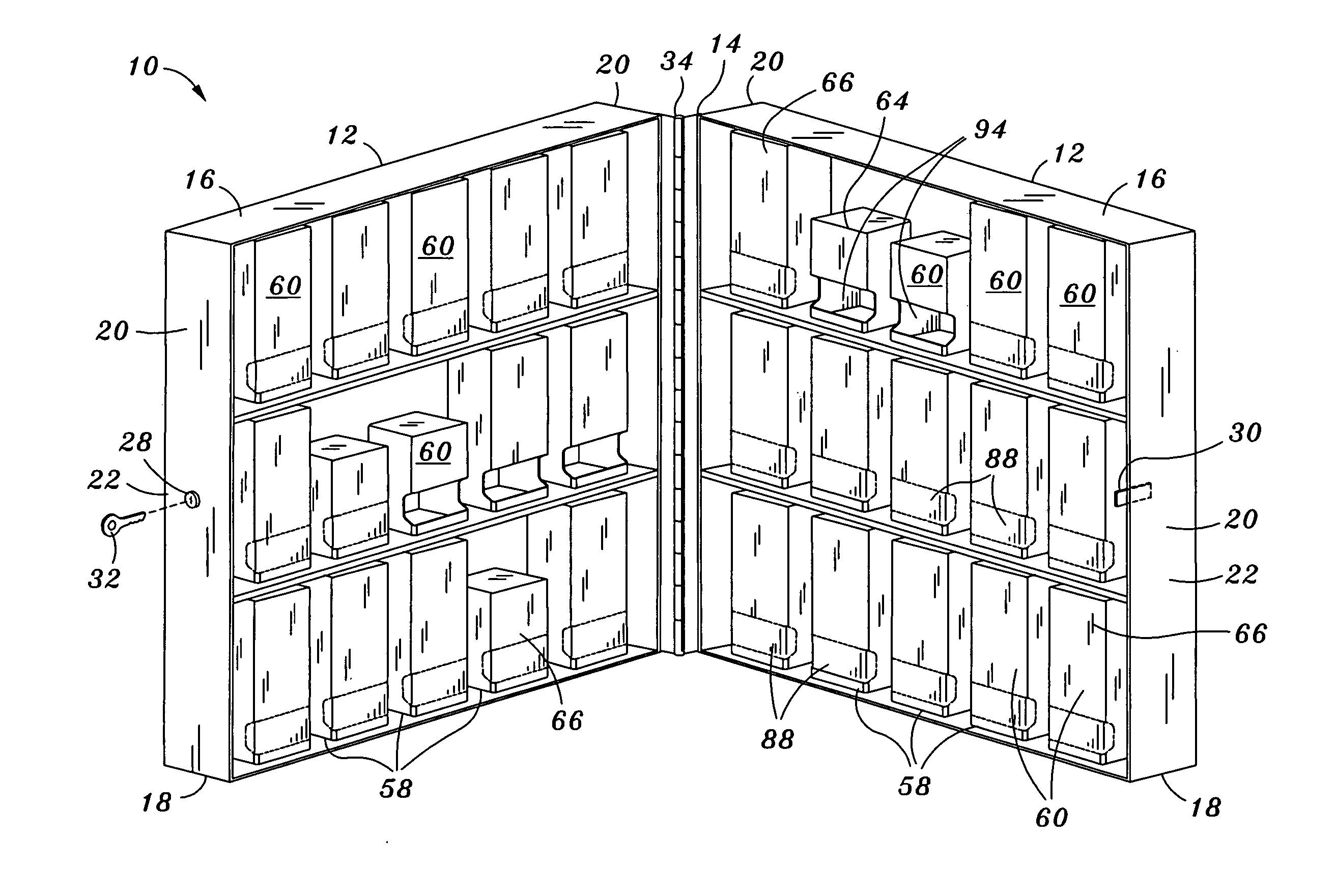

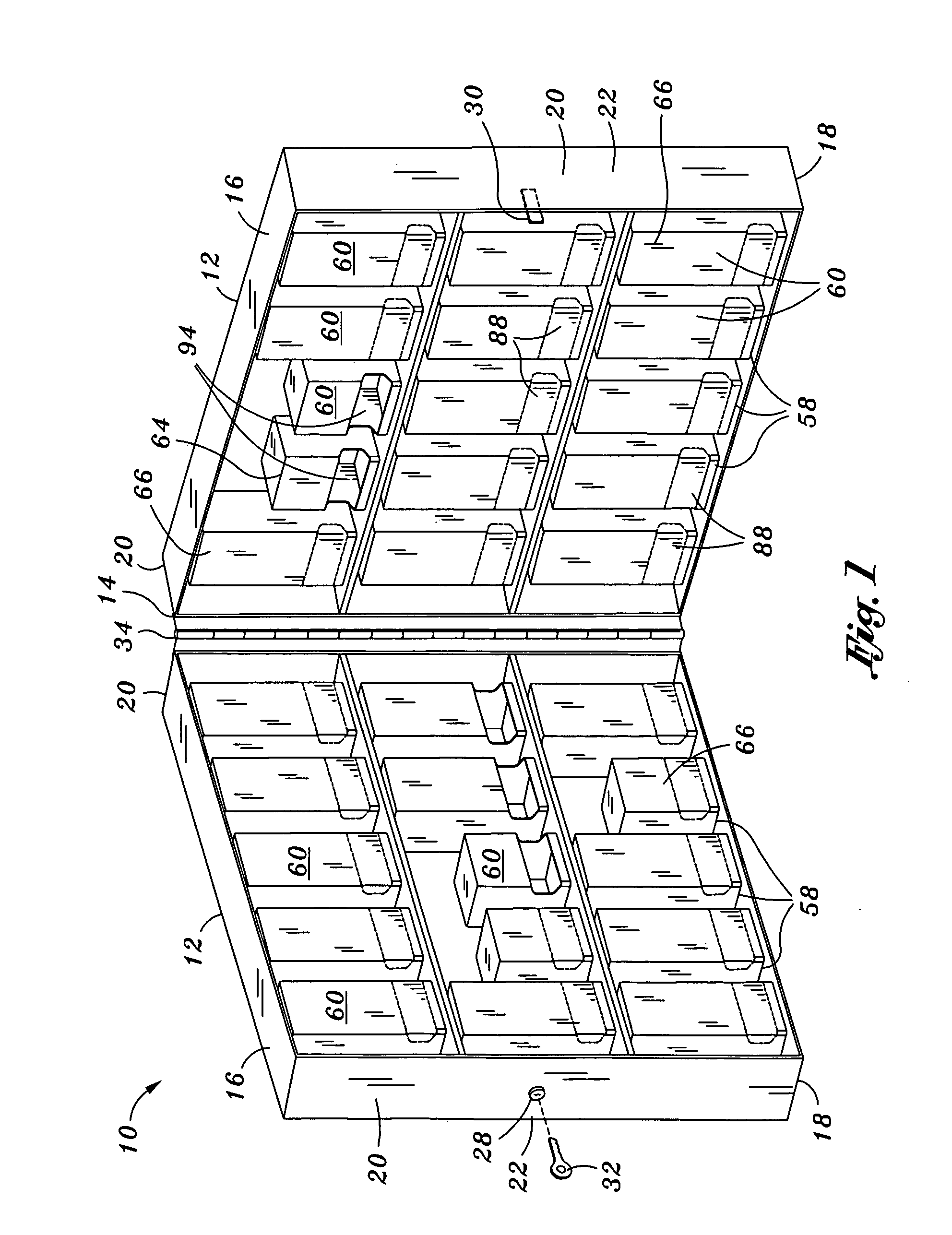

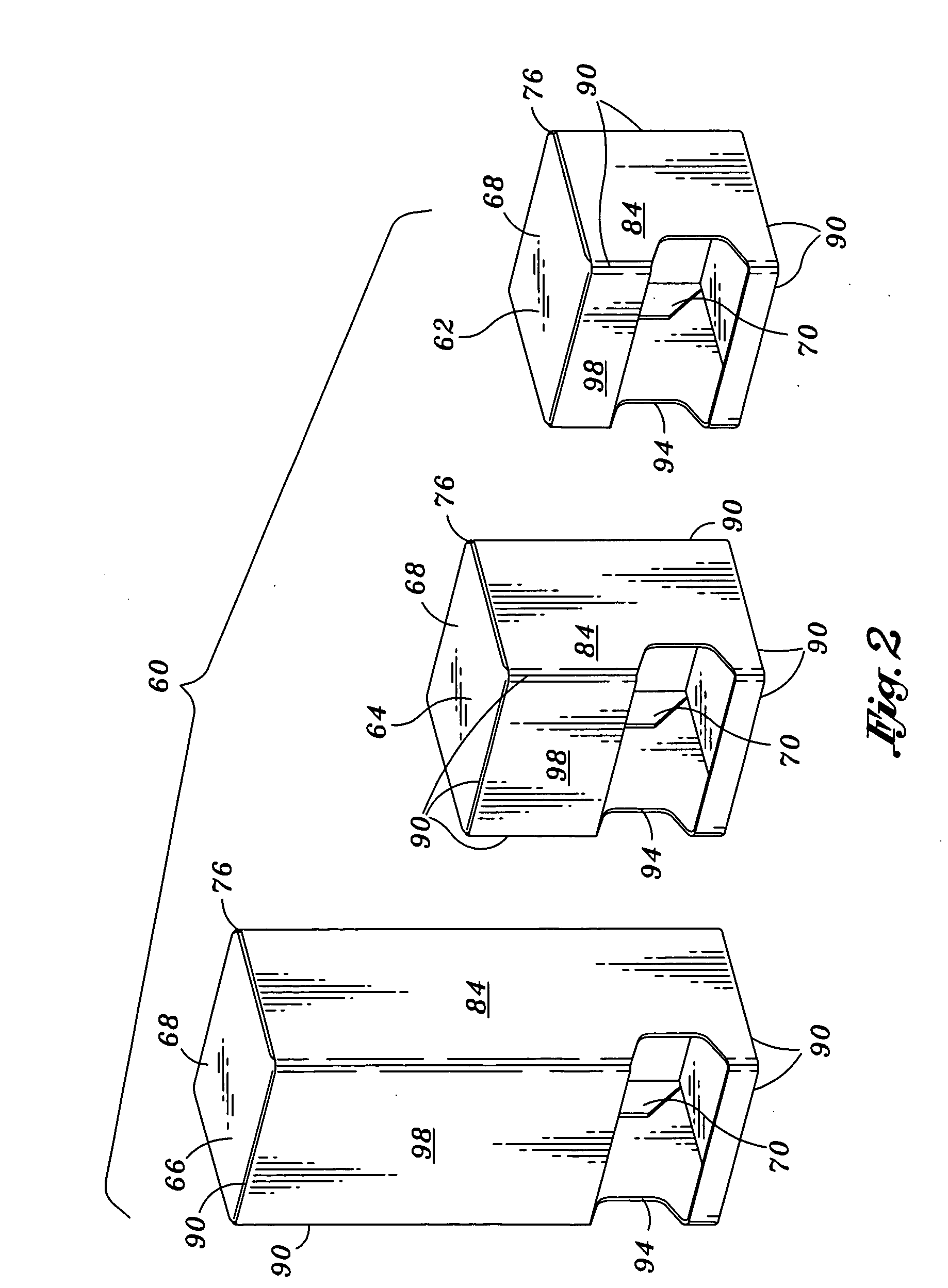

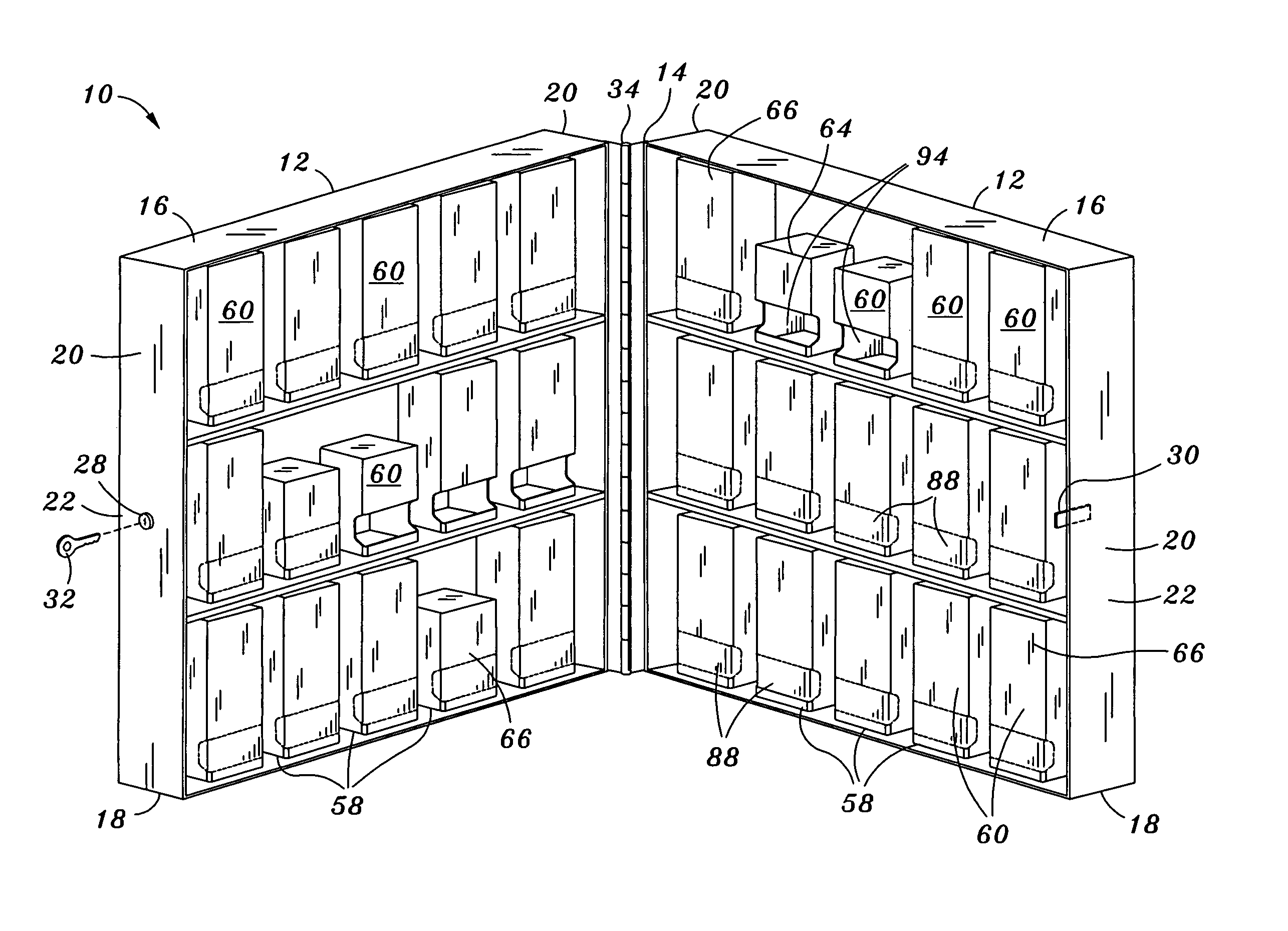

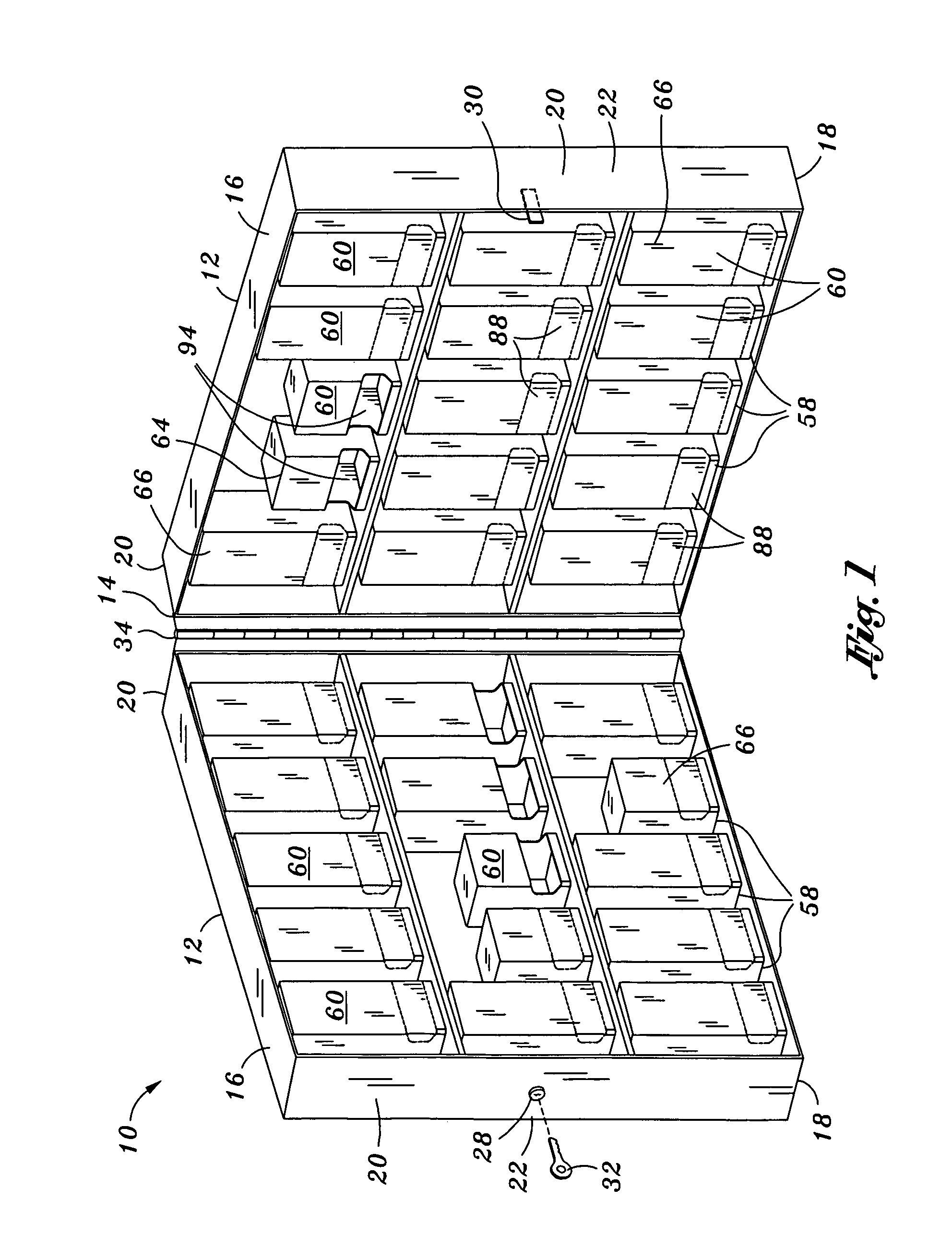

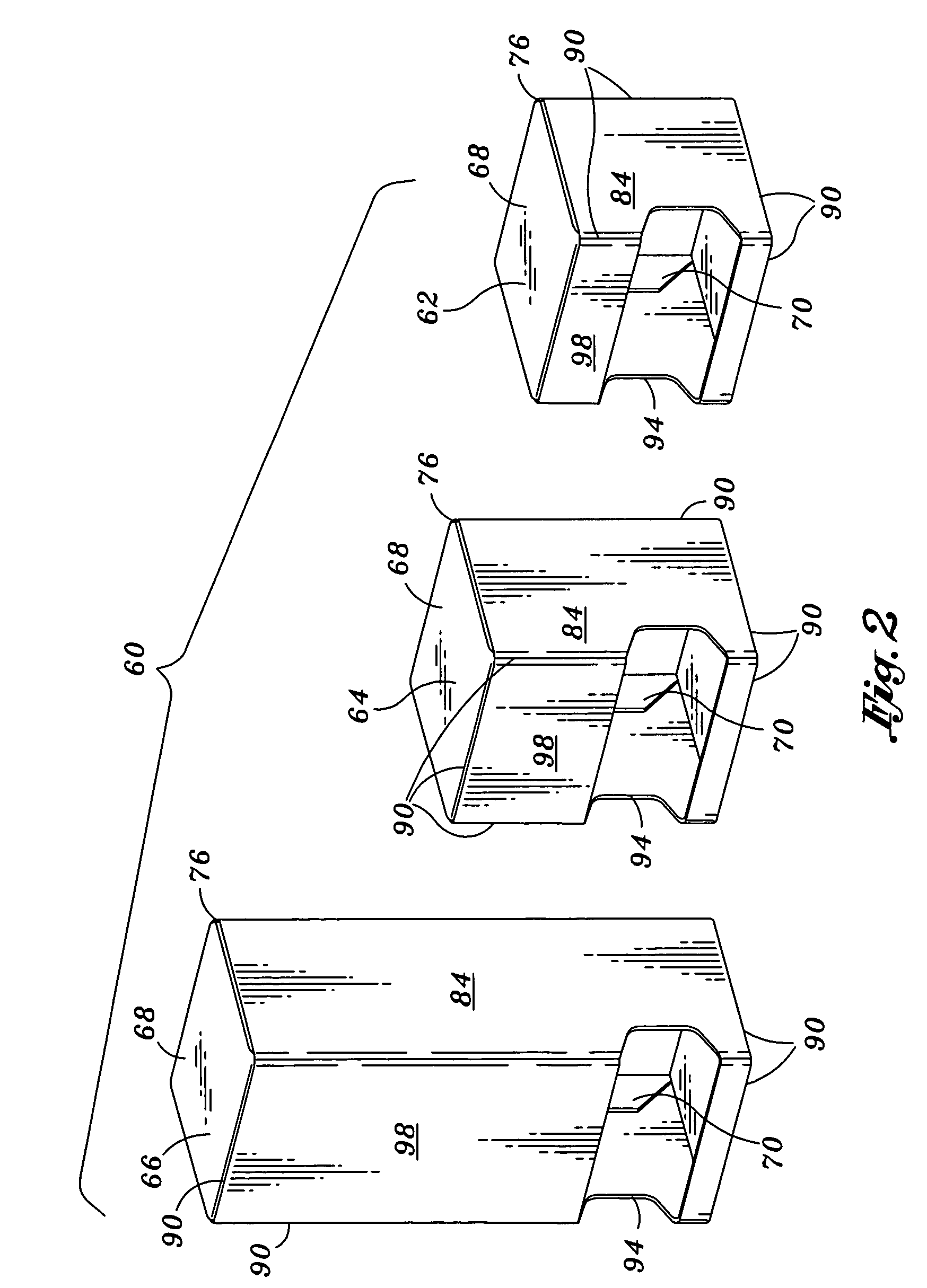

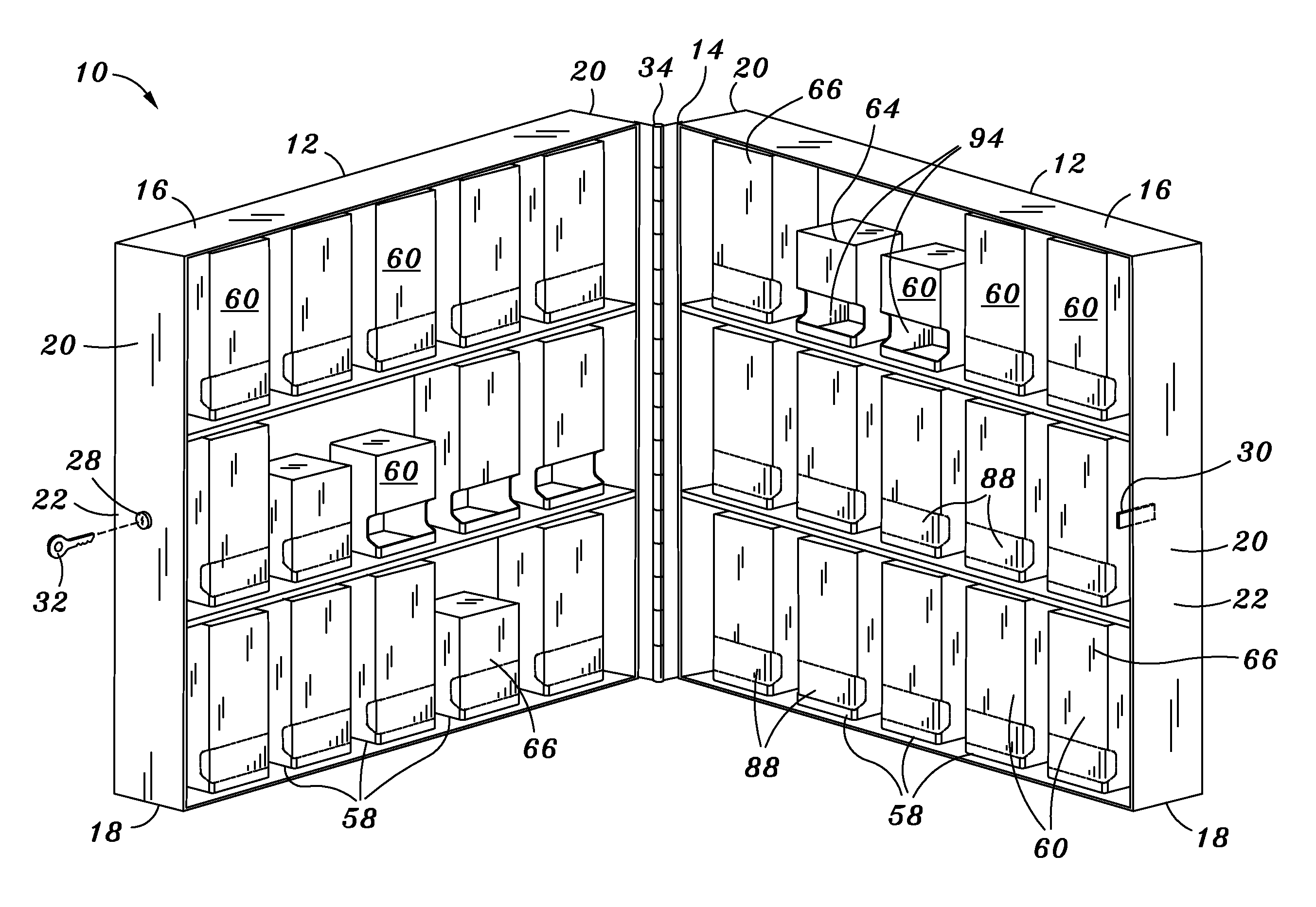

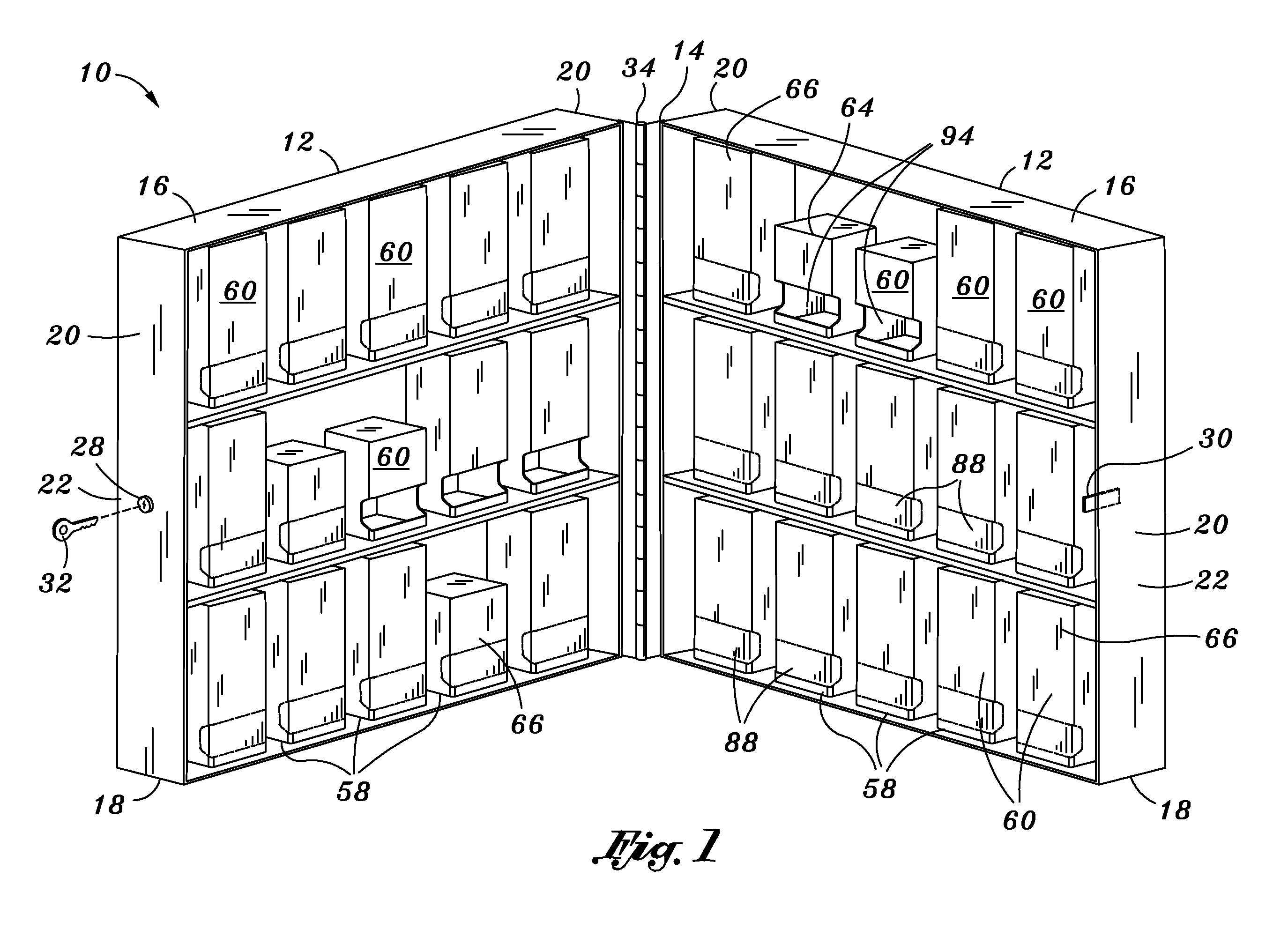

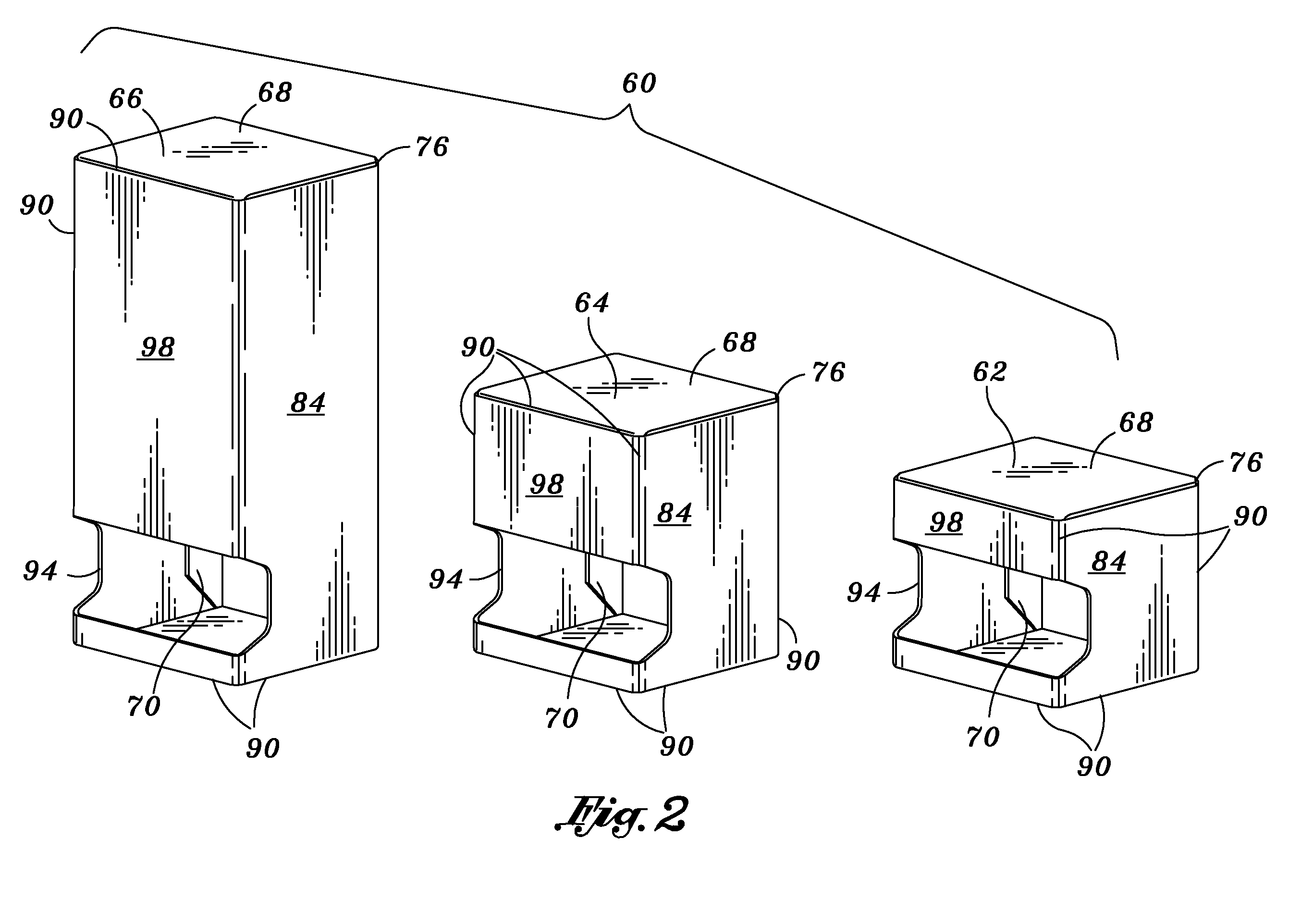

Quick dispense system

ActiveUS20070000934A1Easy to shipEasy to storeSmall article dispensingCoin-freed apparatus detailsDrug dispensingEngineering

Provided as a drug dispensing system comprising a cabinet and at least one cartridge. A cabinet has opposing door portions which are hingedly attached to one another and which are configured to be closable against one another such as via a lock member. Each one of the door portions includes at least one shelf which defines a shelf depth and which has an upwardly turned lip extending along the length of the shelf. The cartridge has a cartridge depth that is sized to be complementary to the shelf depth such that the cartridge may be retained by the lip when the cartridge is stored on the shelf. Each one of the cartridges is configured to store a plurality of vials. A punch-out is disposed in a lower end of the cartridge and through which the vials may be dispensed from the cartridge. The cartridge itself may be comprised of a top panel, a bottom panel, a front panel, a back panel and a pair of side panels foldable connected to one another along a plurality of fold lines and to define an interior compartment that is sized and configured to dispensibly store the vials.

Owner:DS HLDG LLC

Film and process for producing the same

ActiveUS7476712B2Excellent gasImprove solubilitySynthetic resin layered productsCoatingsWater vaporCompound (substance)

The invention is directed to a film which comprises a poly(carboxylic acid) polymer and a polyvalent metal compound, which is endowed with excellent gas barrier property against, for example oxygen, which has such resistance that the appearance, shape, and gas-barrier properties are not impaired by neutral water, high-temperature water vapor, or hot water; a laminate produced by use of the film; and a process for producing the film or laminate industrially conveniently at low cost. The film or laminate of the present invention is suitable for use as a package, packaging container, or vacuum insulation material for articles which are apt to be deteriorated by oxygen, etc., such as foods, beverages, chemicals, medicines, and metallic precision parts; e.g., electronic parts. Furthermore, there can be provided a packaging material suitable for use with articles which are required to be reliably insulated from gases for prolonged periods and should be treated under high-temperature, hot-water conditions as in boiling or pressurized high-temperature sterilization.

Owner:TOPPAN PRINTING CO LTD

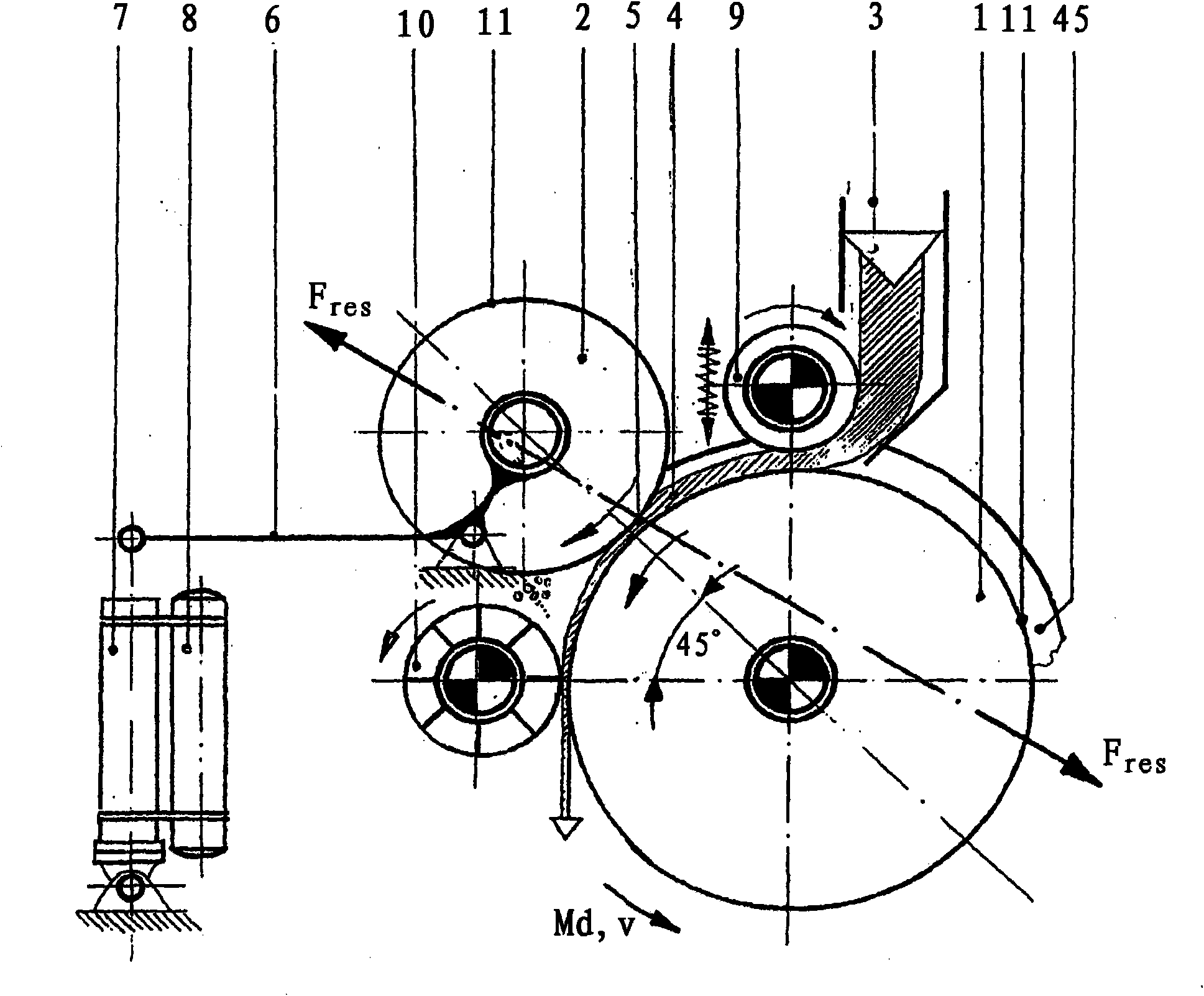

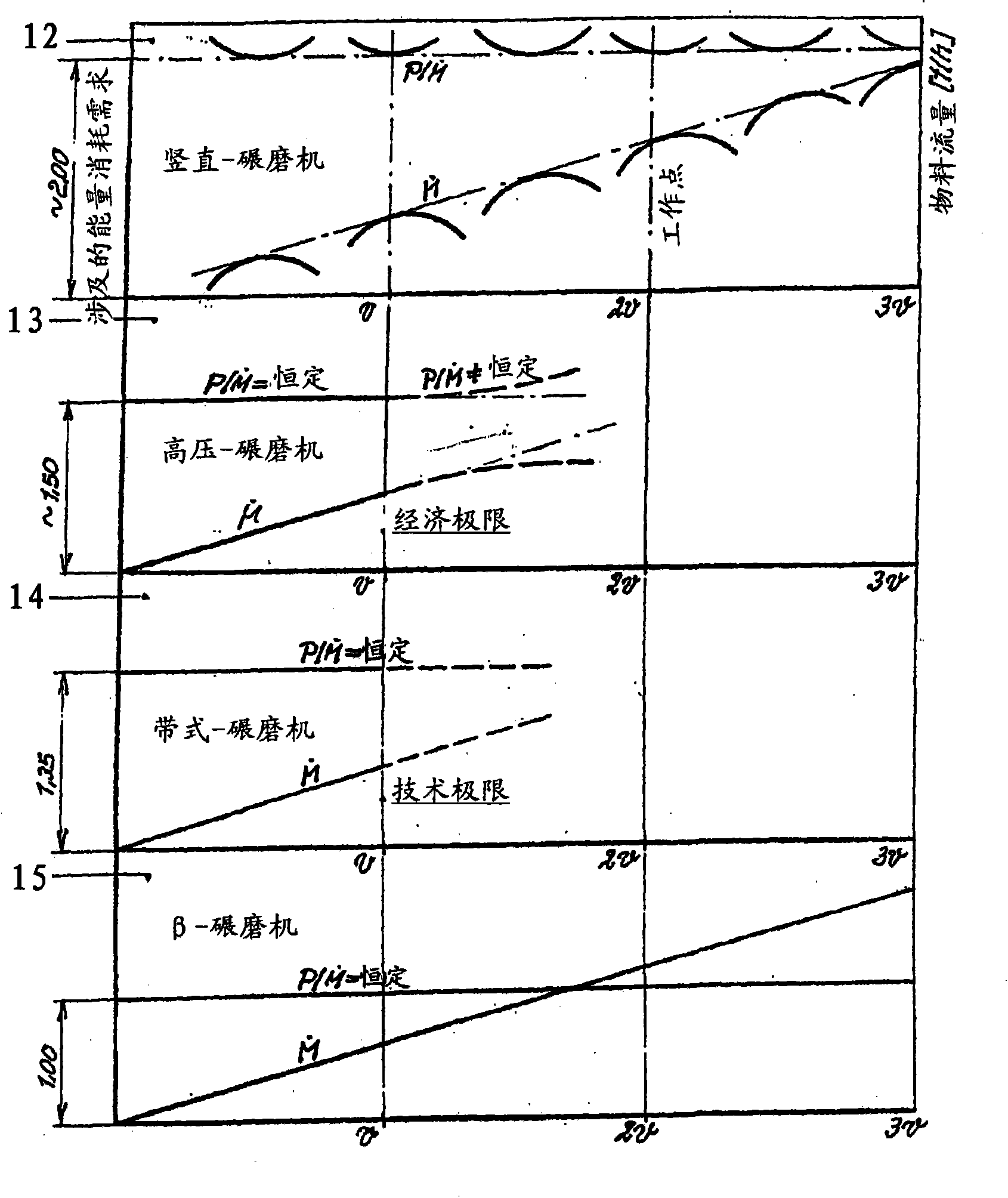

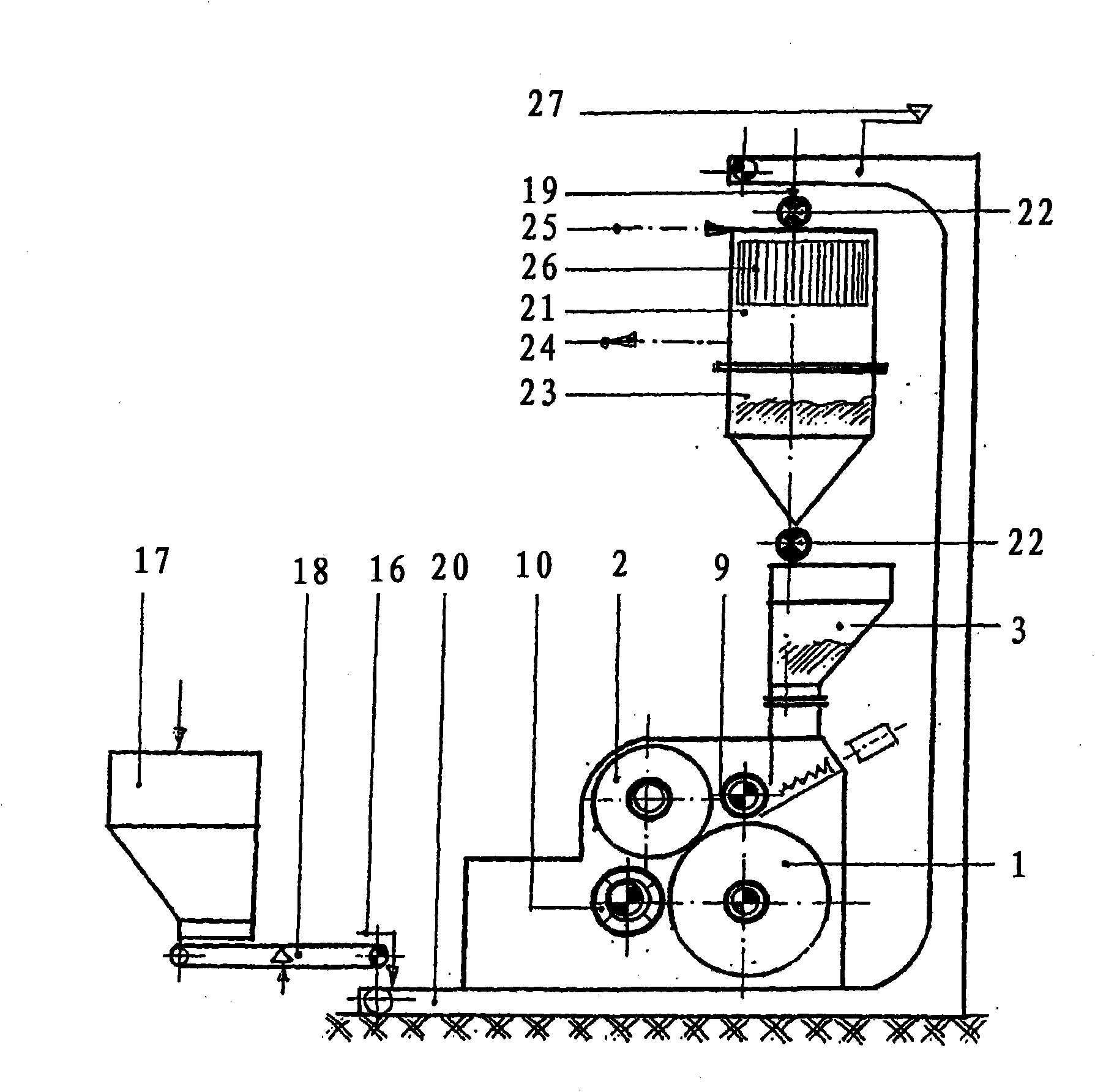

Method of, and apparatus for, the preliminary grinding and finishing of mineral and non-mineral materials

