Container for electromagnetic cookers

a technology for electromagnetic cookers and containers, applied in the direction of electric/magnetic/electromagnetic heating, packaged goods, food packaging, etc., can solve the problems of difficult to properly and easily set the heat generation properties, the container is not economical, etc., and achieves low cost, high heating efficiency, and convenient setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

(Experiment 1)

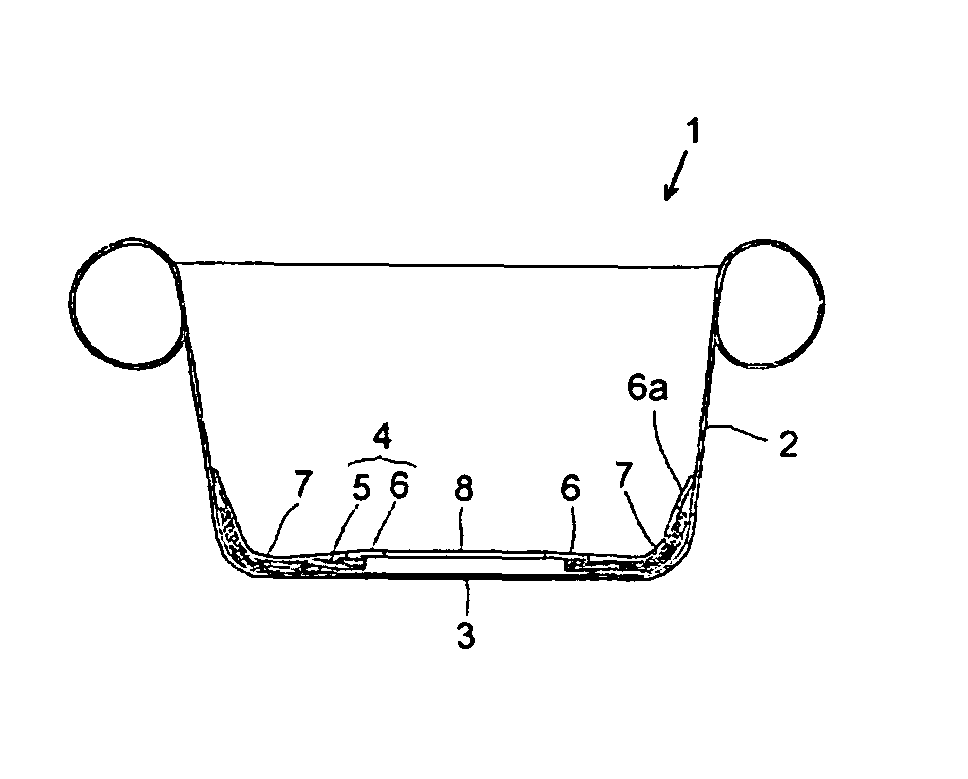

[0072]A container body having an inner diameter of 175 mm, a height of 120 mm and an inner volume of 1200 cc is formed using a polypropylene sheet having a thickness of 2.5 mm.

