Method of, and apparatus for, the preliminary grinding and finishing of mineral and non-mineral materials

A non-mineral and material technology, which is applied to the equipment field with the characteristics described in the preamble, can solve the problems of large technical consumption, limitation, material blockage, etc., so as to reduce the technical cost, improve the energy utilization rate, and reduce the mechanical technical loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

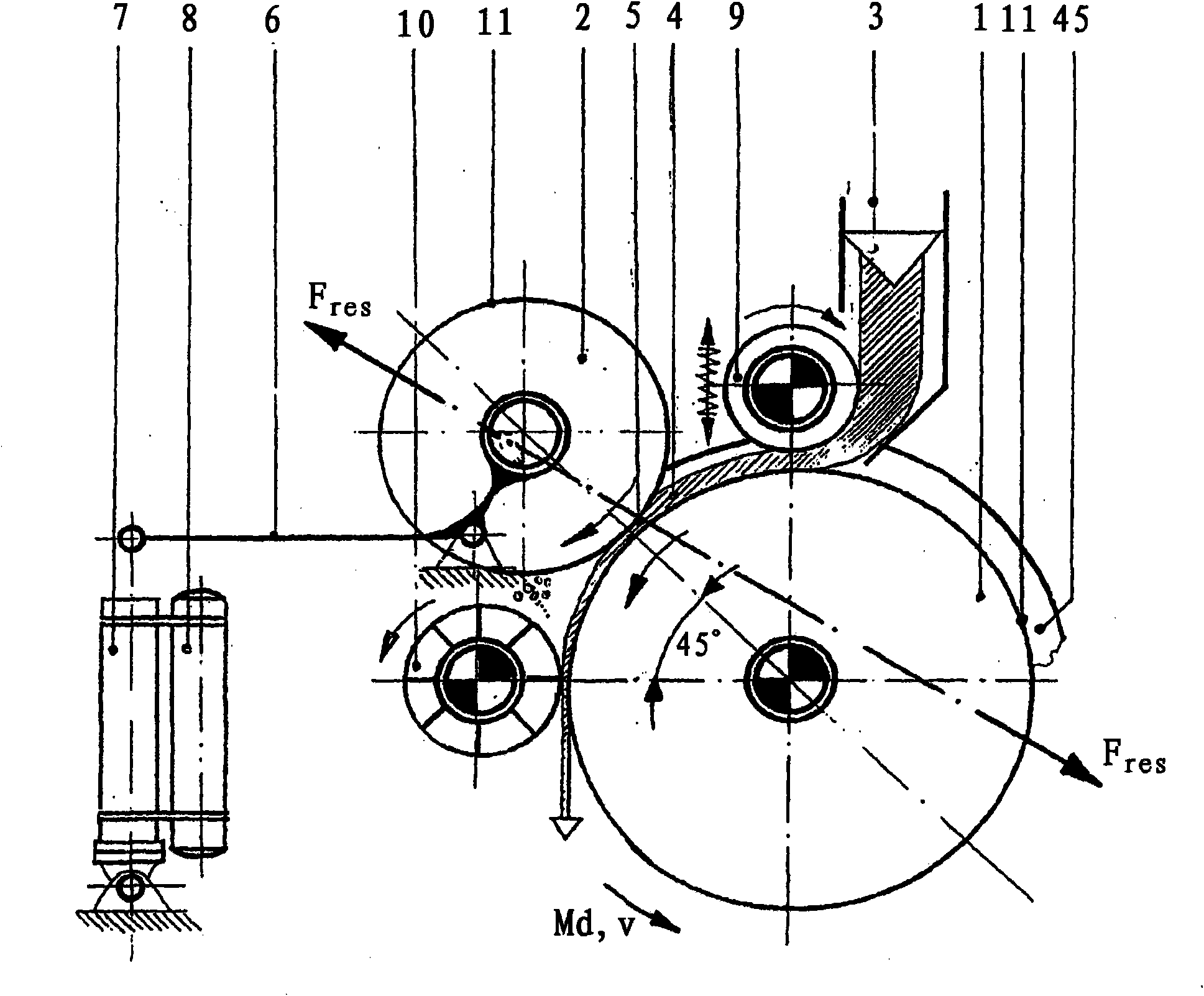

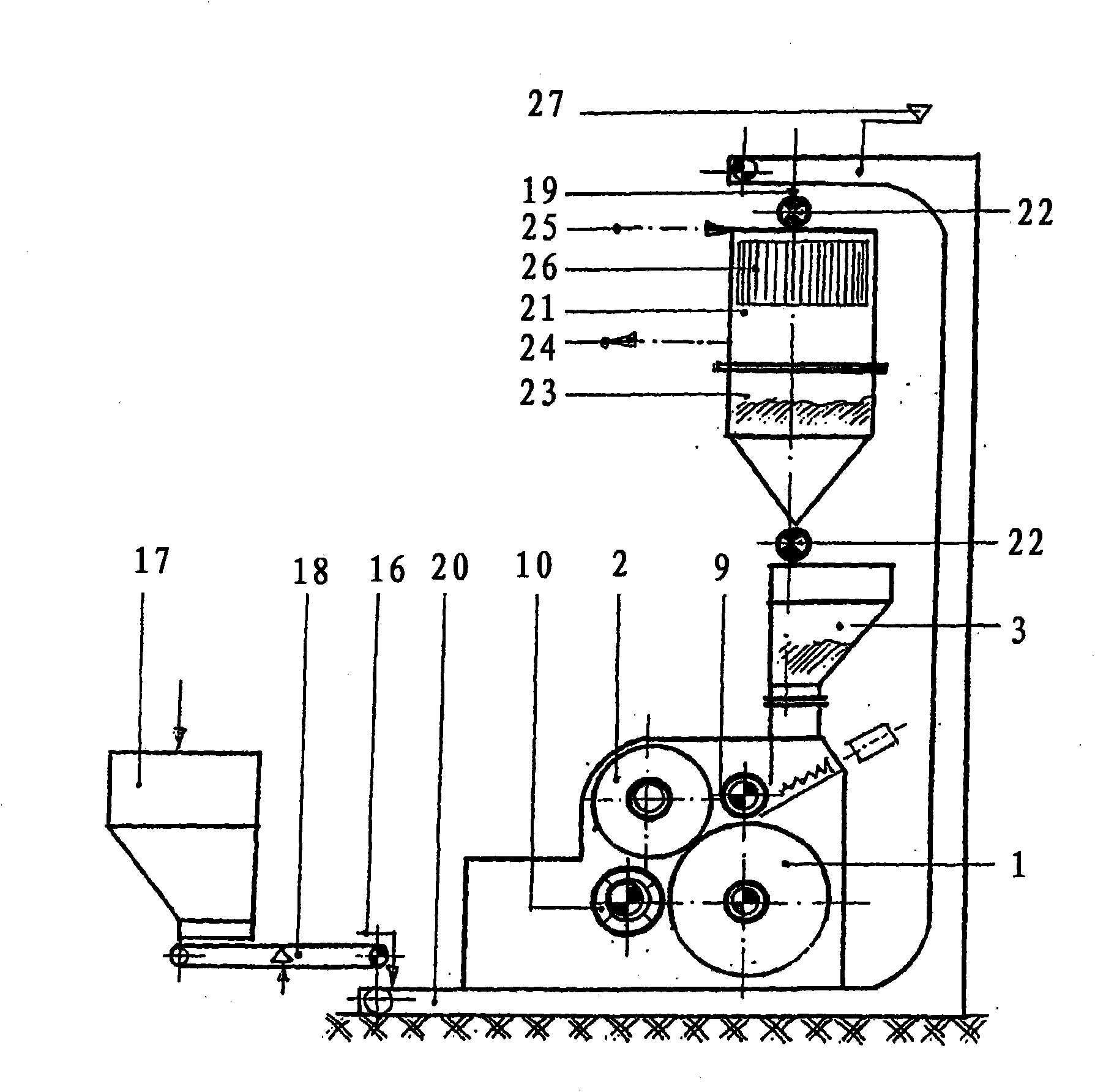

[0054] figure 1 The comminution device of the present invention is shown schematically, which comprises two horizontally supported and staggered rollers 1 and 2 arranged one above the other, an integrated breaker 10 and a system consisting of a feed container 3 and a roller feeder 9. Feeding and discharging device. The lower roller 1 corresponds to the figure 1 are driven in the direction of the arrow shown. Roller 2 is arranged vertically offset from roller 1 above driven roller 1 . The upper roller 2 is fed hydropneumatically towards the roller 1 via a lever system 6 by means of a hydraulic cylinder 7 . The upper roller 2 is dragged by the friction of the load surface of the driven roller 1 covered by the material or substance or can have its own drive. The diameter ratio of the lower roller 2 to the upper roller 2 is preferably 1.0 to 2.0 and particularly preferably 1.0 to 1.5.

[0055] The feed and discharge devices are arranged in the region of the apex of the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com