In the preliminary grinding and finishing of mineral and non-mineral materials, e.g. limestone, cement clinker, blast-furnace slag, old concrete or ashes, the grinding material, usually comprising new and recirculated stock, is fed as a defined and laterally bounded material layer (4) of predetermined thickness from a material-supply container (3), belonging to the comminuting apparatus, by way of a roller-type or rotary-vane feeder (9), which is arranged at the outlet and can be changed in a stepless manner in respect of its rotational speed, onto the vertex of the laterally rimmed (45), driven, bottom roller (1), accelerated to the roller speed and transported continuously into the gap formed (5) with the top roller (2), arranged in an offset manner above the driven roller (1), is subjected to hydropneumatic loading using specific compressive forces of 2 to 7.5 kN / mm and is then deagglomerated within the comminuting apparatus by a preferably high-speed rotary crusher (10). This results in good utilization of energy and in low mechanical structural, servicing and maintenance outlay. Usage over a wide spectrum for comminuting different materials is made possible, and linear throughput and speed behaviour both in partial-load operation and with high mass throughputs can be realized.

Owner:彼得拉·梅马里·法尔德 +2

Quick dispense system

ActiveUS7513367B2Facilitates shipping and storage and handlingAbility to disassemble and unfold the cartridgeSmall article dispensingCoin-freed apparatus detailsDrug dispensingEngineering

Provided as a drug dispensing system comprising a cabinet and at least one cartridge. A cabinet has opposing door portions which are hingedly attached to one another and which are configured to be closable against one another such as via a lock member. Each one of the door portions includes at least one shelf which defines a shelf depth and which has an upwardly turned lip extending along the length of the shelf. The cartridge has a cartridge depth that is sized to be complementary to the shelf depth such that the cartridge may be retained by the lip when the cartridge is stored on the shelf. Each one of the cartridges is configured to store a plurality of vials. A punch-out is disposed in a lower end of the cartridge and through which the vials may be dispensed from the cartridge. The cartridge itself may be comprised of a top panel, a bottom panel, a front panel, a back panel and a pair of side panels foldable connected to one another along a plurality of fold lines and to define an interior compartment that is sized and configured to dispensibly store the vials.

Owner:DS HLDG LLC

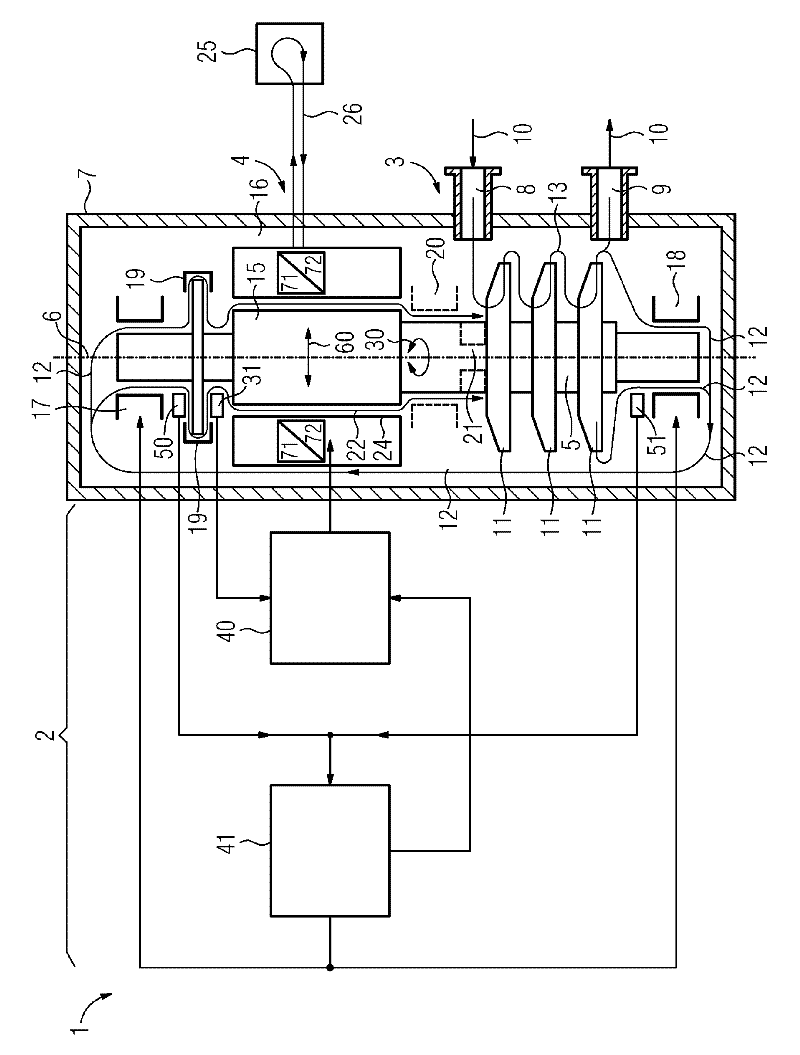

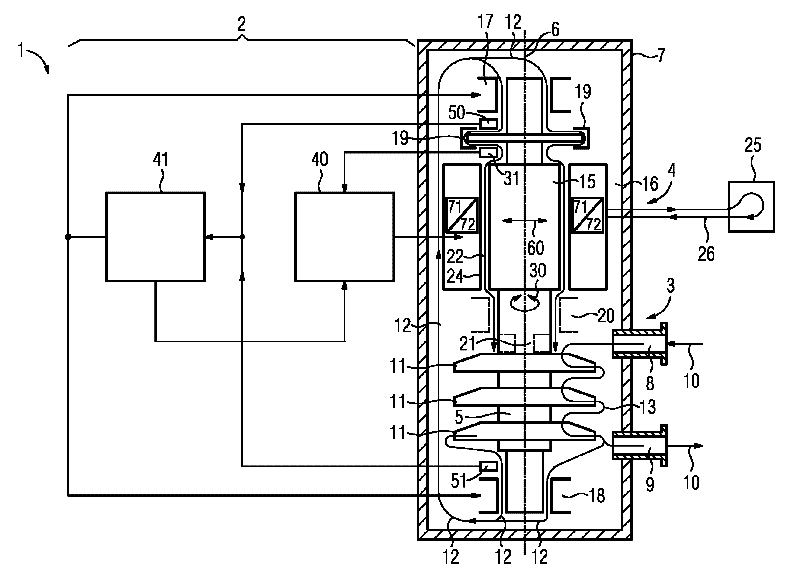

Fluid energy machine

The invention relates to a fluid energy machine (1), in particular compressor (3) or pump, having a housing (7), having a motor (4), having at least one impeller (11), having at least two radial bearings (17, 18) and having at least one shaft (5) which extends along a shaft longitudinal axis (6) and which supports the at least one impeller (11) and a rotor (15) of the motor (4), wherein the shaft (5) is mounted in the radial bearings (17, 18), wherein the motor (4) has a stator (16) which at least partially surrounds the rotor (15) in the region of the motor (4), and wherein a gap (22) which extends in the circumferential direction and along the shaft longitudinal axis (6) is formed between the rotor (15) and the stator (16) and between the rotor (15) and the radial bearings (17, 18), which gap (22) is at least partially filled with a fluid. Conventional fluid energy machines (1) have a restricted operating range as a result of destabilizing aerodynamic or hydrodynamic forces in the gap (22) between the stator (16) and the rotor (15). The invention aims to remedy this in that the motor (4) is also embodied as a bearing and is connected to a controller (2), which activates the motor (4) in such a way that forces (60) acting radially with respect to a shaft longitudinal axis (6) can be exerted in addition to torques (30) for driving the fluid energy machine (1).