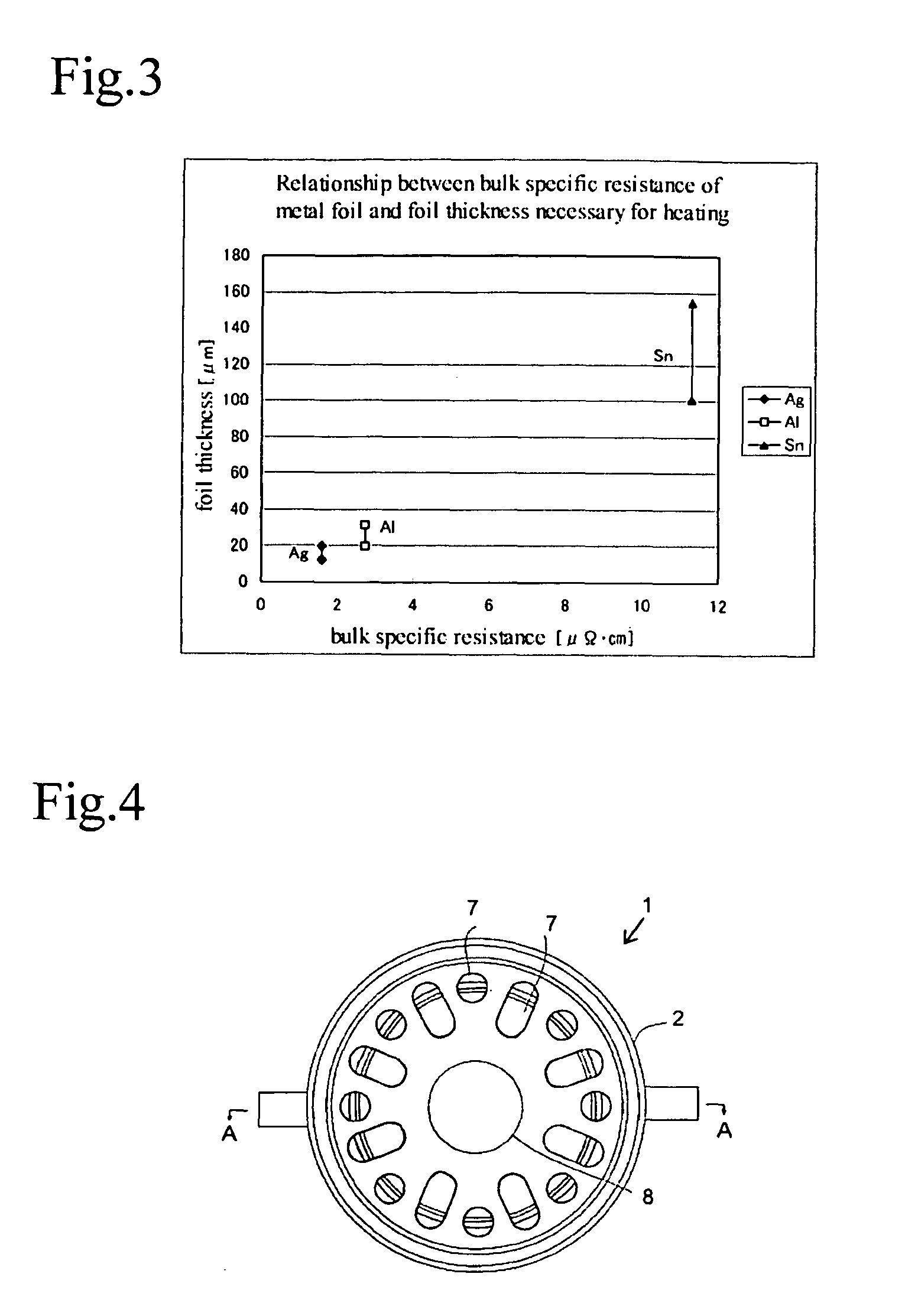

[0073]On the other hand, a conductive material is formed by laminating two aluminum foils having a thickness of 7 μm and an outer diameter of 150 mm, and a polypropylene film is laminated to both surfaces of the conductive material thus forming a conductive layer.

[0074]Then, an end portion of the polypropylene film is heat-sealed to a lower portion of an inner surface of a side wall of the container body such that the aluminum foils which constitute the conductive material are positioned on a bottom portion side of the container body in the container body thus forming a container for an electromagnetic cooker.

