Waterproof polyethylene disposable foot and sock cover

a technology of waterproof polyethylene and foot, applied in the field of articles, can solve the problems of compromising the plastic membrane, the foot is not made of ordinary plastic bags, and the foot is not uniquely adapted, so as to reduce the likelihood of the lower leg section being swollen, and reduce the possibility of water and dirt entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]“Boot” is defined herein as any covering for a foot having a sturdy sole. “Lower leg” is defined herein to either include the ankle area and in some cases the area of the leg above the ankle area.

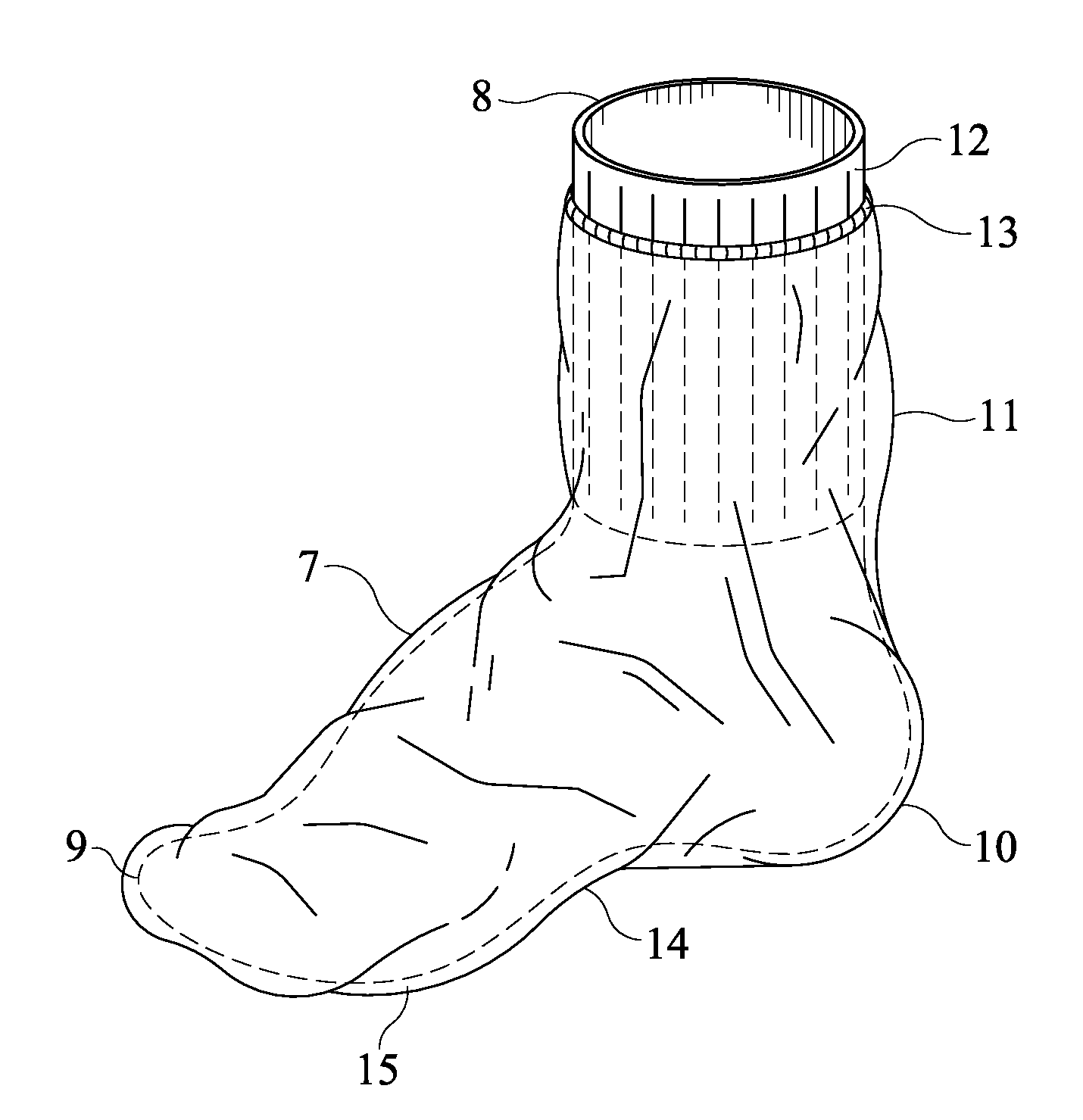

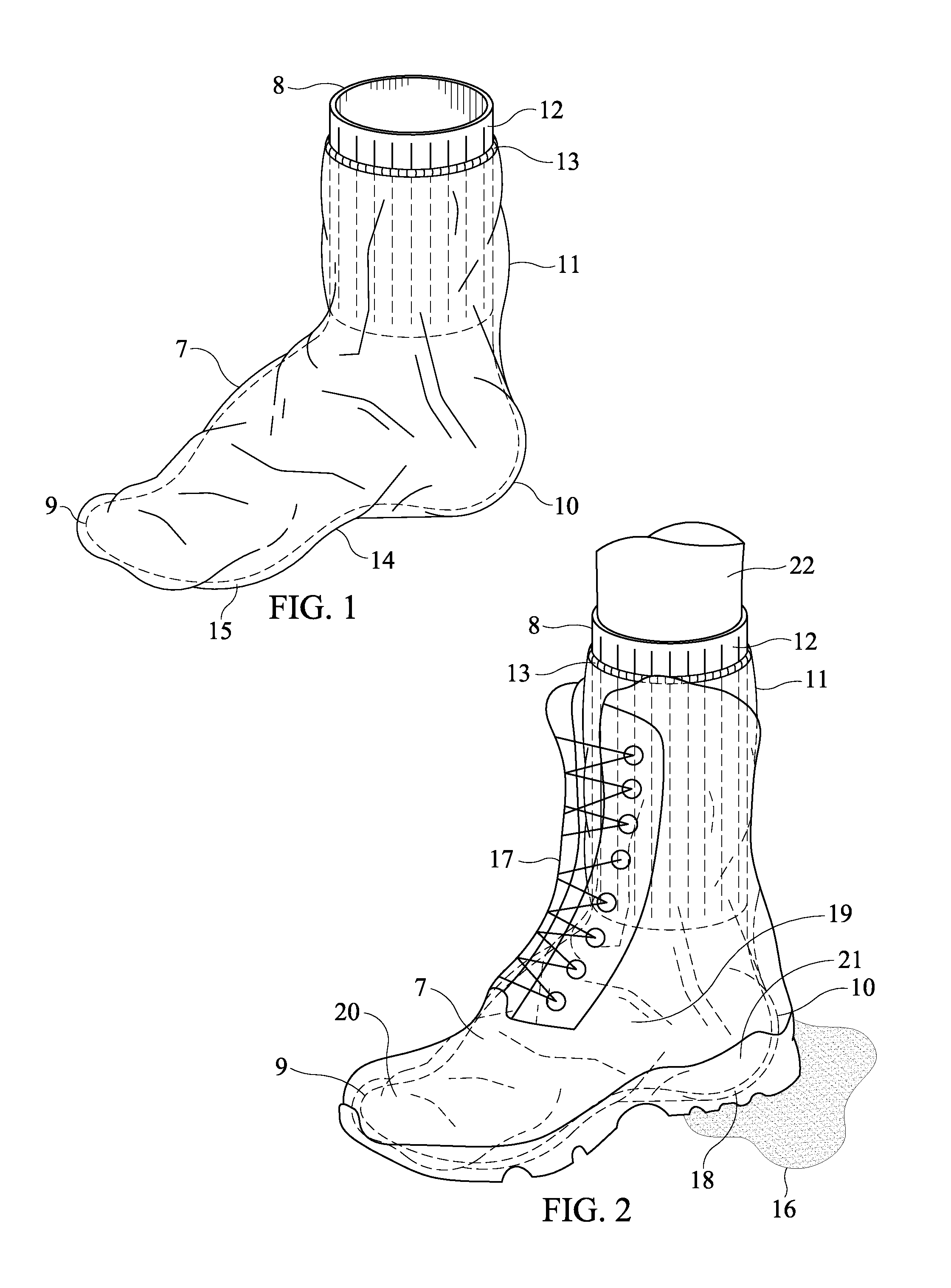

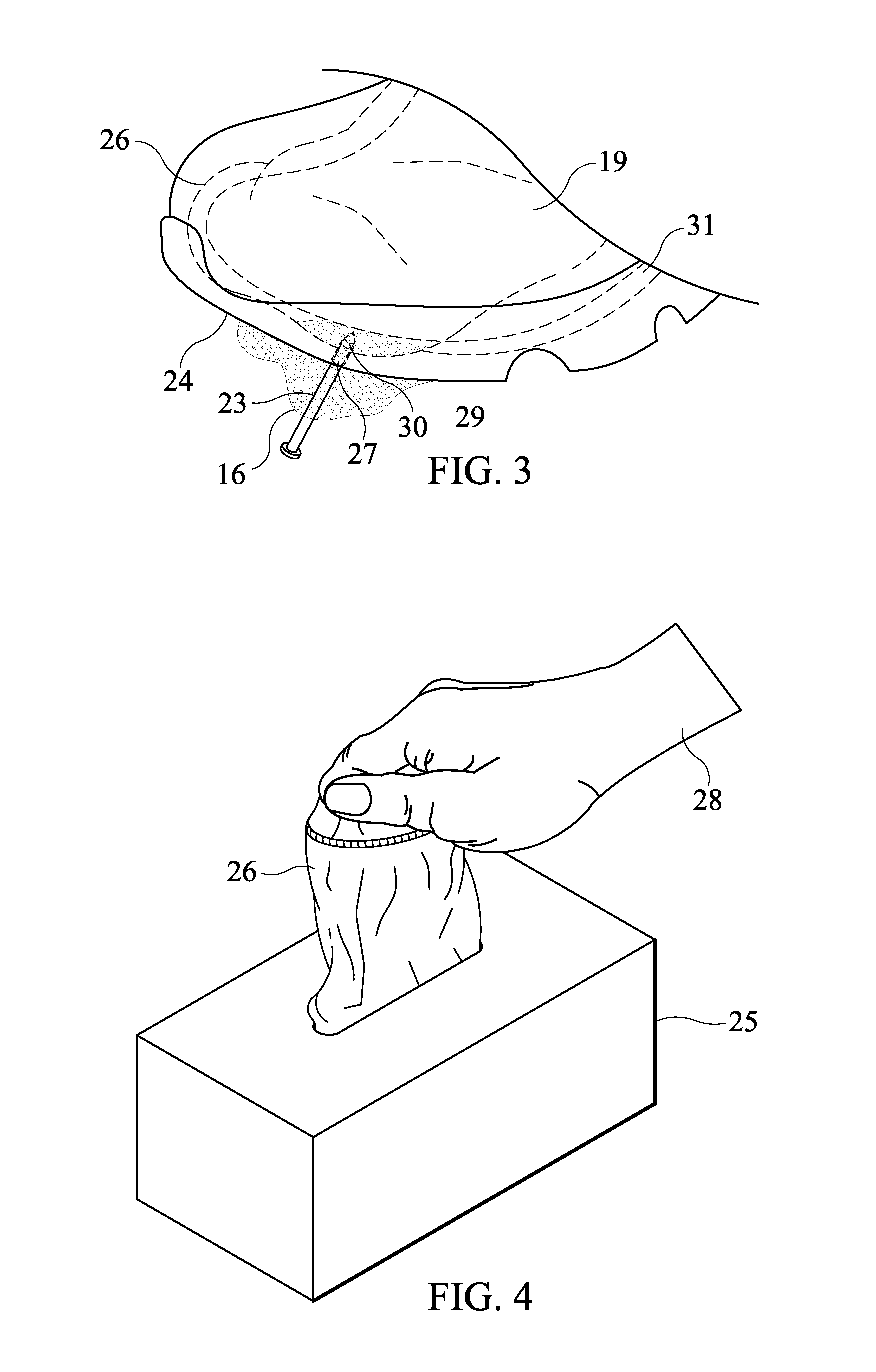

[0023]Turning to the drawings, FIG. 1 illustrates an embodiment of a waterproof polyethylene disposable foot and sock cover article 7, conformed to the shape of a foot, and for placement over a sock 8 (that may also be placed over a foot, as shown in FIG. 2). The article 7 may comprise a toe section 9, a body section 15, and a heel section 10, and a lower leg section 11 above the heel section 10. Above the lower leg section 11 may be a top opening 12 for insertion therein of a sock 8 (and of a foot 19 as shown in FIG. 2, with the sock 8 placed over a foot 19 and lower leg 22). Near the top opening 12 may also be a means 13 for preventing the top opening 12 from falling down, which in the embodiment shown may comprise a band having elastic properties 13, allowing it to expand and contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com