Owner:SIEMENS AG

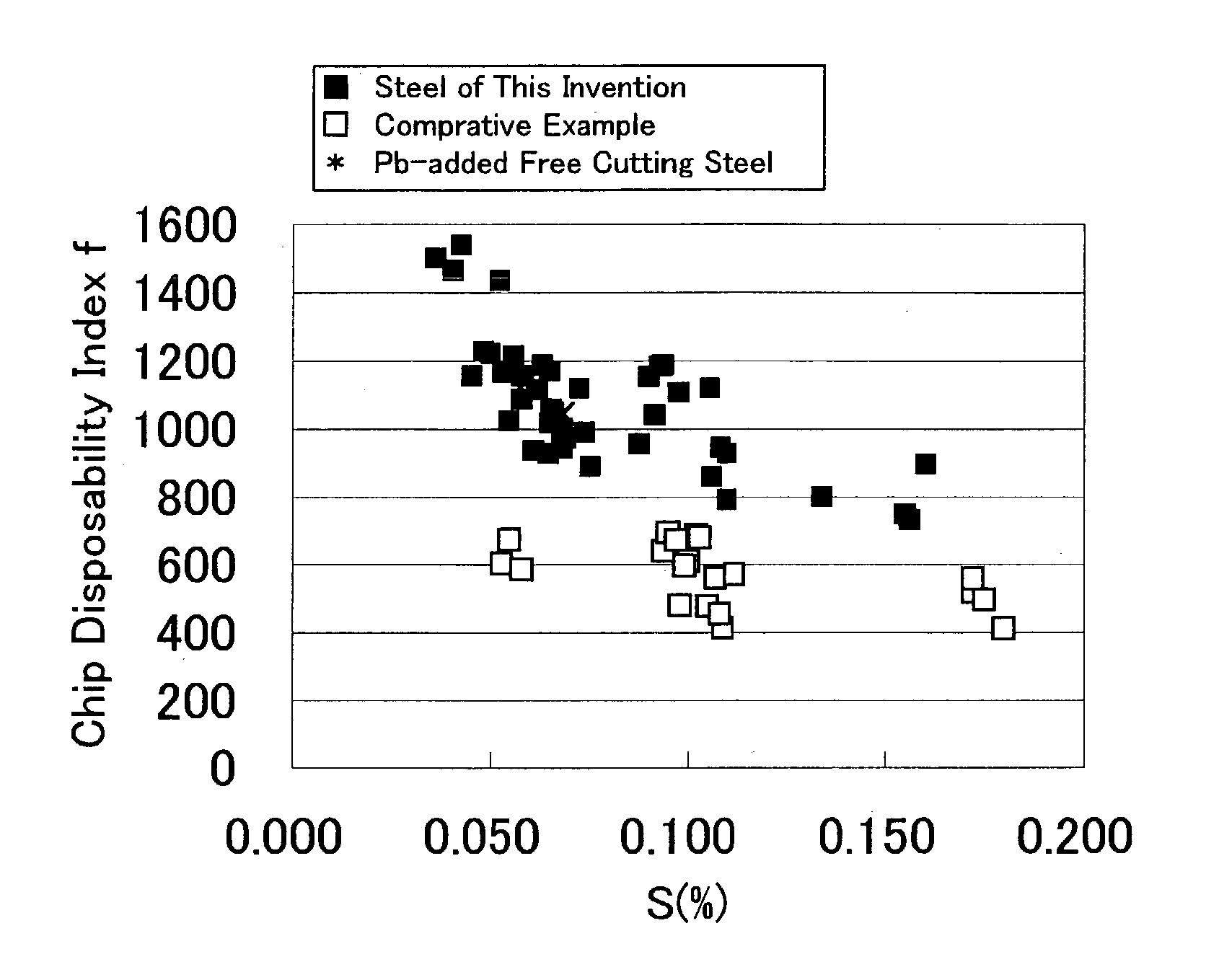

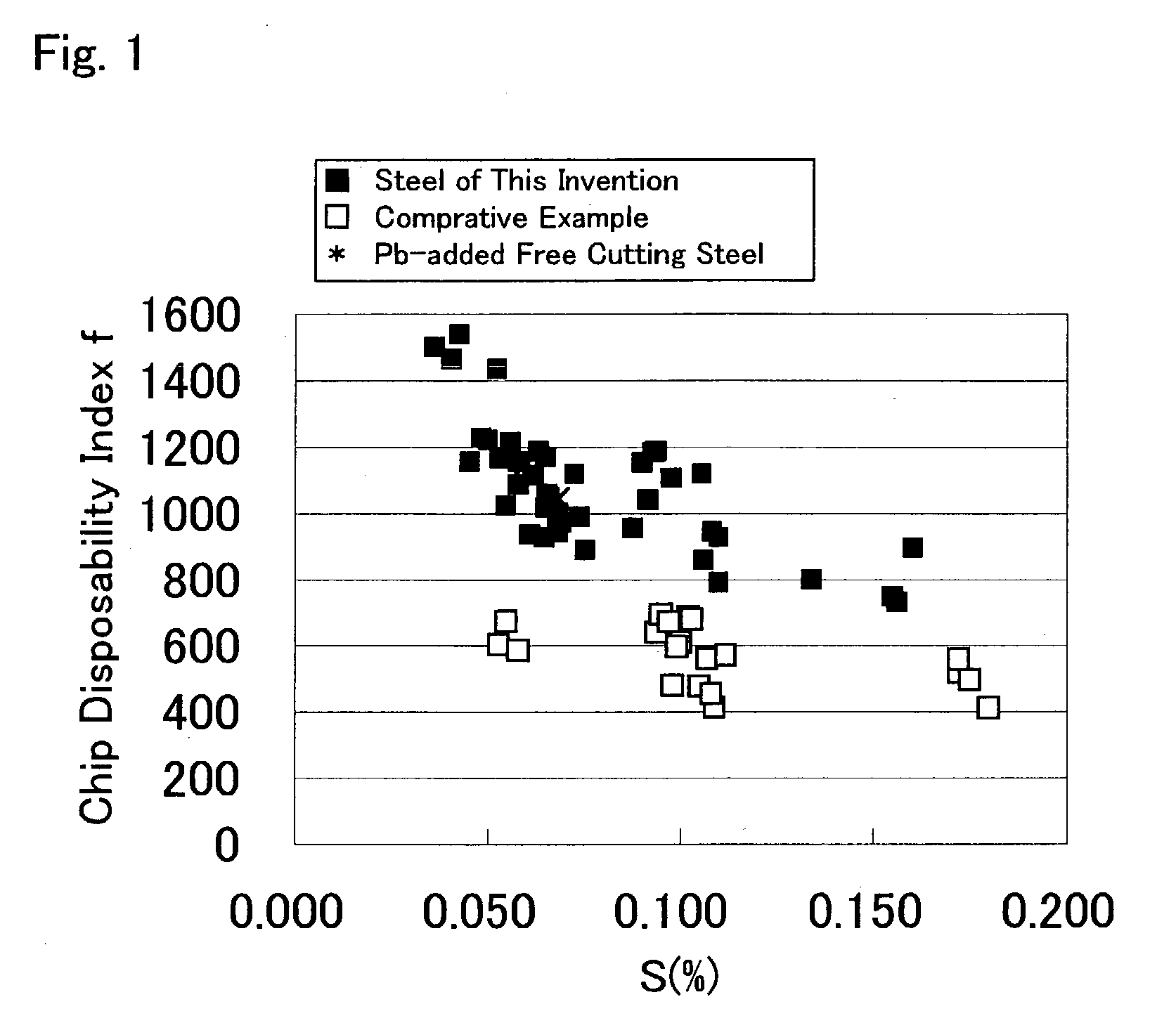

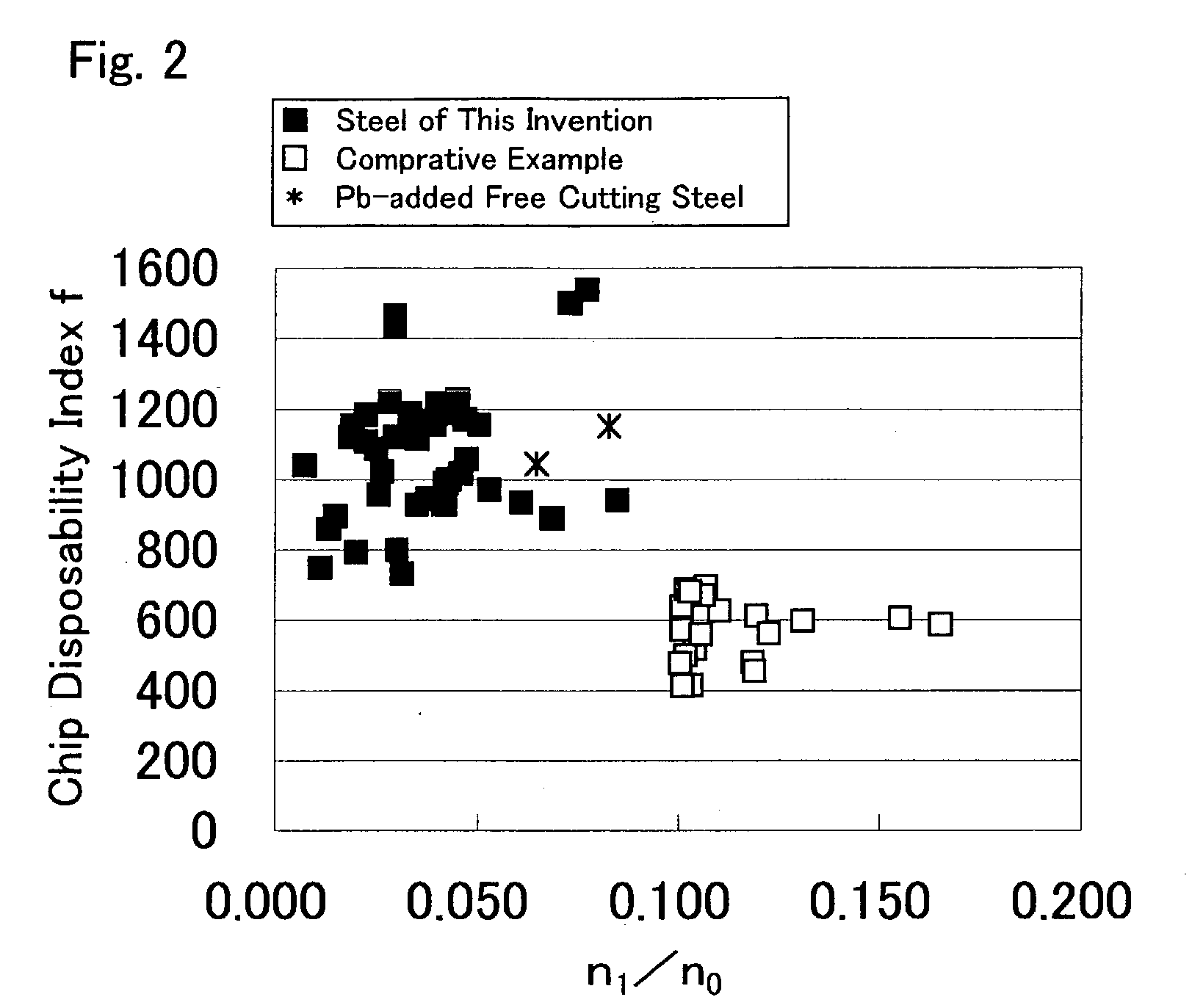

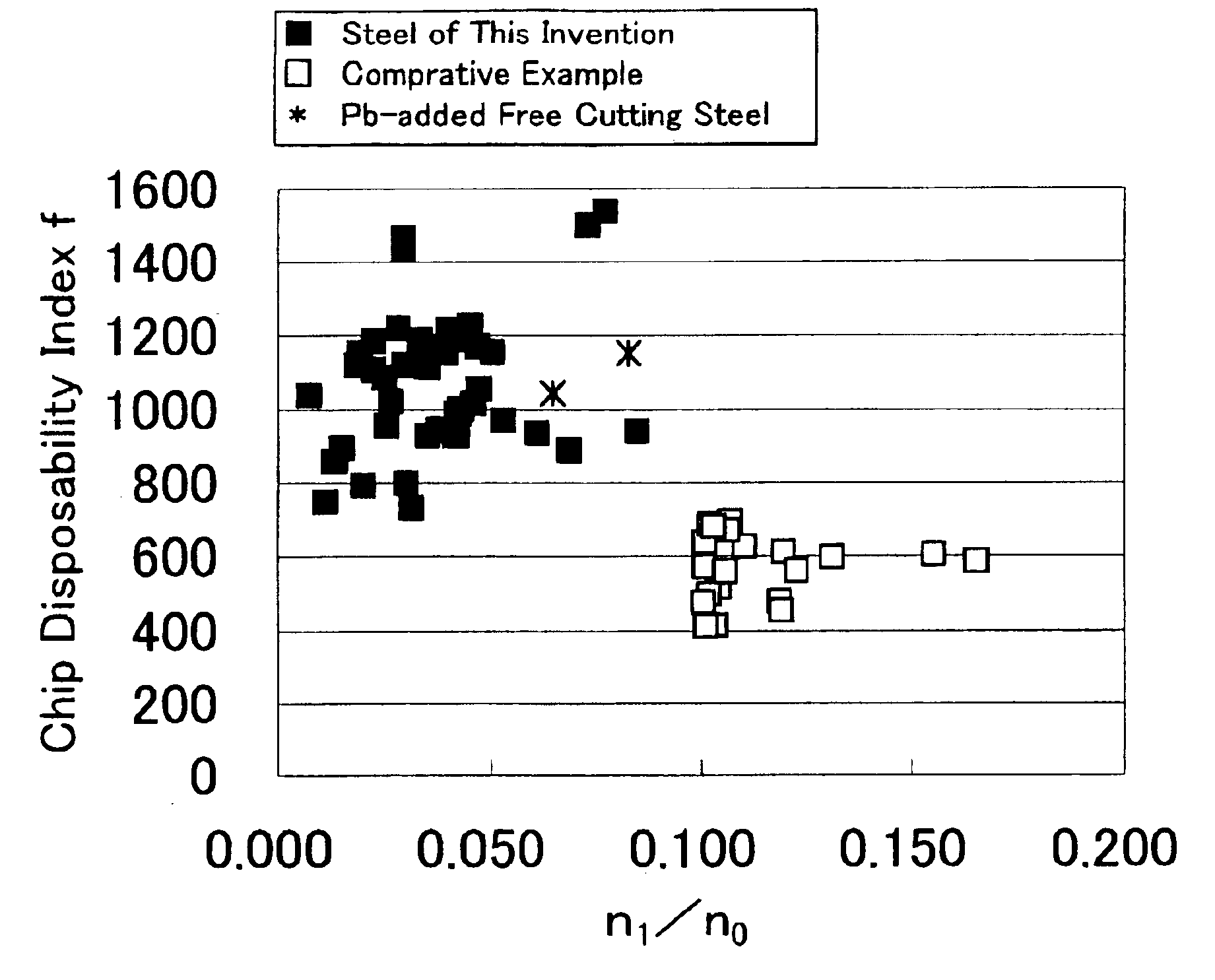

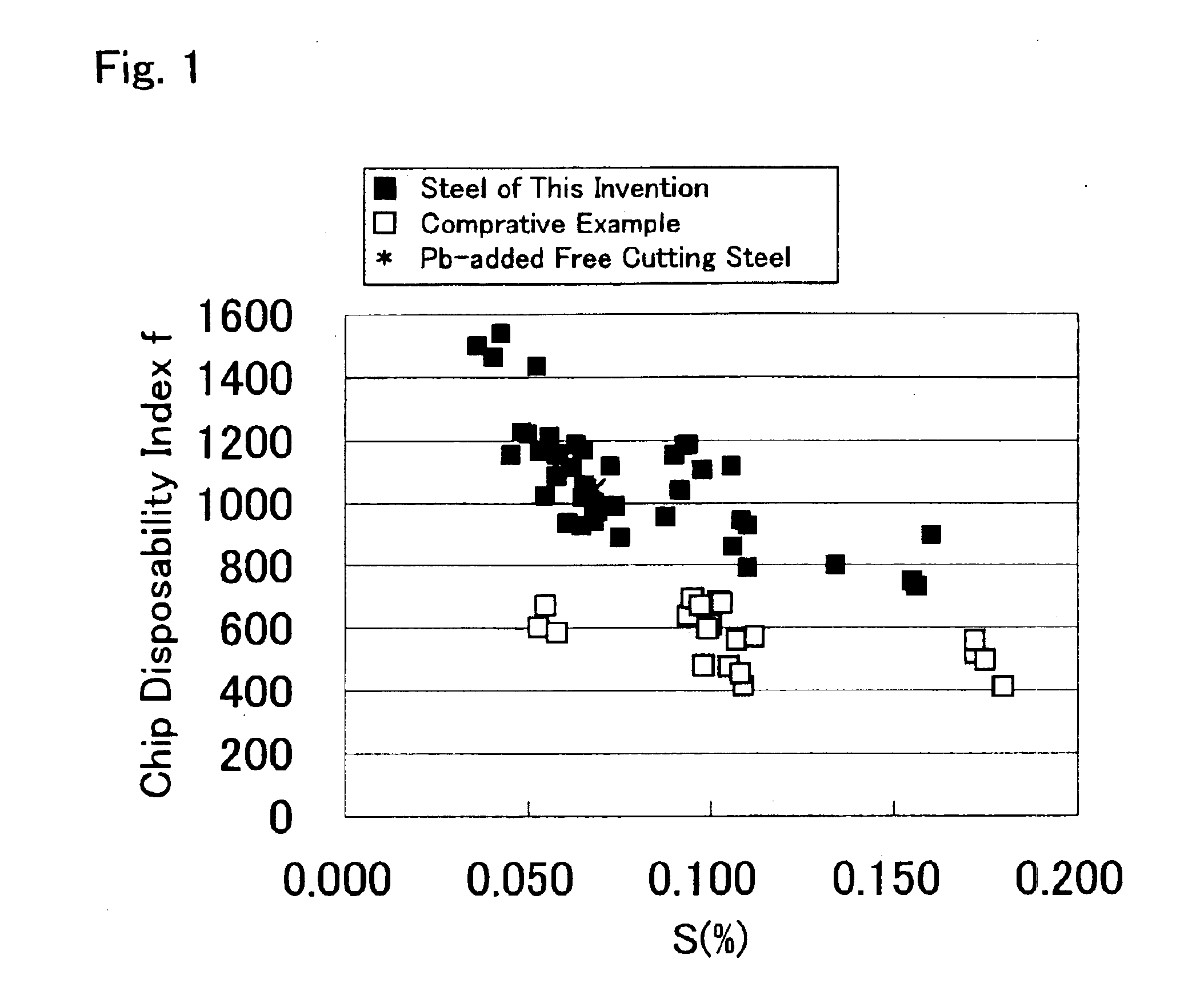

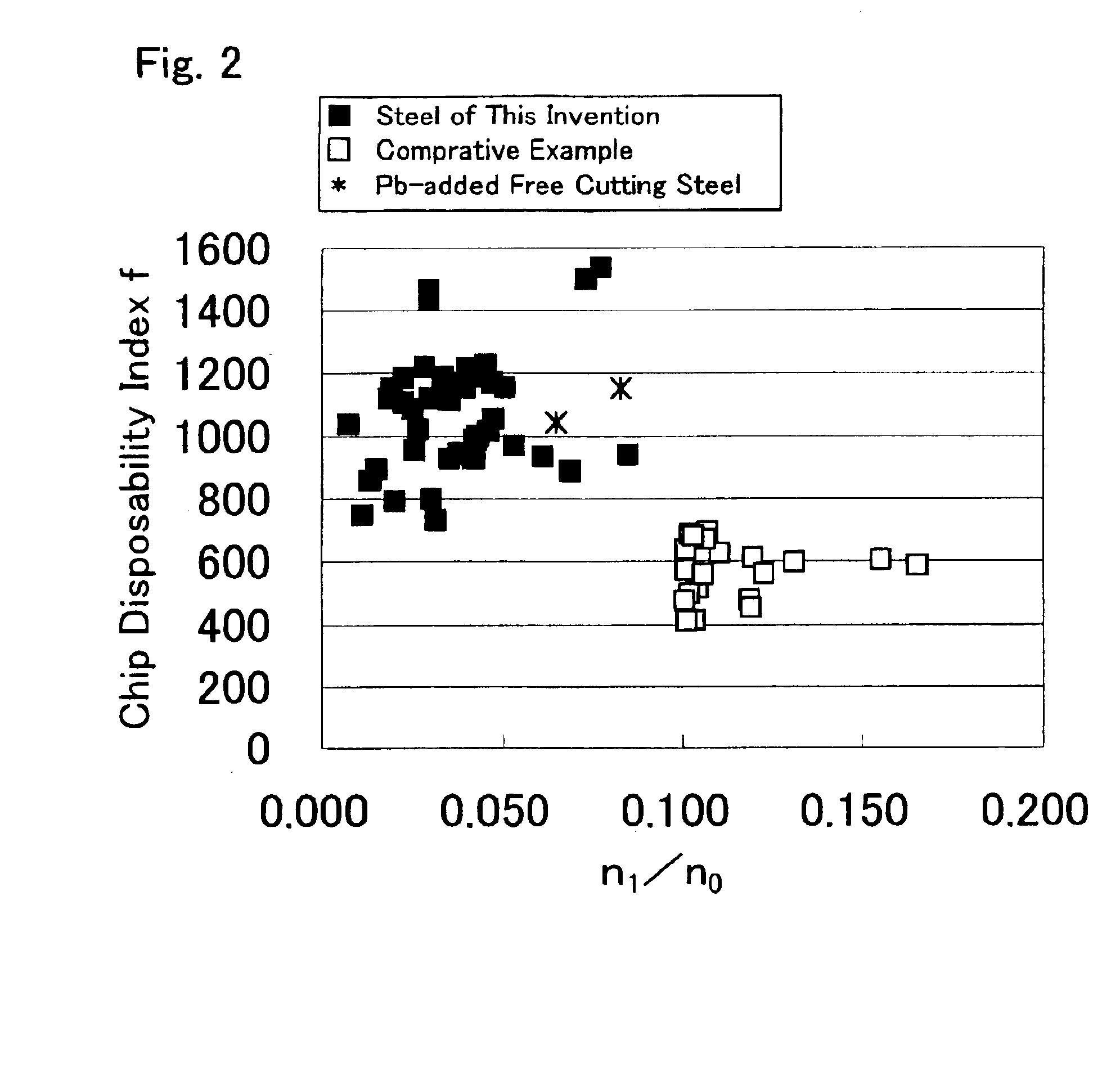

Steel for machine structural use

The invention provides a steel for machine structural use, which is excellent in machinability, comprising, in percent by mass, C: 0.1-0.6%, Si: 0.01-2.0%, Mn: 0.2-2.0%, S: 0.005-0.2%, Al: not more than 0.009%, Ti: not less than 0.001% but less than 0.04%, Ca: 0.0001-0.01%, O (oxygen): 0.001-0.01%, and N: not more than 0.02% and satisfying the following relations (1) to (3):n0 / S (%)>=2500 (1)n1 / n0<=0.1 (2)n2>=10 (3)where n0: total number of sulfide inclusions not smaller than 1 mum per mm2 of a cross section parallel to the direction of rolling (number / mm2); n1: number of MnS inclusions having not smaller than 1 mum and containing not less than 1.0% of Ca per mm2 of a cross section parallel to the direction of rolling (number / mm2); n2: number, per mm2 of a cross section parallel to the direction of rolling, of oxide inclusions having a specific composition comprising CaO-Al2O3-SiO2-TiO2 and having a diameter of not less than 1 mum (number / mm2).