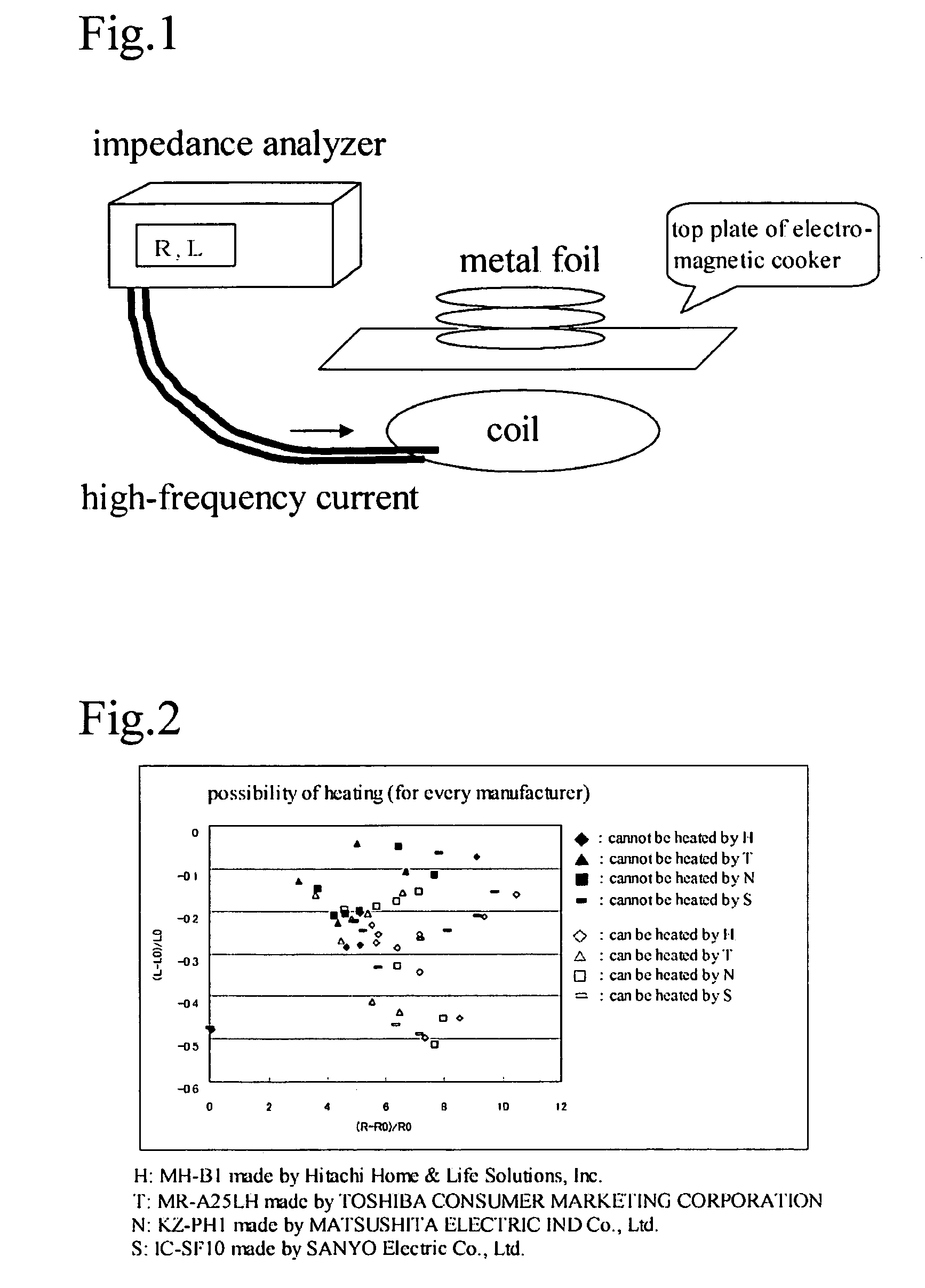

[0075]The container is heated using four kinds of electromagnetic cookers, that is, KZ-PH1 made by MATSUSHITA ELECTRIC IND CO LTD, MH-B1 made by Hitachi Home & Life Solutions, Inc., IC-SF10 ...

experiment 2

(Experiment 2)

[0076]Heating of a container for an electromagnetic cooker and evaluation on whether or not the container can be heated by electromagnetic cookers are performed in the same manner as the experiment 1 except for that a hole having a diameter of 60 mm is formed in a center portion of the conductive layer of the experiment 1 thus forming the conductive layer into a donut shape.

experiment 3

(Experiment 3)

[0077]A container body having an inner diameter of 110 mm, a height of 50 mm and an inner volume of 600 cc is formed using a polypropylene sheet having a thickness of 0.5 mm.

[0078]On the other hand, a conductive material is formed by laminating three aluminum foils having a thickness of 7 μm and an outer diameters of 110 mm, 105 mm and 100 mm, a polypropylene film is laminated to both surfaces of the conductive material, and a hole having a diameter of 60 mm is formed in a center portion of the polypropylene film thus forming a conductive layer.

[0079]Then, an end portion of the polypropylene film is heat-sealed to a lower portion of an inner surface of a side wall of the container body such that the conductive material of the conductive layer is positioned on a bottom portion side of the container body in the container body thus forming a container for an electromagnetic cooker. Thereafter, heating of a container for an electromagnetic cooker and evaluation of whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com