Method and device for detecting a malfunction of an electric machine

一种故障、特性的技术,应用在电动发电机测试、测量电、测量电变量等方向,能够解决没有实施制动力矩等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

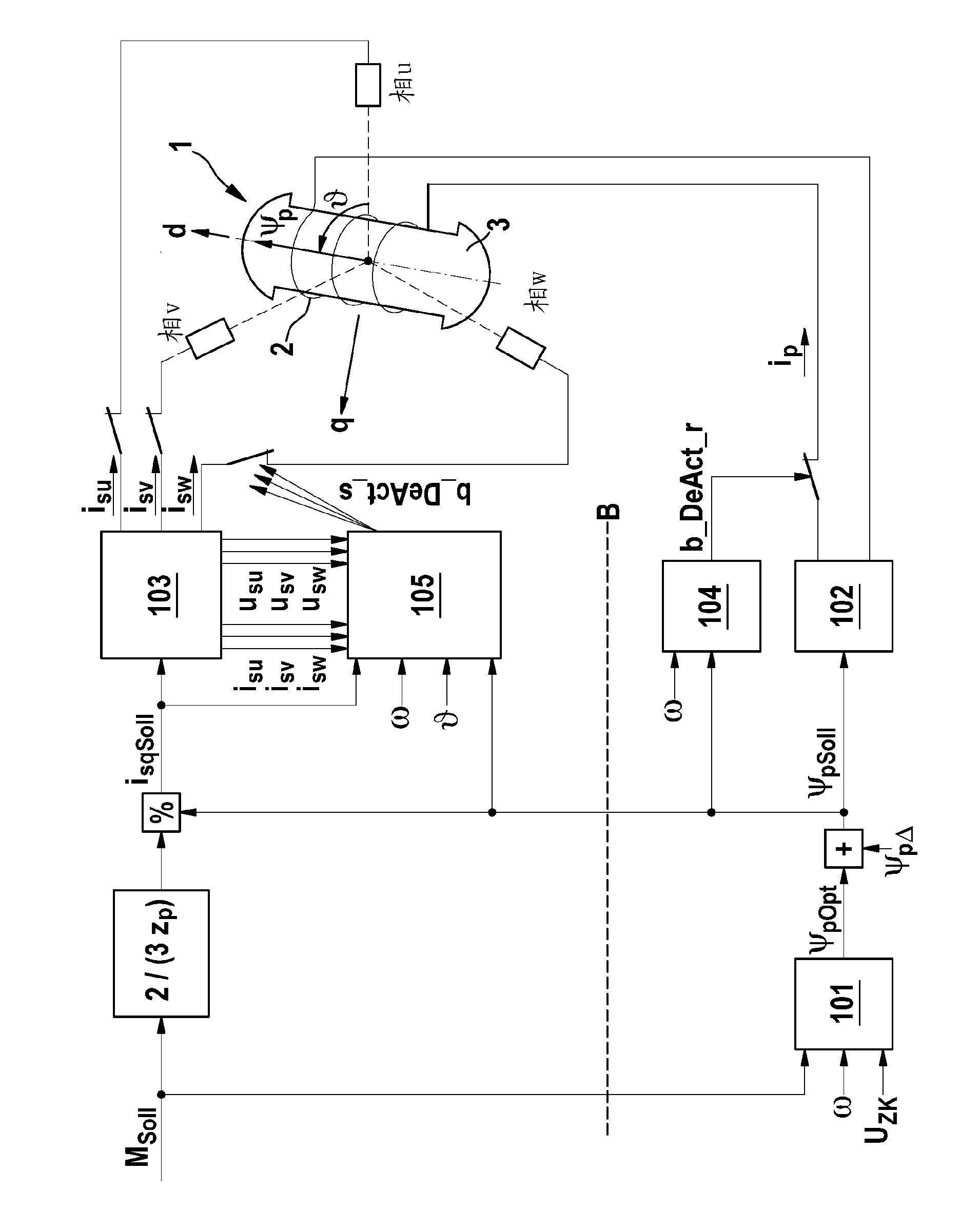

[0031] figure 1 The embodiment of the present invention is shown by taking a separately excited three-phase synchronous motor 1 as an example, which is used to drive an electric vehicle. The windings of the stator, not shown further, are called phase u, phase v and phase w and are shown in a very simplified manner. The coil axes of these windings are each rotated by 120 degrees relative to each other. The field winding 2 through which the current in the rotor 3 flows produces the rotor flux Ψ p . The driver of the motor vehicle or a safety system or driver assistance system of the motor vehicle specifies the desired torque M Soll . Desired torque M Soll During the switching process of the automated gear, it is influenced by the automated gear.

[0032] The field-oriented view of the three-phase electric machine 1 is based on the principle of space vectors. This relationship can be simplified when looking at a standard orthogonal d-q coordinate system operating in synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com