Owner:NIPPON STEEL CORP

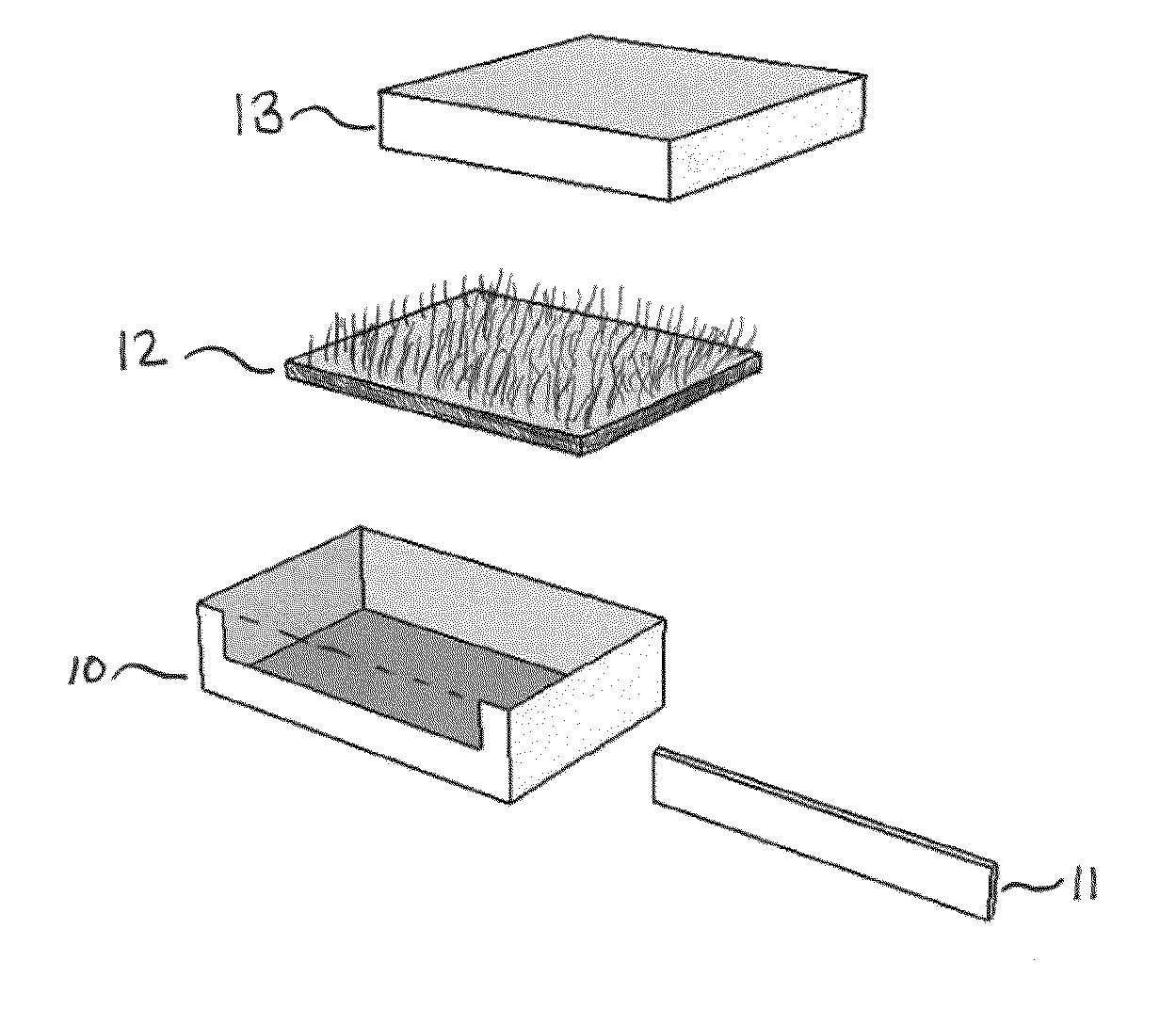

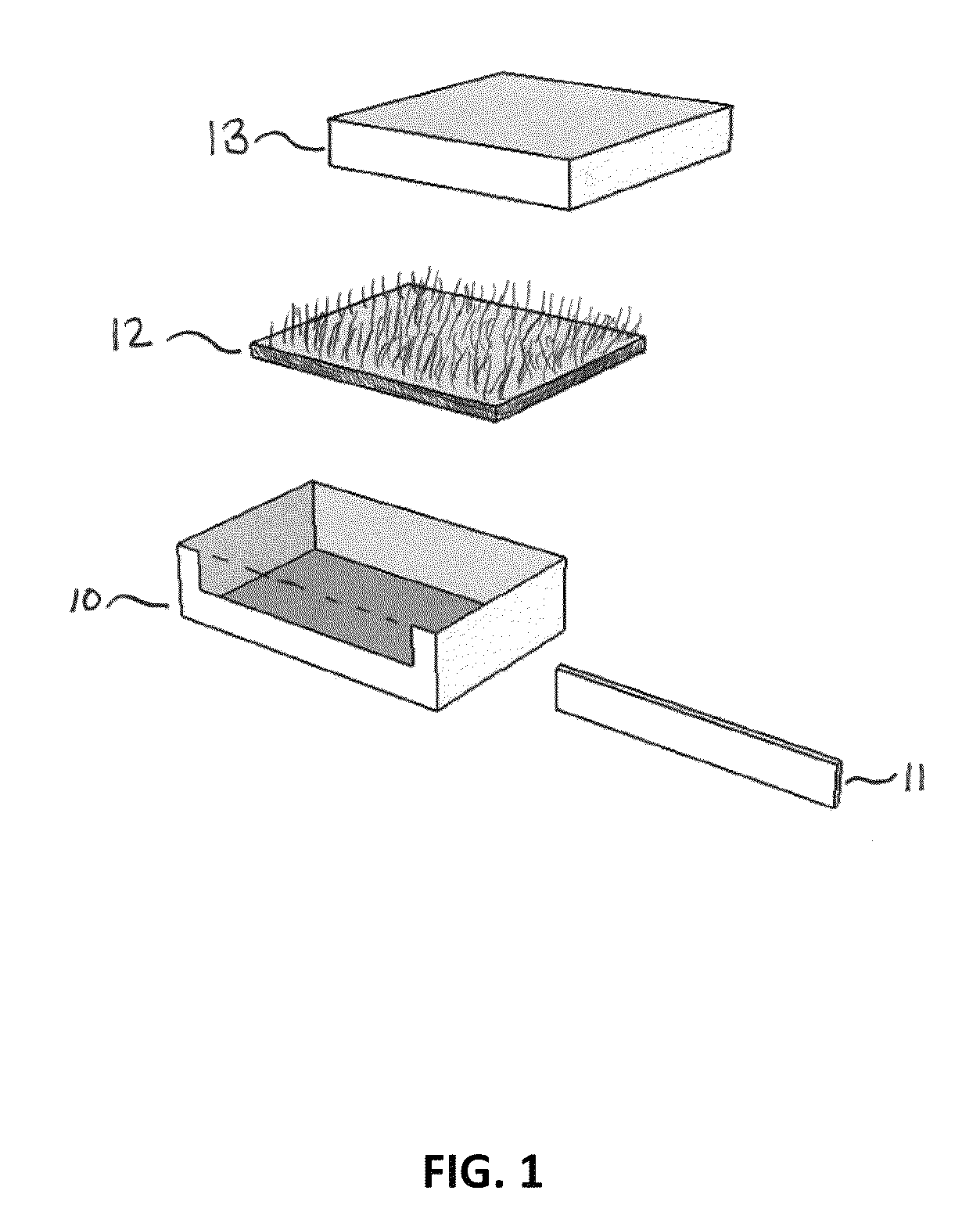

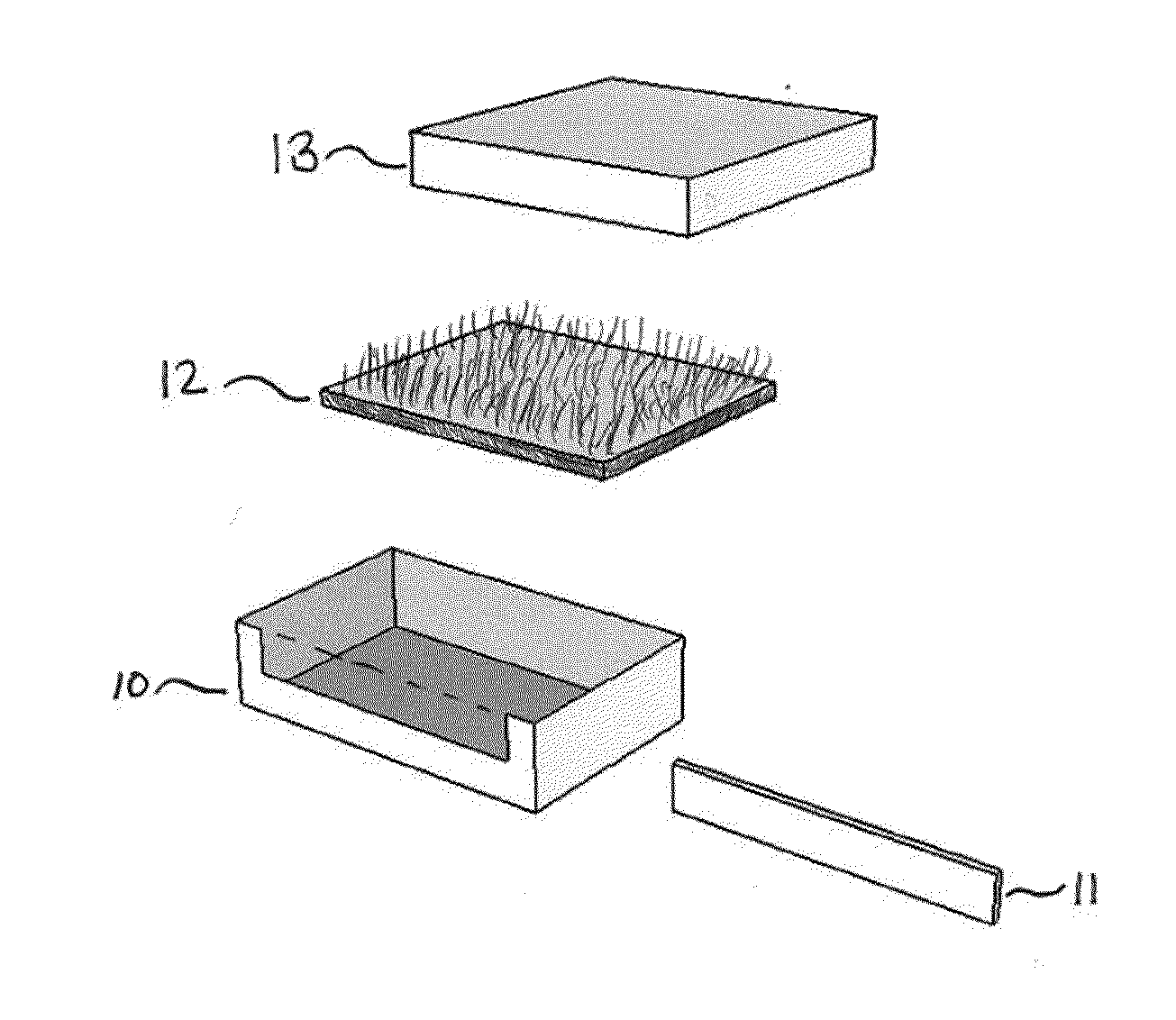

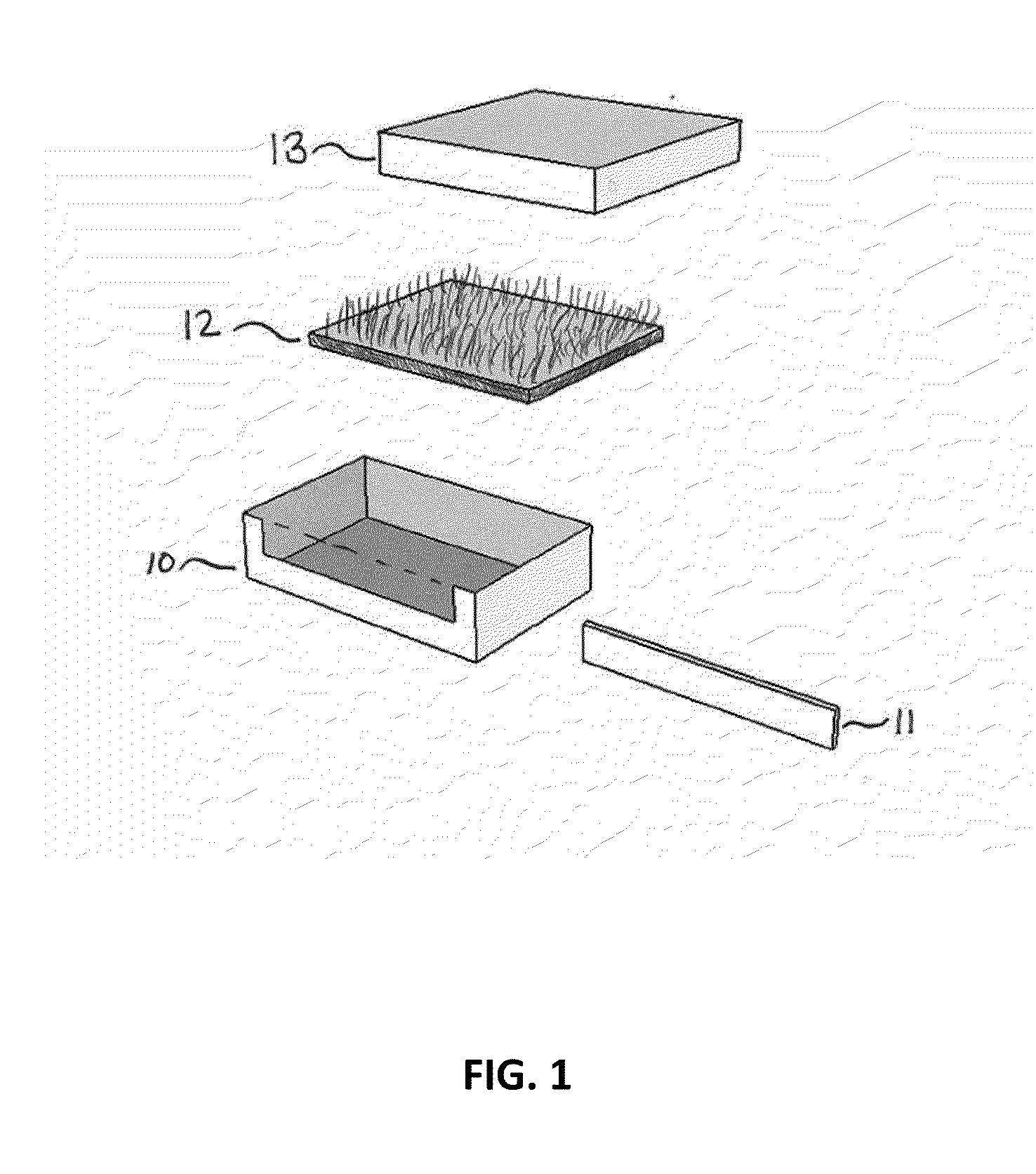

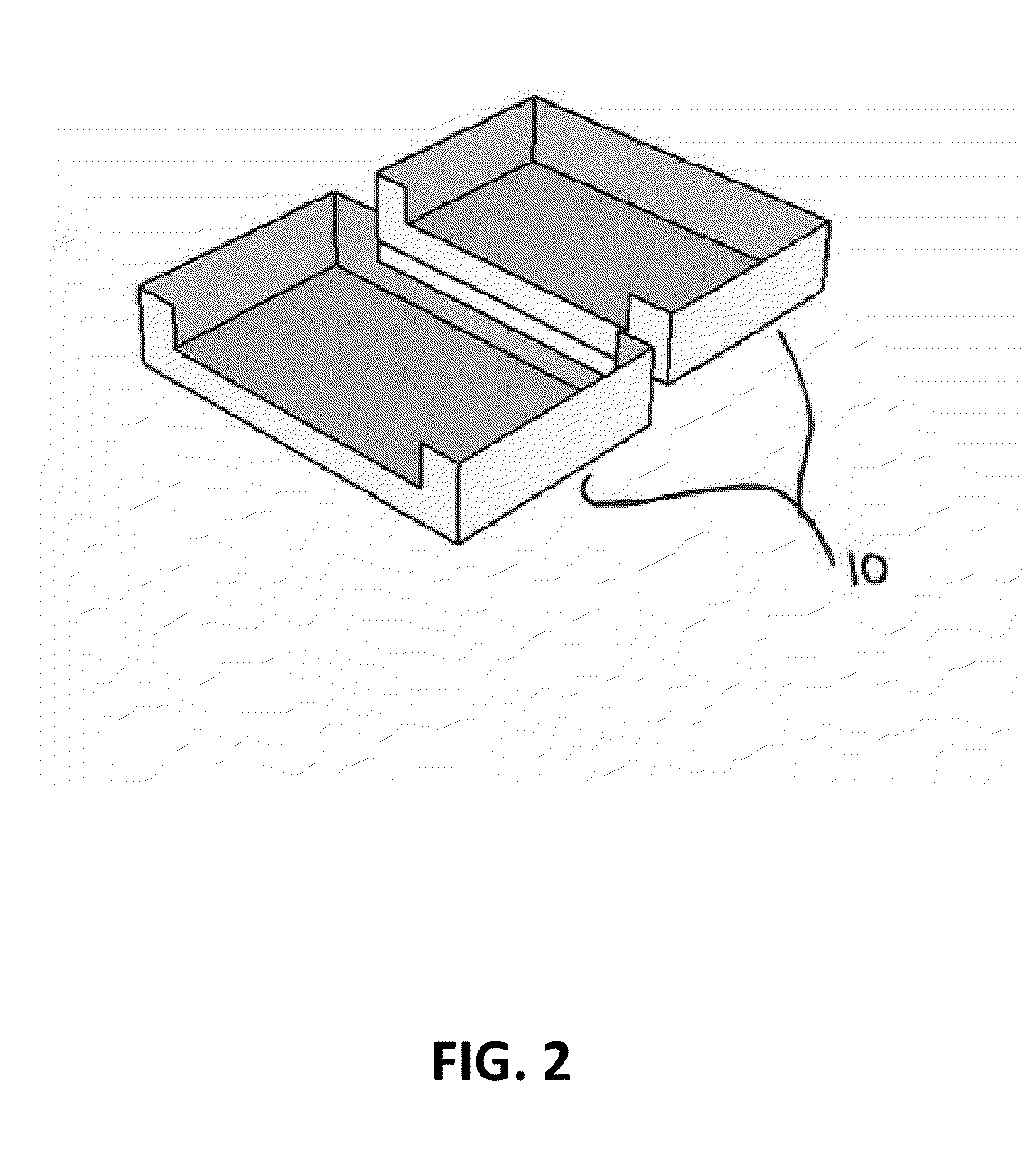

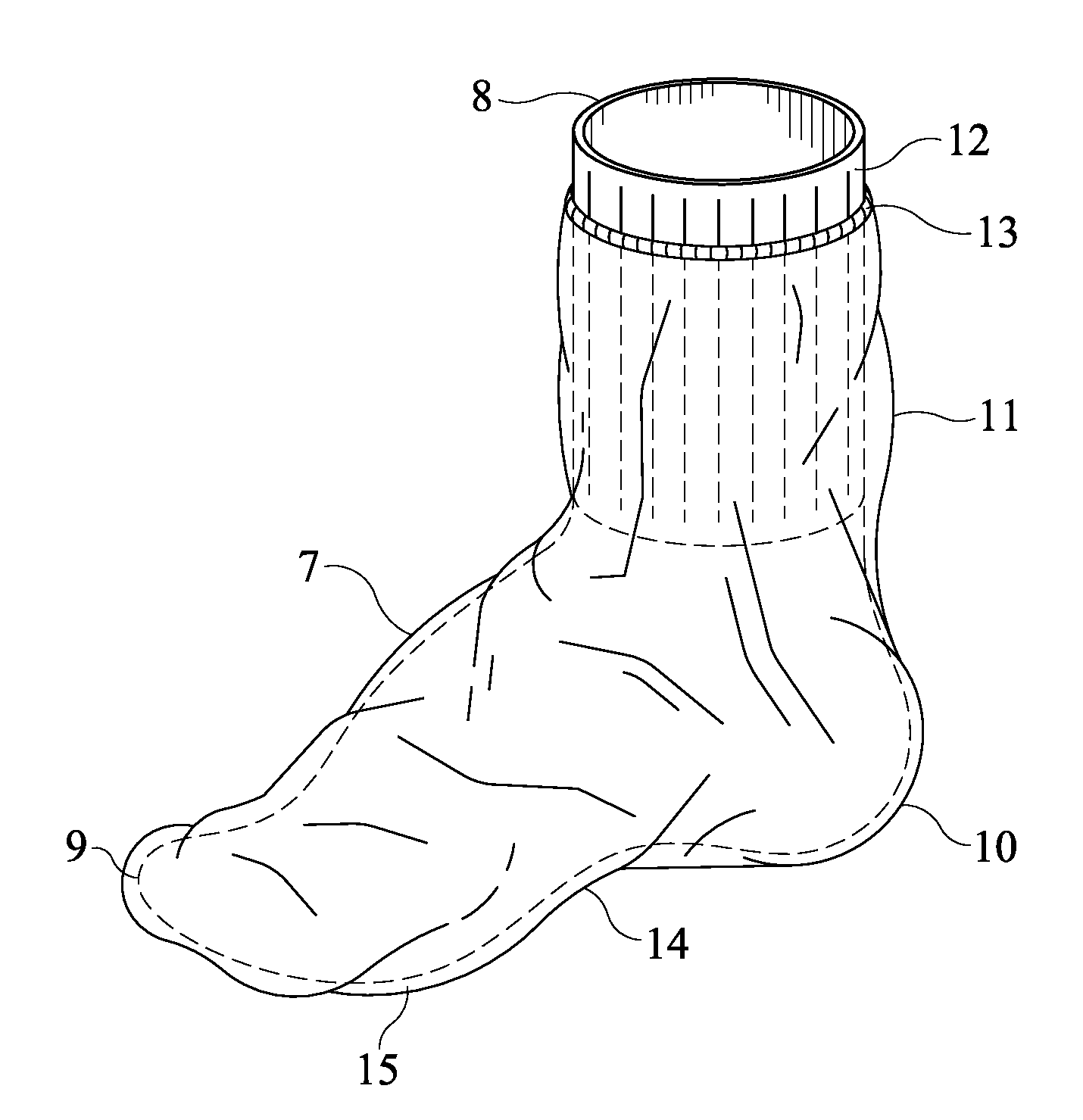

Portable and disposable living-grass pet toilet

ActiveUS8522719B2Improve DisposabilityEasy to transportAnimal housingTurf growingEngineeringCompanion animal

A portable, fully-disposable, pet toilet is comprised of a receptacle whose cavity is fitted with living grass, living sod (including washed or soil-free sod), or a grass-seed medium. The unit has a fitted, removable cover or fold-back lid to enable the convenient shipping and disposal of the unit in its entirety. The pet toilet is used by the pet for a set period of time, at which point it is completely disposed of and replaced with a new one.

Owner:FRESH PATCH

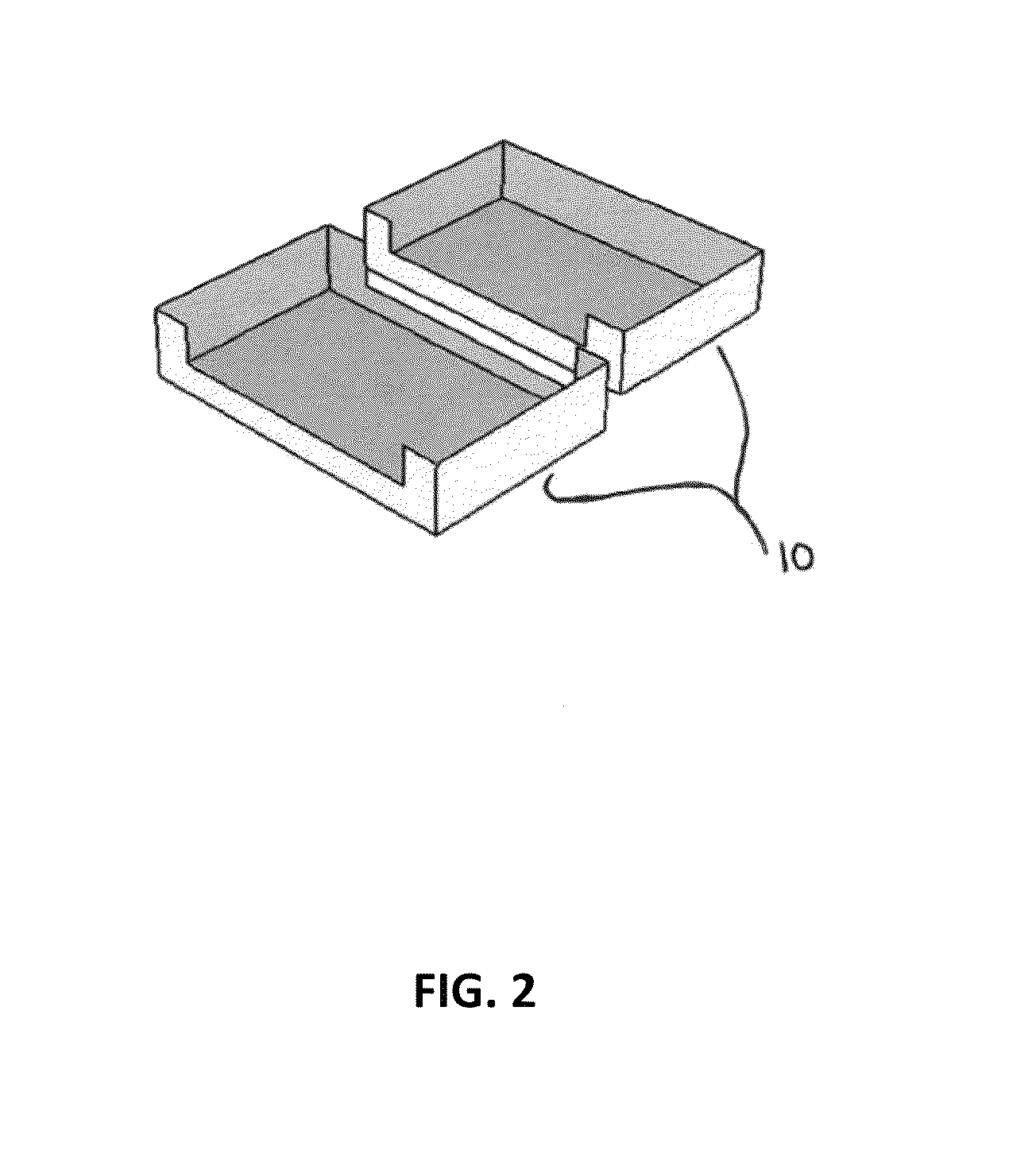

Adjustable suction tips for dental and medical uses

InactiveUS20130164706A1Simple designVersatile and easy to useMedical devicesIntravenous devicesEngineeringMedical procedure

An implement useful in dental and medical procedures, particularly aspiration, but that can also be readily adapted for irrigation or retraction, is described. In a preferred embodiment, the invention features a hollow handle portion 2 having a source end 2a for connecting to a vacuum line or pump, and a second end 2b; a hollow nozzle portion 1 having a contacting end 1a for engaging a patient surface to be suctioned and a second end 1b for functionally engaging, directly or indirectly, the second end of the handle 2b; and a hollow joint at least partially defined by the second end of the handle and the second end of the nozzle. In some embodiments, the joint may comprise an adaptor 3.

