Fluid energy machine

An energy and fluid technology, applied in the direction of mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve size and weight constraints, fluid dynamics instability, multi-stage structures that cannot be considered, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

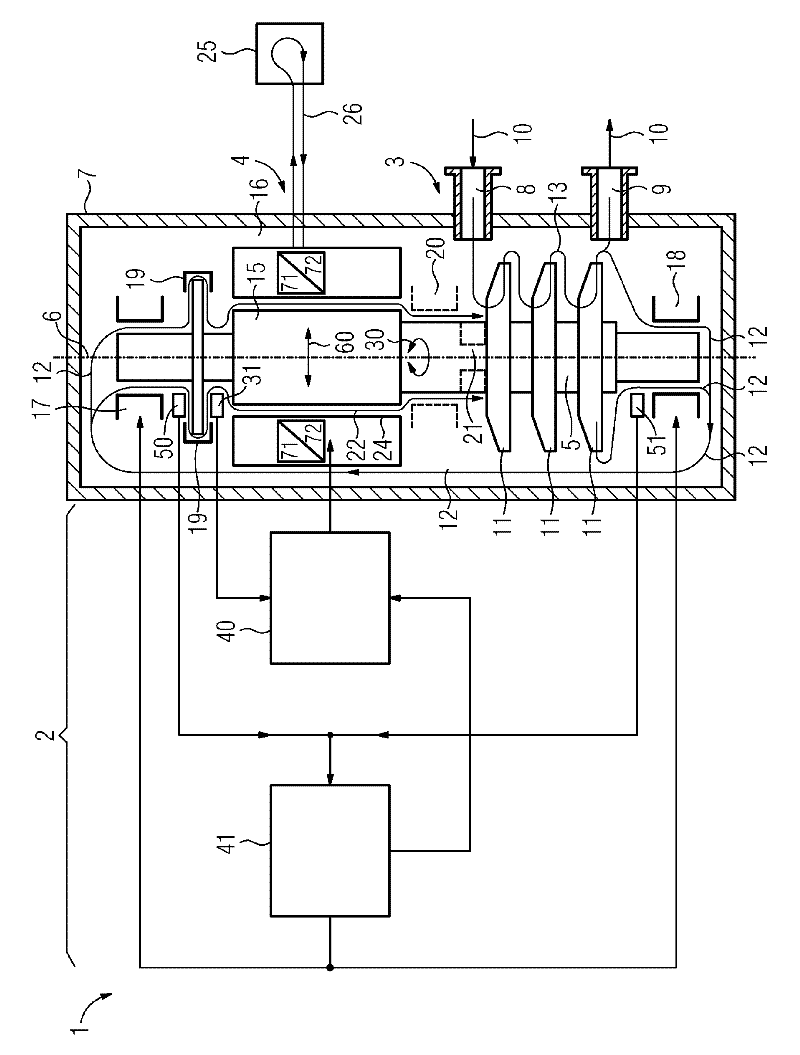

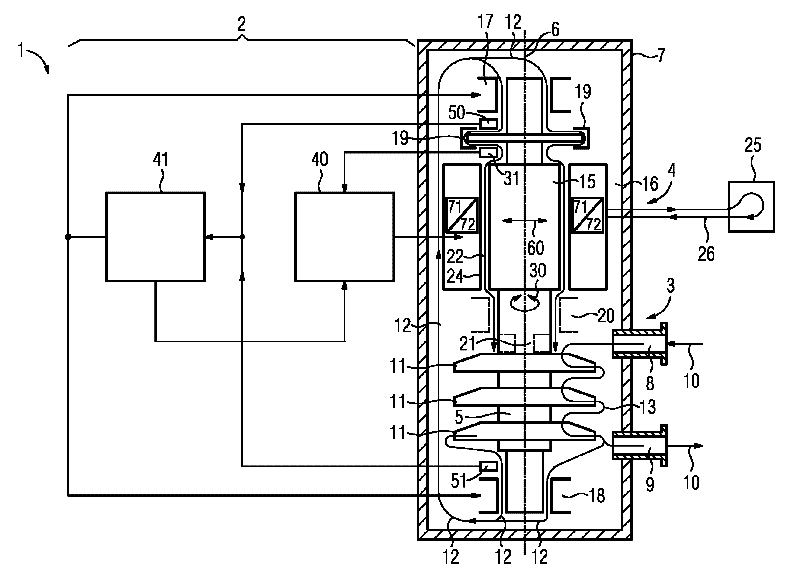

[0023] The drawing shows a longitudinal section of a fluid energy machine 1 and an adjusting device 2 as a block diagram in each case in a simplified illustration. The fluid energy machine 1 has a compressor 3 and a motor 4 which are arranged connected by means of a common shaft 5 along a longitudinal axis 6 of the shaft in a housing 7 which is gas-tight to the outside. The gas-tight housing 7 is gas-tight because no passage is provided for the shaft 5 that must be sealed by means of a shaft seal. In this regard, the fluid energy machine 1 can be described as seal-free, although there are shaft seals between the individual stages of the compressor 3 to reduce the pressure differences occurring in the stages.

[0024] The housing 7 has an inlet 8 and an outlet 9 for a process fluid 10 which is compressed by means of a compressor 3 . In addition to passing through the inlet 8 and outlet 9 or the main flow 13 of the plurality of impellers 11 of the compressor 3 , a smaller porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com