Owner:GSN PROD

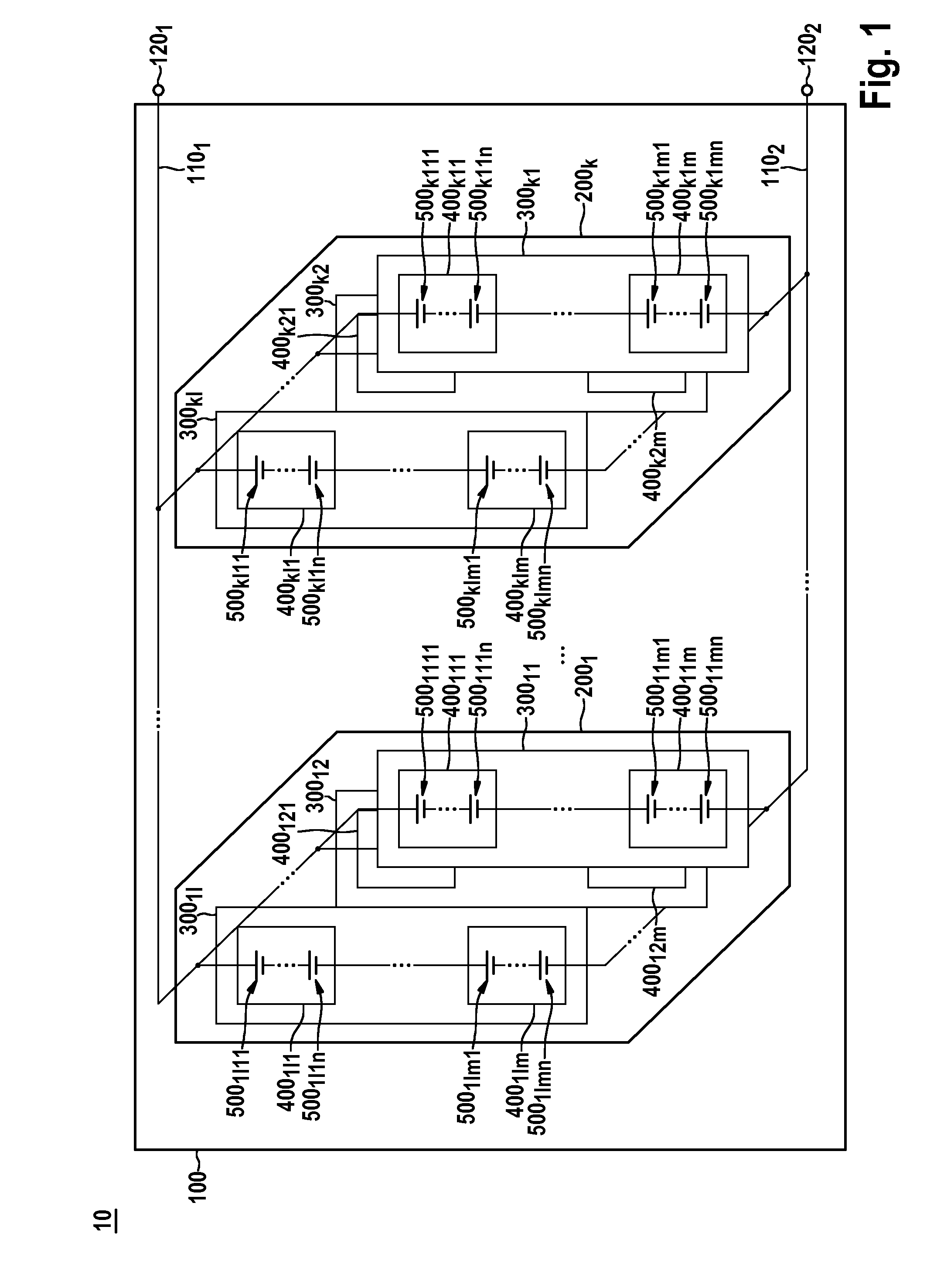

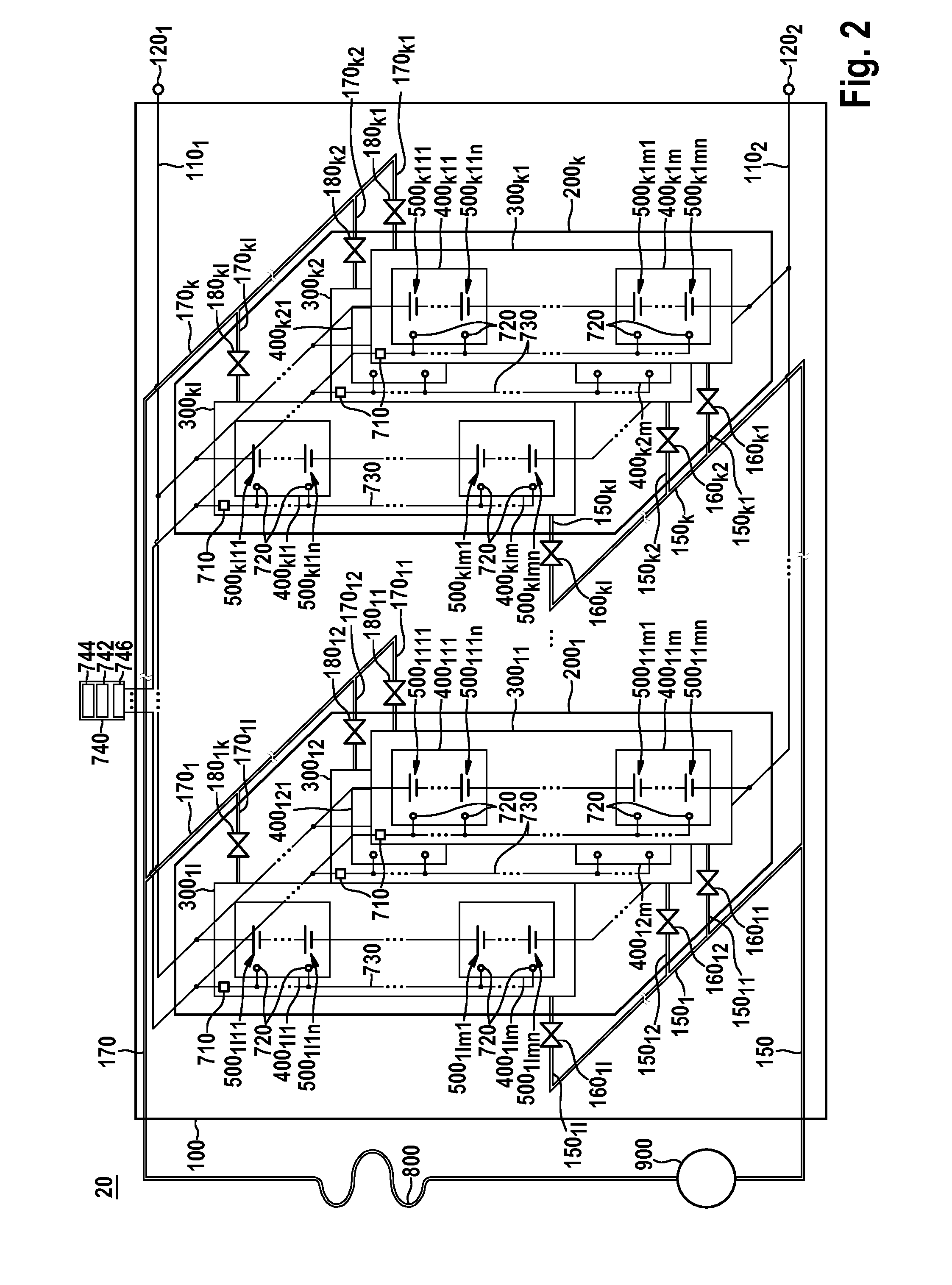

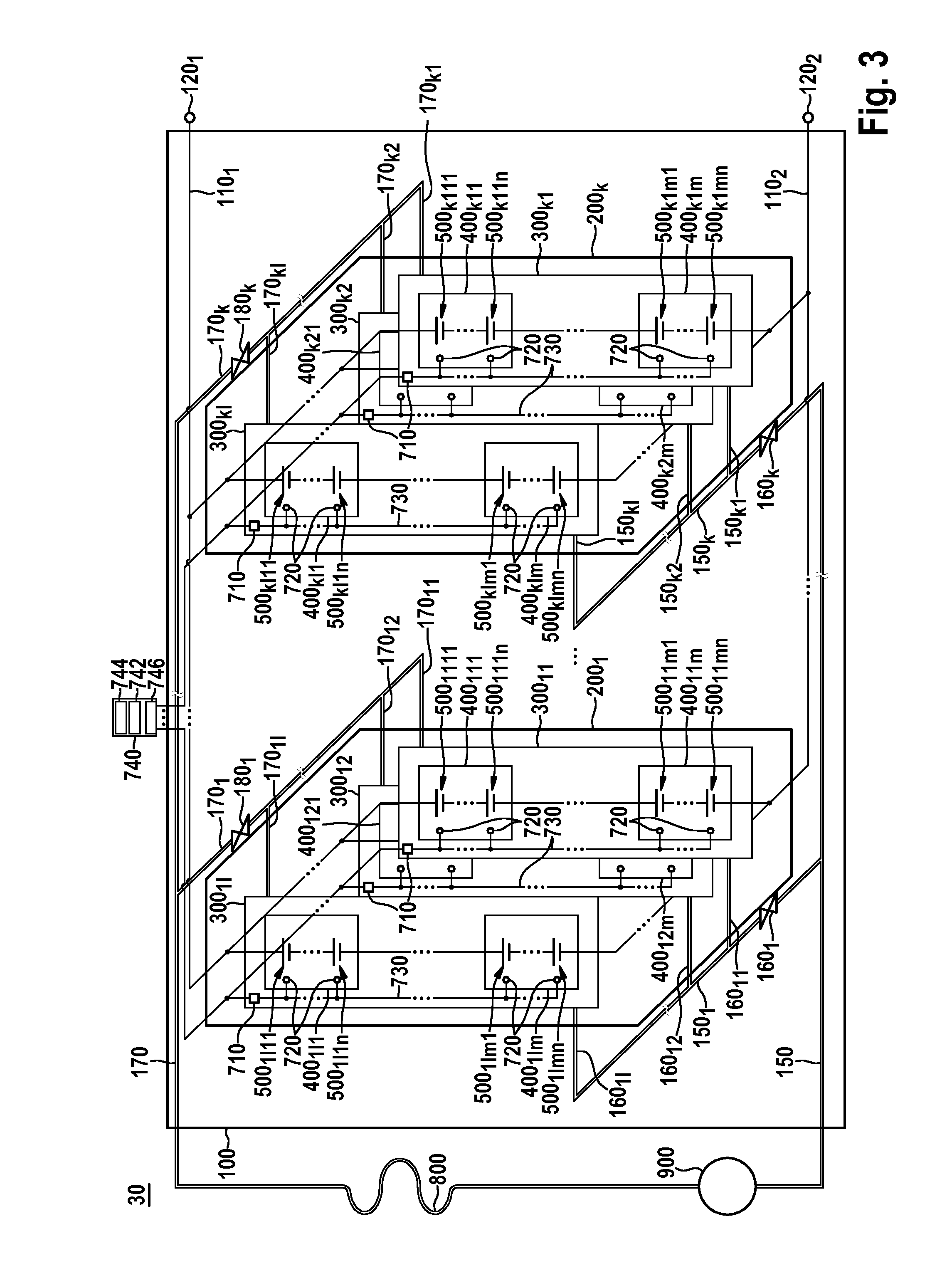

Device and method for monitoring an energy store and energy store having the device

InactiveUS20160315363A1Flow can be eliminatedSimple designSecondary cellsVehicular energy storageTemperature controlBattery system

The invention relates to a device (710, 720, 730, 740) for monitoring an energy store (20; 30) comprising a plurality of battery cells (5001111-500klmn), which are arranged in a plurality of battery groups (2001-200k, 30011-300kl, 400111-400klm), and a temperature-control device for controlling the temperature of the battery cells (5001111-500klmn) by means of a plurality of partial flows of a temperature-control medium, each of the partial flows being associated with one of the battery groups (2001-200k, 30011-300kl, 400111-400klmn), characterized by: a plurality of sensor apparatuses (720) for sensing temperature measurement values of the battery cells (5001111-500klmn), each of the sensor apparatuses (720) being arranged in such a way that the sensor apparatus can sense the temperature measurement value of one of the battery cells (5001111-500klmn); an apparatus (710, 740) for determining a plurality of average temperature values from the sensed temperature measurement values, each of the determined average temperature values being determined in such a way that the determined average temperature value is associated with one of the battery groups (2001-200k, 30011-300kl, 400111-400klmn); and an apparatus (740) for evaluating the plurality of determined average temperature values and, if one of the determined average temperature values exceeds a temperature threshold value, determining that the partial flow associated with the associated battery group (2001-200k, 30011-300kl, 400111-400klm) has a fault. The invention further relates to a battery system, a vehicle, a method, a computer program, and a computer program product.

Owner:ROBERT BOSCH GMBH

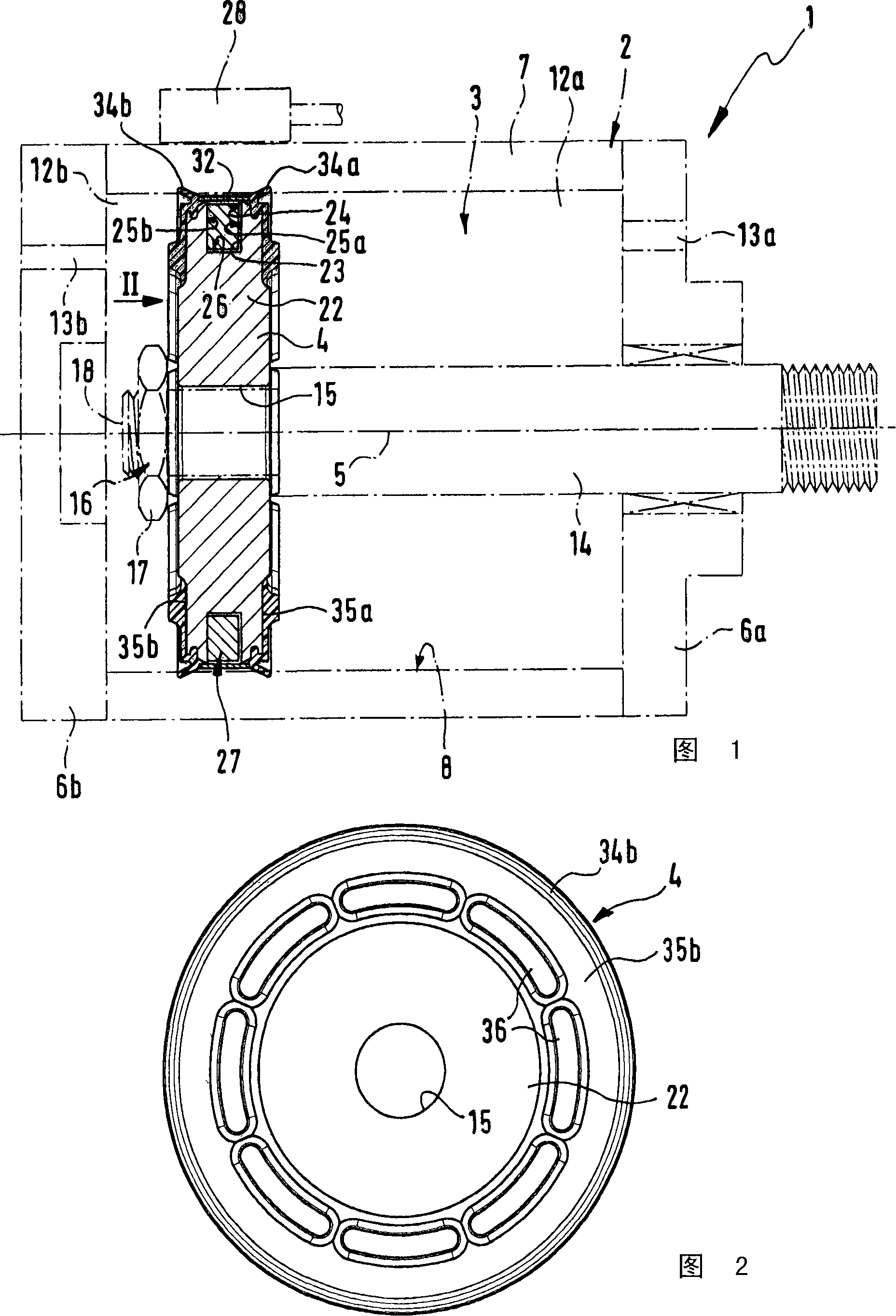

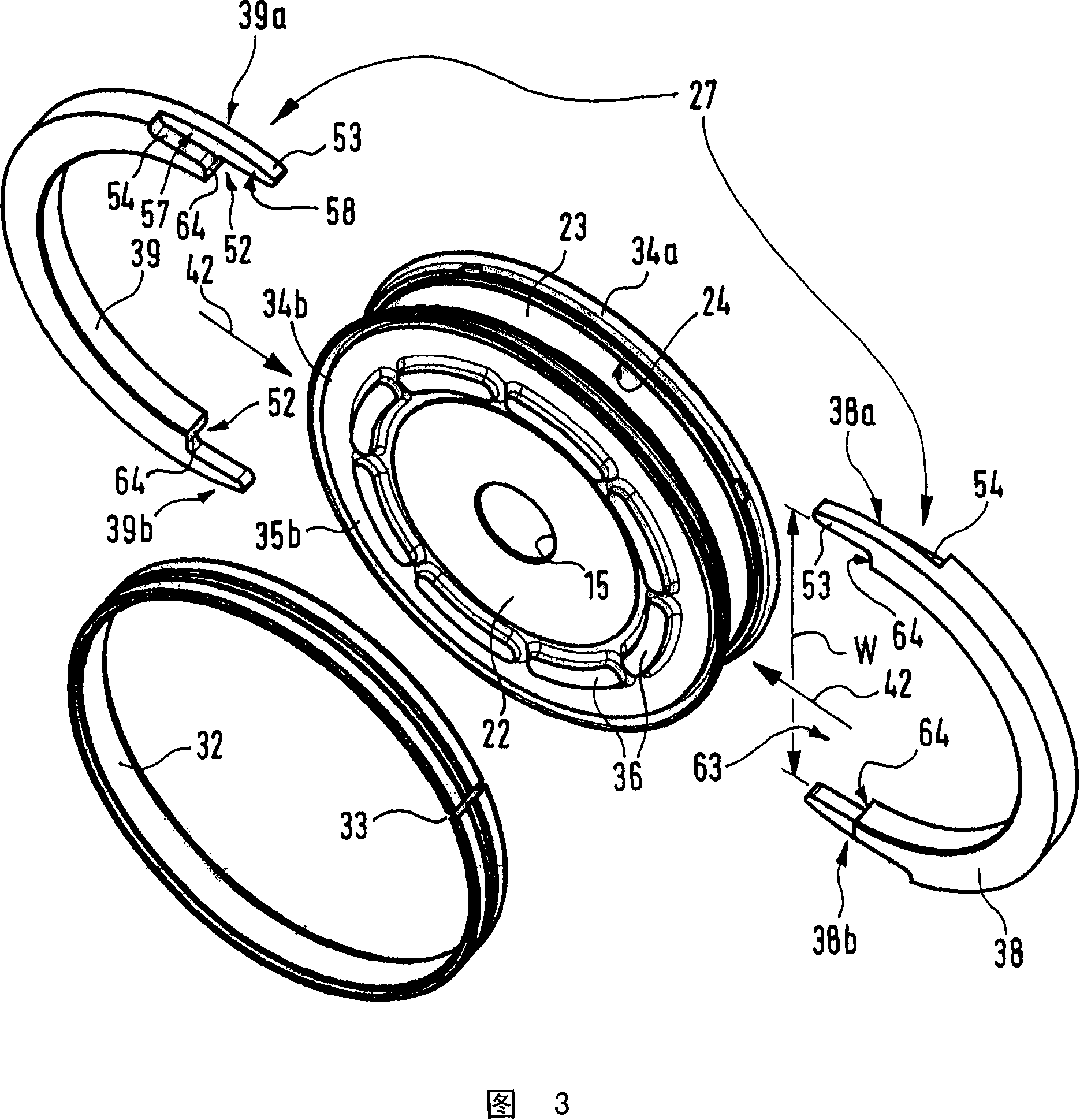

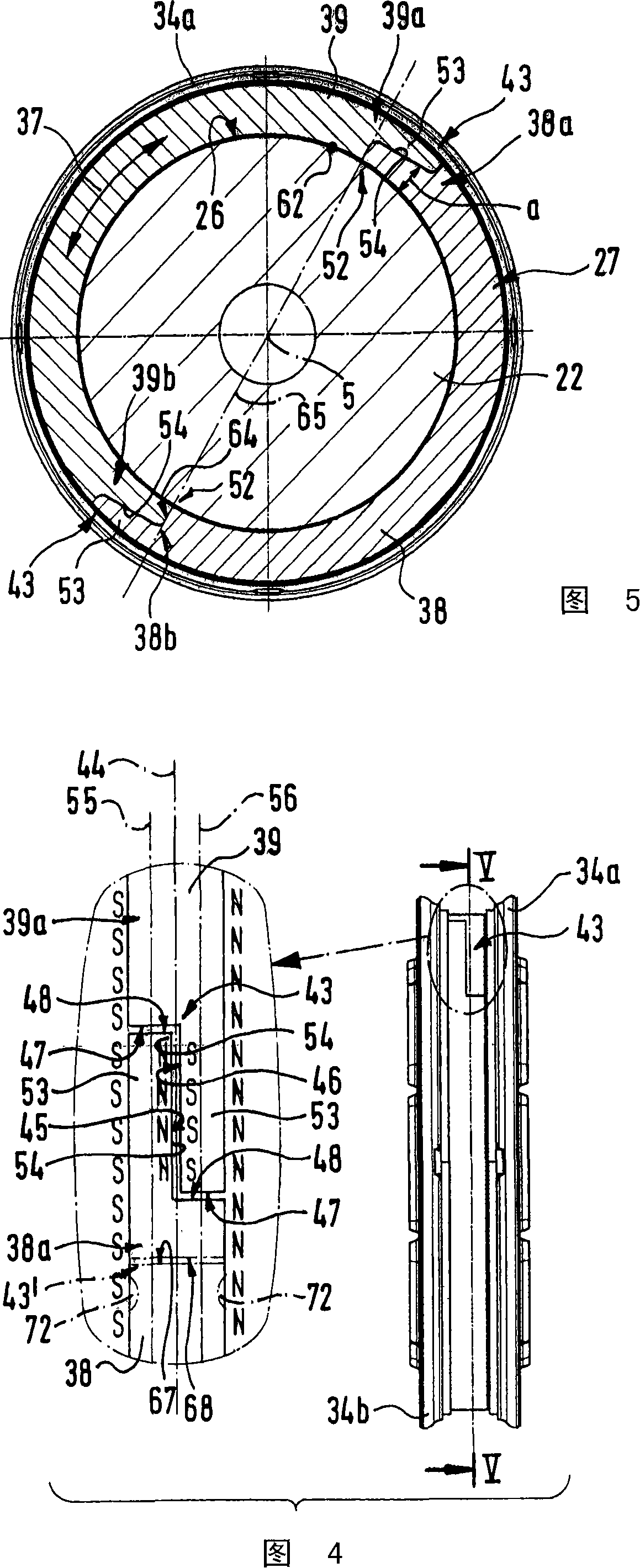

Piston and fluidically actuated positioning device comprising the same

ActiveCN101151468AReduce storage costsImprove DisposabilityFluid-pressure actuatorsEngineeringRabbet

The present invention presents a piston of the adjusting device which can be run using the fluid. The piston includes a supporting body (22) which is provided with an annular groove that is coaxial to the longitudinal axis of the piston, and at least one annular permanent magnet device (27) is arranged in the groove. The permanent magnet device (27) is divided in the circumference direction (37) and is composed of at least two arc shaped magnet subsections (38 and 39). The annular groove is constructed to be an annular groove (23) which is provided with a rabbet that is oriented to the external side of the radial direction, and the magnet subsections (38 and 39) are loaded in the annular groove at the condition of forming the annular molding.

Owner:FESTO AG & CO KG

Steel for machine structural use

The invention provides a steel for machine structural use, which is excellent in machinability, comprising, in percent by mass, C: 0.1-0.6%. Si: 0.01-2.0%, Mn: 0.2-2.0%, S: 0.005-0.2%, Al: not more than 0.009%, Ti: not less than 0.001% but less than 0.04%, Ca: 0.0001-0.01%, O (oxygen): 0.0010-0.01%, and N: not more than 0.02% and satisfying the following relations (1) to (3):where n0: total number of sulfide inclusions not smaller than 1 mum per mm<2 >of a cross section parallel to the direction of rolling (number / mm<2>); n1: number of MnS inclusions having not smaller than 1 mum and containing not less than 1.0% of Ca per mm<2 >of a cross section parallel to the direction of rolling (number / mm<2>); n2: number, per mm<2 >of a cross section parallel to the direction of rolling, of oxide inclusions having a specific composition comprising CaO-Al2O3-SiO2-TiO2 and having a diameter of not less than 1 mum (number / mm<2>).

Owner:NIPPON STEEL CORP

Portable and disposable living-grass pet toilet

ActiveUS20120006274A1Improve DisposabilityEasy to transportAnimal housingTurf growingCompanion animalBiomedical engineering

A portable, fully-disposable, pet toilet is comprised of a receptacle whose cavity is fitted with living grass, living sod (including washed or soil-free sod), or a grass-seed medium. The unit has a fitted, removable cover or fold-back lid to enable the convenient shipping and disposal of the unit in its entirety. The pet toilet is used by the pet for a set period of time, at which point it is completely disposed of and replaced with a new one.

Owner:FRESH PATCH

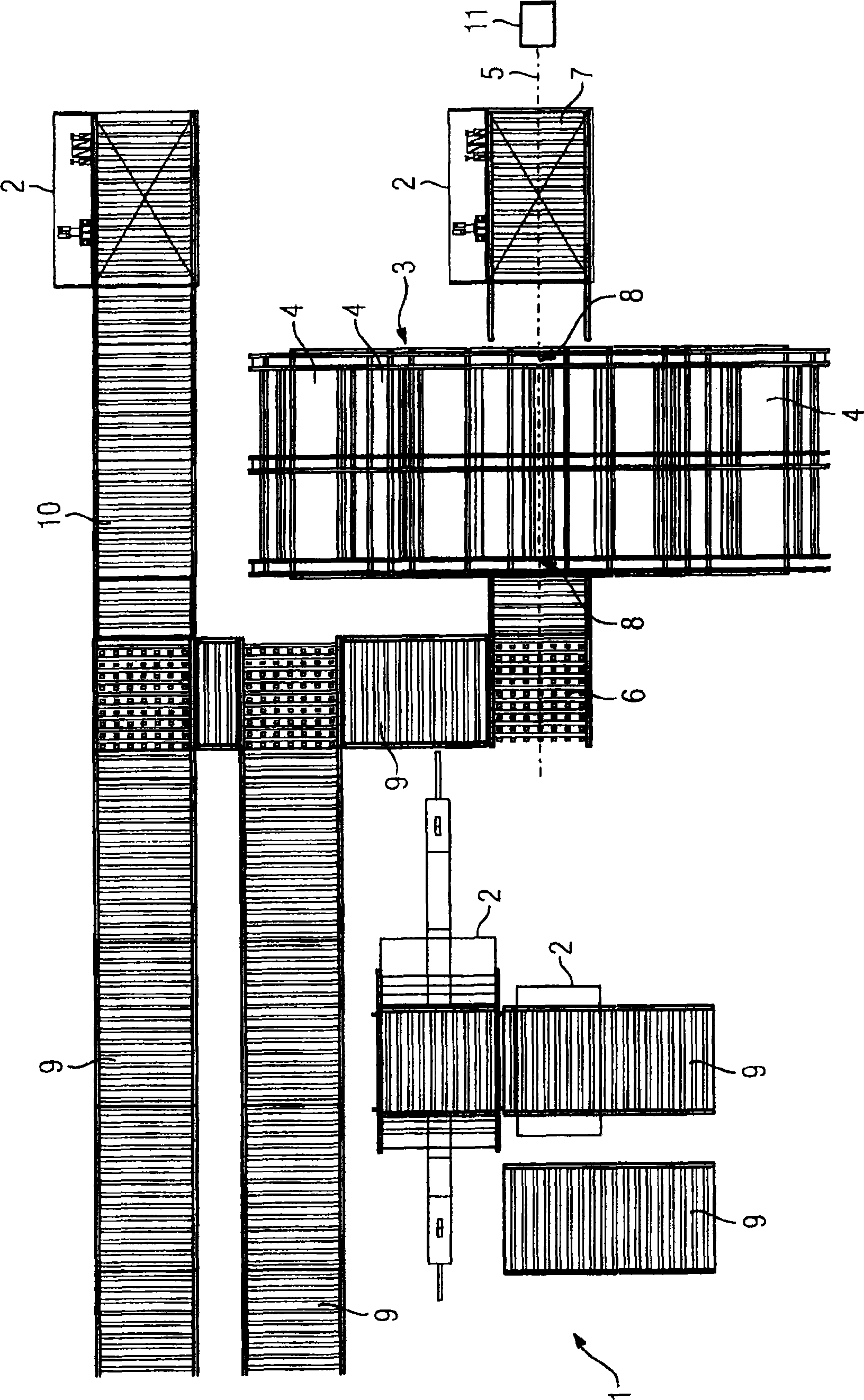

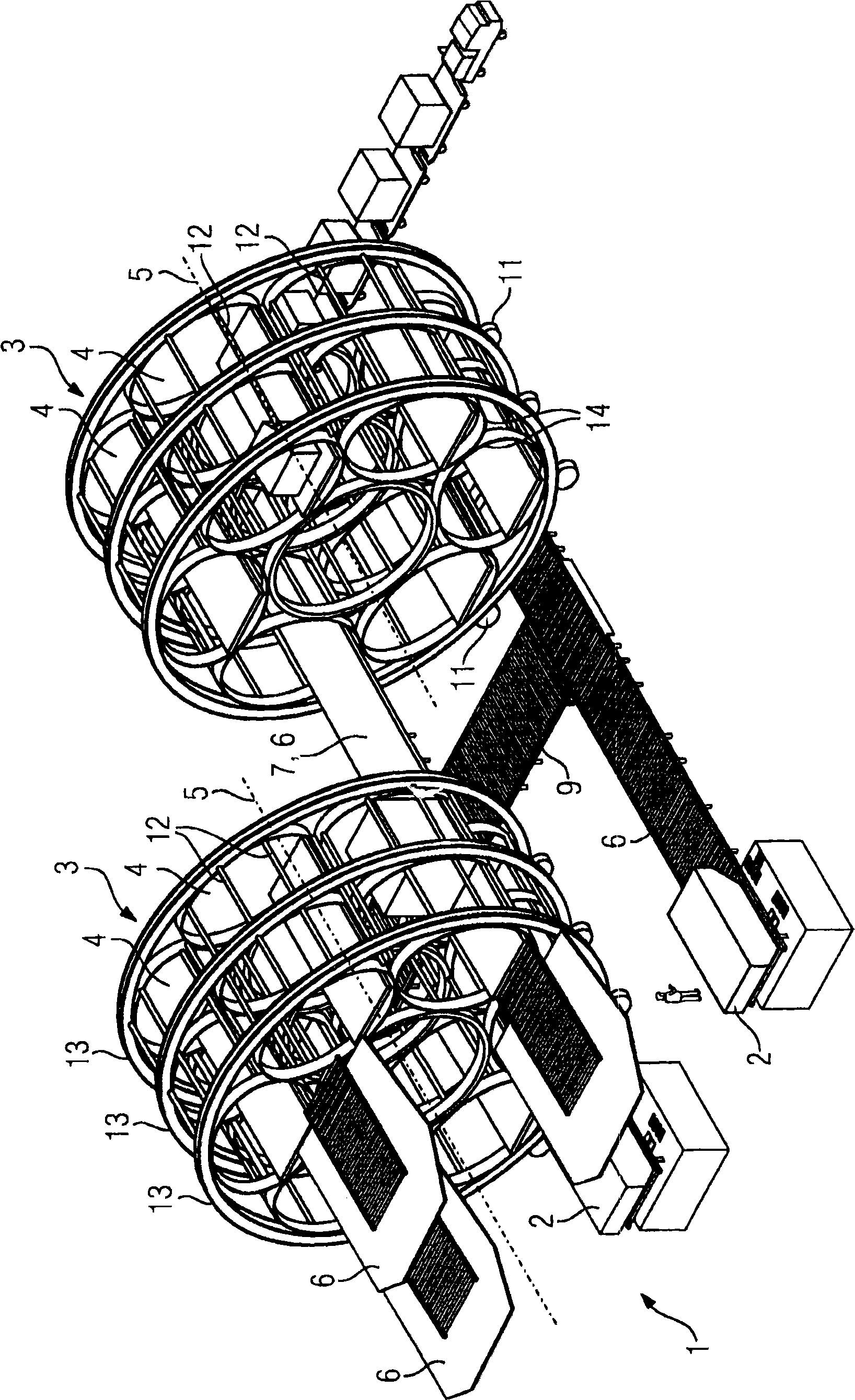

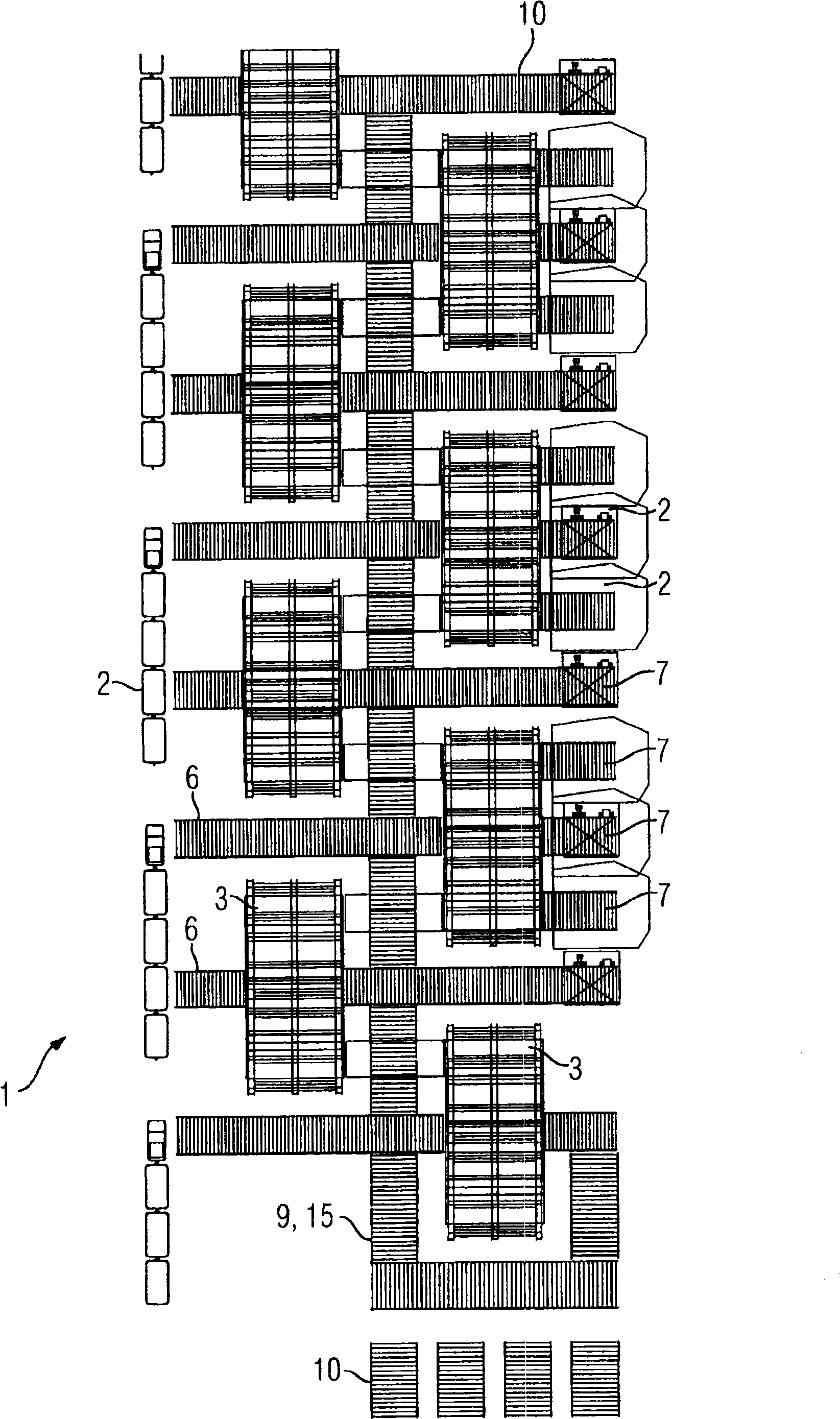

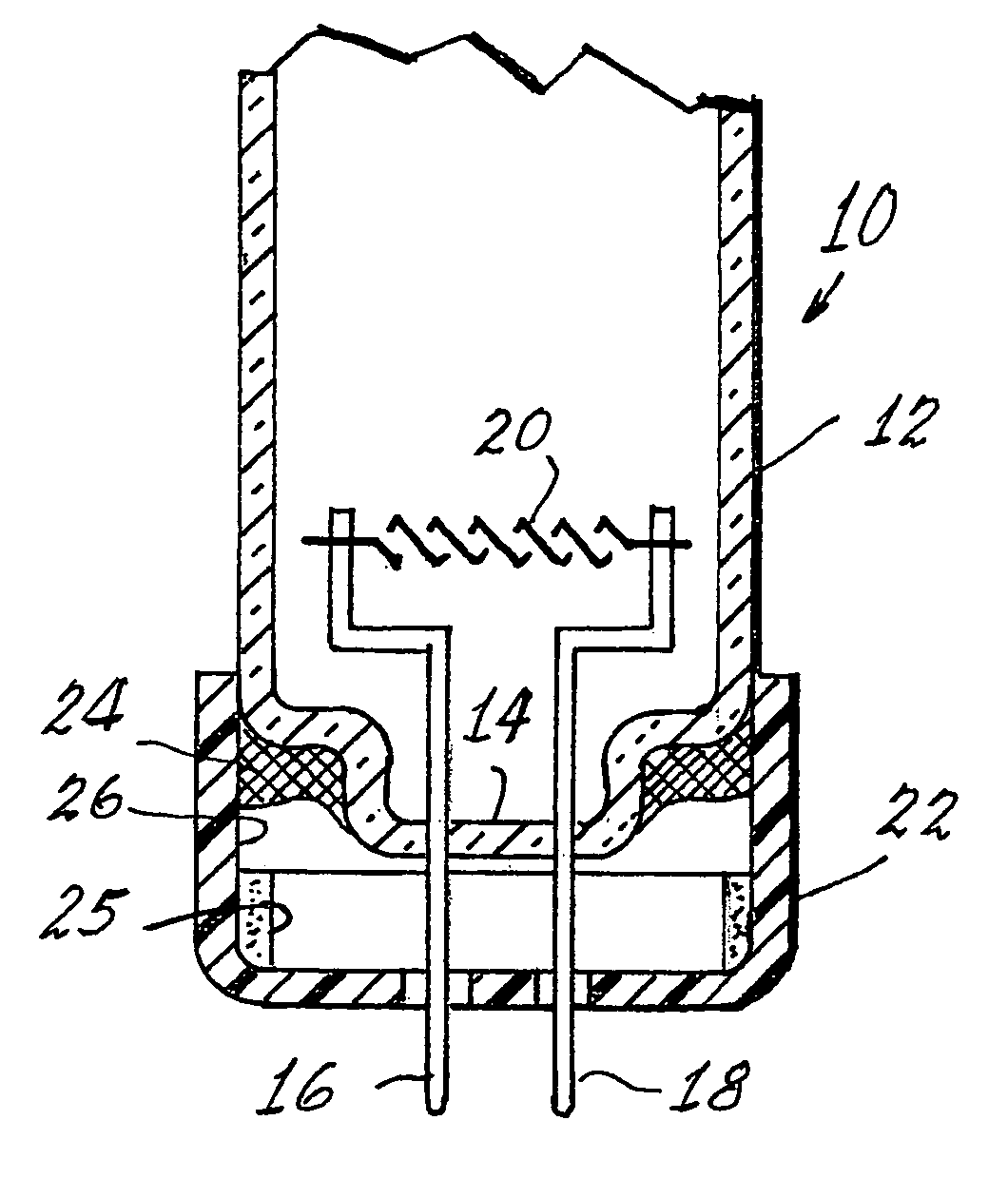

Apparatus and method for storing storage units

InactiveCN101489890AIncrease capacityLarge transfer redundancyStorage devicesConveyor partsRotational axisEngineering

The invention relates to an apparatus (1) for storing storage units (2), in particular piece-goods containers, comprising at least one circular bearing (3) which can rotate about a rotational axis (5) and has a plurality of storage places (4) which are arranged in a circular manner around the rotational axis (5).

Owner:SIEMENS AG

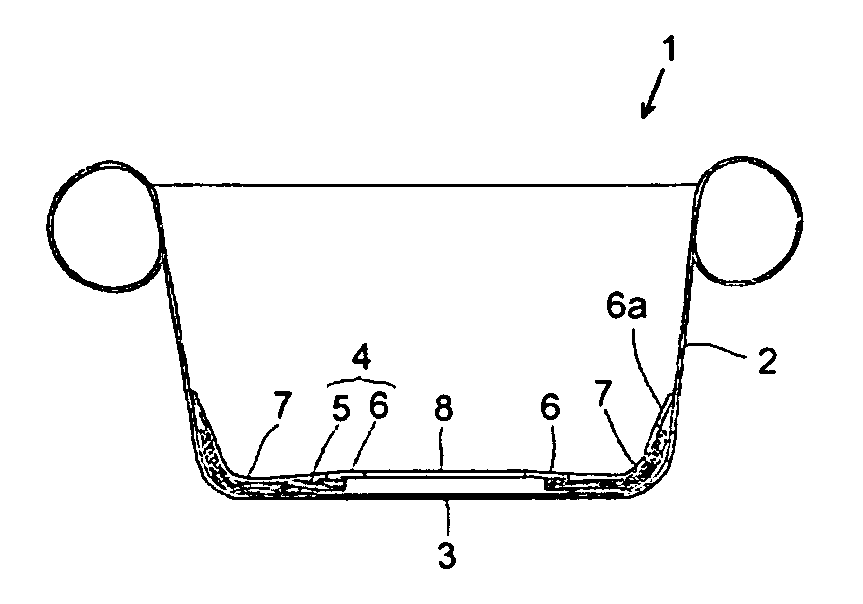

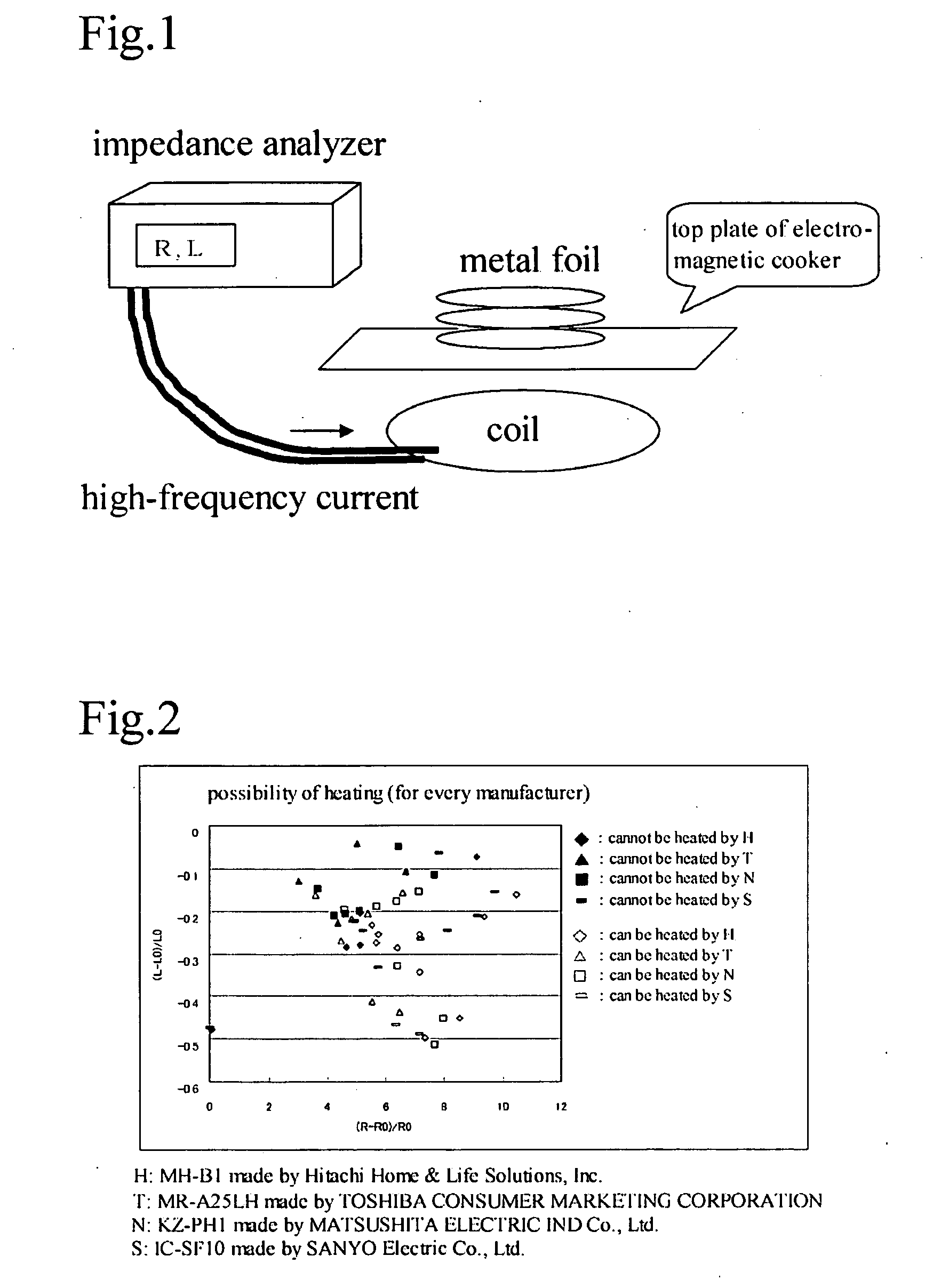

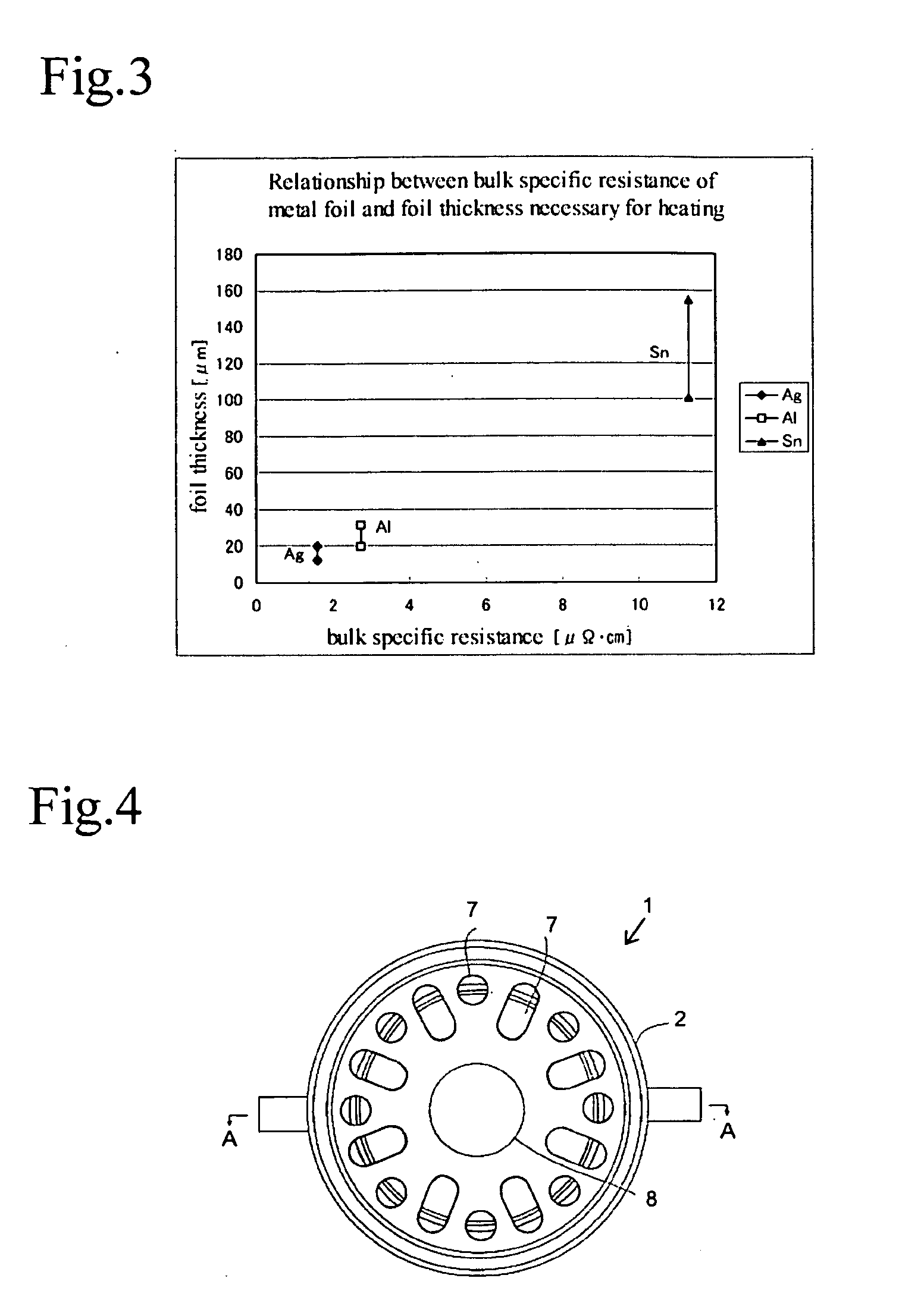

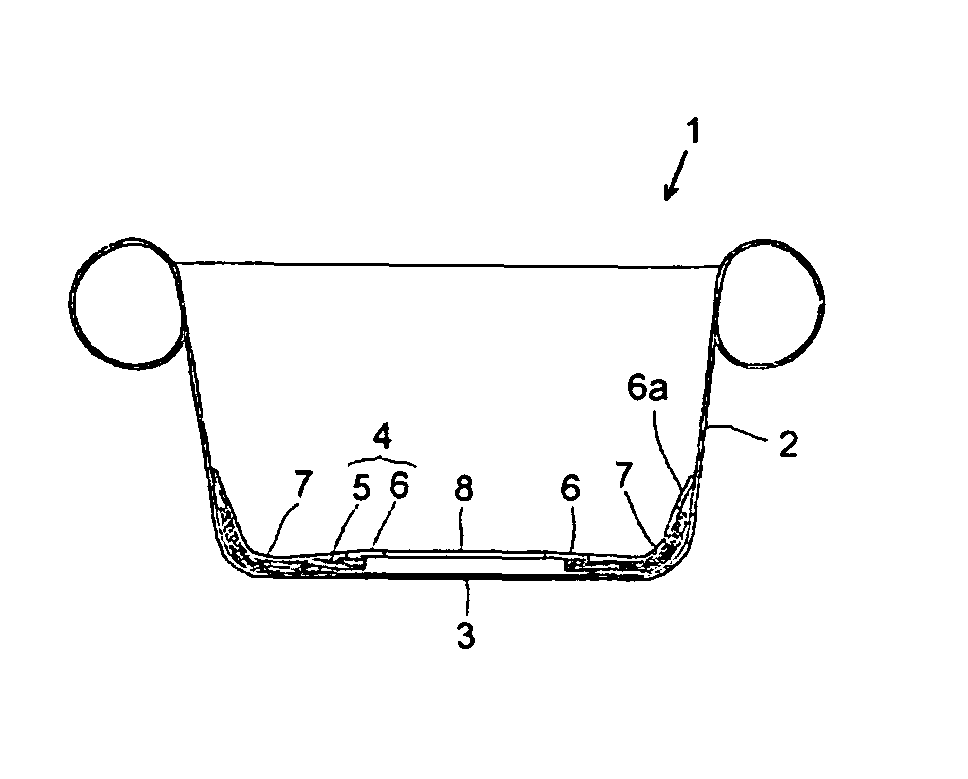

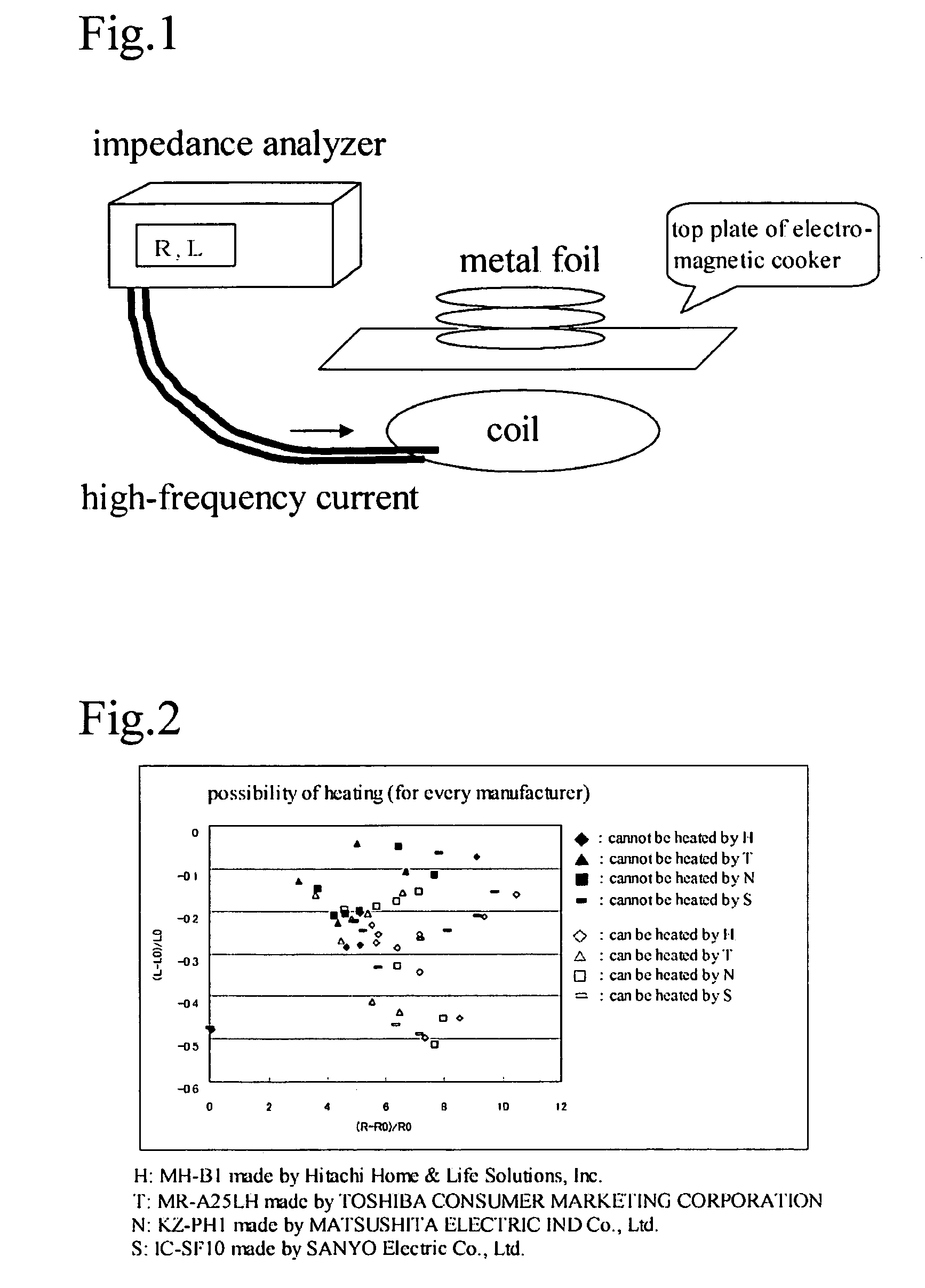

Container for electromagnetic cookers

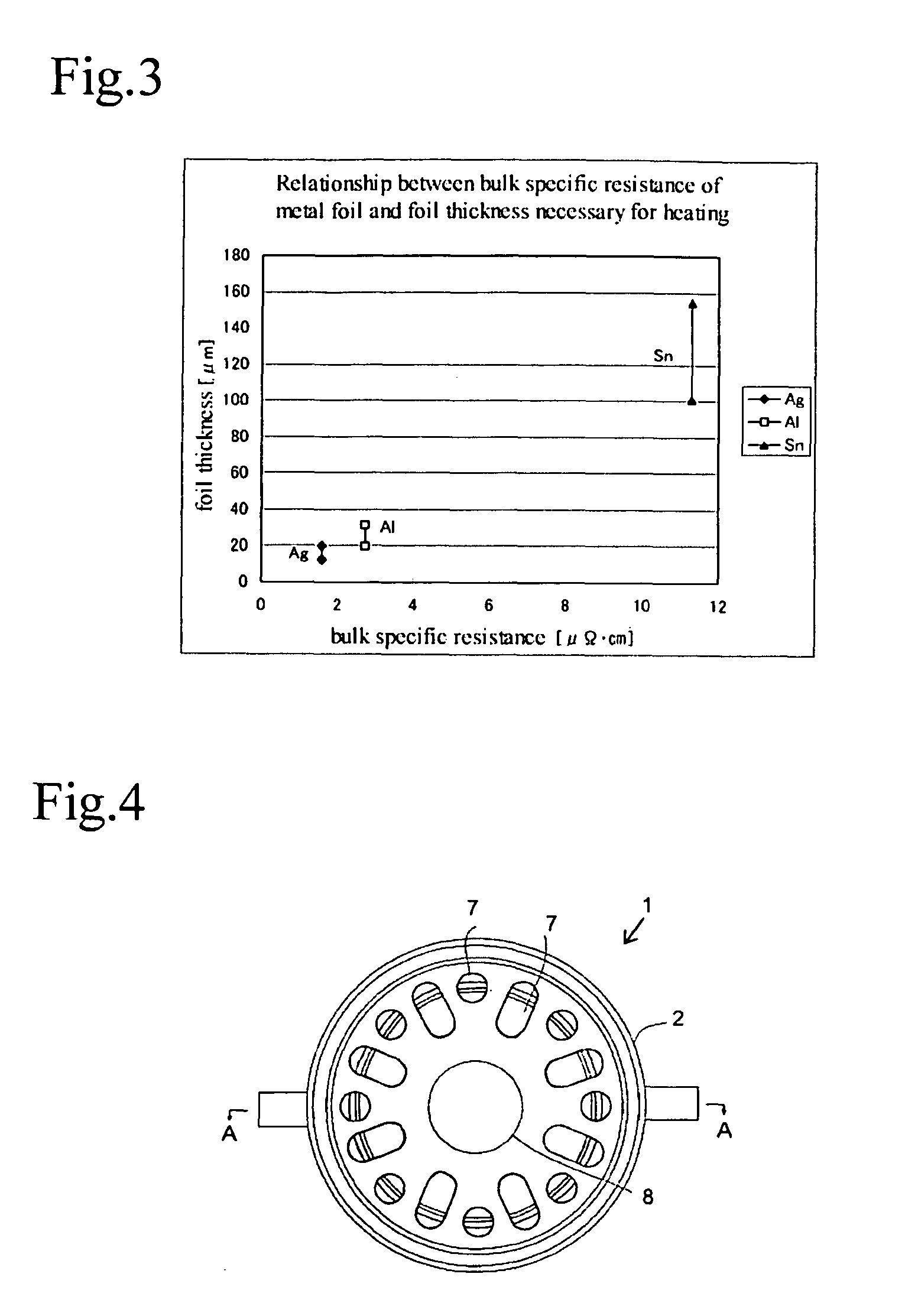

ActiveUS20100059505A1Low costEasily setCooking-vessel materialsContainers for heating foodCookerRetort

[Problem] To provide a container for an electromagnetic cooker which can be heated corresponding to impedance check frequency which differs depending on a manufacturer of an electromagnetic cooker or the like, can properly and easily set a heat generation characteristic, is excellent in marketability, configuration in use, disposability, handiness in cooking and the like, is suitable for retort foods, instant foods and the like, and exhibits high heating efficiency.[Means for Resolution] A container for an electromagnetic cooker includes a container body made of a non-conductive material and a conductive layer in a bottom portion of the container, wherein the ratio of resistance change (R−R0) / R0 of the conductive layer with respect to the impedance check frequency of a heating coil is set to 5.3 or more, and a ratio of inductance change (L−L0) / L0 of the conductive layer with respect to the impedance check frequency of the heating coil is set to −0.17 or less. Here, R indicates the high-frequency resistance (Ω) on a heating coil side with a load, R0 indicates the high-frequency resistance (Ω) on the heating coil side without a load, L indicates the inductance (μH) on the heating coil side with a load, and L0 indicates the inductance (μH) on the heating coil side without a load.

Owner:TOYO SEIKAN KAISHA LTD

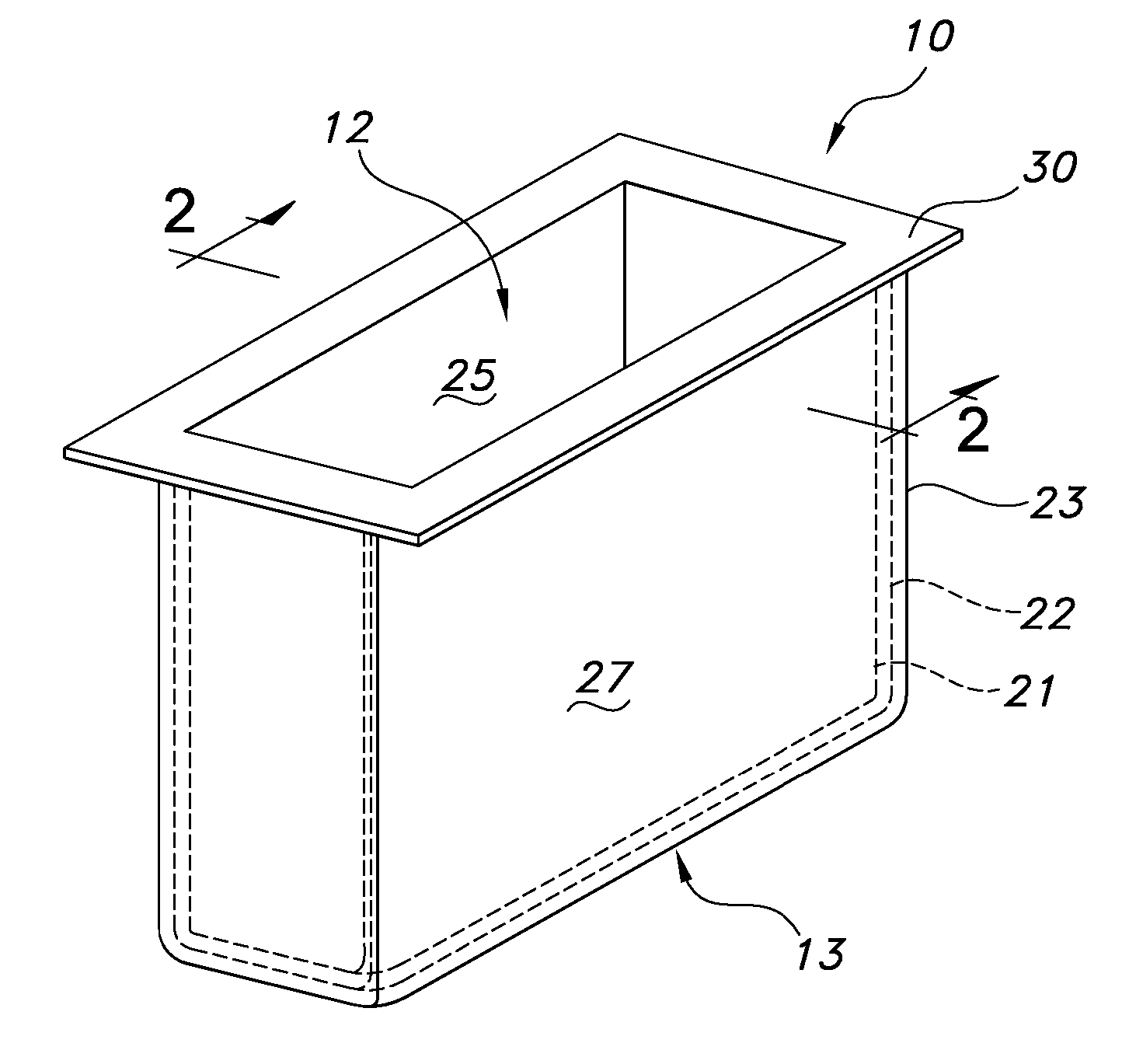

Storage container

A flexible or semi-flexible storage container comprises a container body formed from one or more pieces of flexible or semi-flexible sheet material. Flexibly attached to the container body by one or more flexible assembly mechanisms are complimentary enclosure pieces, which when assembled together form an enclosed container. The flexible assembly mechanism comprises a zipper mechanism, however equivalent mechanisms, such as hook and loop fasteners and the like are considered in various other exemplary embodiments. The flexible or semi-flexible storage container may be selectively opened, sealed, and resealed, as described herein. In addition to being self-supporting, flexible or semi-flexible storage containers are also readily foldable or collapsible to provide easy storage that occupies minimal space.

Owner:DYNO SEASONAL SOLUTIONS

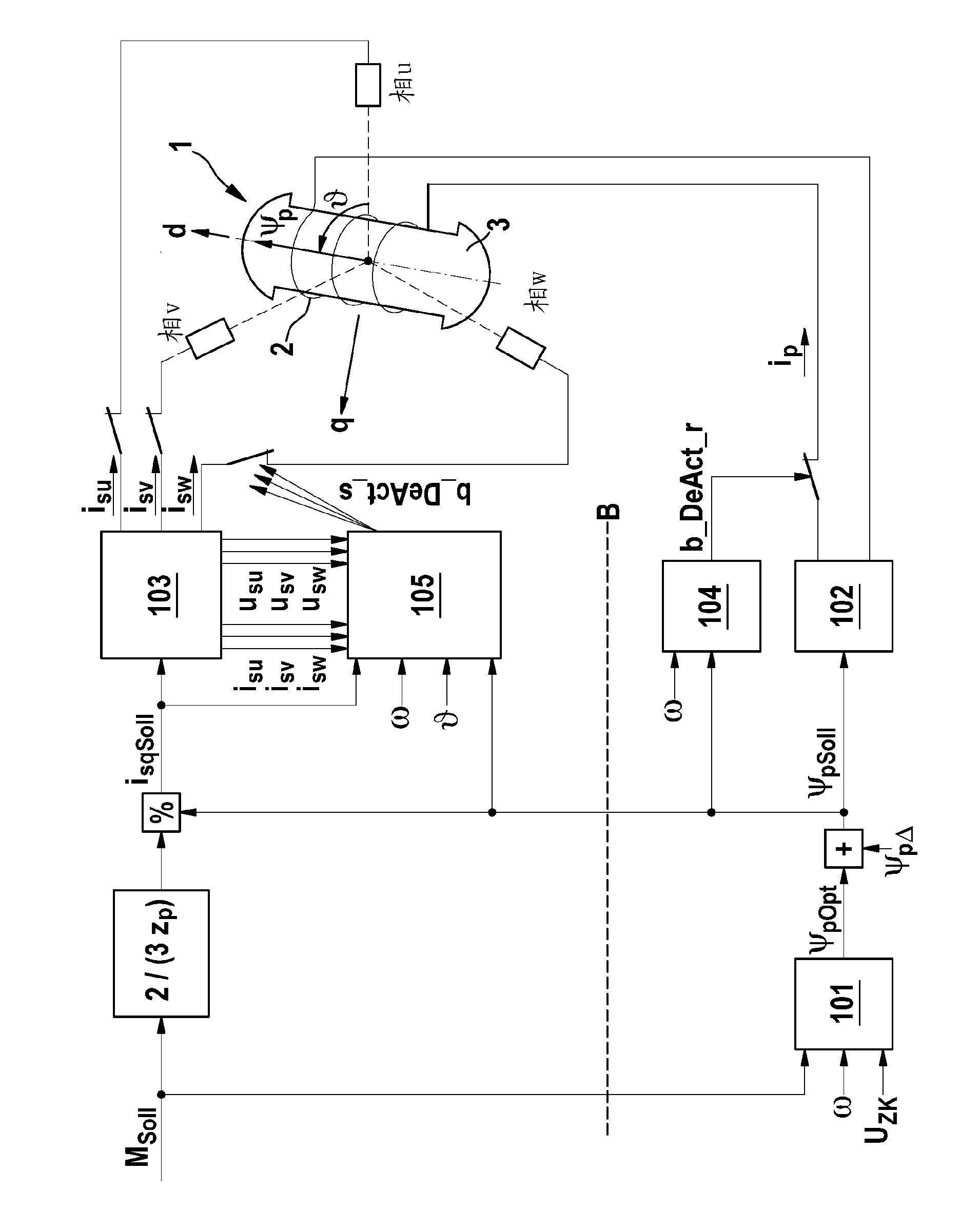

Method and device for detecting a malfunction of an electric machine

ActiveCN103328995AIncrease the oscillation frequencyMonitor driving conditionsDynamo-electric machine testingElectric machineControl theory

The invention relates to a method for detecting a malfunction of an electric machine, a first variable (isq) influencing the torque (M) of the electric machine (1) being modulated. In order to reliably detect the malfunction of an electric machine and to prevent an associated unwanted torque or power output of the electric machine, a second variable ([psi]p) influencing the torque of the electric machine is modulated, the two variables ([psi]p, isq) influencing the torque (M) cancelling each other out, when the electric machine functions properly, with respect to their effect onto a parameter of the electric machine (1), especially a torque (M), a speed, an electric parameter and / or a magnetic parameter, while it is concluded that there is a malfunction in the event of the lack of such a cancellation.

Owner:ROBERT BOSCH GMBH

Quick dispense system

InactiveUS20130037561A1Facilitates shipping and storage and handlingAbility to disassemble and unfold the cartridgeRacksDispensing apparatusDrug dispensingEngineering

Provided as a drug dispensing system comprising a cabinet and at least one cartridge. A cabinet has opposing door portions which are hingedly attached to one another and which are configured to be closable against one another such as via a lock member. Each one of the door portions includes at least one shelf which defines a shelf depth and which has an upwardly turned lip extending along the length of the shelf. The cartridge has a cartridge depth that is sized to be complementary to the shelf depth such that the cartridge may be retained by the lip when the cartridge is stored on the shelf. Each one of the cartridges is configured to store a plurality of vials. A punch-out is disposed in a lower end of the cartridge and through which the vials may be dispensed from the cartridge. The cartridge itself may be comprised of a top panel, a bottom panel, a front panel, a back panel and a pair of side panels foldable connected to one another along a plurality of fold lines and to define an interior compartment that is sized and configured to dispensibly store the vials.

Owner:WOLPOW RICHARD

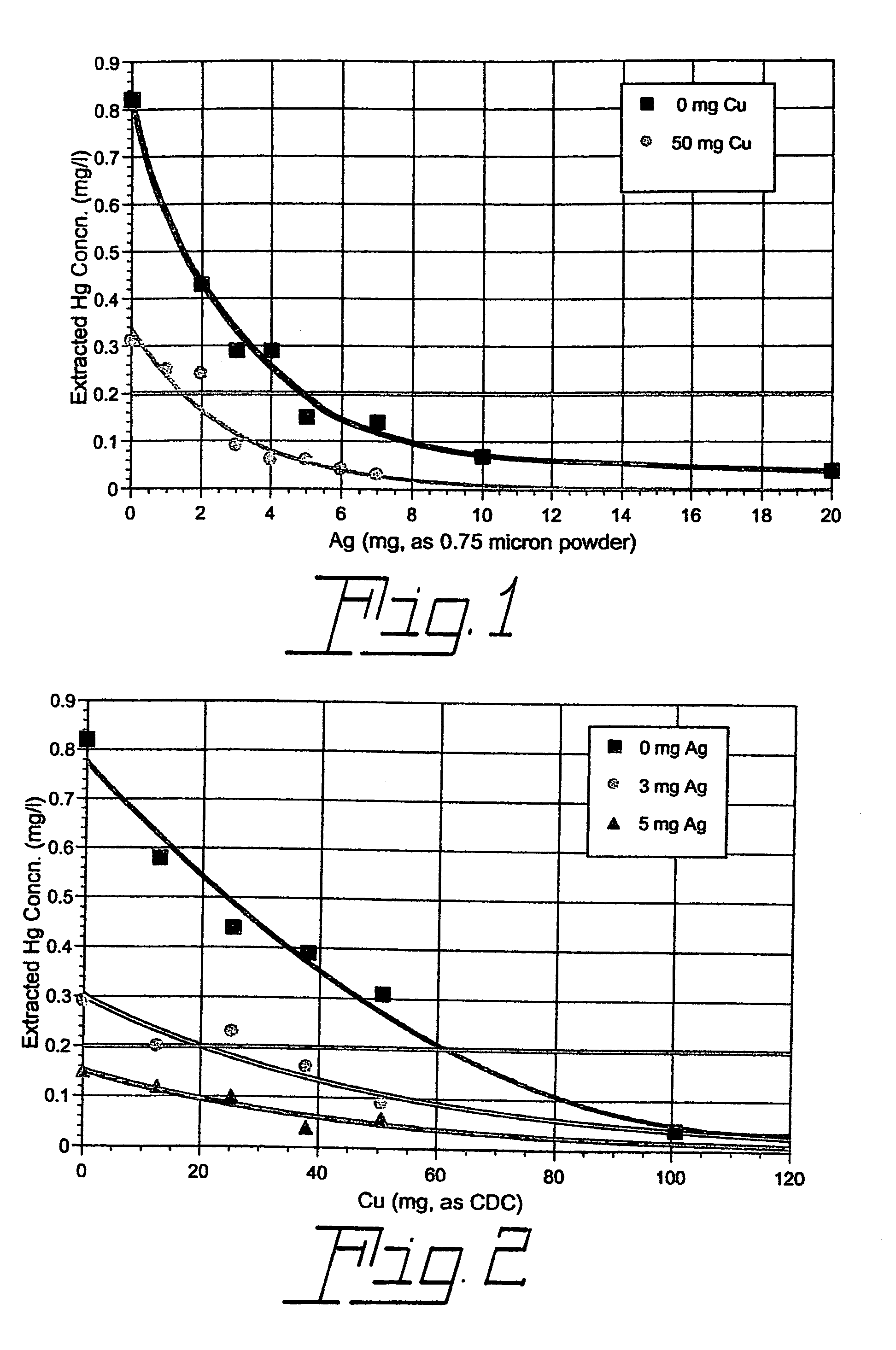

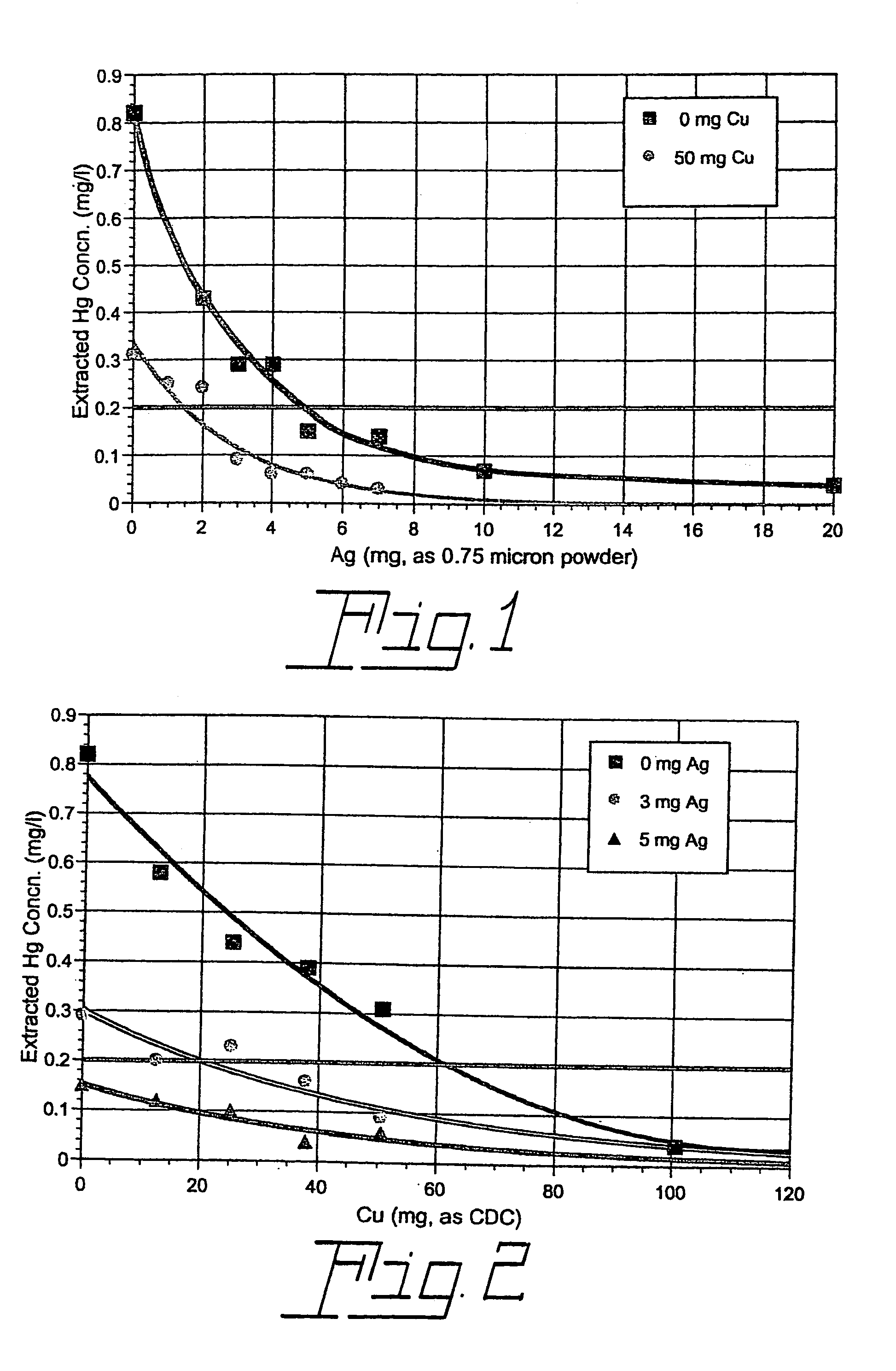

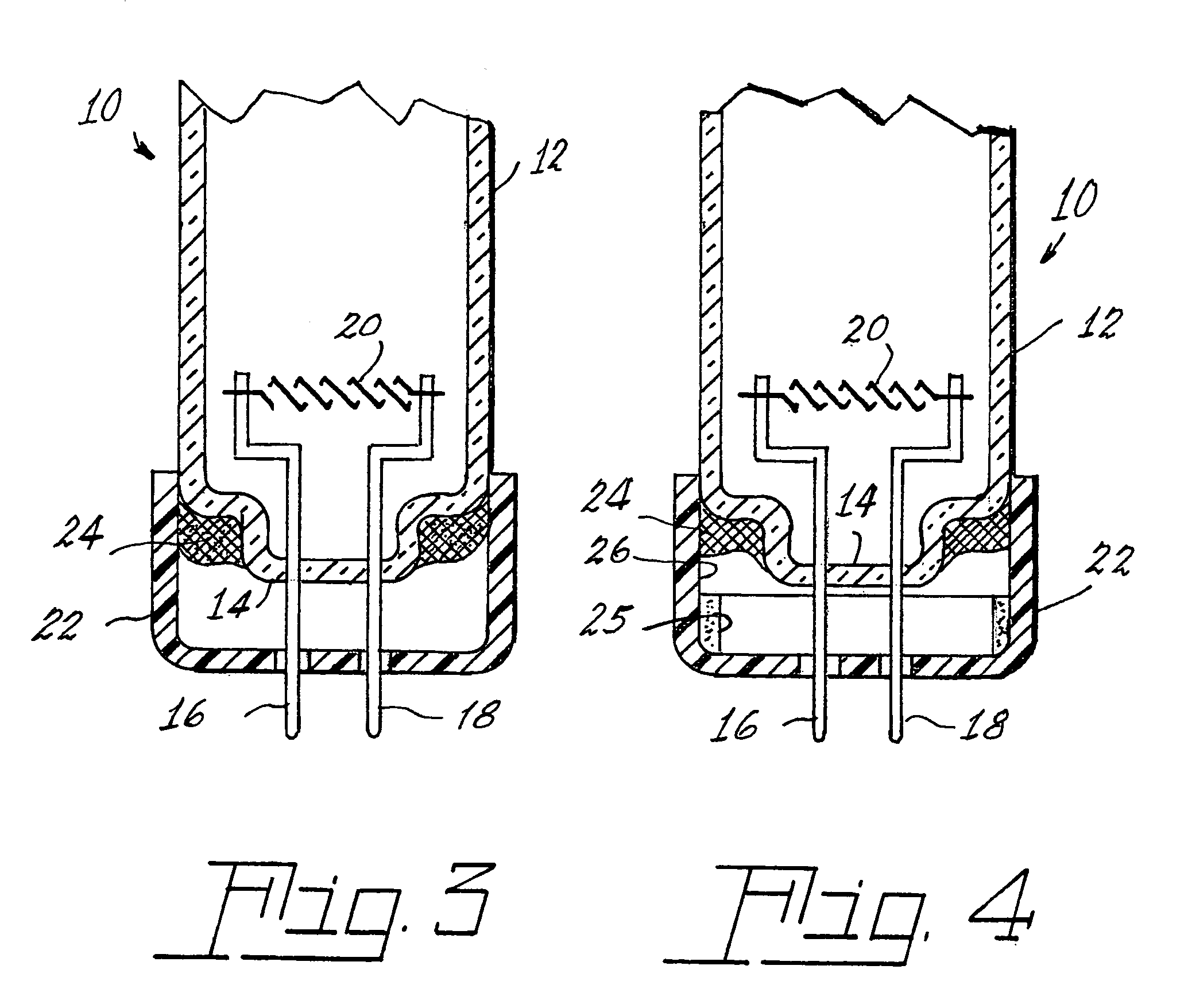

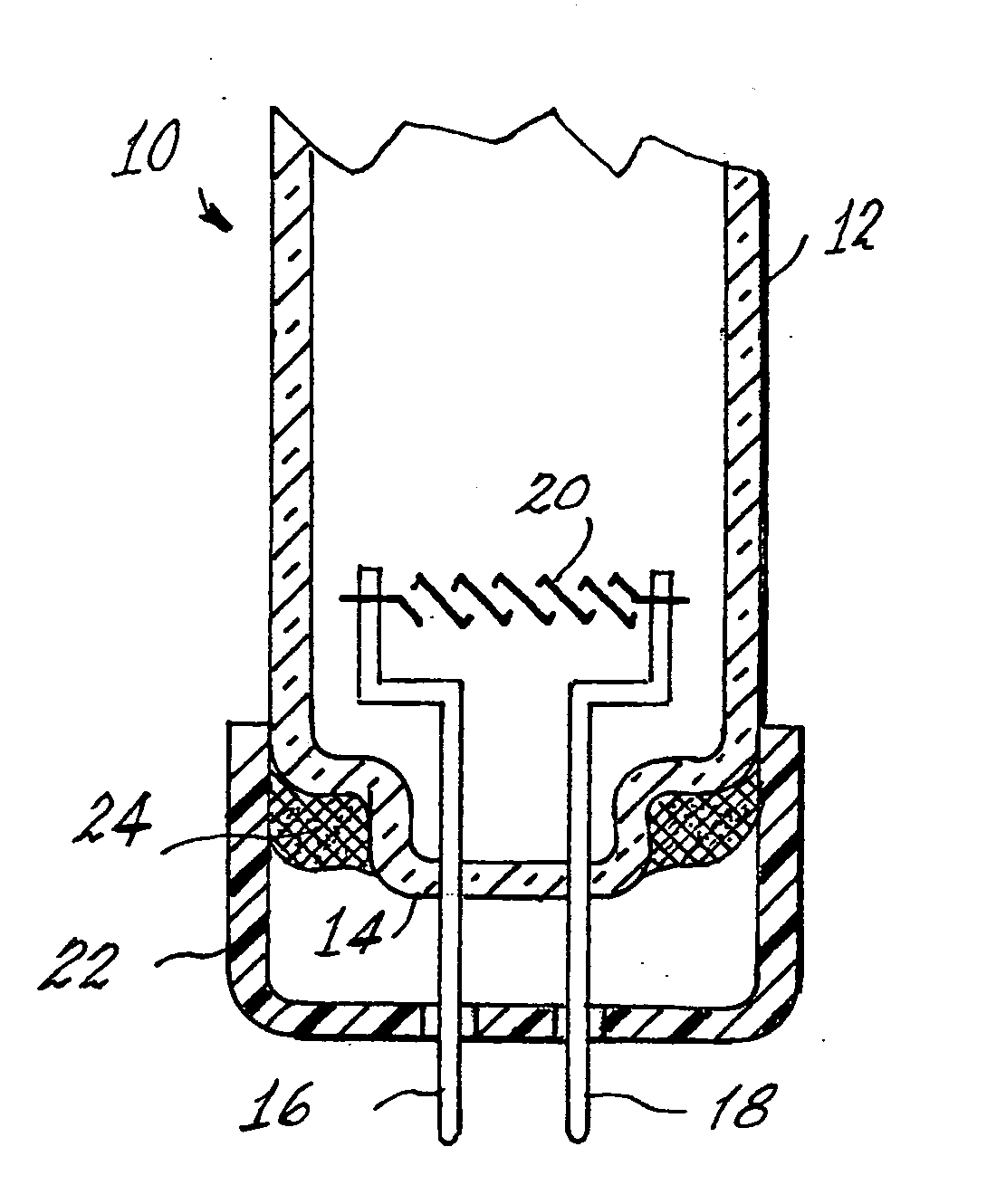

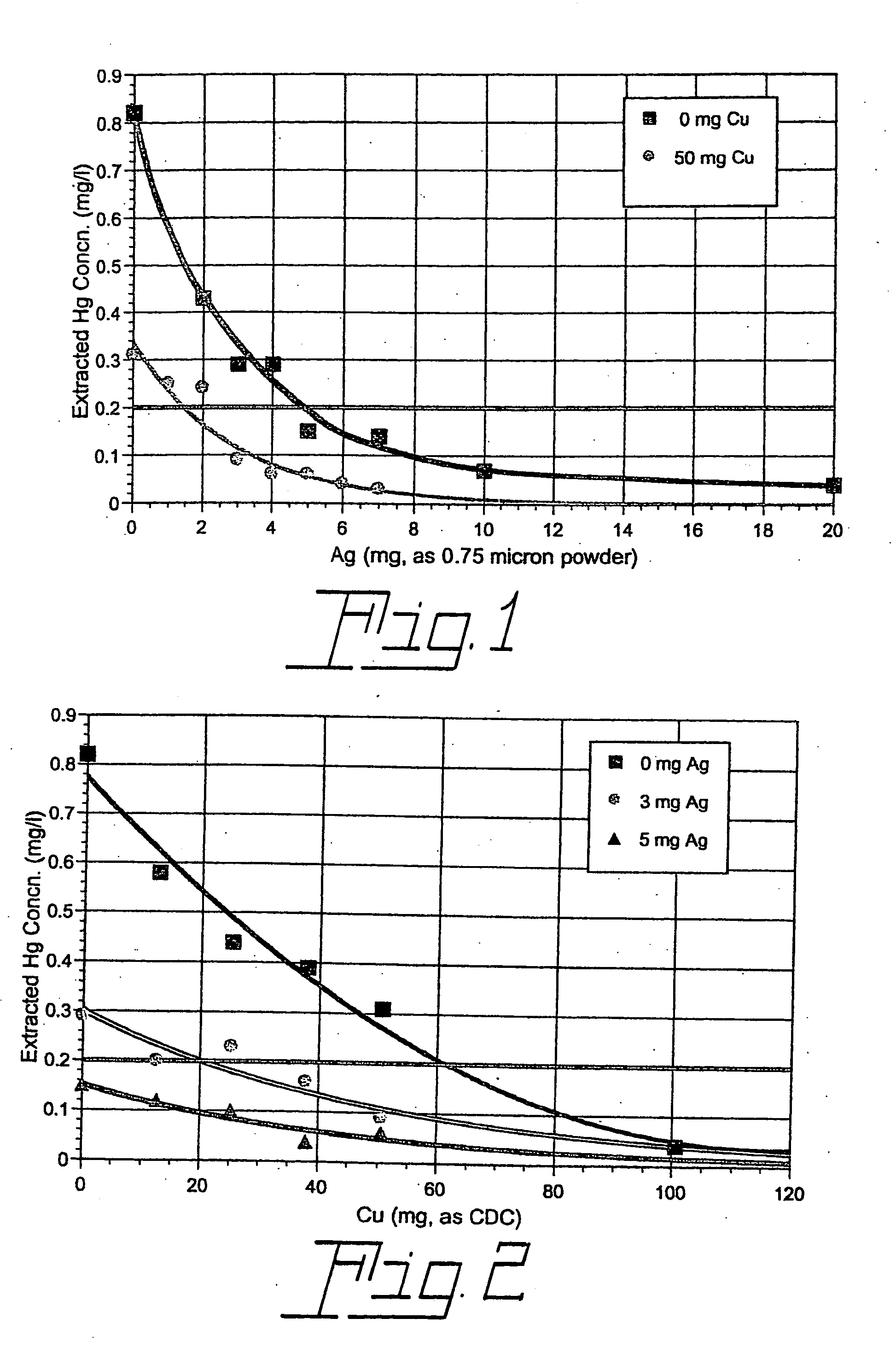

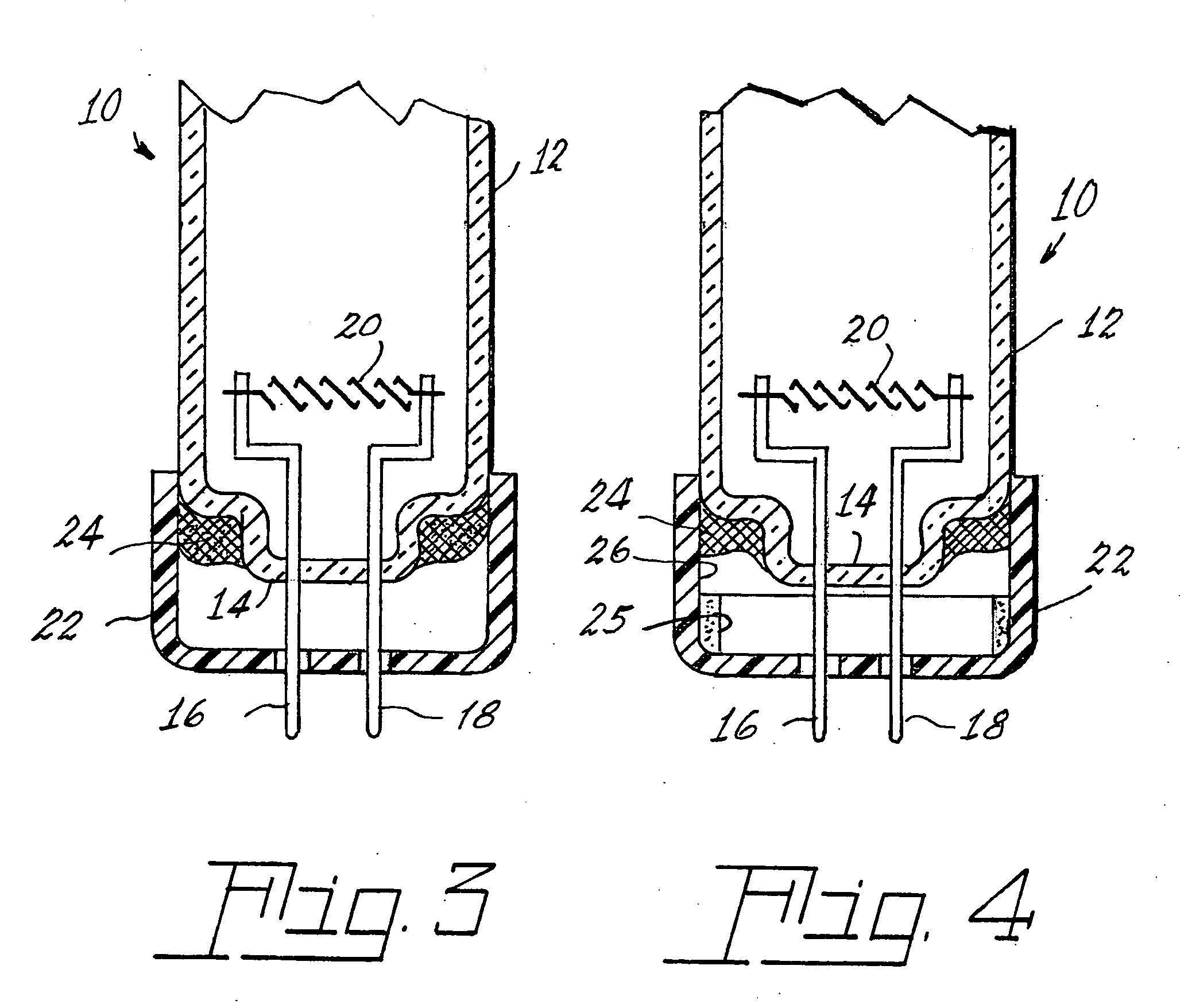

Arc discharge lamp containing means for reducing mercury leaching

InactiveUS7030559B2Improve DisposabilityEffective and inexpensive and easy to applyLow-pressure discharge lampsSolid cathode detailsPlatinumGas-discharge lamp

An arc discharge lamp containing a quantity of elemental mercury at least partially convertible to soluble mercury, provides for including within the lamp a quantity of a non-metallic copper-containing compound and an ingredient X, said ingredient X including a noble metal or a noble metal compound selected from the group consisting of silver and compounds of silver, gold and platinum, and a lamp containing same.

Owner:OSRAM SYLVANIA INC

Container for electromagnetic cookers

ActiveUS8344297B2Improve heating efficiencyLow costCooking-vessel materialsContainers for heating foodElectrical resistance and conductanceEngineering

Problem to provide a container for an electromagnetic cooker which can be heated corresponding to impedance check frequency which differs depending on a manufacturer of an electromagnetic cooker or the like, can properly and easily set a heat generation characteristic, is excellent in marketability, configuration in use, disposability, handiness in cooking and the like, is suitable for retort foods, instant foods and the like, and exhibits high heating efficiency, means for resolution a container for an electromagnetic cooker includes a container body made of a non-conductive material and a conductive layer in a bottom portion of the container, wherein the ratio of resistance change (R−R0) / R0 of the conductive layer with respect to the impedance check frequency of a heating coil is set to 5.3 or more, and a ratio of inductance change (L−L0) / L0 of the conductive layer with respect to the impedance check frequency of the heating coil is set to −0.17 or less. Here, R indicates the high-frequency resistance (.OMEGA.) on a heating coil side with a load, R0 indicates the high-frequency resistance (.OMEGA.) on the heating coil side without a load, L indicates the inductance (.mu.H) on the heating coil side with a load, and L0 indicates the inductance (.mu.H) on the heating coil side without a load.

Owner:TOYO SEIKAN KAISHA LTD

Method of controlling leachable mercury in lamps

InactiveUS7176626B2Improve DisposabilityEffective and inexpensive and easy to applyLow-pressure discharge lampsSolid cathode detailsPlatinumCopper

A method for inhibiting mercury from leaching from a land-filled arc discharge lamp containing a quantity of elemental mercury at least partially convertible to soluble mercury, provides for including within the lamp a quantity of a non-metallic copper-containing compound and an ingredient X, said ingredient X including a noble metal or a noble metal compound selected from the group consisting of silver and compounds of silver, gold and platinum, and a lamp containing same. The inhibiting compound is preferably included with the basing cement.

Owner:OSRAM SYLVANIA INC

Method of controlling leachable mercury in lamps

InactiveUS20060001367A1Effective and inexpensive and easy to applyImprove DisposabilityLow-pressure discharge lampsSolid cathode detailsPlatinumAdditive ingredient

A method for inhibiting mercury from leaching from a land-filled arc discharge lamp containing a quantity of elemental mercury at least partially convertible to soluble mercury, provides for including within the lamp a quantity of a non-metallic copper-containing compound and an ingredient X, said ingredient X including a noble metal or a noble metal compound selected from the group consisting of silver and compounds of silver, gold and platinum, and a lamp containing same. The inhibiting compound is preferably included with the basing cement.

Owner:OSRAM SYLVANIA INC

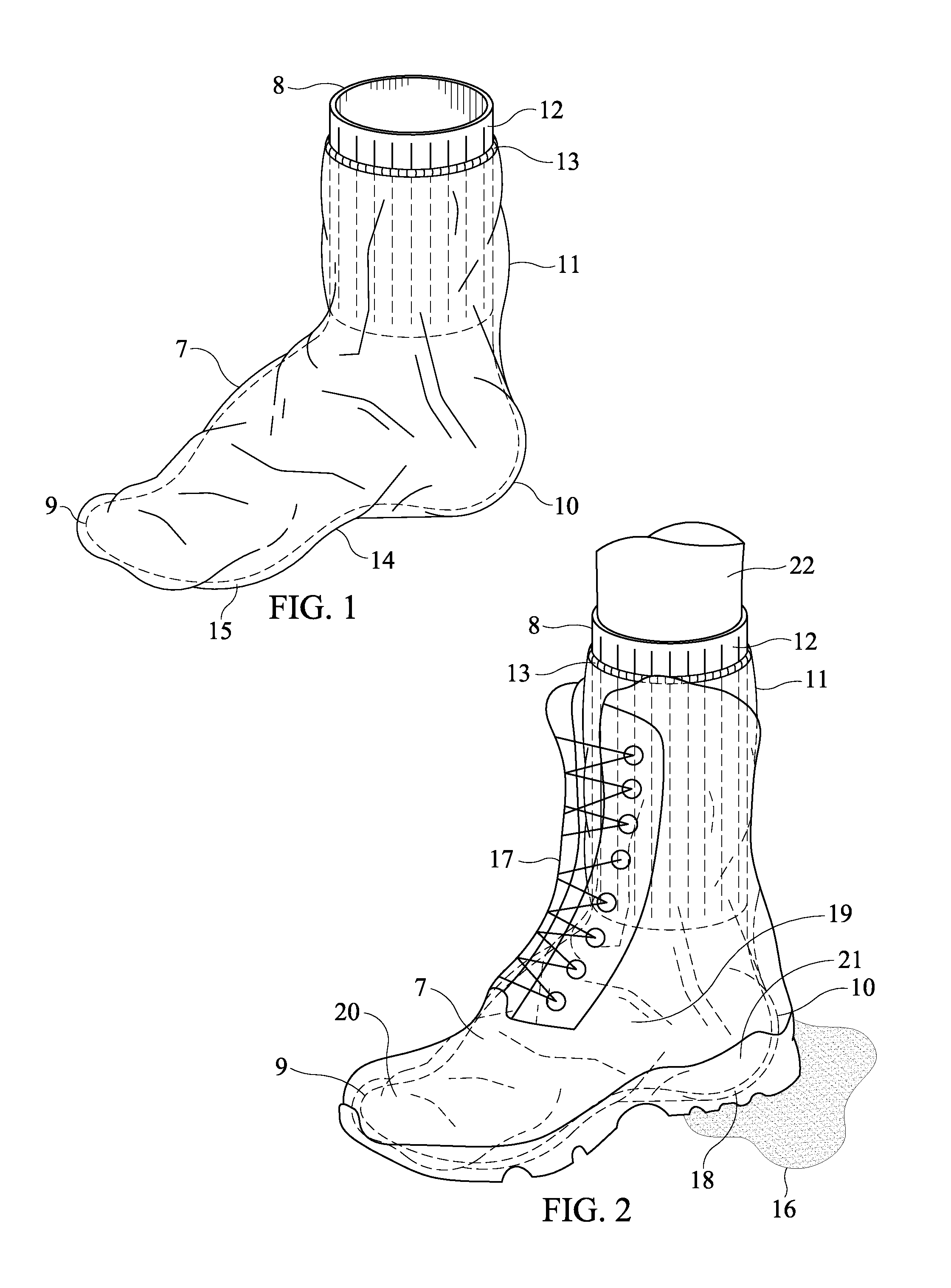

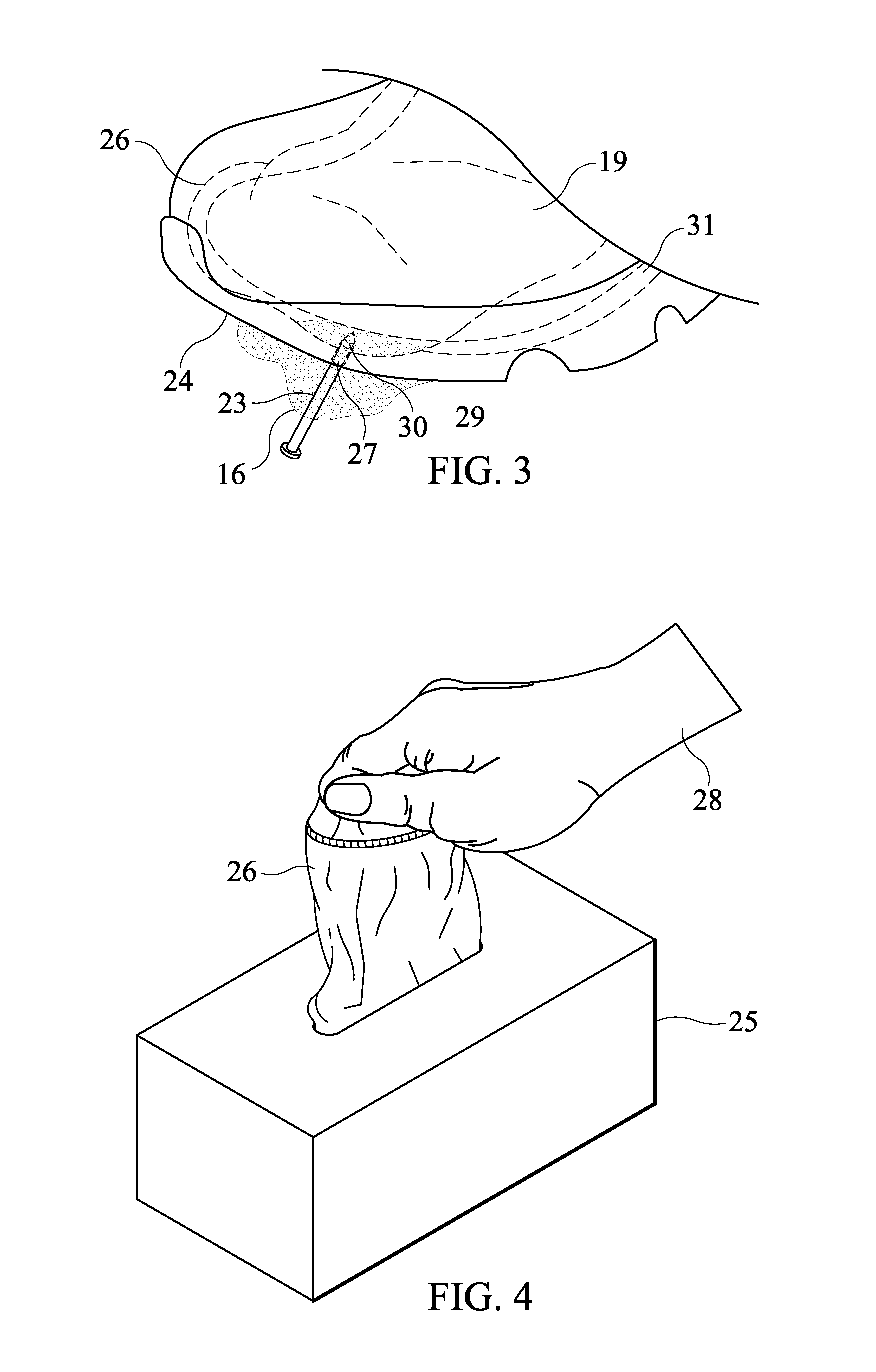

Waterproof polyethylene disposable foot and sock cover

InactiveUS20160165982A1Avoid replacementOpportunities decreaseGarment special featuresInsolesEngineeringMechanical engineering

An article for keeping a foot (and potentially a sock) dry, when placed within a boot, the article comprising a non-rigid membrane impermeable to water and disposable material, and conformed to the shape of the foot so that there is little or no excess material when the article is placed over the foot (and potentially the sock, and both are) placed within the boot. The article may comprise a toe section, heel section, lower leg section, top opening, and a means for preventing the lower leg section and the top opening from falling down. Notwithstanding its disposability, the material comprising the article may be sufficiently resilient and durable for withstanding the frequent and substantial forces that the boot and foot may be subjected to during a work day at a wet construction site. The article may also allow continued use of a punctured previously-waterproof boot without the foot becoming wet.

Owner:RODGER ERIC SEAN

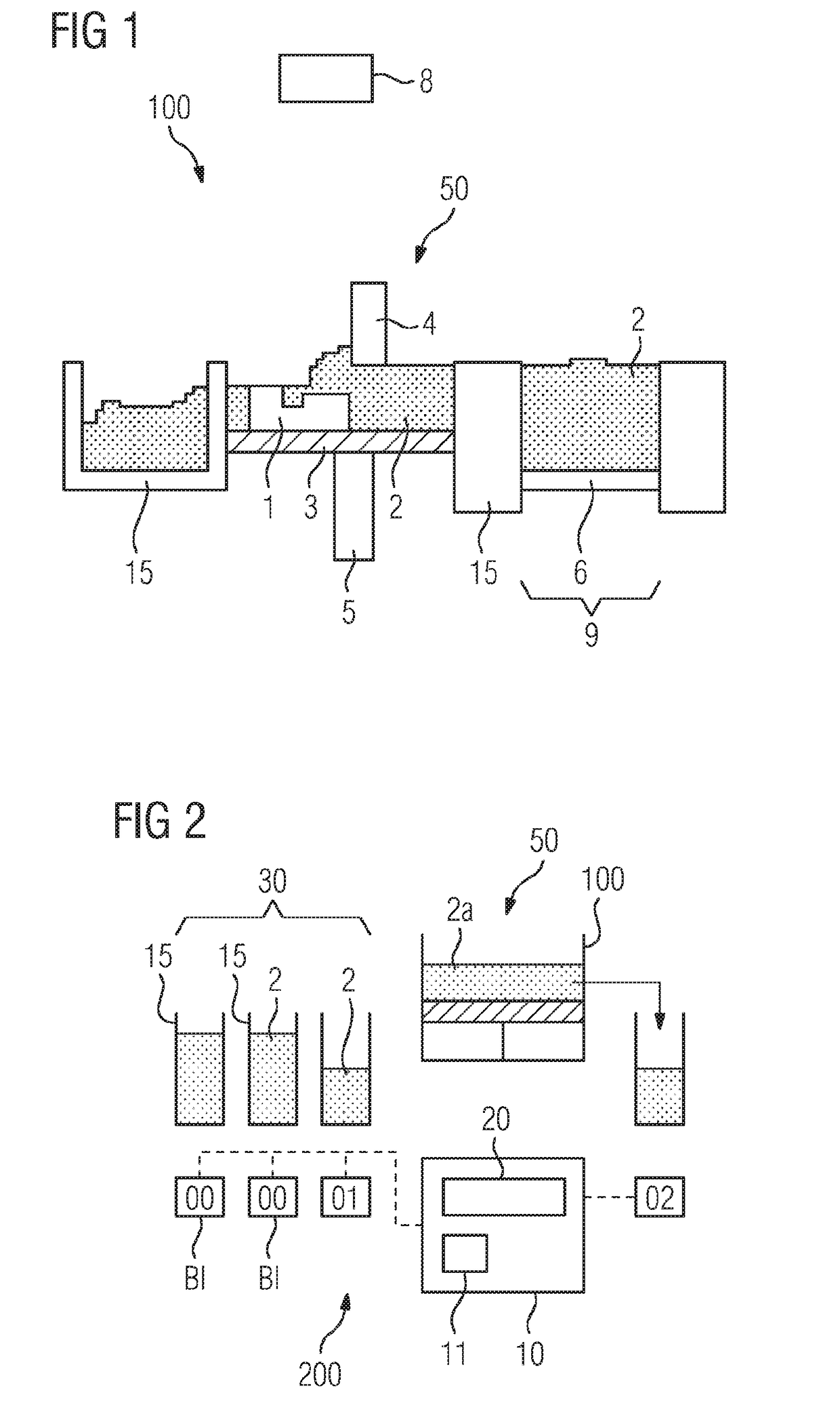

Control system and method for additive manufacturing

ActiveUS20190054703A1Easy to operateRapid overviewManufacturing enclosuresAuxillary shaping apparatusControl systemQuality control

Quality control method and control system for a stock of a base material for the additive manufacture of components includes selecting a batch of a base material out of a plurality of indexed batches of the stock, wherein base material assigned to the same batch index is indicative to the quality of the respective base material, loading a quantity of base material of the selected batch into a manufacturing system, additively manufacturing the component from the base material, wherein the base material of the selected batch is exposed to manufacturing conditions in a build area and updating the batch index of the base material remaining from the additive manufacture in the build area according to the exposure.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com